A Concrete Pouring Document Sample for Structural Construction outlines detailed procedures and guidelines to ensure proper mixing, pouring, and curing of concrete for structural elements. It includes essential information such as mix design, environmental conditions, safety measures, and quality control checks to guarantee structural integrity. This document serves as a critical reference for contractors, engineers, and site supervisors during the concrete pouring process.

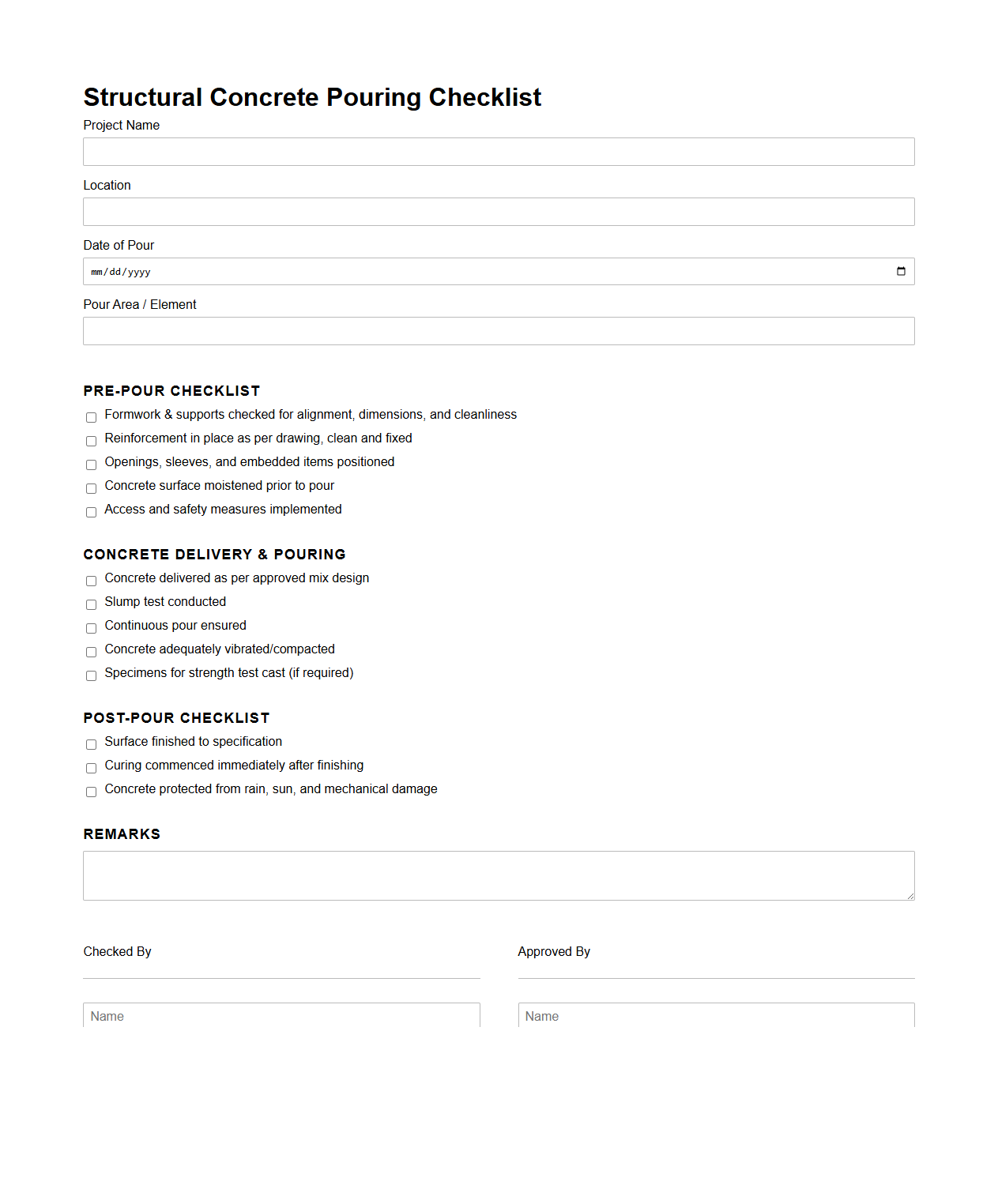

Structural Concrete Pouring Checklist Template

A

Structural Concrete Pouring Checklist Template document serves as a systematic guide to ensure all essential steps and quality controls are followed during the concrete pouring process in construction projects. It includes critical items such as formwork inspection, reinforcement placement, mix verification, and curing procedures to guarantee structural integrity and compliance with engineering standards. This template streamlines project workflows, minimizes errors, and enhances safety by providing a clear, organized framework for site personnel.

