A Quality Assurance Document Sample for Civil Construction outlines standardized procedures and criteria to ensure project quality meets industry standards and client requirements. It includes detailed checklists, inspection records, and compliance verification steps to monitor construction processes effectively. This document serves as a critical tool for maintaining consistency and accountability throughout the civil construction lifecycle.

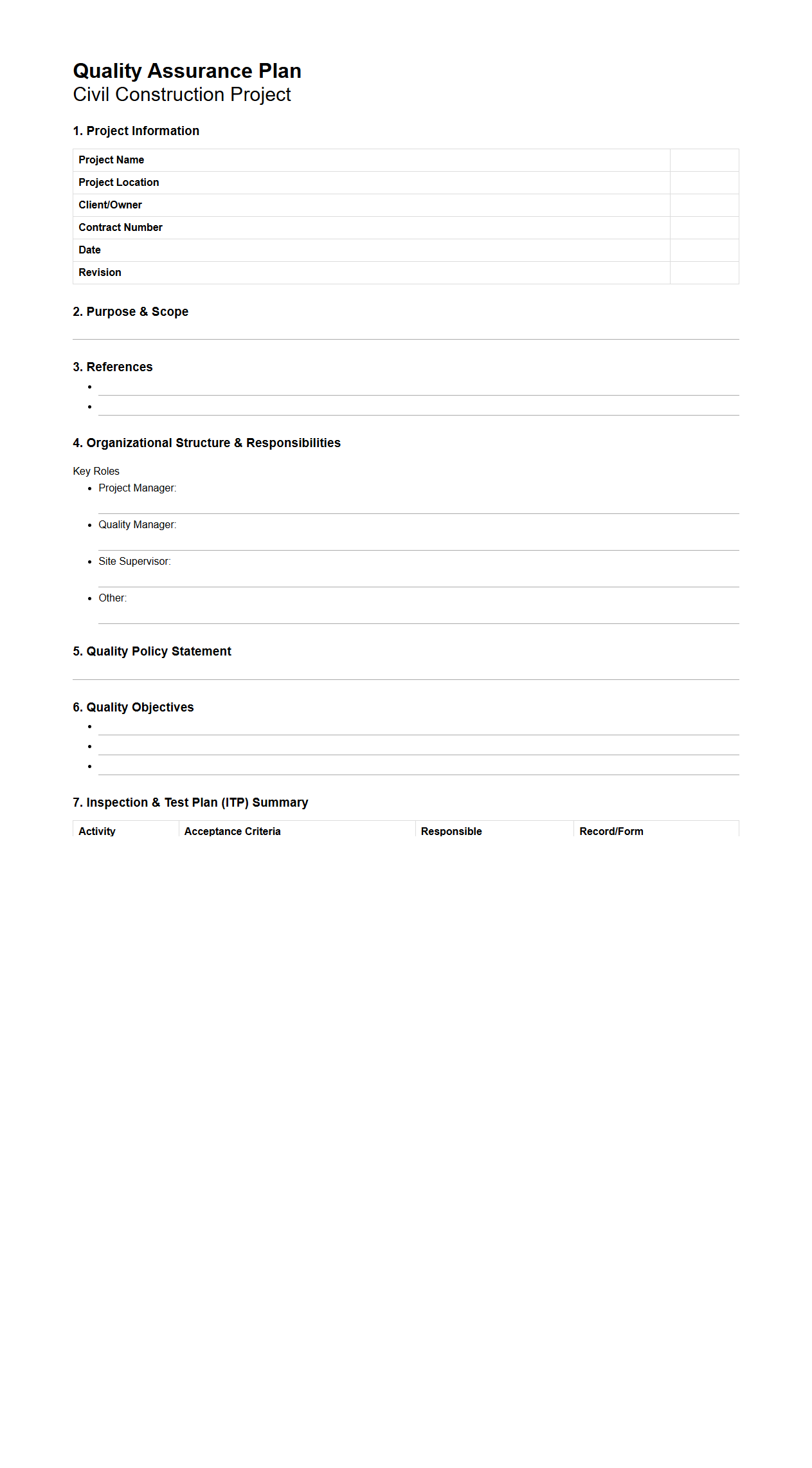

Quality Assurance Plan Template for Civil Construction

A

Quality Assurance Plan Template for Civil Construction document outlines the systematic procedures and standards to ensure project deliverables meet specified quality criteria. It includes detailed information on quality control measures, inspection schedules, material testing requirements, and roles and responsibilities for quality management. This template serves as a critical tool to maintain compliance with regulatory standards and enhance project efficiency in civil construction projects.

