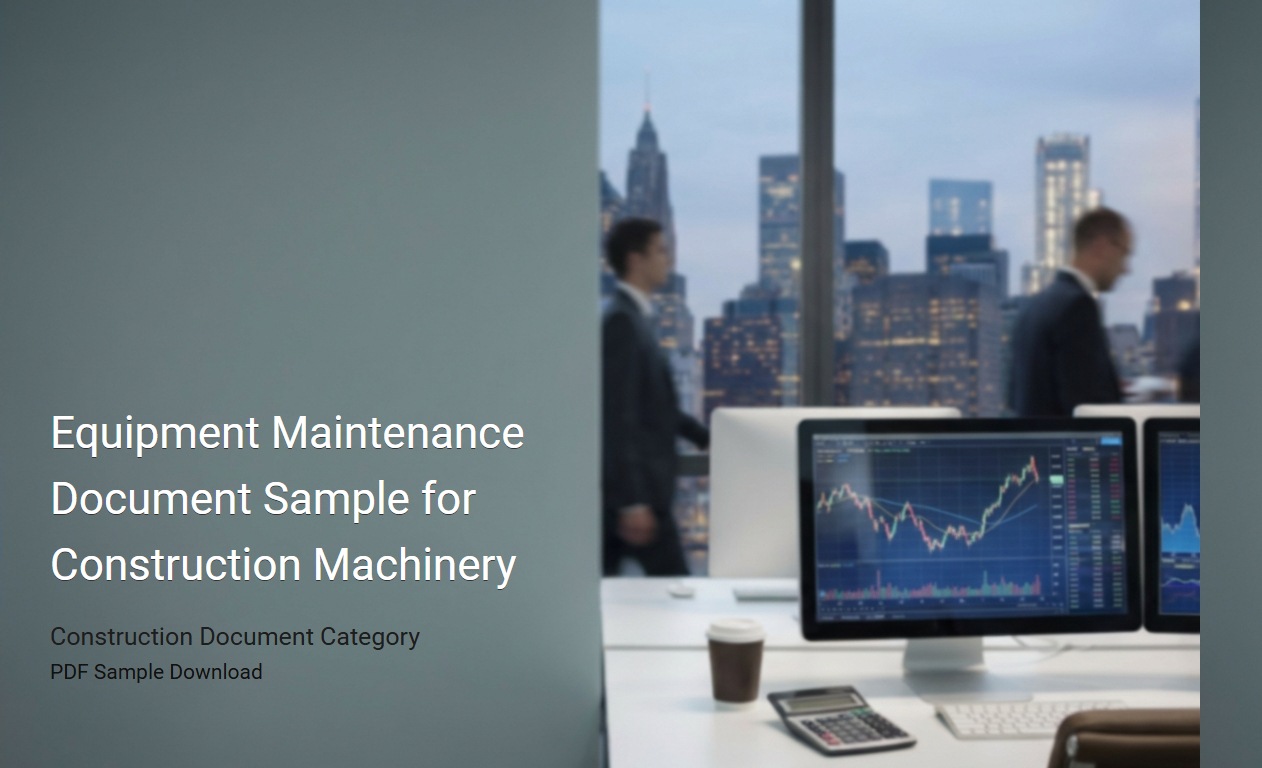

Excavator Preventive Maintenance Checklist Template

The

Excavator Preventive Maintenance Checklist Template document is a structured tool designed to ensure regular inspection and servicing of excavators to prevent breakdowns and extend machinery lifespan. It typically includes detailed checkpoints for engine condition, hydraulic systems, tracks, and safety features, enabling operators and maintenance teams to systematically address potential issues. Using this template helps improve operational efficiency, reduce unexpected downtime, and maintain compliance with safety standards.

