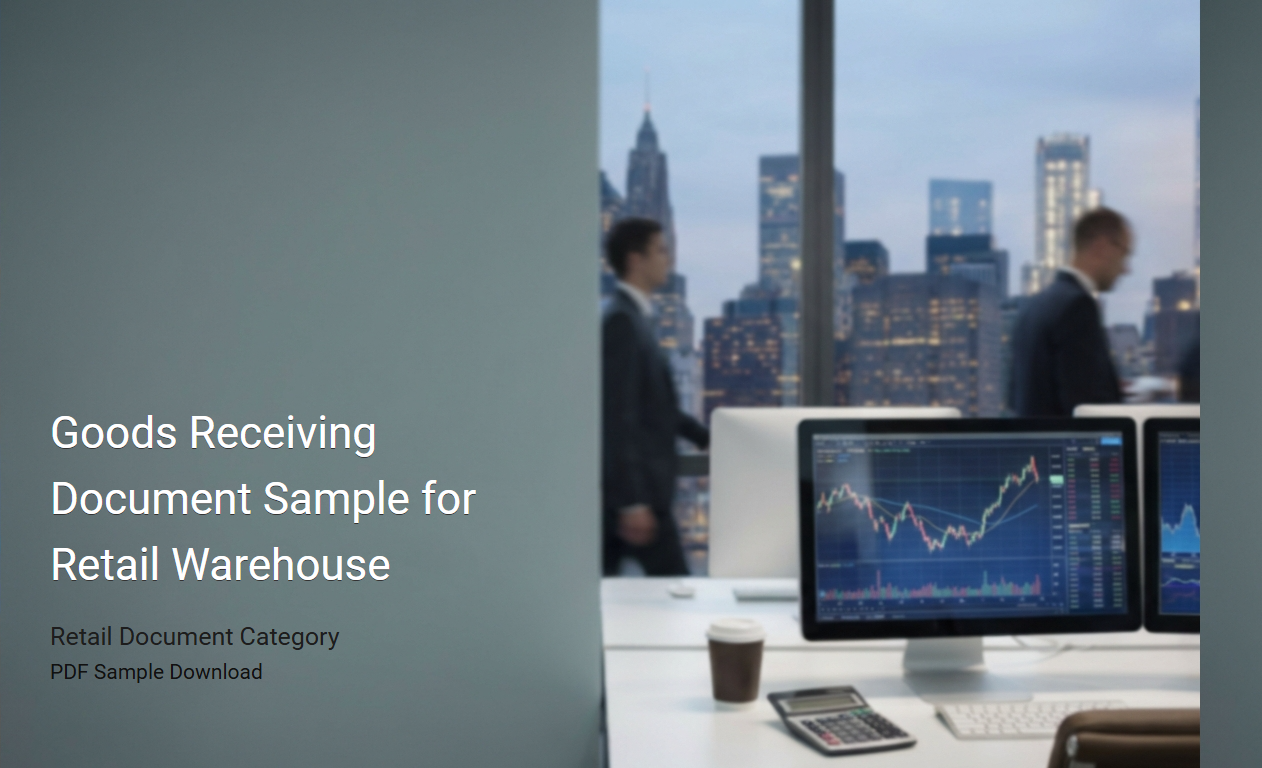

Goods Receipt Note Template for Retail Warehouse

A

Goods Receipt Note Template for a retail warehouse is a standardized document used to record the receipt of products from suppliers, ensuring accurate inventory management and verification. It captures essential details such as item descriptions, quantities received, delivery dates, and supplier information, helping streamline the checking process. This document supports efficient stock control, reduces discrepancies, and facilitates seamless communication between warehouse and procurement teams.

