A Quality Control Report Document Sample for Civil Works provides a detailed record of inspection and testing activities to ensure construction standards are met. It includes data on material quality, workmanship, and compliance with project specifications. This report helps maintain project integrity and facilitates effective communication between contractors and stakeholders.

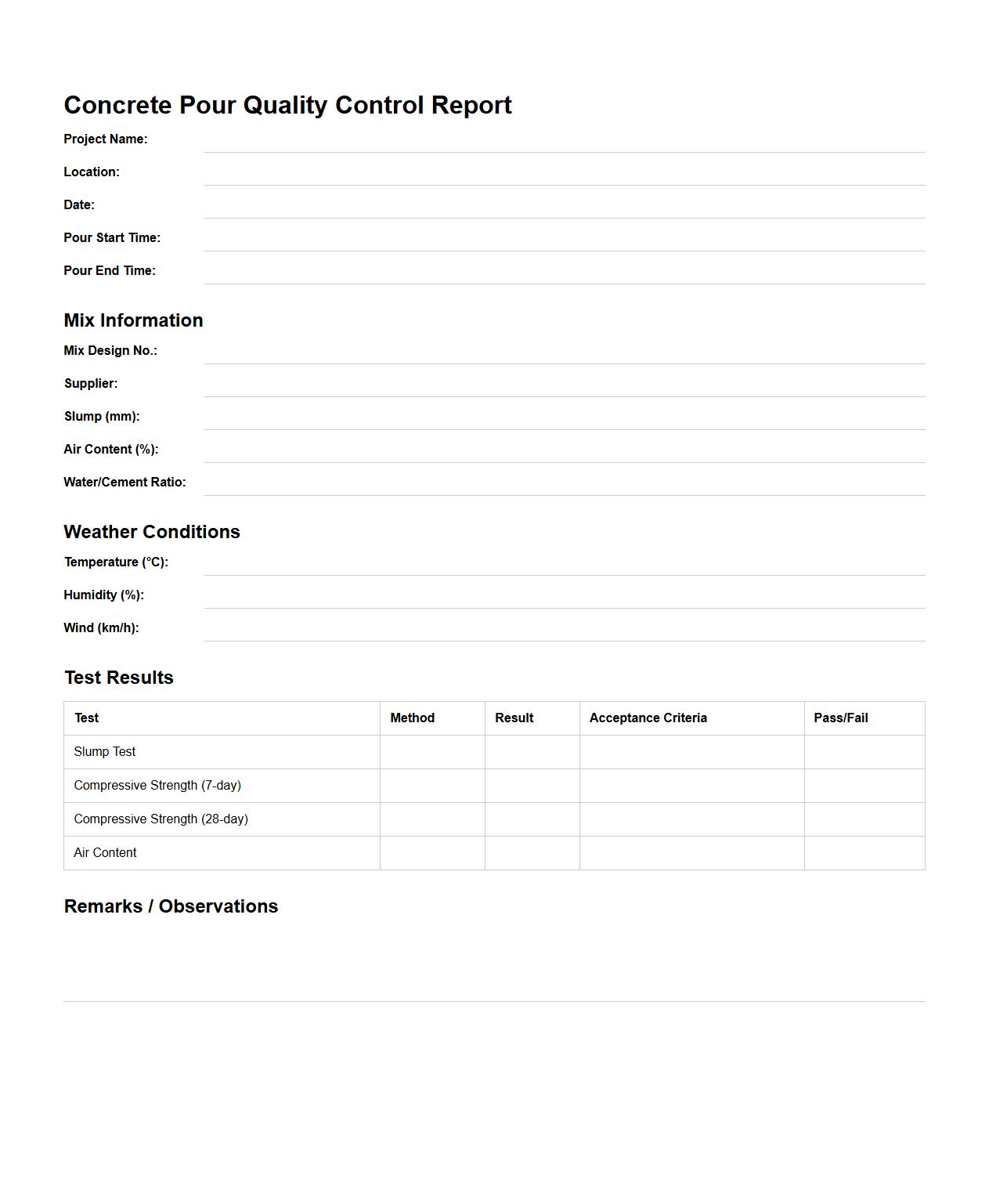

Concrete Pour Quality Control Report Sample

A

Concrete Pour Quality Control Report Sample document serves as a standardized template to record and verify the quality parameters of concrete during a pour. It includes critical data such as slump test results, temperature, mixing time, batch numbers, and compliance with project specifications to ensure structural integrity. This report is essential for maintaining construction standards and facilitating traceability in quality assurance processes.

