A Transfer Order Document Sample for Distribution Centers outlines the process of moving inventory between locations within a supply chain. This document includes details such as item descriptions, quantities, source and destination warehouses, and transfer dates to ensure accurate record-keeping and inventory control. Using a standardized transfer order helps streamline operations and minimize errors in the distribution process.

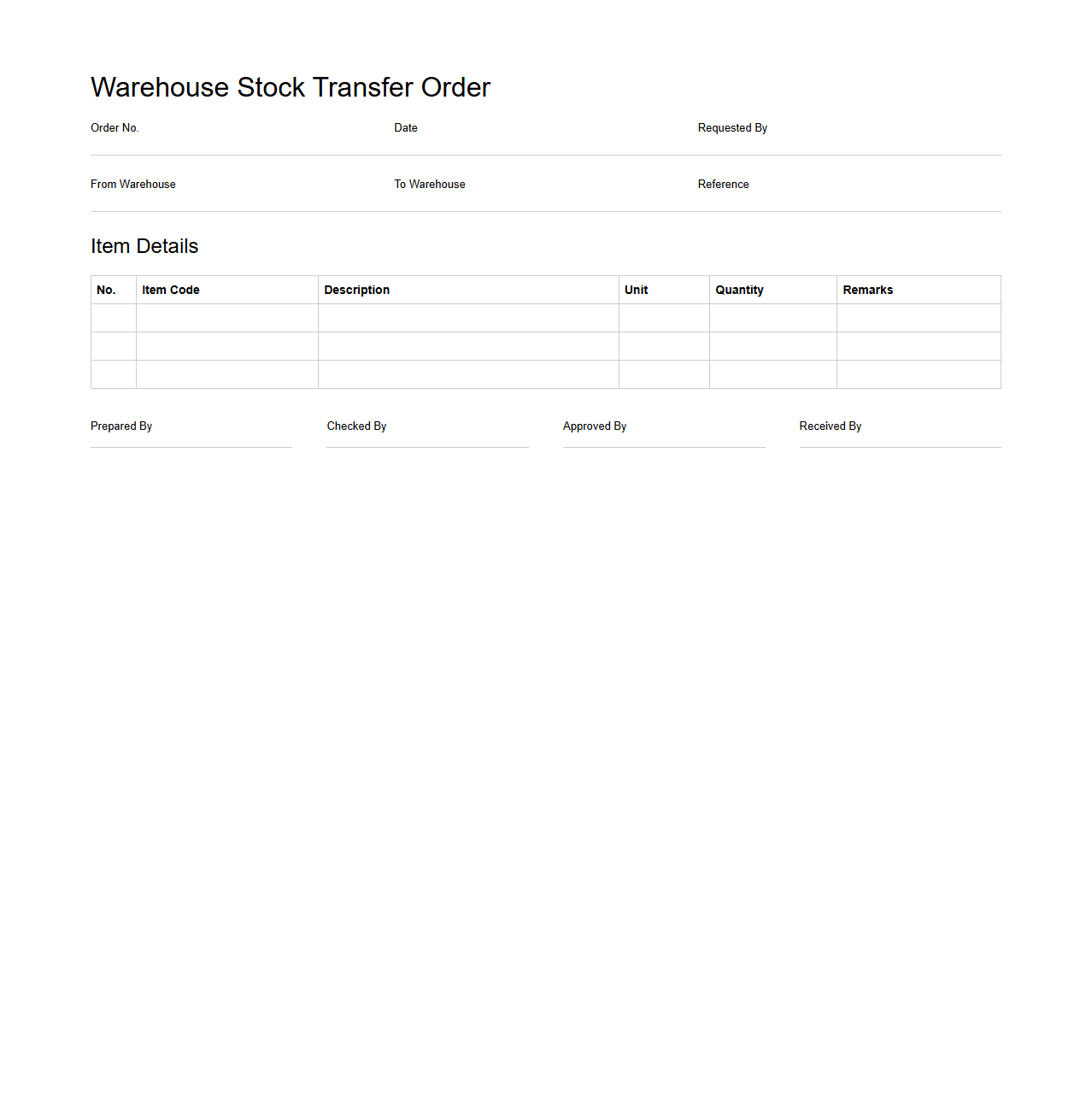

Warehouse Stock Transfer Order Template

A

Warehouse Stock Transfer Order Template document standardizes the process of transferring inventory between warehouse locations, ensuring accuracy and efficiency in stock movements. It captures essential details such as item descriptions, quantities, source and destination warehouses, and transfer dates to maintain seamless inventory management. This template helps reduce errors, streamline operations, and improve overall supply chain coordination.