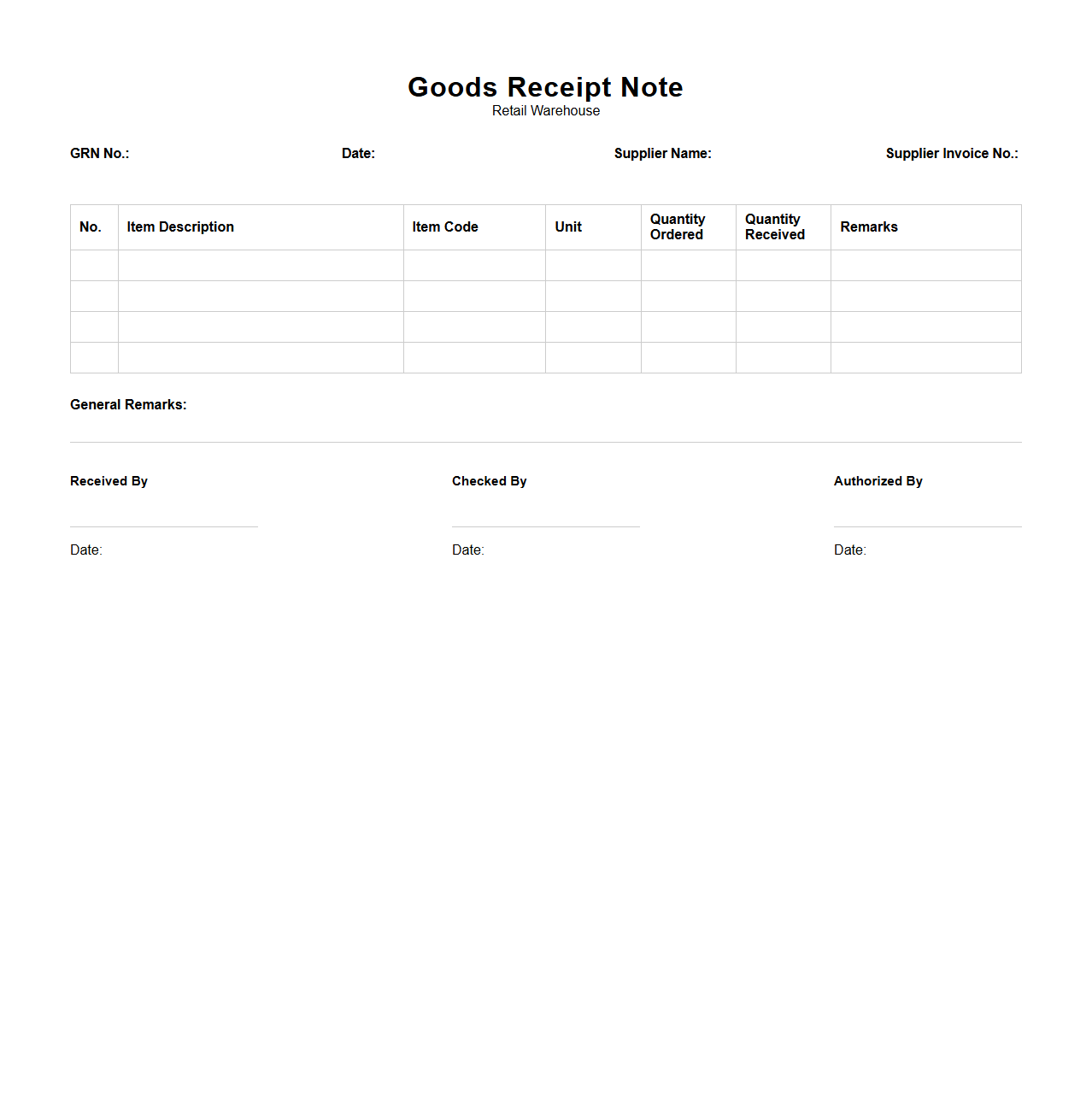

Retail Warehouse Incoming Goods Inspection Form

The

Retail Warehouse Incoming Goods Inspection Form is a crucial document used to verify the quality and accuracy of products delivered to a retail warehouse. It records details such as item descriptions, quantities, supplier information, and any discrepancies or damages found during the inspection process. This form helps maintain inventory accuracy, ensures compliance with purchase orders, and supports smooth warehouse operations.