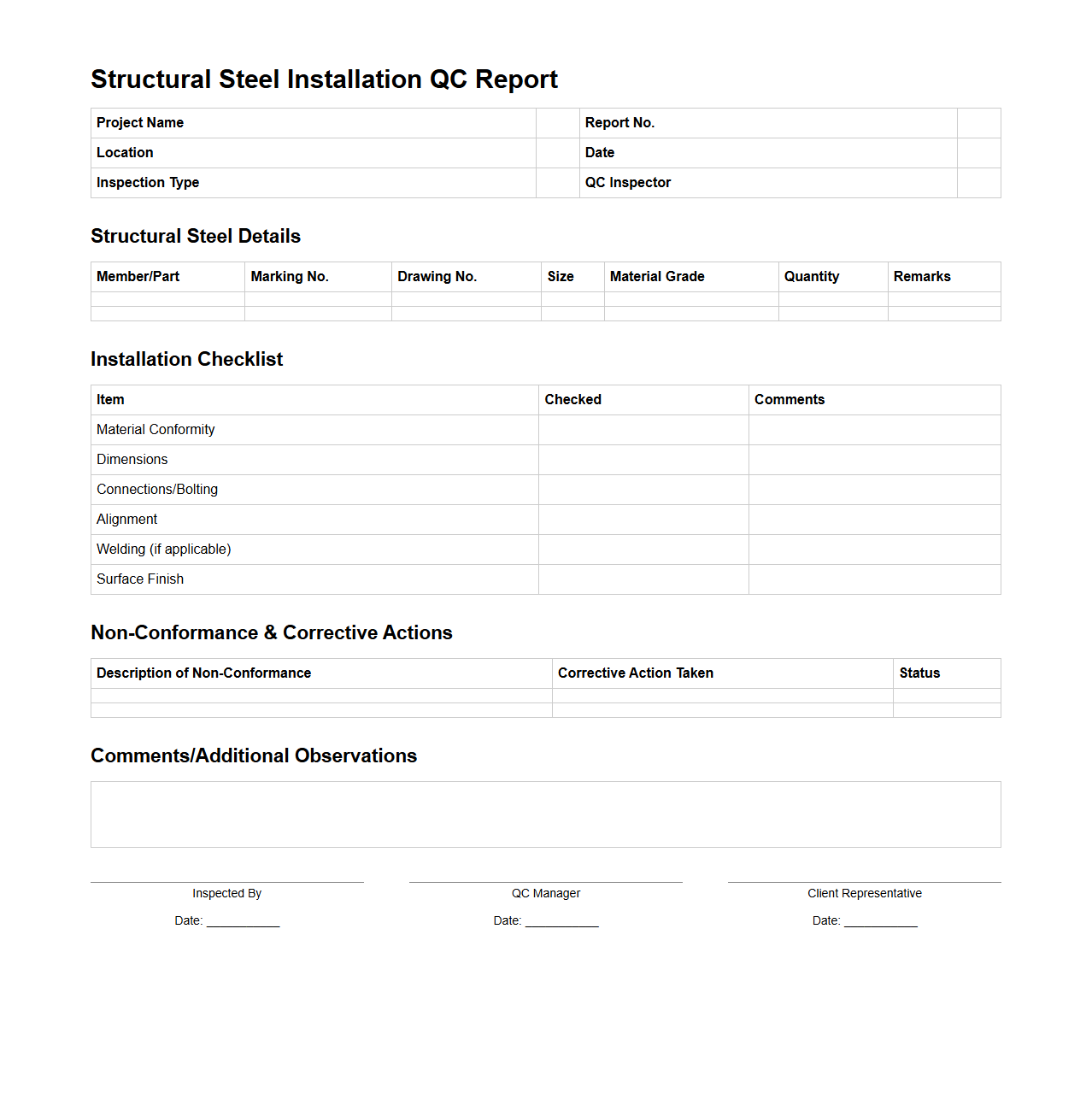

Structural Steel Installation QC Report Template

A

Structural Steel Installation QC Report Template document is designed to systematically record quality control inspections and verify compliance with engineering specifications during steel erection. It includes key data fields such as material certifications, welding records, dimensional checks, and non-destructive test results to ensure structural integrity. This template streamlines reporting, facilitates consistency, and supports regulatory adherence in construction projects.