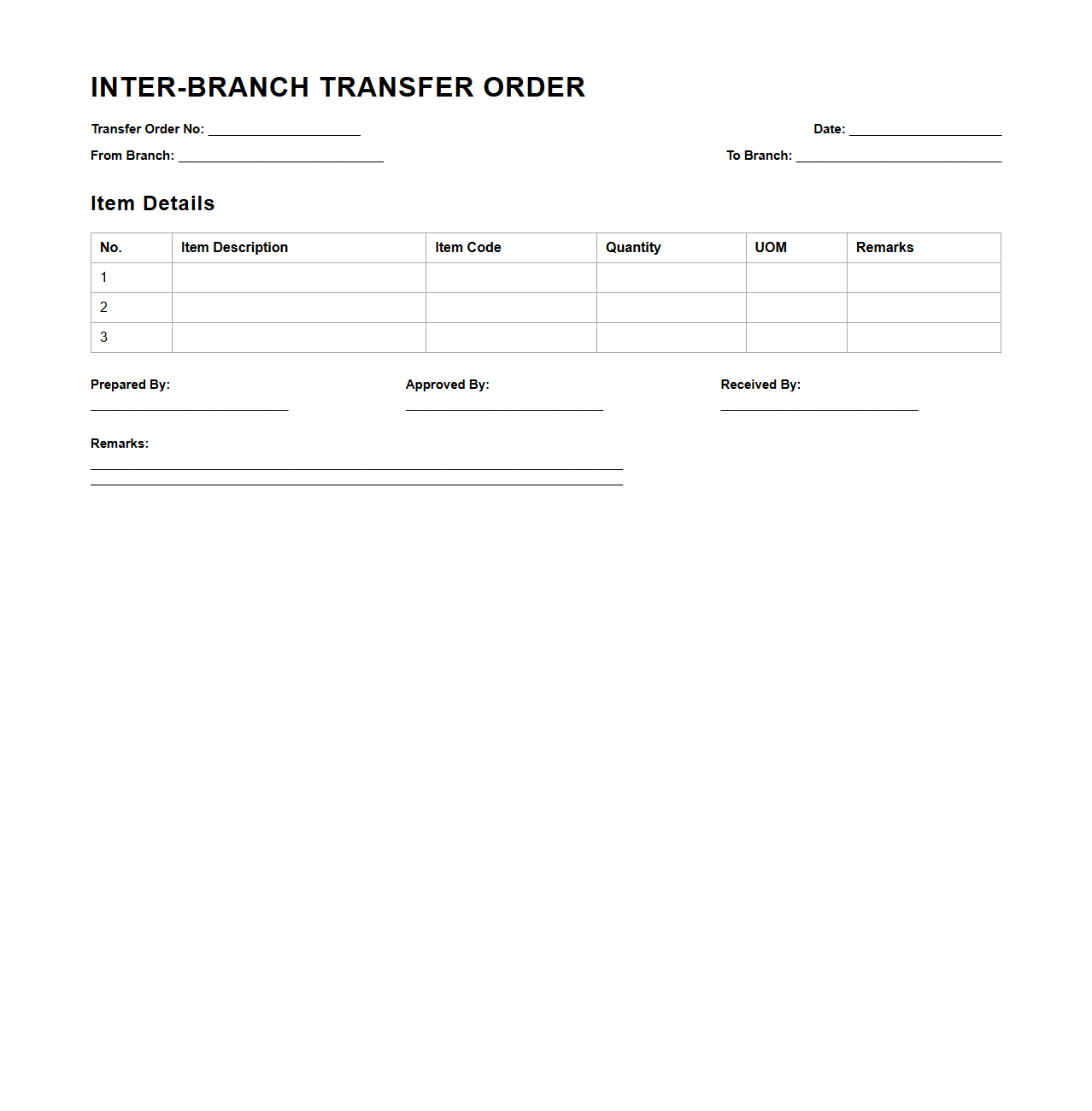

Inter-Branch Transfer Order Sample

An

Inter-Branch Transfer Order Sample document outlines the formal process for transferring inventory, goods, or assets between different branches of the same organization. It includes key details such as item descriptions, quantities, transfer dates, and authorized signatures to ensure accountability and accurate record-keeping. This document helps streamline logistics, maintain inventory control, and track inter-branch movements efficiently.

