A Method Statement Document Sample for Concrete Works provides a detailed procedure outlining the steps and safety measures for executing concrete construction tasks efficiently. It includes information on material handling, mixing, pouring, curing, and quality control to ensure compliance with industry standards. This document serves as a vital reference for project managers and site engineers to maintain consistency and safety throughout the concrete works process.

Method Statement for Concrete Pouring Activities

A

Method Statement for Concrete Pouring Activities is a detailed document outlining the step-by-step procedures, safety measures, and quality control methods required for efficient and safe concrete pouring on a construction site. It includes information on materials, equipment, workforce responsibilities, environmental considerations, and compliance with relevant standards and regulations. This document ensures consistency, minimizes risks, and enhances the overall quality and durability of the concrete structure.

Concrete Surface Preparation Method Statement

A

Concrete Surface Preparation Method Statement document outlines the step-by-step procedures and techniques required to properly prepare concrete surfaces before applying coatings, sealants, or other treatments. It specifies surface cleaning methods, repair protocols, moisture testing, and safety precautions to ensure optimal adhesion and durability of the subsequent material layers. This document serves as a crucial reference to maintain quality standards and compliance with industry regulations during construction or renovation projects.

Formwork Installation Method Statement for Concrete

The

Formwork Installation Method Statement for Concrete document outlines the procedures, materials, and safety measures required for setting up formwork systems used to mold concrete structures. It defines the step-by-step process for assembling, supporting, and bracing formwork to ensure dimensional accuracy and structural stability during concrete pouring and curing. This method statement also includes quality control checkpoints and compliance with relevant construction standards to prevent defects and ensure worker safety.

