A Inspection Certificate Document Sample for Quality Control serves as a formal verification that products meet specified quality standards before shipment. This document outlines inspection results, including measurements, test outcomes, and compliance status, ensuring transparency and accountability. It is essential for maintaining product reliability and satisfying customer requirements in various industries.

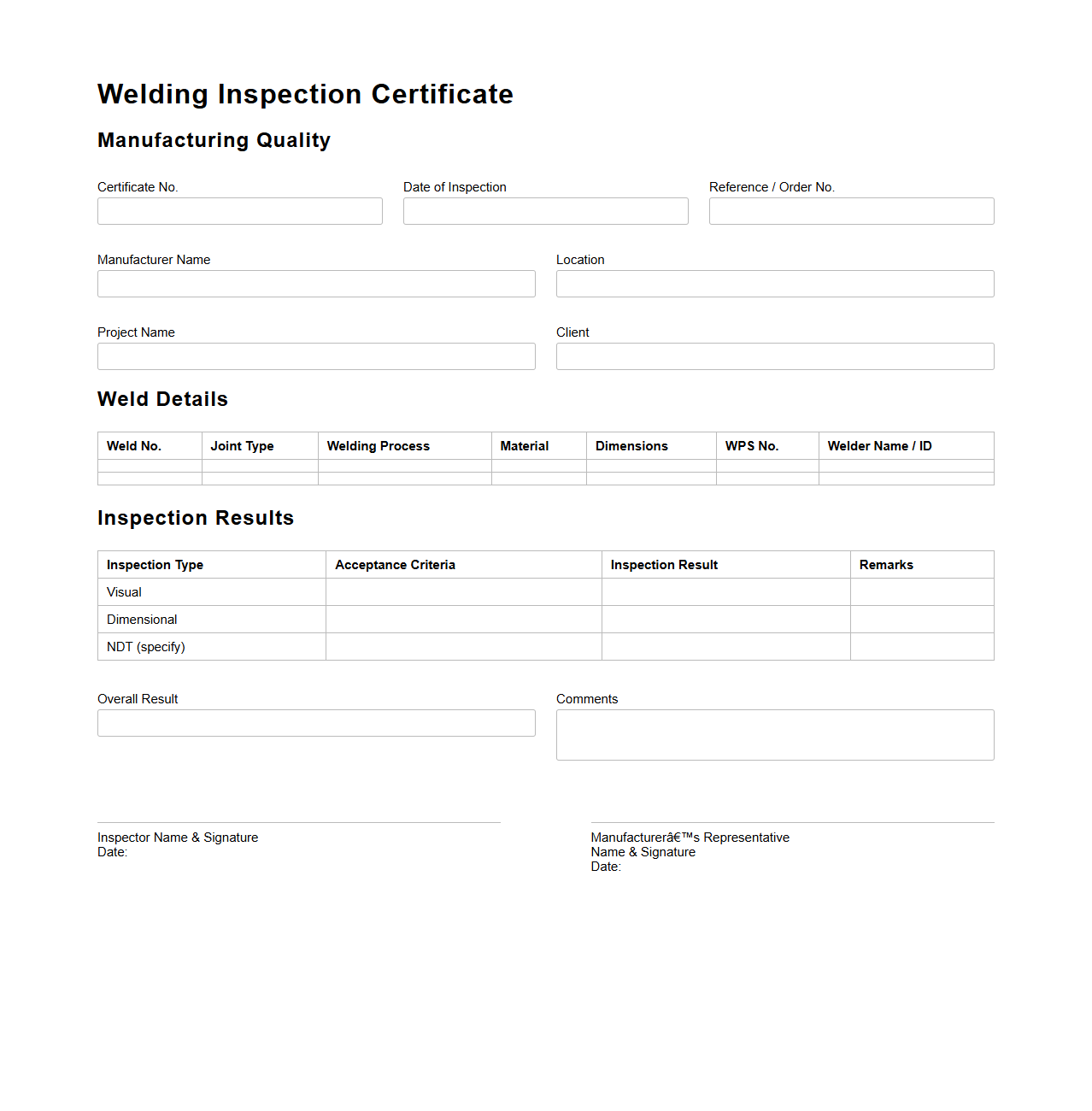

Welding Inspection Certificate Template for Manufacturing Quality

A

Welding Inspection Certificate Template is a standardized document used in manufacturing to verify that welding operations meet specified quality standards and safety requirements. It records critical inspection details such as welder qualifications, welding procedures, inspection methods, and acceptance criteria to ensure compliance with industry codes like ASME or AWS. This template helps manufacturers maintain traceability, document quality control, and support regulatory audits effectively.

