A Material Delivery Document Sample for Construction Sites provides a detailed record of materials delivered, including quantities, specifications, and delivery dates to ensure accuracy and accountability. This document helps track inventory, verifies compliance with purchase orders, and supports efficient project management. Proper use of such samples minimizes delays and discrepancies on construction sites.

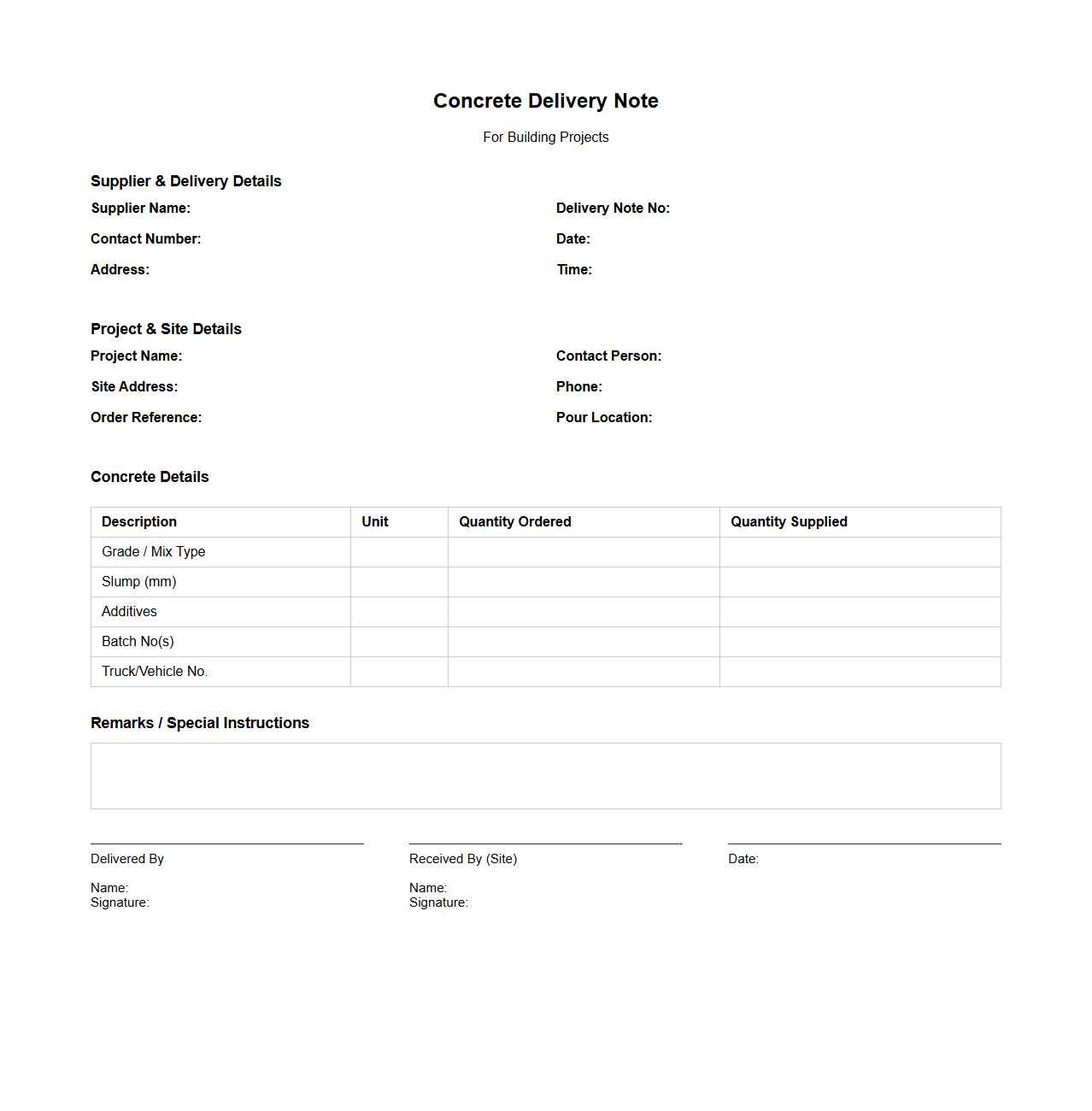

Concrete Delivery Note Template for Building Projects

A

Concrete Delivery Note Template for building projects is a standardized document used to record detailed information about the delivery of concrete to a construction site. It typically includes specifics such as delivery date, batch number, volume of concrete, supplier details, and site location to ensure accurate tracking and verification of materials used. This document helps in maintaining quality control, project management efficiency, and compliance with construction standards.