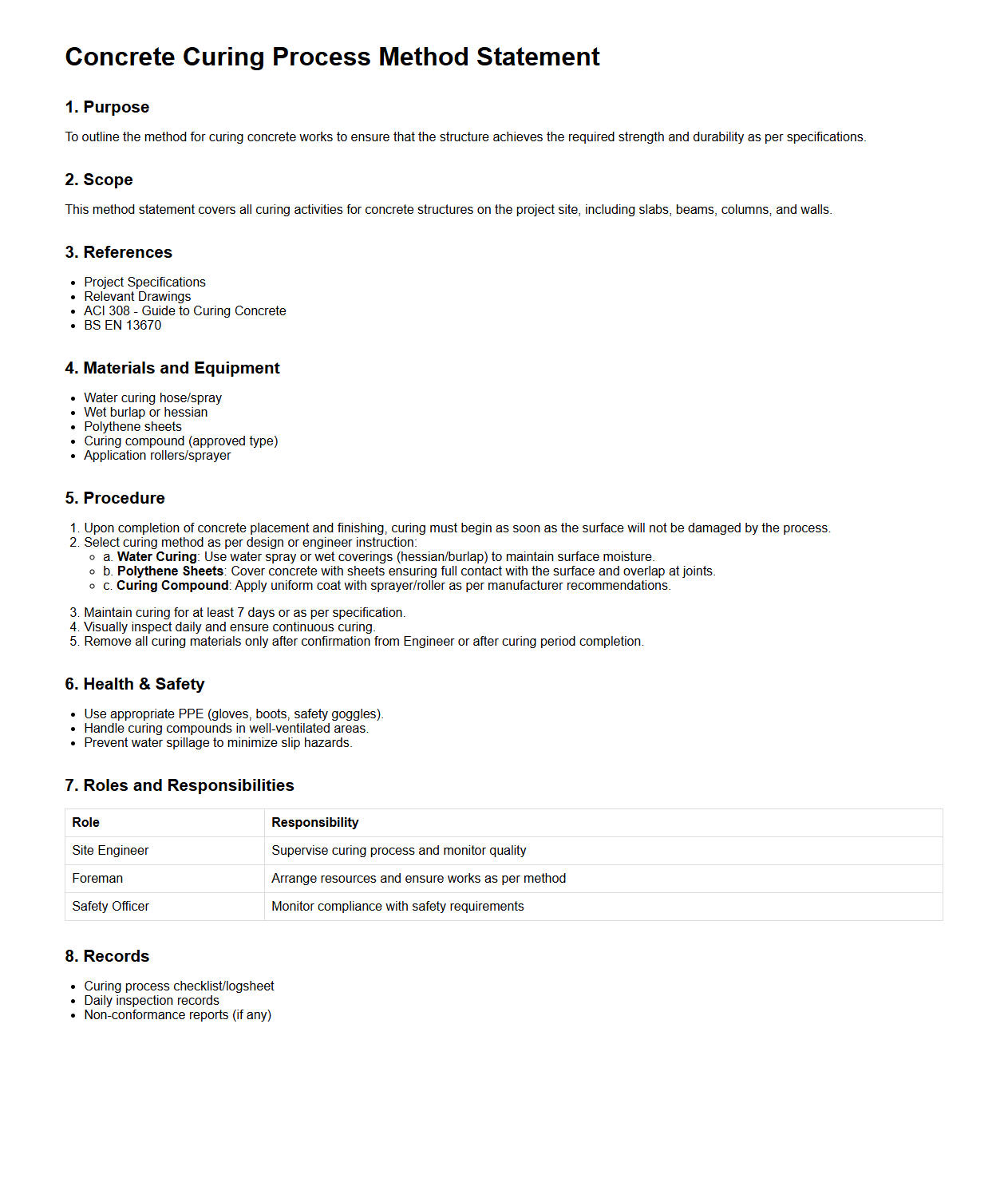

Concrete Curing Process Method Statement

A

Concrete Curing Process Method Statement document outlines the specific procedures and standards required to ensure proper curing of concrete, which is critical for achieving its desired strength and durability. It details the curing methods, environmental conditions, duration, and quality control measures to prevent premature drying and cracking. This document serves as a guideline for construction teams to maintain optimal moisture and temperature levels during the curing phase, ensuring structural integrity and compliance with industry specifications.

