A Quality Control Report Document Sample for Commercial Construction outlines the standards and procedures used to ensure that all construction activities meet specified quality requirements. It includes detailed inspections, testing results, and corrective actions to maintain compliance and project integrity throughout the construction process. This document serves as a critical tool for project managers and contractors to monitor quality and identify areas needing improvement.

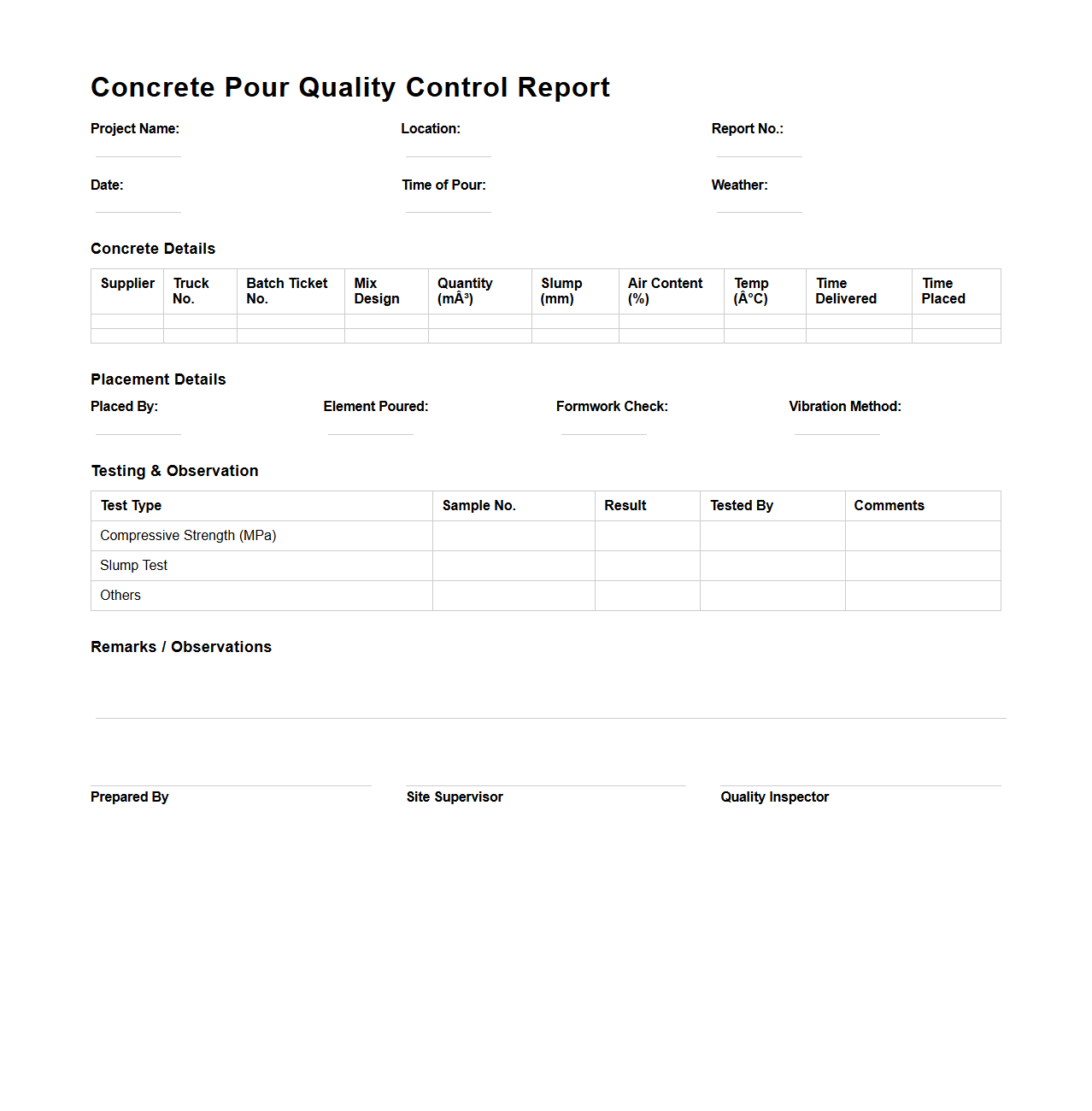

Concrete Pour Quality Control Report Template

A

Concrete Pour Quality Control Report Template is a structured document used to record and evaluate the quality of concrete during pouring operations. It includes critical data such as mix design specifications, temperature, slump test results, and curing conditions to ensure compliance with industry standards. This template helps construction teams maintain consistency, identify defects early, and improve overall project quality management.