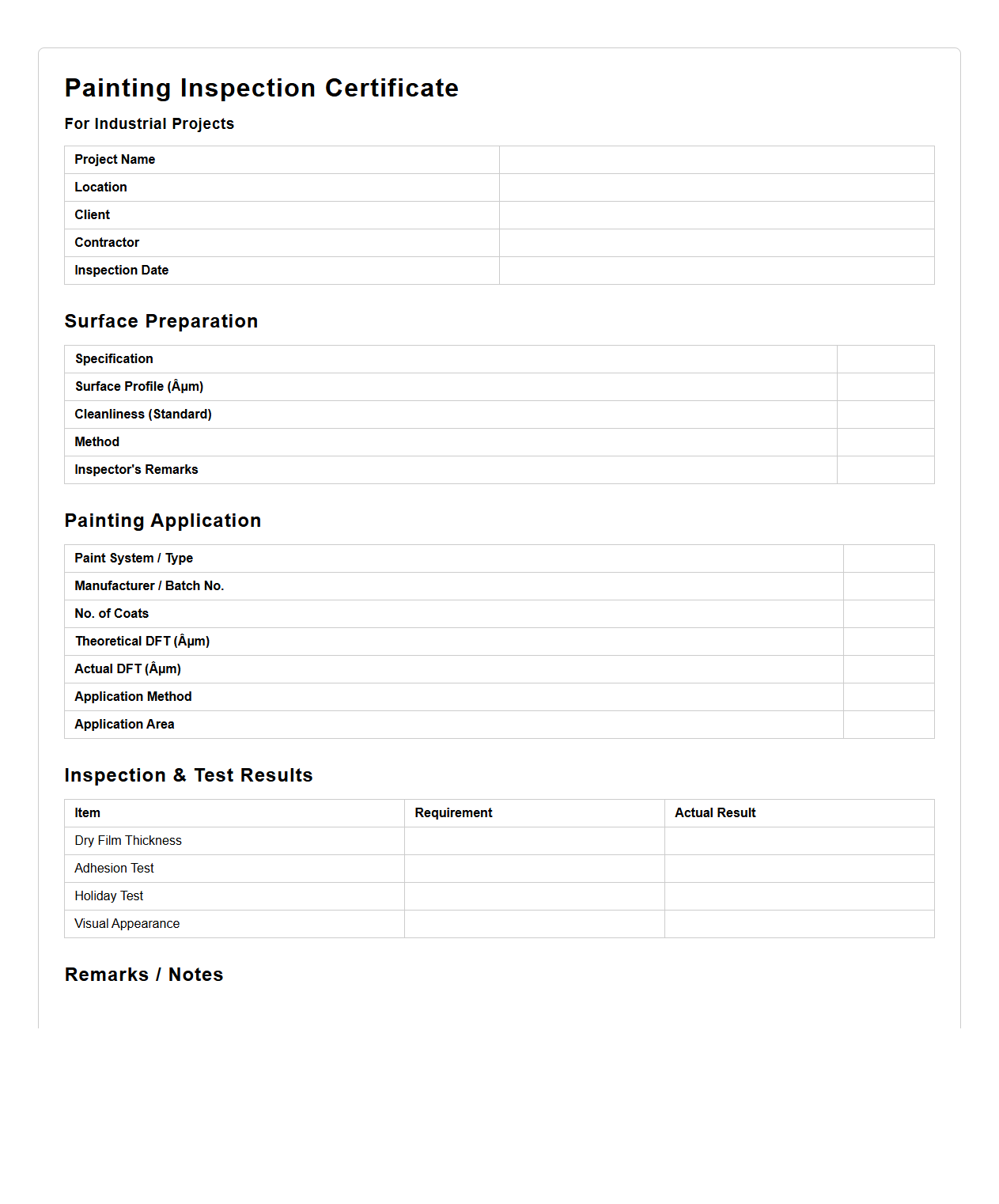

Painting Inspection Certificate Example for Industrial Projects

A

Painting Inspection Certificate for industrial projects is a formal document verifying that the coating application on structures meets specified quality standards and project requirements. It details inspection results, including surface preparation, paint type, thickness, and curing conditions, ensuring protective coatings prevent corrosion and enhance durability. This certificate is crucial for compliance, quality assurance, and validating that painting work aligns with industry standards such as SSPC or NACE.