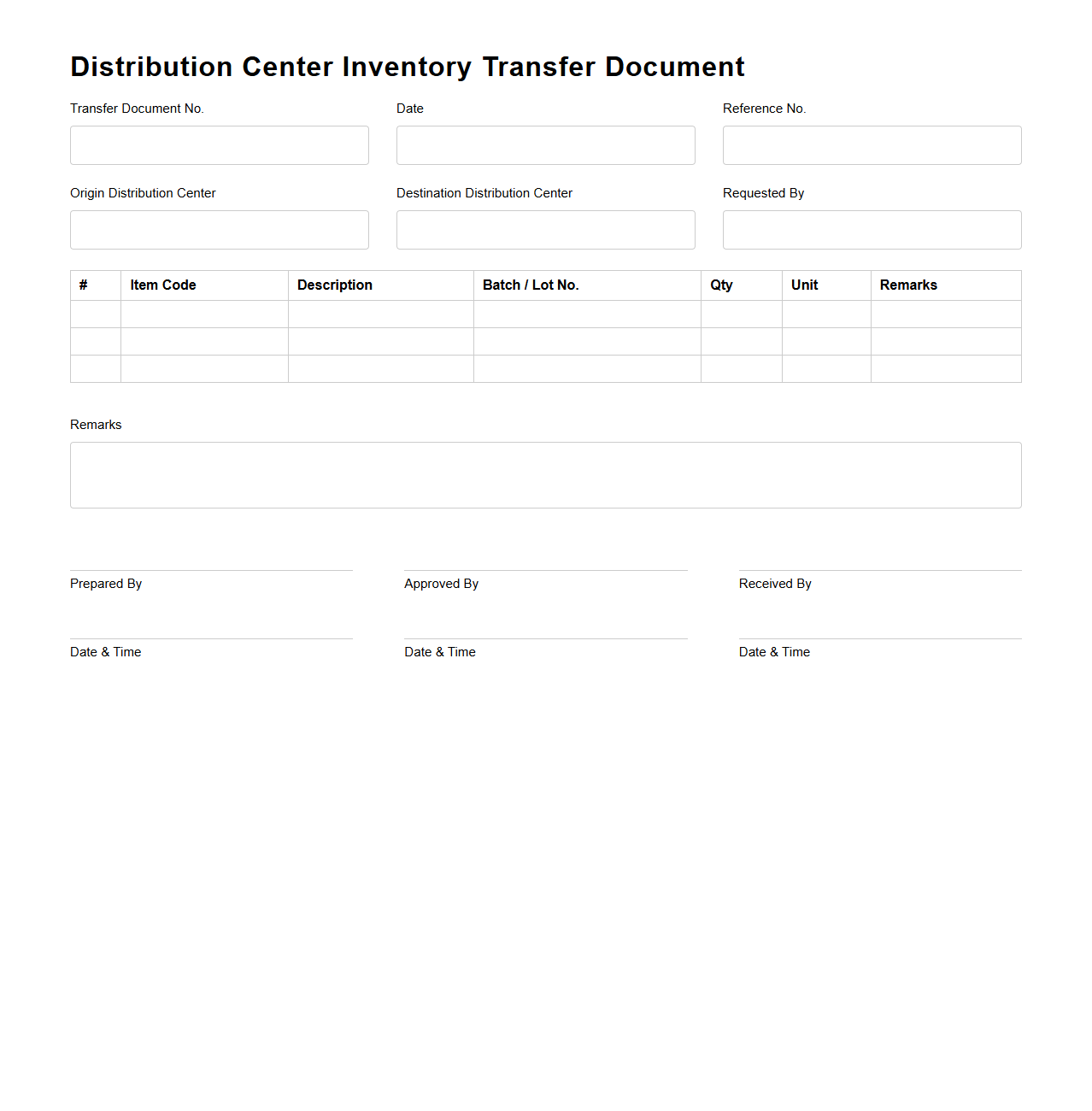

Distribution Center Inventory Transfer Document

A

Distribution Center Inventory Transfer Document serves as an official record for tracking the movement of inventory between distribution centers within a supply chain network. It includes detailed information such as item descriptions, quantities transferred, source and destination locations, and transfer dates to ensure accuracy and accountability. This document is essential for maintaining inventory visibility, reducing discrepancies, and supporting efficient warehouse management operations.

