A Non-Conformance Report Document Sample for Construction Quality provides a structured format to identify, document, and address deviations from specified construction standards. This report ensures that quality issues are clearly communicated and corrective actions are implemented promptly to maintain project integrity. Using this document helps construction teams uphold compliance and improve overall site safety and workmanship.

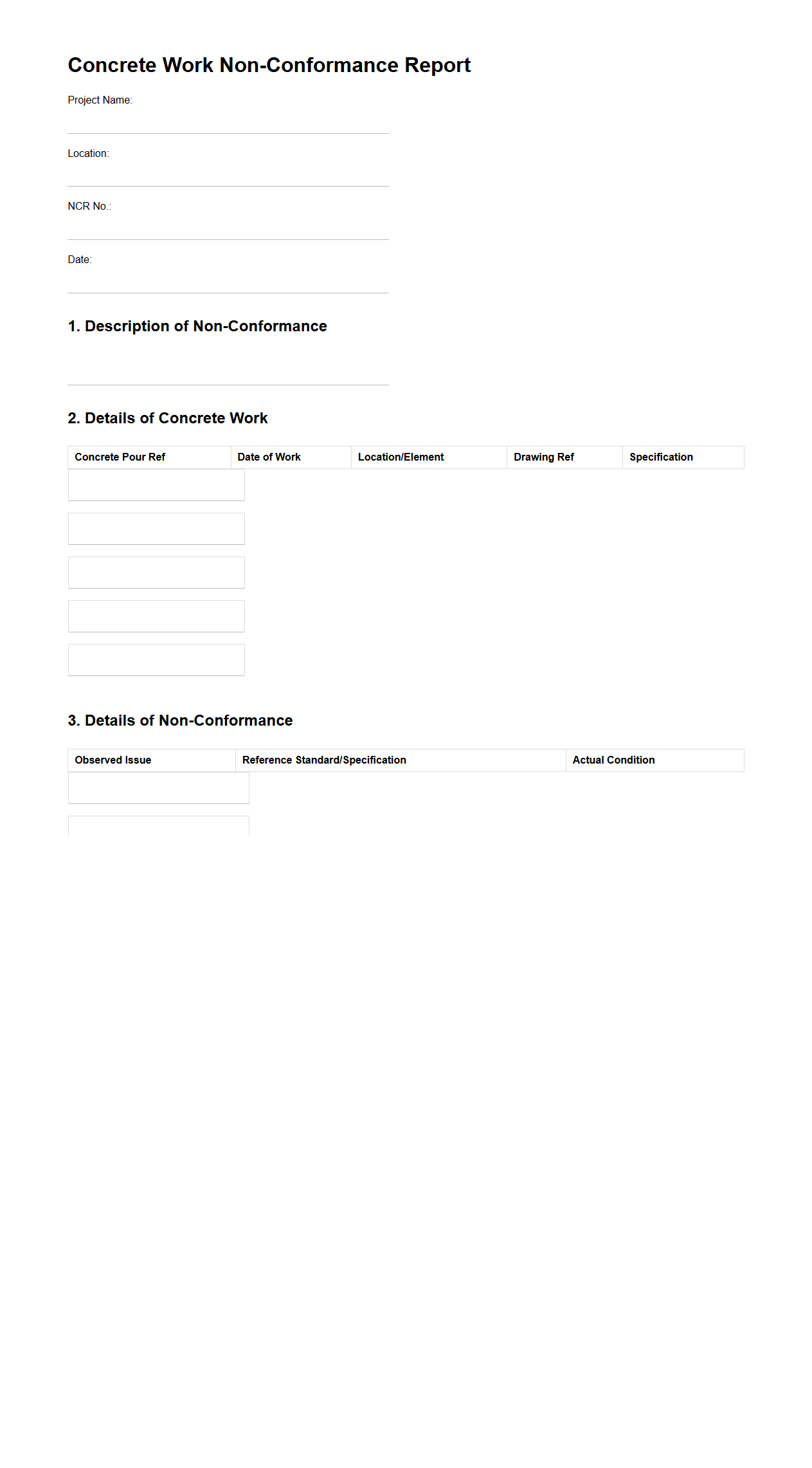

Concrete Work Non-Conformance Report Example

A

Concrete Work Non-Conformance Report (NCR) Example document details deviations from specified concrete mix designs, curing procedures, or structural requirements during construction. It includes key information such as the non-conformance description, location, responsible parties, corrective actions, and verification methods. This report ensures accountability and facilitates effective resolution to maintain construction quality standards.

