A Goods Received Note Document Sample for Inventory Management provides a clear template to record the receipt of products accurately. This document ensures precise tracking of stock levels, confirming quantities and conditions of goods received. Utilizing a well-structured sample enhances inventory accuracy and streamlines warehouse operations.

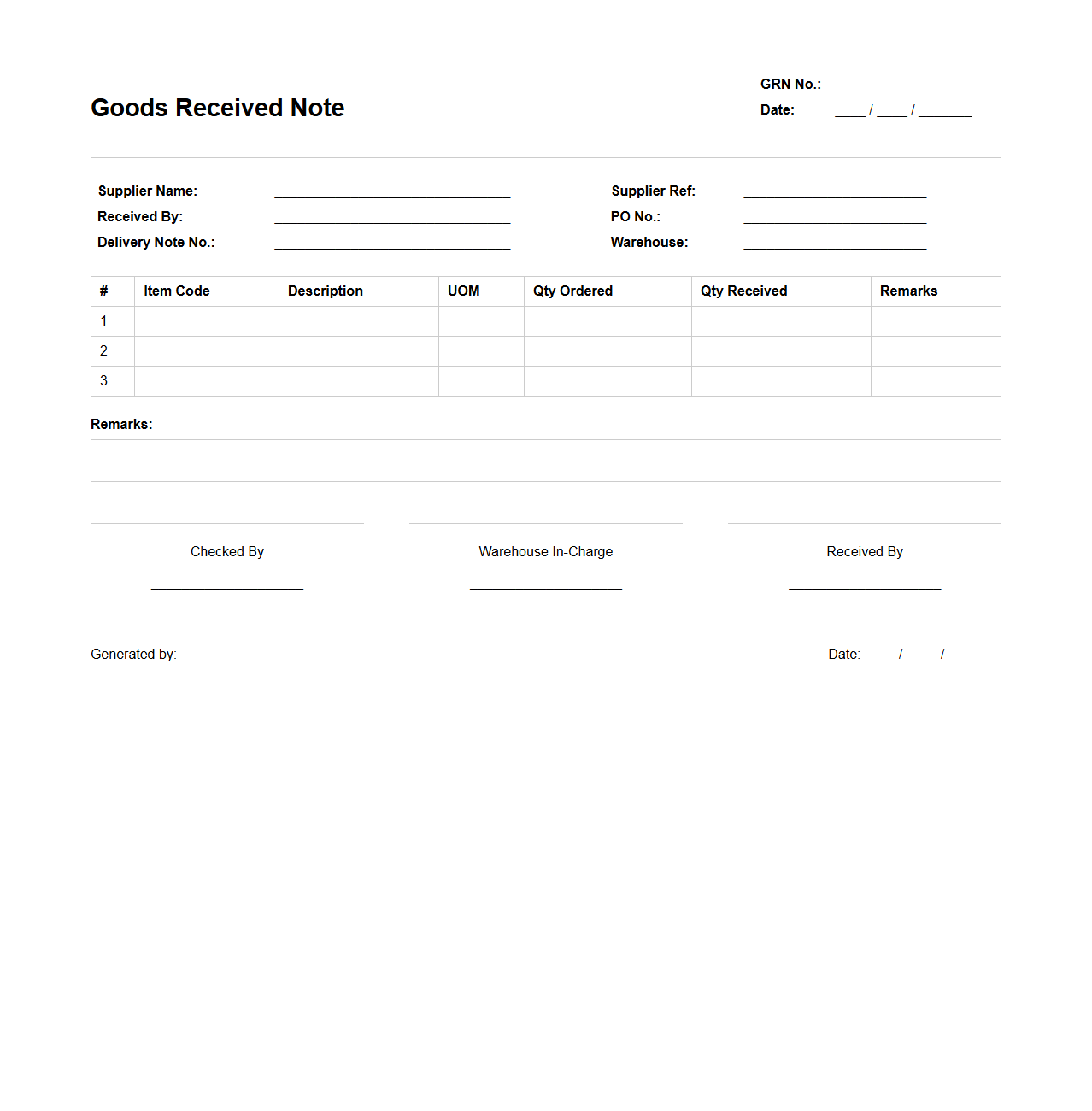

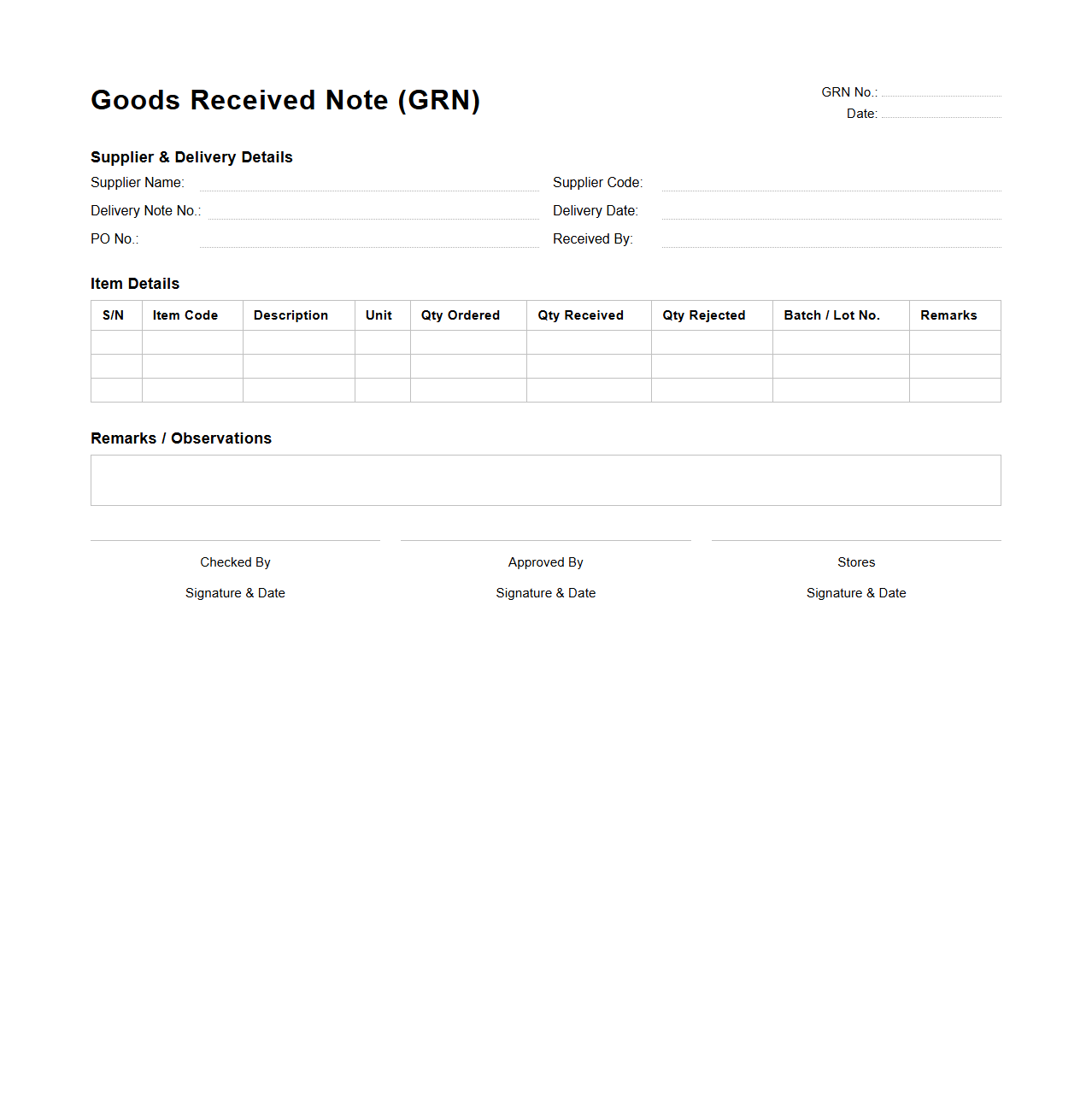

Goods Received Note Template for Warehouse Operations

A

Goods Received Note Template for warehouse operations is a standardized document used to record the details of items delivered to the warehouse, including quantity, description, and condition at the time of receipt. This template ensures accurate tracking of inventory, facilitates verification against purchase orders, and helps maintain accountability throughout the supply chain process. Utilizing this document reduces discrepancies and supports efficient stock management in warehouse operations.