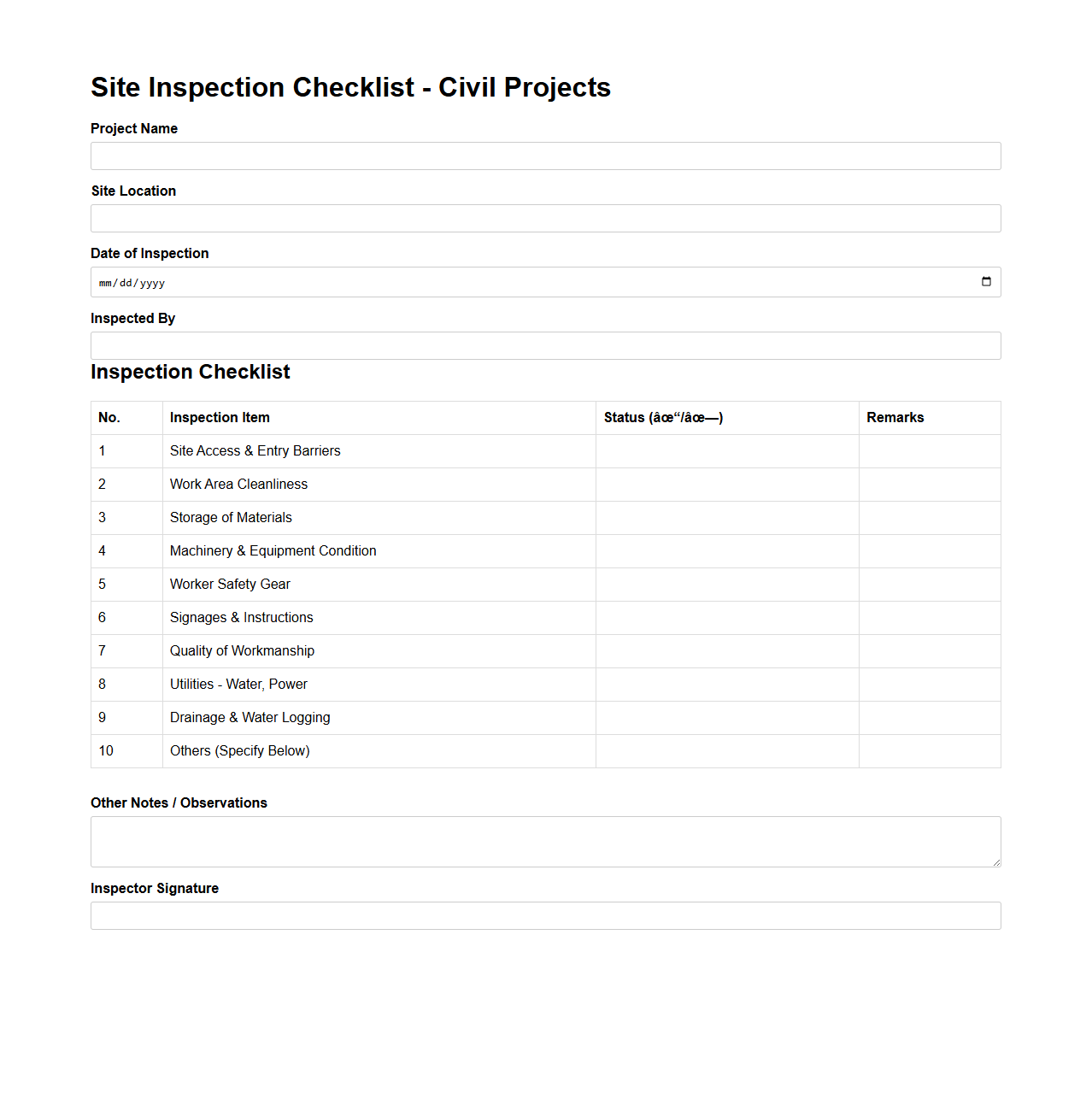

Site Inspection Checklist for Civil Projects

A

Site Inspection Checklist for civil projects is a comprehensive document used to systematically verify that all project elements meet specified standards and regulatory requirements during construction. This checklist typically includes detailed criteria for safety measures, material quality, structural integrity, environmental compliance, and site organization to ensure consistent project monitoring. It serves as a critical tool for project managers, engineers, and inspectors to identify and address potential issues early, minimizing risks and ensuring successful project completion.