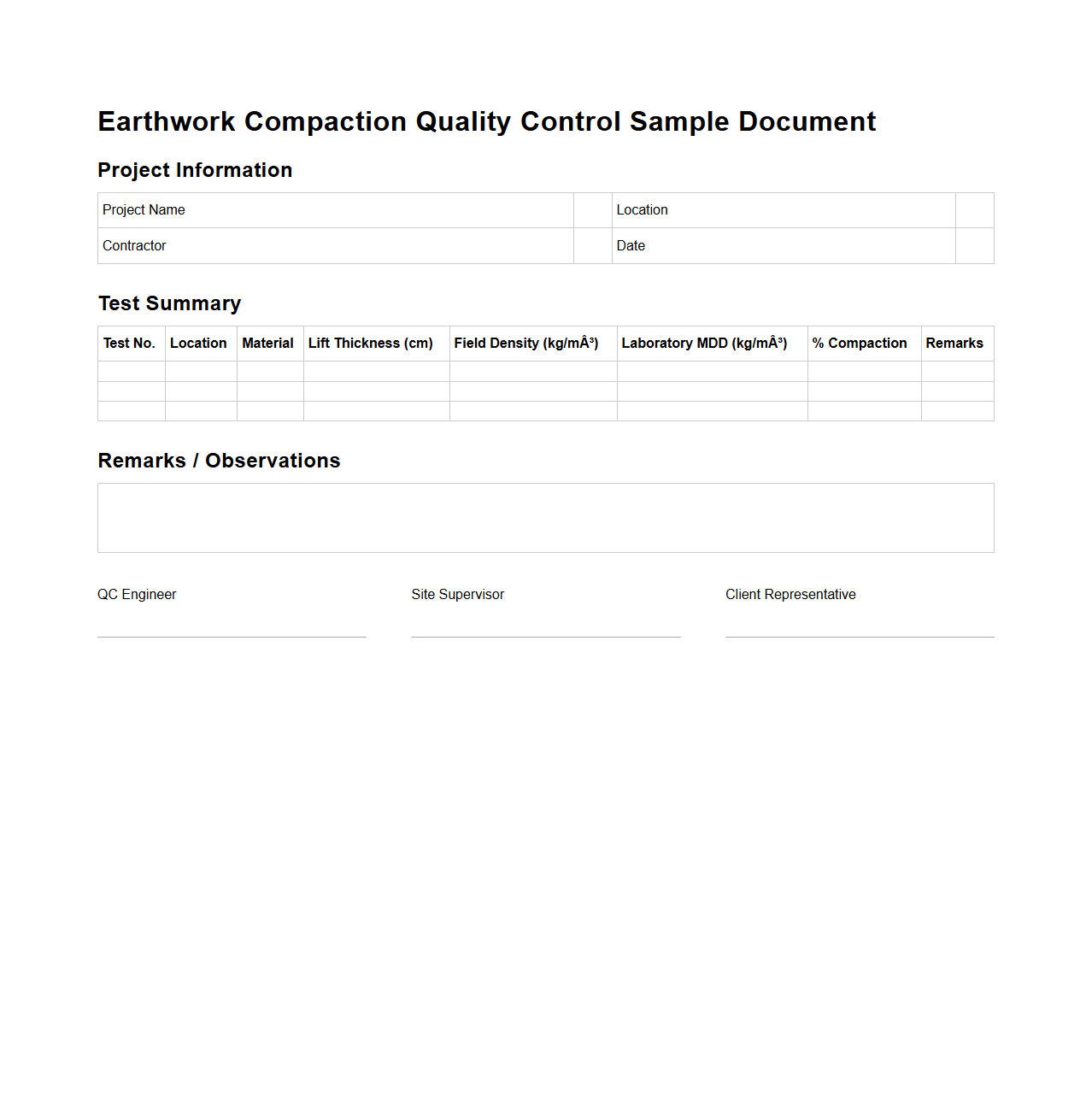

Earthwork Compaction Quality Control Sample Document

The

Earthwork Compaction Quality Control Sample Document is a critical record used to verify the density and stability of soil during construction projects. It contains detailed test results, such as Proctor test values and in-situ density measurements, to ensure that compaction meets engineering specifications and project standards. This document serves as essential evidence for compliance with quality assurance protocols and regulatory requirements in geotechnical and civil engineering works.

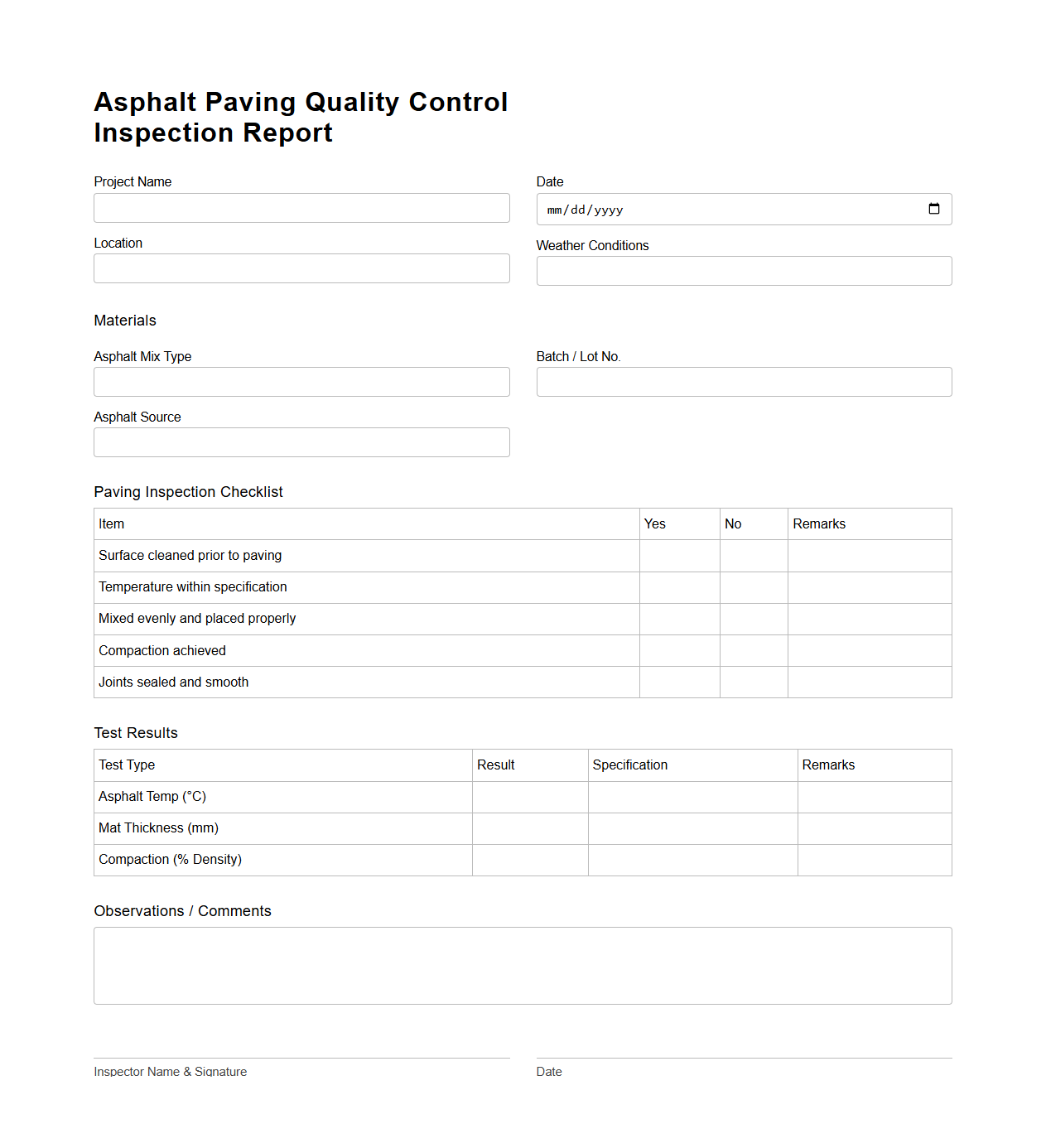

Asphalt Paving Quality Control Inspection Report

An

Asphalt Paving Quality Control Inspection Report document details the systematic evaluation of asphalt pavement construction to ensure compliance with project specifications and industry standards. It records key parameters such as temperature, compaction density, material properties, and layer thickness, helping identify any deviations that could affect the pavement's durability and performance. This report is essential for maintaining construction quality, verifying contractor adherence, and providing documentation for project approval and future maintenance planning.