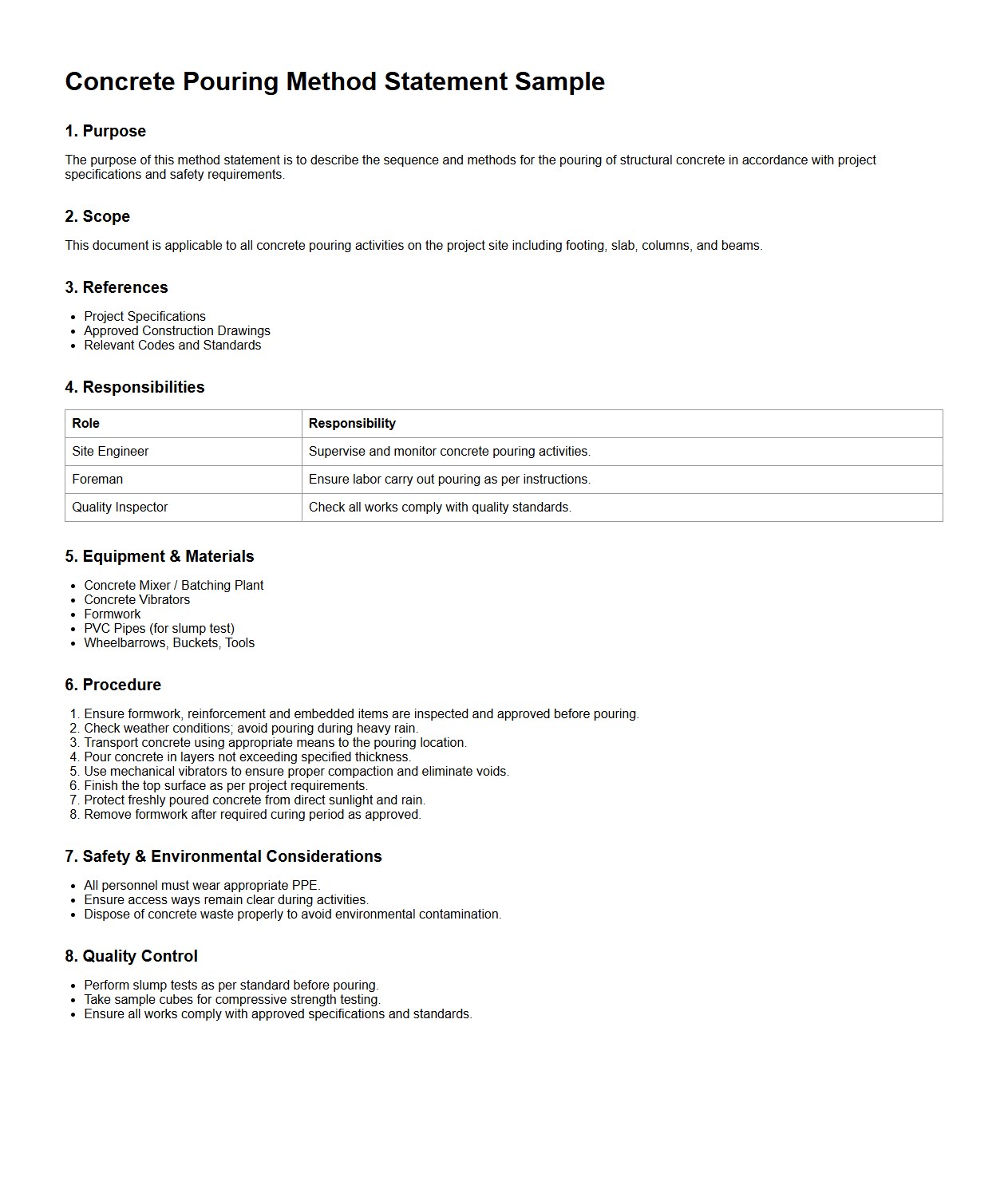

Concrete Pouring Method Statement Sample

A

Concrete Pouring Method Statement Sample document outlines the step-by-step procedures, safety measures, and quality control practices required for the correct placement of concrete in construction projects. It serves as a guideline to ensure efficient coordination among workforce, machinery, and materials, minimizing risks of errors and structural defects. This method statement is crucial for compliance with industry standards and achieving desired strength and durability in concrete works.

Concrete Mix Design Approval Form

The

Concrete Mix Design Approval Form document serves as a formal record verifying that a specific concrete mix design meets project requirements and industry standards before use in construction. It includes detailed information such as mix proportions, material properties, test results, and compliance with specifications like compressive strength and durability. This approval ensures quality control and consistency in concrete production, minimizing risks associated with structural performance.