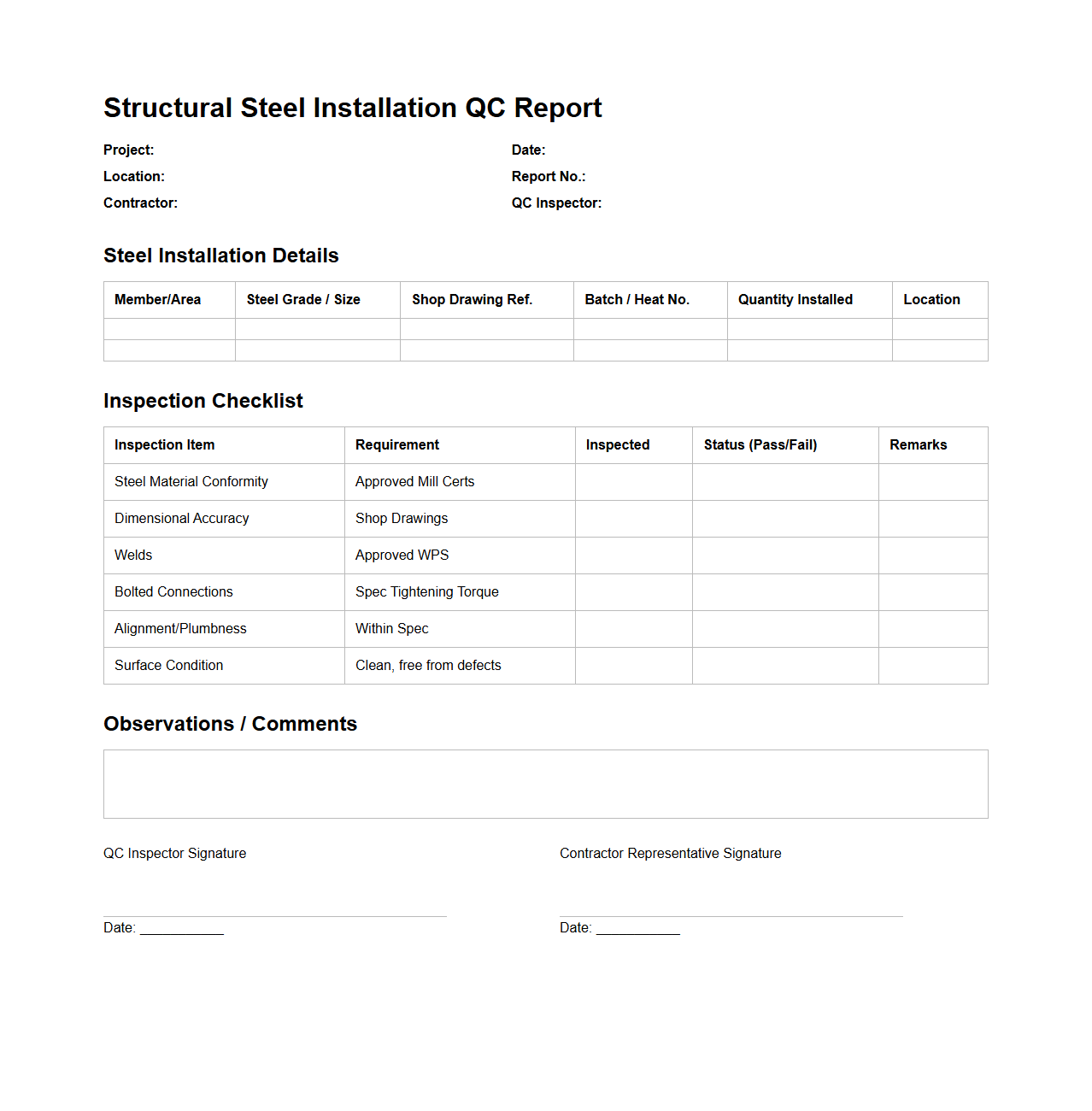

Structural Steel Installation QC Report Sample

A

Structural Steel Installation QC Report Sample document provides a detailed record of quality control measures and inspections conducted during the installation of structural steel elements in construction projects. It includes verification of compliance with design specifications, alignment checks, welding inspections, and material certifications to ensure structural integrity and safety. This report serves as a critical tool for project managers and quality assurance teams to track installation quality and address any deviations promptly.

