A Container Loading Plan Document Sample for Maritime Transport provides a detailed layout of how cargo containers are arranged on a vessel to maximize space and ensure safety during transit. It includes important information such as container numbers, weight distribution, and stowage positions, facilitating efficient loading and unloading. This document is essential for optimizing maritime logistics, preventing damage, and complying with shipping regulations.

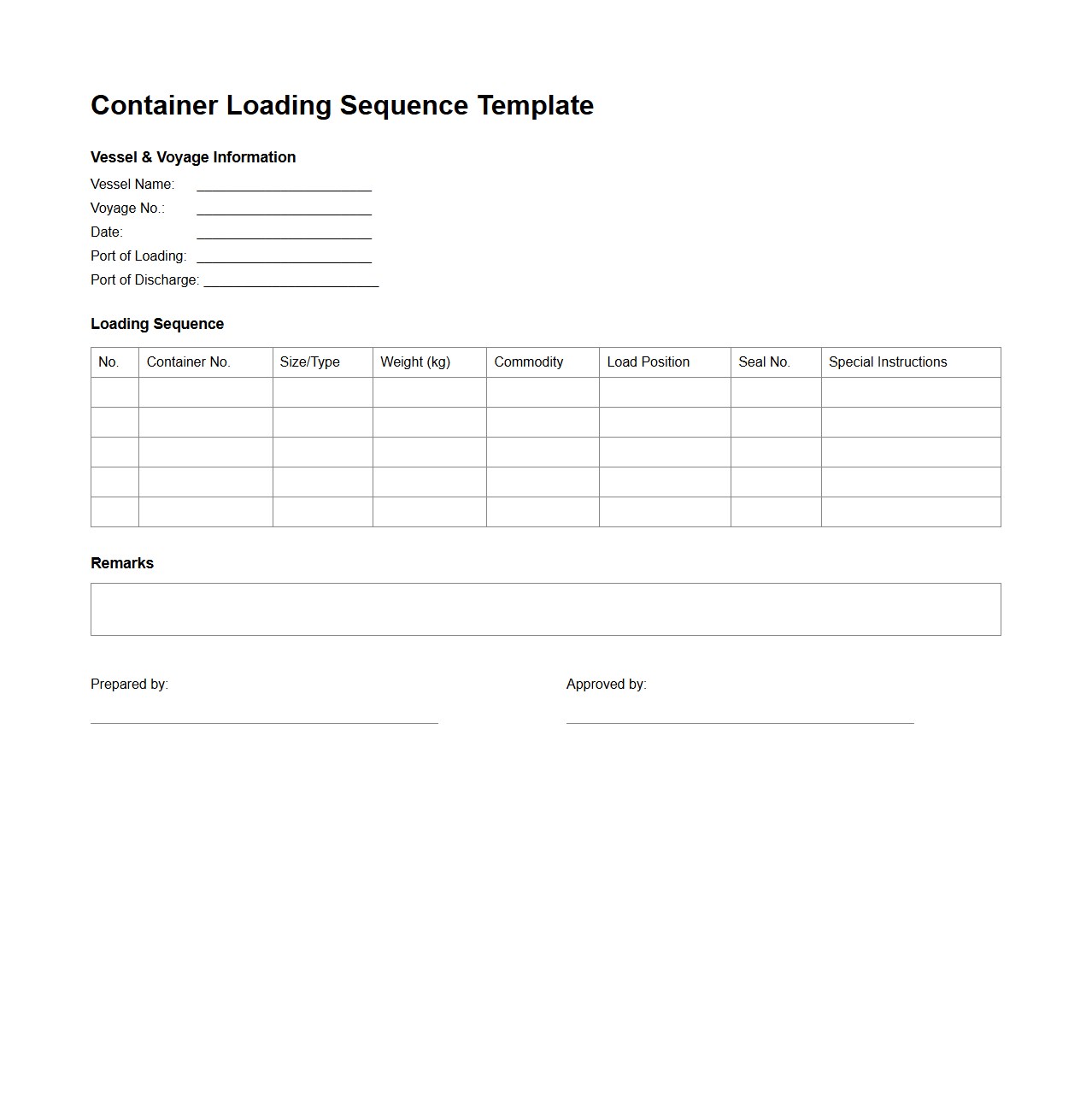

Container Loading Sequence Template for Maritime Shipping

The

Container Loading Sequence Template for maritime shipping is a detailed document outlining the precise order and positioning of containers on a vessel to optimize space utilization and ensure vessel stability. It includes critical data such as container dimensions, weight distribution, and sequence for efficient loading and unloading at multiple ports. This template helps reduce delays, prevent damage, and comply with safety regulations throughout the shipping process.