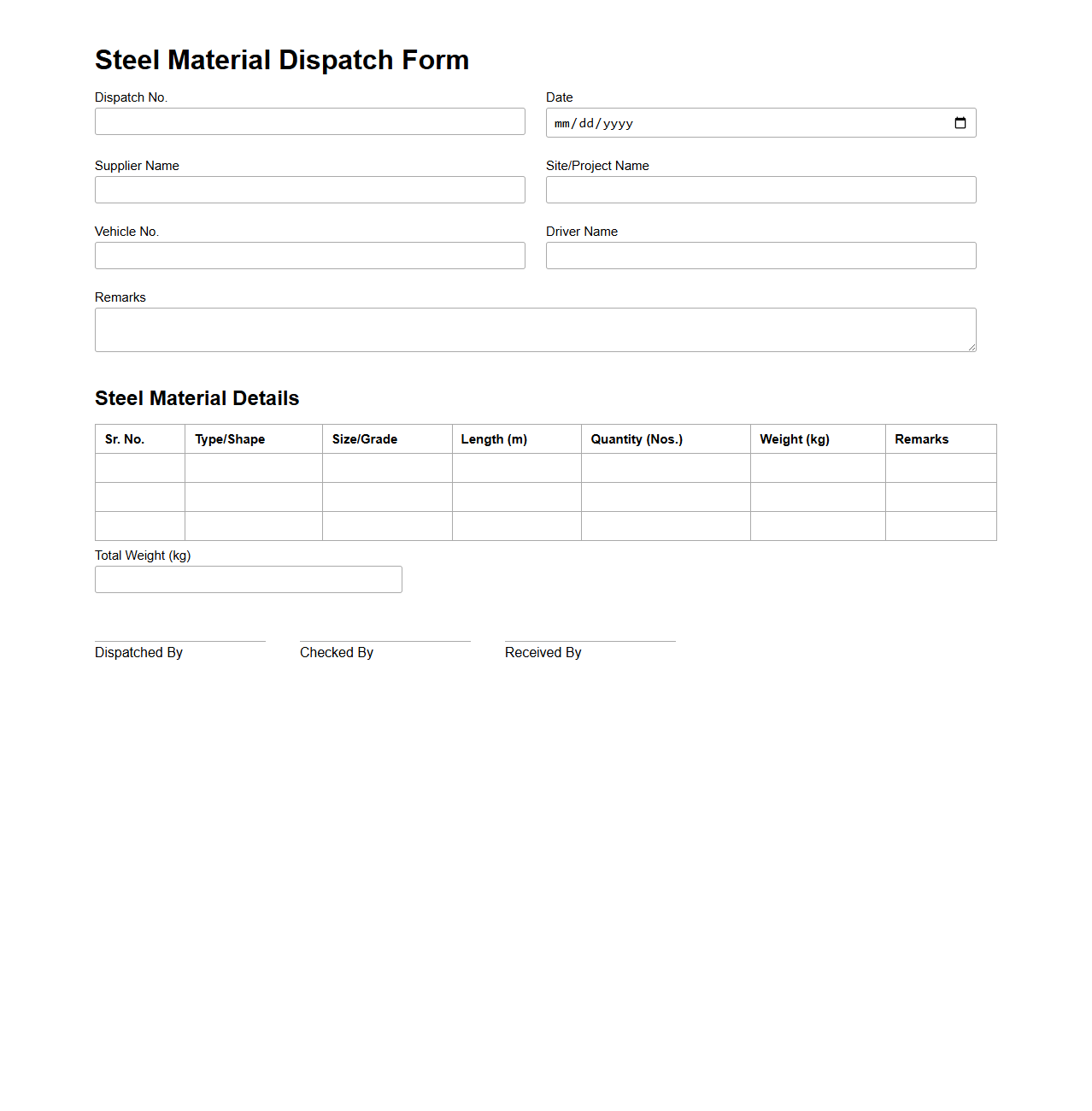

Steel Material Dispatch Form for Construction Sites

A

Steel Material Dispatch Form for construction sites is a critical document used to track and record the delivery of steel materials from suppliers to the project location. It details quantities, specifications, batch numbers, and delivery dates, ensuring accurate inventory management and preventing material shortages or discrepancies. This form also supports quality control and accountability by verifying that the dispatched steel meets project standards and contractual requirements.