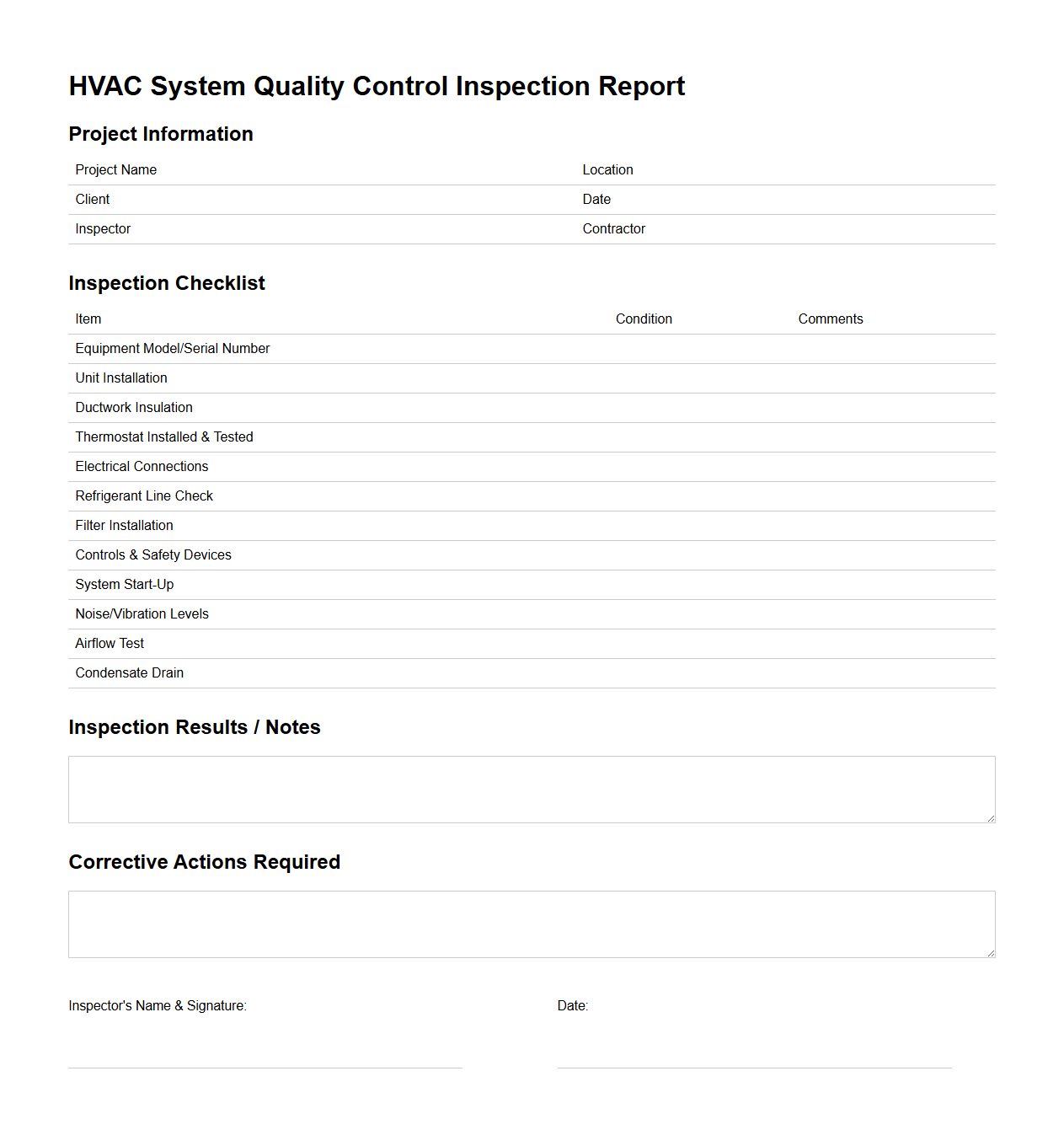

HVAC System Quality Control Inspection Report

The

HVAC System Quality Control Inspection Report document thoroughly evaluates the performance, installation, and safety compliance of heating, ventilation, and air conditioning systems. It includes detailed assessments of system components, airflow measurements, refrigerant levels, and adherence to industry standards such as ASHRAE guidelines. This report ensures that the HVAC system operates efficiently and meets regulatory requirements before project completion or handover.

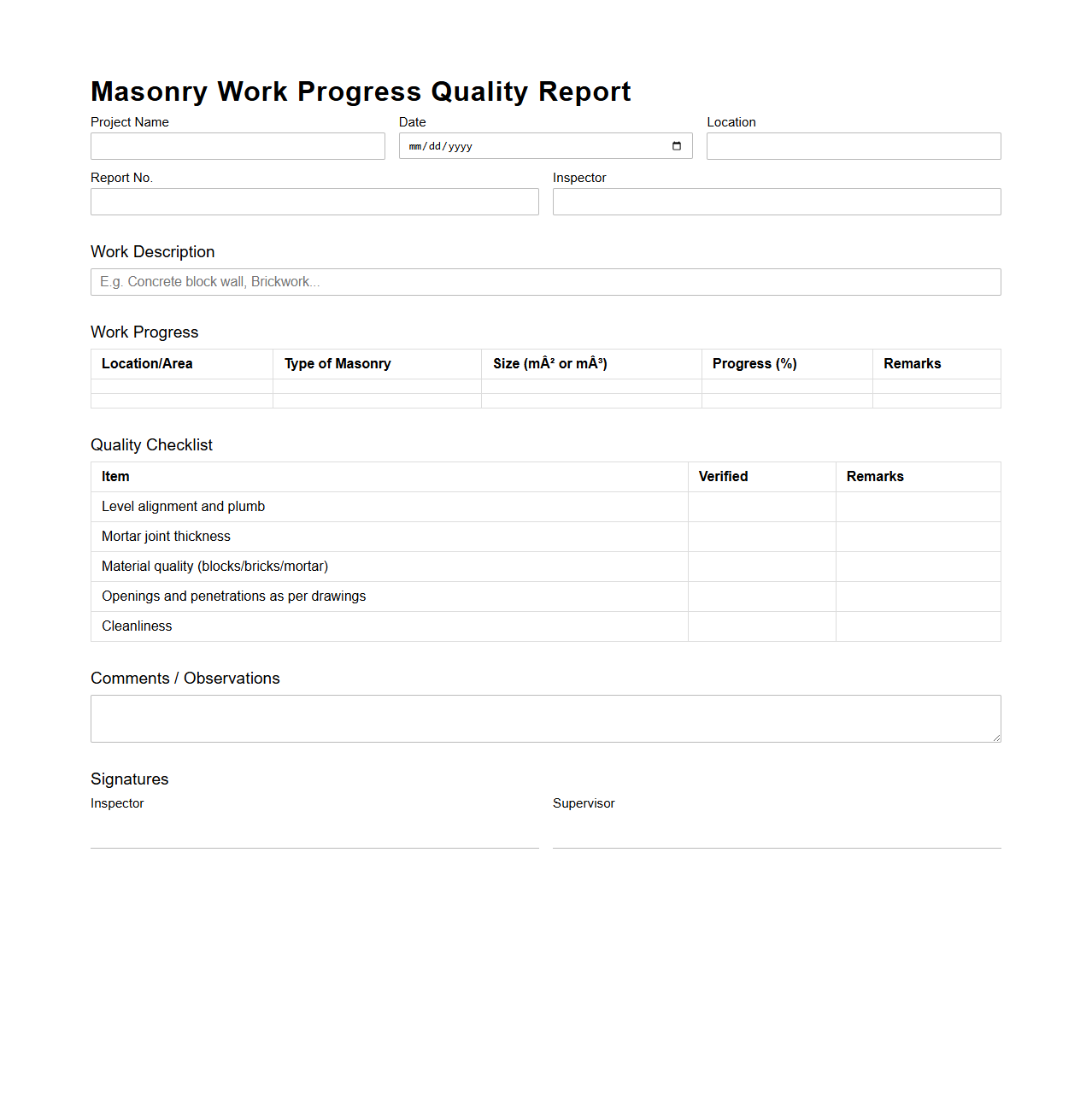

Masonry Work Progress Quality Report Example

A

Masonry Work Progress Quality Report Example document serves as a detailed record that tracks the status, quality, and compliance of masonry construction tasks on a project site. It includes data on materials used, workmanship standards, adherence to project specifications, inspection results, and any defects or corrective actions needed. This report ensures transparent communication between contractors, engineers, and stakeholders to maintain high construction quality and timely progress.