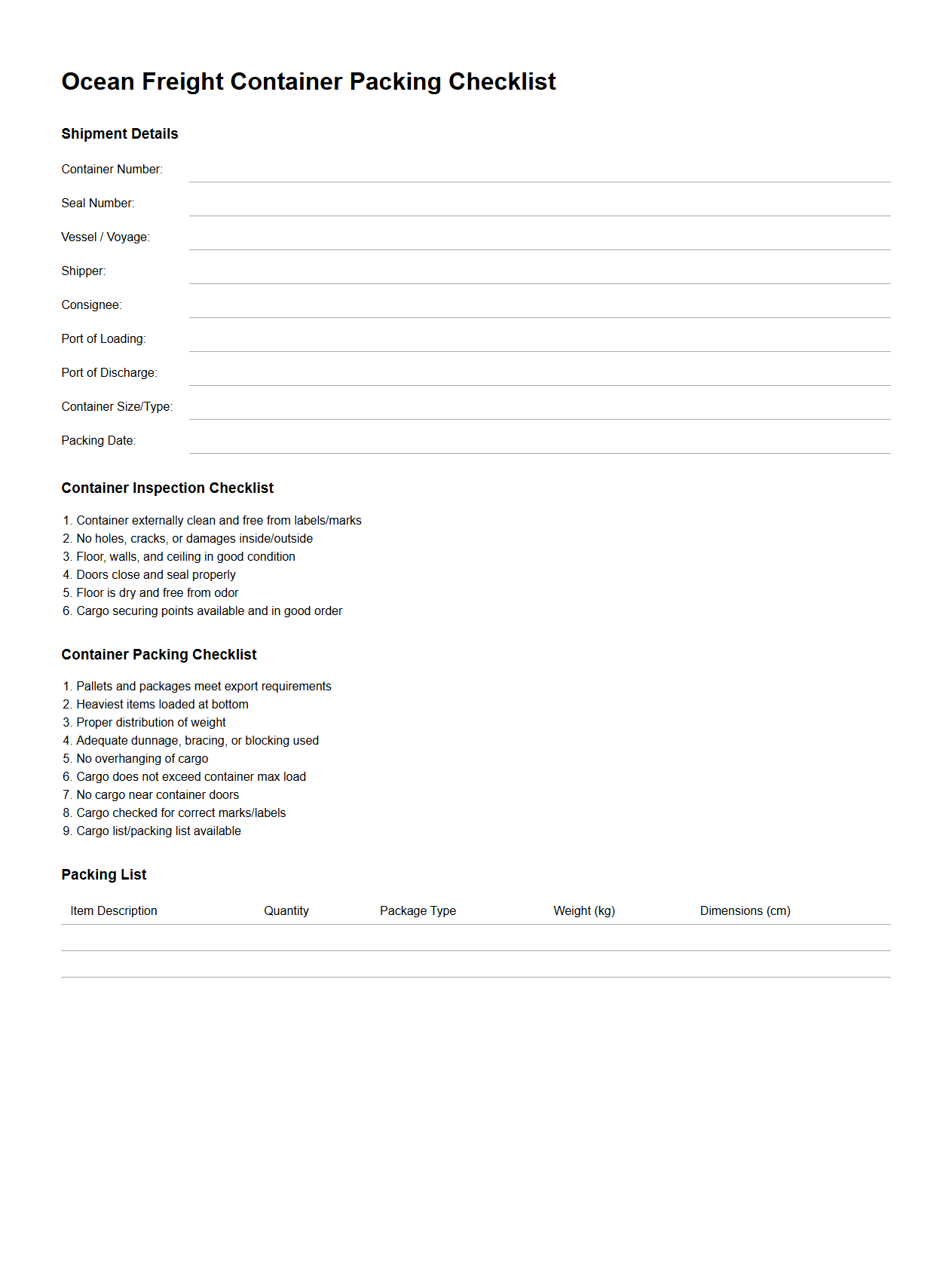

Ocean Freight Container Packing Checklist Example

An

Ocean Freight Container Packing Checklist Example document serves as a detailed guide to ensure all necessary steps and materials are accounted for when packing goods into shipping containers for ocean freight transport. It helps verify proper loading procedures, weight distribution, item protection, and compliance with shipping regulations to prevent damage and delays. This checklist is essential for logistics managers and freight handlers aiming to optimize container space and maintain cargo integrity.