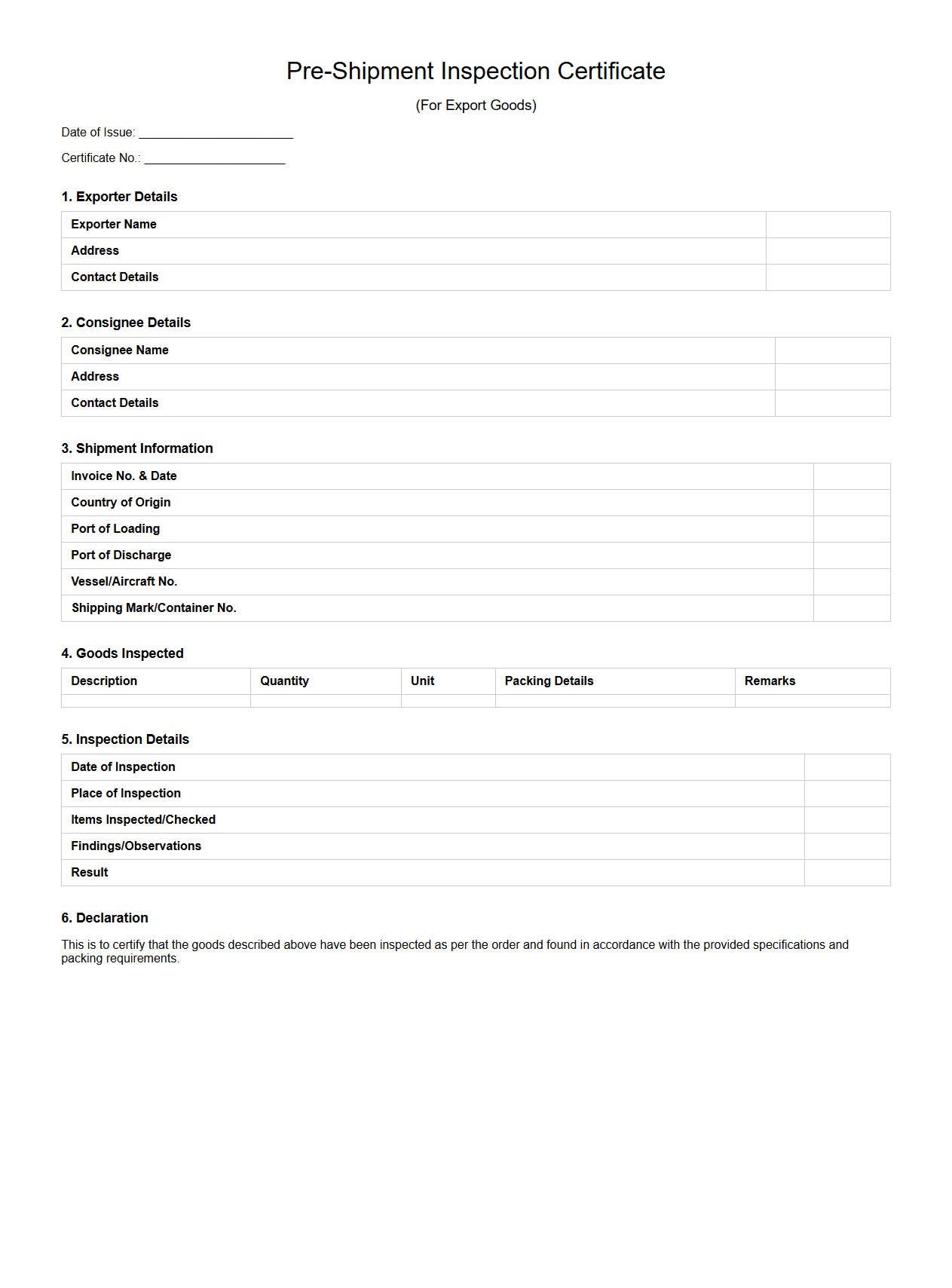

Pre-Shipment Inspection Certificate Format for Export Goods

A

Pre-Shipment Inspection Certificate Format for Export Goods is a standardized document used to verify the quality, quantity, and compliance of goods before shipment. It details inspection results conducted by authorized agencies, ensuring exports meet buyer specifications and regulatory requirements. This certificate helps minimize disputes and delays during customs clearance in the destination country.

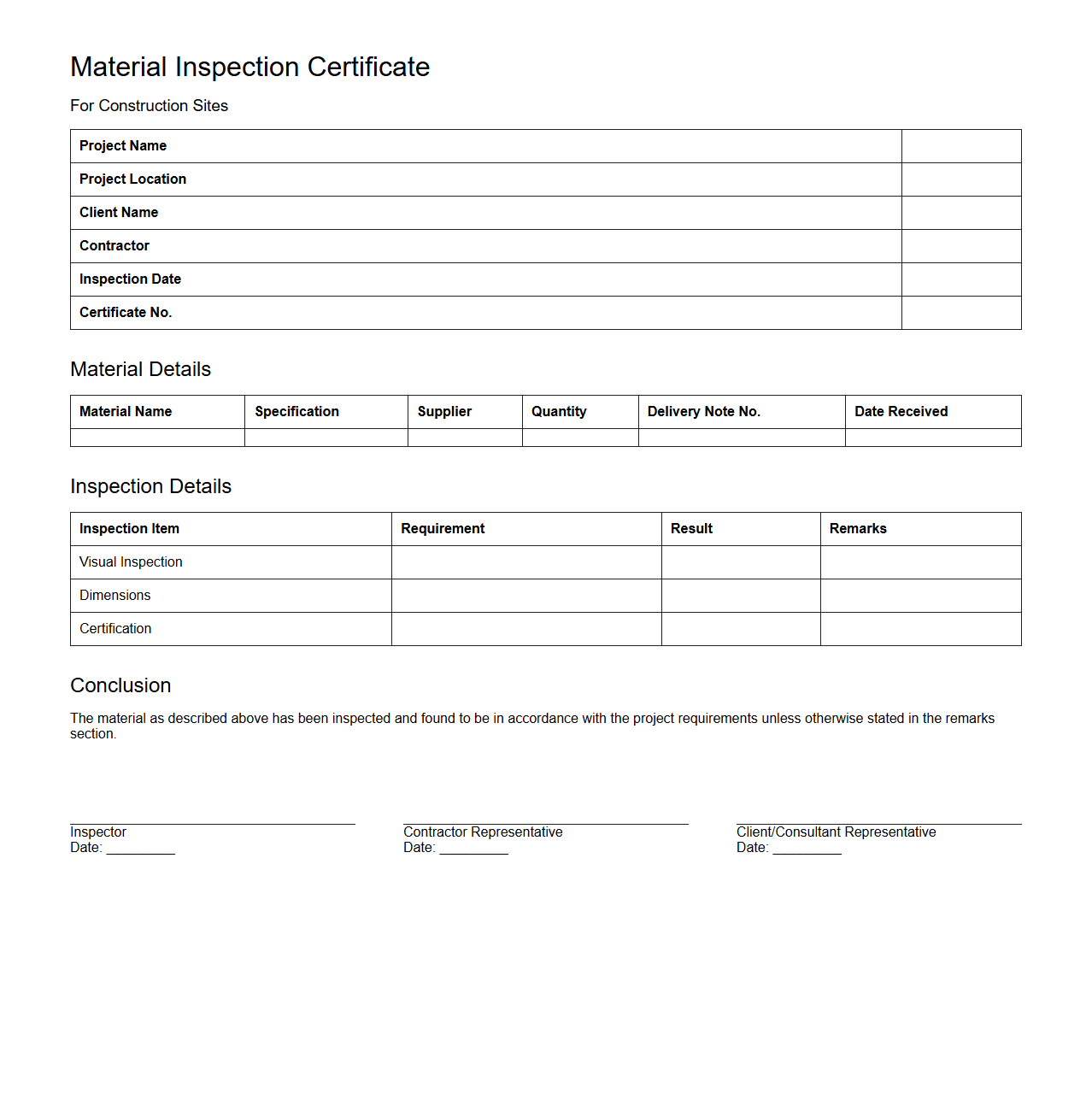

Material Inspection Certificate Specimen for Construction Sites

A

Material Inspection Certificate Specimen for construction sites is a formal document that verifies the quality and specifications of materials delivered to a project. It includes detailed information such as material type, batch number, test results, compliance with standards, and supplier details to ensure all materials meet project requirements. This certificate helps project managers and engineers maintain quality control and traceability throughout the construction process.