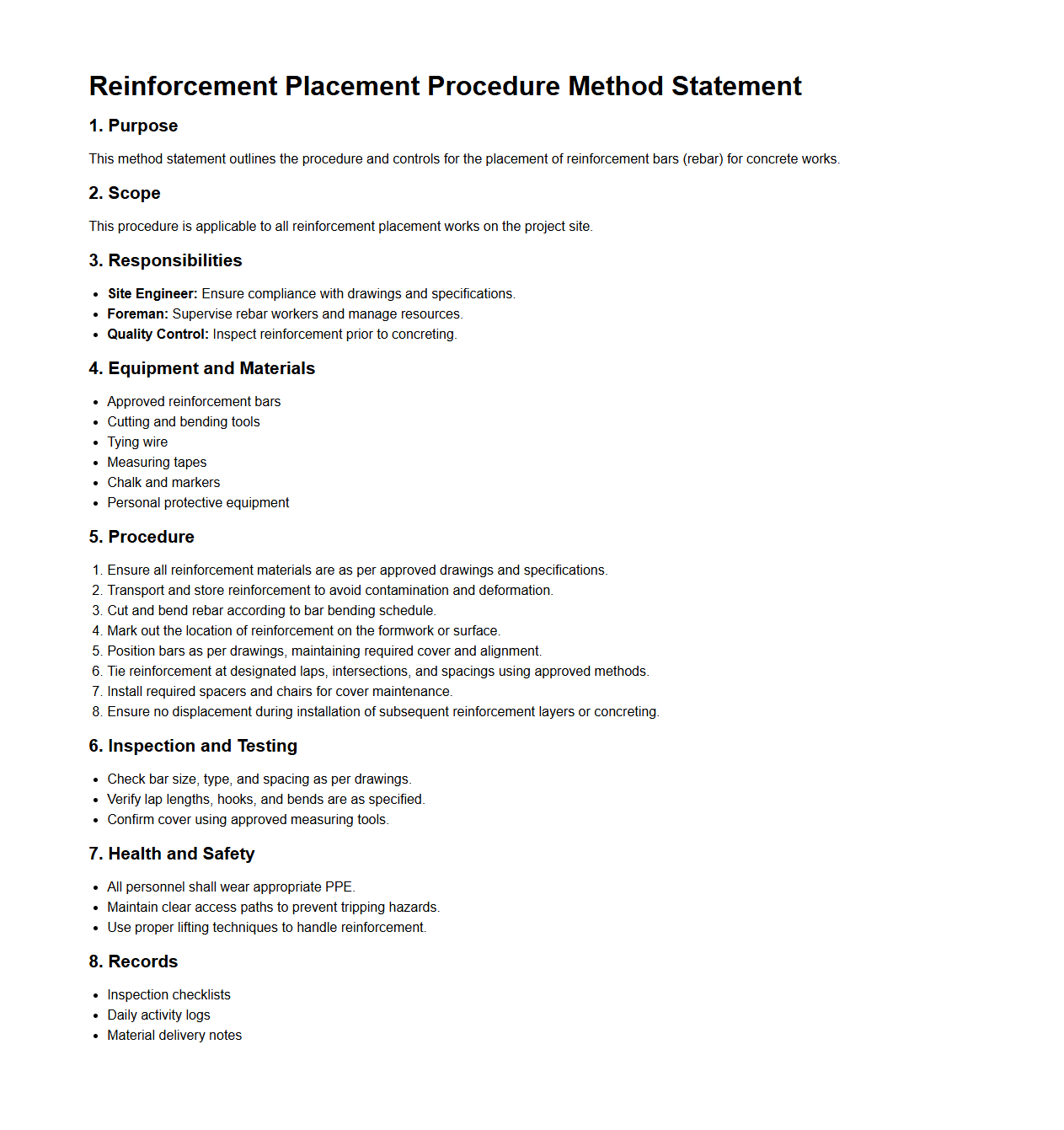

Reinforcement Placement Procedure Method Statement

A

Reinforcement Placement Procedure Method Statement document outlines the step-by-step process for accurately installing reinforcement bars in concrete structures, ensuring compliance with design specifications and safety standards. It details material handling, positioning techniques, secure fixing methods, and quality control measures to prevent structural failures. This document is essential for coordinating construction tasks, maintaining project integrity, and achieving durable, high-performance concrete works.