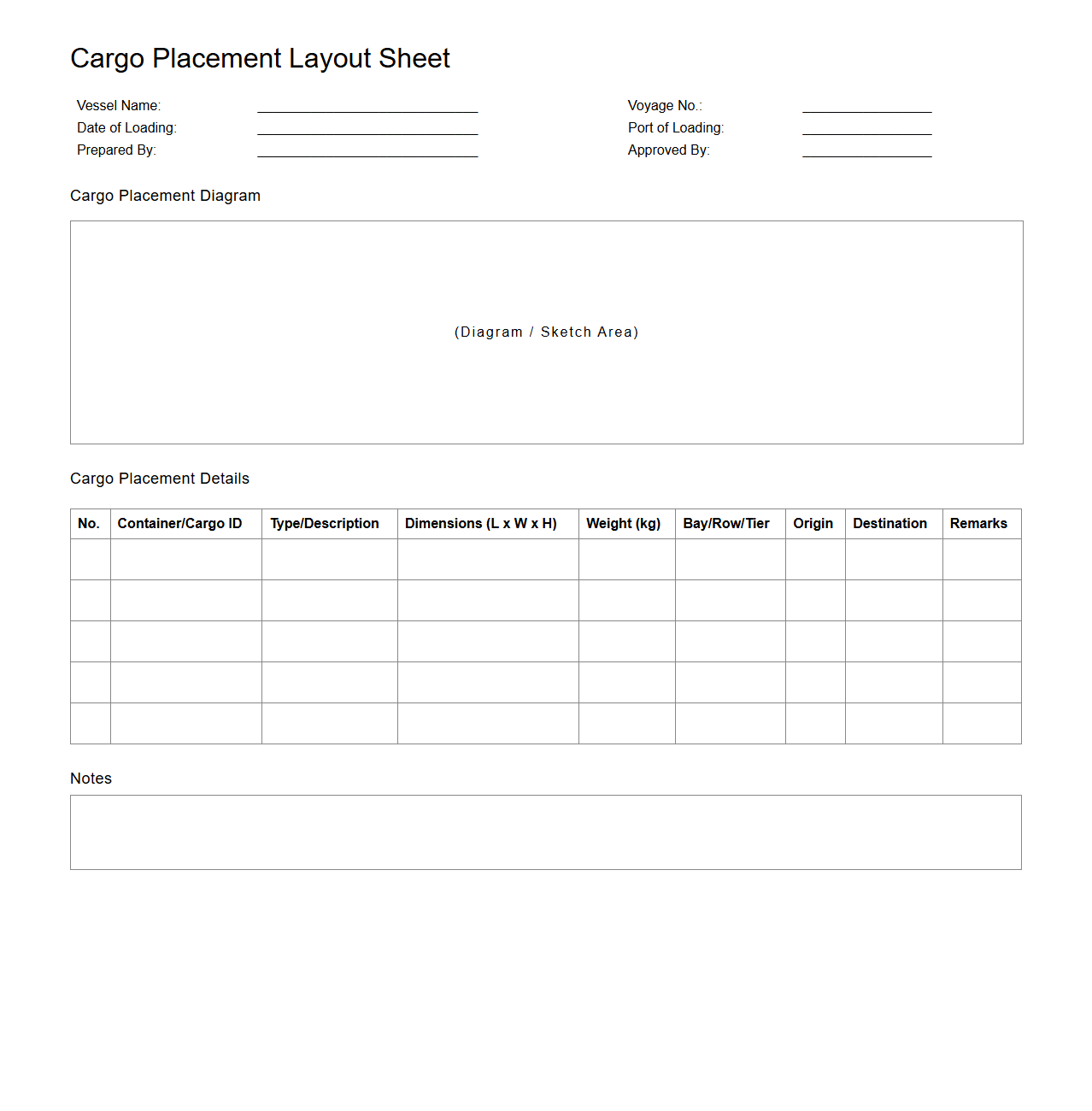

Cargo Placement Layout Sheet for Sea Transport

A

Cargo Placement Layout Sheet for sea transport is a detailed document that outlines the exact positioning of cargo within a vessel's hold or container to ensure balanced weight distribution and optimal space utilization. This sheet helps in preventing load shifts during transit, enhancing safety and compliance with maritime regulations. It also serves as a vital reference for loading and unloading operations, improving efficiency and minimizing damage risk.

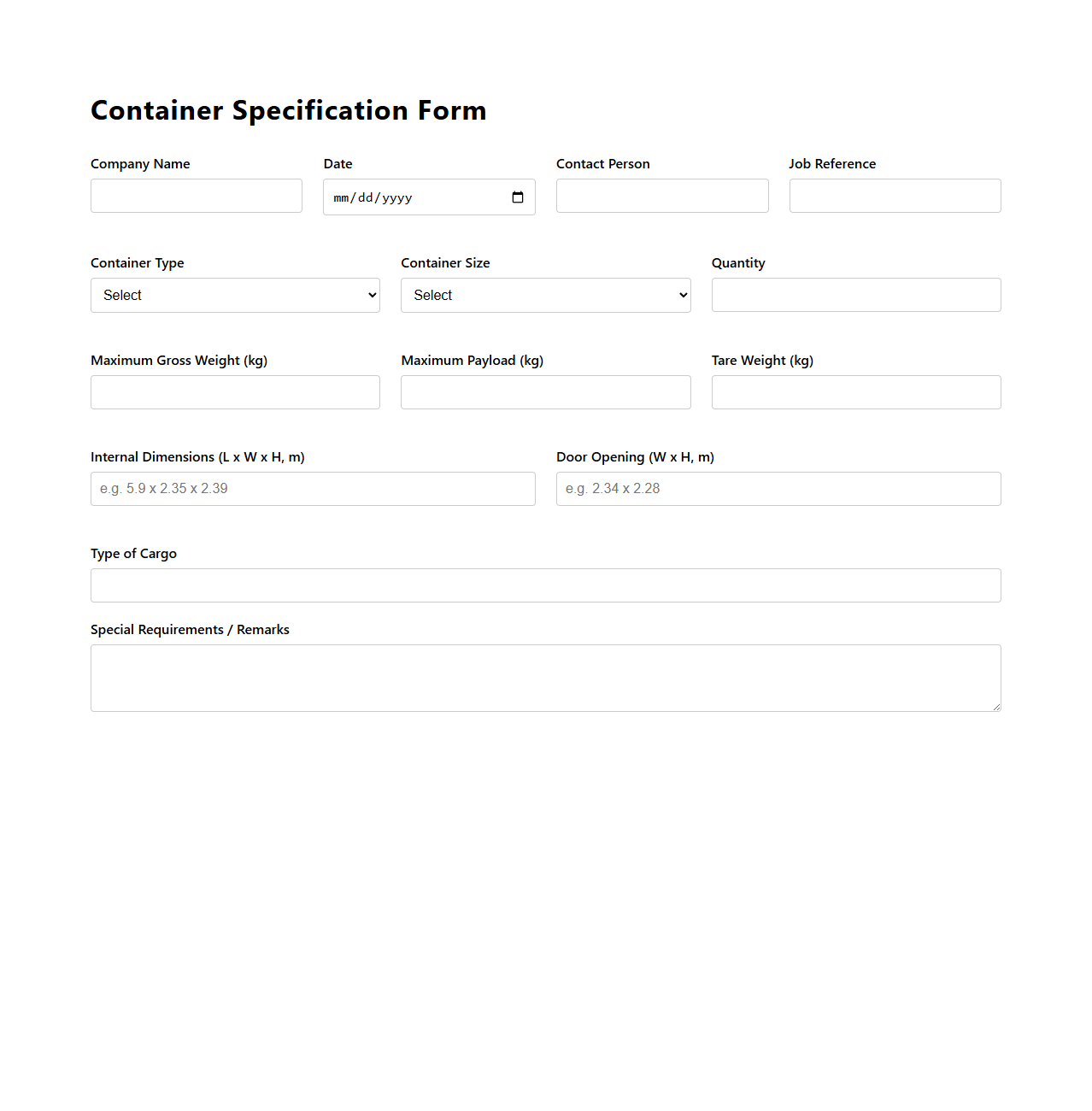

Container Specification Form for Marine Logistics

The

Container Specification Form in marine logistics is a detailed document that outlines the exact dimensions, weight limits, and structural features of a shipping container to ensure compatibility with cargo and transport regulations. It serves as a critical reference to verify container suitability for specific types of goods, helping prevent damage and optimize load efficiency during maritime transport. This form facilitates communication between shippers, carriers, and port operators to maintain operational standards and compliance with international shipping requirements.