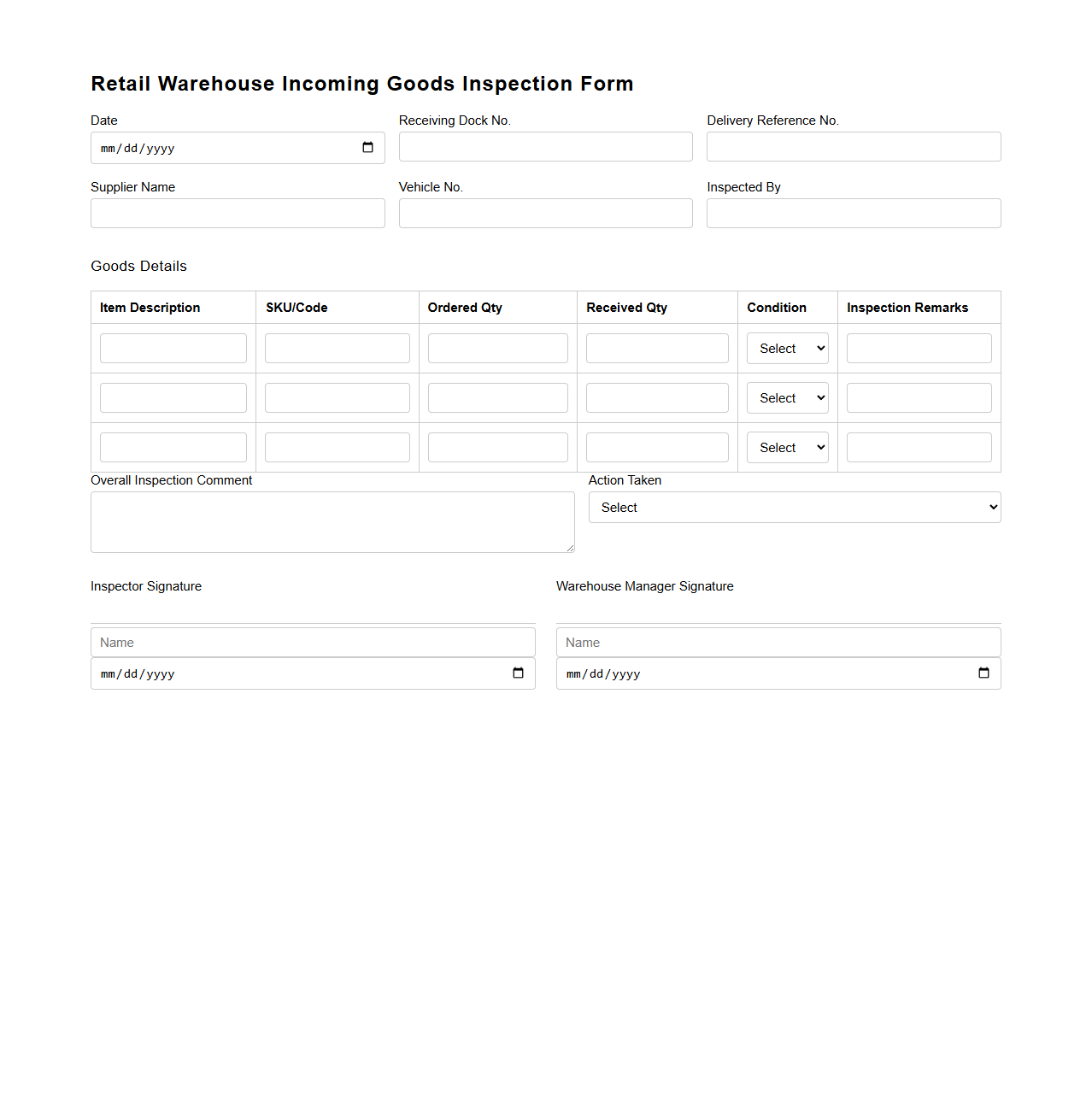

Warehouse Delivery Acknowledgement Document

A

Warehouse Delivery Acknowledgement Document is a formal record used to confirm the receipt of goods at a warehouse. It details the quantity, condition, and specifications of the delivered items to ensure accuracy and accountability between suppliers and warehouse personnel. This document serves as essential proof for inventory management, dispute resolution, and payment processing.

