A Material Receipt Document Sample for Inventory Management provides a standardized format to record the receipt of materials into inventory accurately. It includes essential details such as item descriptions, quantities received, supplier information, and date of receipt, ensuring effective tracking and accountability. This document helps streamline inventory control processes and reduces discrepancies in stock records.

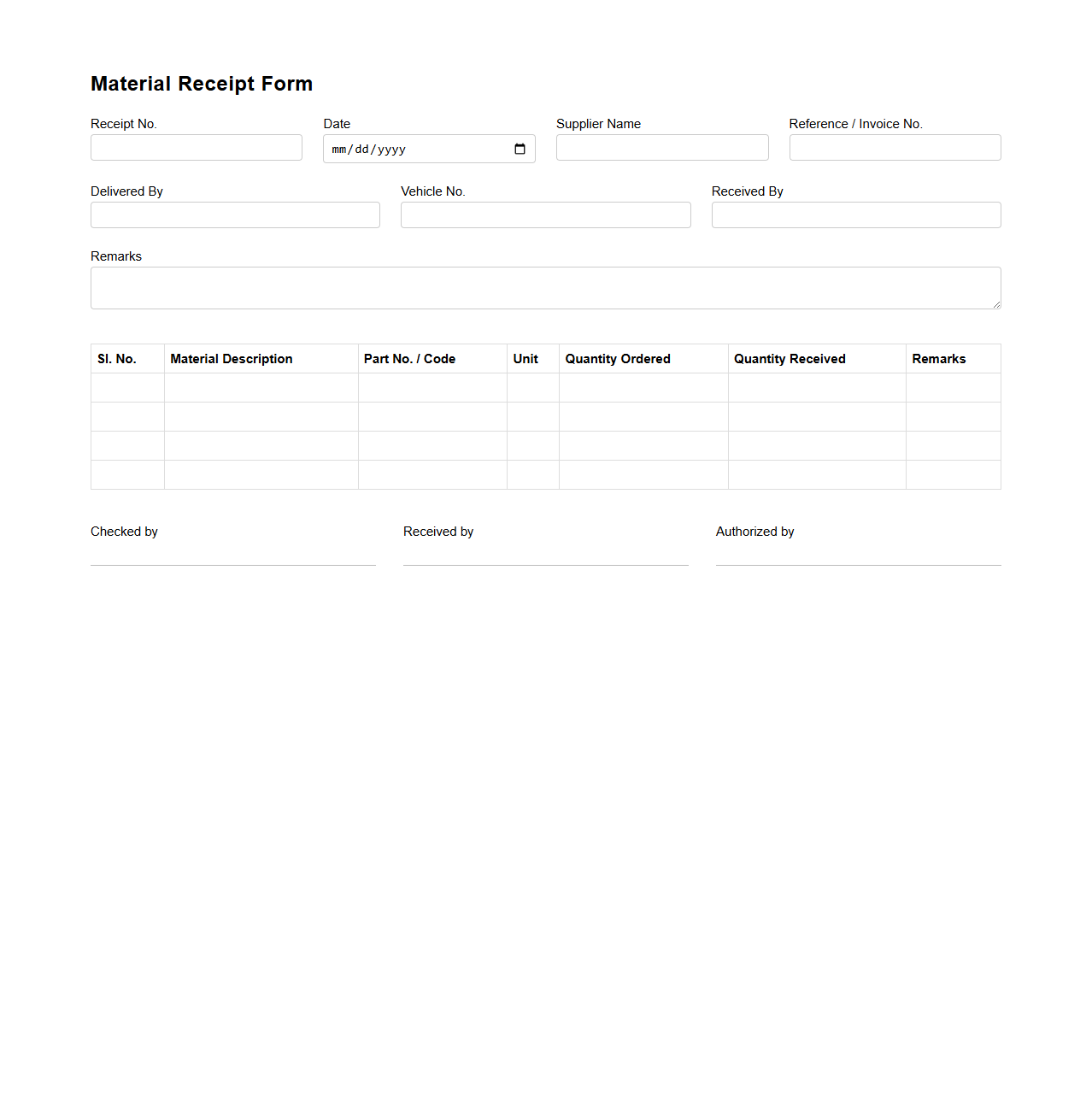

Material Receipt Form Template for Warehouse Inventory

A

Material Receipt Form Template for warehouse inventory is a standardized document used to record the details of incoming materials received in a warehouse. It captures critical information such as item descriptions, quantities, supplier details, and receipt dates, ensuring accurate inventory tracking and accountability. This template facilitates efficient warehouse management by streamlining the verification process and maintaining reliable inventory records.