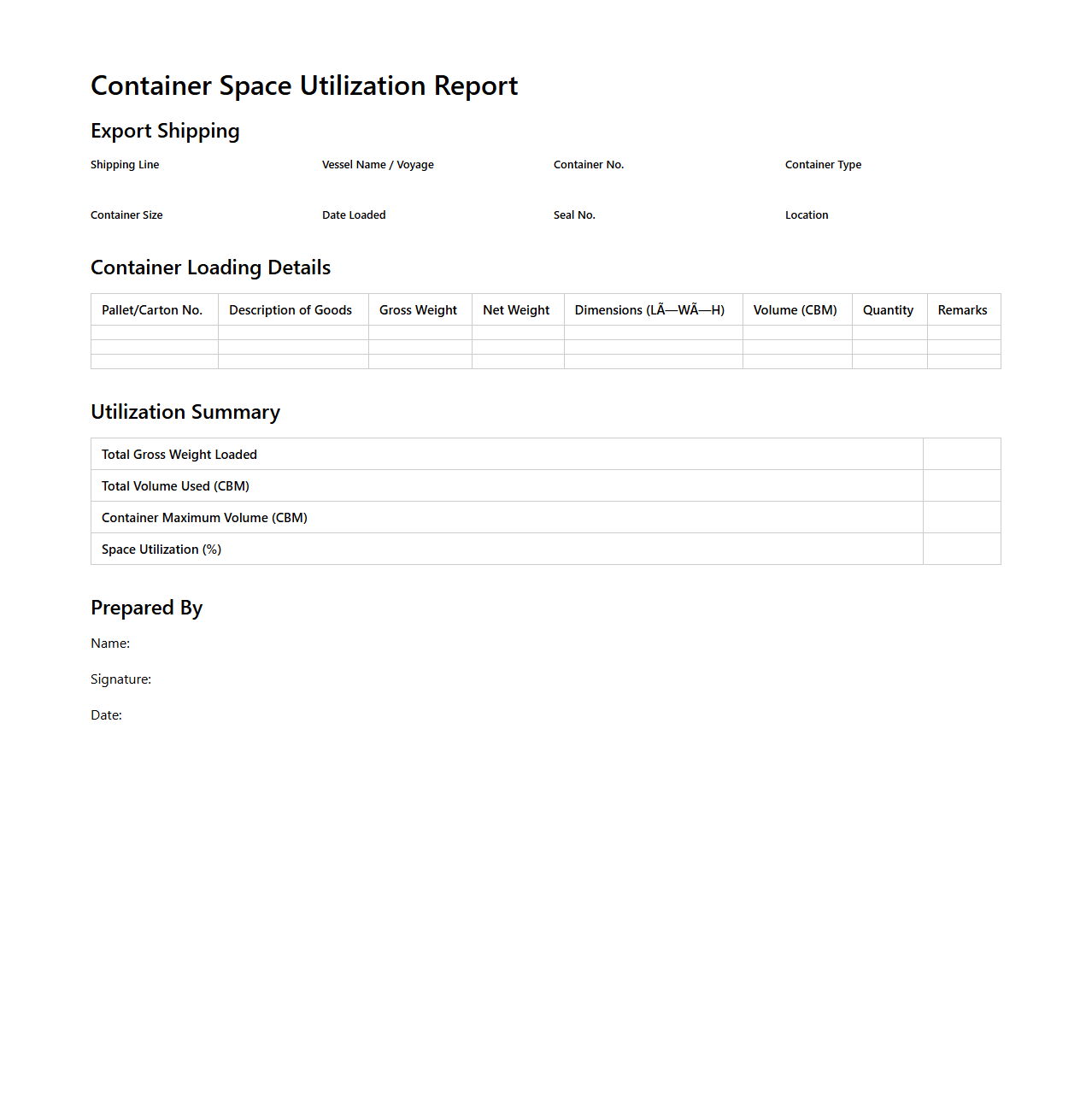

Container Space Utilization Report for Export Shipping

The

Container Space Utilization Report for export shipping documents provides detailed information on how cargo is arranged and loaded within a shipping container to maximize space efficiency. This report includes data on volume, weight distribution, and pallet placement, ensuring compliance with shipping regulations and optimizing freight costs. Shipping companies and exporters use this report to improve load planning and avoid damage during transit.