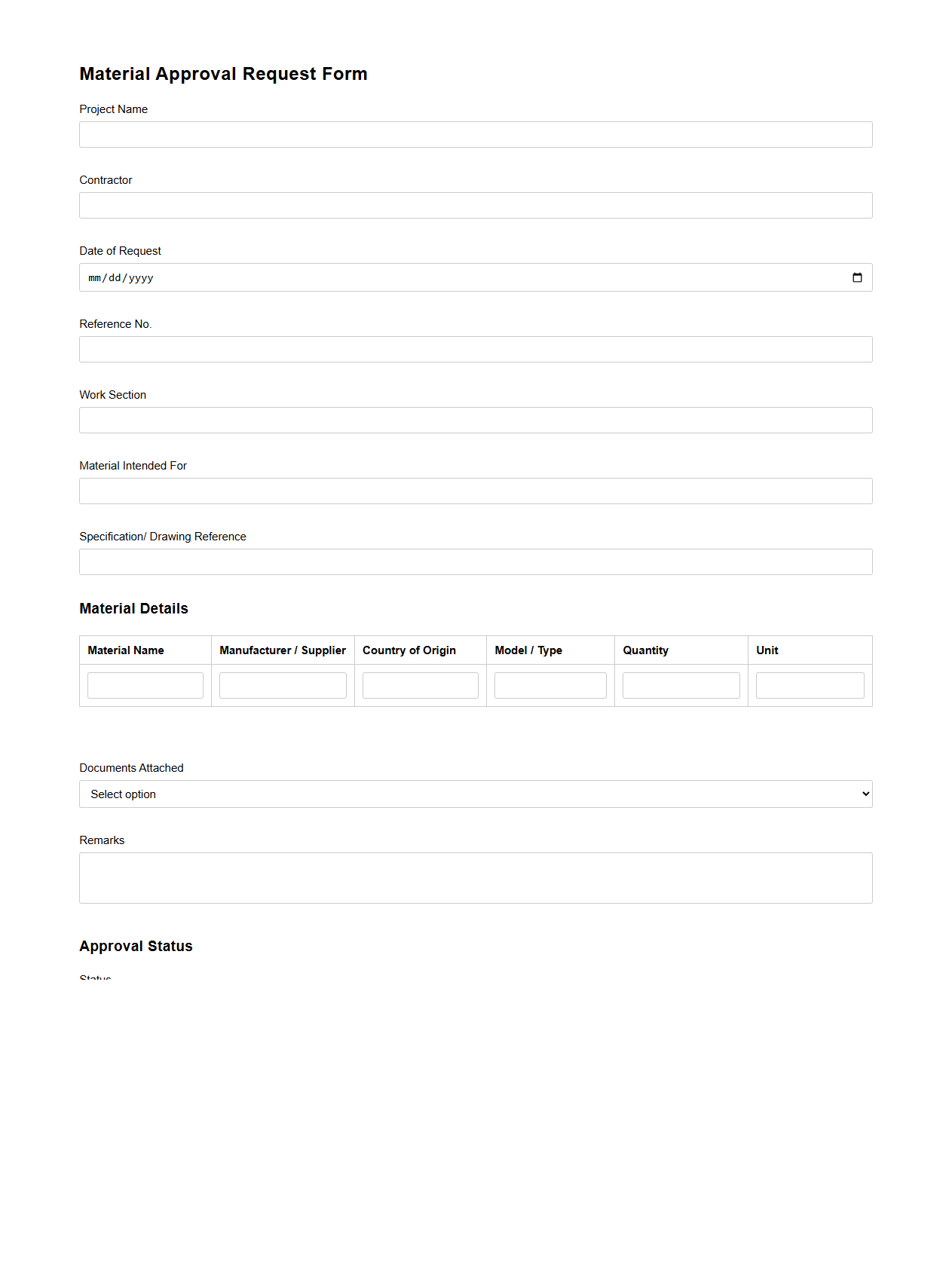

Material Approval Request Form for Construction Works

A

Material Approval Request Form for construction works is a formal document used to seek authorization for the materials intended for use on a project. It ensures that all materials meet specified quality standards, project requirements, and compliance regulations before procurement and installation. This process helps prevent delays, reduces the risk of rework, and maintains the integrity of construction quality control.

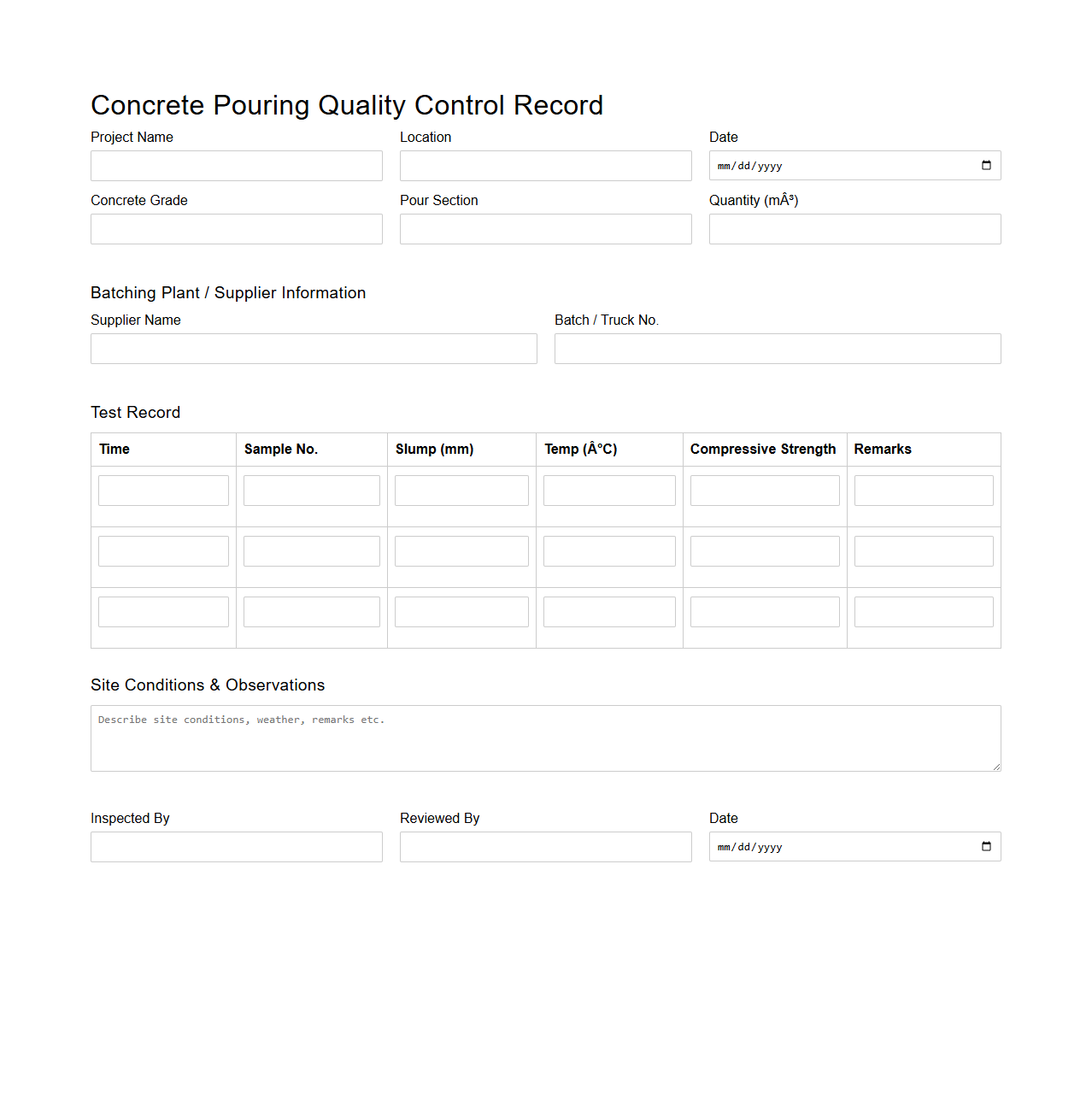

Concrete Pouring Quality Control Record

The

Concrete Pouring Quality Control Record document is a critical record used to ensure the quality and consistency of concrete during construction projects. It systematically documents key parameters such as mix proportions, environmental conditions, slump tests, temperature, and curing processes to verify compliance with project specifications. Maintaining this record helps in identifying any deviations, supporting quality assurance, and enhancing structural integrity.