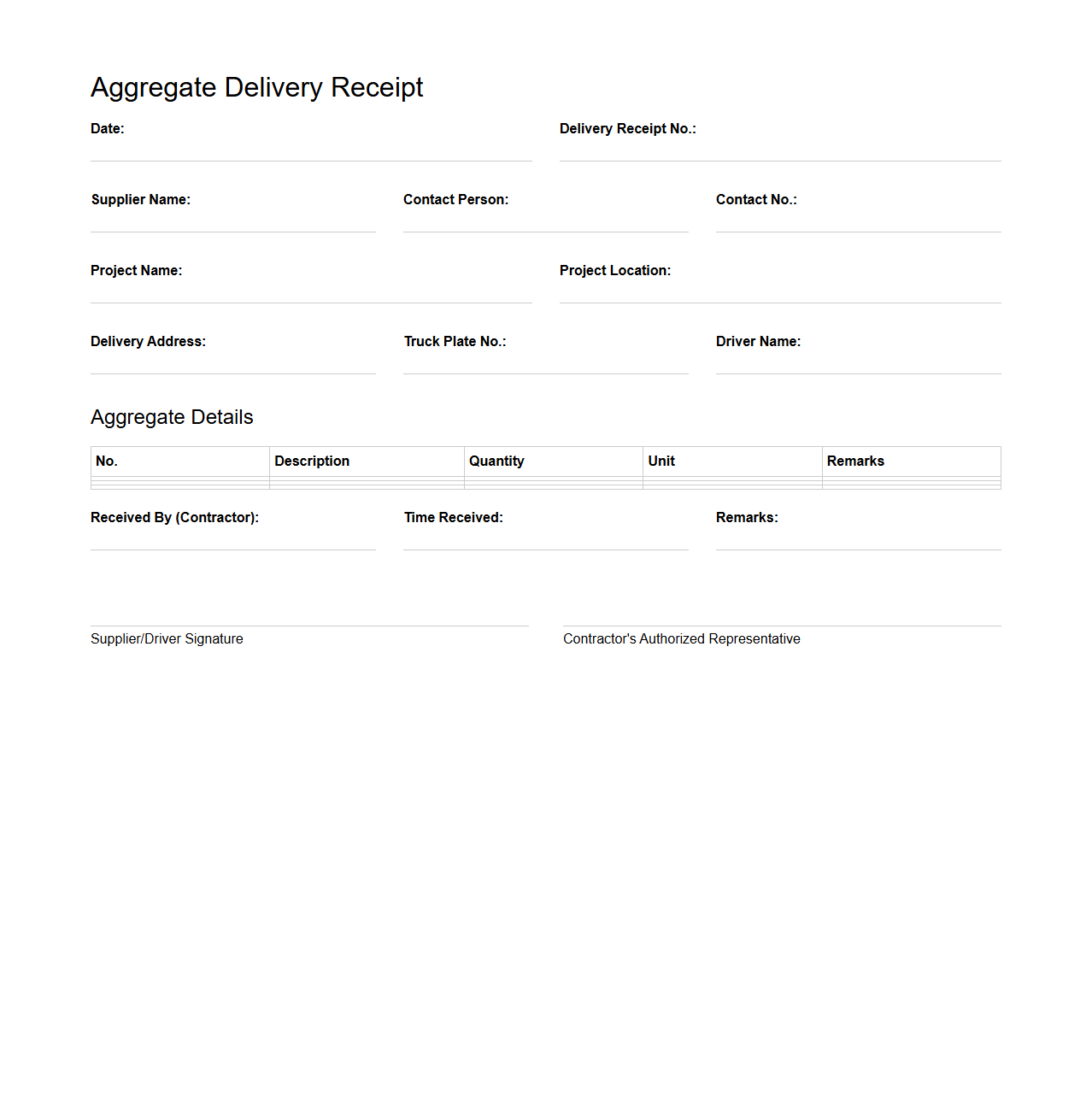

Aggregate Delivery Receipt Format for Contractors

The

Aggregate Delivery Receipt Format for Contractors document is a standardized form used to record the total quantities of goods or materials delivered by contractors to a project site. It ensures accurate tracking and verification of cumulative deliveries, facilitating payment processing and inventory management. This format typically includes details such as delivery dates, item descriptions, quantities, and contractor information to maintain transparency and accountability.

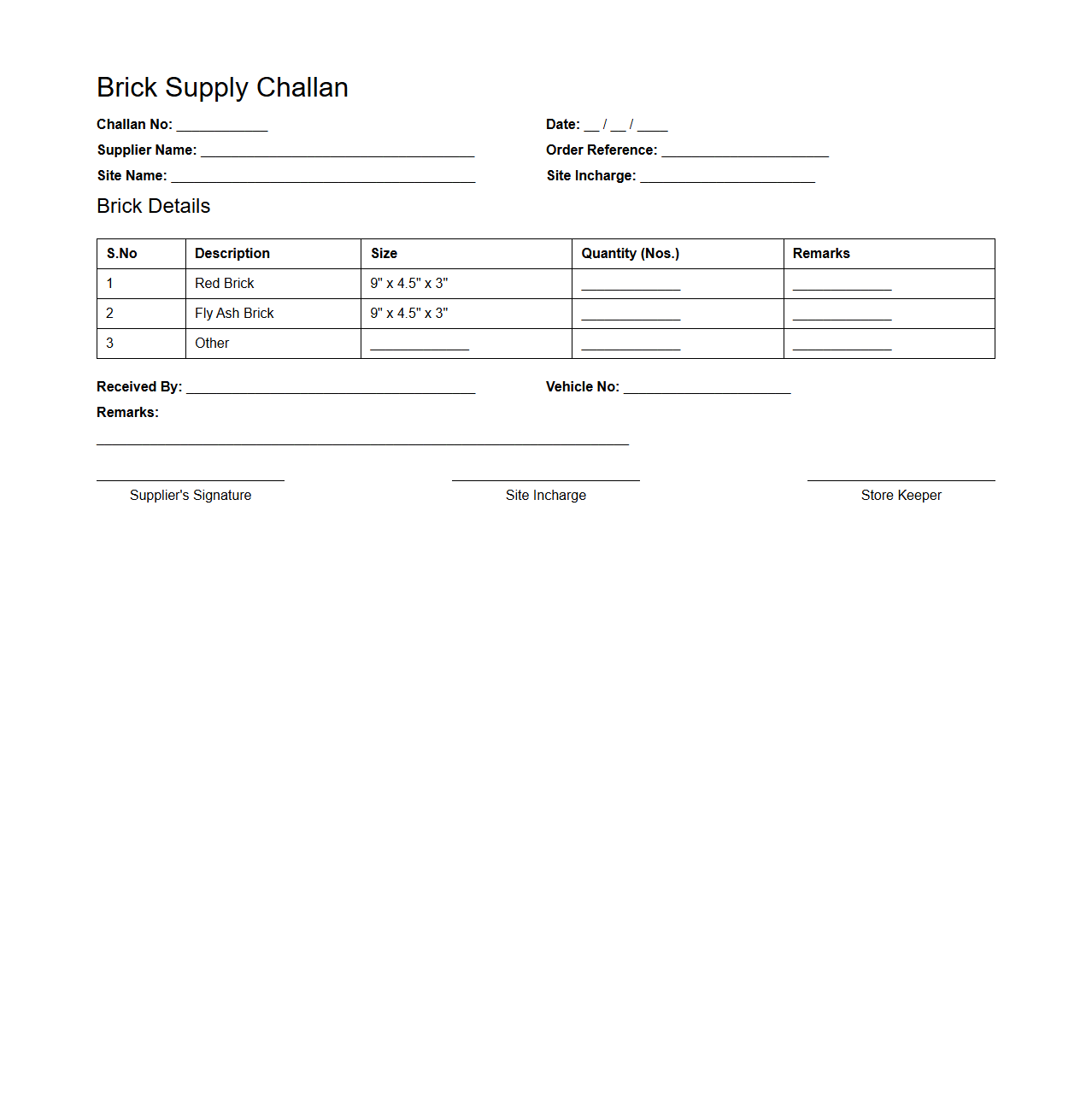

Brick Supply Challan Example for Site Management

A

Brick Supply Challan Example for Site Management document serves as a detailed record of brick deliveries to a construction site, including quantities, supplier details, and delivery dates. This document ensures accurate tracking of inventory, assists in verifying supplier compliance, and supports project budgeting by providing transparent proof of material receipt. Site managers rely on this challan to streamline resource allocation and maintain organized site logistics.