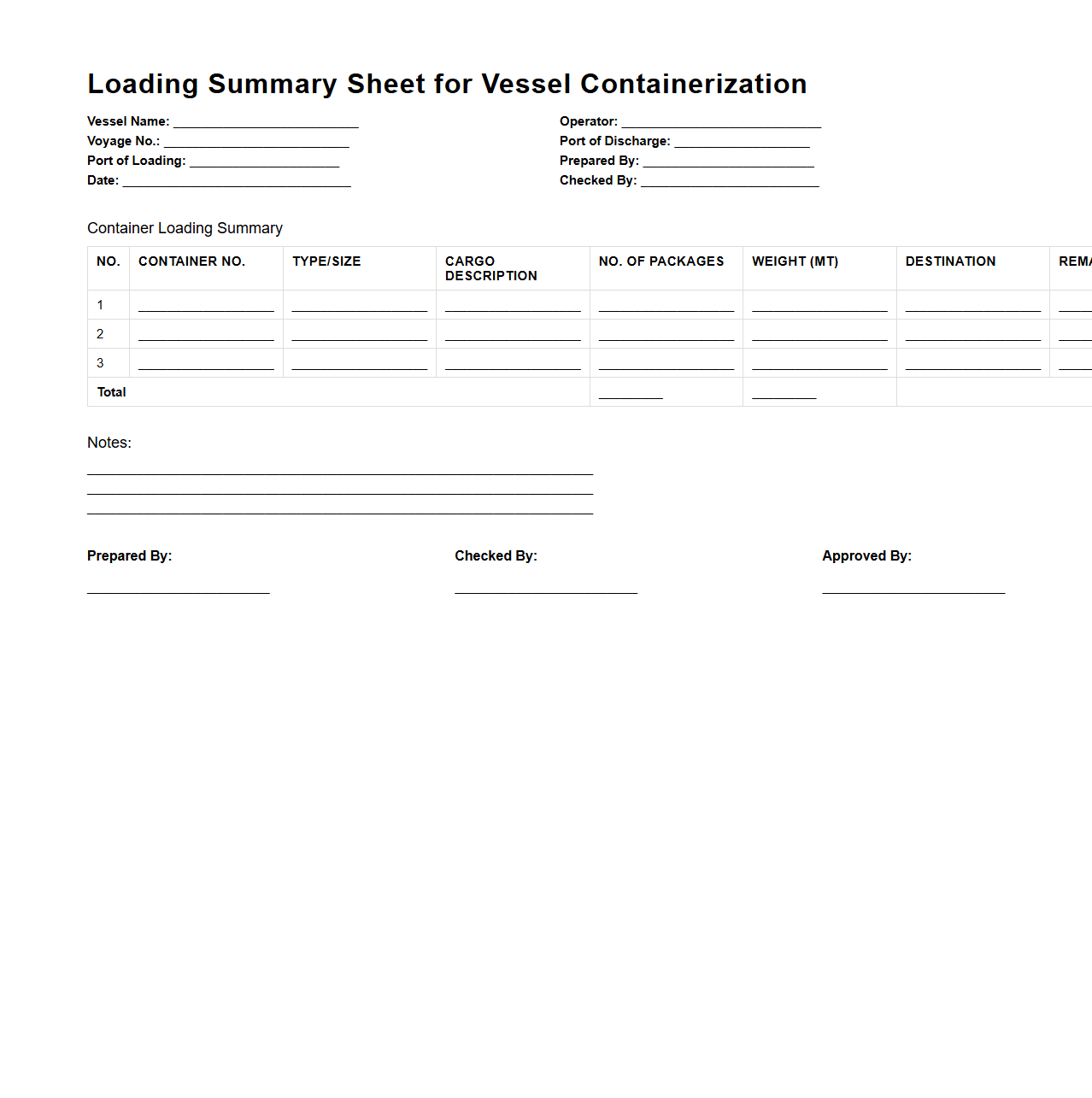

Loading Summary Sheet for Vessel Containerization

The

Loading Summary Sheet for Vessel Containerization is a crucial document that outlines the detailed plan for stowing containers on a vessel, ensuring optimal space utilization and balance. It includes container numbers, weights, dimensions, and positions within the ship to facilitate safe and efficient loading operations. This summary aids port authorities and shipping personnel in verifying cargo details and streamlining vessel loading procedures.