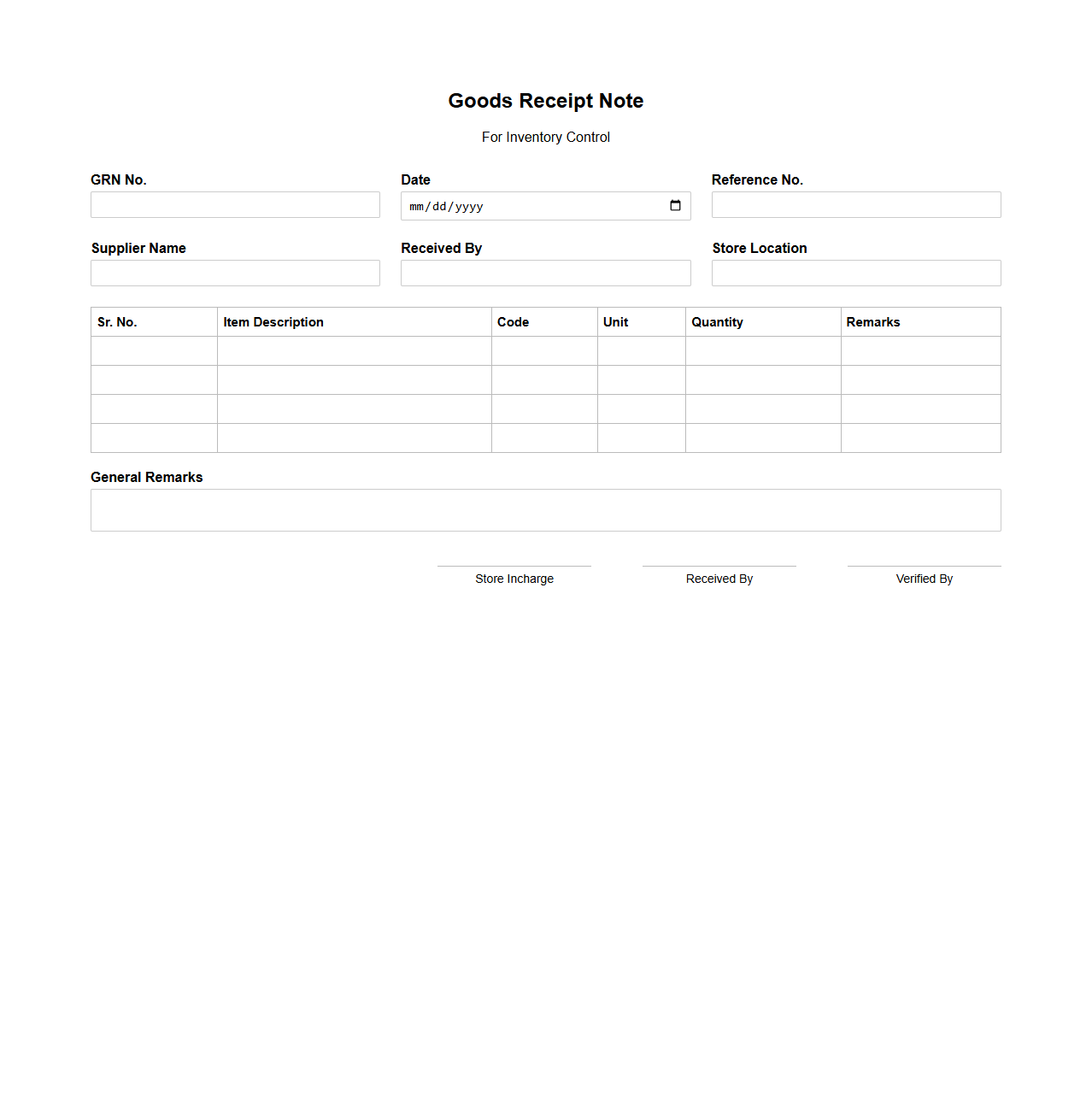

Standard Goods Receipt Note Format for Inventory Control

The

Standard Goods Receipt Note Format for Inventory Control is a structured document used to record the receipt of goods into inventory, ensuring accurate tracking of stock levels. It typically includes details such as item descriptions, quantities received, supplier information, delivery dates, and condition of goods. This format helps maintain consistency, facilitates inventory audits, and supports efficient warehouse management by providing a clear record of inbound shipments.