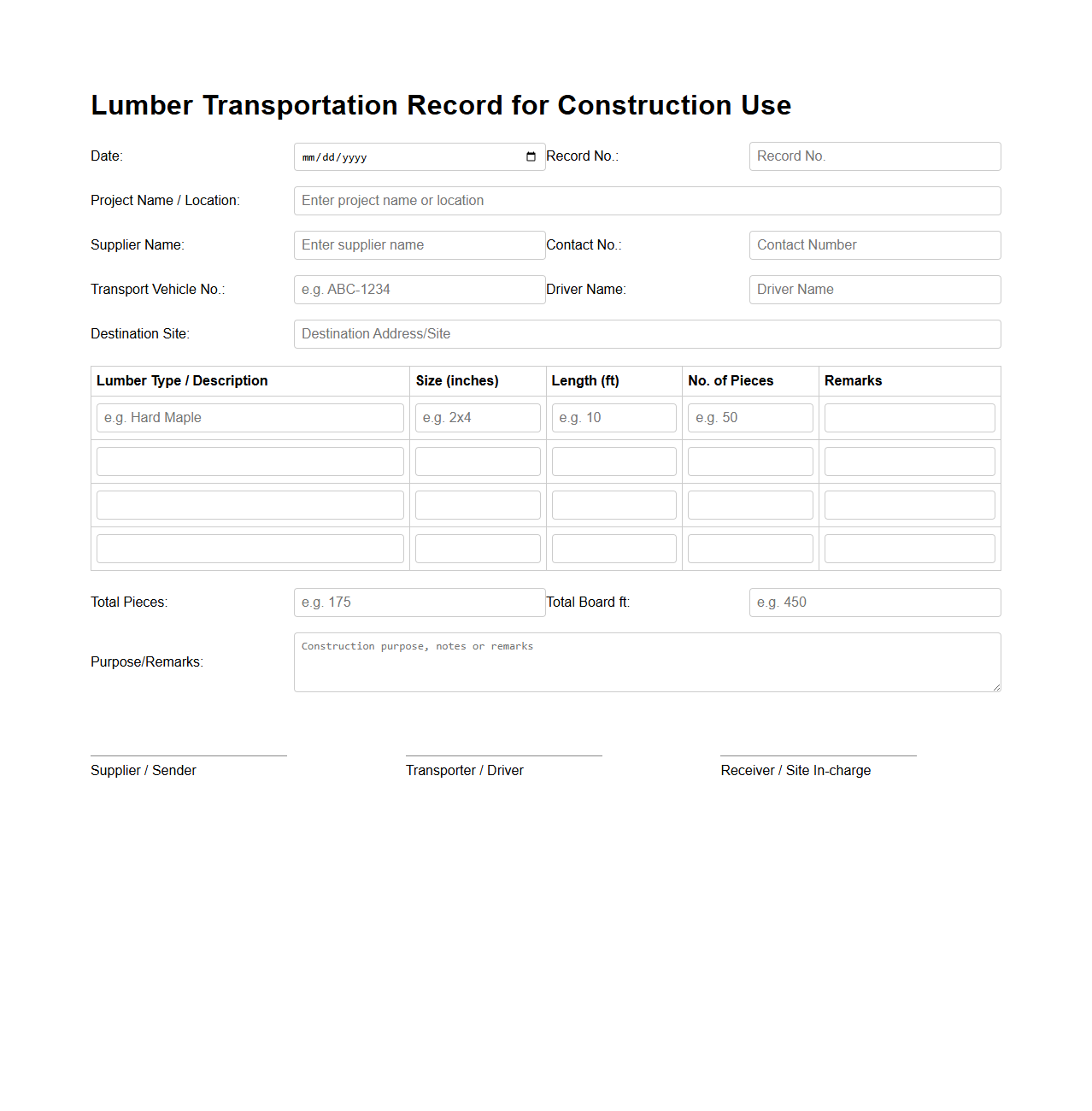

Lumber Transportation Record for Construction Use

A

Lumber Transportation Record for Construction Use document tracks the movement and delivery of timber specifically designated for building projects. It ensures compliance with regional regulations by documenting the source, quantity, and destination of lumber, preventing the use of unauthorized or illegally sourced wood. This record is essential for maintaining transparency and accountability throughout the supply chain in construction operations.