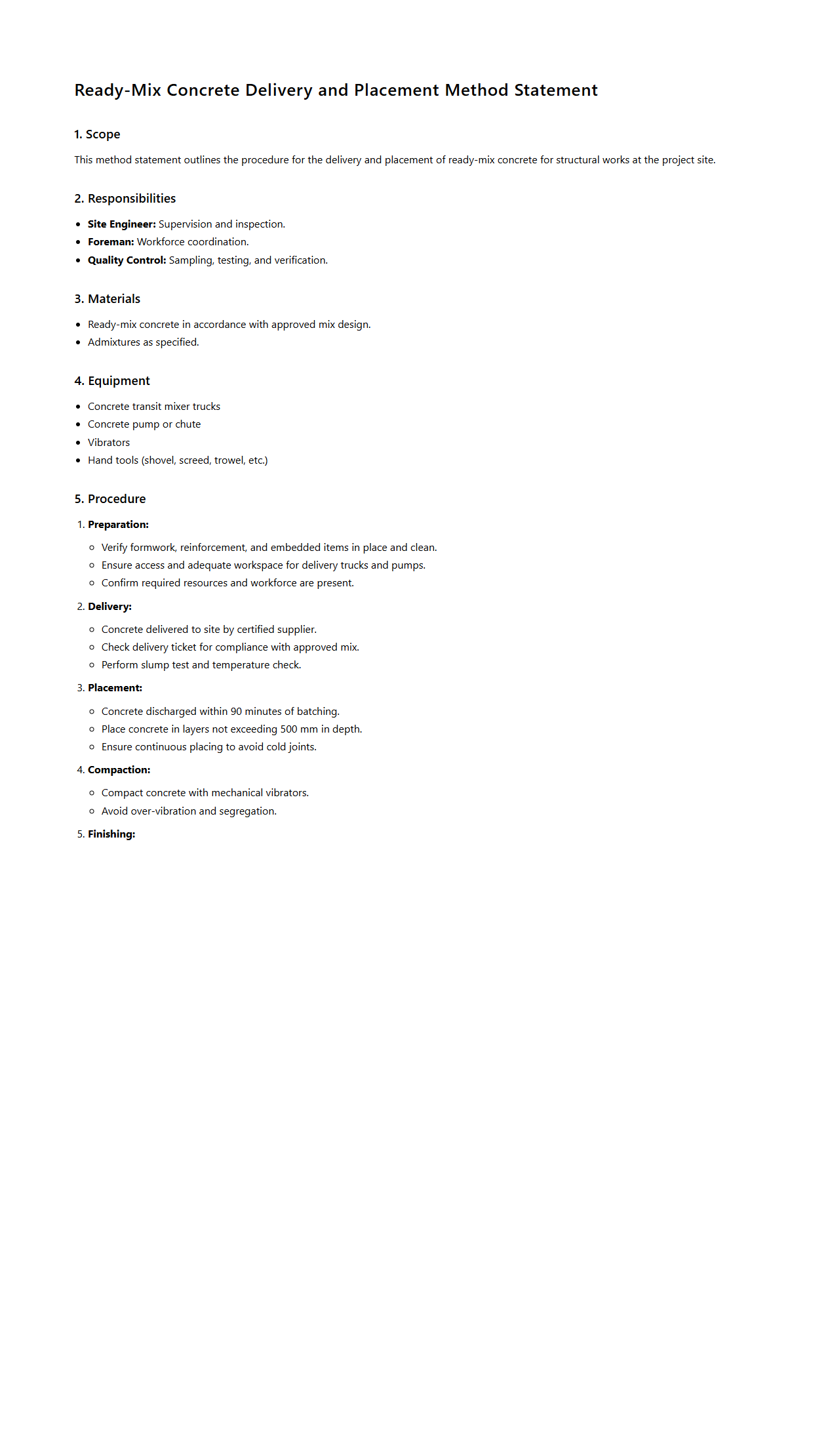

Ready-Mix Concrete Delivery and Placement Method Statement

A

Ready-Mix Concrete Delivery and Placement Method Statement document outlines the procedures for transporting, handling, and placing ready-mix concrete to ensure quality and safety compliance. It details the steps involved in unloading, positioning, and compacting concrete at the construction site to achieve specified structural requirements. This document serves as a crucial reference for project managers, contractors, and site engineers to maintain control over concrete work execution and minimize risks.