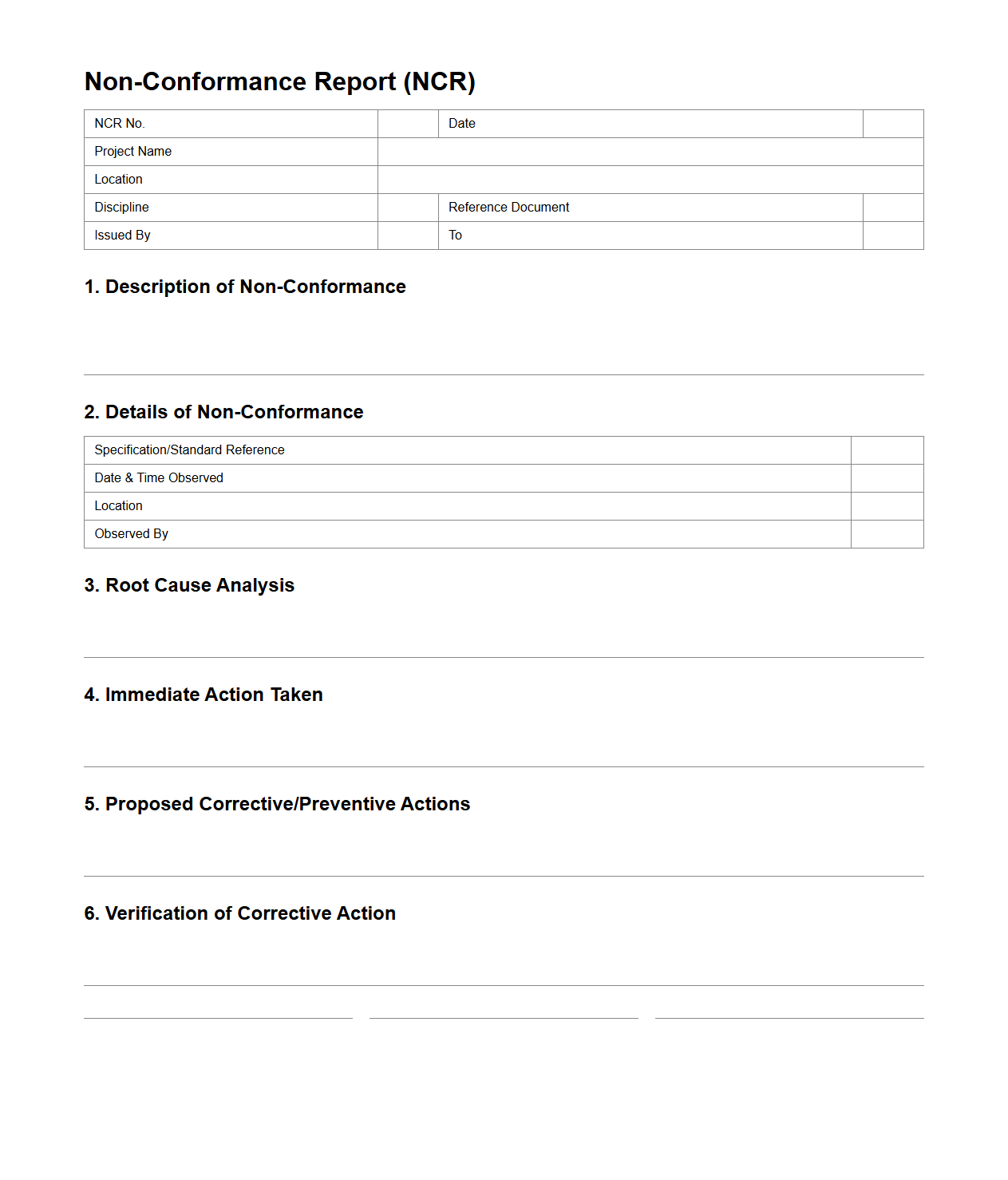

Non-Conformance Report for Civil Engineering

A

Non-Conformance Report (NCR) in civil engineering is a formal document used to identify and record deviations from project specifications, standards, or contract requirements. It details the nature of the non-conformance, its location, impact on the project, and recommended corrective actions to ensure compliance and maintain quality control. The NCR serves as a crucial tool for tracking issues, facilitating communication among stakeholders, and preventing recurrence in construction processes.