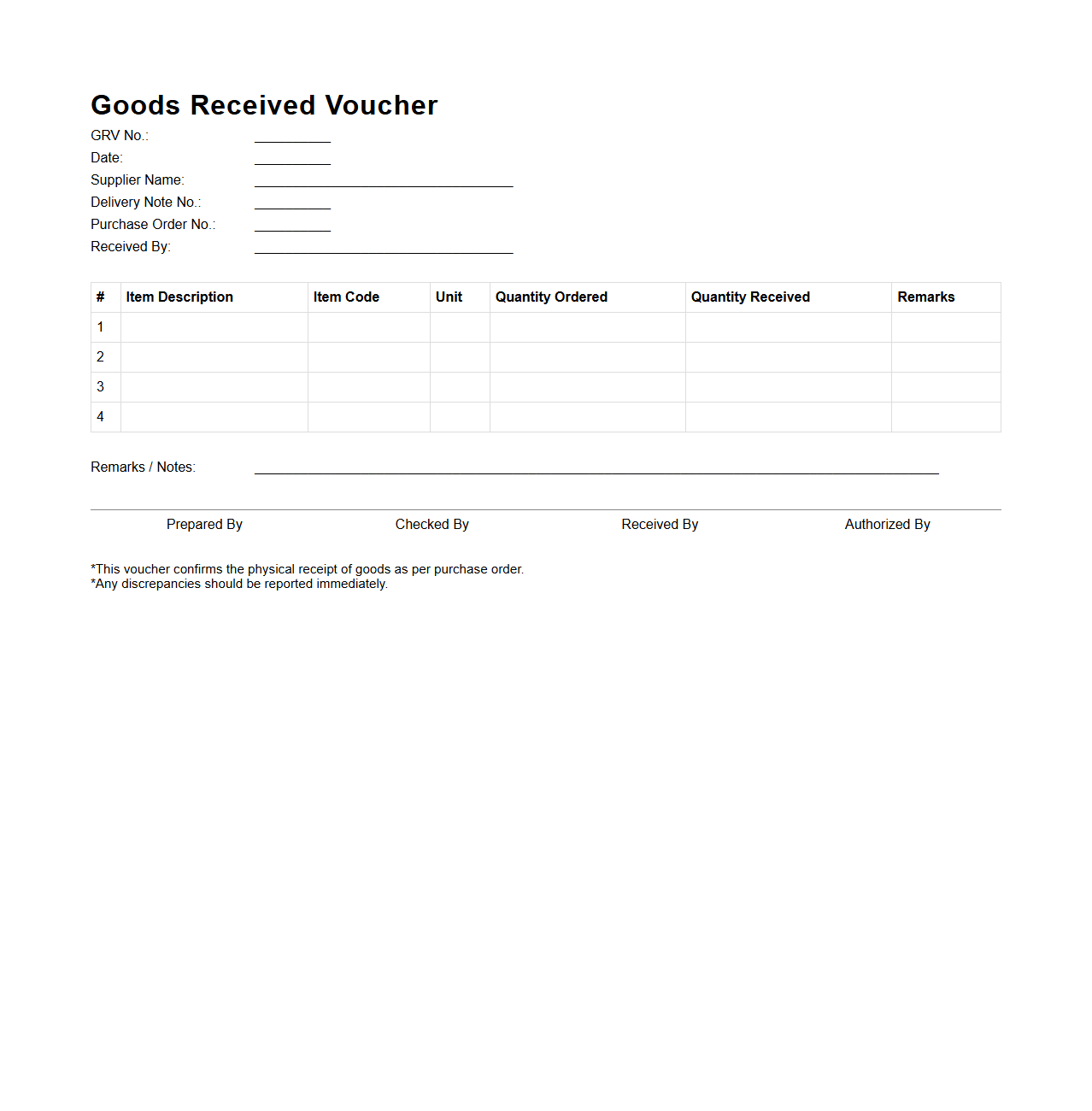

Goods Received Voucher Sample for Supply Chain

A

Goods Received Voucher (GRV) sample in supply chain documents serves as an official record confirming the receipt of goods from a supplier, detailing item descriptions, quantities, and delivery dates. This document is crucial for inventory management and verifying supplier performance, ensuring accuracy in stock levels and payment processing. It facilitates transparent communication between procurement, warehouse, and accounting departments, reducing discrepancies and enabling efficient audit trails.

GRN Document Layout for Manufacturing Plants

The

GRN Document Layout for manufacturing plants is a structured template used to record and verify the Goods Received Note details, ensuring accurate tracking of raw materials and components entering the facility. It includes key fields such as supplier information, item descriptions, quantities received, batch numbers, and inspection results, facilitating efficient inventory management and quality control. This document plays a critical role in streamlining procurement processes and maintaining transparency within the supply chain.