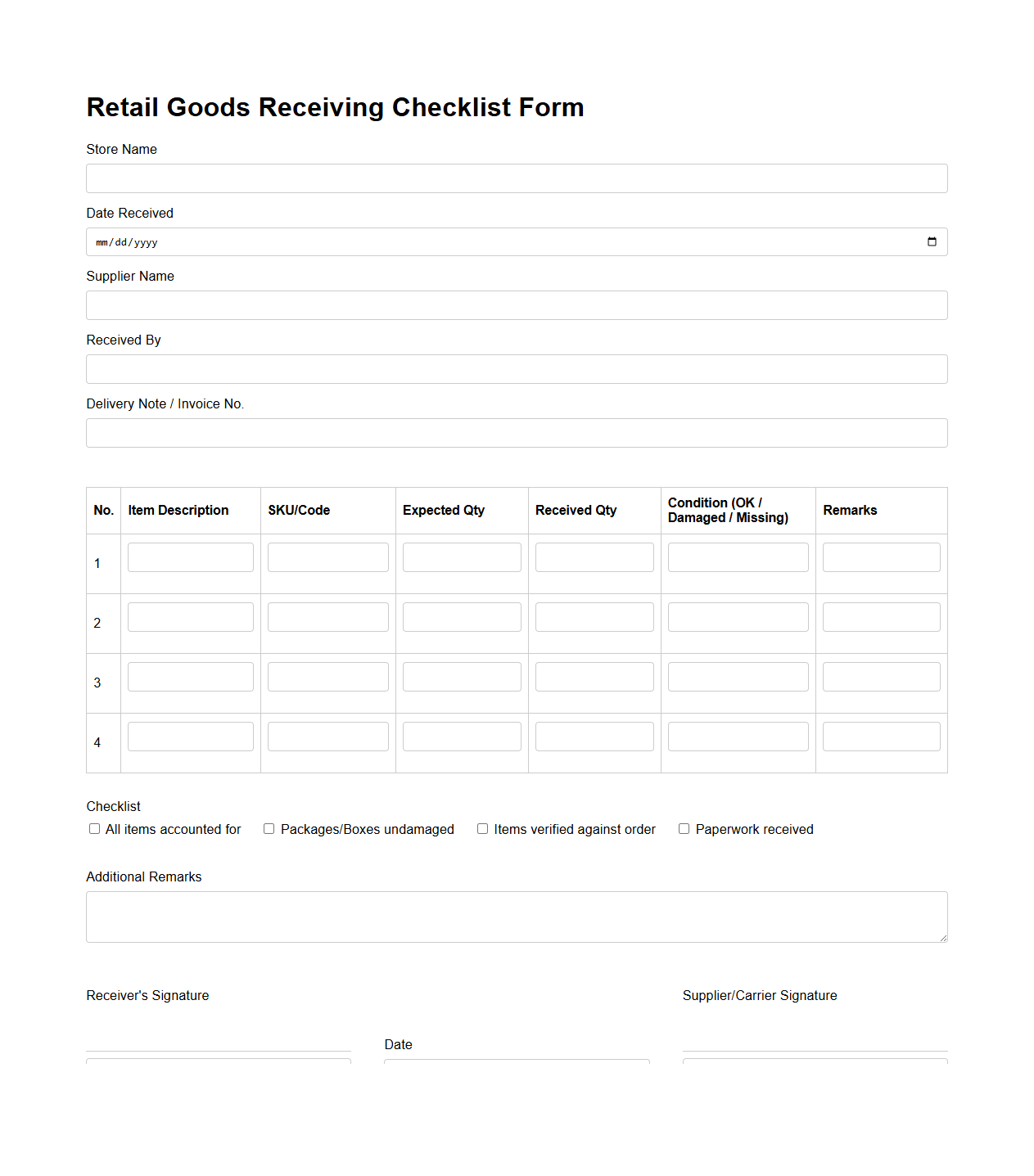

Retail Goods Receiving Checklist Form

A

Retail Goods Receiving Checklist Form is a structured document used by retail businesses to verify and record the receipt of inventory shipments. It ensures all products delivered match the purchase order in terms of quantity, quality, and specifications, helping to identify discrepancies or damages promptly. This form supports efficient inventory management, accurate record-keeping, and reduces errors during the stock intake process.