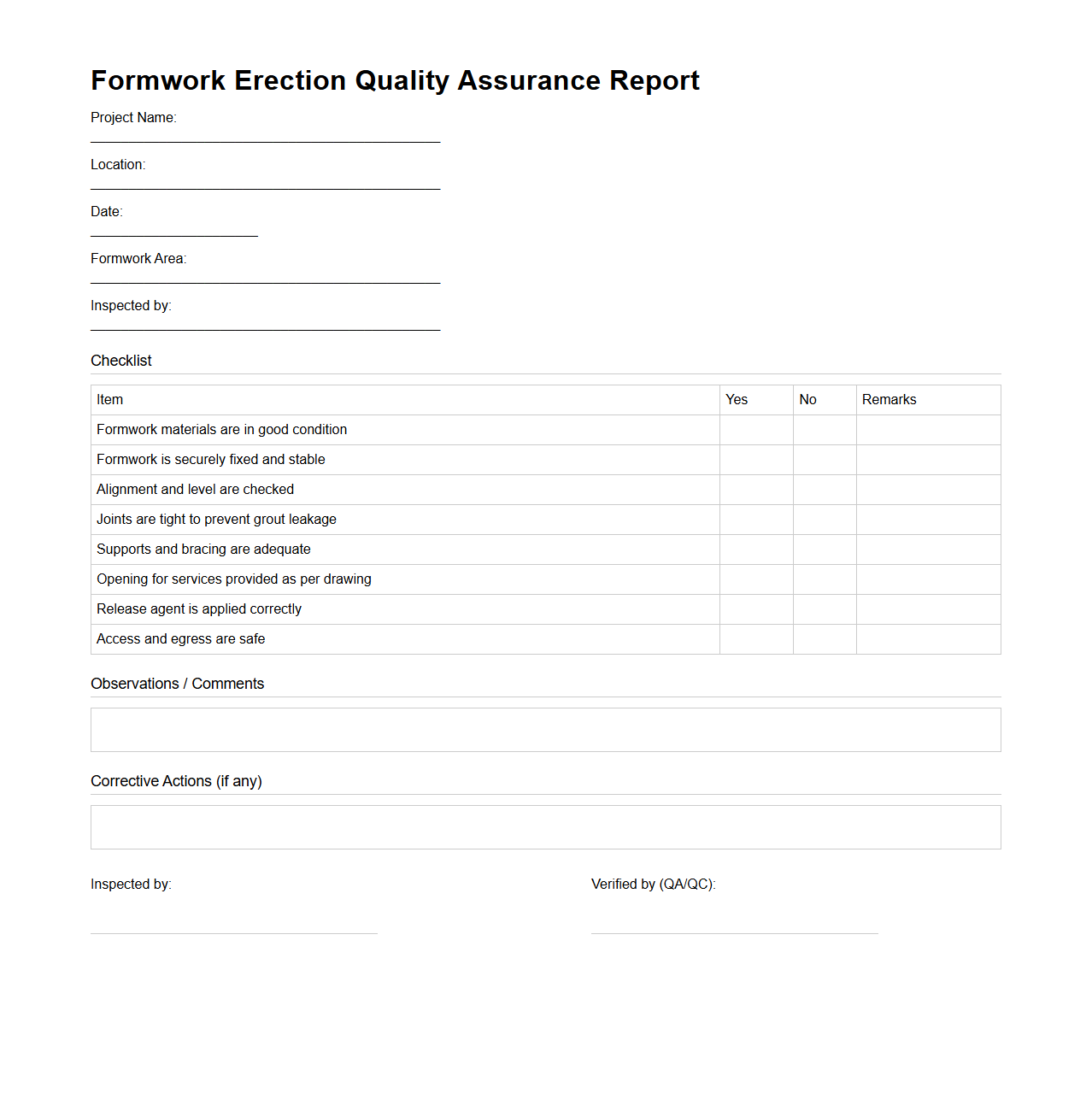

Formwork Erection Quality Assurance Report Sample

A

Formwork Erection Quality Assurance Report Sample document outlines the systematic process of inspecting and verifying the proper installation of formwork used in concrete construction. It includes detailed checklists, inspection criteria, and compliance assessments to ensure structural integrity and safety standards are met before concrete placement. This report serves as essential evidence for quality control and aids in minimizing construction defects and delays.