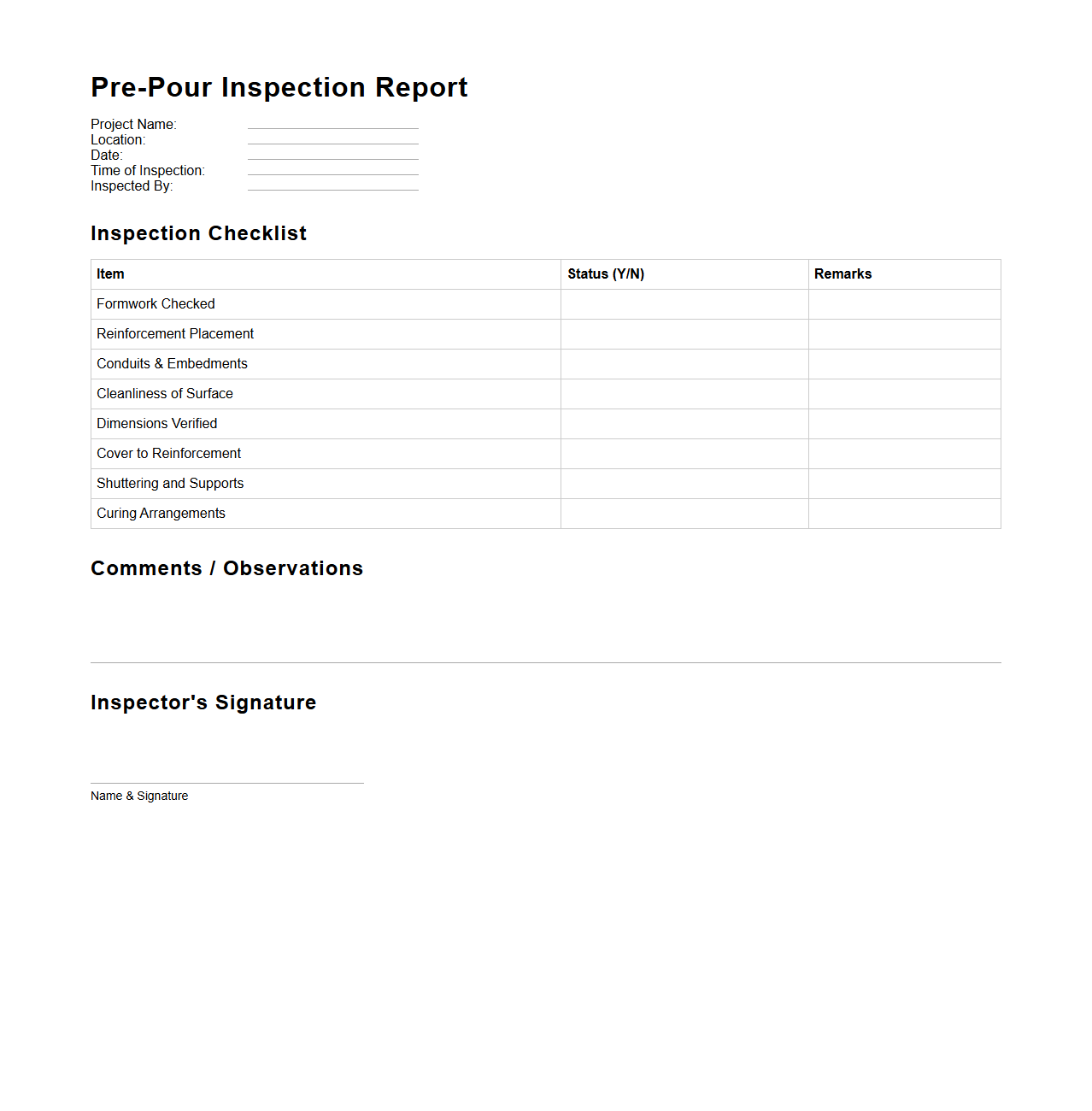

Pre-Pour Inspection Report Format

A

Pre-Pour Inspection Report Format document is a standardized template used in construction to record the condition and readiness of a site before concrete is poured. It ensures all necessary checks such as formwork, rebar placement, and embedments meet project specifications and safety standards. This report helps identify potential issues early, minimizing costly delays and ensuring compliance with engineering requirements.