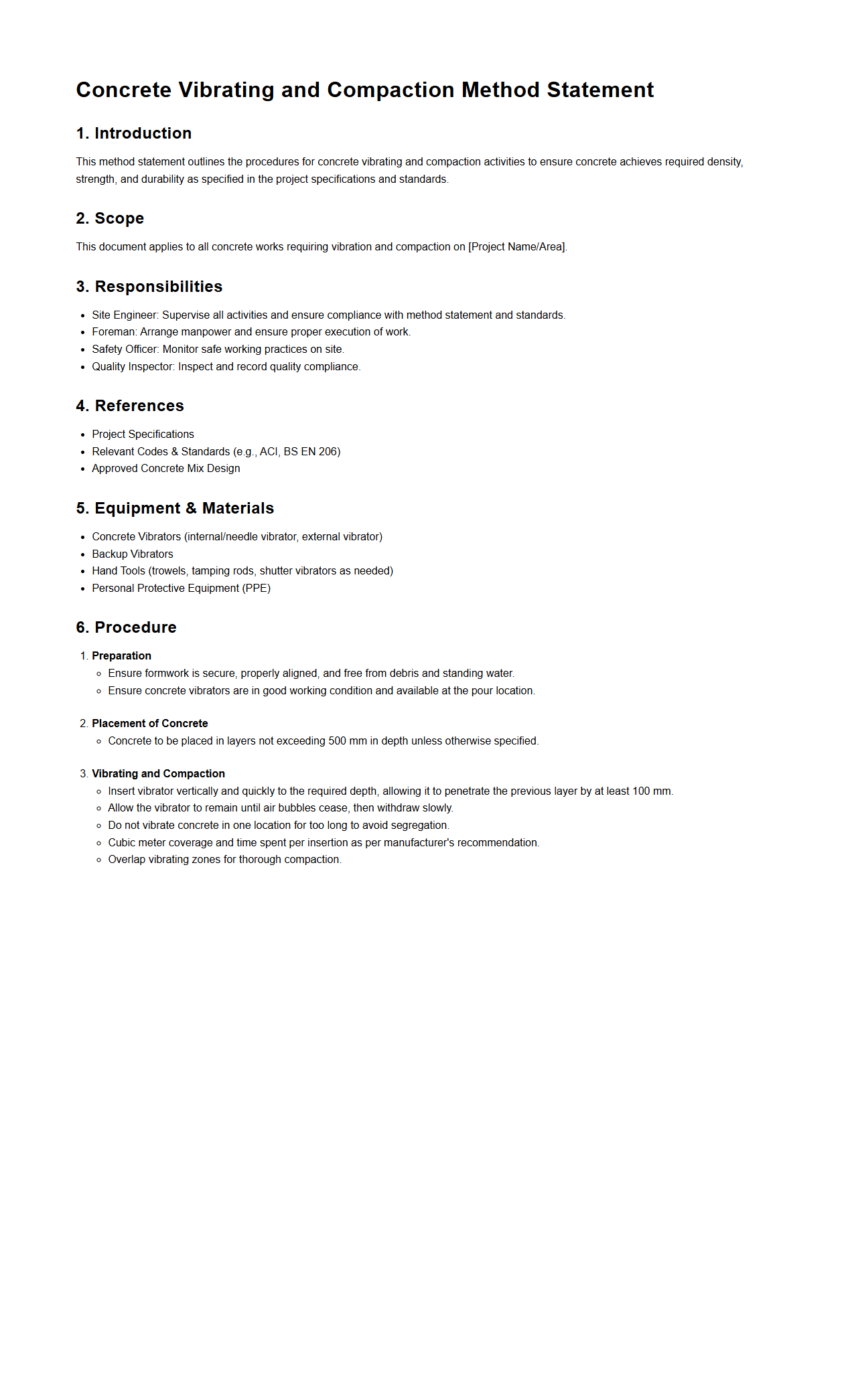

Concrete Vibrating and Compaction Method Statement

The

Concrete Vibrating and Compaction Method Statement document outlines the procedures and techniques used to eliminate air pockets and achieve uniform densification within freshly poured concrete. It details the selection of appropriate vibrators, compaction timing, and operator safety measures to ensure optimal concrete strength and durability. This document serves as a crucial guide to maintaining high-quality standards and compliance with construction specifications.