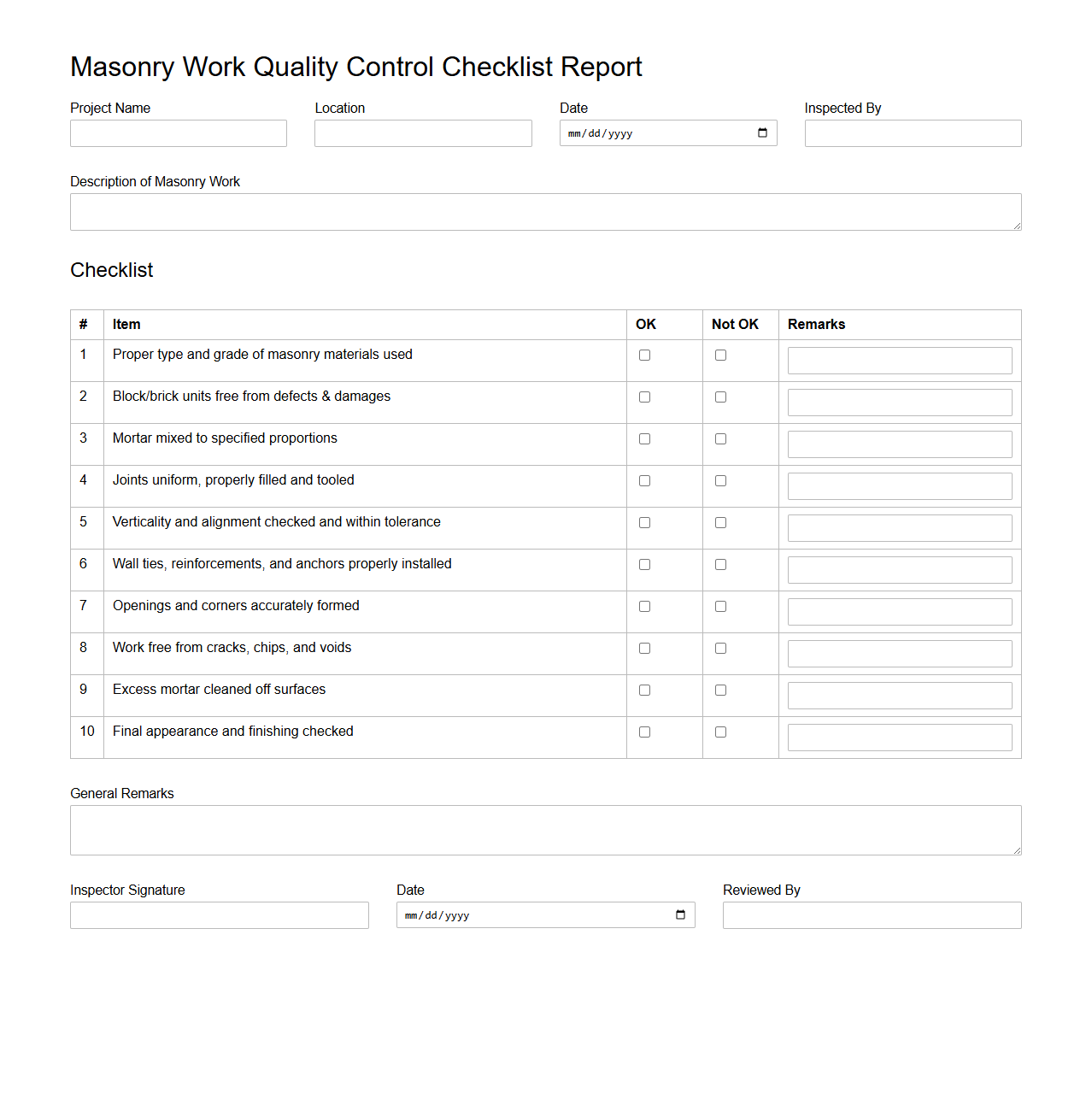

Masonry Work Quality Control Checklist Report

A

Masonry Work Quality Control Checklist Report document systematically outlines the standards and criteria for inspecting masonry construction projects. It ensures that all materials, workmanship, and installation methods comply with project specifications and industry regulations. This report helps identify defects early, maintain consistent quality, and facilitate effective communication between contractors, inspectors, and project managers.