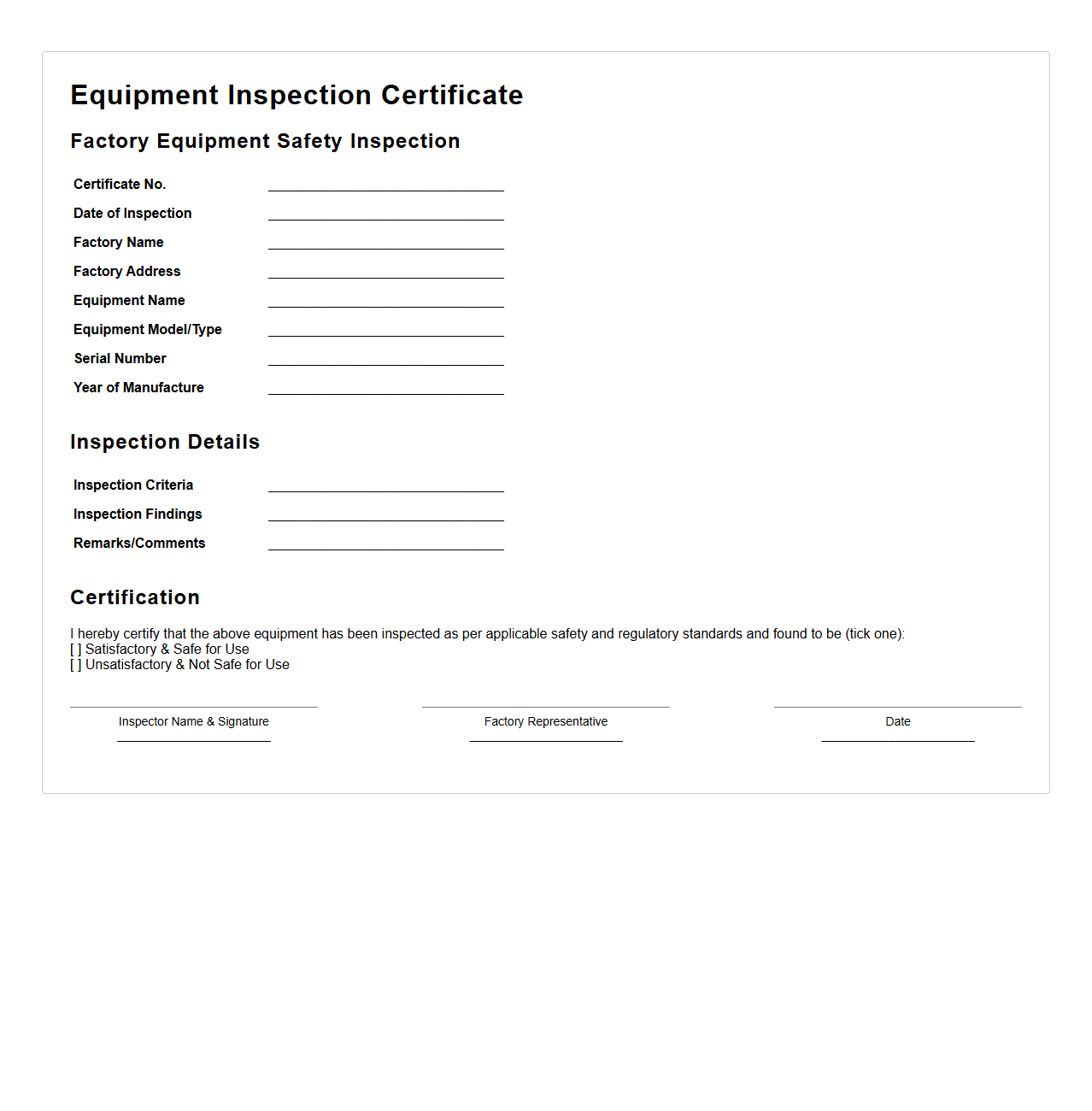

Equipment Inspection Certificate Sample for Factories

An

Equipment Inspection Certificate Sample for Factories is a formal document that verifies the condition and safety compliance of industrial machinery within a manufacturing facility. It includes detailed information about the equipment inspected, inspection dates, findings, and certification by a qualified inspector to ensure adherence to safety standards. This certificate is essential for factory audits, regulatory compliance, and maintaining operational safety.