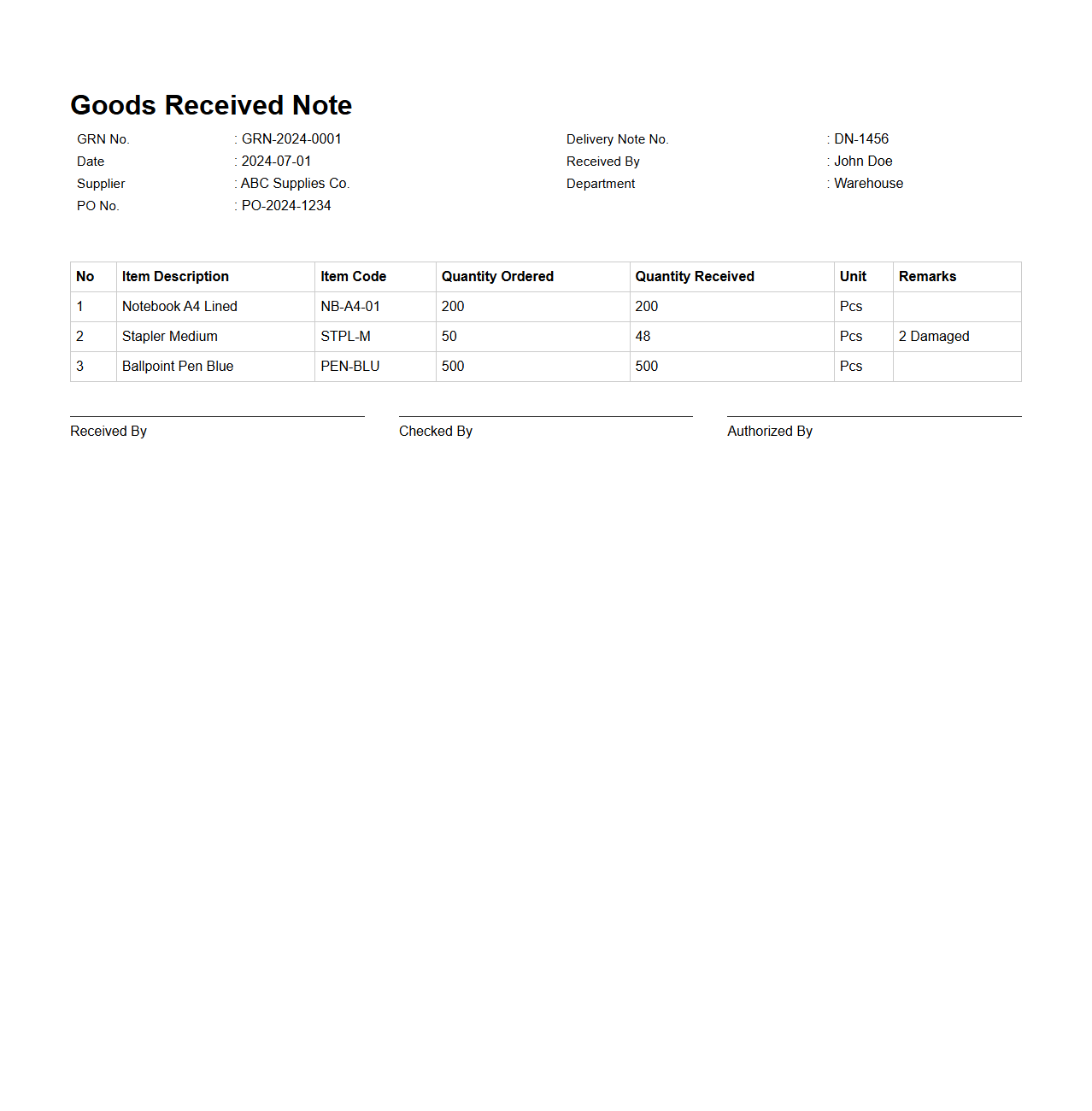

Goods Received Note Example for Stock Management

A

Goods Received Note (GRN) is a crucial stock management document used to record the receipt of goods from suppliers, ensuring accurate inventory tracking and verification against purchase orders. It typically includes details such as item descriptions, quantities received, delivery date, and supplier information to maintain accountability and prevent discrepancies. Maintaining thorough GRN records helps streamline stock reconciliation processes and supports efficient warehouse operations.