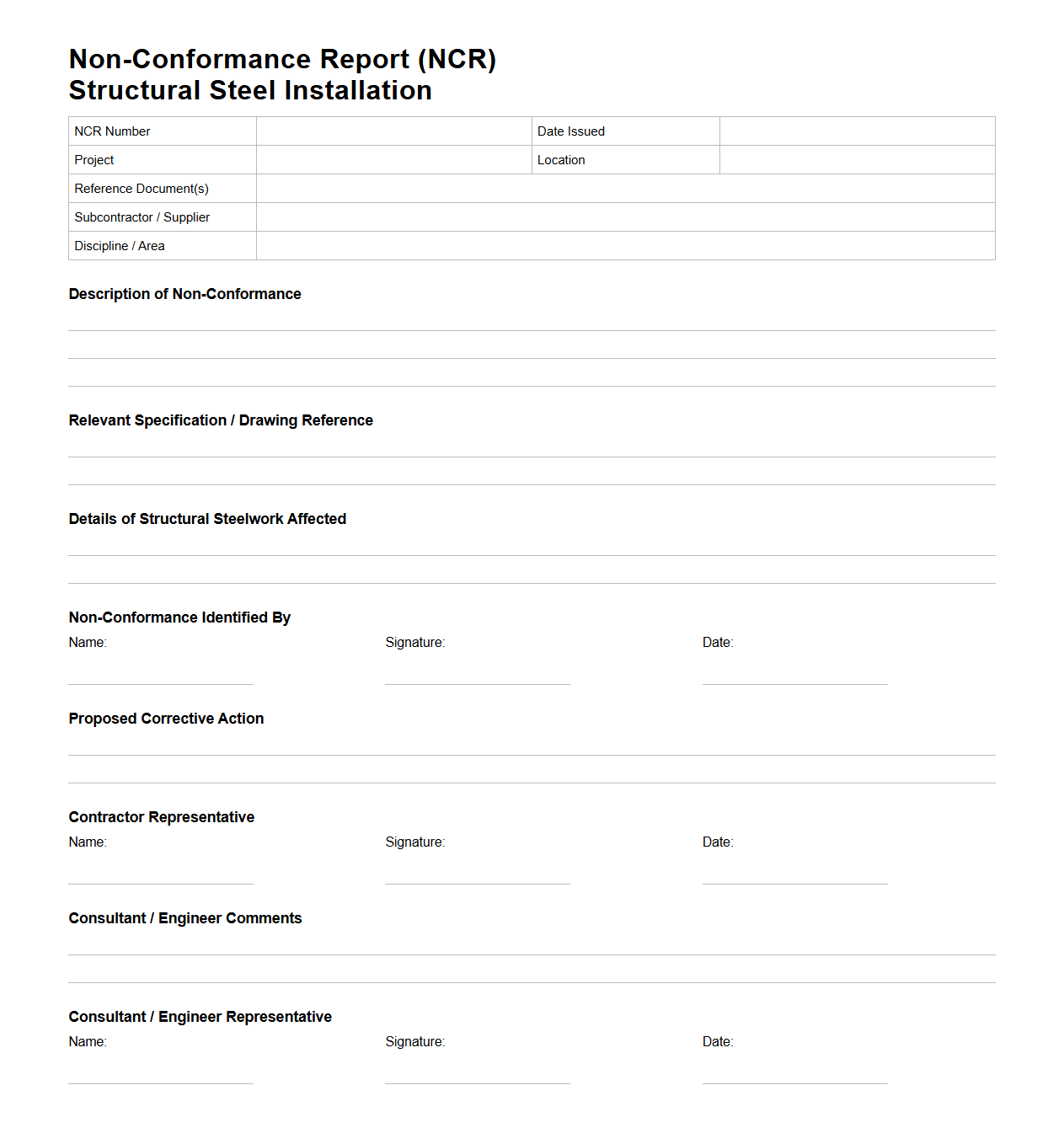

Structural Steel Installation NCR Template

The

Structural Steel Installation NCR Template document serves as a standardized form for recording non-conformance reports specifically related to the installation of structural steel components. It captures detailed information about discrepancies, defects, or deviations from project specifications to ensure compliance with engineering standards and facilitate corrective actions. This template streamlines reporting, enhances communication between stakeholders, and supports quality control in construction projects.