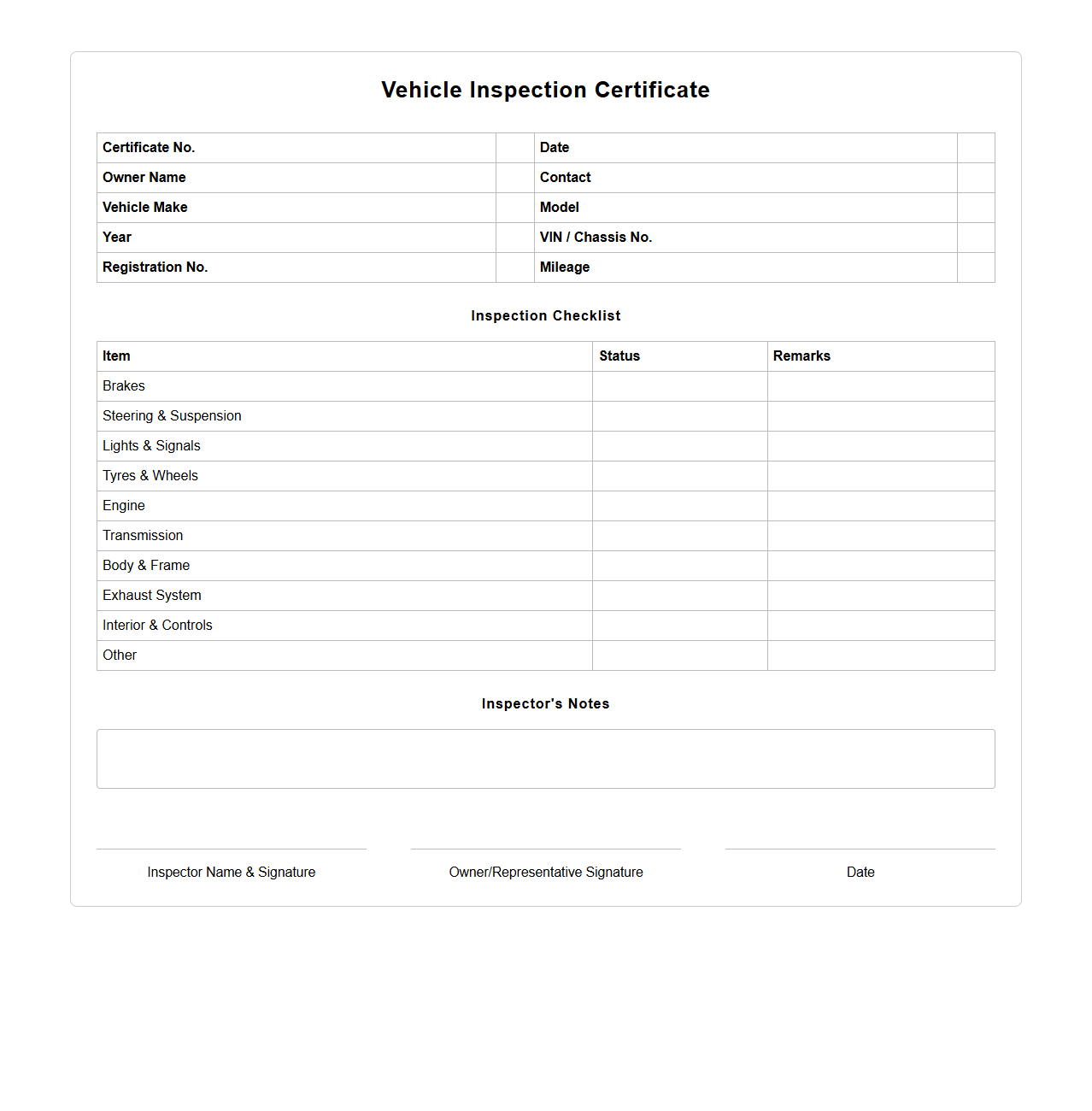

Vehicle Inspection Certificate Layout for Automotive Industry

The

Vehicle Inspection Certificate Layout is a standardized document used in the automotive industry to present and verify the results of a vehicle's safety and emissions inspections. This layout ensures all critical data such as vehicle identification number (VIN), inspection dates, test results, and certification stamps are clearly organized and easily readable. It plays a crucial role in regulatory compliance, vehicle registration, and consumer assurance by providing a trusted record of a vehicle's condition.