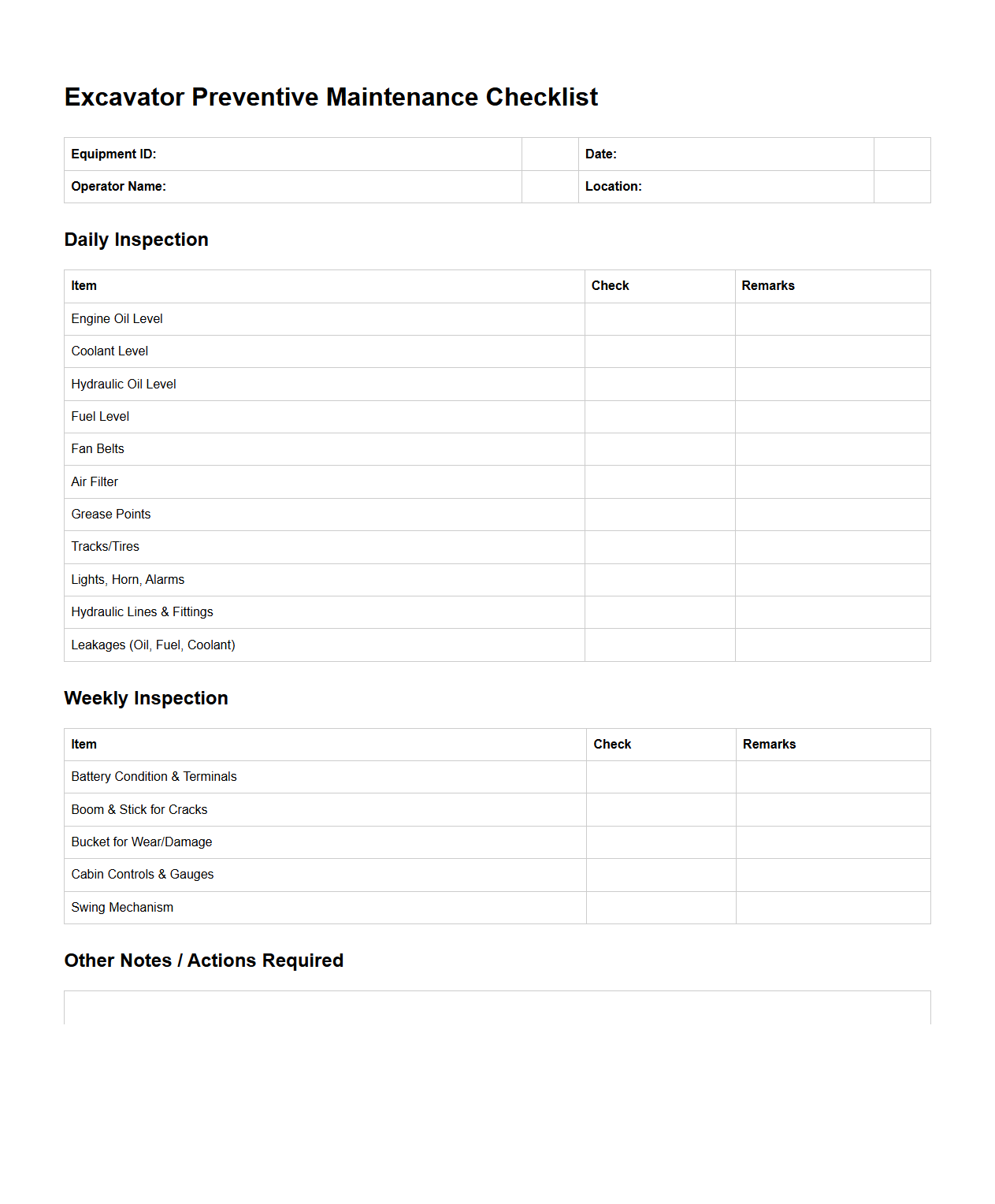

Bulldozer Routine Service Report Form

The

Bulldozer Routine Service Report Form document is a detailed record used to track the maintenance and operational status of bulldozers during routine servicing. It captures essential data such as inspection results, parts replaced, lubrication performed, and any detected mechanical issues to ensure optimal performance and longevity of the equipment. This form helps maintenance teams identify potential problems early and maintain compliance with safety and operational standards.