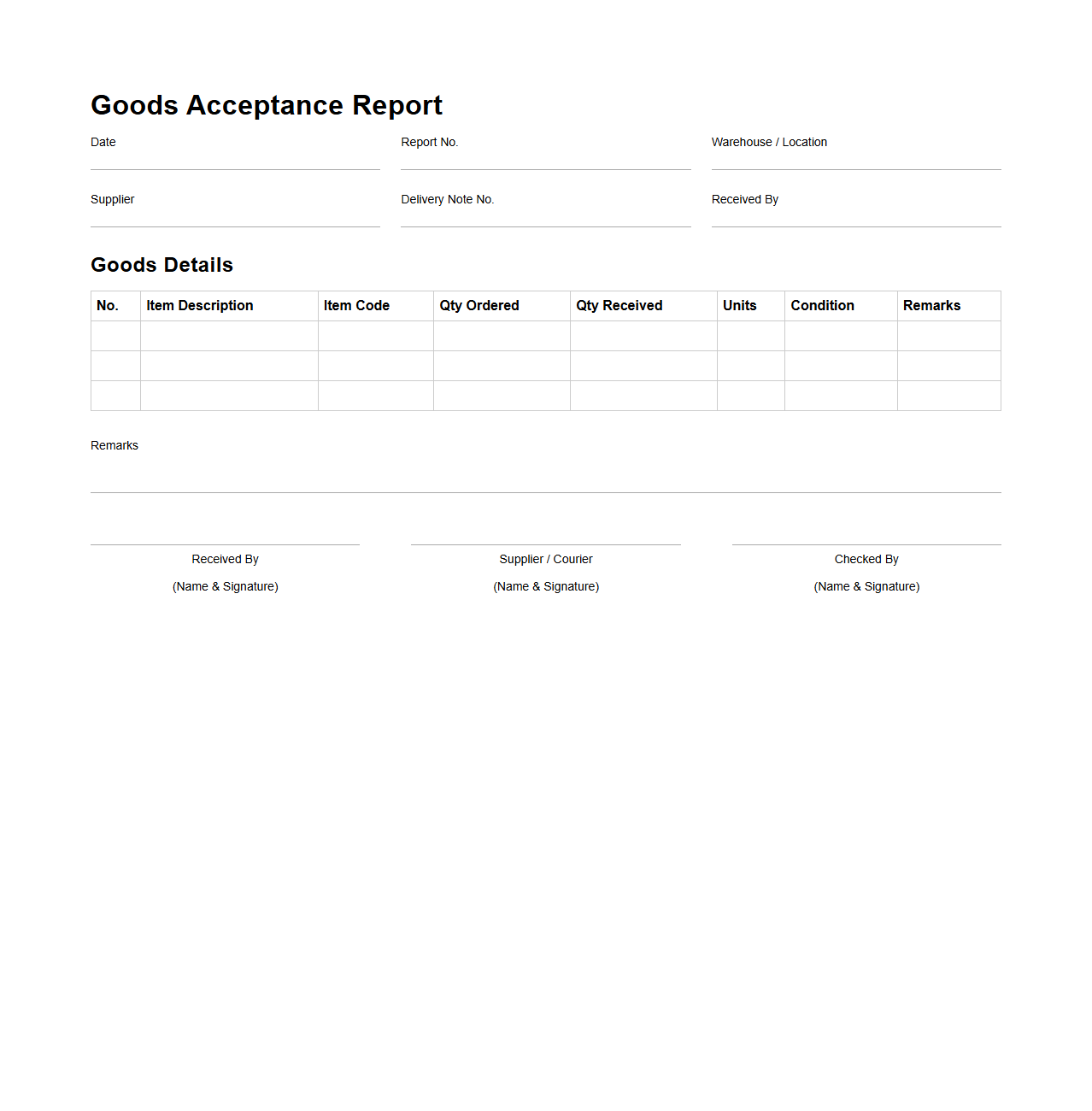

Goods Acceptance Report Example for Logistics

A

Goods Acceptance Report in logistics is a document used to verify and record the receipt of products or materials from a supplier, ensuring that the delivered goods meet predefined quality and quantity standards. It typically includes details such as supplier information, delivery date, product descriptions, quantities received, and any discrepancies or damages noted during inspection. This report serves as a critical reference for inventory management, payment processing, and dispute resolution within the supply chain.