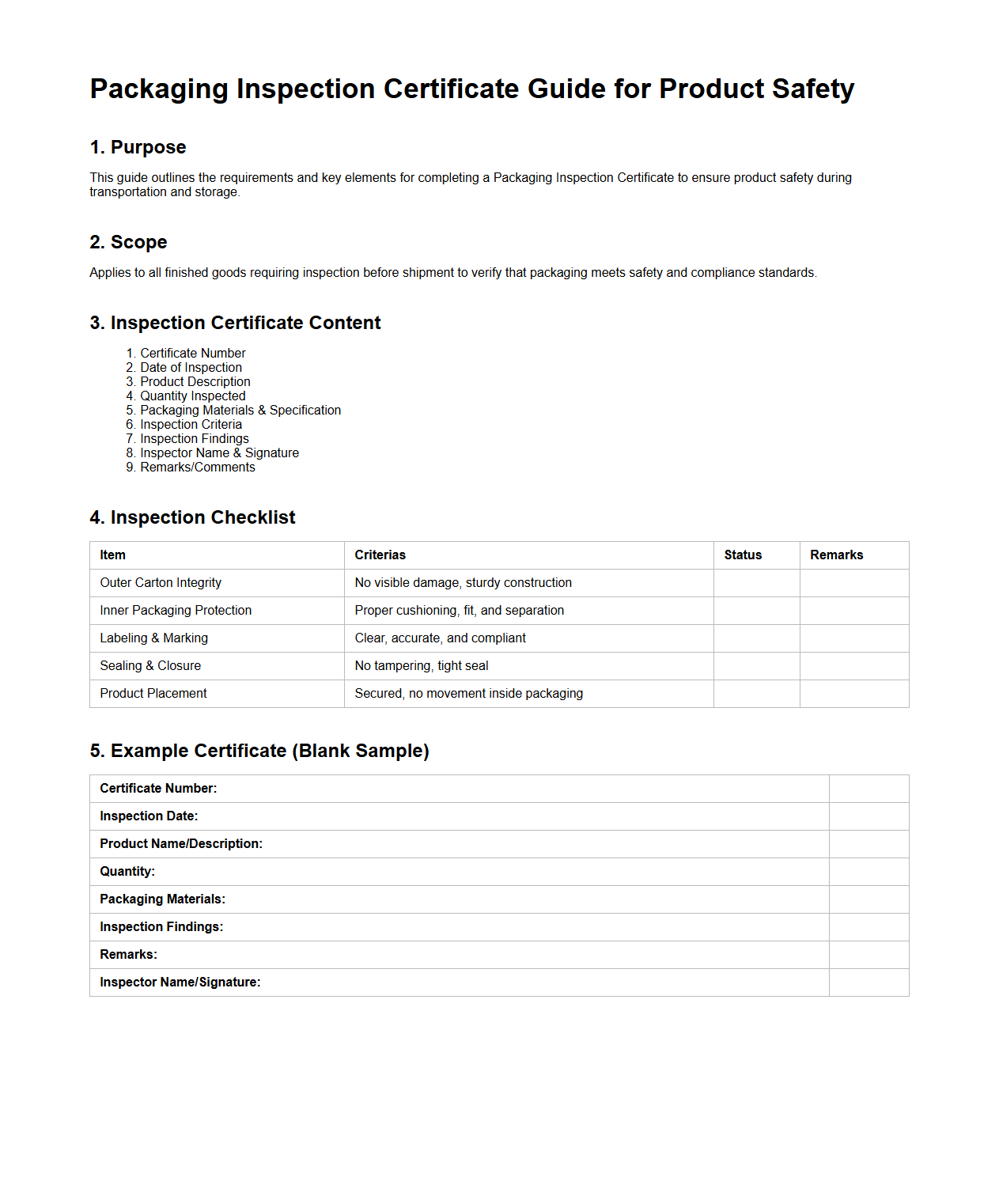

Packaging Inspection Certificate Guide for Product Safety

A

Packaging Inspection Certificate Guide for Product Safety is a detailed document that outlines the standards and procedures for verifying the integrity and compliance of packaging materials used in product distribution. It ensures that packaging meets regulatory requirements to prevent contamination, damage, or safety hazards during transit and storage. This guide helps manufacturers and quality control teams maintain consistent product protection and consumer safety.