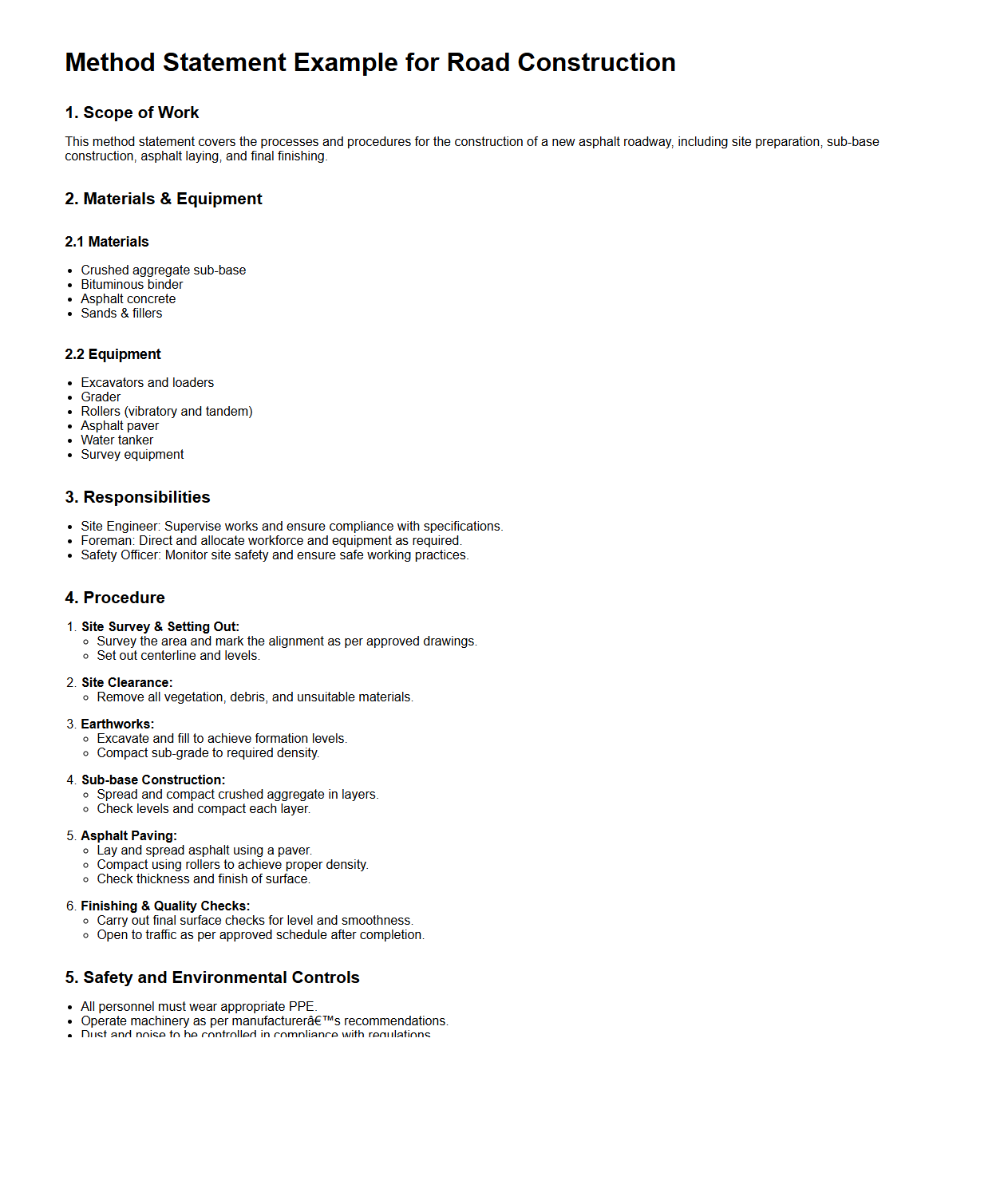

Method Statement Example for Road Construction

A

Method Statement Example for Road Construction document outlines the detailed procedures, safety measures, and resources required to complete specific road construction tasks efficiently and safely. It serves as a practical guide for contractors and workers, ensuring compliance with industry standards and minimizing risks during construction activities. This document typically includes step-by-step instructions, equipment specifications, labor roles, and environmental considerations to promote effective project execution.