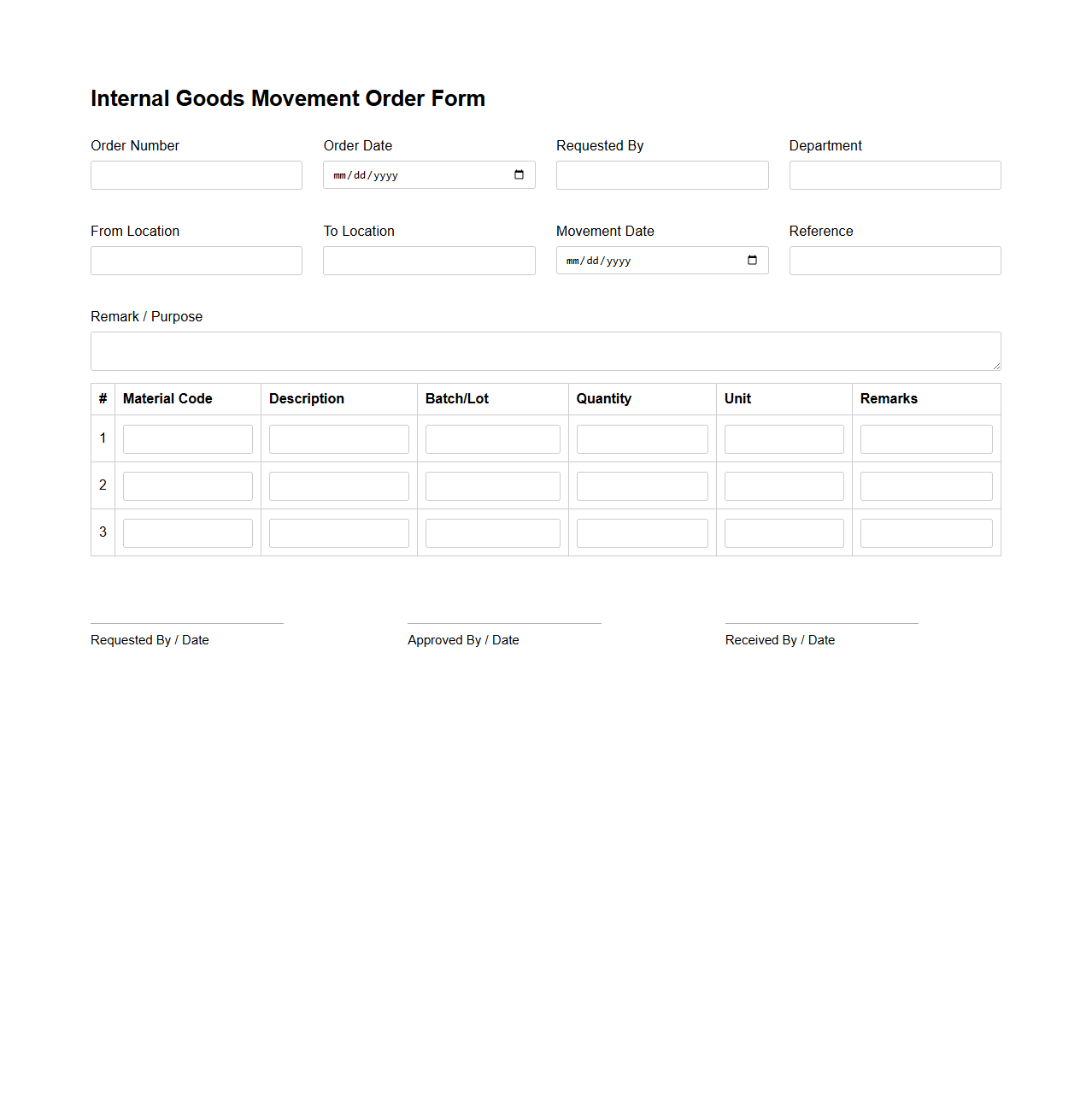

Internal Goods Movement Order Form

The

Internal Goods Movement Order Form document facilitates the tracking and management of inventory transfers within an organization's various departments or locations. It details essential information such as item descriptions, quantities, origin and destination points, and authorization signatures to ensure accurate record-keeping and accountability. This form streamlines internal logistics processes, reduces errors, and supports efficient inventory control.

Distribution Hub Stock Replenishment Transfer

The

Distribution Hub Stock Replenishment Transfer document tracks the movement of inventory from central warehouses to regional distribution hubs to maintain optimal stock levels. It ensures timely replenishment by recording quantities, transfer dates, and destination hubs, facilitating efficient supply chain management. This document plays a crucial role in minimizing stockouts and balancing inventory across multiple locations.