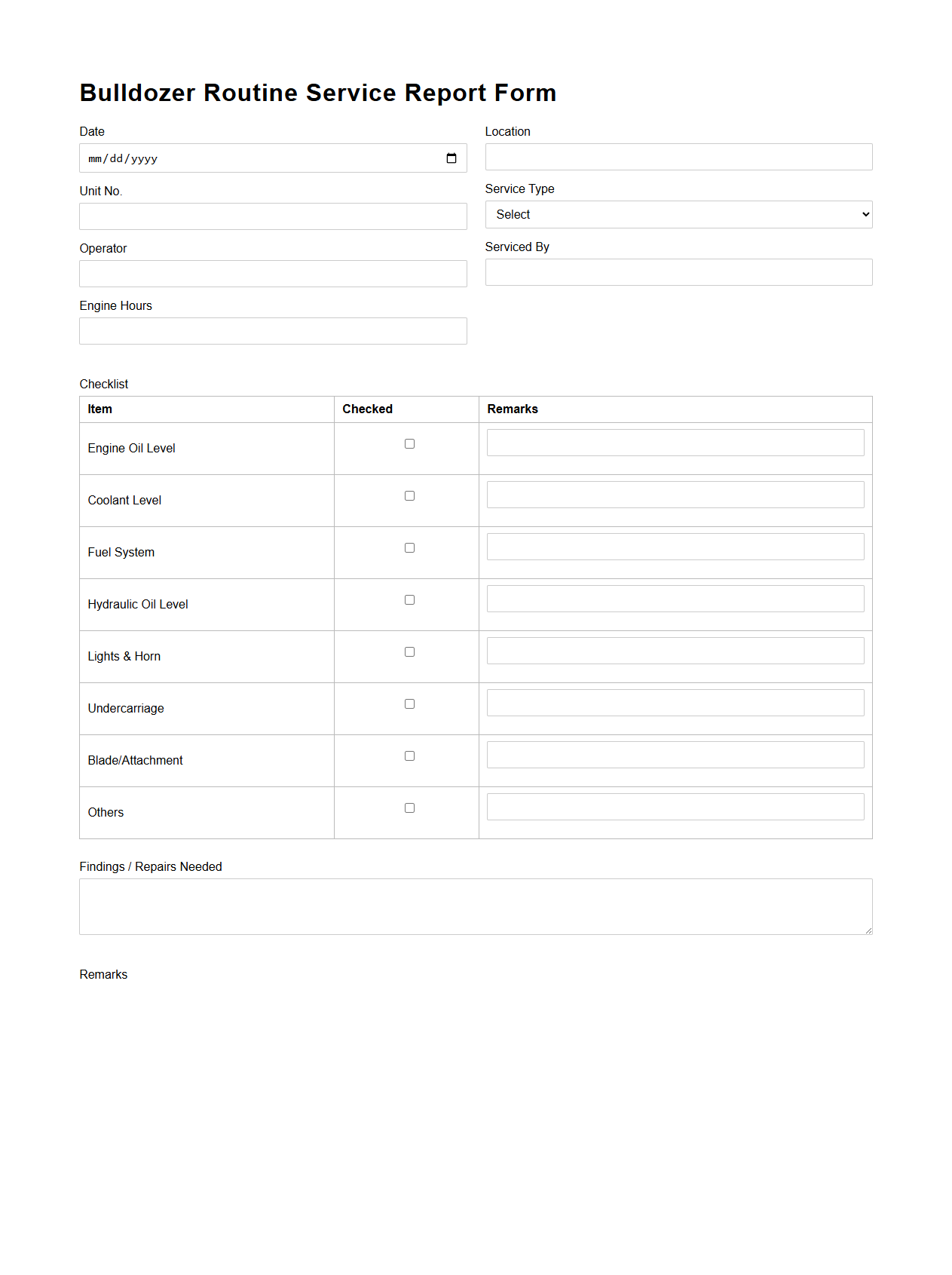

Crane Inspection Log Sheet

A

Crane Inspection Log Sheet is a crucial document used to record the detailed inspection results of cranes to ensure safety and compliance with industry regulations. It captures essential data such as inspection dates, operator details, identified defects, maintenance actions, and load capacity checks. Regular use of this log sheet helps prevent accidents, extends equipment lifespan, and supports regulatory audits.