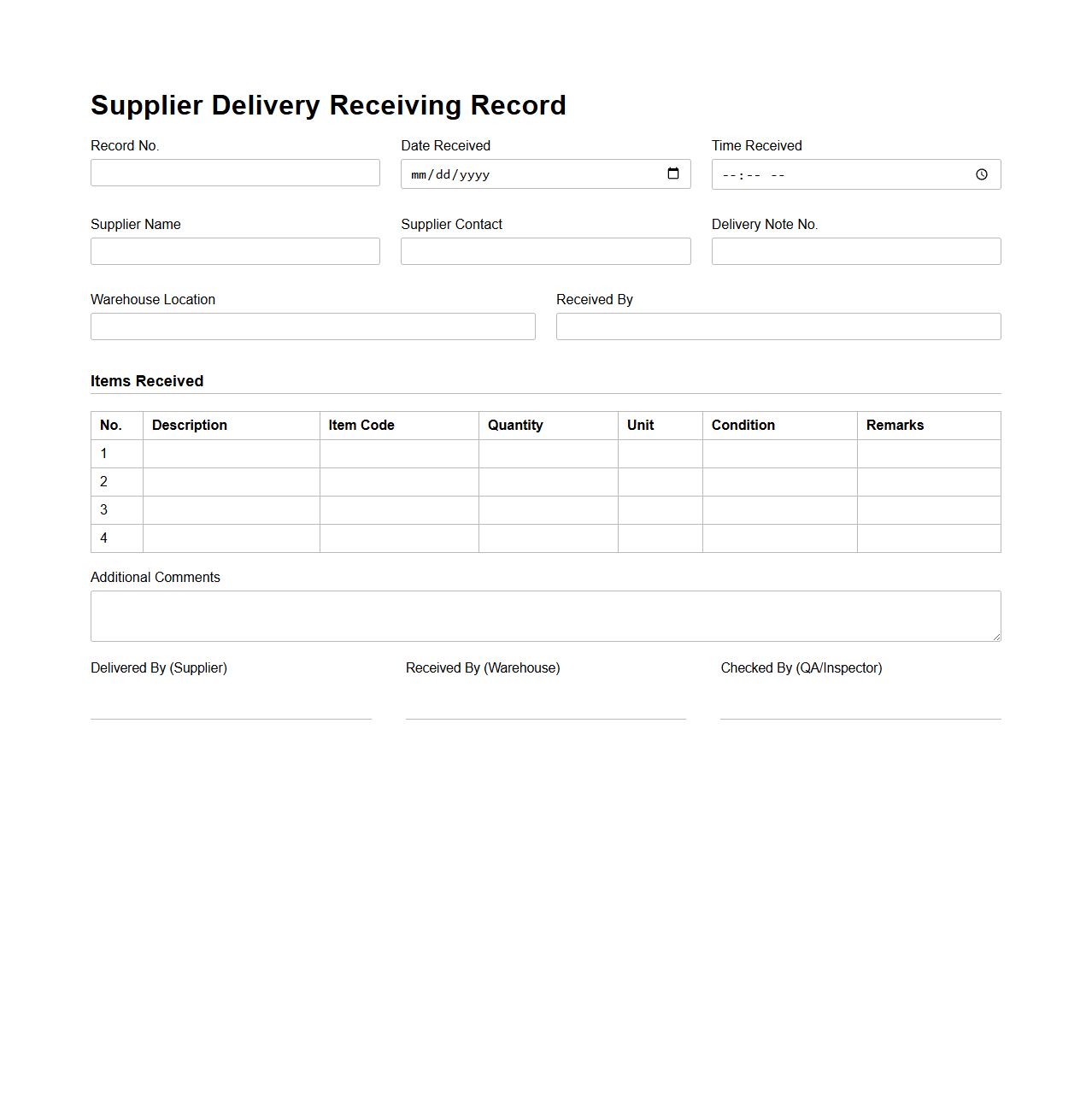

Supplier Delivery Receiving Record for Warehouses

A

Supplier Delivery Receiving Record for warehouses is a crucial document that tracks the receipt of goods delivered by suppliers, ensuring accurate inventory management and verification of order fulfillment. It contains detailed information such as delivery date, supplier details, item descriptions, quantities received, and condition of the goods upon arrival. This document facilitates inventory accuracy, helps resolve discrepancies, and supports accountability in warehouse operations.