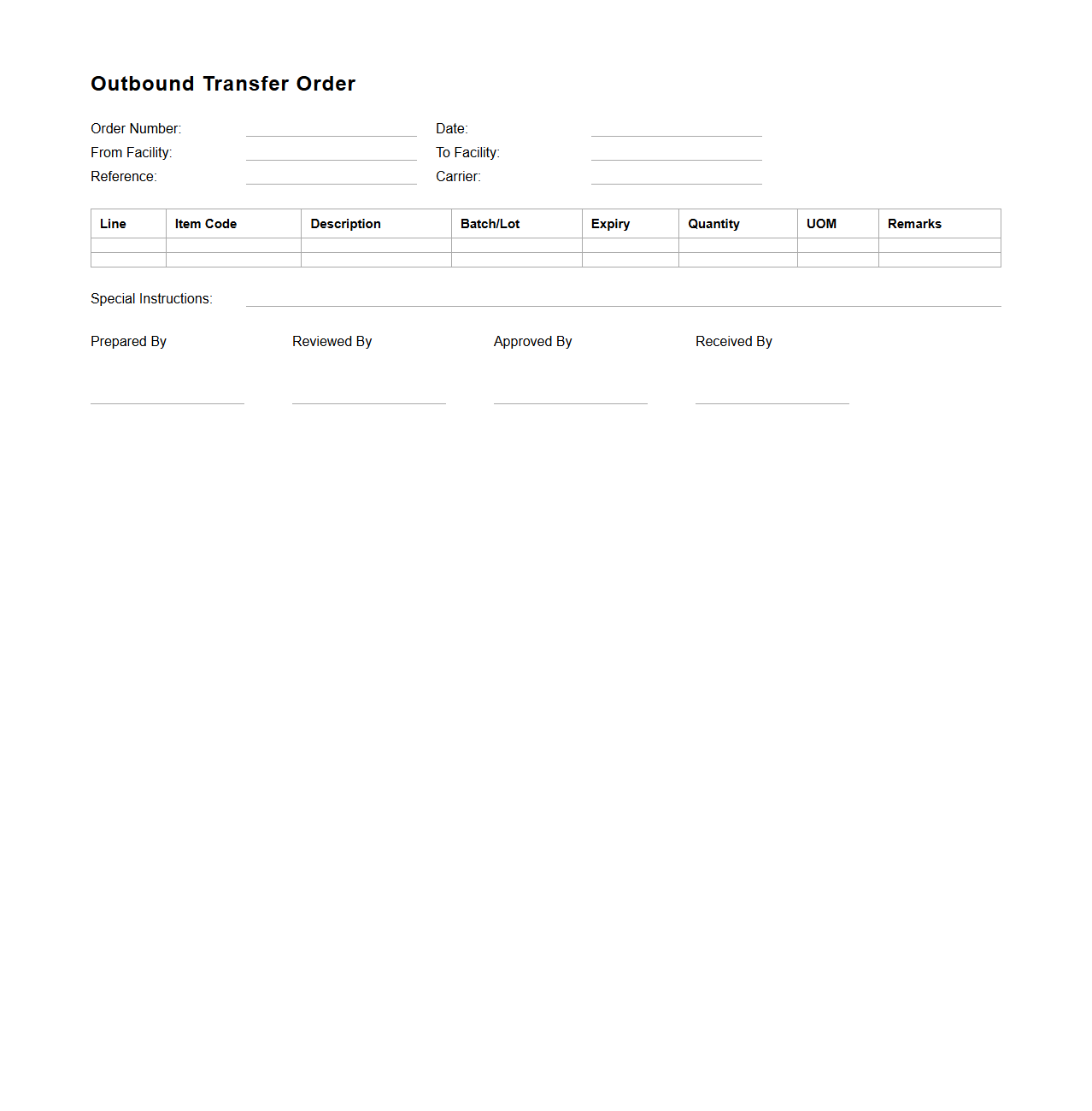

Outbound Transfer Order for Distribution Facility

An

Outbound Transfer Order for Distribution Facility document facilitates the organized movement of inventory from a central warehouse to various distribution centers. It details specific item quantities, destination locations, and shipment schedules to ensure accurate stock replenishment and efficient supply chain operations. This document supports inventory tracking, reduces errors, and streamlines logistics for timely product delivery.