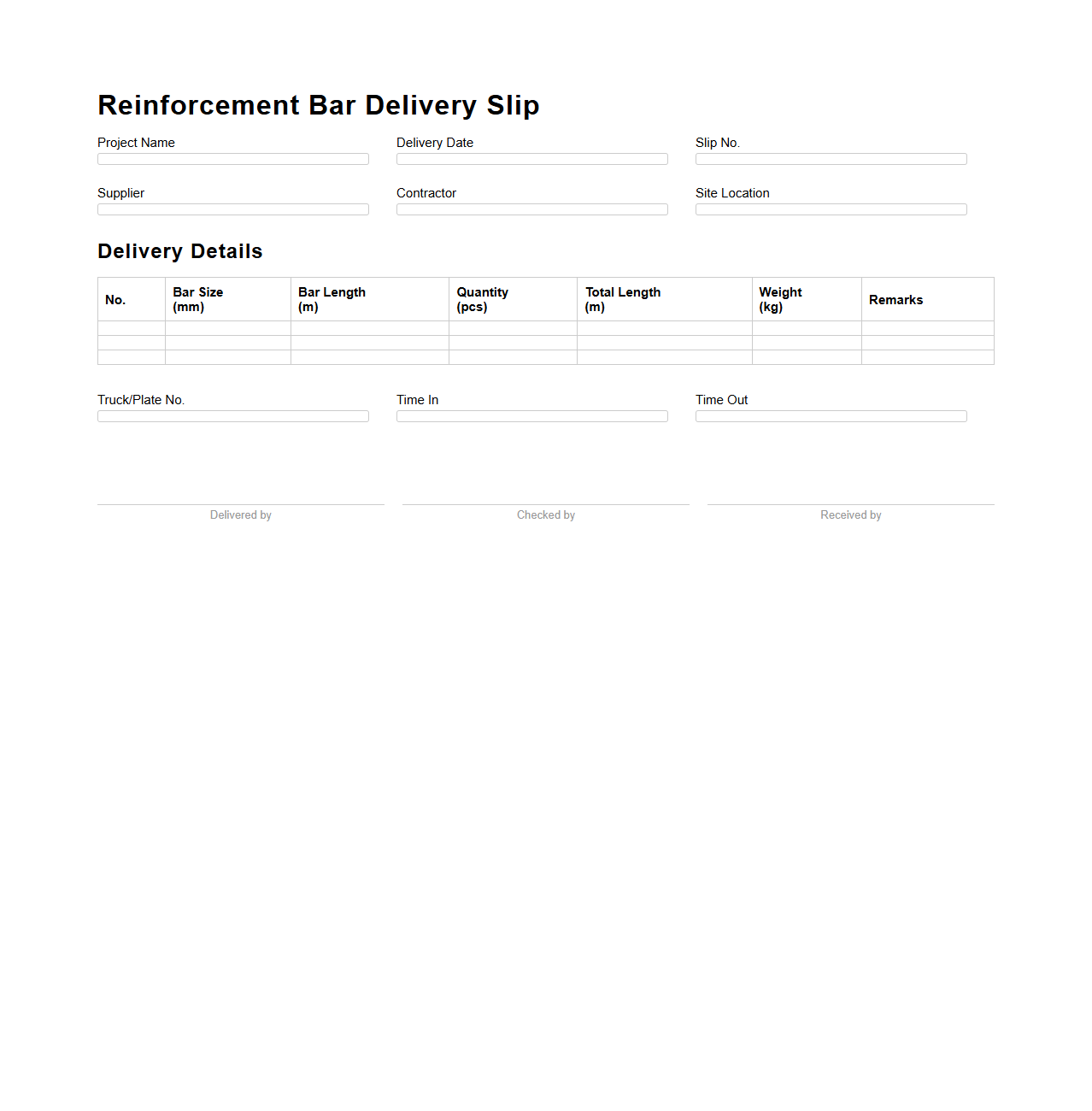

Reinforcement Bar Delivery Slip for Structural Works

A

Reinforcement Bar Delivery Slip for Structural Works document serves as a formal record confirming the quantity, type, and specifications of reinforcement bars delivered to a construction site. It ensures accurate tracking and verification of materials against project requirements, facilitating quality control and inventory management. This document often includes details such as supplier information, delivery date, batch numbers, and inspection approvals, critical for maintaining compliance with engineering standards.