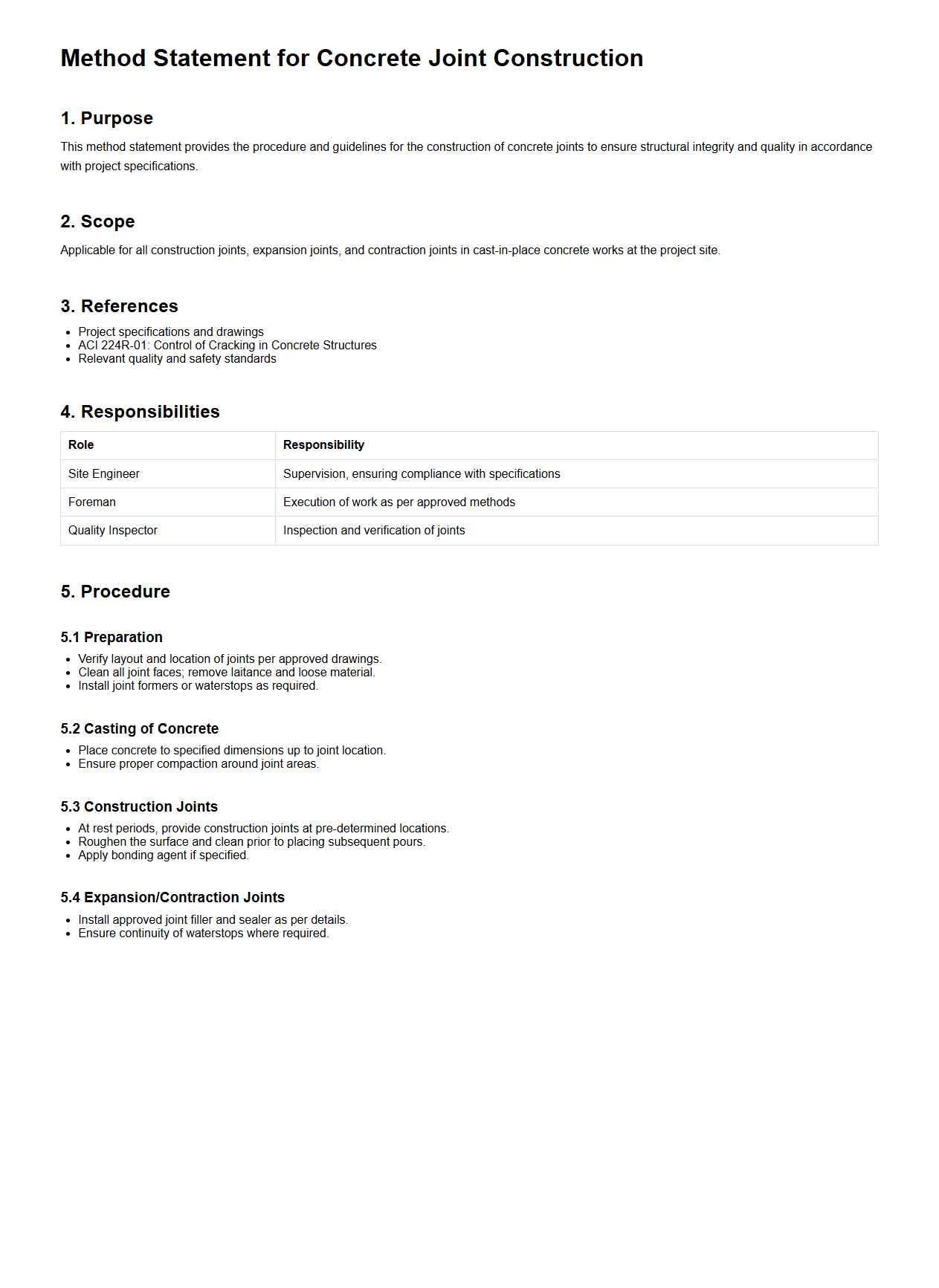

Concrete Joint Construction Method Statement

A

Concrete Joint Construction Method Statement document outlines the detailed procedures and best practices for creating joints in concrete structures to ensure structural integrity and durability. It specifies materials, equipment, joint types, placement techniques, curing methods, and quality control measures essential for preventing cracks and accommodating movements. This document is essential for project managers, contractors, and site engineers to coordinate work and comply with construction standards.