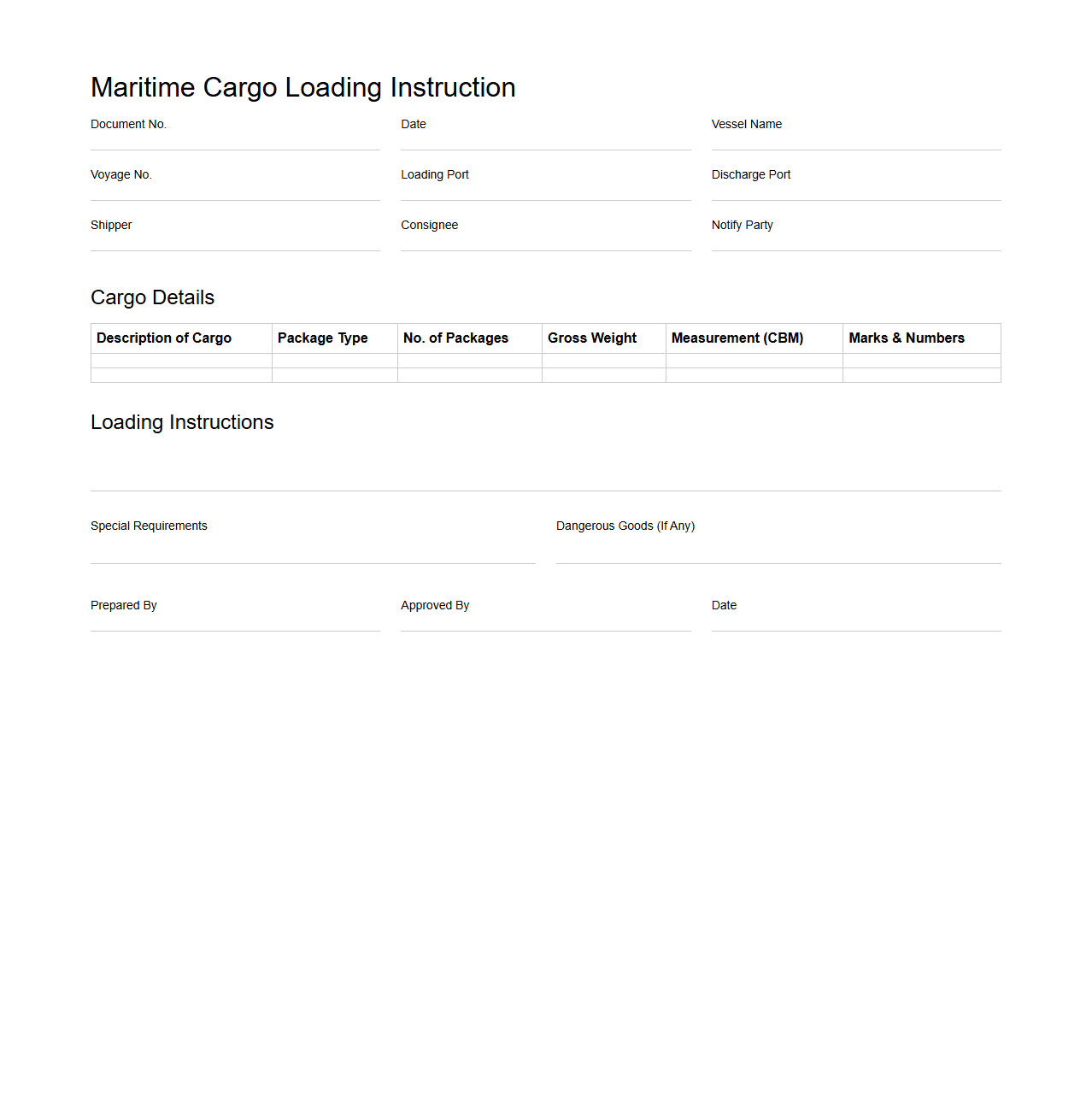

Maritime Cargo Loading Instruction Template

A

Maritime Cargo Loading Instruction Template is a standardized document that provides detailed guidelines for the proper loading, stowage, and securing of cargo on vessels. It ensures compliance with safety regulations and optimizes space utilization, minimizing the risks of damage during maritime transport. This template typically includes information on cargo weight, dimensions, handling instructions, and specific loading sequences to facilitate efficient and safe operations.

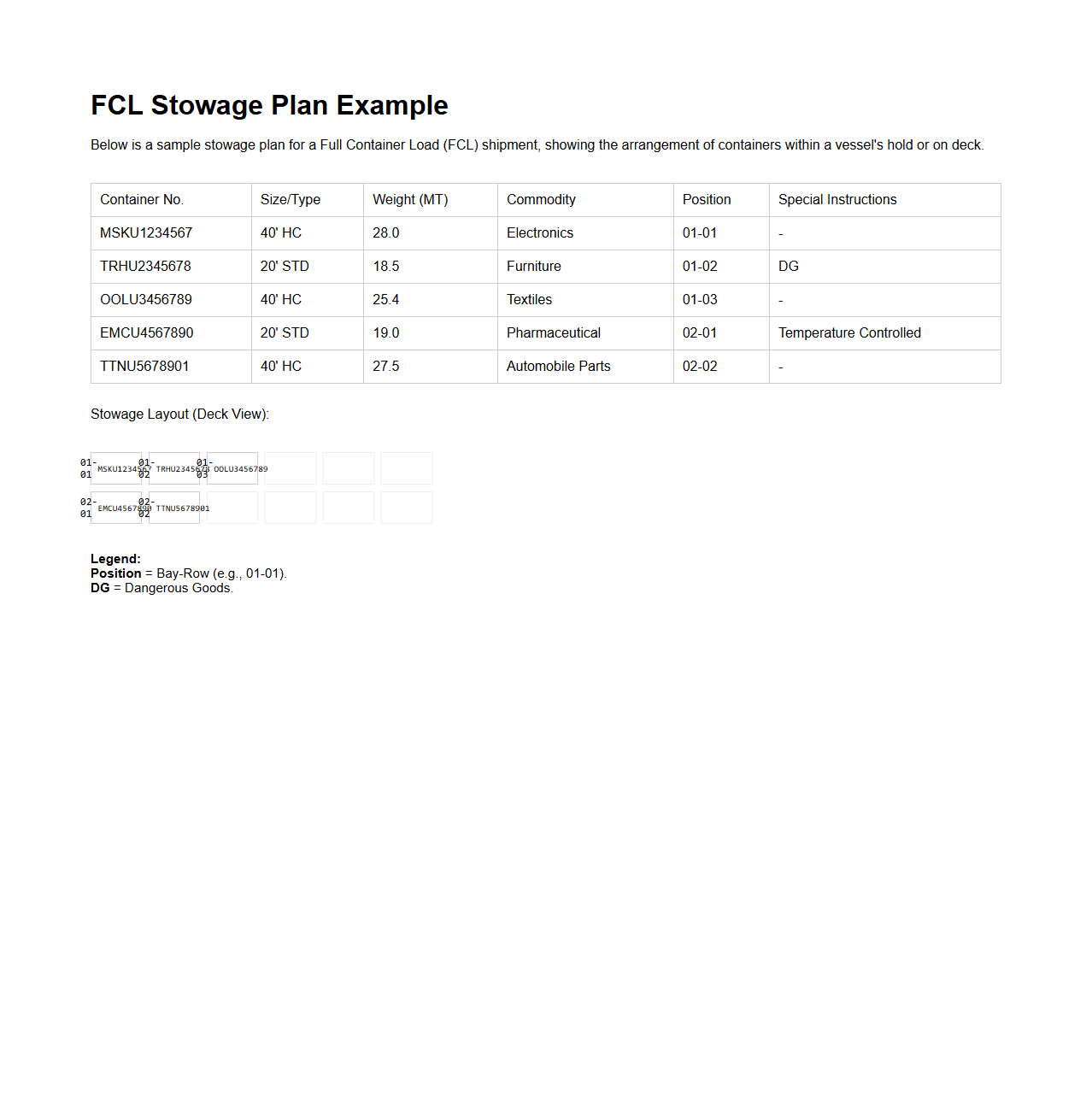

Full Container Load (FCL) Stowage Plan Example

A

Full Container Load (FCL) Stowage Plan Example document outlines the detailed arrangement of cargo within a shipping container to maximize space utilization and ensure safe transportation. It includes information such as container dimensions, cargo types, weight distribution, and loading sequence, which helps prevent damage and improves handling efficiency during shipping. This plan serves as a crucial reference for freight forwarders, shipping lines, and warehouse personnel to coordinate precise loading and unloading operations.