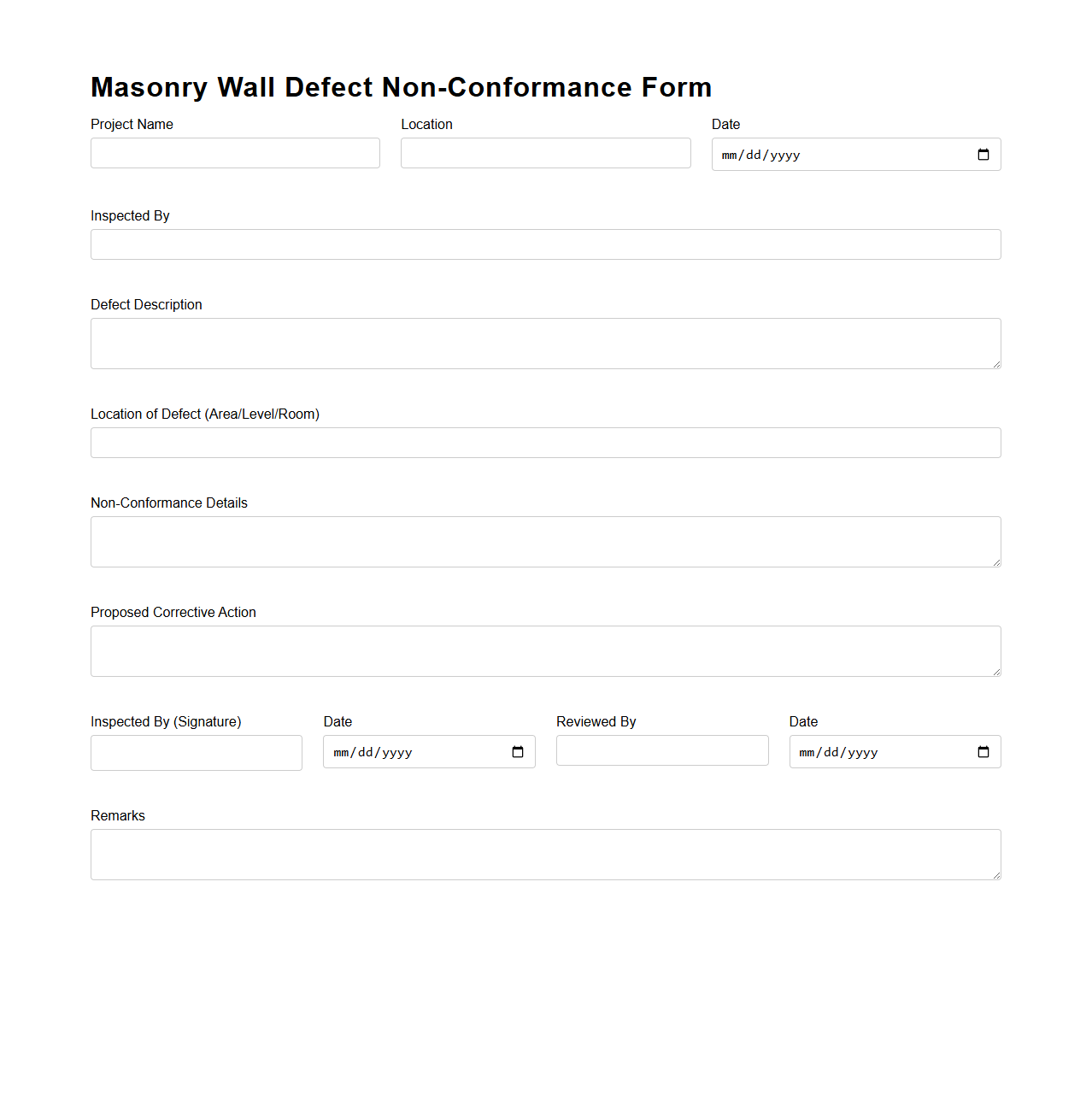

Masonry Wall Defect Non-Conformance Form

The

Masonry Wall Defect Non-Conformance Form document is used to systematically identify, record, and report defects or non-conformities found in masonry walls during construction or inspection. It ensures that all deviations from project specifications, building codes, and quality standards are documented for corrective action. This form facilitates effective communication between contractors, inspectors, and quality control teams to maintain structural integrity and compliance.

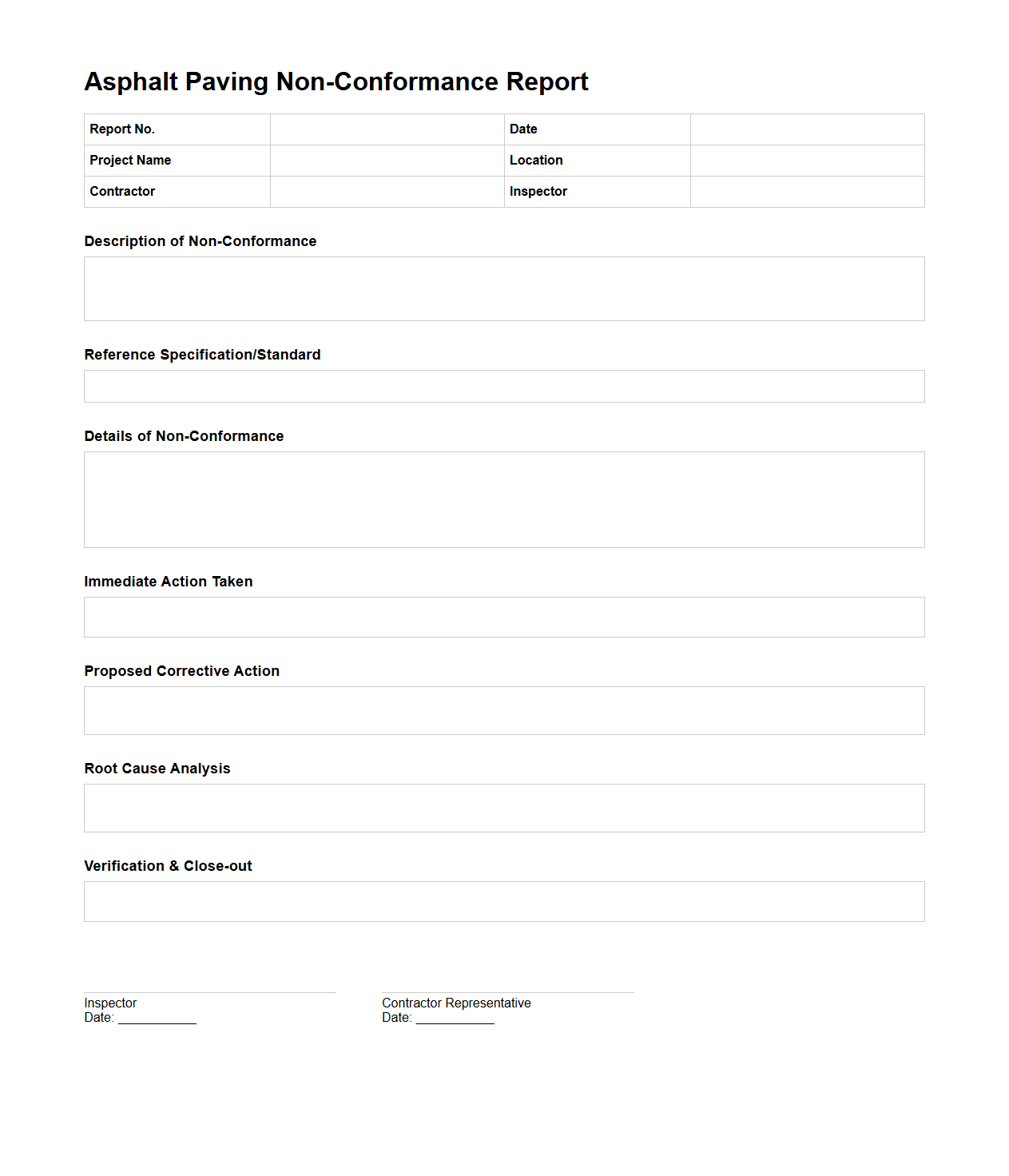

Asphalt Paving Non-Conformance Report Sample

An

Asphalt Paving Non-Conformance Report Sample document serves as a formal record identifying deviations from specified asphalt paving standards and project requirements. It details issues such as incorrect material composition, improper compaction, or surface irregularities, facilitating corrective actions to ensure compliance with industry regulations. This report helps maintain quality control and documentation for accountability in asphalt paving projects.