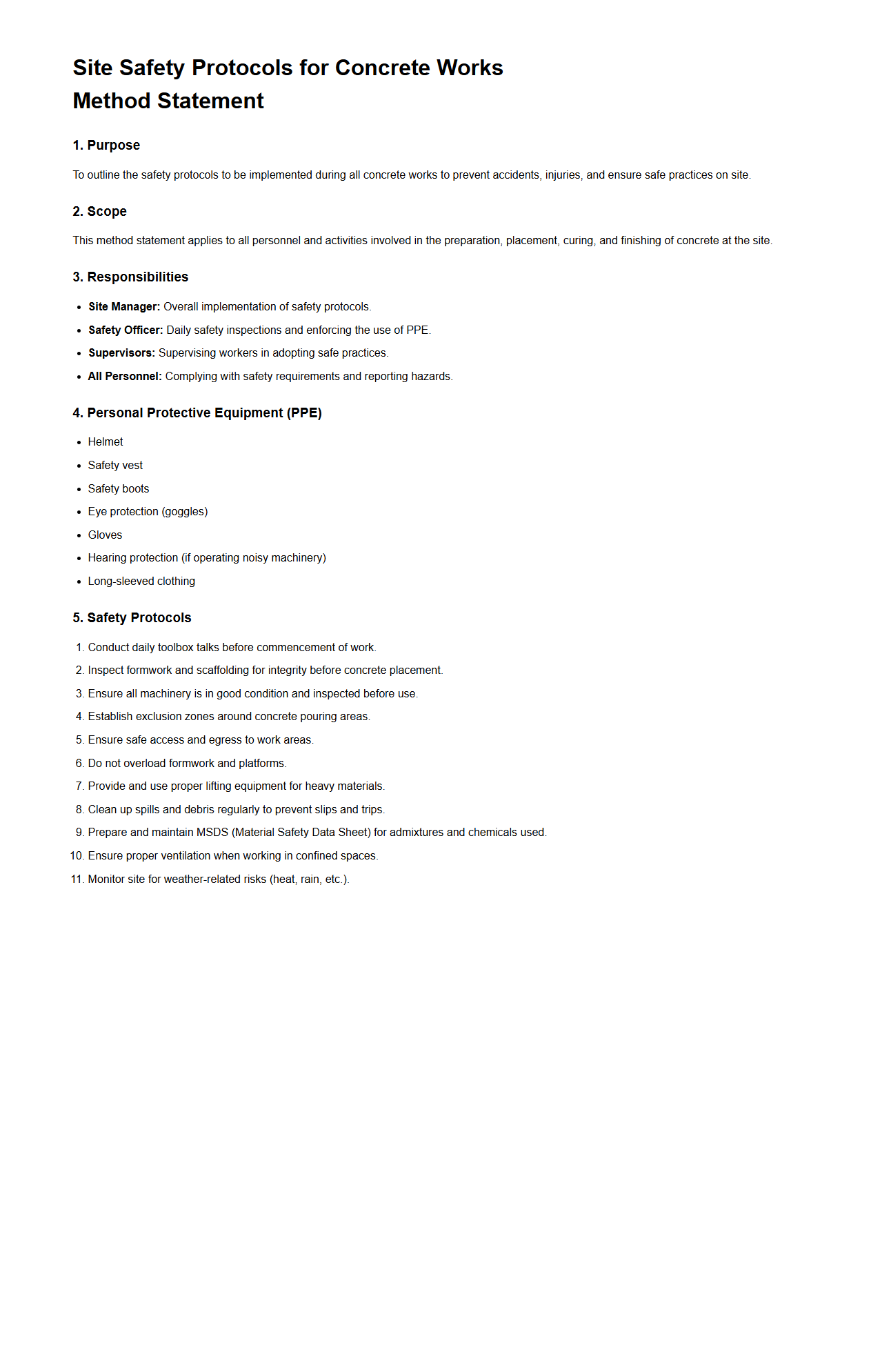

Site Safety Protocols for Concrete Works Method Statement

A

Site Safety Protocols for Concrete Works Method Statement document outlines the specific safety measures and procedures to be followed during concrete construction activities to minimize risks and ensure worker protection. It details hazard identification, risk assessments, personal protective equipment (PPE) requirements, emergency response plans, and safe operating practices related to concrete mixing, pouring, and curing. This document serves as a critical guide to maintaining compliance with occupational health and safety regulations while promoting a secure work environment on construction sites.