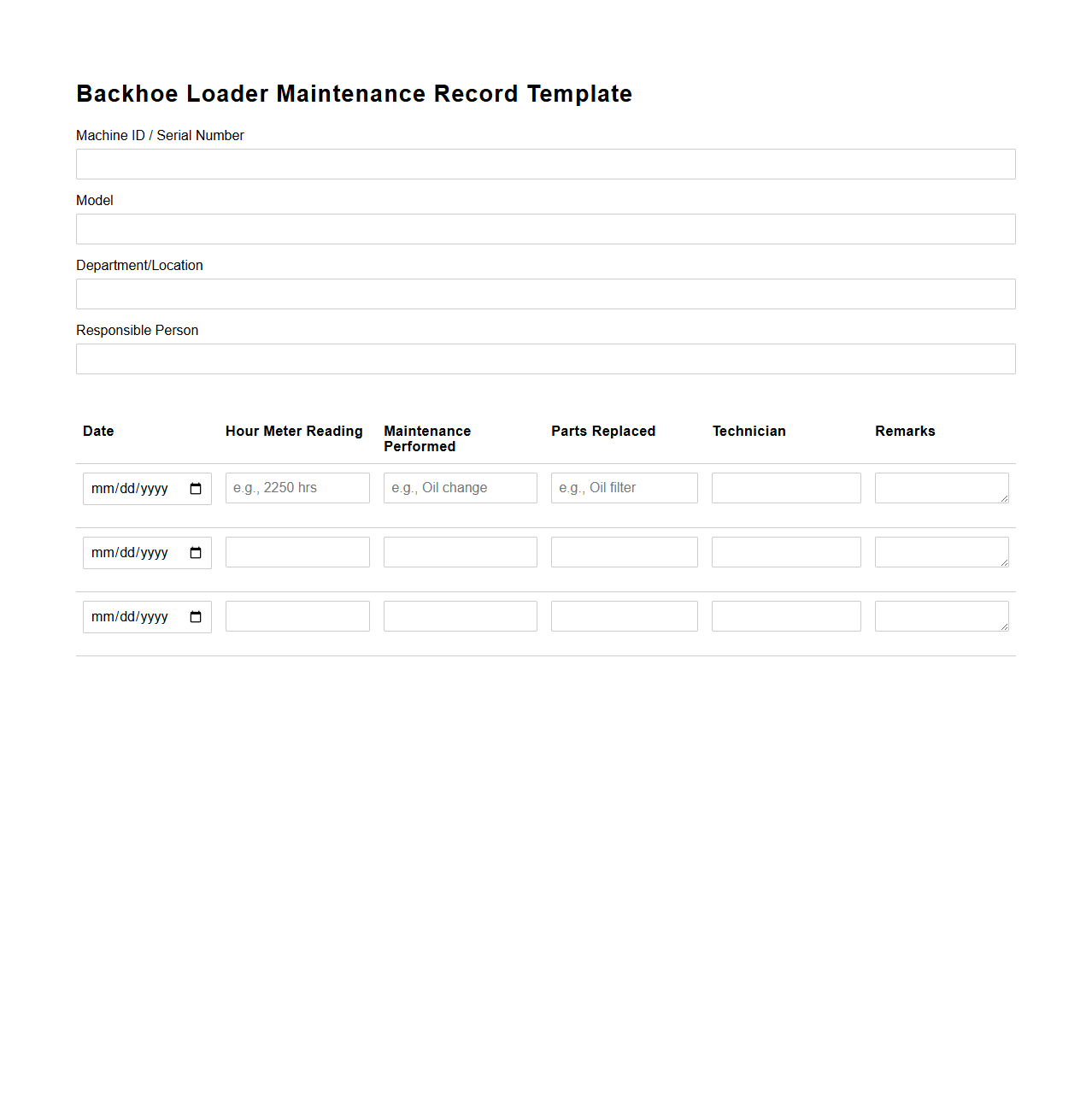

Backhoe Loader Maintenance Record Template

A

Backhoe Loader Maintenance Record Template document serves as a structured tool for tracking scheduled inspections, repairs, and servicing of backhoe loaders. It ensures efficient monitoring of equipment condition, minimizing downtime and extending operational lifespan. This template typically includes fields for date, maintenance type, parts replaced, technician notes, and next service due.