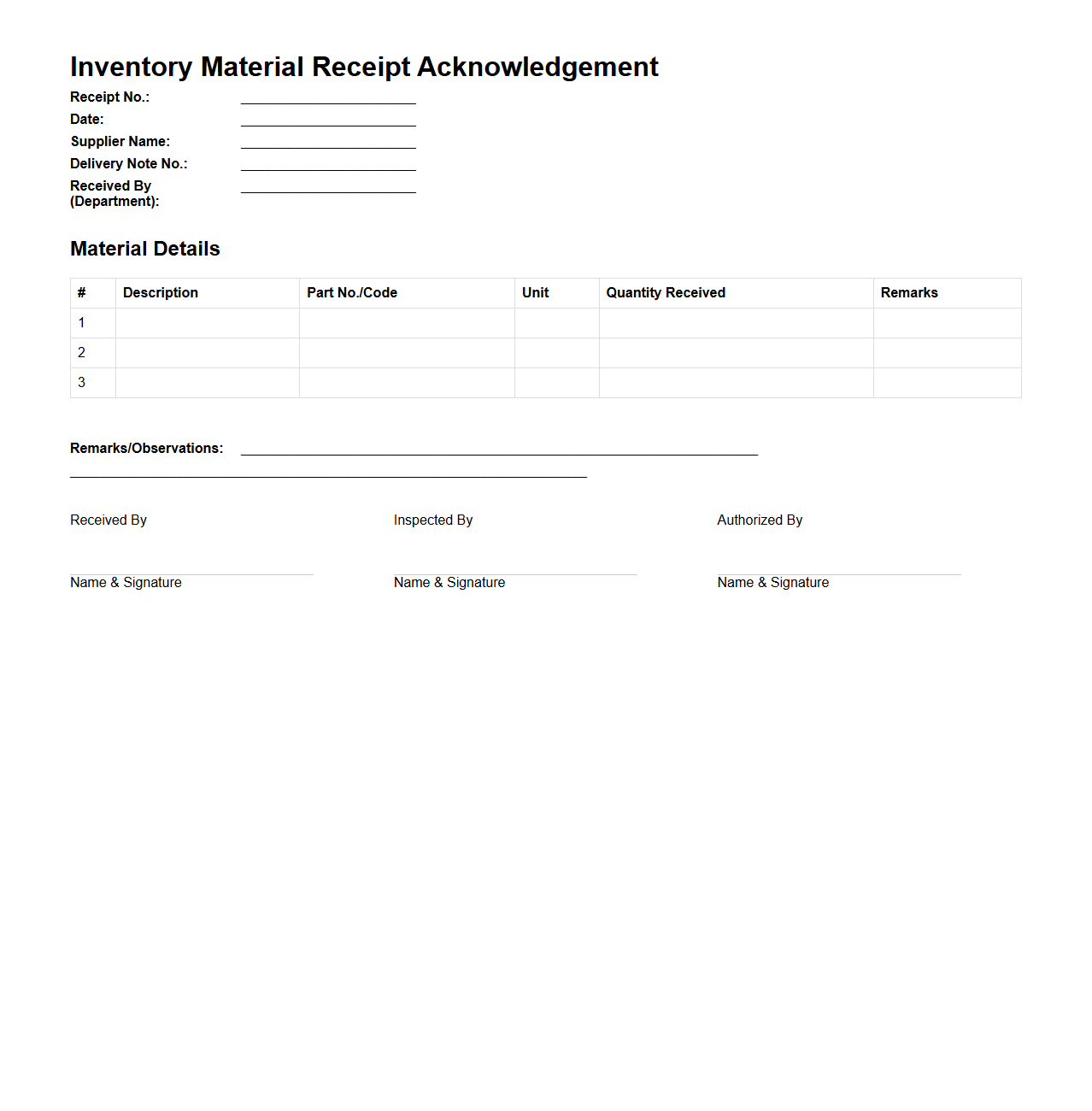

Inventory Material Receipt Acknowledgement Sample

An

Inventory Material Receipt Acknowledgement Sample document serves as proof that materials listed in a purchase order have been received in satisfactory condition. It details quantities, item descriptions, and delivery dates, ensuring accuracy and accountability in inventory management. This document is crucial for verifying goods receipt, facilitating inventory updates, and resolving any discrepancies between ordered and received materials.

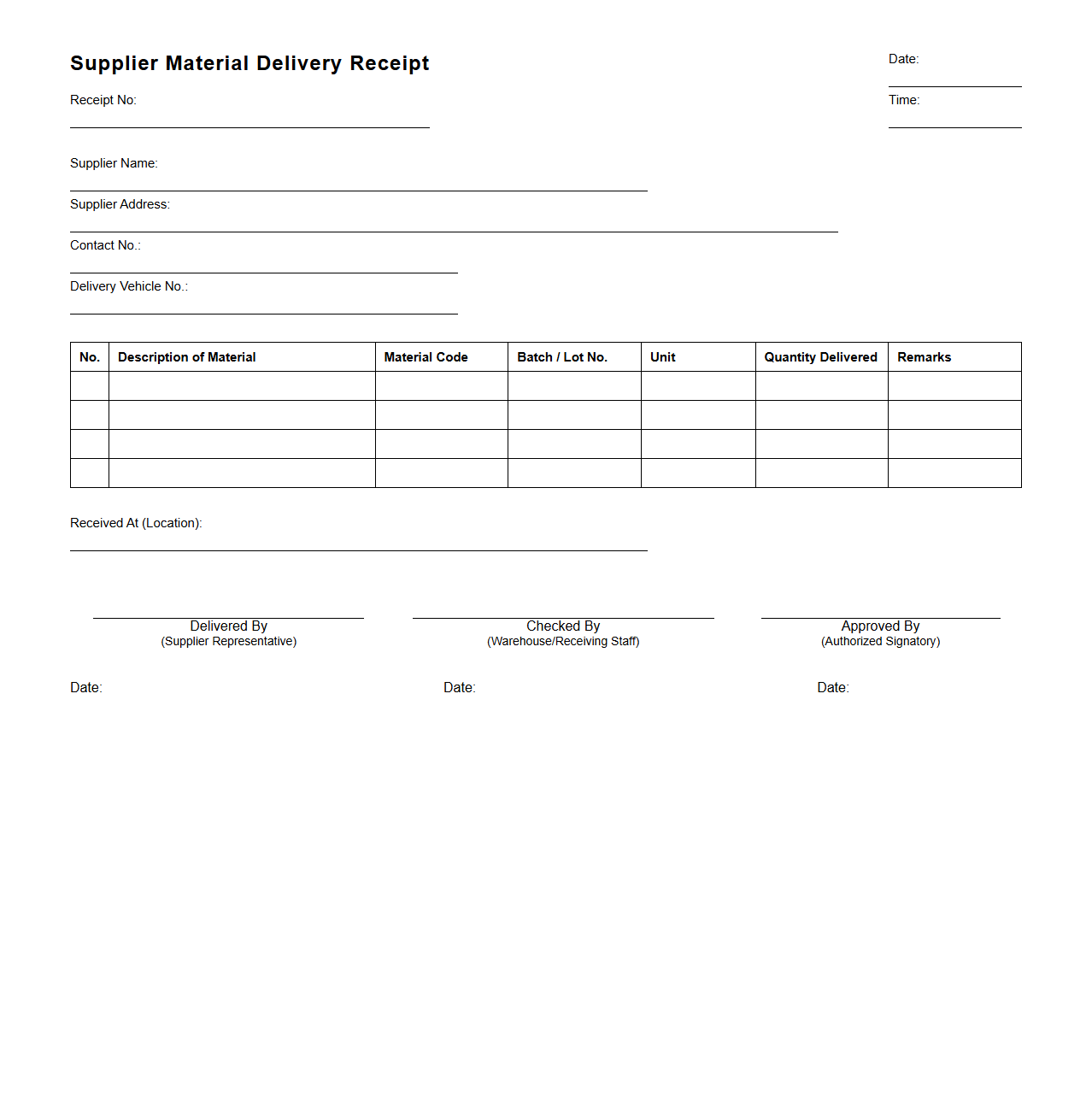

Supplier Material Delivery Receipt Format

The

Supplier Material Delivery Receipt Format document serves as an official record confirming the delivery of materials from a supplier to a recipient, detailing item descriptions, quantities, delivery dates, and condition upon arrival. This format ensures transparency and accountability in supply chain management, enabling accurate tracking and verification of received goods. It is essential for inventory control, payment processing, and dispute resolution between suppliers and buyers.