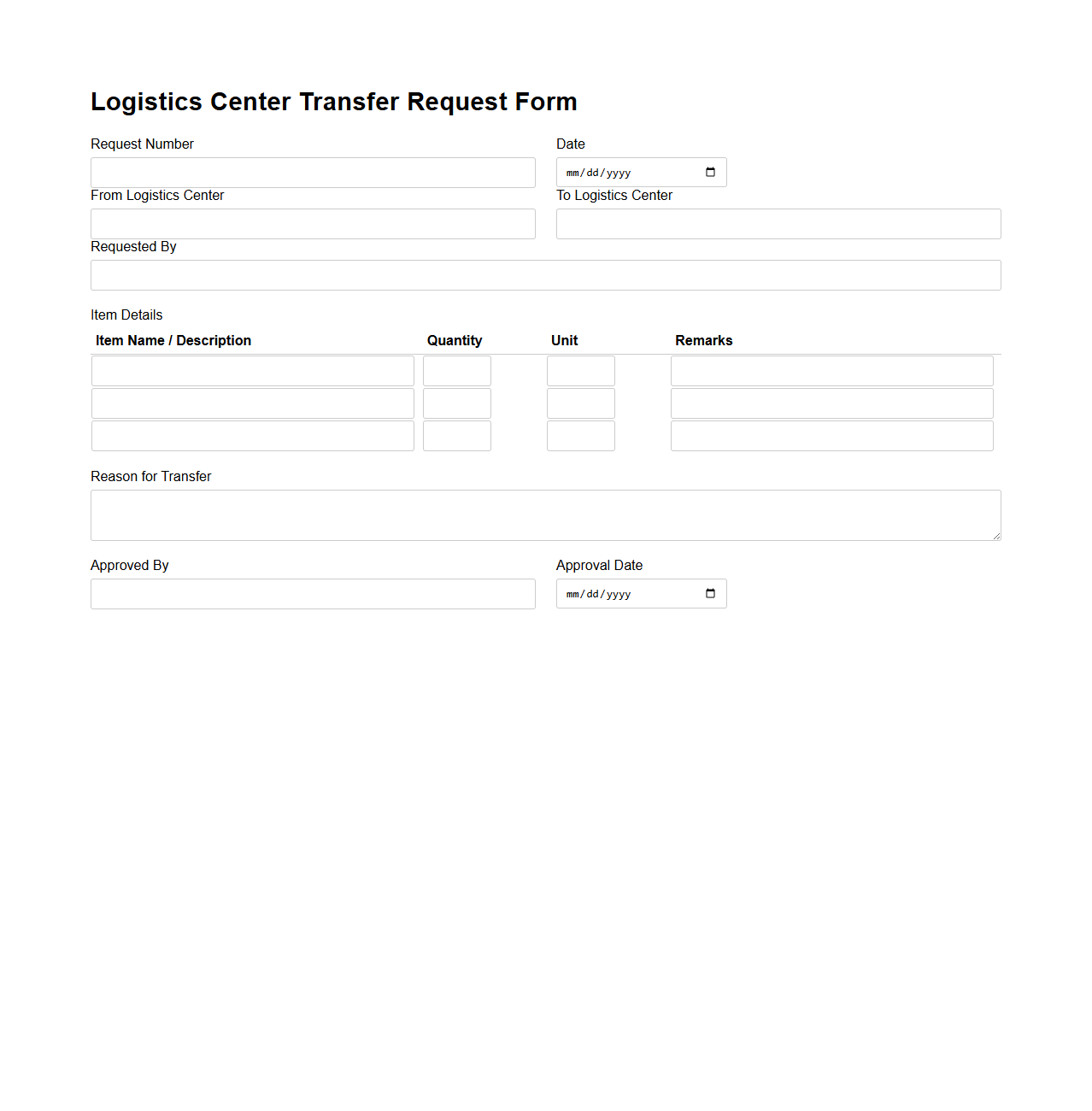

Logistics Center Transfer Request Form

A

Logistics Center Transfer Request Form is a crucial document used to initiate and authorize the transfer of inventory or goods between logistics centers within a supply chain network. This form typically includes detailed information such as product descriptions, quantities, transfer dates, and destination logistics center, ensuring accurate tracking and accountability. It streamlines internal communication and supports efficient inventory management, minimizing delays and errors in the transfer process.

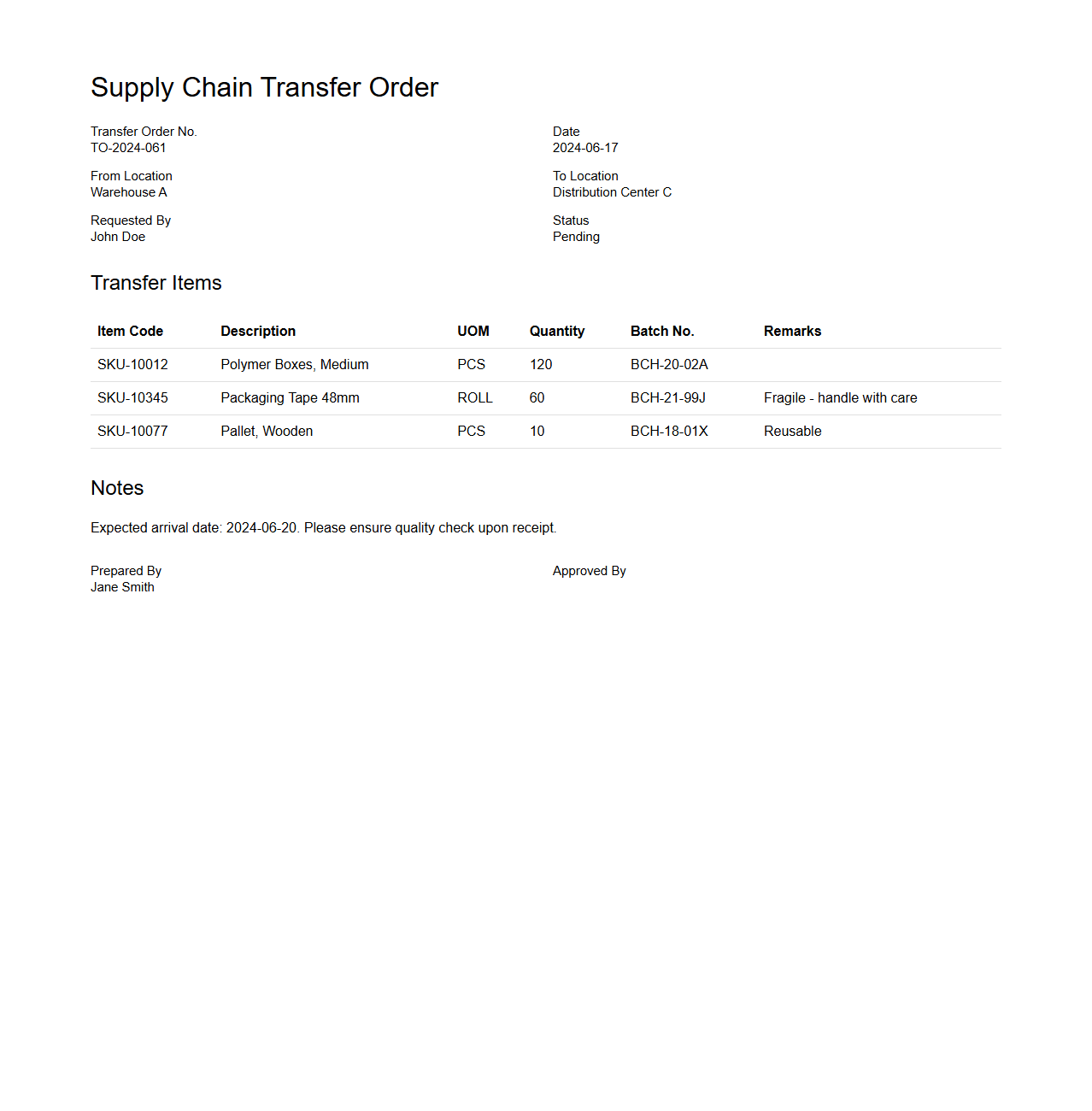

Supply Chain Transfer Order Example

A

Supply Chain Transfer Order Example document outlines the instructions for moving inventory between different locations within a company's supply chain. It specifies details such as product quantities, source and destination warehouses, and transfer dates to ensure accurate and timely stock relocation. This document is essential for maintaining inventory accuracy and optimizing logistics operations.