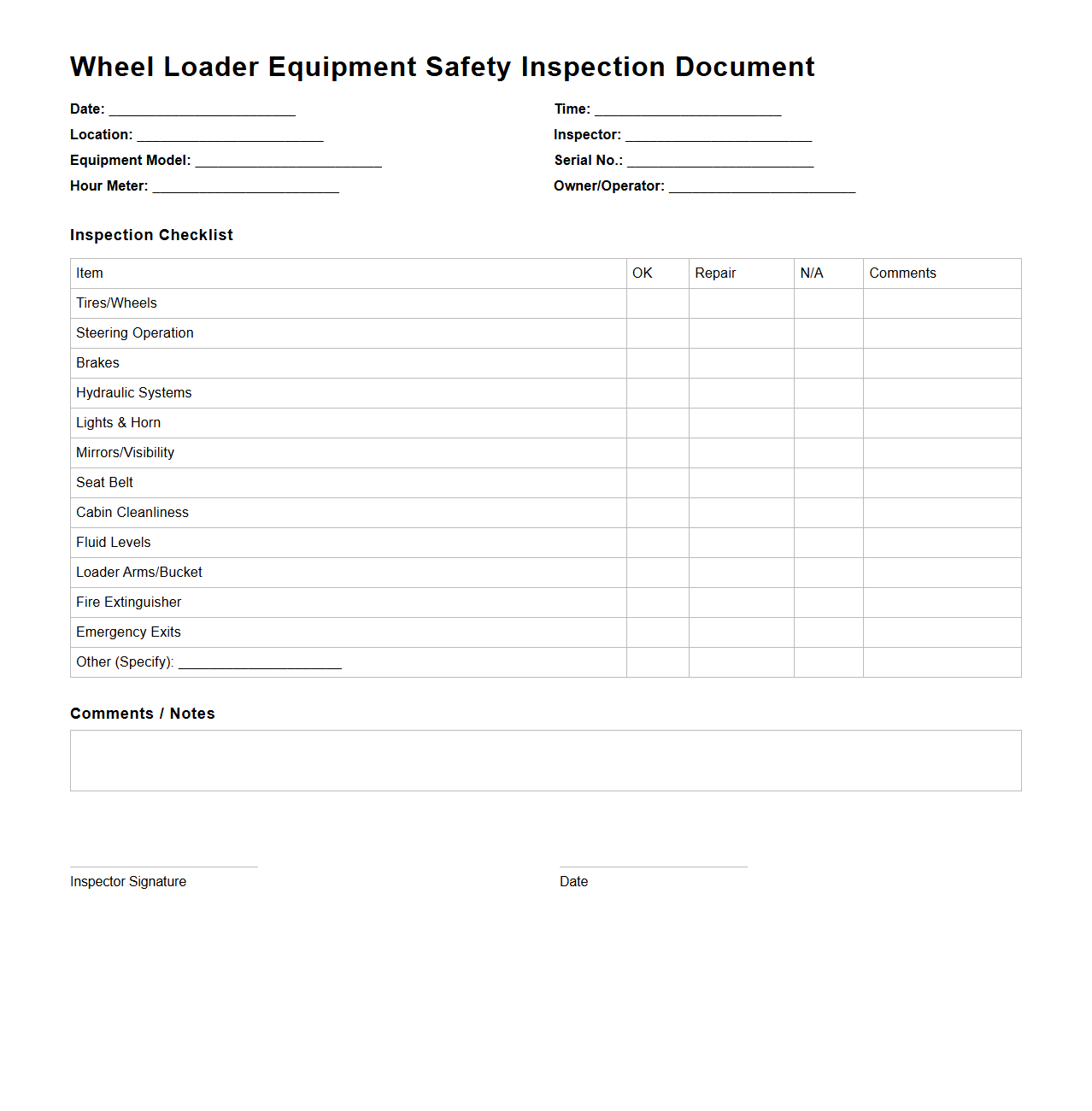

Wheel Loader Equipment Safety Inspection Document

The

Wheel Loader Equipment Safety Inspection Document is a critical record designed to ensure the operational safety and maintenance standards of wheel loaders before use. It typically includes detailed checklists covering key components such as brakes, tires, hydraulic systems, and safety devices to identify potential hazards or defects. Maintaining this document helps prevent equipment failure, promotes compliance with safety regulations, and enhances workplace safety for operators and nearby personnel.

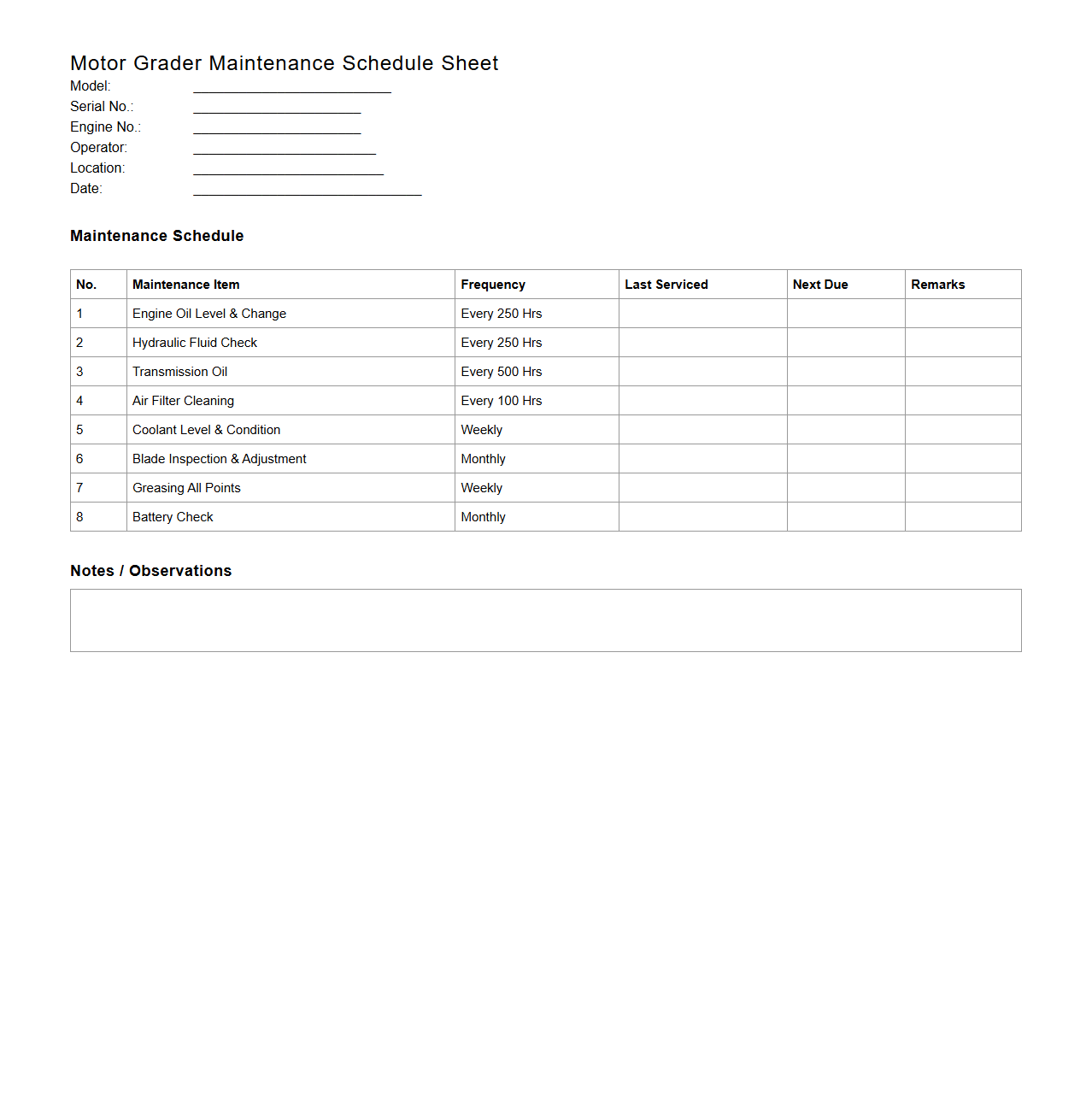

Motor Grader Maintenance Schedule Sheet

The

Motor Grader Maintenance Schedule Sheet document outlines routine inspection and servicing tasks to ensure optimal performance and longevity of motor graders. It includes detailed checklists for engine, hydraulic system, blade, tires, and electrical components, specifying frequency and procedures for each maintenance activity. This systematic approach helps prevent breakdowns, reduce repair costs, and enhance safety during operation.