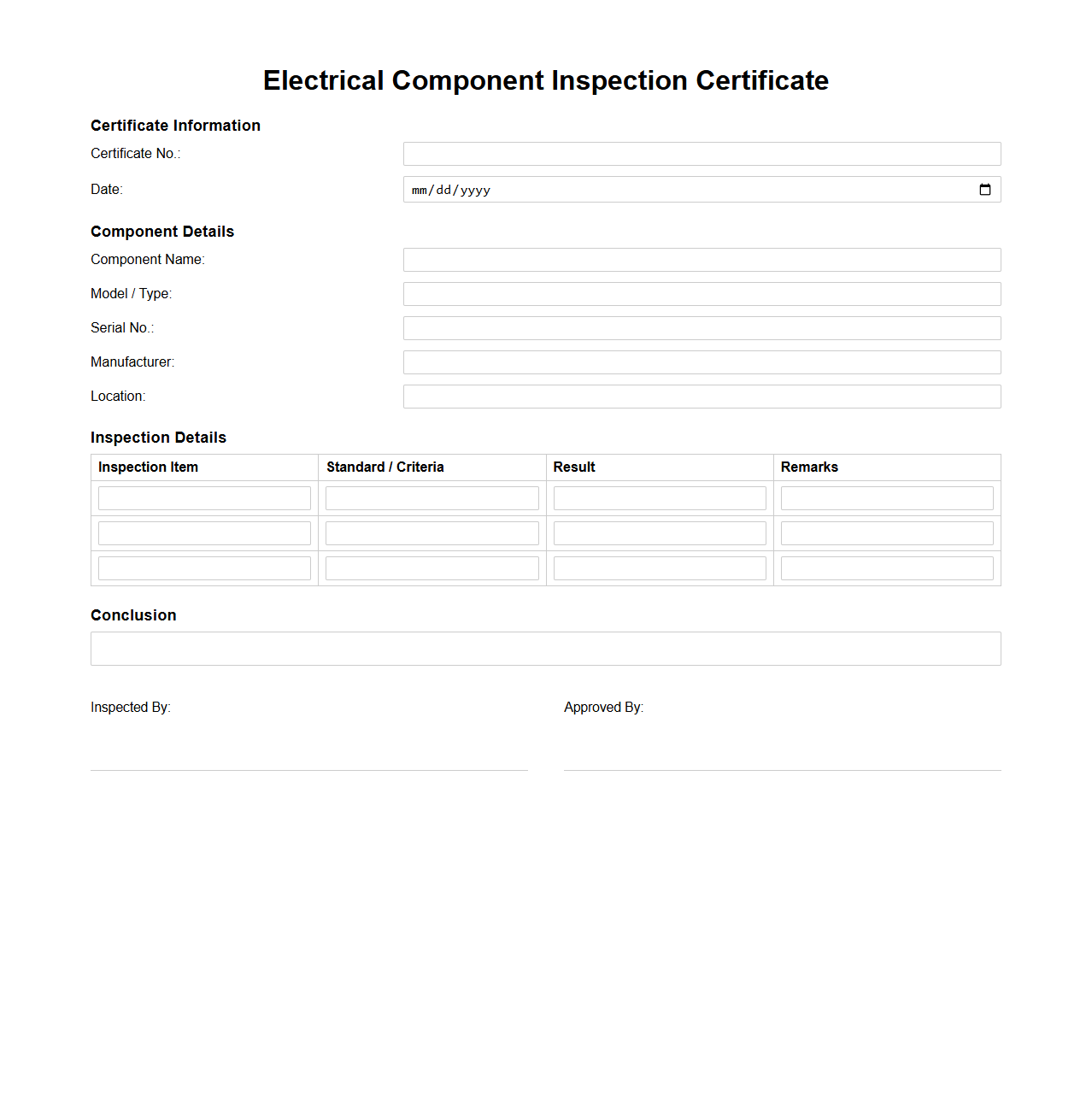

Electrical Component Inspection Certificate Model

An

Electrical Component Inspection Certificate Model document serves as a standardized template that verifies the compliance and quality of electrical components according to industry standards. It outlines essential inspection criteria, test results, and certification details to ensure product reliability and safety. This document is crucial for manufacturers, suppliers, and quality assurance teams to maintain regulatory adherence and traceability.

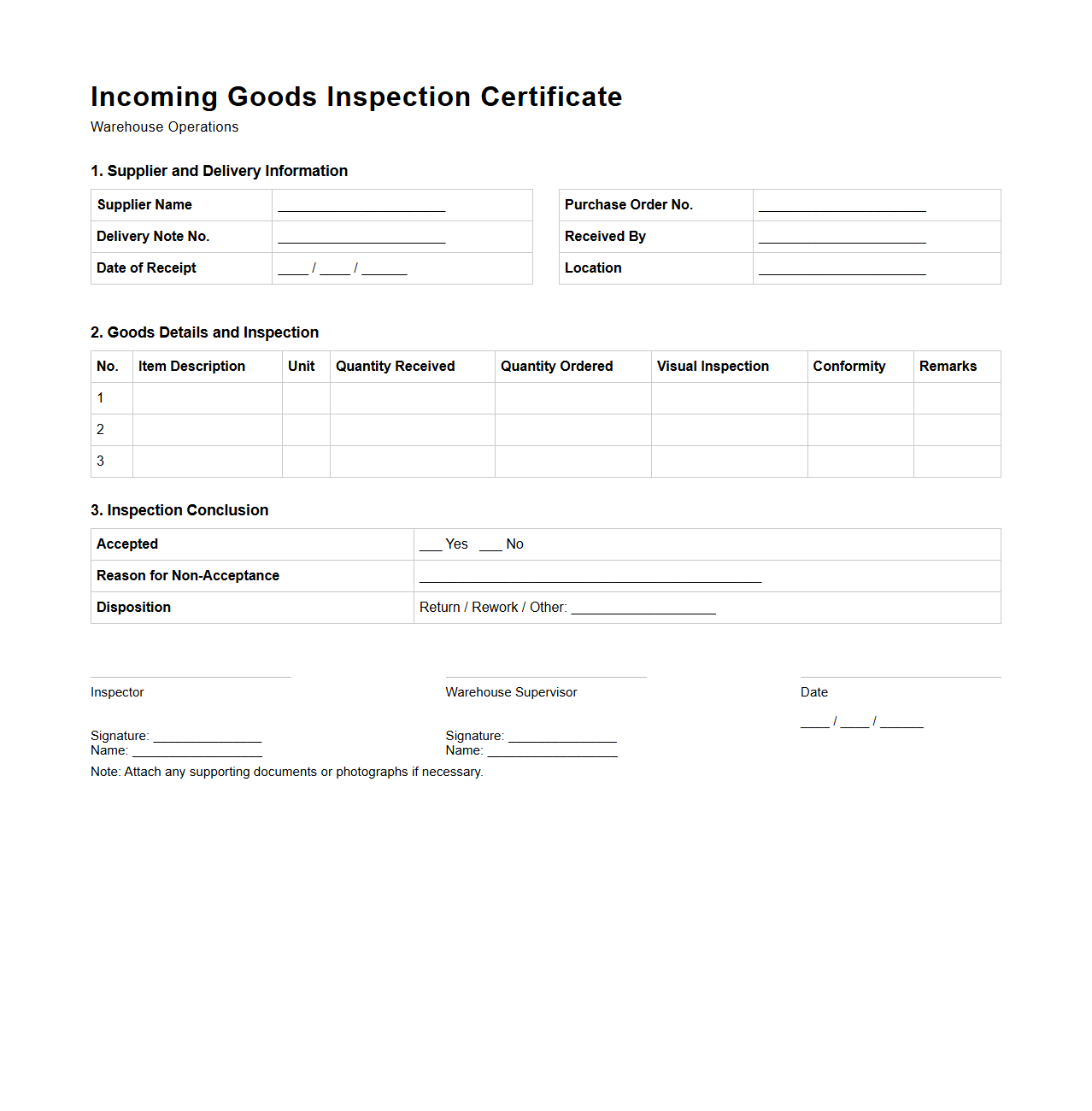

Incoming Goods Inspection Certificate for Warehouse Operations

The

Incoming Goods Inspection Certificate is a crucial document in warehouse operations that verifies the quality and quantity of received goods against purchase orders and specifications. It ensures that all items meet predefined standards, helping to prevent defective or incorrect inventory from entering storage. This certificate supports inventory accuracy and streamlines the supply chain by enabling prompt identification and resolution of discrepancies.