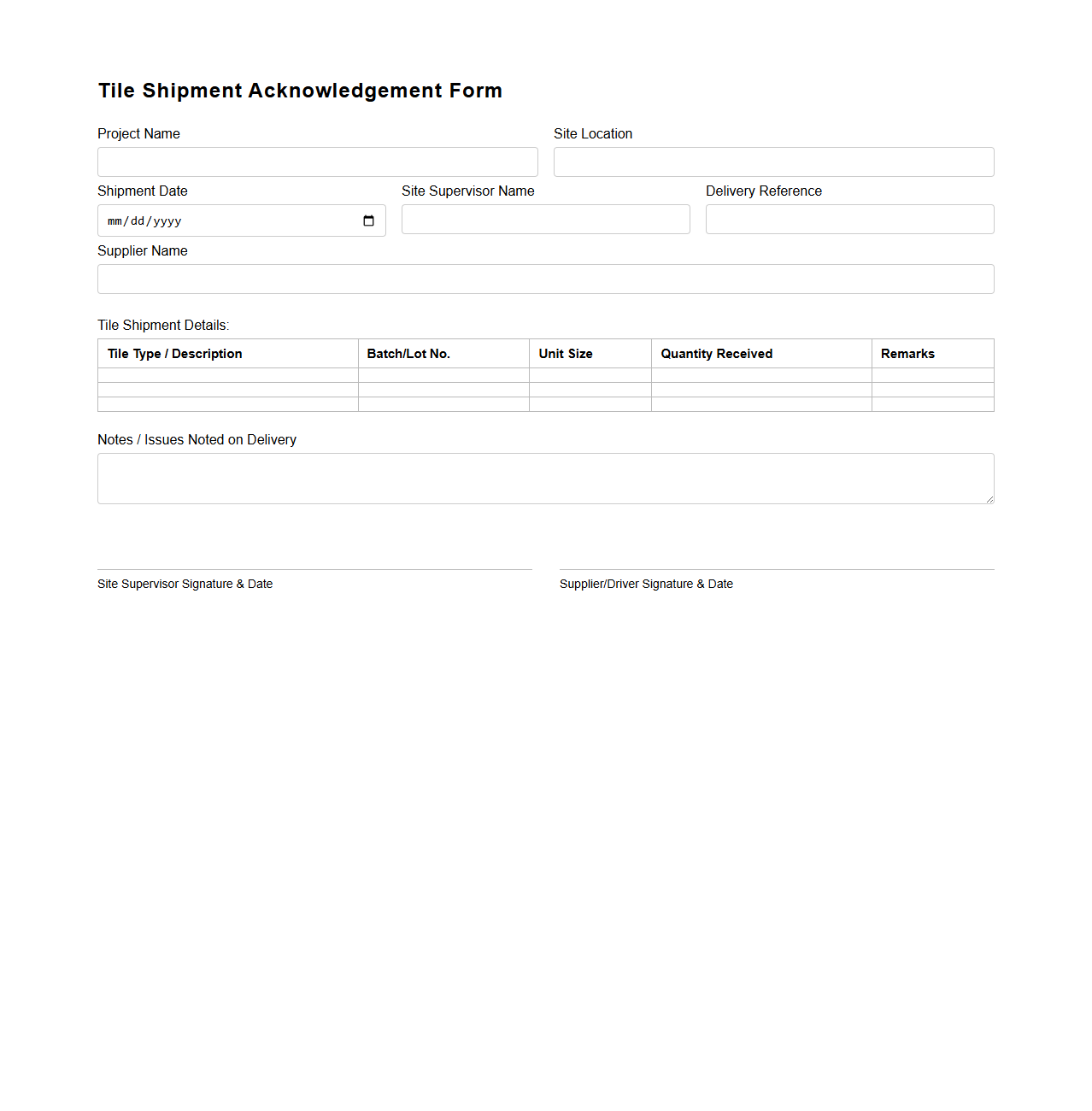

Tile Shipment Acknowledgement Form for Site Supervisors

The

Tile Shipment Acknowledgement Form for Site Supervisors is a crucial document used to confirm the receipt and condition of tile shipments on construction sites. It ensures accurate tracking of inventory and facilitates communication between suppliers and site management. This form typically records shipment details, quantities, and any discrepancies to maintain project quality and prevent material shortages.