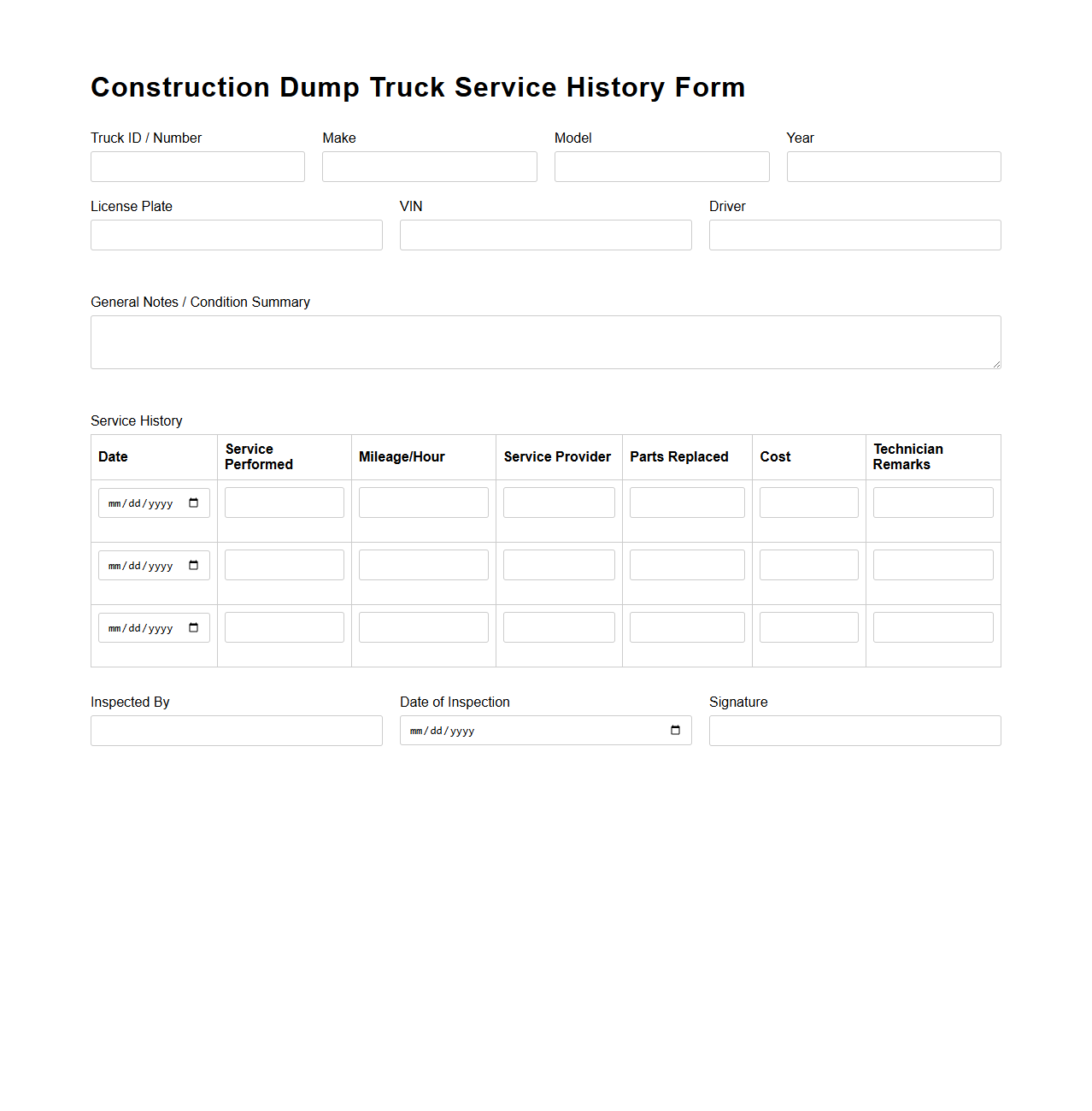

Construction Dump Truck Service History Form

The

Construction Dump Truck Service History Form is a detailed record used to track maintenance, repairs, and inspections of dump trucks used in construction projects. This document helps ensure the vehicle's operational reliability and safety by providing a comprehensive log of service dates, types of work performed, and parts replaced. Maintaining accurate service history supports regulatory compliance and extends the lifespan of construction dump trucks.