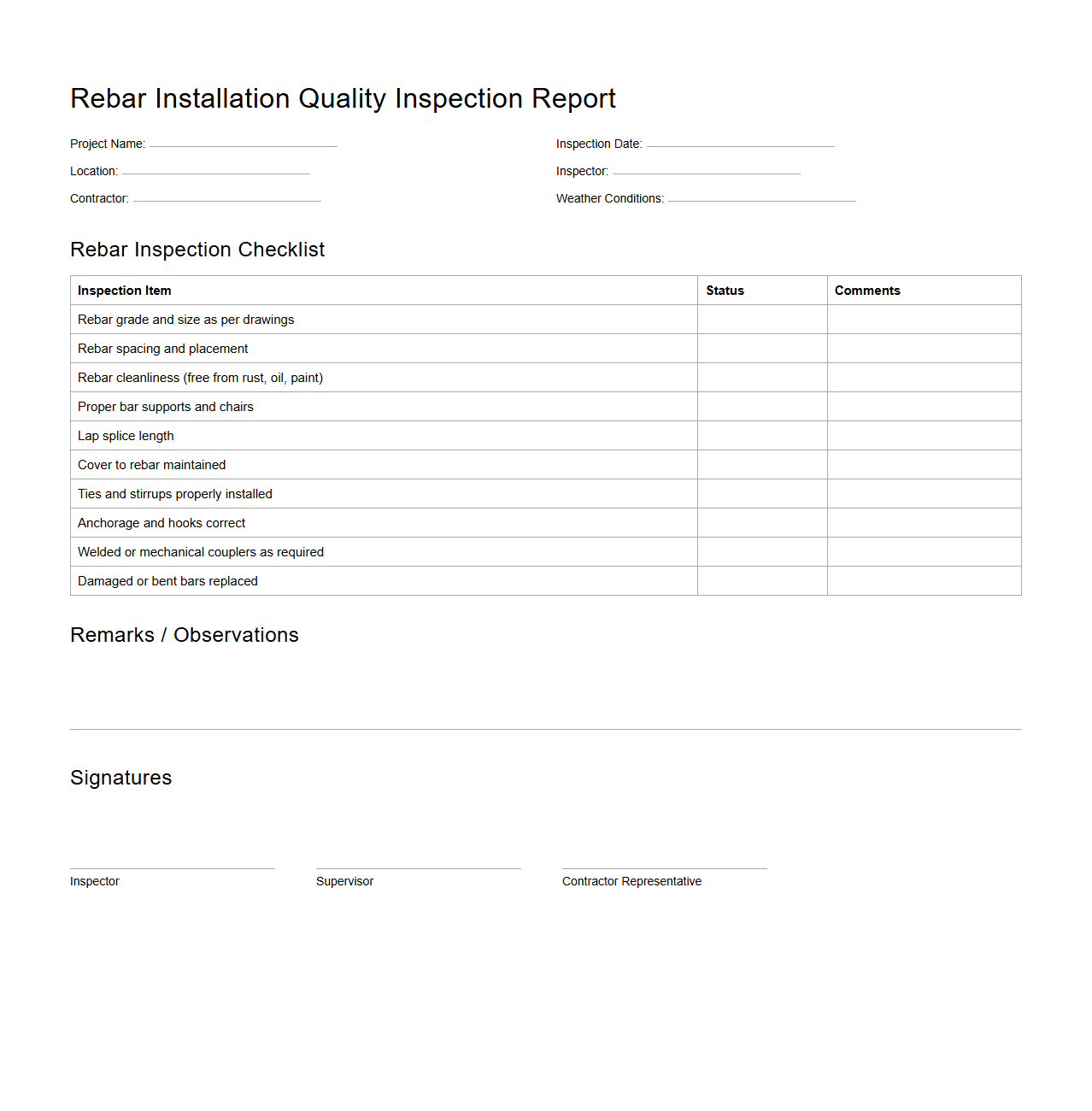

Rebar Installation Quality Inspection Report

A

Rebar Installation Quality Inspection Report document records the assessment of reinforcing steel placement in construction projects to ensure compliance with design specifications and safety standards. It details parameters such as bar size, spacing, alignment, and anchorage, confirming that the rebar installation meets structural integrity requirements. This report is critical for verifying quality control before concrete pouring, helping to prevent structural failures and ensuring project durability.