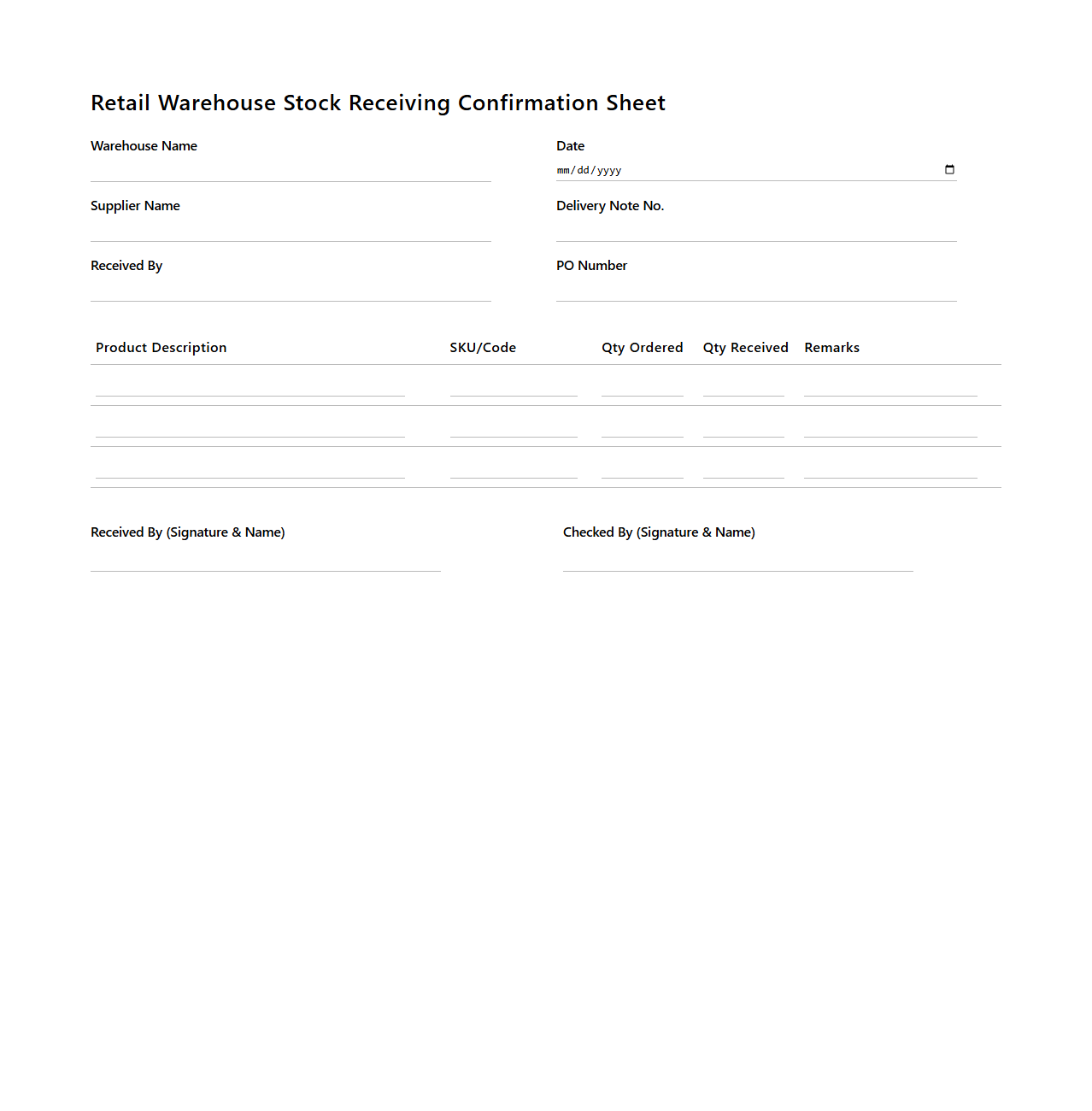

Retail Warehouse Stock Receiving Confirmation Sheet

The

Retail Warehouse Stock Receiving Confirmation Sheet document serves as an official record verifying the receipt of goods at a retail warehouse. It details the quantity, condition, and specifications of received stock, ensuring accuracy between ordered and delivered items. This document is essential for inventory management, quality control, and audit purposes in retail supply chain operations.