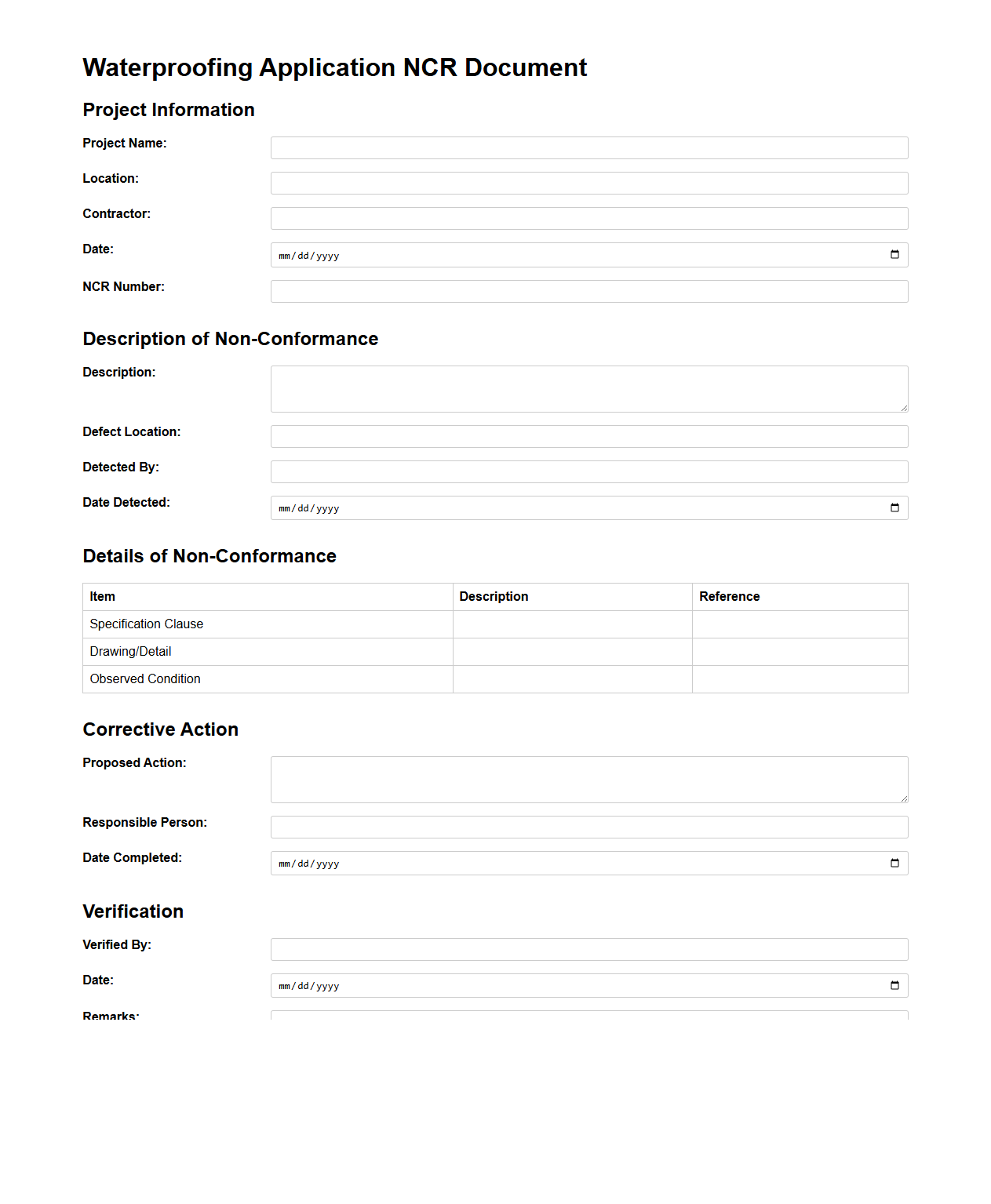

Waterproofing Application NCR Document

The

Waterproofing Application NCR Document is a formal report used to identify and address non-conformities in waterproofing procedures on construction projects. It details deviations from project specifications, material standards, or application methods that could compromise the waterproofing system's integrity. This document serves as a critical tool for quality control teams to ensure corrective actions are implemented promptly, maintaining structural durability and preventing water infiltration issues.