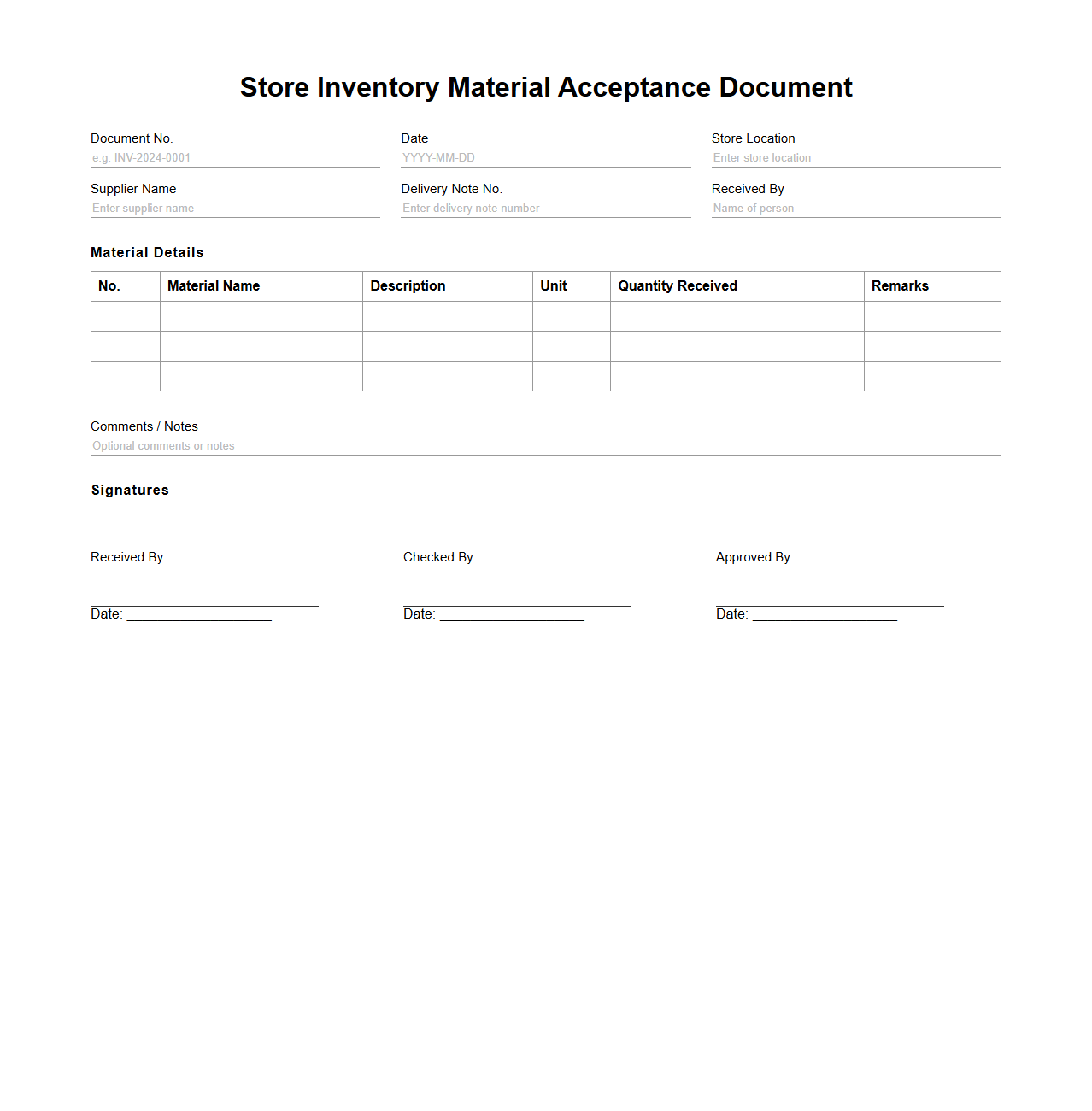

Store Inventory Material Acceptance Document

The

Store Inventory Material Acceptance Document is a formal record used to verify the receipt and condition of materials delivered to a store or warehouse. It ensures accurate tracking of inventory by documenting details such as item descriptions, quantities, and acceptance status. This document plays a crucial role in maintaining inventory accuracy, preventing discrepancies, and facilitating audit compliance.