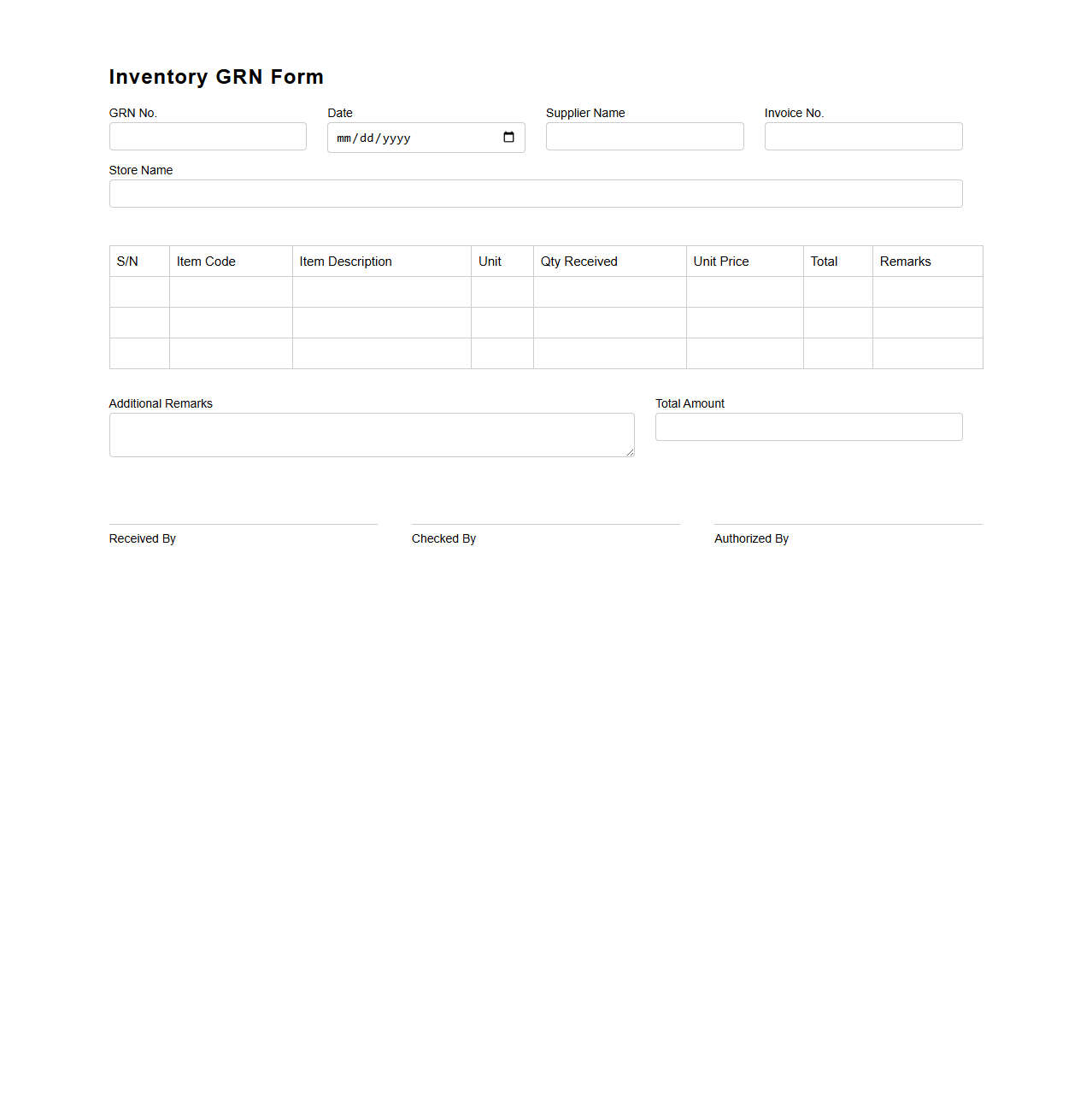

Inventory GRN Form Sample for Retail Stores

The

Inventory GRN Form Sample for retail stores is a standardized document used to record the receipt of goods from suppliers, ensuring accurate tracking of stock levels. It typically includes details such as item descriptions, quantities received, supplier information, and delivery dates. This form helps retail businesses maintain organized inventory records, streamline stock management, and verify order accuracy.