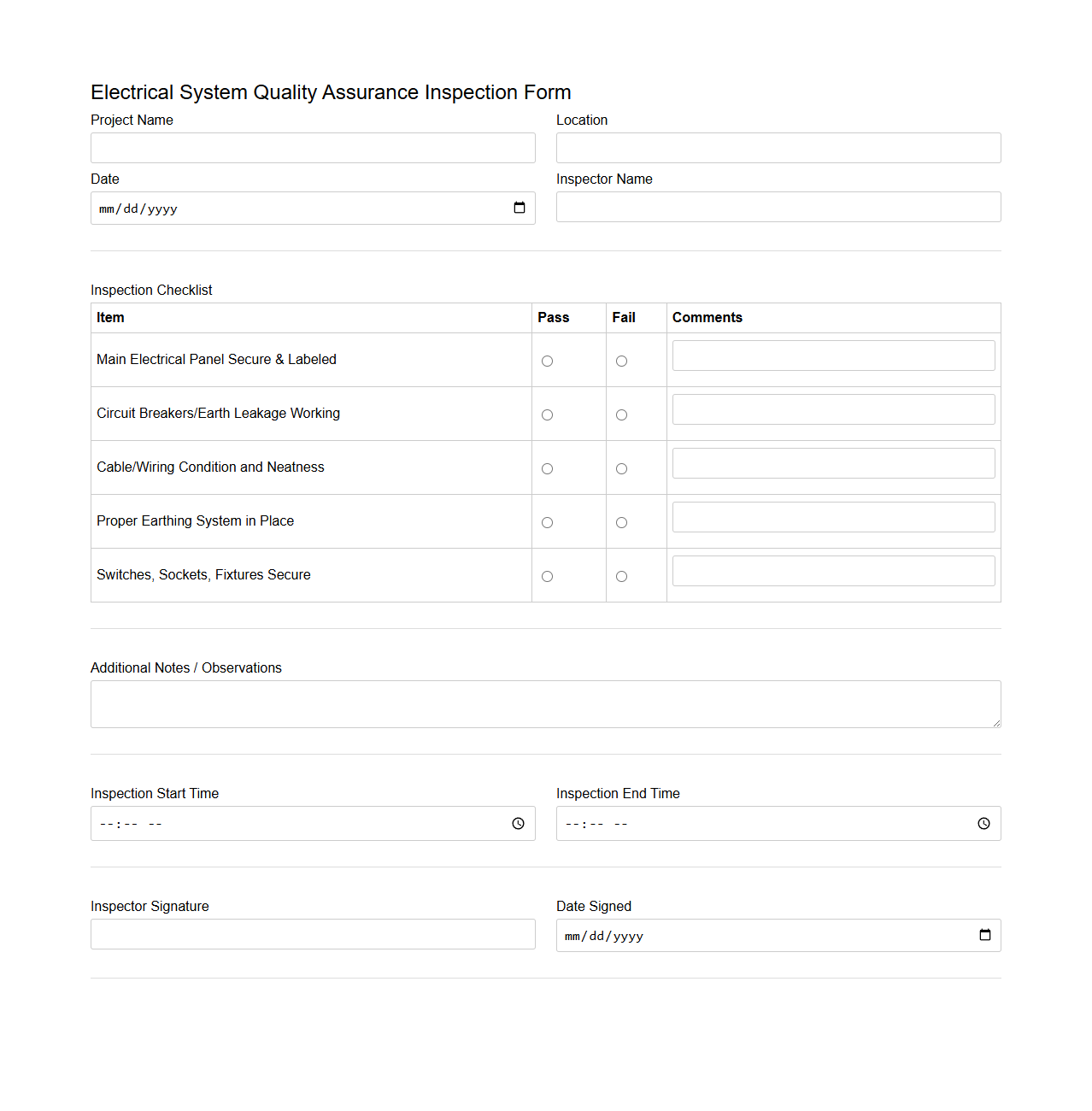

Electrical System Quality Assurance Inspection Form

The

Electrical System Quality Assurance Inspection Form document is utilized to systematically verify that electrical systems comply with industry standards, safety regulations, and project specifications. This form records detailed inspection results, including component integrity, wiring quality, and functional testing outcomes, ensuring all aspects meet required performance criteria. It serves as a critical tool for maintaining electrical system reliability and facilitating regulatory audits.