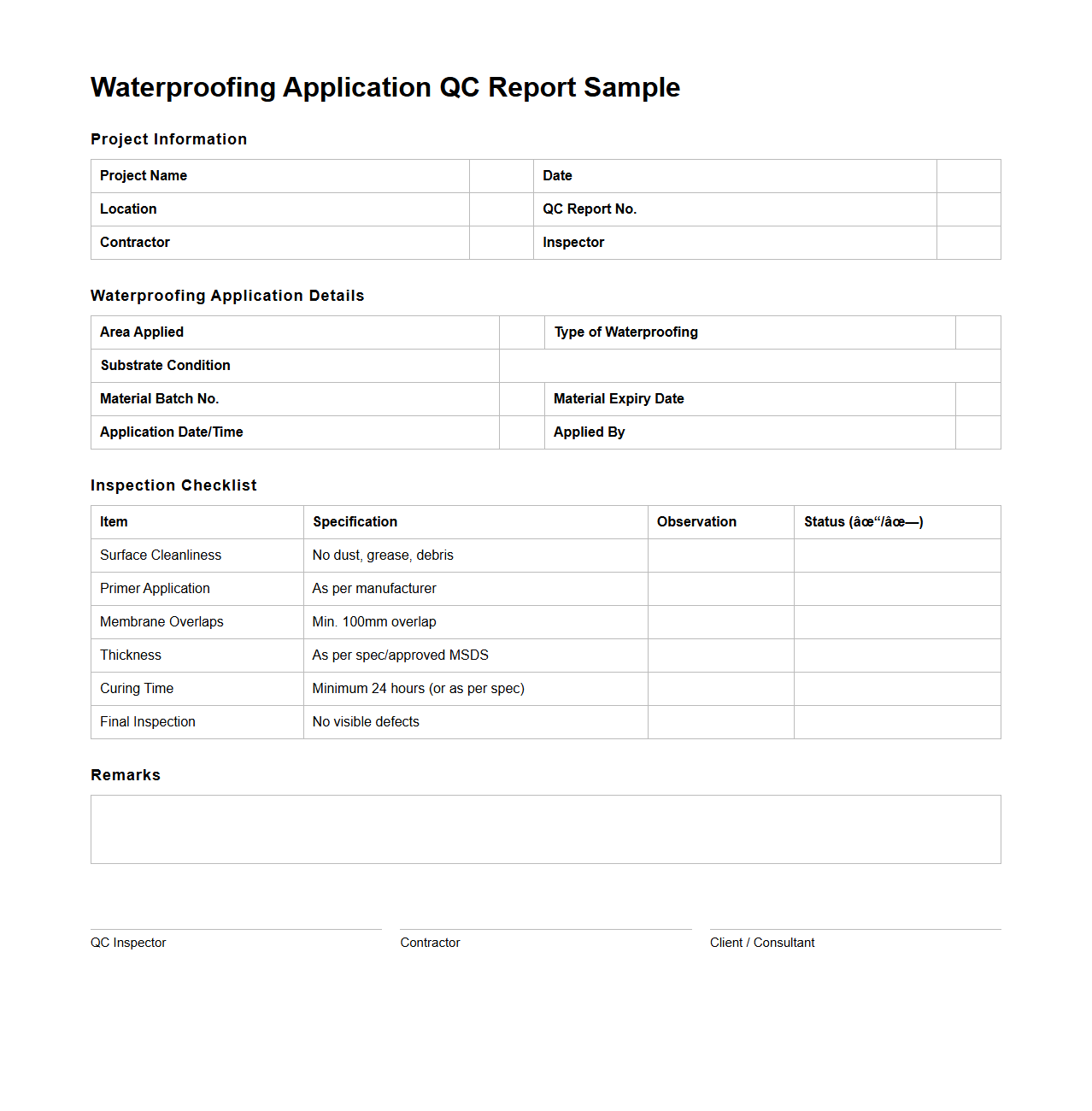

Waterproofing Application QC Report Sample

A

Waterproofing Application QC Report Sample document serves as a detailed quality control record to verify the proper application of waterproofing materials on construction projects. It typically includes data on material specifications, surface preparation, environmental conditions, application methods, inspection results, and compliance with industry standards. This report helps ensure the durability and effectiveness of waterproofing systems while preventing potential structural damage from water ingress.

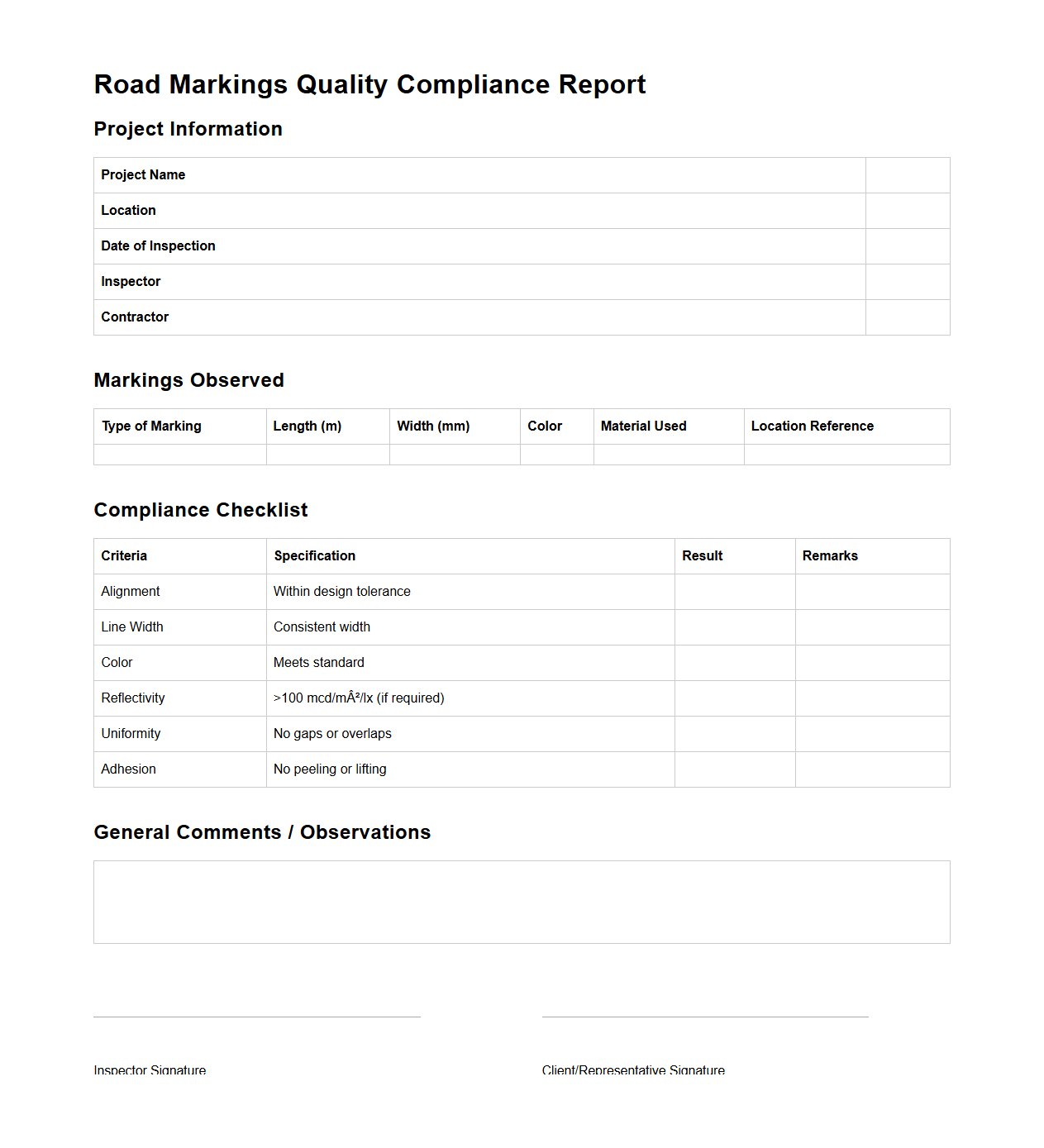

Road Markings Quality Compliance Report

A

Road Markings Quality Compliance Report document assesses the adherence of road marking installations to specified industry standards and safety regulations. It evaluates parameters such as material durability, visibility, alignment, and thickness to ensure optimal performance and road safety. This report serves as a critical tool for contractors and regulatory bodies to verify that road markings meet quality benchmarks and comply with government guidelines.