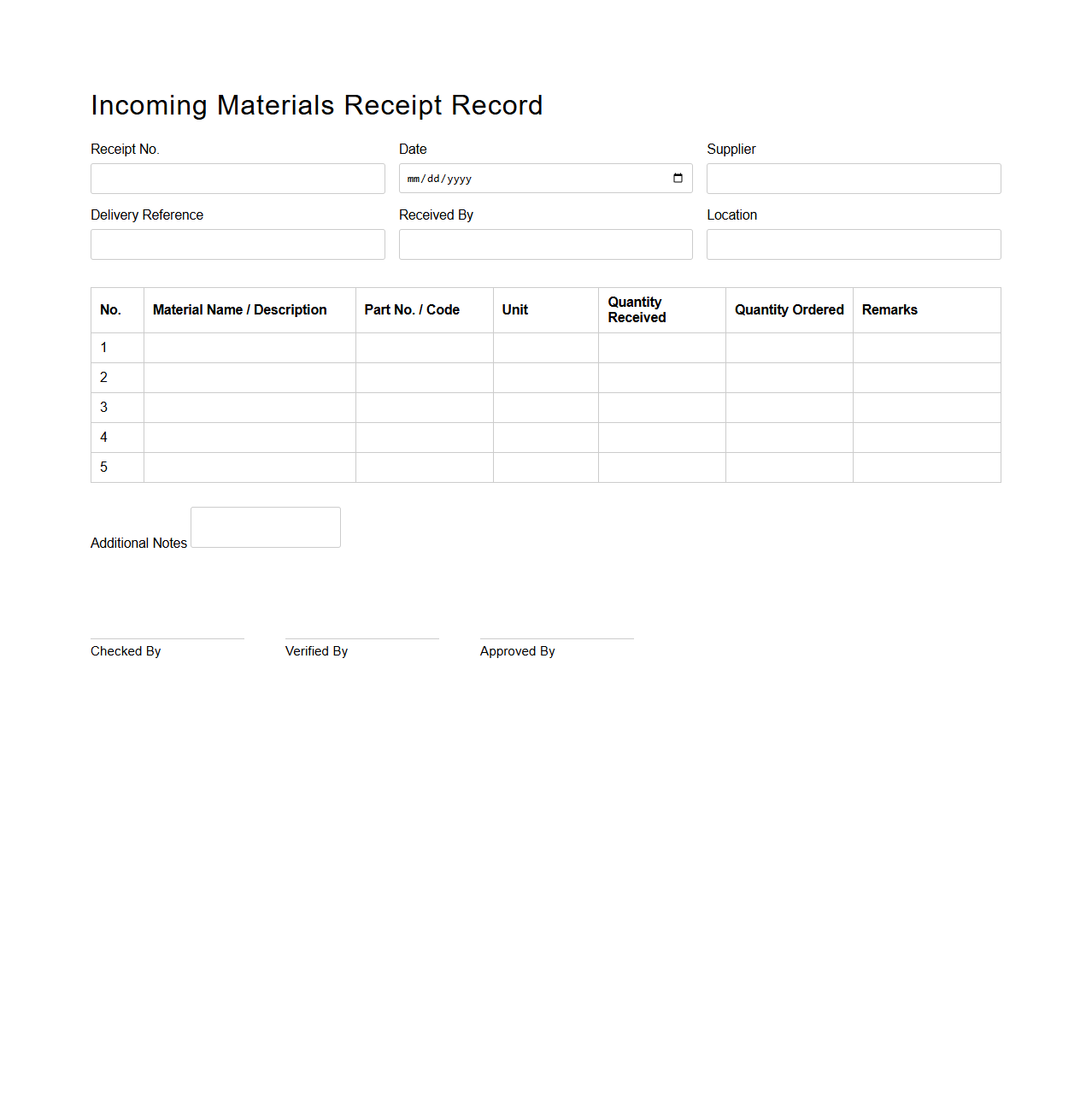

Incoming Materials Receipt Record for Logistics

The

Incoming Materials Receipt Record is a crucial logistics document that verifies the delivery and condition of materials received from suppliers. It includes detailed information such as quantity, item specifications, delivery date, and supplier details. This record ensures accurate inventory management and supports traceability in the supply chain process.