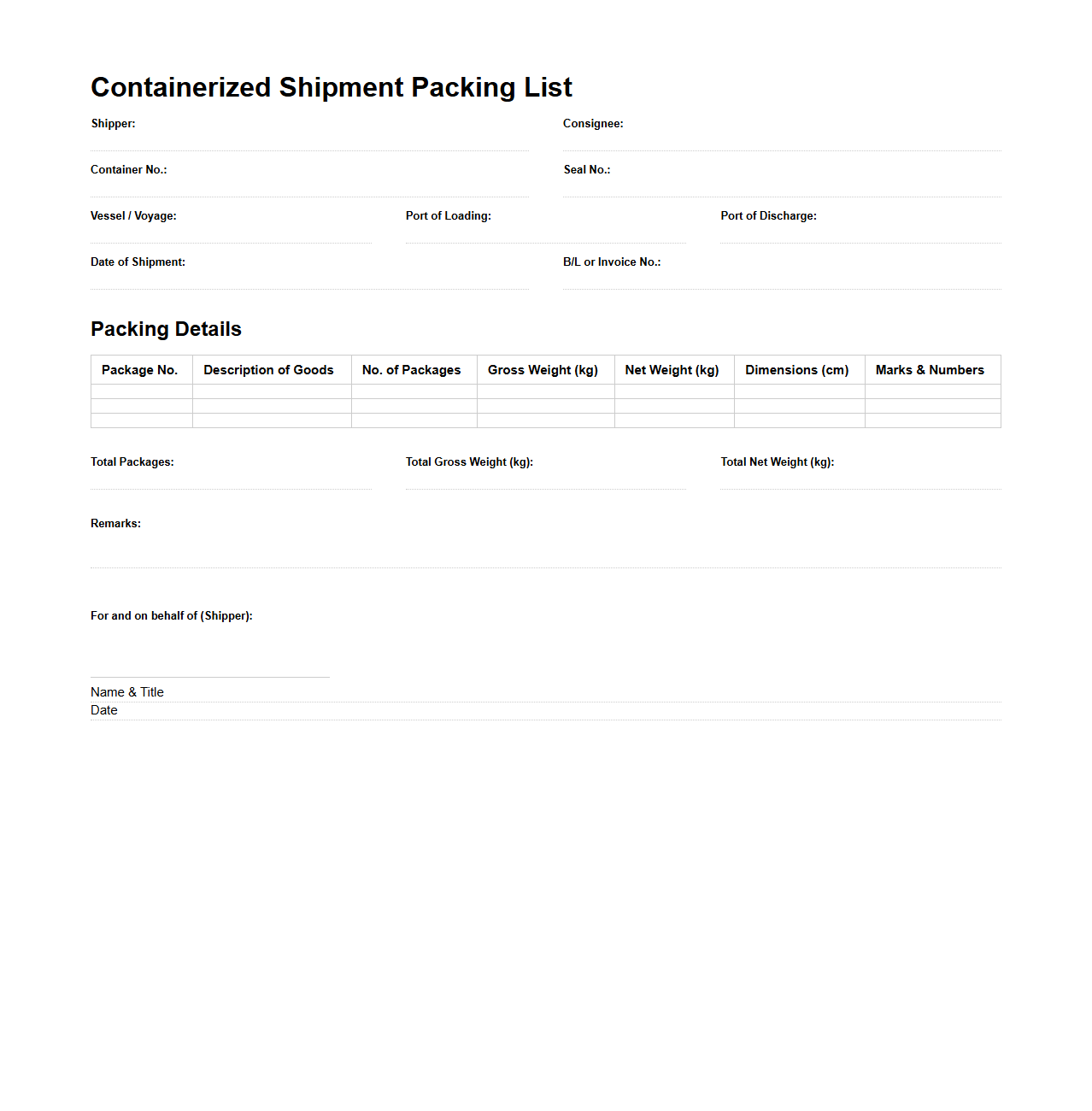

Containerized Shipment Packing List Format

A

Containerized Shipment Packing List Format document outlines detailed information about the contents of a shipping container, including item descriptions, quantities, weights, and packaging types. It facilitates efficient customs clearance, inventory management, and accurate shipping records by providing a standardized layout for all cargo details. This format ensures seamless communication between shippers, carriers, and recipients, minimizing errors and delays in the supply chain.