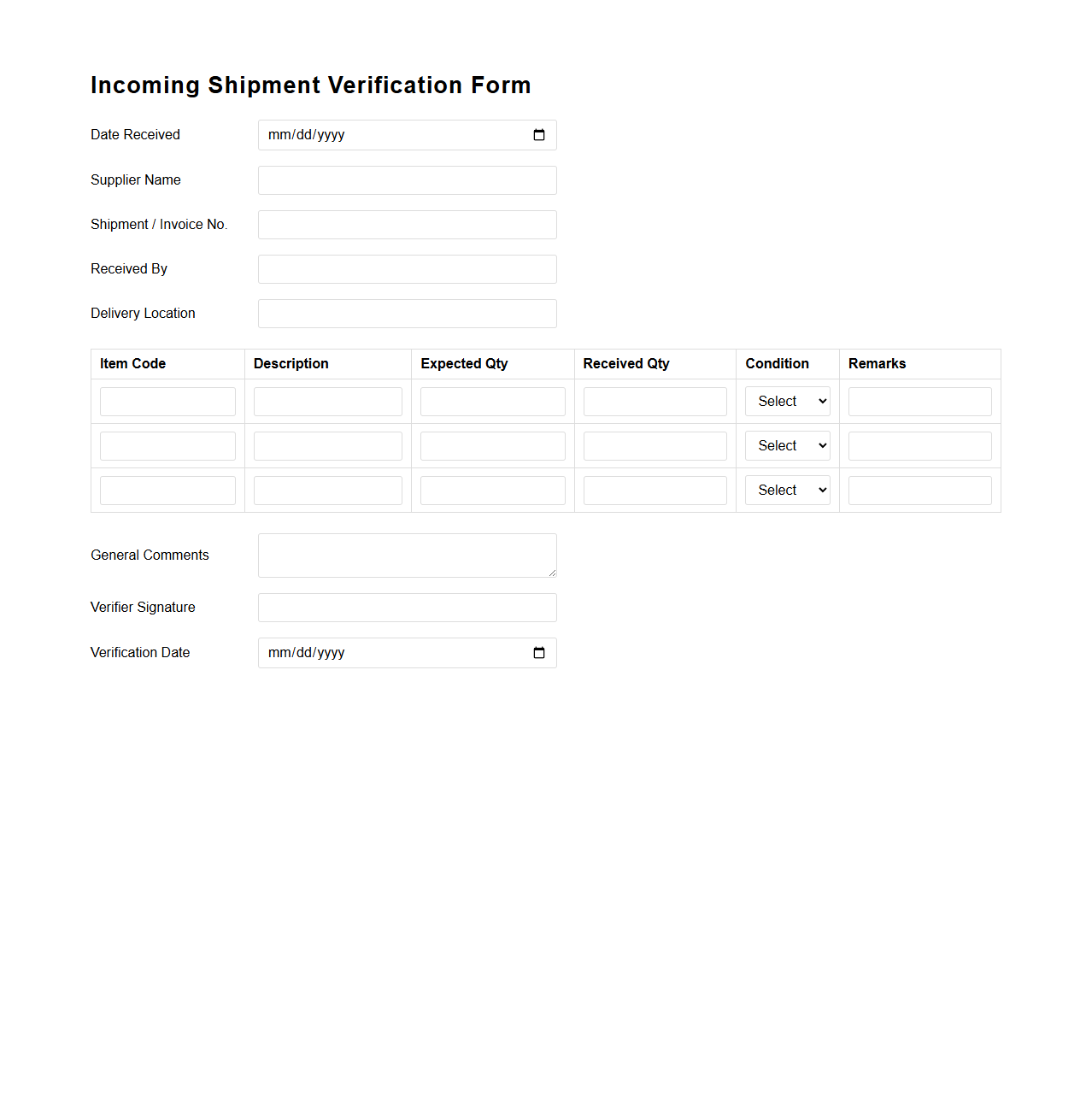

Incoming Shipment Verification Form for Retail

The

Incoming Shipment Verification Form for retail is a crucial document used to confirm and record the receipt of goods from suppliers. It includes detailed information such as product quantities, descriptions, and condition upon arrival to ensure accuracy against purchase orders. This form helps retailers maintain inventory integrity, prevent discrepancies, and streamline the receiving process.