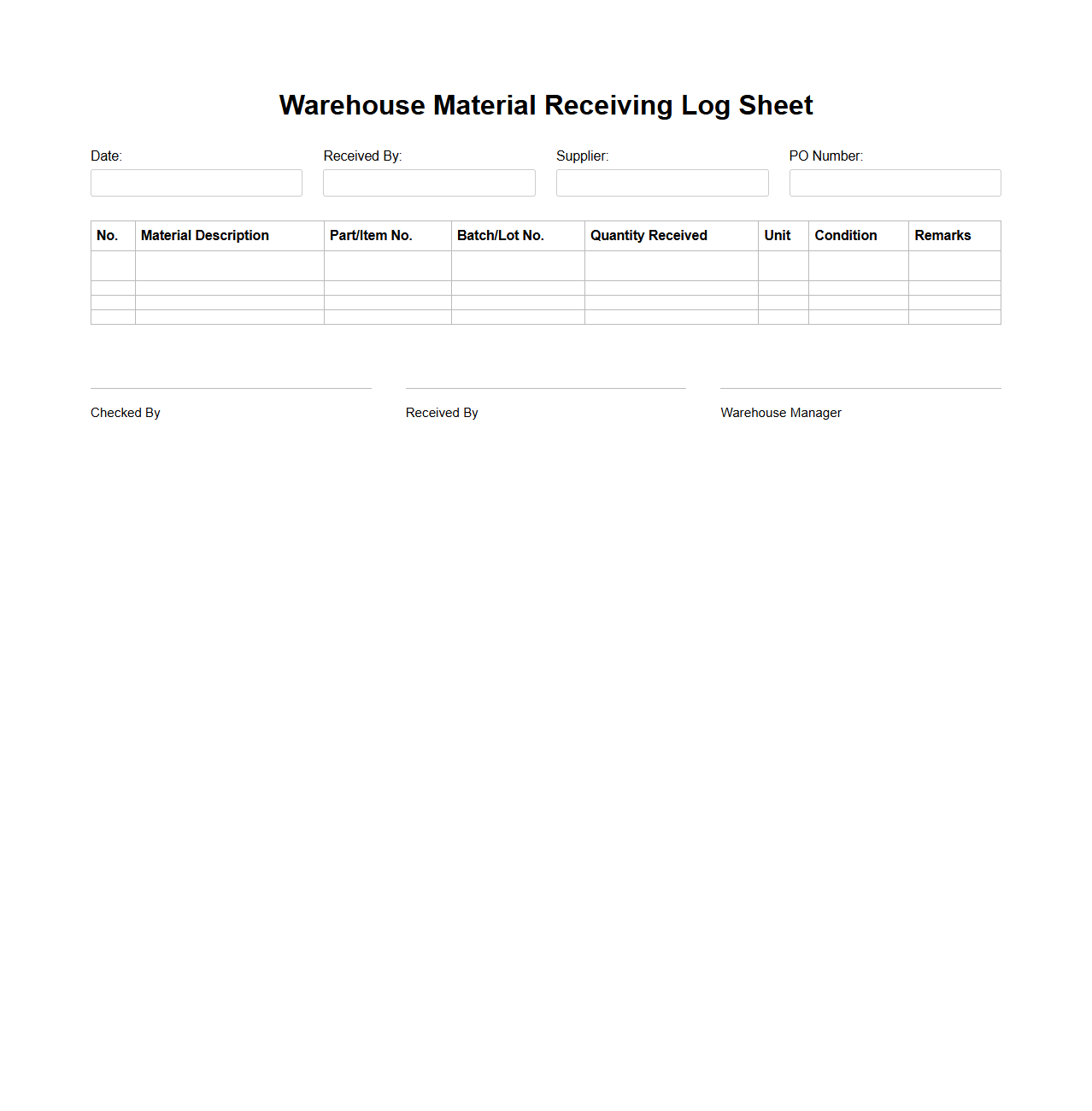

Warehouse Material Receiving Log Sheet

A

Warehouse Material Receiving Log Sheet is a document used to record the details of incoming shipments, including material descriptions, quantities, supplier information, and delivery dates. It ensures accurate tracking of received goods, helps prevent inventory discrepancies, and maintains accountability in warehouse operations. This log sheet supports efficient inventory management by providing a reliable reference for stock intake verification and audit purposes.