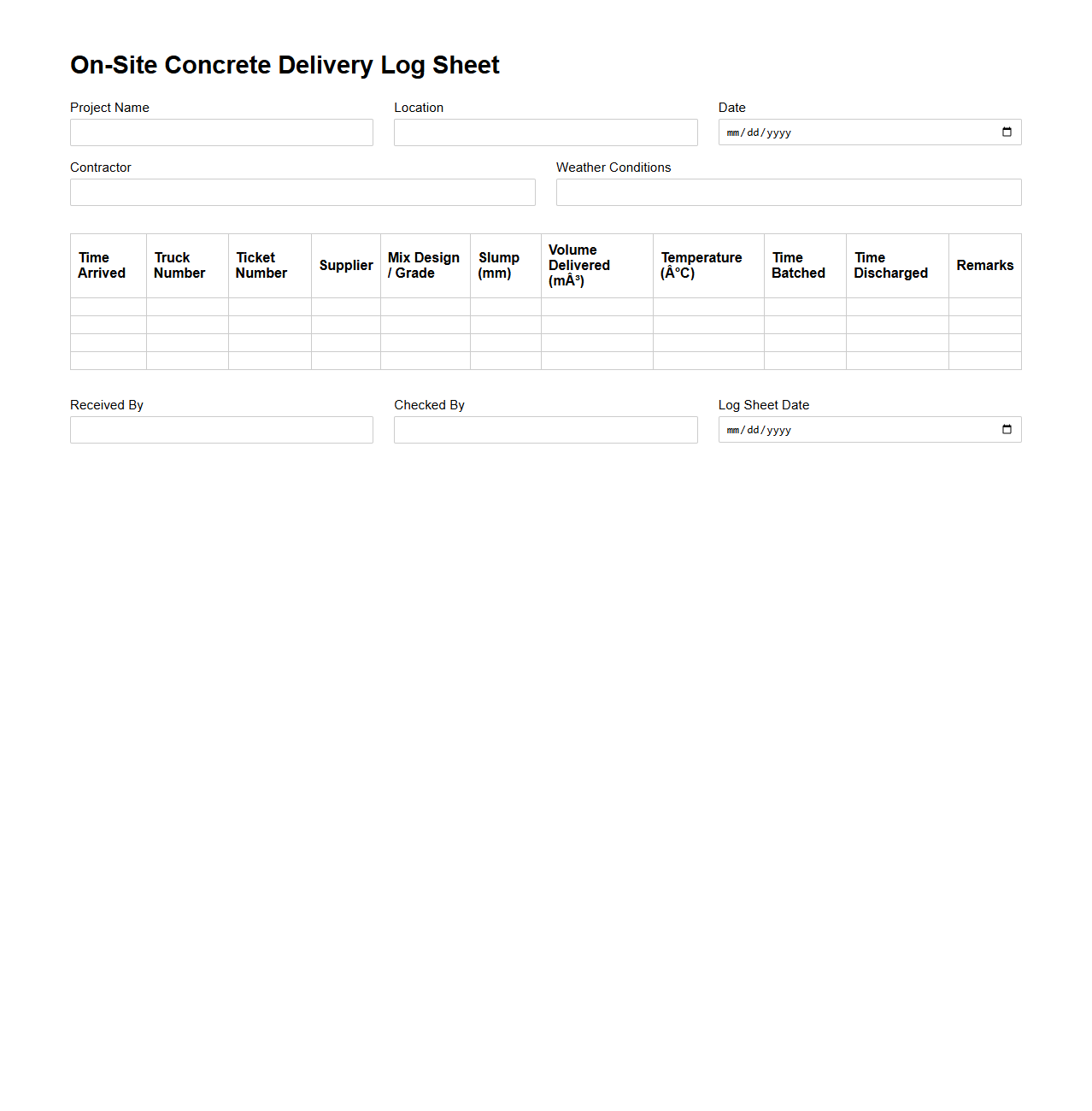

On-Site Concrete Delivery Log Sheet

The

On-Site Concrete Delivery Log Sheet is a critical document used to track and record all concrete deliveries at a construction site. It includes key details such as delivery times, quantities, supplier information, and batch numbers, ensuring accurate monitoring of materials and quality control. This log sheet helps maintain transparency, facilitates project management, and supports compliance with construction standards.