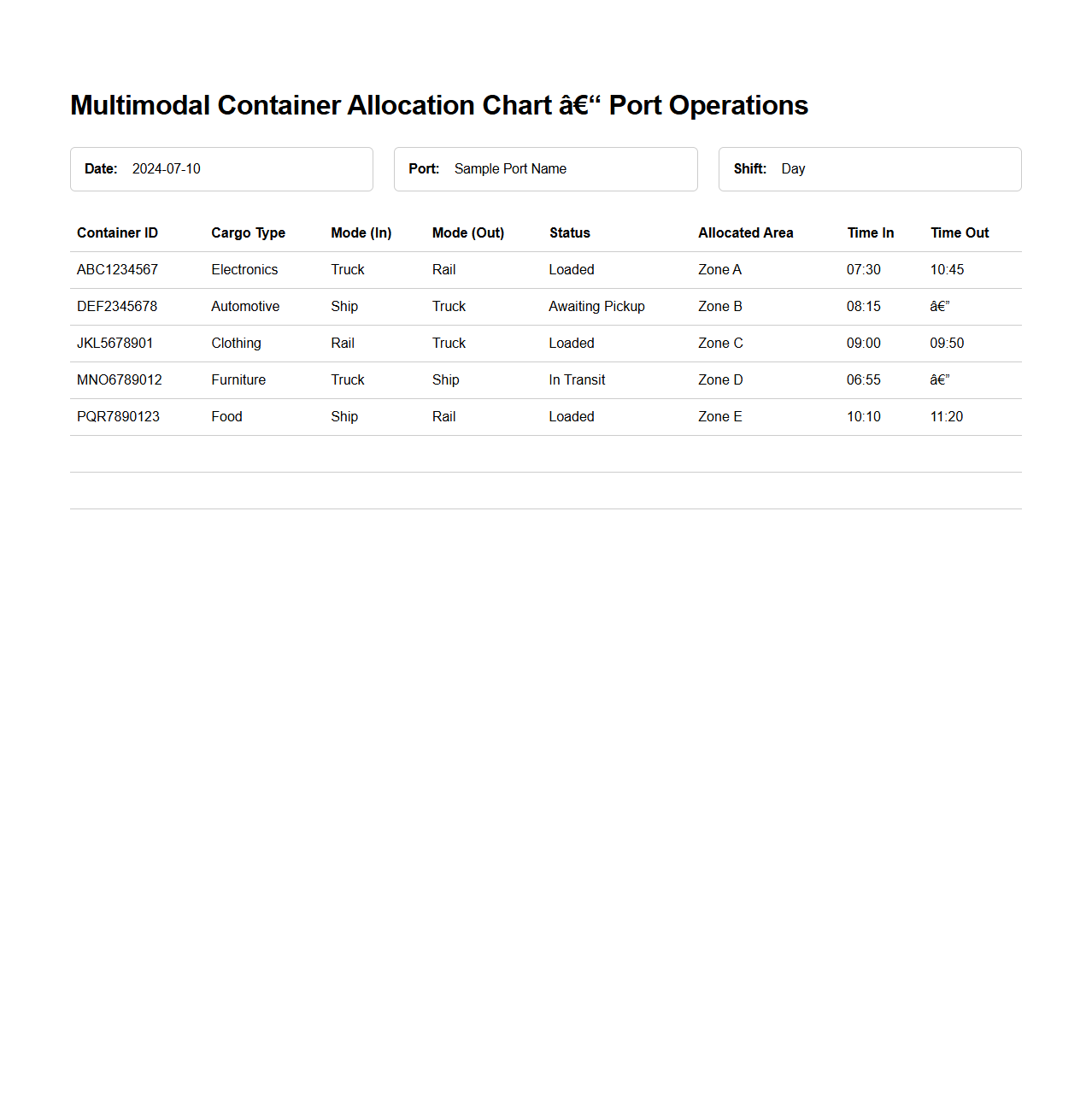

Multimodal Container Allocation Chart for Port Operations

The

Multimodal Container Allocation Chart for Port Operations is a strategic document used to optimize the assignment of shipping containers across various transport modes such as sea, rail, and road, ensuring efficient cargo handling and logistics flow. It integrates real-time data on container availability, vessel schedules, and transport capacity to minimize delays and maximize port throughput. This chart plays a critical role in coordinating multimodal transport, reducing congestion, and improving overall supply chain visibility.

What key information should be included in a Container Loading Plan Document for maritime transport?

The Container Loading Plan Document must clearly outline the container identification numbers, their respective sizes, and weight details to ensure proper tracking and handling. It should also specify the exact position of each container within the vessel's hold or deck, including bay, row, and tier. Additionally, the plan includes a detailed description of the cargo type and any special handling instructions necessary for efficient and safe loading.

How does the Container Loading Plan ensure compliance with vessel stability and weight distribution requirements?

The Container Loading Plan addresses vessel stability by meticulously organizing containers to maintain the ship's center of gravity within safe limits. Weight distribution is optimized by balancing heavy and light containers across the vessel to prevent undue stress and listing. This strategic placement is critical to adhere to maritime safety regulations and avoid compromising the vessel's structural integrity during transit.

Which parties are typically responsible for preparing, reviewing, and approving the Container Loading Plan Document?

The initial preparation of the Container Loading Plan is usually handled by the shipper's logistics team or a specialized stowage planner. It is then reviewed by the vessel's chief officer and the carrier's operations team to ensure feasibility and safety compliance. Final approval often rests with the port authorities and the vessel's master before cargo operations commence.

How are hazardous materials or special cargo items indicated and accommodated within the loading plan?

Hazardous materials are distinctly marked in the Container Loading Plan with internationally recognized hazard symbols and classification codes for easy identification. Their placement is carefully planned to comply with segregation rules, keeping them distant from incompatible substances and sensitive cargo. Special cargo items, such as refrigerated or oversized containers, are allocated specific locations equipped to handle their unique requirements.

What systems or tools are commonly used to generate and manage Container Loading Plans in maritime logistics?

Modern Container Loading Plans are generated using advanced stowage planning software like CAPSTAN, AutoStow, or SPARCS N4, which optimize loading sequences and space utilization. These systems integrate real-time data on container dimensions, weights, and hazardous classifications to enhance accuracy. Additionally, they provide electronic documentation and facilitate communication between all stakeholders involved in the shipping process.