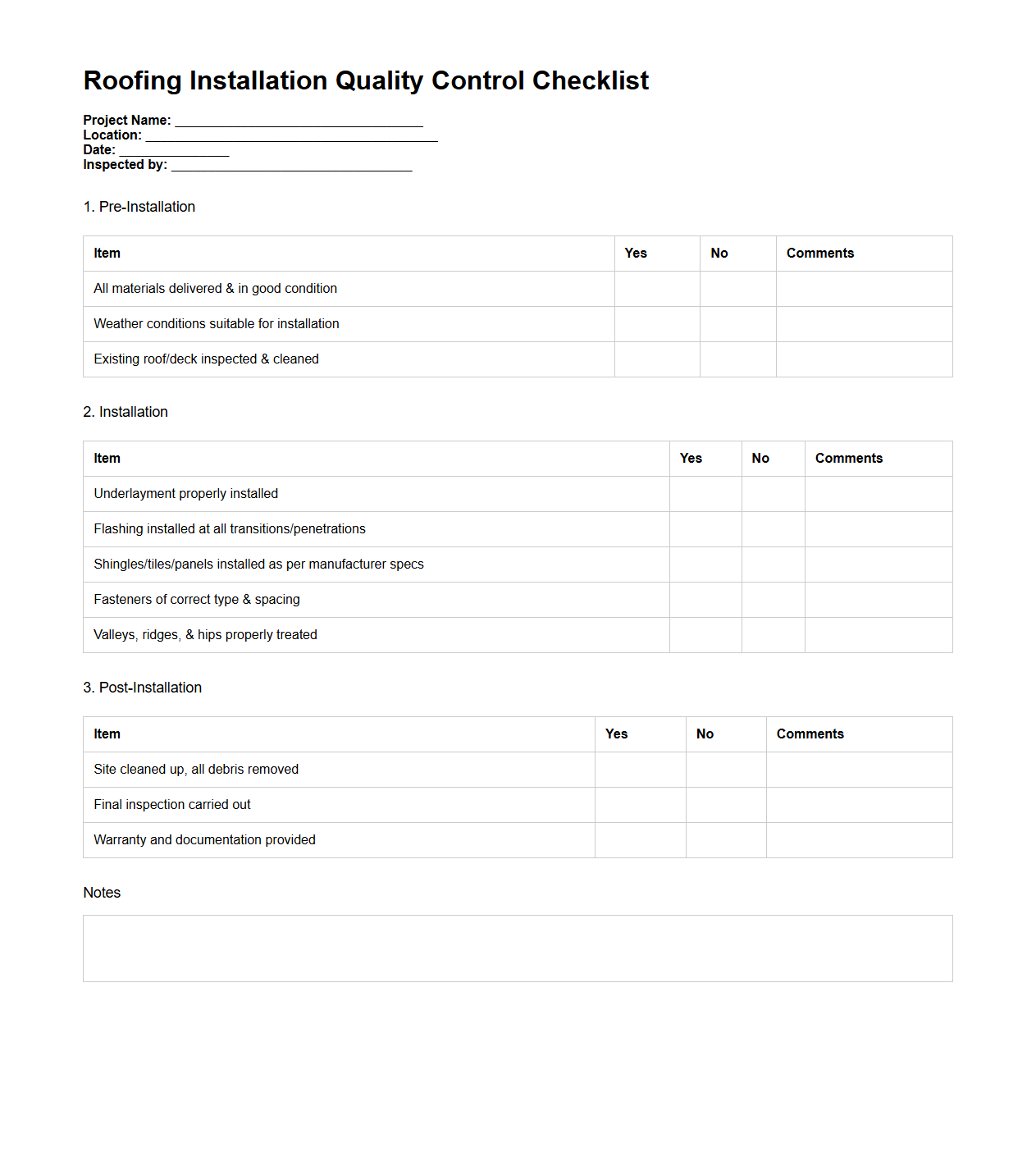

Roofing Installation Quality Control Checklist

The

Roofing Installation Quality Control Checklist document ensures that every step of the roofing process meets established industry standards and project specifications. It systematically verifies material quality, installation procedures, and safety compliance to prevent defects and extend roof longevity. This checklist serves as a critical tool for inspectors and contractors to maintain consistent workmanship and identify potential issues early.