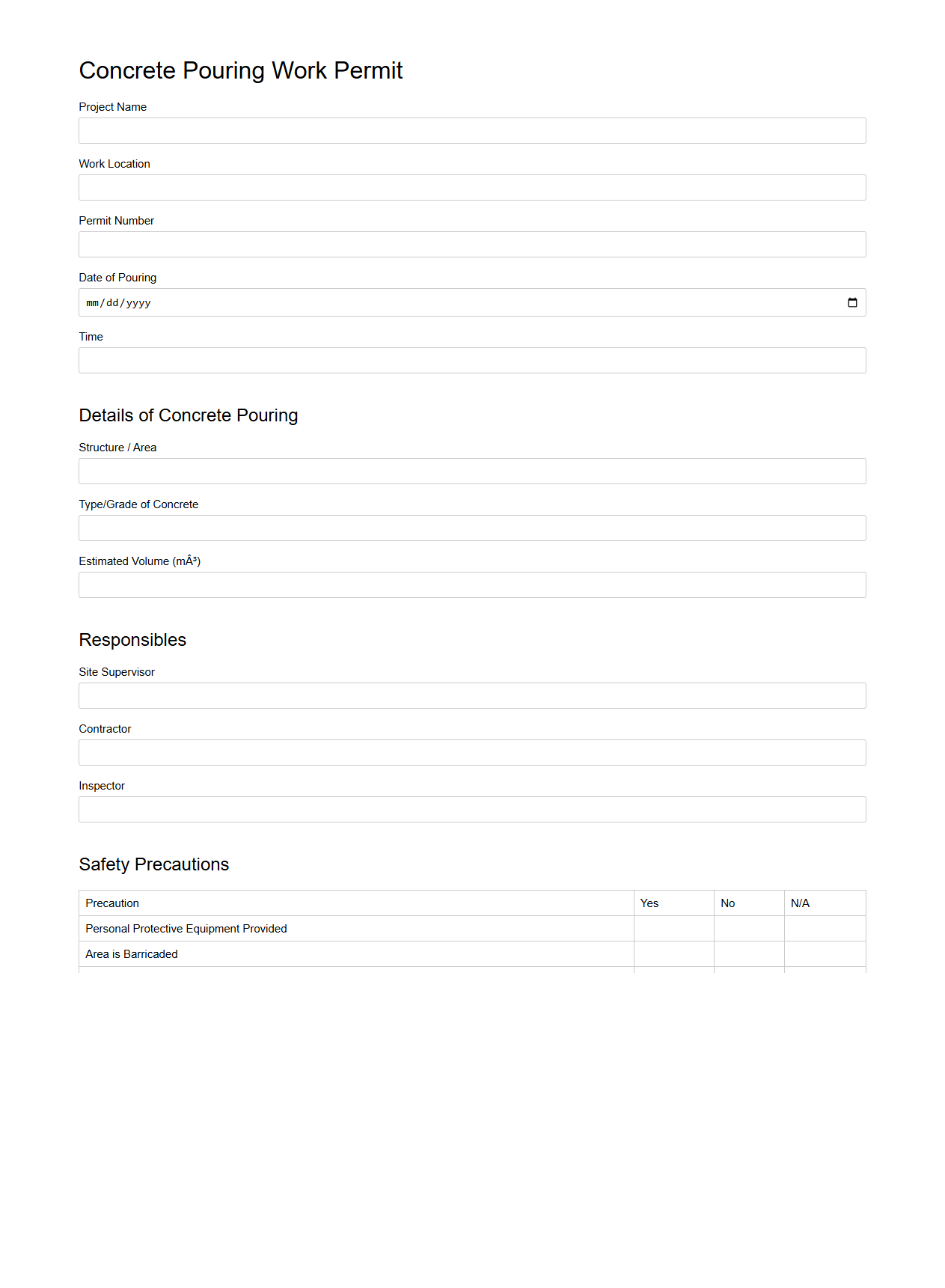

Concrete Pouring Work Permit Example

A

Concrete Pouring Work Permit Example document is an official authorization form used to ensure safety and compliance during concrete pouring activities on construction sites. It outlines necessary precautions, equipment requirements, and environmental conditions to minimize risks and hazards. This permit also verifies that all personnel involved are trained and informed about safety protocols before commencement of the work.