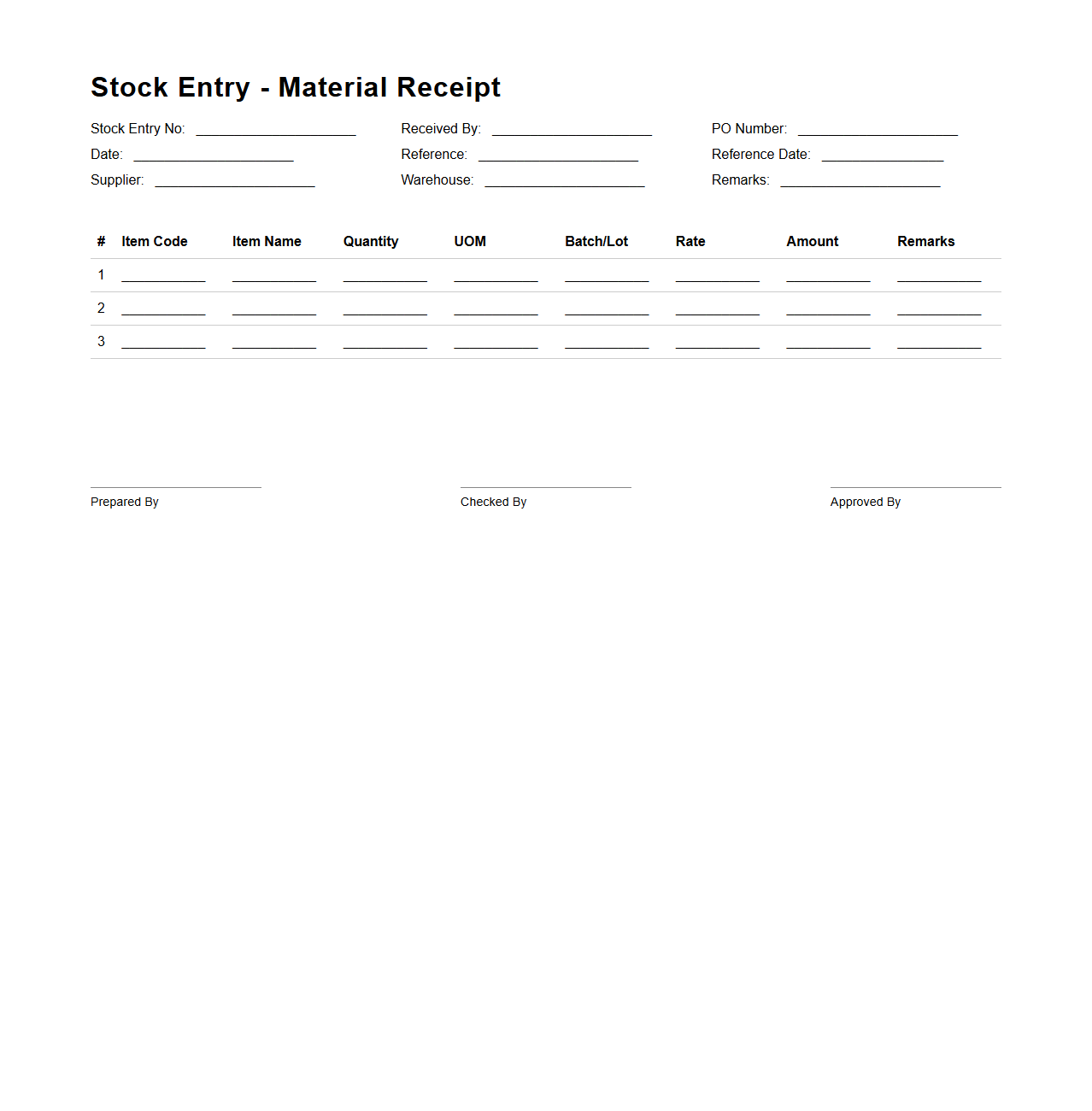

Stock Entry Material Receipt Sample

A

Stock Entry Material Receipt Sample document records the receipt of materials into inventory, ensuring accurate tracking and verification of incoming goods. It includes details such as material descriptions, quantities, batch numbers, and supplier information to maintain inventory integrity. This document plays a critical role in inventory management by providing evidence for stock updates and facilitating audit trails.

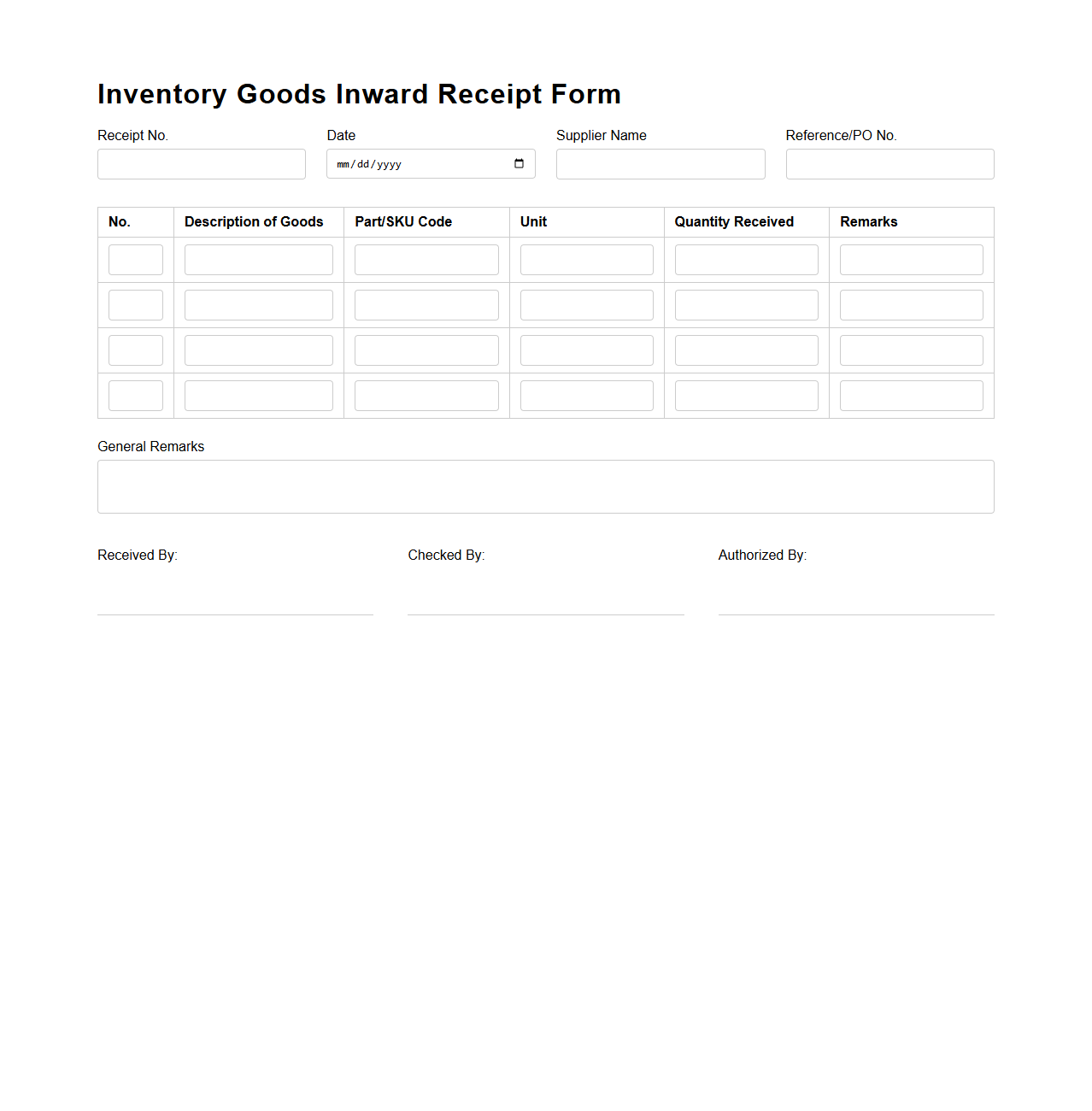

Inventory Goods Inward Receipt Form

An

Inventory Goods Inward Receipt Form documents the details of products received into inventory, including quantities, descriptions, supplier information, and delivery dates. This form ensures accurate tracking of incoming stock, aids in verifying goods against purchase orders, and supports efficient inventory management processes. Proper use of this document helps prevent discrepancies and maintains updated inventory records essential for operational accuracy.