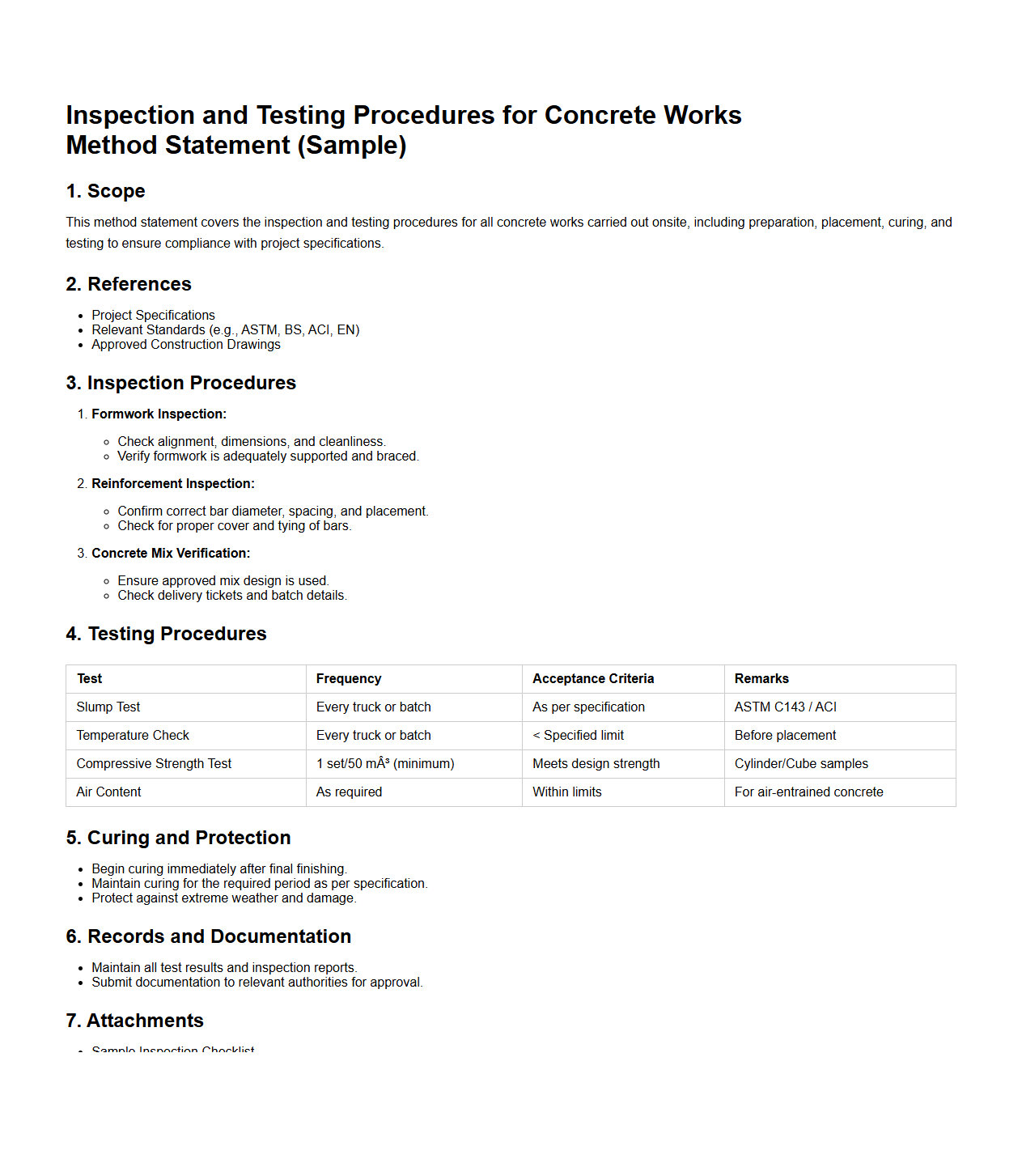

Inspection and Testing Procedures for Concrete Works Method Statement

The

Inspection and Testing Procedures for Concrete Works Method Statement document outlines the systematic approach and standards for verifying the quality, integrity, and compliance of concrete during construction. It includes detailed instructions on sample collection, testing methods such as slump tests and compressive strength tests, and criteria for acceptance to ensure durability and safety. This document serves as a critical reference for contractors and inspectors to maintain consistent quality control throughout the concrete placement process.

What specific curing methods are outlined for concrete in the Method Statement Document?

The Method Statement Document specifies curing methods such as continuous water spraying and wet curing with curing compounds to ensure concrete hydration. It emphasizes the importance of maintaining moisture for at least seven days to achieve optimal strength. Additionally, the document highlights the use of insulated coverings during cold weather to prevent thermal cracking.

How does the document address quality control and testing procedures for concrete mix?

The document mandates regular quality control through sampling and testing of concrete fresh properties and hardened strength. It includes procedures like slump tests, compressive strength tests, and air content measurements at specified intervals. Furthermore, all test results must be documented for traceability and compliance with project specifications.

Which safety measures for reinforcement placement are detailed in the Method Statement?

The Method Statement outlines critical safety measures such as proper securing of reinforcement bars and the use of personal protective equipment by workers. It requires inspection of reinforcement for stability before concrete pouring to prevent accidents. Moreover, clear access pathways and lifting protocols are established to minimize risks during placement.

Are there any specifications for pour sequence and joint treatment in the document?

The document specifies a precise pour sequence to minimize cold joints and ensure structural integrity. It also details joint treatment methods including cleaning, application of bonding agents, and proper alignment before subsequent pours. These measures are designed to achieve continuity and durability in the concrete structure.

How does the Method Statement Document define responsibilities for concrete waste management?

The Method Statement assigns clear responsibilities for the segregation, collection, and disposal of concrete waste to designated personnel. It promotes the recycling of unused concrete and mandates compliance with environmental regulations. Regular monitoring and reporting on waste management practices are also required to maintain site cleanliness and sustainability.

More Construction Templates