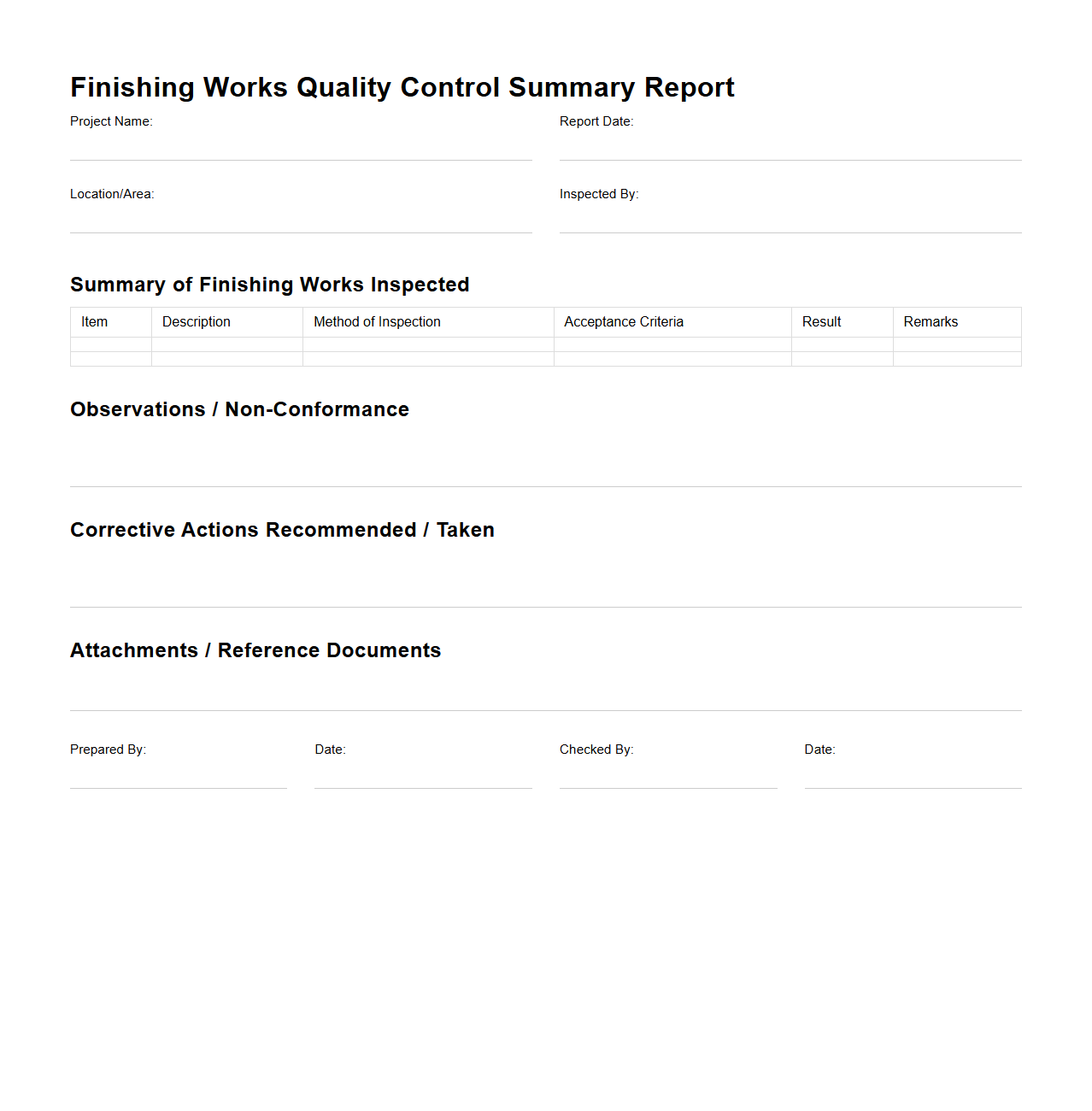

Finishing Works Quality Control Summary Report

The

Finishing Works Quality Control Summary Report document provides a comprehensive overview of the quality inspection results for finishing tasks in construction or manufacturing projects. It consolidates data on compliance with industry standards, identifies defects or deviations, and tracks corrective actions taken to ensure the final output meets specified requirements. This report serves as a critical tool for project managers and quality assurance teams to maintain high standards and verify that finishing works adhere to contractual and regulatory guidelines.

What key parameters are typically monitored in a Civil Works Quality Control Report?

The key parameters typically monitored include material quality, workmanship, and conformity to design specifications. These parameters ensure that all construction activities meet the required standards and project requirements. Monitoring these aspects is critical to maintaining the overall integrity and safety of the civil works.

How is material compliance verified and documented in the Quality Control Report?

Material compliance is verified by conducting material tests and inspections as per specified standards and project guidelines. Documentation involves recording test results, supplier certificates, and material delivery receipts in the Quality Control Report. This process ensures accountability and confirms that only approved materials are used on the project.

What section records non-conformance and corrective actions taken on-site?

The Non-Conformance Report (NCR) section of the Quality Control Report records all deviations from specifications. It also details the corrective actions implemented to address and rectify these issues promptly. This section is essential for tracking quality issues and ensuring continuous improvement.

Which standardized test results must be attached to the report for soil compaction?

Standardized test results for soil compaction typically include Proctor tests, field density tests, and moisture content analysis. These test certificates and data provide evidence that the soil compaction meets project and regulatory requirements. Including these results in the report validates the construction quality and supports compliance.

How does the report ensure traceability of construction activities and inspection dates?

The report ensures traceability by including detailed logs of inspection dates, personnel involved, and specific construction activities performed. This information creates an audit trail that can be reviewed for quality assurance and accountability purposes. Maintaining this traceability helps in managing project milestones and verifying compliance throughout the construction process.

More Construction Templates