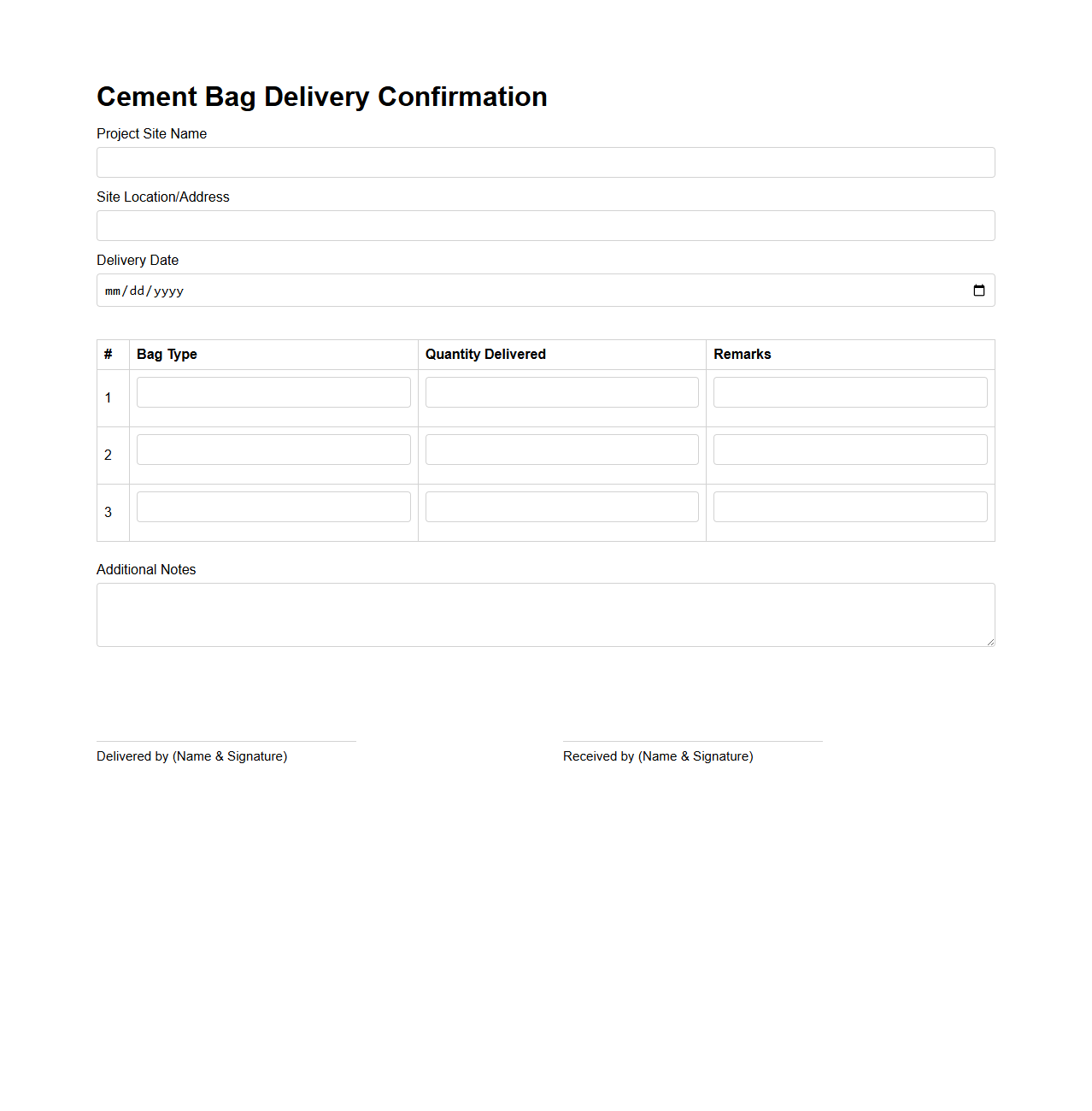

Cement Bag Delivery Confirmation for Project Sites

The

Cement Bag Delivery Confirmation for Project Sites document serves as a formal acknowledgment verifying the receipt of cement bags at construction locations. It records essential details such as delivery date, quantity, supplier information, and site representative signatures to ensure accurate tracking and inventory management. This document plays a crucial role in maintaining project accountability and preventing disputes related to material supply.

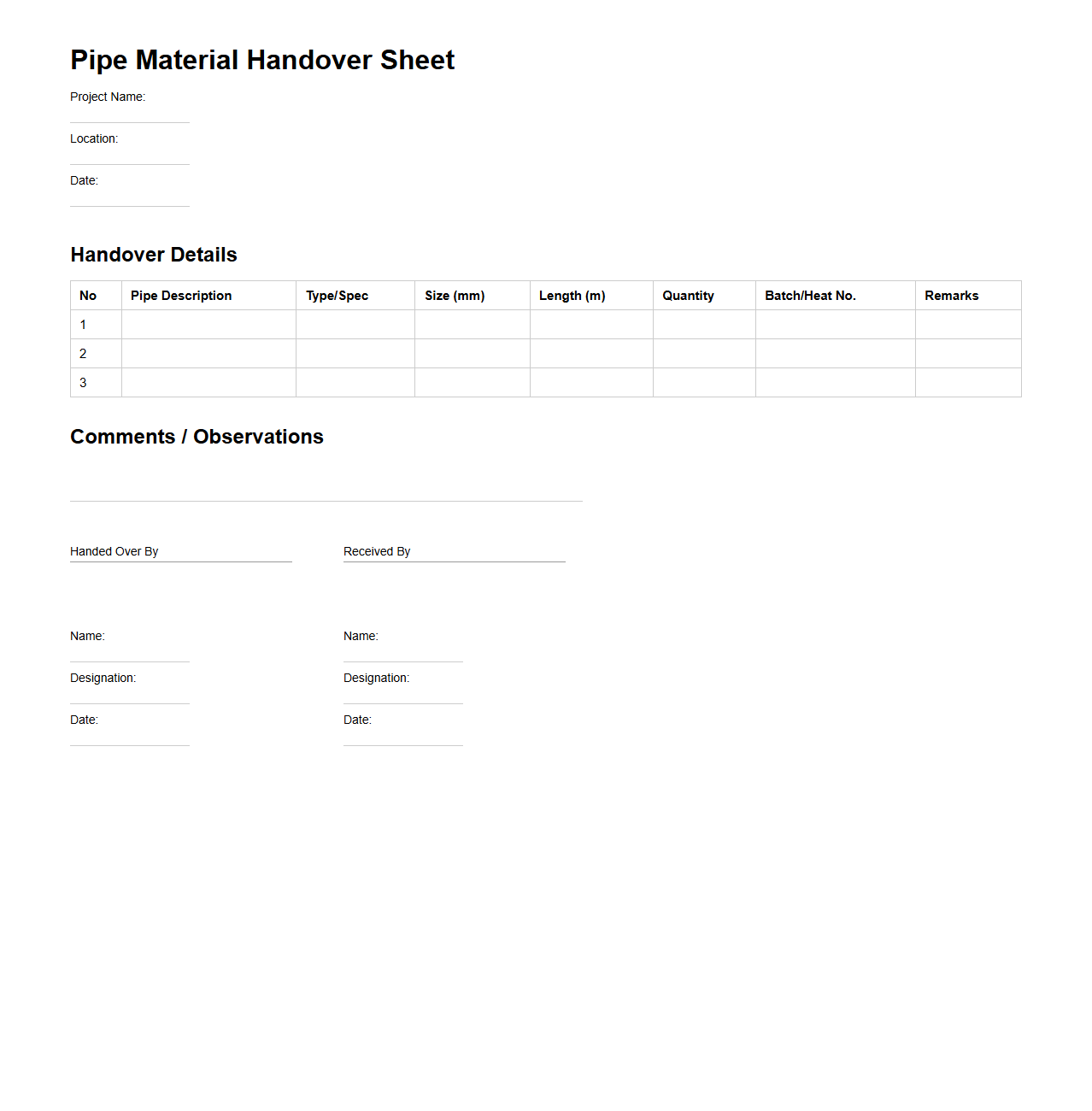

Pipe Material Handover Sheet for Construction Teams

A

Pipe Material Handover Sheet for construction teams is a critical document that records the transfer of pipe materials from storage or suppliers to on-site personnel. It ensures accurate tracking of pipe specifications, quantities, and conditions, facilitating accountability and minimizing discrepancies during installation. This sheet serves as a reference for quality control, inventory management, and compliance with project requirements.