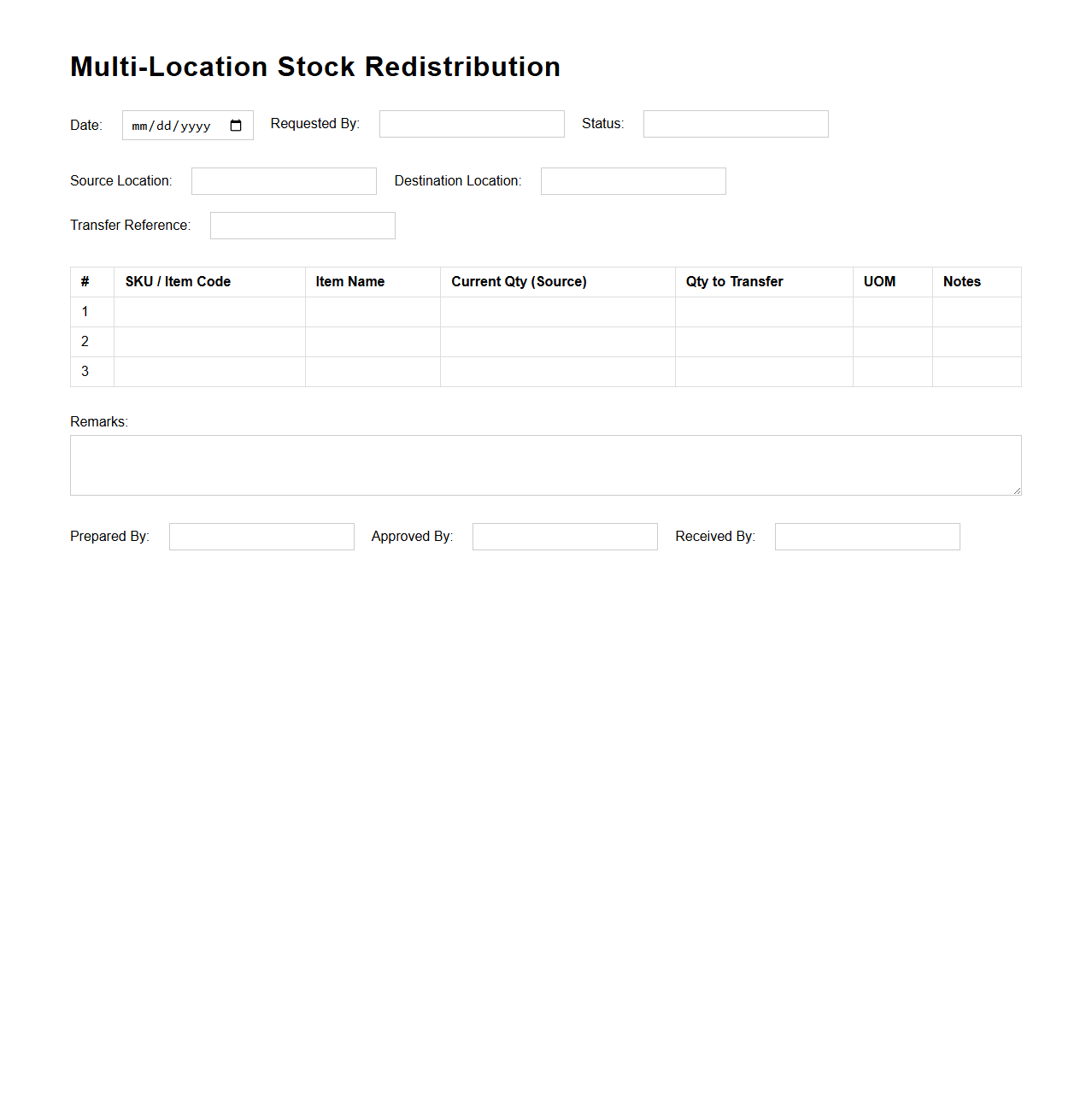

Multi-Location Stock Redistribution Template

The

Multi-Location Stock Redistribution Template is a strategic document designed to facilitate the efficient transfer of inventory between multiple warehouse locations. It outlines key data such as item quantities, source and destination warehouses, and transfer timelines, optimizing stock levels to prevent overstocking or stockouts. Utilizing this template improves inventory visibility and enhances supply chain responsiveness across various distribution centers.