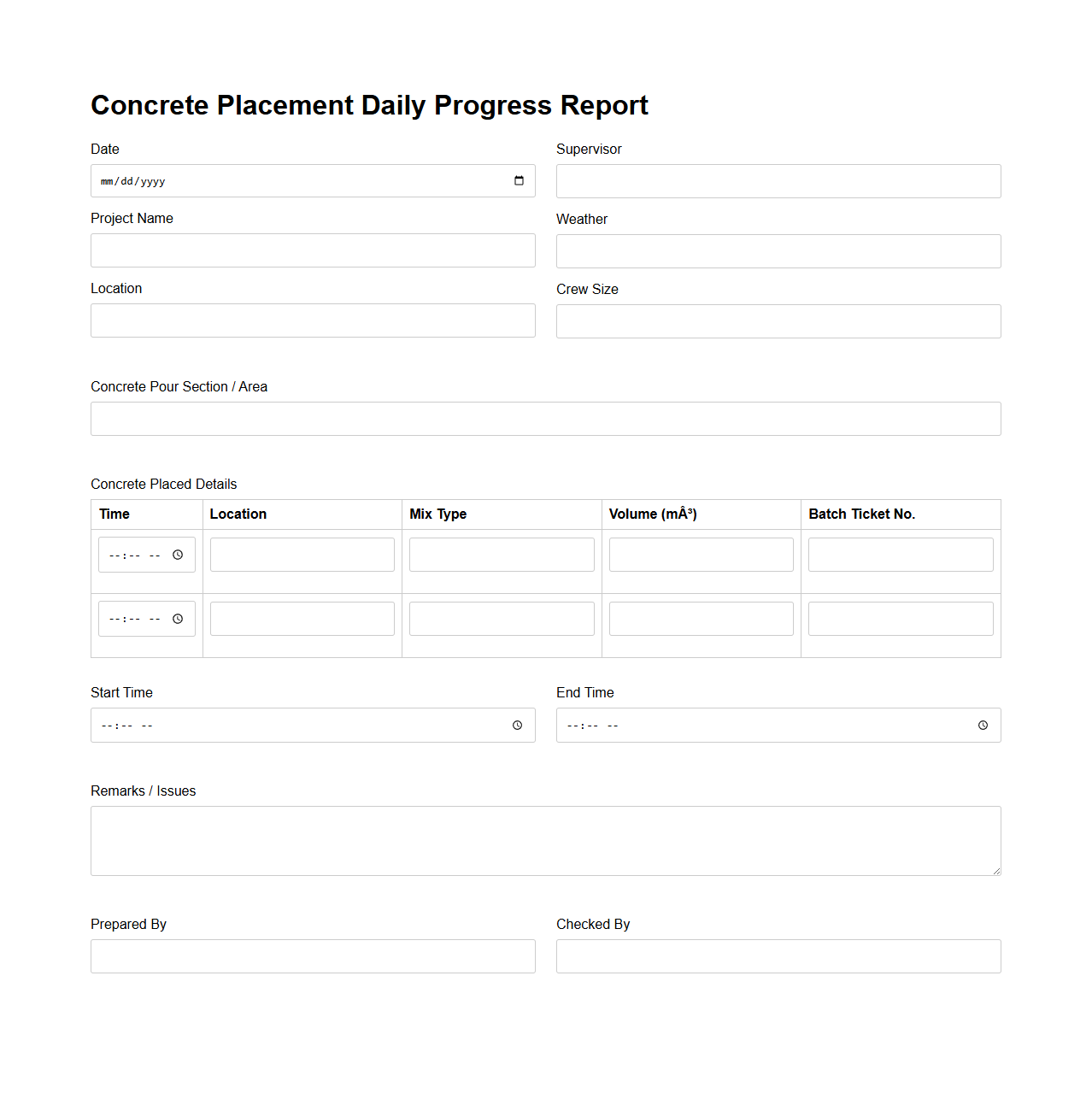

Concrete Placement Daily Progress Report

A

Concrete Placement Daily Progress Report is a detailed document used in construction projects to record the daily activities related to the placement of concrete. It tracks critical information such as the volume of concrete poured, weather conditions, equipment used, labor force involved, and any issues or delays encountered during the process. This report ensures accurate monitoring of progress, quality control, and facilitates communication between project stakeholders.

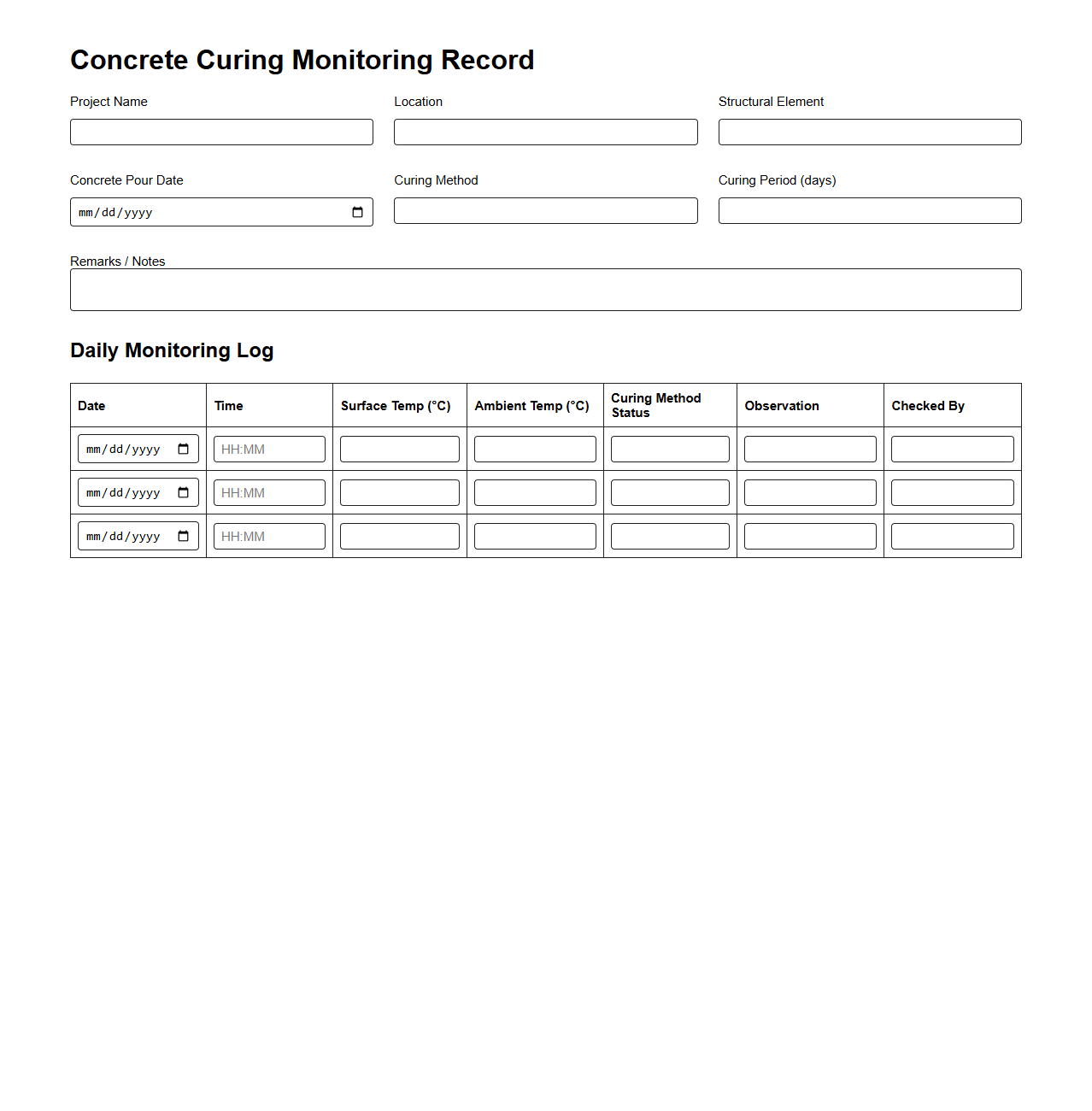

Concrete Curing Monitoring Record

A

Concrete Curing Monitoring Record document systematically tracks the temperature, humidity, and duration of the curing process to ensure optimal concrete strength and durability. It records vital data such as curing start time, environmental conditions, moisture levels, and any deviations from prescribed curing methods. This documentation is essential for quality control, compliance with construction standards, and long-term structural performance verification.