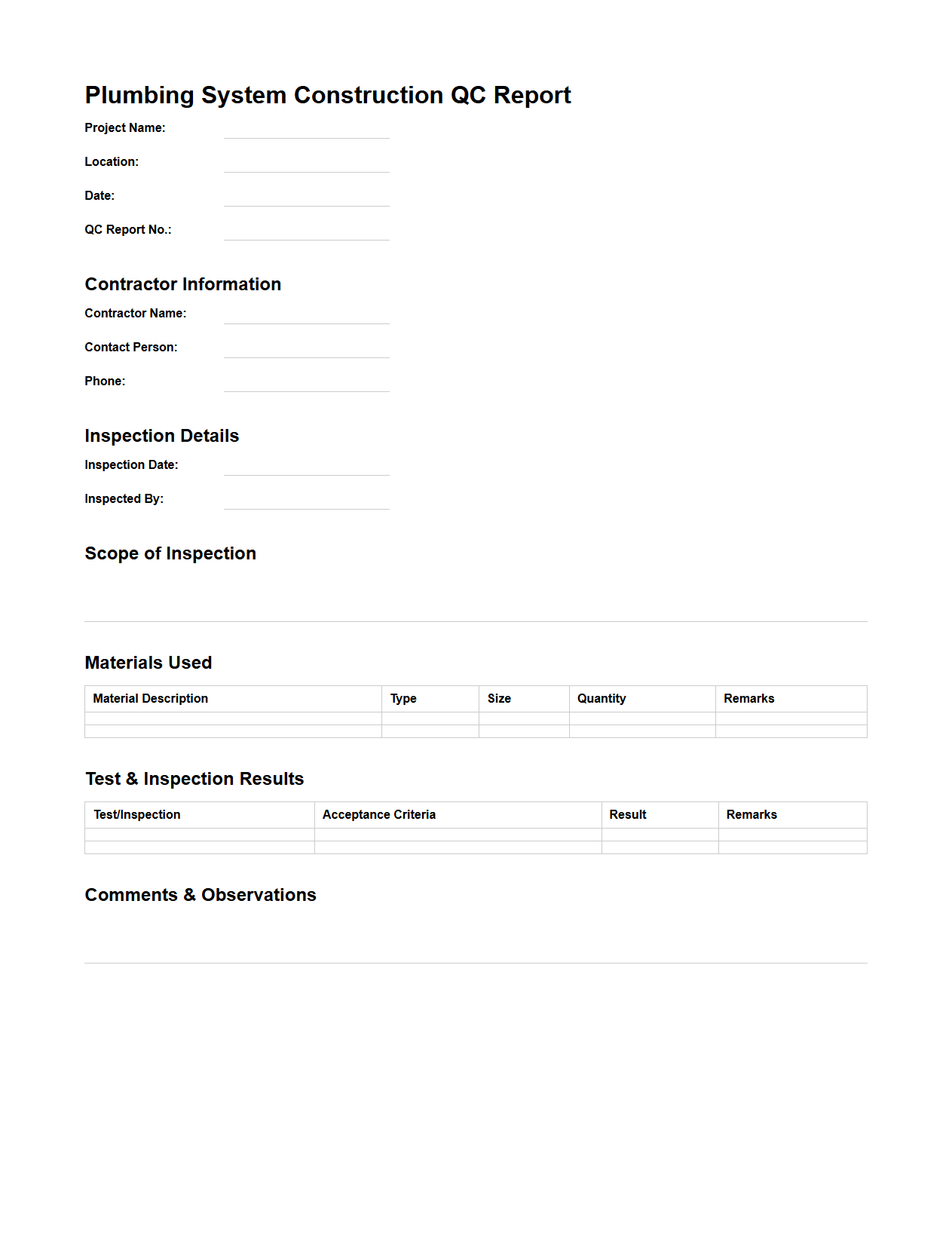

Plumbing System Construction QC Report Sample

A

Plumbing System Construction QC Report Sample document provides a detailed evaluation of plumbing installations to ensure compliance with design specifications, standards, and safety regulations. It typically includes inspections of pipework, fixtures, fittings, pressure tests, and material quality, identifying any defects or necessary corrections. This report serves as a critical tool for quality control teams to verify workmanship and maintain project integrity throughout construction phases.