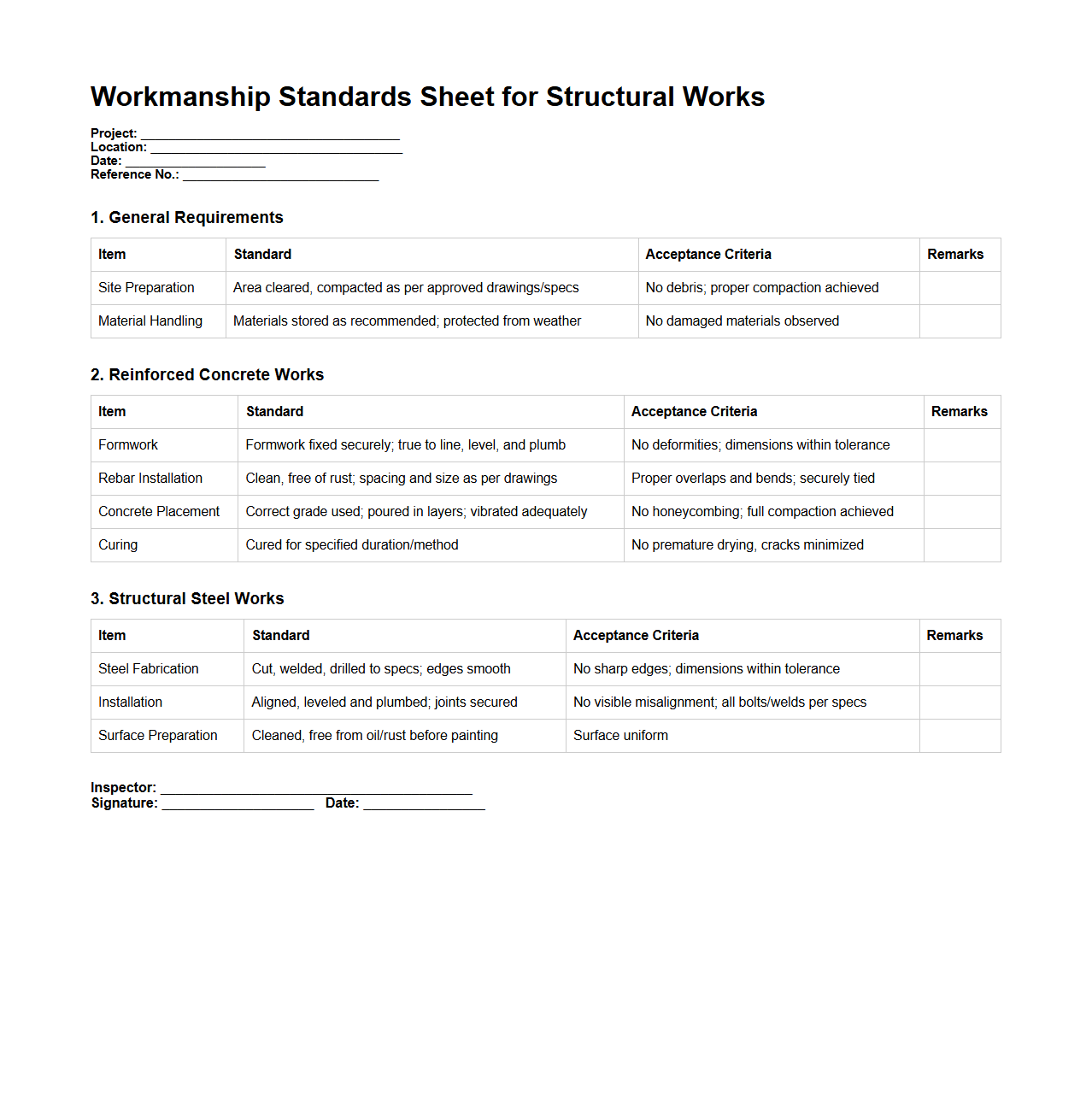

Workmanship Standards Sheet for Structural Works

The

Workmanship Standards Sheet for Structural Works document outlines the quality requirements and best practices for executing structural construction tasks, ensuring compliance with engineering specifications and safety regulations. It serves as a guideline for laborers, supervisors, and inspectors to maintain consistency and high standards in material handling, assembly, and finishing processes. This document is essential for minimizing defects, enhancing durability, and achieving regulatory approvals in construction projects.