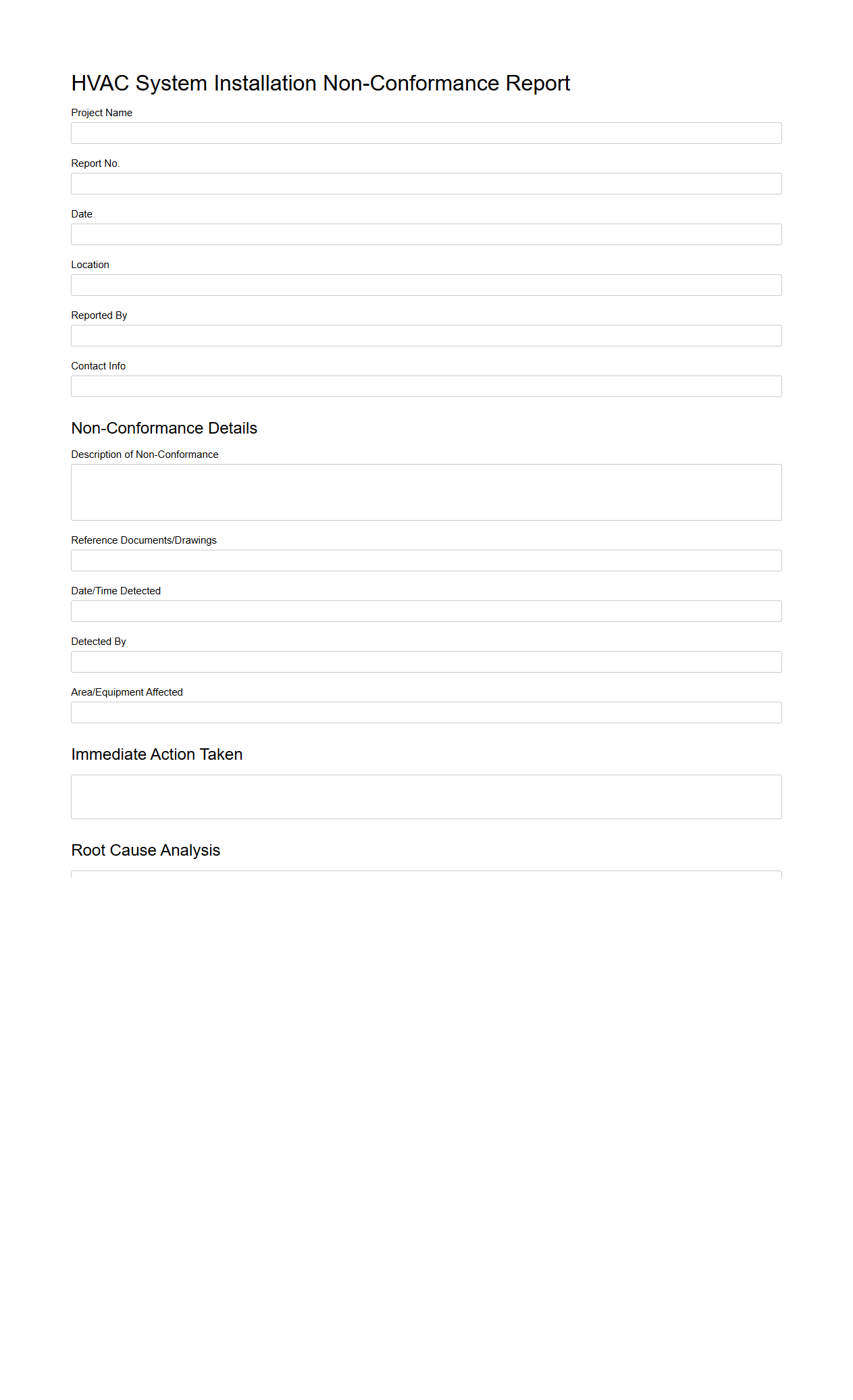

HVAC System Installation Non-Conformance Report

A

HVAC System Installation Non-Conformance Report document identifies deviations from specified installation standards or project requirements during HVAC system setup. It details the nature of the non-conformance, its potential impact on system performance, and corrective actions to be taken. This report ensures compliance with design specifications, enhances quality control, and supports project documentation for auditing purposes.