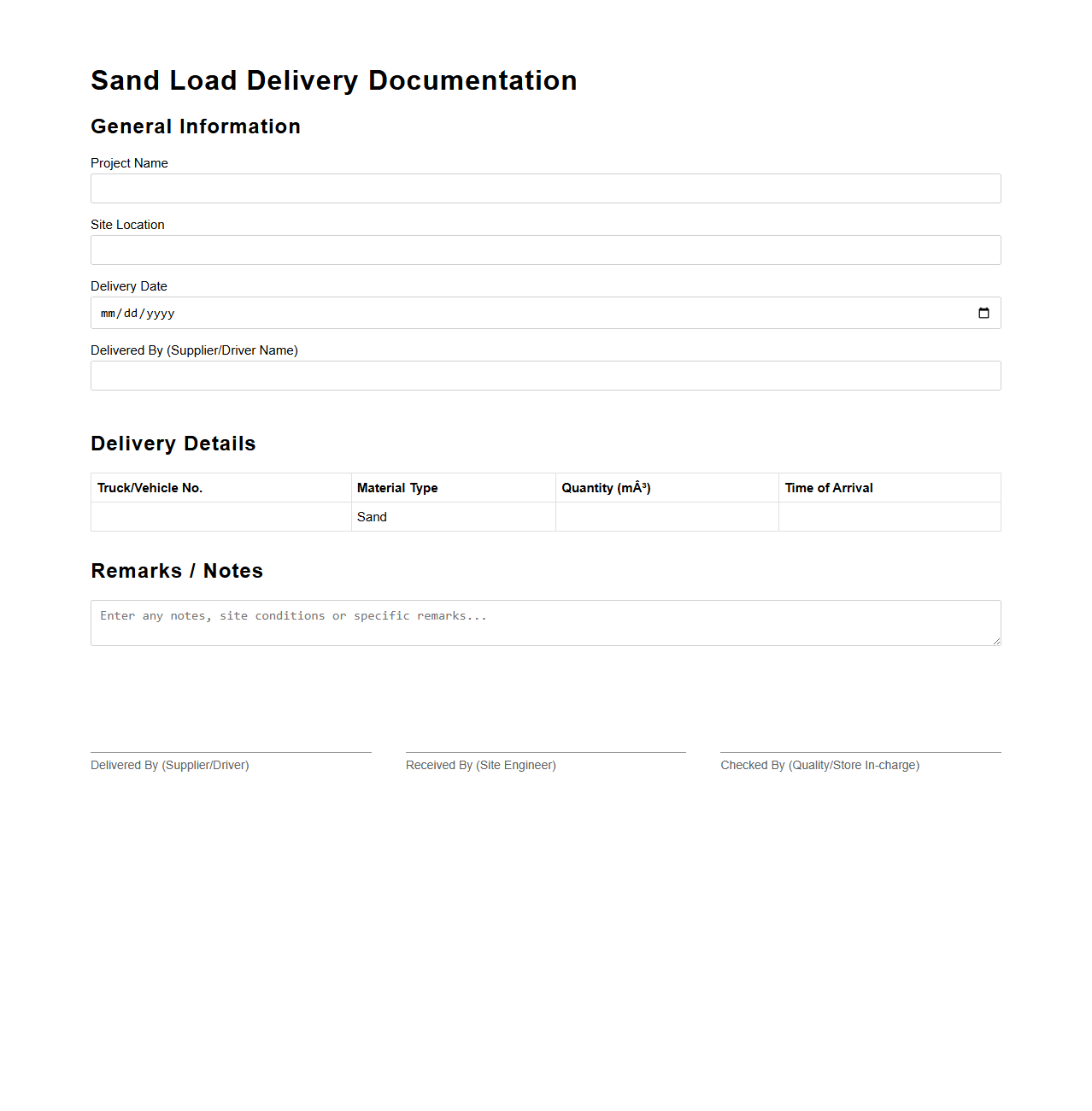

Sand Load Delivery Documentation for Site Engineers

Sand Load Delivery Documentation for Site Engineers provides essential records detailing the quantity, quality, and delivery schedule of sand supplied to construction sites. This document ensures compliance with project specifications and facilitates inventory management by tracking sand load weights and source verification. Accurate documentation supports effective site planning and quality control by enabling site engineers to monitor material usage and delivery consistency.

What key details must be included in a Material Delivery Document for onsite verification?

A Material Delivery Document must include the supplier's name, delivery date, and description of the items delivered. It should also detail the quantity, batch or lot numbers, and any relevant specifications of the materials. Including these key details ensures accurate onsite verification and accountability.

How does the Material Delivery Document ensure traceability of delivered construction materials?

The Material Delivery Document provides a unique reference number linking each delivery to its source supplier and specific batch. This enables tracking of materials from the point of delivery back to procurement records and quality certification. Through meticulous documentation, it guarantees traceability for quality control and audit purposes.

What are common discrepancies recorded in Material Delivery Documents at construction sites?

Common discrepancies include mismatched quantities, incorrect material types, and damaged or defective items. Delivery documents often note shortages or surplus compared to purchase orders. Timely identification of these issues on the document helps prevent project delays and maintain quality standards.

How is material acceptance or rejection documented on the delivery form?

Material acceptance or rejection is recorded through designated sections on the Material Delivery Document, where onsite inspectors mark approval or specify reasons for rejection. Photographic evidence and comments may also be included for clarity. This formal documentation ensures proper handling of accepted and rejected materials.

Which stakeholders are required to sign off on the Material Delivery Document upon receipt?

Typically, the site manager, delivery personnel, and quality control inspector must sign the document upon receipt of materials. Their signatures confirm that the delivery was inspected, verified, and documented. This multi-stakeholder signoff enhances accountability and confirms material receipt.

More Construction Templates