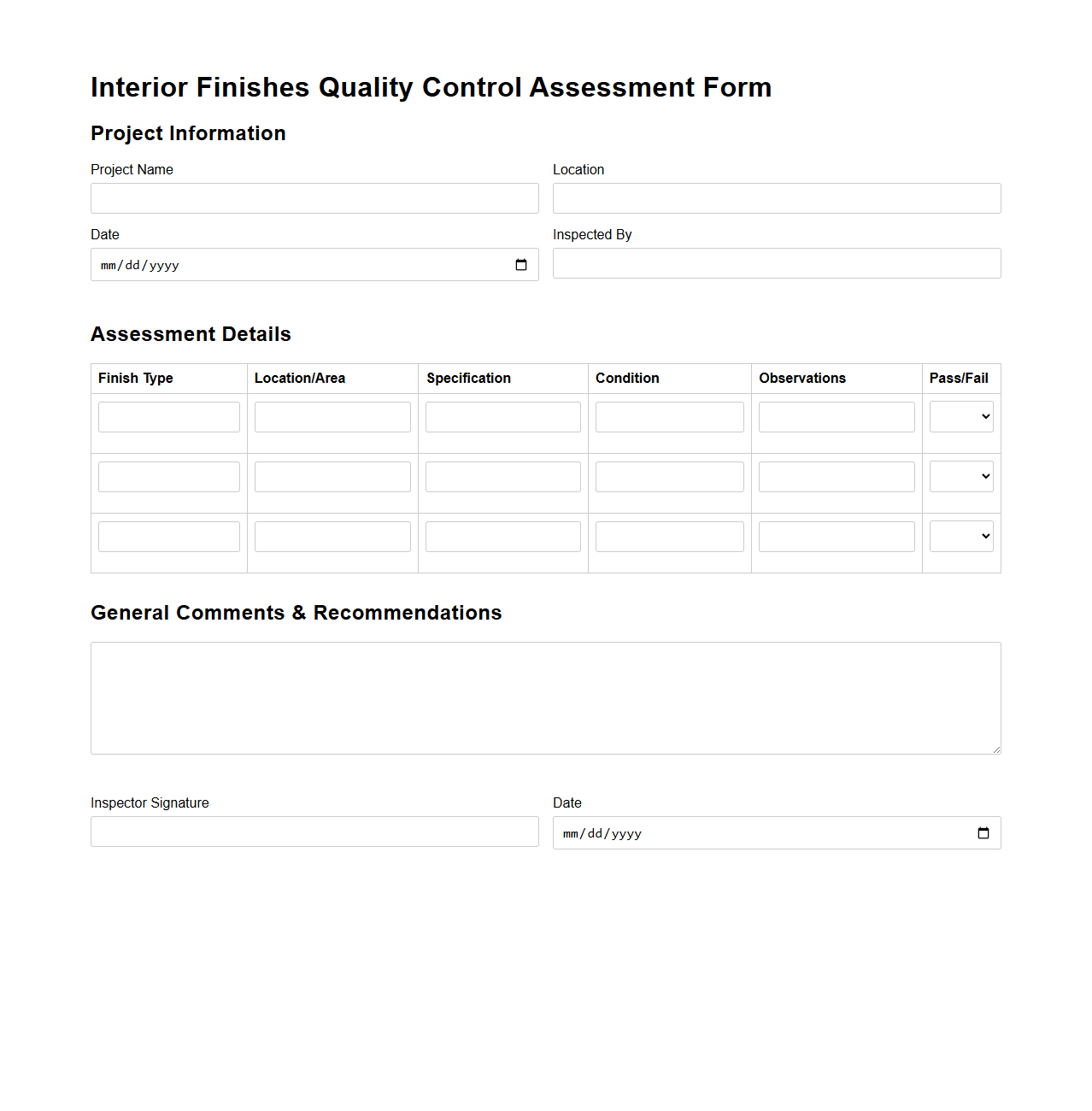

Interior Finishes Quality Control Assessment Form

The

Interior Finishes Quality Control Assessment Form document serves as a standardized tool for evaluating the quality and compliance of interior finishing work in construction projects. It systematically records inspections of materials, workmanship, and adherence to design specifications, ensuring defects and deviations are identified and corrected promptly. This form supports maintaining high standards, enhancing client satisfaction, and facilitating smooth project completion.

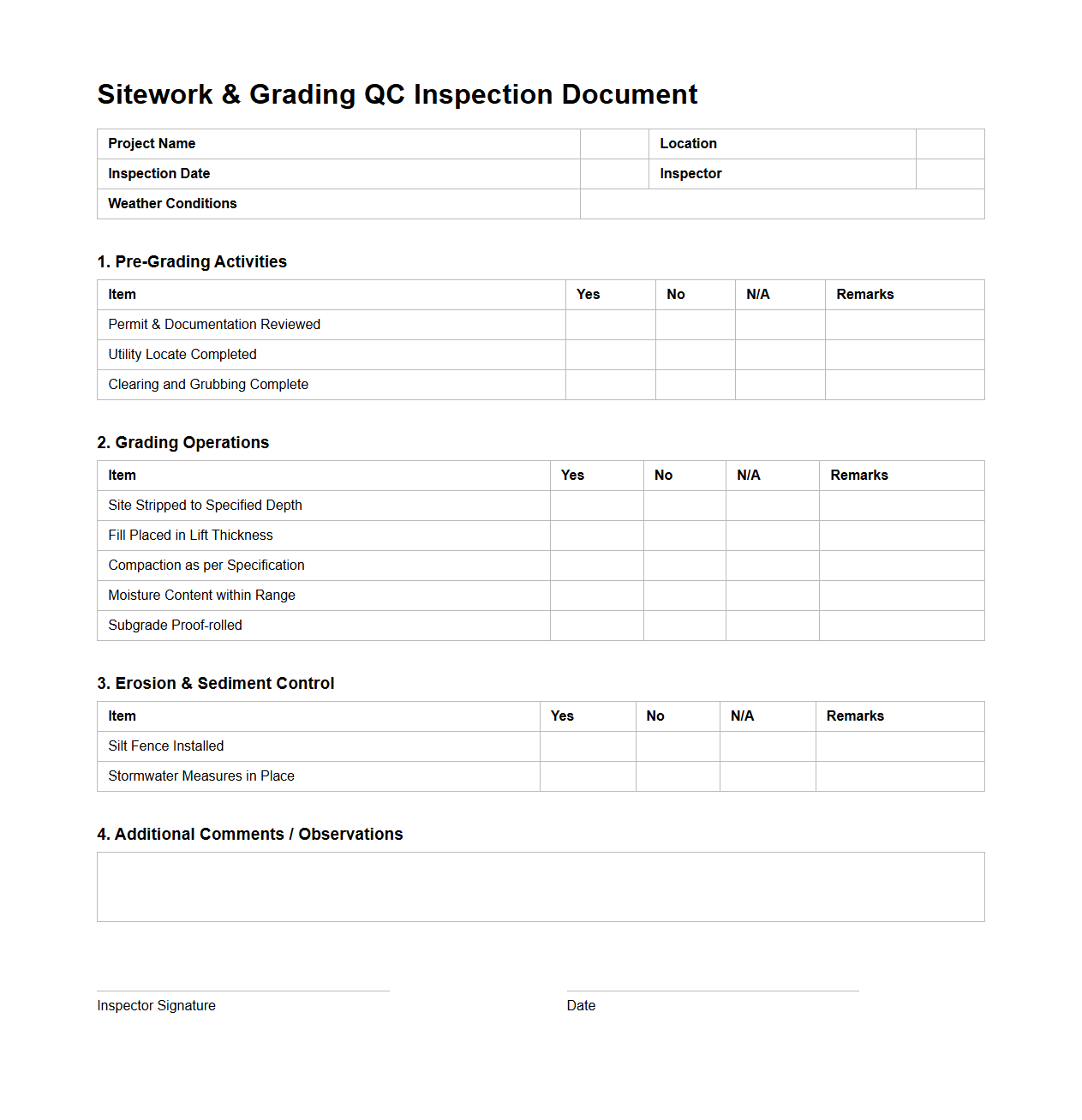

Sitework and Grading QC Inspection Document

Sitework and Grading QC Inspection Document ensures adherence to project specifications by systematically verifying earthwork, drainage, and soil compaction activities. It records critical data such as elevation checks, slope measurements, and material quality to guarantee

site grading meets engineering and environmental standards. This document is essential for maintaining construction quality control and preventing future site stability issues.