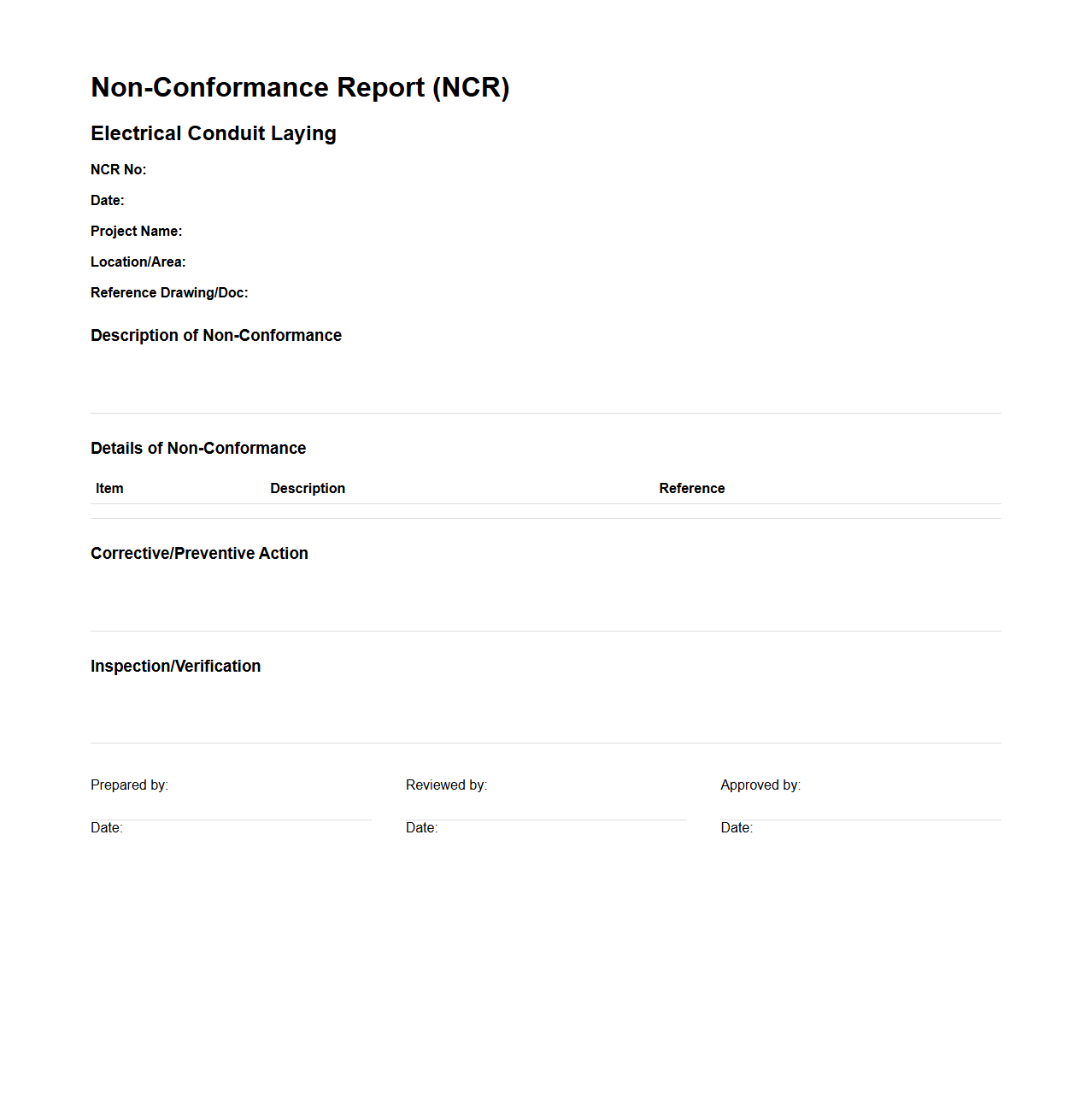

Electrical Conduit Laying NCR Example

An

Electrical Conduit Laying NCR Example document is a formal record used to identify and report non-conformities found during the installation of electrical conduits in the NCR (National Capital Region) construction projects. It details the specific issues such as incorrect conduit alignment, improper securing, or material defects, along with photographic evidence and corrective action plans. This document ensures compliance with safety standards and project specifications, facilitating quality control and timely rectification.