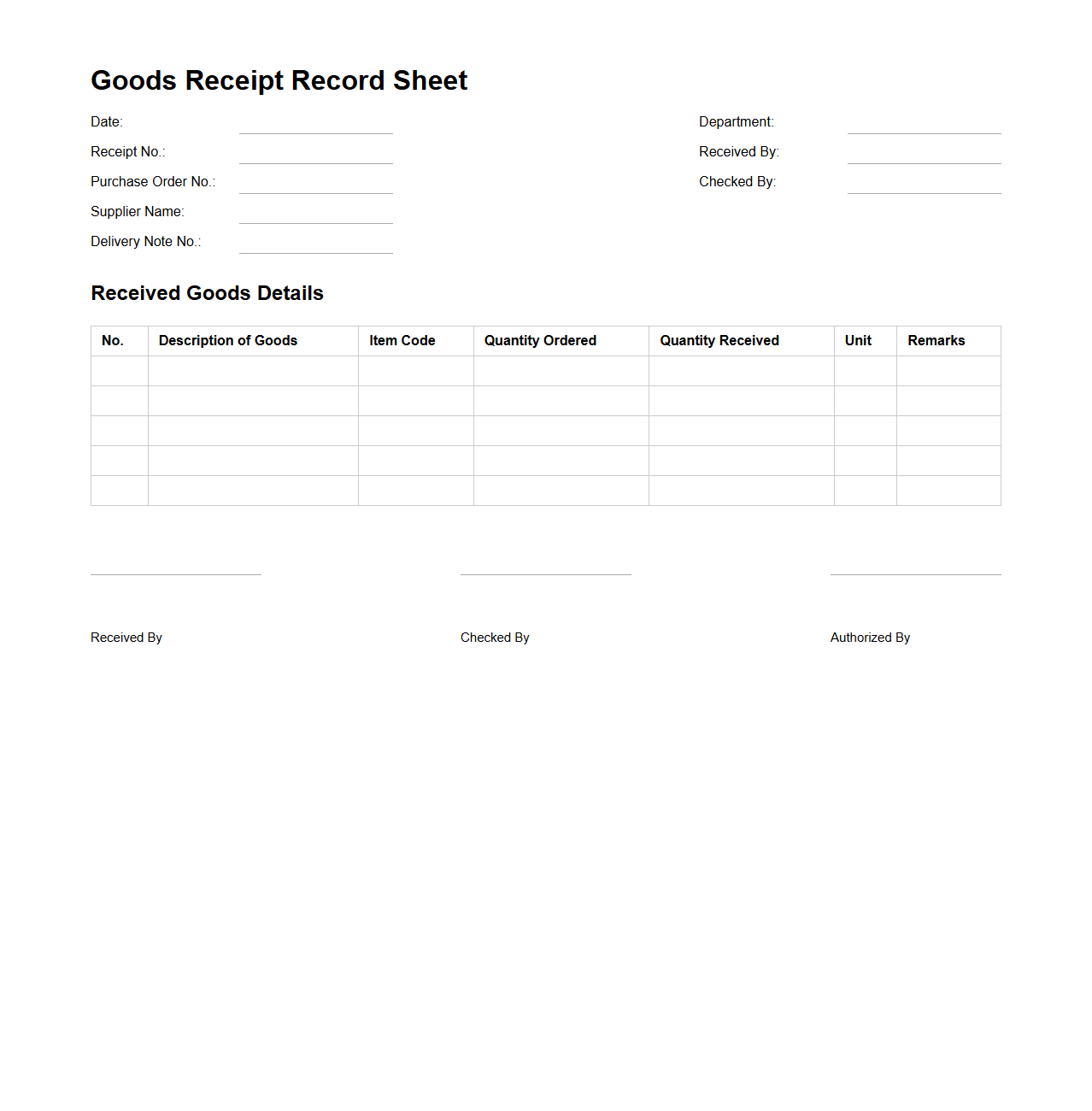

Goods Receipt Record Sheet Template for Procurement

A

Goods Receipt Record Sheet Template for procurement is a standardized document used to systematically log details of received goods, including item descriptions, quantities, delivery dates, and supplier information. This template ensures accuracy in inventory management and provides a verifiable record for audit and quality control purposes. It streamlines the verification process by maintaining consistent data capture during the receipt of purchased items from suppliers.