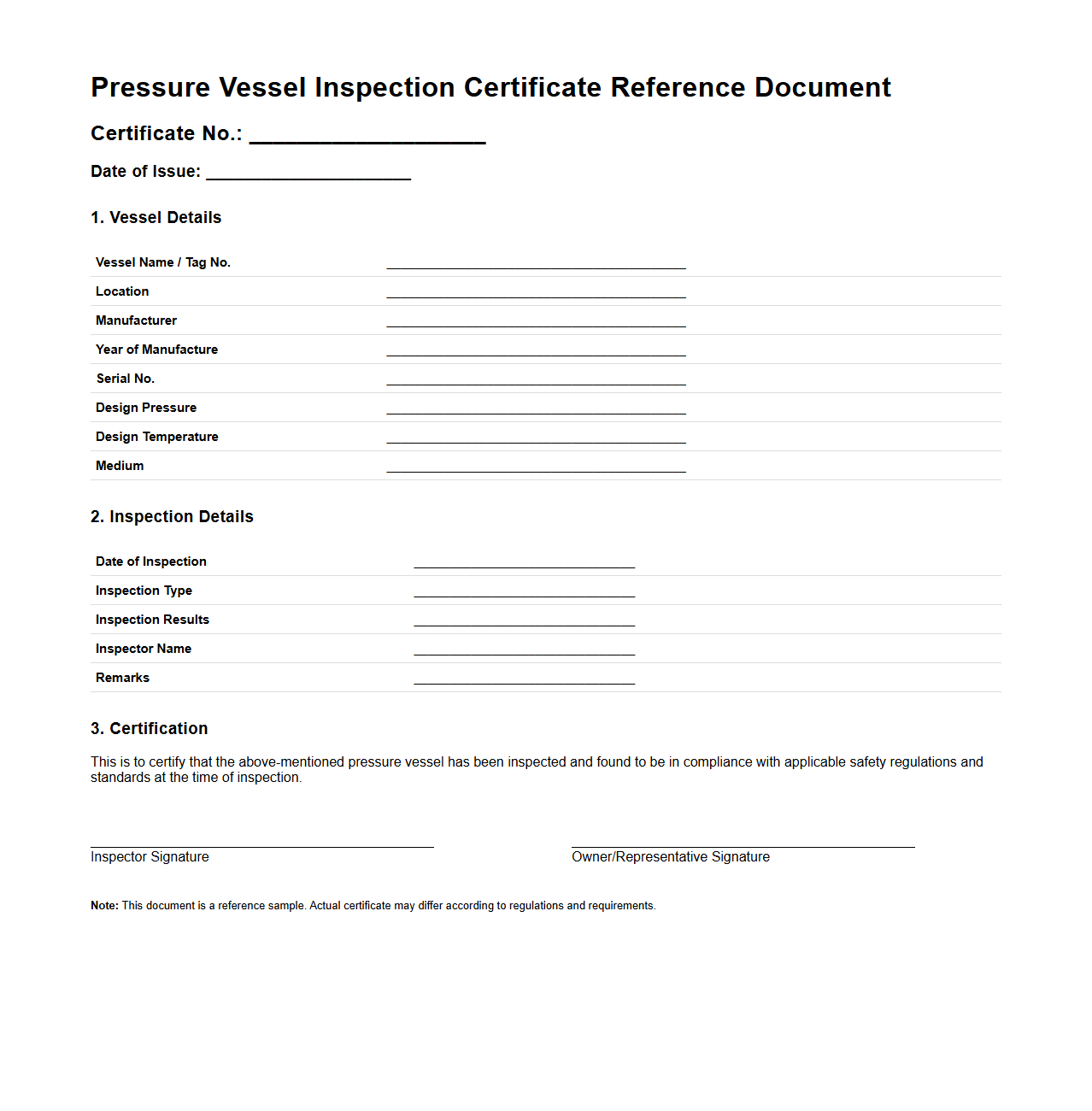

Pressure Vessel Inspection Certificate Reference Document

The

Pressure Vessel Inspection Certificate Reference Document is a critical record used to verify the compliance of pressure vessels with safety and regulatory standards. It contains essential information such as inspection dates, test results, certification numbers, and details of the inspecting authority. This document ensures that pressure vessels are safe for operation and meet the required industry codes, helping to prevent accidents and maintain operational integrity.

What are the essential data fields required in an Inspection Certificate for quality control?

An Inspection Certificate must include identification details such as product name, batch number, and production date to ensure accurate verification. It should also have comprehensive inspection criteria and the specific tests performed. Additionally, the certificate requires fields for inspection date and the responsible inspector's details to maintain accountability.

How does the Inspection Certificate document confirm compliance with specified quality standards?

The Inspection Certificate confirms compliance by explicitly stating the quality standards or specifications followed during inspection. It details the test results and measurements compared against allowable tolerances. A clear declaration of conformity is included to certify that the product meets all required standards.

What roles and signatures are typically included in a standard Inspection Certificate sample?

Standard Inspection Certificates feature signatures from the quality control inspector, responsible for conducting tests and evaluations. Often, a supervisory authority or quality manager also signs off to validate the inspection process. These signatures confirm the authenticity and endorsement of the inspection results reported.

Which inspection outcomes or test results are documented in the certificate for quality verification?

The certificate includes detailed inspection outcomes such as dimensional checks, functional tests, and material analysis results. It records any non-conformities detected and corrective actions taken. All results are presented clearly to provide a transparent record for quality verification.

How is traceability of inspected materials or products ensured in the Inspection Certificate?

Traceability is ensured by documenting unique identifiers like serial numbers, batch codes, or lot numbers on the certificate. This allows linking the certificate directly to the corresponding inspected items. Additionally, detailed records of inspection dates and location support full traceability throughout the supply chain.