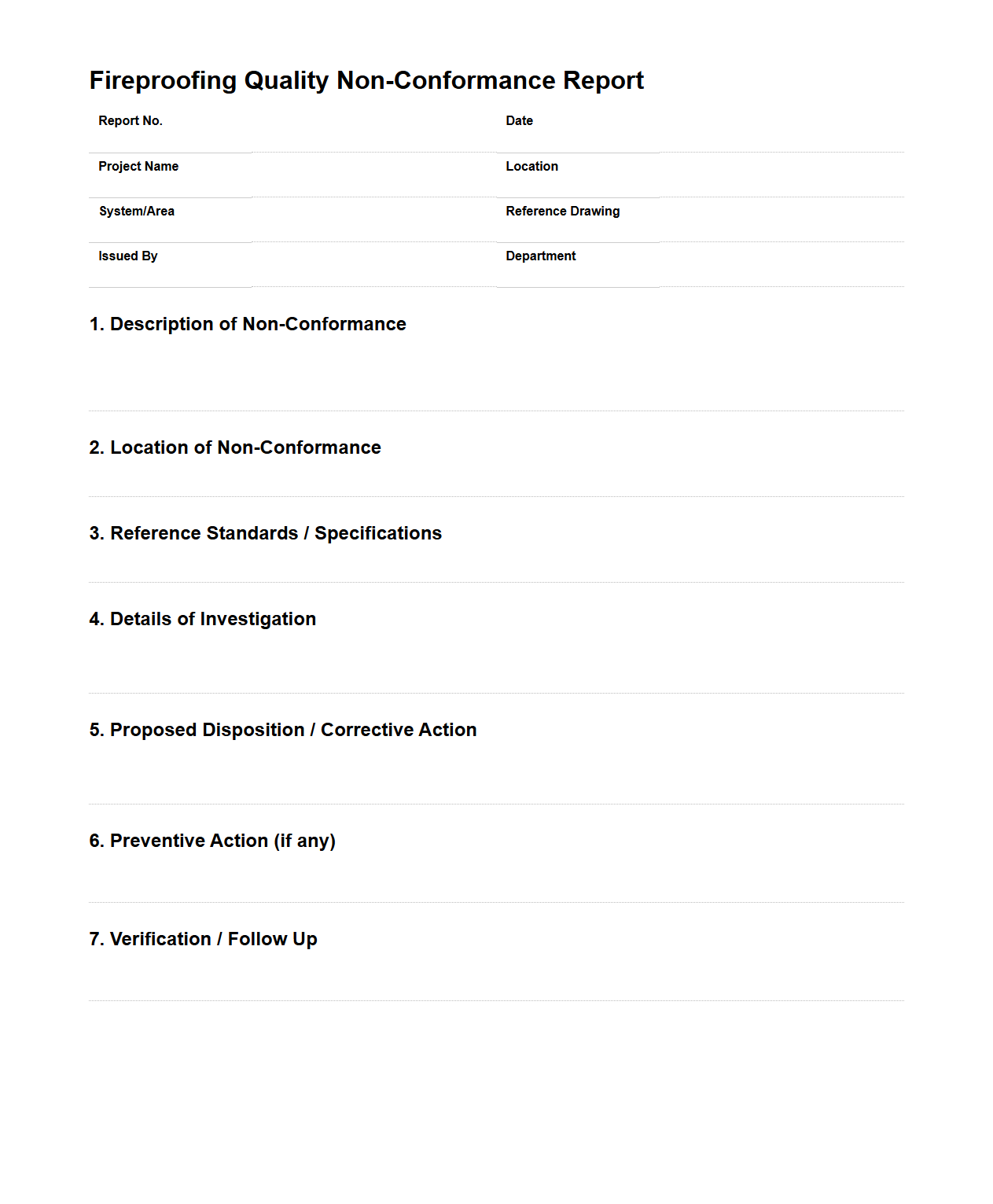

Fireproofing Quality Non-Conformance Report

A

Fireproofing Quality Non-Conformance Report document identifies deviations or defects in fireproofing materials or application processes that fail to meet specified quality standards. This report is essential for tracking non-conformities, detailing the nature of the issue, the affected components, and corrective actions required to ensure compliance with fire safety regulations. Maintaining accurate records in this report helps prevent fire hazards, ensures regulatory adherence, and supports continuous improvement in fireproofing quality control.

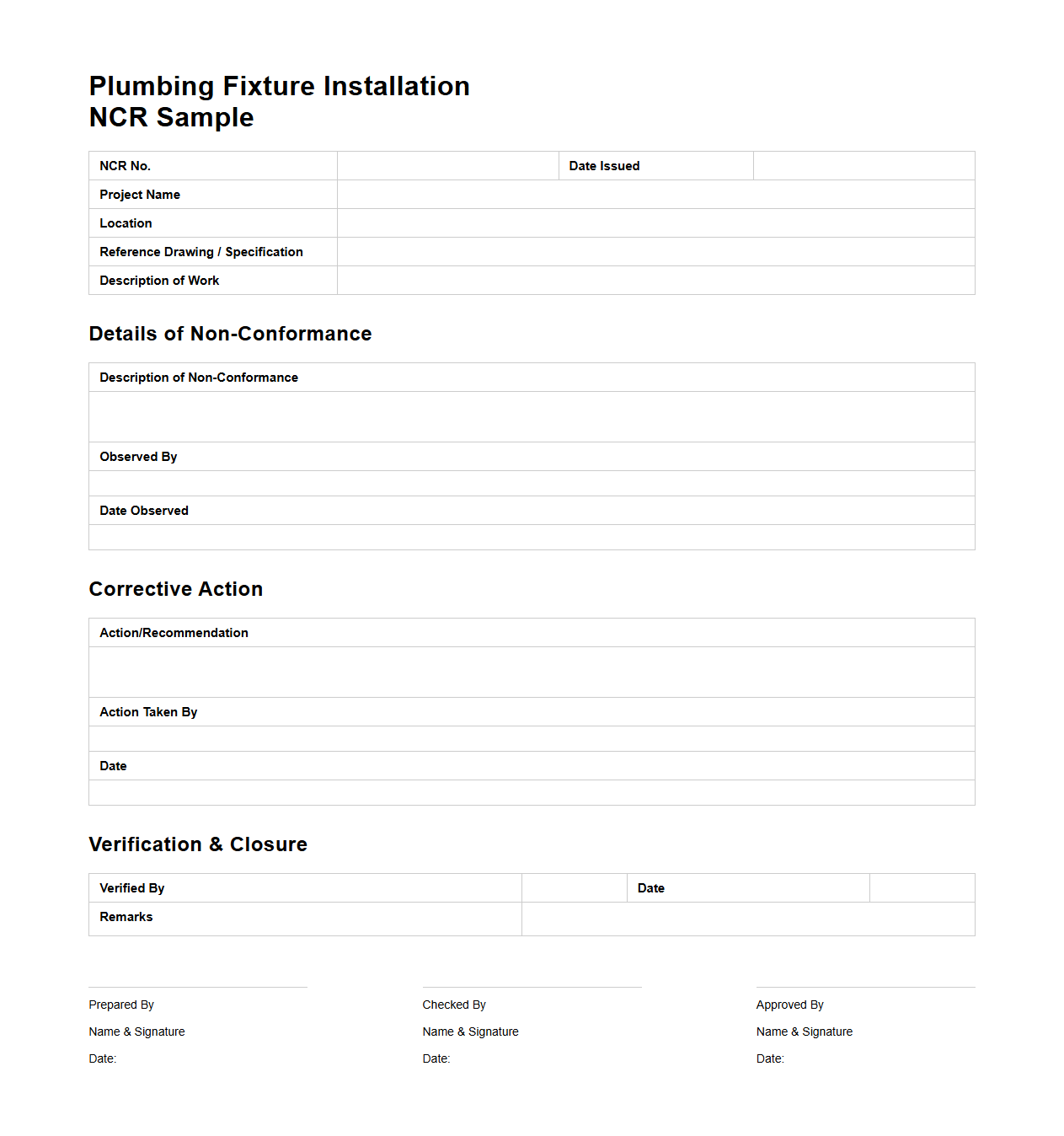

Plumbing Fixture Installation NCR Sample

A

Plumbing Fixture Installation NCR Sample document serves as a formal record identifying non-conformance in the installation of plumbing fixtures according to project specifications and industry standards. It details the specific issues, such as leaks, incorrect placement, or non-compliance with codes, and provides evidence for corrective actions. This document is essential for quality control, ensuring that all plumbing fixtures meet safety, functionality, and regulatory requirements before project completion.