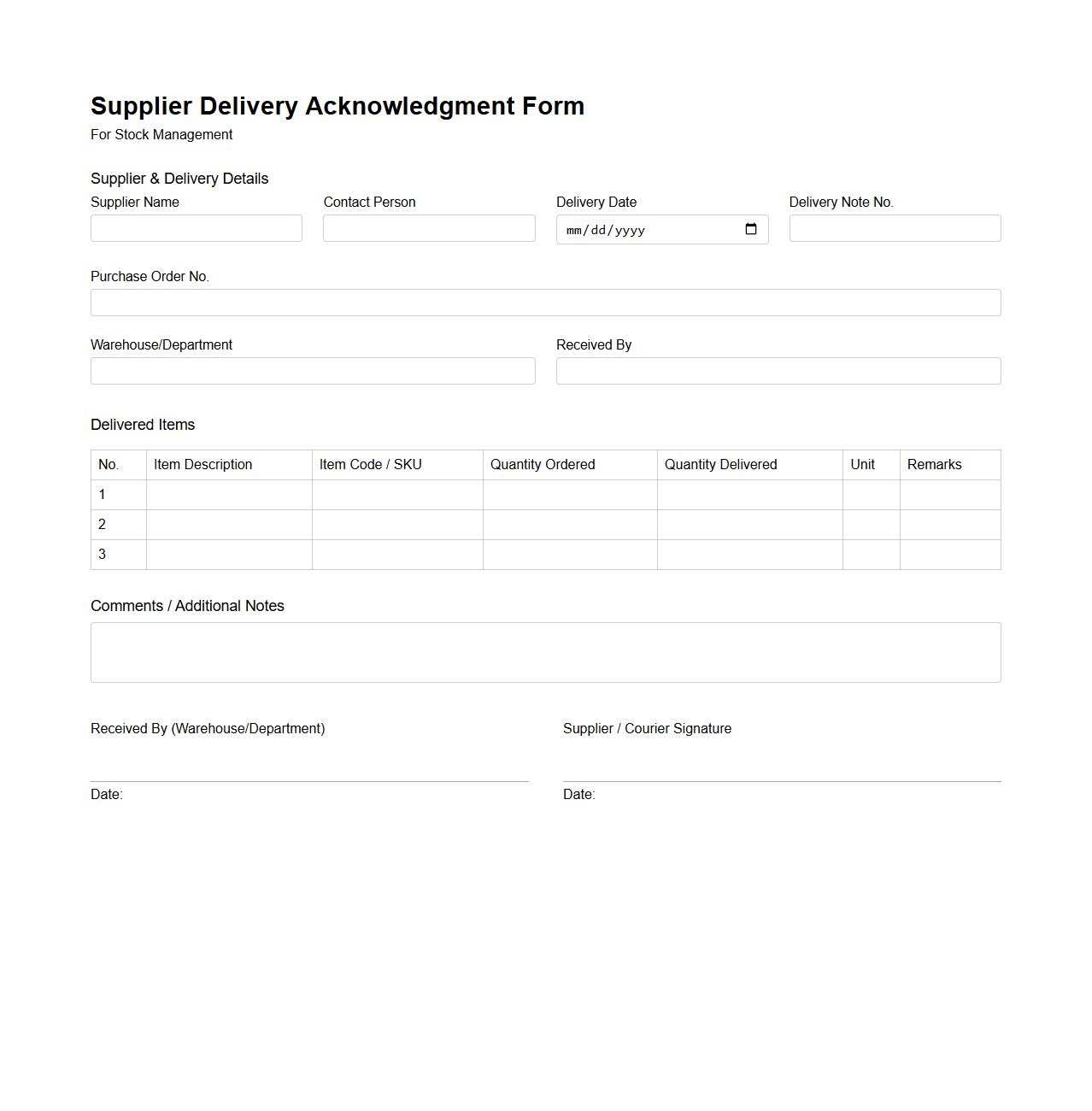

Supplier Delivery Acknowledgment Form for Stock Management

The

Supplier Delivery Acknowledgment Form is a crucial document used in stock management to confirm the receipt of goods from suppliers. It details the quantity, condition, and specifications of delivered items, ensuring accuracy in inventory records and facilitating efficient stock control. This form helps prevent discrepancies between ordered and received stock, supporting transparent communication between suppliers and warehouse teams.