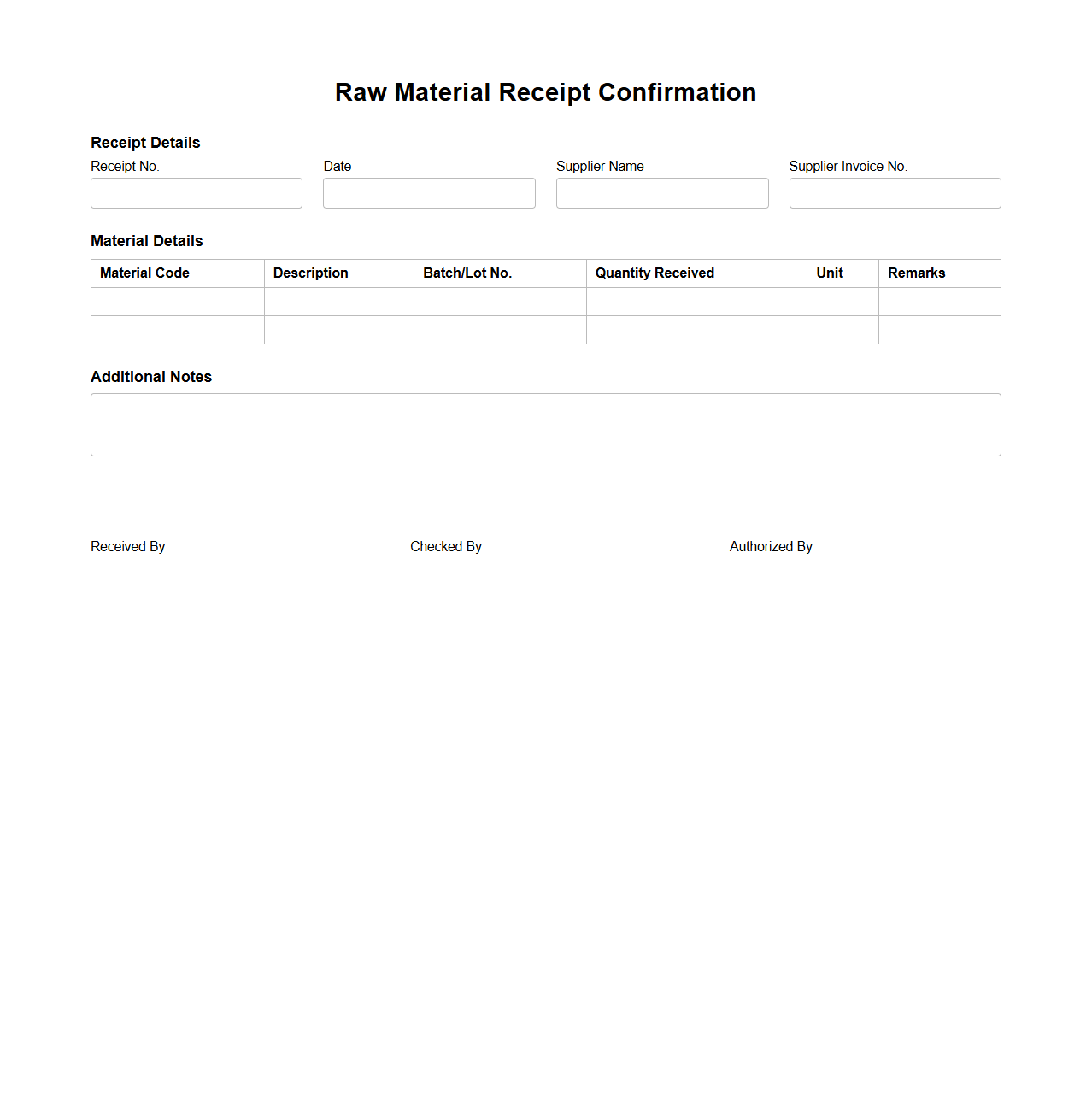

Raw Material Receipt Confirmation for Inventory Control

Raw Material Receipt Confirmation is a crucial document in

inventory control that verifies the accurate delivery of raw materials from suppliers. It records the quantity, quality, and condition of received goods, ensuring alignment with purchase orders and preventing discrepancies. This document supports efficient stock management, reduces errors, and enhances supply chain transparency.

What essential information must be included in a Material Receipt Document for inventory tracking?

The Material Receipt Document must include the date of receipt, supplier details, and a complete list of received items with their quantities. It should also contain unique identification numbers like purchase order references and batch numbers to ensure traceability. Accurate item descriptions and condition notes are critical for effective inventory tracking.

How does a Material Receipt Document support stock verification processes in inventory management?

The Material Receipt Document serves as a primary record for verifying physical stock against recorded inventory data. It provides a reference point to reconcile quantities received with quantities recorded in the system, ensuring accuracy. This document also aids in identifying discrepancies early during stock verification processes.

Which parties are typically responsible for authorizing and signing a Material Receipt Document?

Typically, the warehouse manager or inventory control personnel are responsible for verifying and signing the Material Receipt Document upon delivery. Additionally, the supplier's representative usually acknowledges the receipt by signing the document as confirmation. These authorizations ensure accountability and authorization in the inventory process.

How is the accuracy of quantities and item descriptions validated in a Material Receipt Document?

Accuracy is validated through a thorough physical inspection and counting of items received against the purchase order and delivery note. The inventory team cross-checks each item's description, specifications, and quantity to match the documentation. Any discrepancies are documented immediately to maintain the integrity of inventory records.

What role does a Material Receipt Document play in resolving discrepancies between purchase orders and delivered materials?

The Material Receipt Document acts as evidence to identify and address any variances between what was ordered and what was delivered. It helps facilitate communication between the buyer and supplier to resolve shortages, damages, or incorrect items. This document is crucial for initiating corrective actions, returns, or claims in the procurement process.