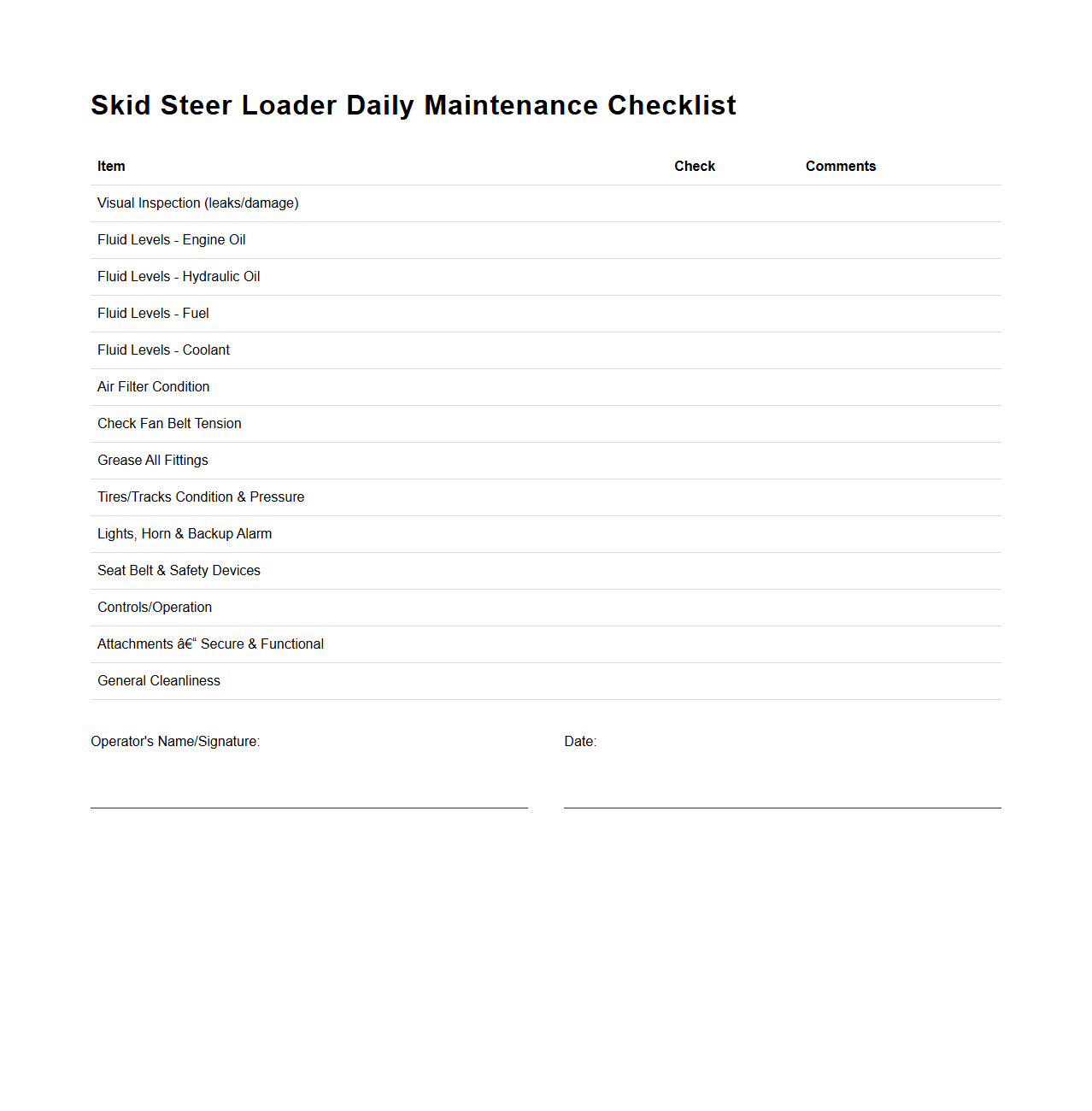

Skid Steer Loader Daily Maintenance Checklist

The

Skid Steer Loader Daily Maintenance Checklist document ensures systematic inspection of essential components such as hydraulic fluid levels, tire pressure, and engine oil before operation. It promotes early detection of wear or damage, helping to prevent equipment failure and costly repairs. Regular use of this checklist enhances safety, reliability, and extends the lifespan of skid steer loaders.

Concrete Mixer Machine Maintenance Tracking Sheet

A

Concrete Mixer Machine Maintenance Tracking Sheet is a document designed to systematically record and monitor the maintenance activities of concrete mixer machines. It includes detailed entries such as inspection dates, types of services performed, parts replaced, and machine operating hours to ensure optimal performance and prevent unexpected breakdowns. Using this tracking sheet helps construction companies enhance equipment longevity, reduce repair costs, and maintain consistent production quality.