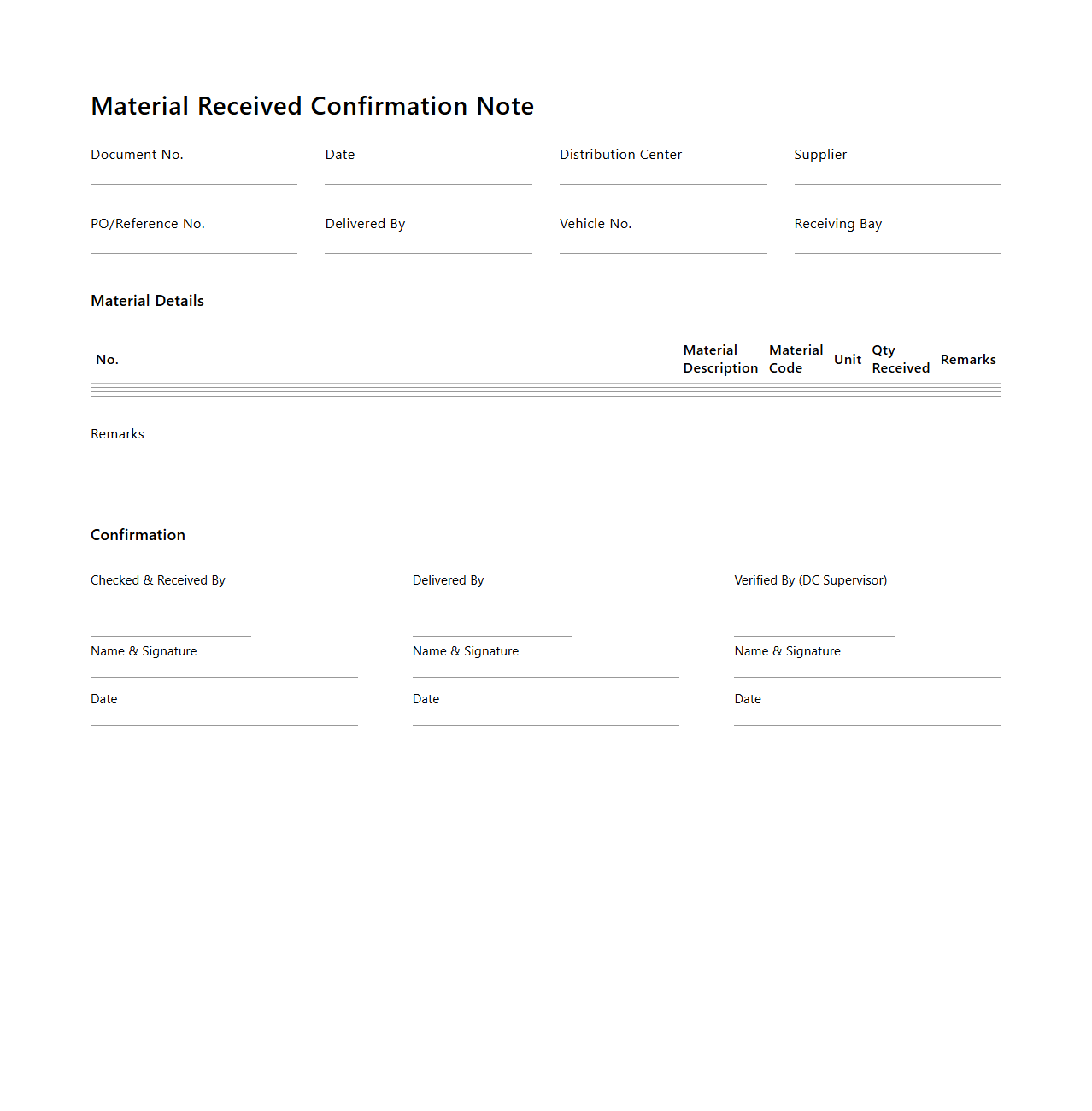

Material Received Confirmation Note for Distribution Centers

The

Material Received Confirmation Note for Distribution Centers is a critical document used to verify and record the receipt of goods delivered from suppliers or manufacturing units. It ensures accuracy in inventory management by confirming that the quantities and quality of materials match the purchase order specifications. This note serves as an official acknowledgment for inventory updates and facilitates smooth operational workflows within the distribution network.

Product Receipt Acknowledgement Format for Inventory Tracking

Product Receipt Acknowledgement Format for Inventory Tracking is a standardized document used to confirm the receipt of goods in a warehouse or storage facility. This format records essential details such as product name, quantity received, date of receipt, supplier information, and condition of the items, ensuring accurate inventory updates and accountability. Maintaining a

Product Receipt Acknowledgement is crucial for validating shipments, preventing discrepancies, and streamlining inventory management processes.

What key information must be included in a Goods Received Note for accurate inventory tracking?

A Goods Received Note (GRN) must include the supplier's name, delivery date, and purchase order number for accurate tracking. It should detail the quantity and description of received items to ensure precise inventory updates. Additionally, the GRN should contain the receiver's signature to confirm the goods have been physically checked.

How does a Goods Received Note differ from a purchase order in document structure and purpose?

A Goods Received Note records the actual receipt of goods, while a purchase order initiates the buying process. The GRN focuses on item verification and quality check, unlike the purchase order that lists requested items and prices. Structurally, a GRN documents delivery details, whereas a purchase order includes terms and conditions for procurement.

What is the process flow for approving and recording a Goods Received Note in inventory management?

The process starts with receiving goods and matching them against the purchase order, followed by generating the Goods Received Note. Upon verification by the inventory team, the GRN is approved and entered into the inventory system. Finally, the recorded GRN facilitates stock adjustments and payment processing.

How does a Goods Received Note help in identifying discrepancies between received goods and order quantities?

A Goods Received Note provides a detailed account of delivered items, enabling easy comparison with the purchase order. It helps identify variances in quantity, quality, or damaged goods during the inspection process. This systematic documentation allows for prompt resolution of any discrepancies before payment.

What are the typical formats or templates used for Goods Received Notes in inventory management systems?

Common formats for Goods Received Notes include table layouts capturing item descriptions, quantities, delivery dates, and signatures. Many inventory management systems use digital templates that integrate with purchase orders for seamless data flow. These templates often feature barcode scanning sections to enhance accuracy and speed during goods receipt.