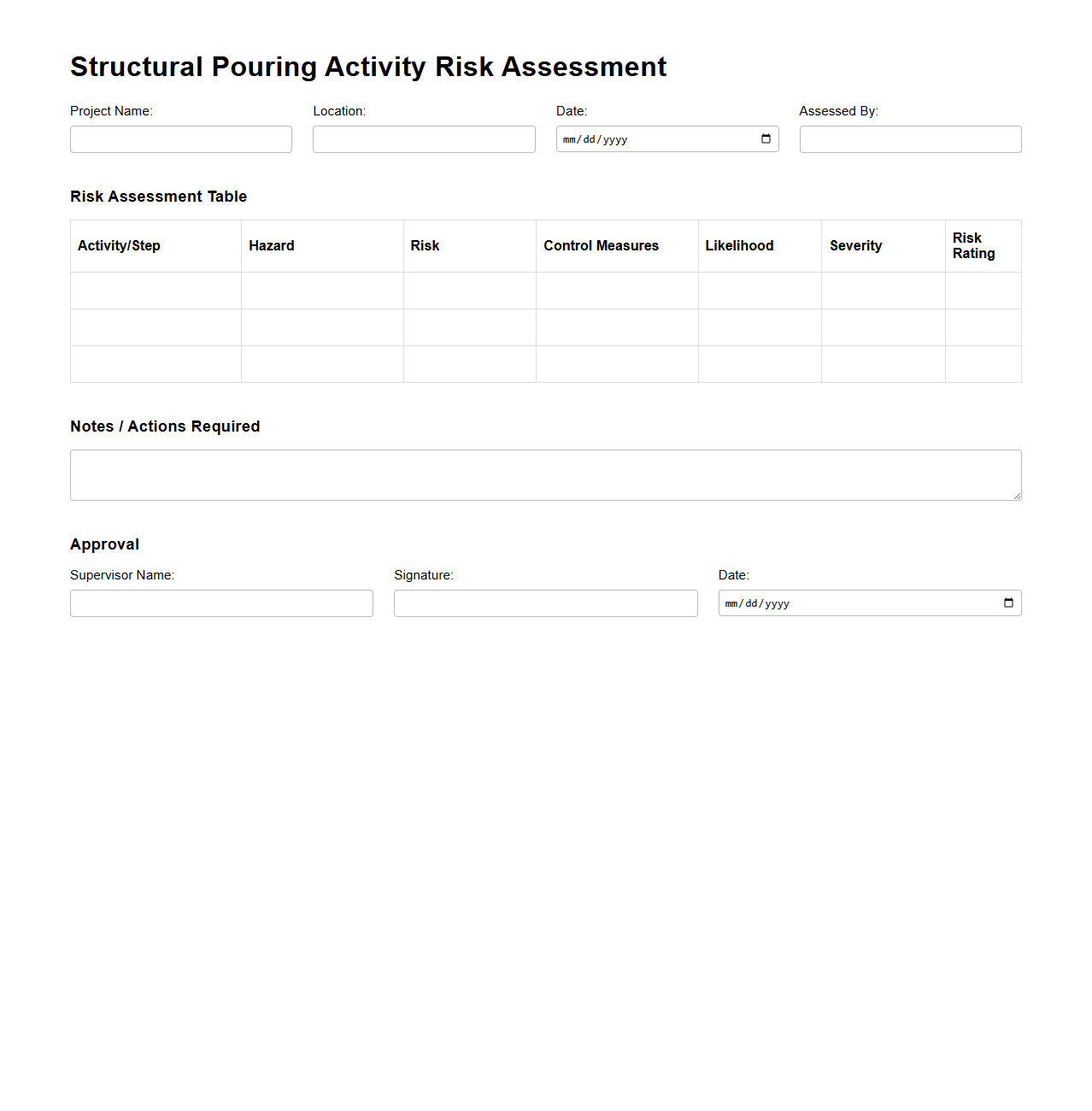

Structural Pouring Activity Risk Assessment

A

Structural Pouring Activity Risk Assessment document identifies potential hazards associated with concrete pouring operations in construction. It evaluates risks such as equipment failure, worker injury, and environmental factors to implement effective safety measures. This assessment ensures compliance with safety regulations and promotes a secure working environment during structural construction.