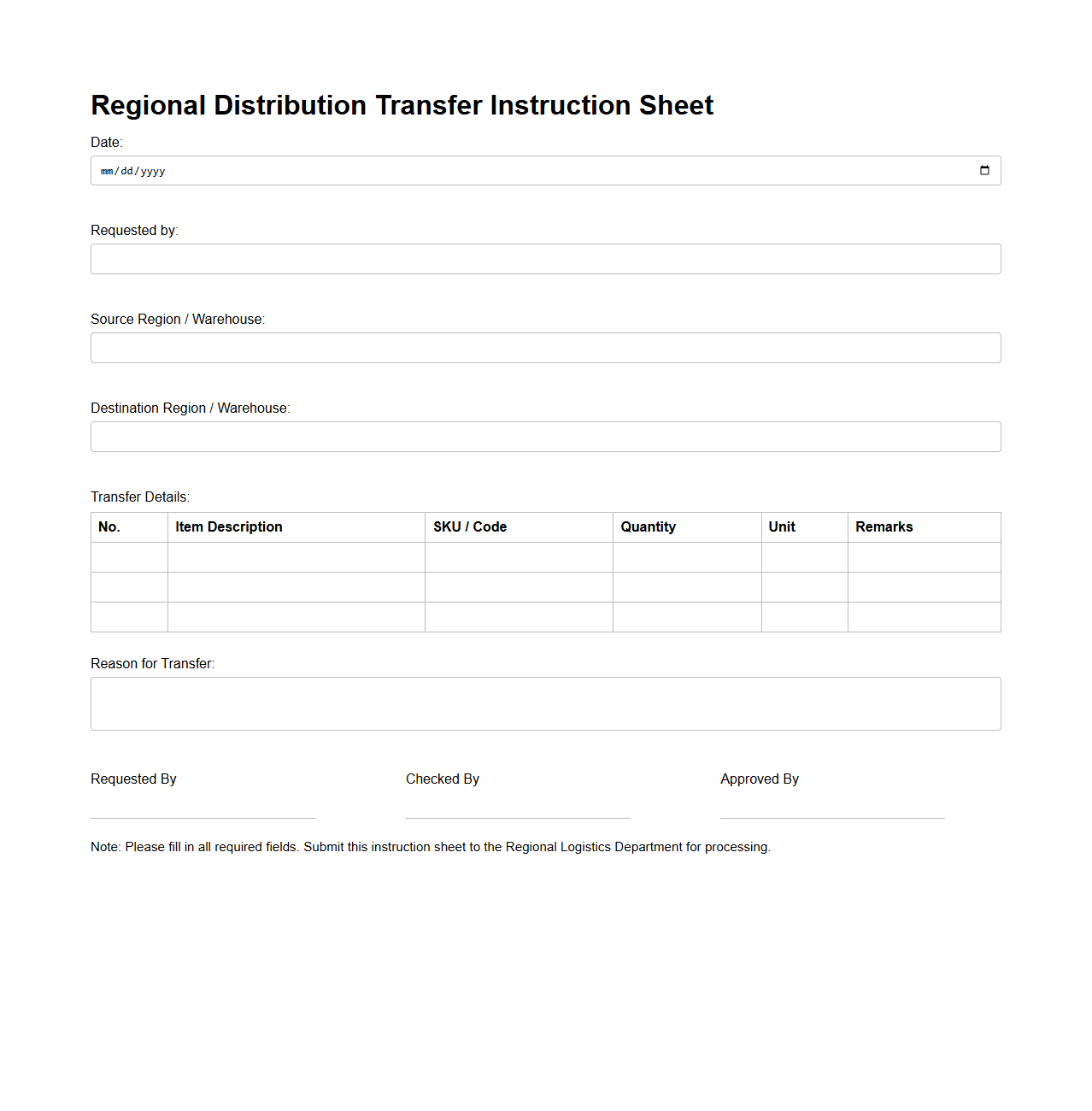

Regional Distribution Transfer Instruction Sheet

A

Regional Distribution Transfer Instruction Sheet is a crucial document that outlines specific guidelines for the transfer of goods between regional distribution centers. It contains detailed instructions on shipment quantities, routing, handling procedures, and delivery schedules to ensure efficient and accurate movement of inventory. This document helps streamline logistics operations, minimize errors, and optimize supply chain management across multiple locations.

What key information must be included in a transfer order document for distribution centers?

A transfer order document must include crucial details such as the item description, quantity to be transferred, and the source and destination warehouse locations. It should also specify unique identifiers like SKU or serial numbers to ensure precise identification. Including the transfer date and authorized signatures is essential for validation and traceability.

How does the transfer order document facilitate inventory movement between warehouse locations?

The transfer order document acts as a formal authorization, guiding warehouse staff in the preparation and shipment of goods. It provides clear instructions that assist in coordinating the picking, packing, and transportation of inventory. This documentation ensures synchronization between sending and receiving locations, minimizing errors and delays.

Which stakeholders are typically responsible for creating, approving, and processing transfer orders?

Typically, inventory managers or warehouse supervisors create the transfer orders based on stock levels and operational needs. Approval is usually required from logistics or supply chain managers to ensure compliance with policies. The warehouse staff then processes the orders by physically executing the inventory movement as per the documented instructions.

What are the critical data fields that ensure accurate tracking in transfer order documentation?

Critical data fields include transfer order number, item codes, quantities, and shipment dates to maintain accurate records. Additionally, fields for authorization signatures and receiving confirmation help validate the transaction. Incorporating barcode or RFID information enhances real-time tracking and minimizes discrepancies.

How does the document ensure compliance with company and regulatory distribution procedures?

The transfer order document includes standardized formats and required approvals that align with company policies. It also incorporates regulatory information, such as safety and handling guidelines, to meet compliance standards. By maintaining thorough records, this document facilitates audits and supports accountability throughout the distribution process.