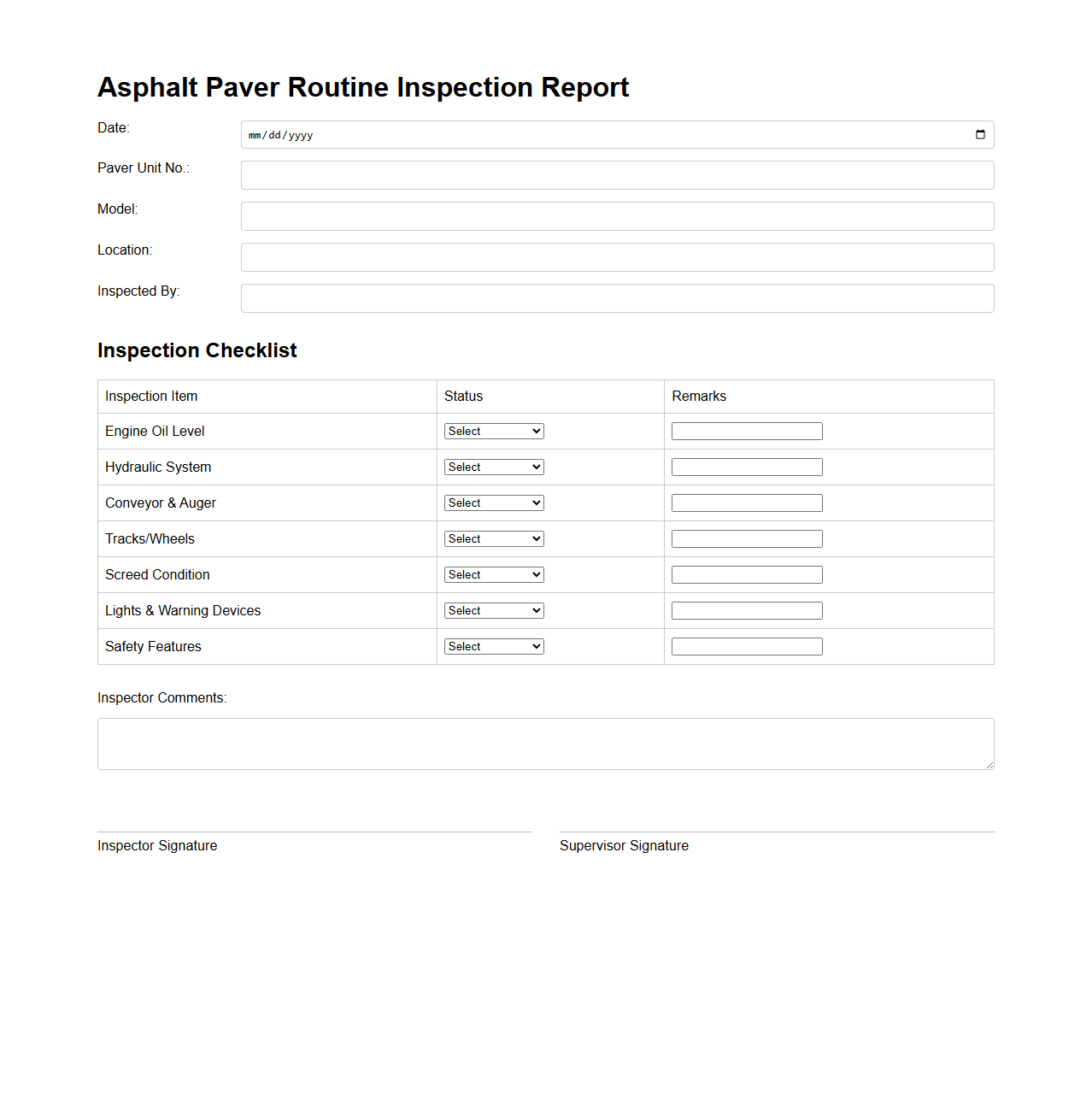

Asphalt Paver Routine Inspection Report

An

Asphalt Paver Routine Inspection Report document systematically records the condition and operational status of asphalt paving equipment before and after use. It includes key inspection points such as engine performance, hydraulic systems, conveyor belts, screed functionality, and safety features to ensure the machinery operates efficiently and safely. This report helps in identifying potential issues early, minimizing downtime, and maintaining compliance with safety and maintenance standards.

Frequency of Preventive Maintenance for Each Machinery Type

The document specifies the frequency of preventive maintenance tailored to each machinery type based on manufacturer guidelines and operational demands. Maintenance intervals vary from daily inspections for critical machinery to quarterly or yearly checks for less critical equipment. This approach ensures optimal performance and longevity of all machinery.

Detailed Checklists for Critical Safety Components

Yes, the document includes detailed checklists specifically designed for critical safety components. These checklists guide technicians through systematic inspections to ensure all safety features are fully functional. Regular use of these checklists enhances workplace safety and compliance with regulatory requirements.

Maintenance Record Section and Manufacturer Warranties Compliance

The maintenance record section includes compliance tracking with manufacturer warranties to ensure all service activities align with warranty conditions. This record helps to avoid voiding warranties due to improper maintenance practices. It also facilitates warranty claims by providing documented evidence of adherence.

Tracking of Consumable Replacement Intervals

The document addresses tracking consumable replacement intervals by implementing a schedule based on manufacturer recommendations and usage data. This systematic tracking prevents unexpected equipment downtime caused by exhausted consumables. It also optimizes inventory management by forecasting replacement needs.

Protocol for Reporting and Documenting Unexpected Equipment Failures

There is a clear protocol for reporting and documenting unexpected equipment failures to ensure swift response and root cause analysis. The document mandates immediate notification, detailed failure reports, and corrective action records. This protocol supports continuous improvement and reduces recurrence of failures.