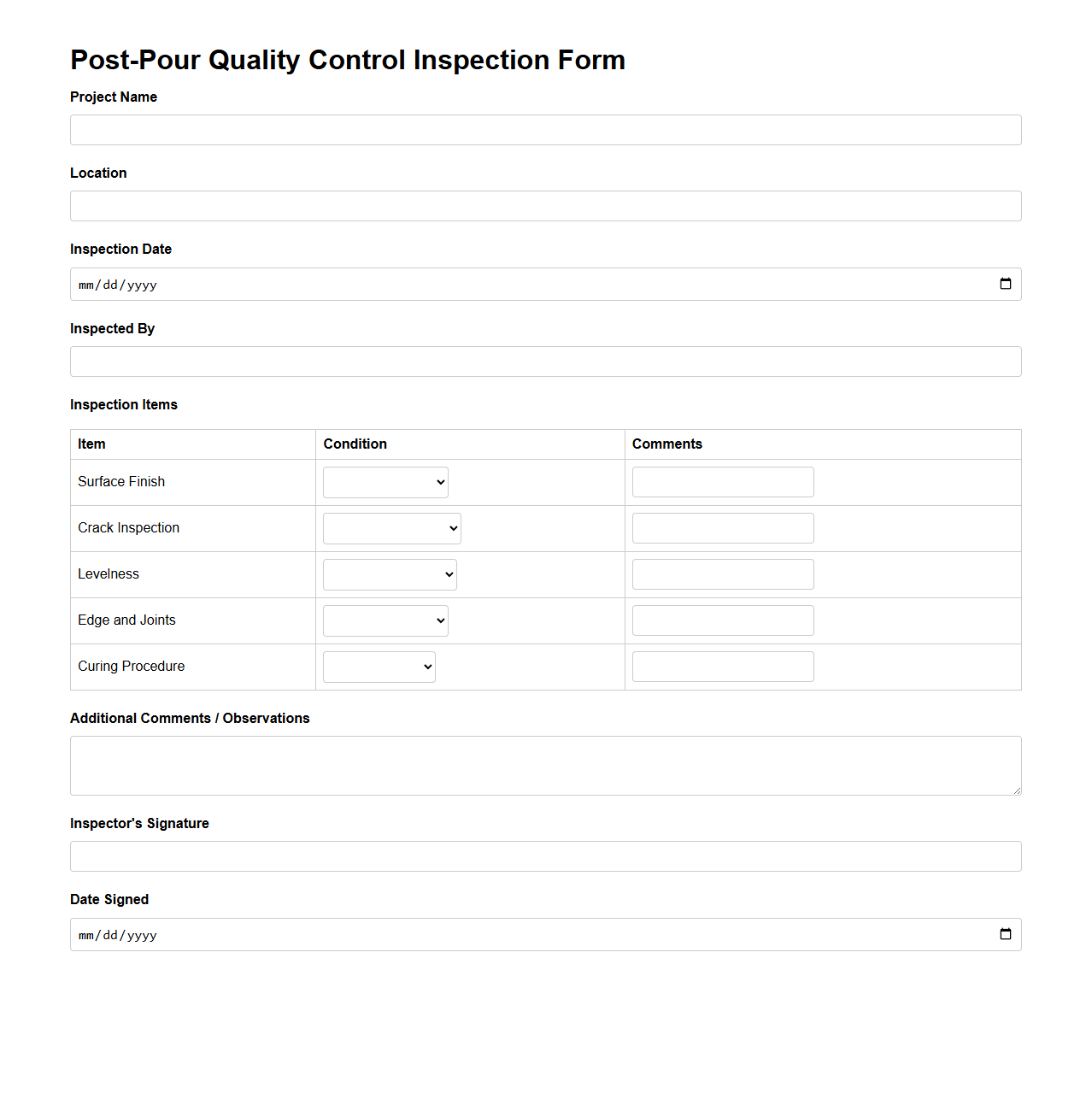

Post-Pour Quality Control Inspection Form

The

Post-Pour Quality Control Inspection Form document is a critical tool used to evaluate the integrity and quality of concrete immediately after pouring. It records essential data such as surface finish, curing conditions, and any visible defects to ensure compliance with project specifications and standards. This form helps prevent structural issues by documenting observations and corrective actions for quality assurance in construction projects.

What inspection checklists are required before issuing a concrete pouring document?

Before issuing a concrete pouring document, it is essential to complete inspection checklists that verify the readiness of site conditions, formwork, and reinforcement placement. These checklists include checks for proper rebar positioning, form integrity, and cleanliness of the pour area. Ensuring all criteria are met mitigates risks and ensures compliance with construction standards.

Which ASTM standards must be referenced in the concrete pour documentation?

Concrete pour documentation must reference relevant ASTM standards such as ASTM C94 for ready-mixed concrete and ASTM C31 for making and curing concrete test specimens. Additionally, ASTM C143 covers slump tests, which are critical for verifying concrete workability. Referencing these standards ensures the concrete meets quality and performance criteria.

How should curing methods be documented for post-pour compliance?

Curing methods must be documented with details on the type of curing technique used, duration, and environmental conditions maintained during the curing period. This documentation should also include temperature and moisture control measures to prevent premature drying. Thorough records guarantee compliance with project specifications and promote proper concrete strength development.

What are the mandatory sign-off procedures for responsible engineers in the pour documentation?

The pour documentation requires mandatory sign-offs from responsible engineers at multiple stages, including verification of inspection checklists, mix design approval, and post-pour evaluations. Each sign-off must include timestamps and clear identification of the signatory. This procedure ensures accountability and validation of concrete quality throughout the process.

How is concrete batch traceability information recorded in the structural pour document?

Concrete batch traceability is recorded by documenting the batch number, mixing time, delivery ticket, and the supplier's identification within the pour document. This traceability information allows tracking of material origins and helps in quality control. Maintaining detailed records supports investigations if any issues arise with the concrete performance.

More Construction Templates