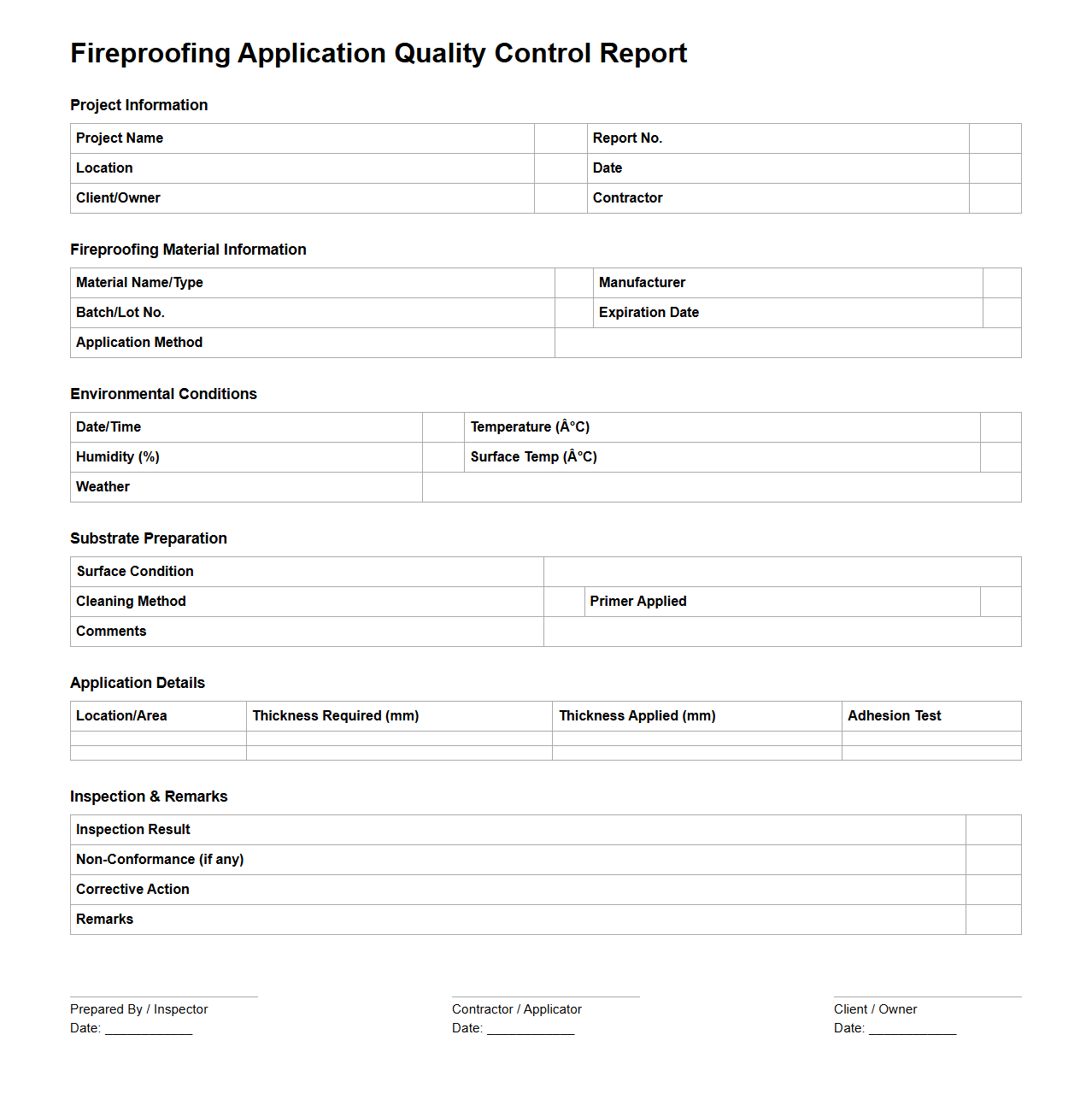

Fireproofing Application Quality Control Report

A

Fireproofing Application Quality Control Report document details the inspection and verification process ensuring that fireproofing materials are applied accurately and meet industry standards. It records measurements, adherence to specifications, environmental conditions, and any corrective actions taken during the application process. This report helps maintain safety compliance and guarantees the integrity of fire protection systems within a building or structure.

What are the required approval signatures for the Quality Control Report Document in commercial construction projects?

The required approval signatures for the Quality Control Report typically include the Quality Control Manager, Project Manager, and the Site Engineer. Each signature signifies the verification and acknowledgment of the accuracy and completeness of the report. These approvals ensure accountability and adherence to project quality standards.

Which specific ASTM standards must be referenced in the Quality Control Report Document for material compliance?

The Quality Control Report must reference relevant ASTM standards based on the material type used in the project, such as ASTM C150 for cement or ASTM A615 for reinforcing steel. Compliance with these standards ensures materials meet recognized quality and safety benchmarks. Referencing specific ASTM standards validates the material testing and acceptance criteria within the report.

How should non-conformance issues be documented and tracked in the Quality Control Report?

Non-conformance issues must be clearly documented with descriptions, photos, and impacted areas specified in the Quality Control Report. A tracking system or log should be maintained to record corrective actions and their completion status. This systematic approach facilitates resolution and compliance verification throughout the project lifecycle.

What is the retention period for storing Quality Control Report Documents according to industry best practices?

Industry best practices recommend retaining Quality Control Report Documents for a minimum of five to seven years after project completion. This retention period supports warranty claims, legal inspections, and quality audits. Proper storage, often in digital form, ensures easy access and preservation of critical quality data.

Are photographic evidences mandatory in the Quality Control Report Document for every inspection phase?

Photographic evidence is highly recommended but may not be mandatory for every inspection phase unless specified by project requirements. Photos provide visual confirmation and transparency of the construction quality and detected issues. Incorporating images strengthens documentation and supports objective quality assessments.

More Construction Templates