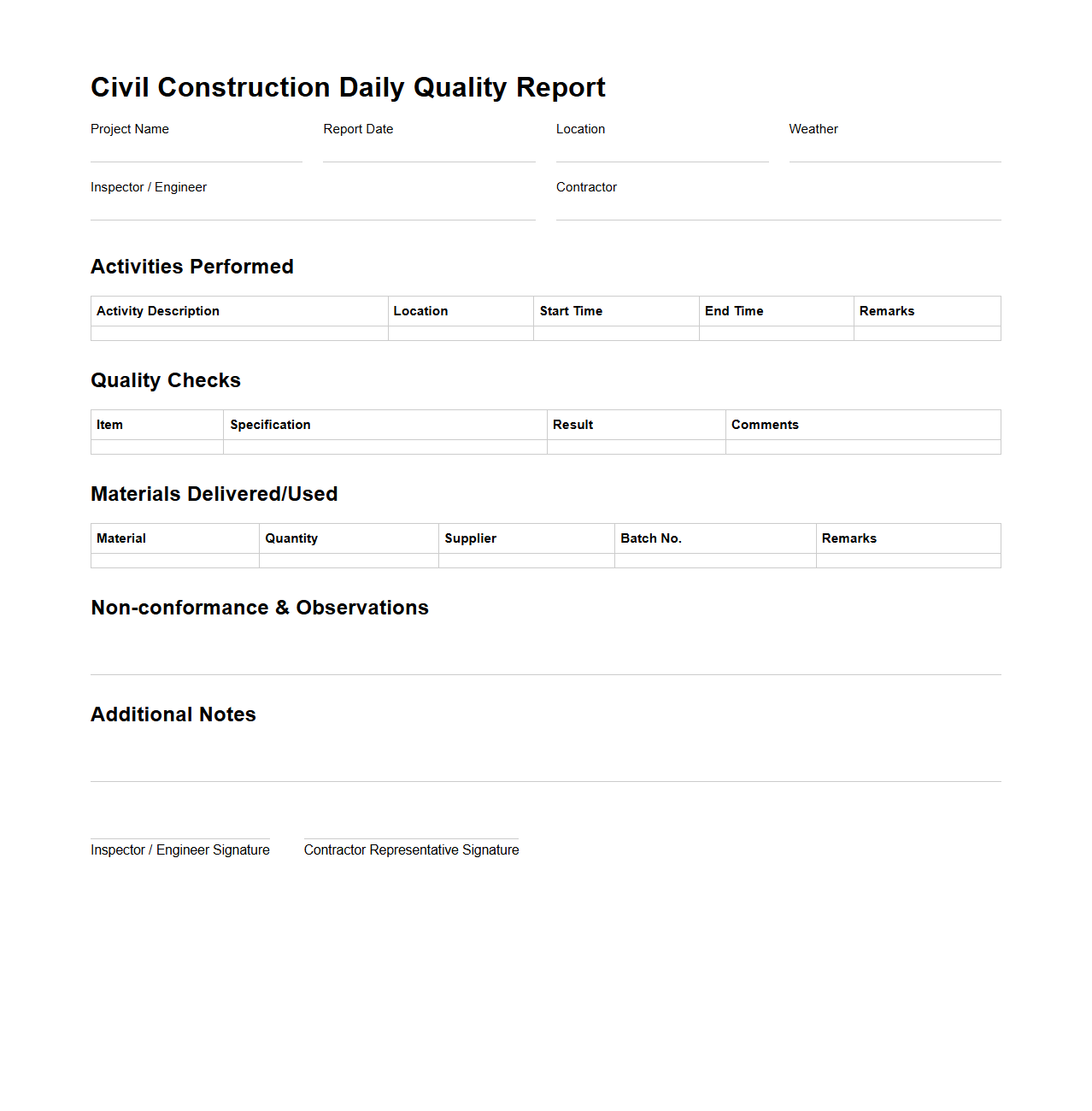

Civil Construction Daily Quality Report Sample

The

Civil Construction Daily Quality Report Sample document serves as a standardized template for recording and tracking daily quality control activities on construction sites. It includes essential data such as inspection results, material compliance, non-conformance issues, corrective actions, and workforce details to ensure adherence to project specifications and industry standards. This report enables project managers and quality inspectors to maintain transparent documentation and support continuous improvement throughout the construction process.

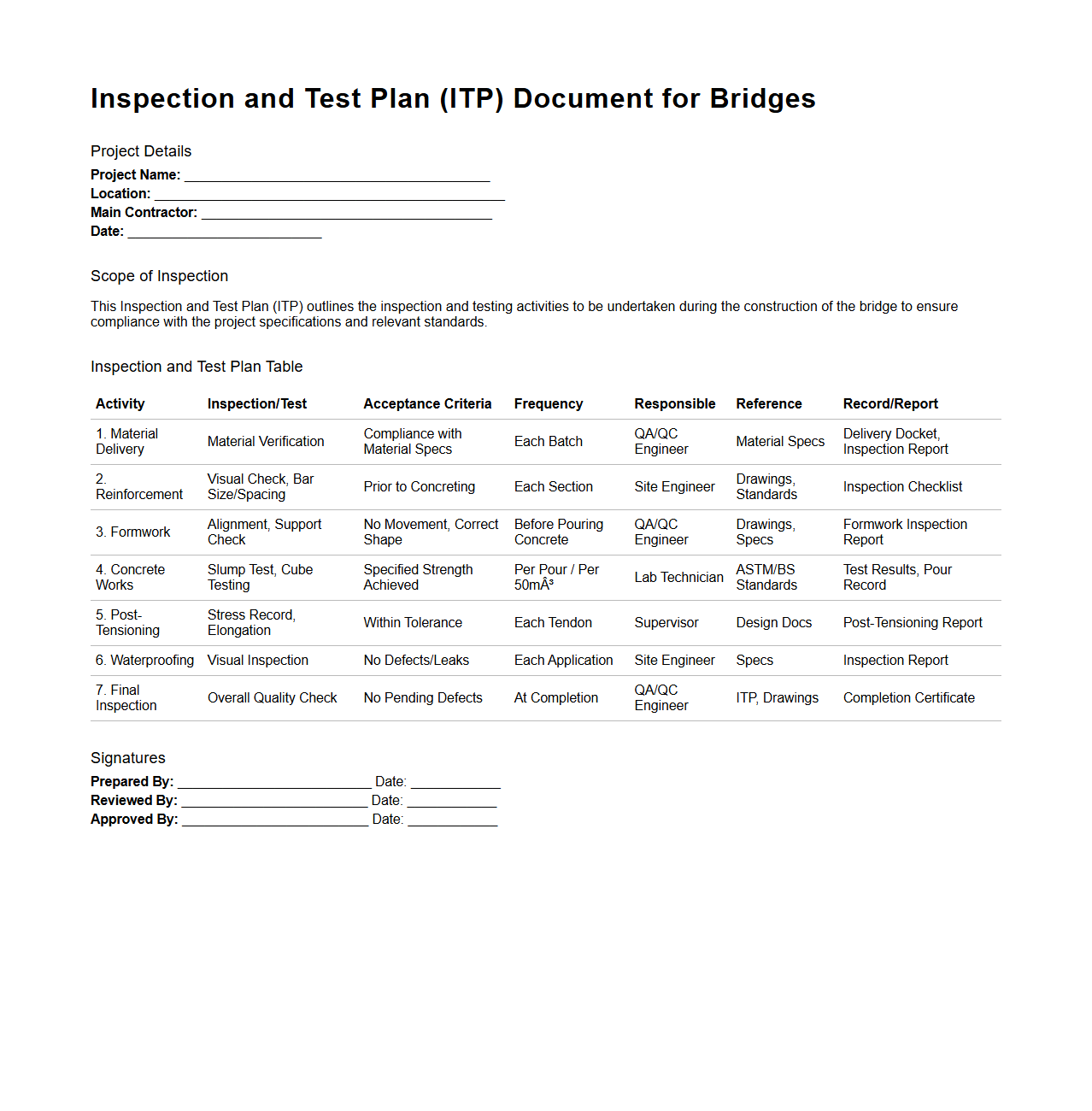

Inspection and Test Plan Document for Bridges

An

Inspection and Test Plan Document for Bridges outlines a systematic approach to verify the quality, safety, and compliance of bridge components during construction and maintenance. It specifies the types of inspections, testing methods, frequency, acceptance criteria, and responsible personnel to ensure all structural elements meet regulatory standards. This document is essential for managing risk, preventing failures, and maintaining the bridge's longevity and reliability.