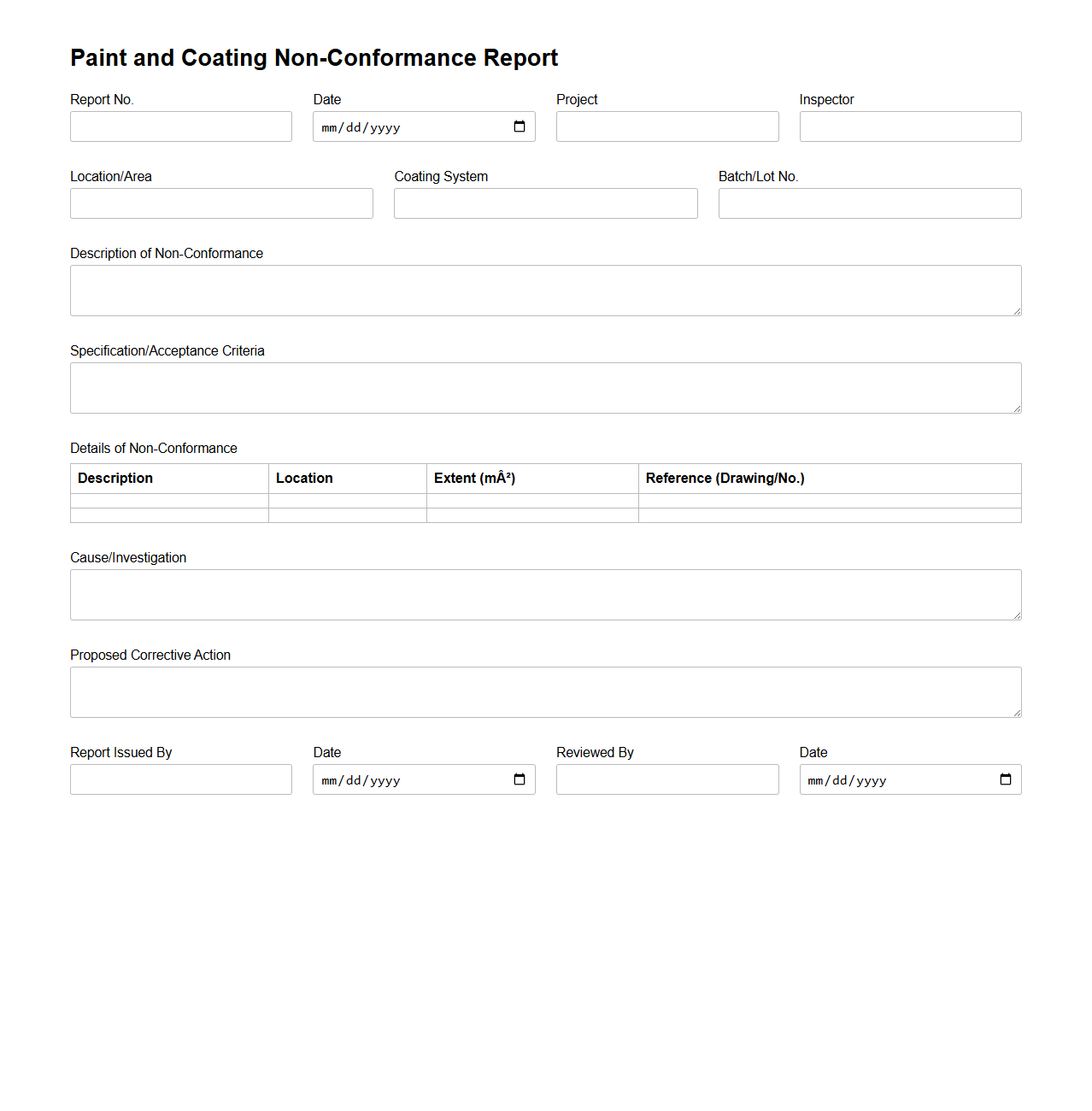

Paint and Coating Non-Conformance Report

A

Paint and Coating Non-Conformance Report document identifies and records deviations from specified standards in painting and coating processes, ensuring quality control in surface protection applications. This report details the nature of the non-conformance, such as improper film thickness, surface contamination, or curing defects, along with corrective actions required to address the issue. Maintaining thorough documentation helps improve compliance with industry standards like ISO 12944 and supports traceability for audits and continuous process improvement.

What is the primary purpose of the Non-Conformance Report (NCR) document in construction quality management?

The primary purpose of the Non-Conformance Report (NCR) in construction quality management is to formally identify and document any deviations from specified standards or contractual requirements. It serves as a critical tool to track and manage non-conformities and ensure accountability. By doing so, the NCR facilitates timely corrective actions to maintain project quality.

Which project details and codes must be included in an NCR document to ensure traceability?

An effective NCR document must include essential project details such as the project name, location, and unique project code. Additionally, it requires references to drawings, specifications, and relevant contractual codes to ensure complete traceability. Including this information allows stakeholders to accurately track where and when the non-conformance occurred within the project scope.

What information should be provided regarding the nature and location of the non-conformance?

The NCR must clearly describe the nature of the non-conformance, detailing the specific issue or defect observed. It should also specify the precise location within the project where the non-conformance was detected, such as a particular structure or area. Accurate description and localization enable efficient evaluation and corrective action planning.

What steps and responsibilities are typically outlined in the NCR for corrective and preventive actions?

The NCR outlines detailed corrective and preventive actions including identifying the root cause, assigning responsible personnel, and specifying timelines for resolution. It also defines roles and responsibilities for implementing these actions to prevent recurrence. This systematic approach ensures accountability and continuous improvement in quality management.

How is the closure and verification of corrective actions documented and approved in the NCR process?

Closure of the NCR is documented by recording the verification of corrective actions taken, confirming that the non-conformance has been resolved. Approval involves sign-offs by quality managers or authorized personnel, ensuring the corrective measures meet the required standards. This formal approval process completes the NCR cycle and updates project quality records.

More Construction Templates