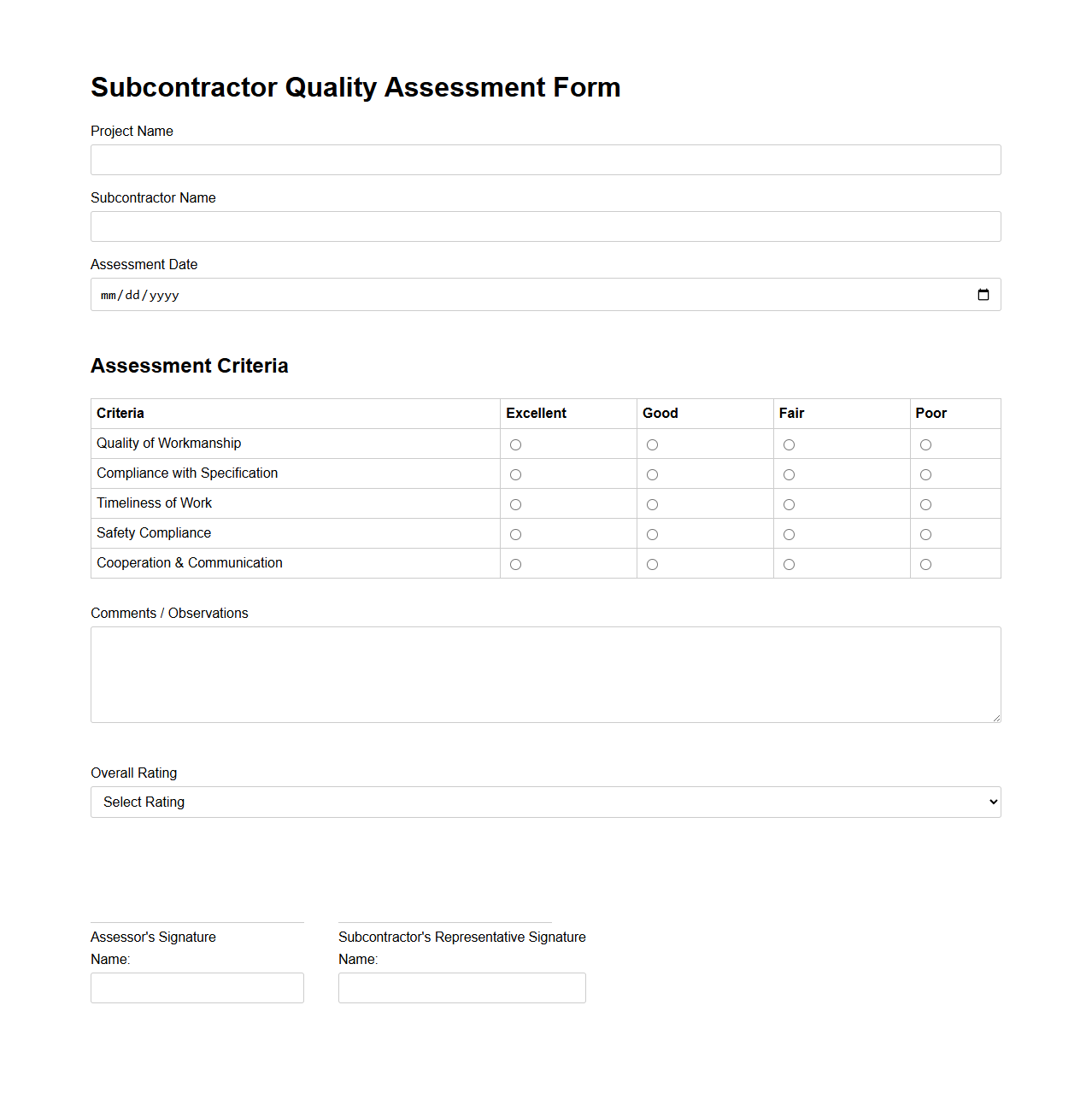

Subcontractor Quality Assessment Form

The

Subcontractor Quality Assessment Form documents the evaluation process of a subcontractor's ability to meet project quality standards. It systematically records performance metrics, compliance with specifications, and areas for improvement to ensure alignment with contractual requirements. This form serves as a critical tool for maintaining quality control and managing subcontractor relationships effectively.

What key elements must be included in a civil construction Quality Assurance document?

A civil construction Quality Assurance (QA) document must include clear project scope, quality objectives, and defined responsibilities. It should outline inspection and testing plans to ensure project standards are met. Detailed records of compliance with specifications and corrective actions are also essential components.

How are material testing protocols documented for QA in civil projects?

Material testing protocols are documented through standardized test plans specifying methods, frequency, and acceptance criteria. Results are recorded in test reports, which form part of the QA documentation for traceability. These documents ensure materials meet project quality standards before use in construction.

What procedures ensure compliance with regulatory QA standards in construction?

Compliance is ensured via regular audits, inspections, and review of project documentation against regulatory requirements. The QA plan integrates statutory standards into daily operations and uses checklists to track adherence. Continuous training and certification of staff also support regulatory compliance.

How are non-conformances recorded and rectified in QA documentation?

Non-conformances are logged in non-conformance reports (NCRs) that describe the issue, cause, and impacted areas. Corrective actions are documented with timelines and responsible personnel assigned to resolve the defects. Follow-up inspections verify the effectiveness of the corrective measures within the QA system.

What role does traceability play in quality assurance documents for civil works?

Traceability ensures that every material, test, and process can be tracked back to its source, maintaining accountability throughout the project. It supports quality control by linking procedures and outcomes to specific standards and personnel. Effective traceability minimizes risks and enhances transparency in quality assurance.

More Construction Templates