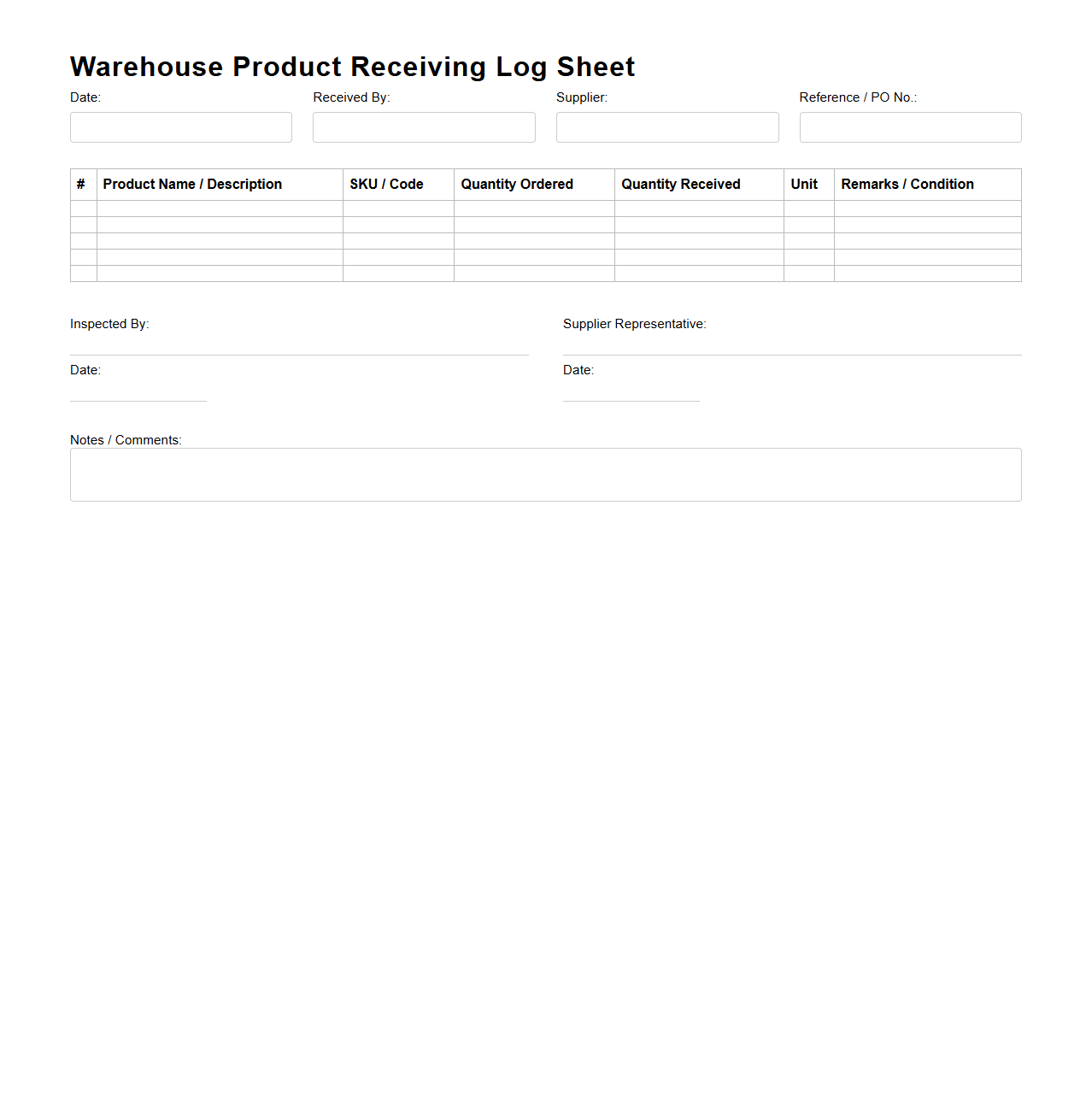

Warehouse Product Receiving Log Sheet

A

Warehouse Product Receiving Log Sheet document is a detailed record used to track the receipt of goods and inventory in a warehouse. It includes essential information such as product names, quantities, shipment dates, supplier details, and condition upon arrival, ensuring accuracy in inventory management. This log sheet helps streamline warehouse operations, reduce errors, and maintain accountability during the receiving process.

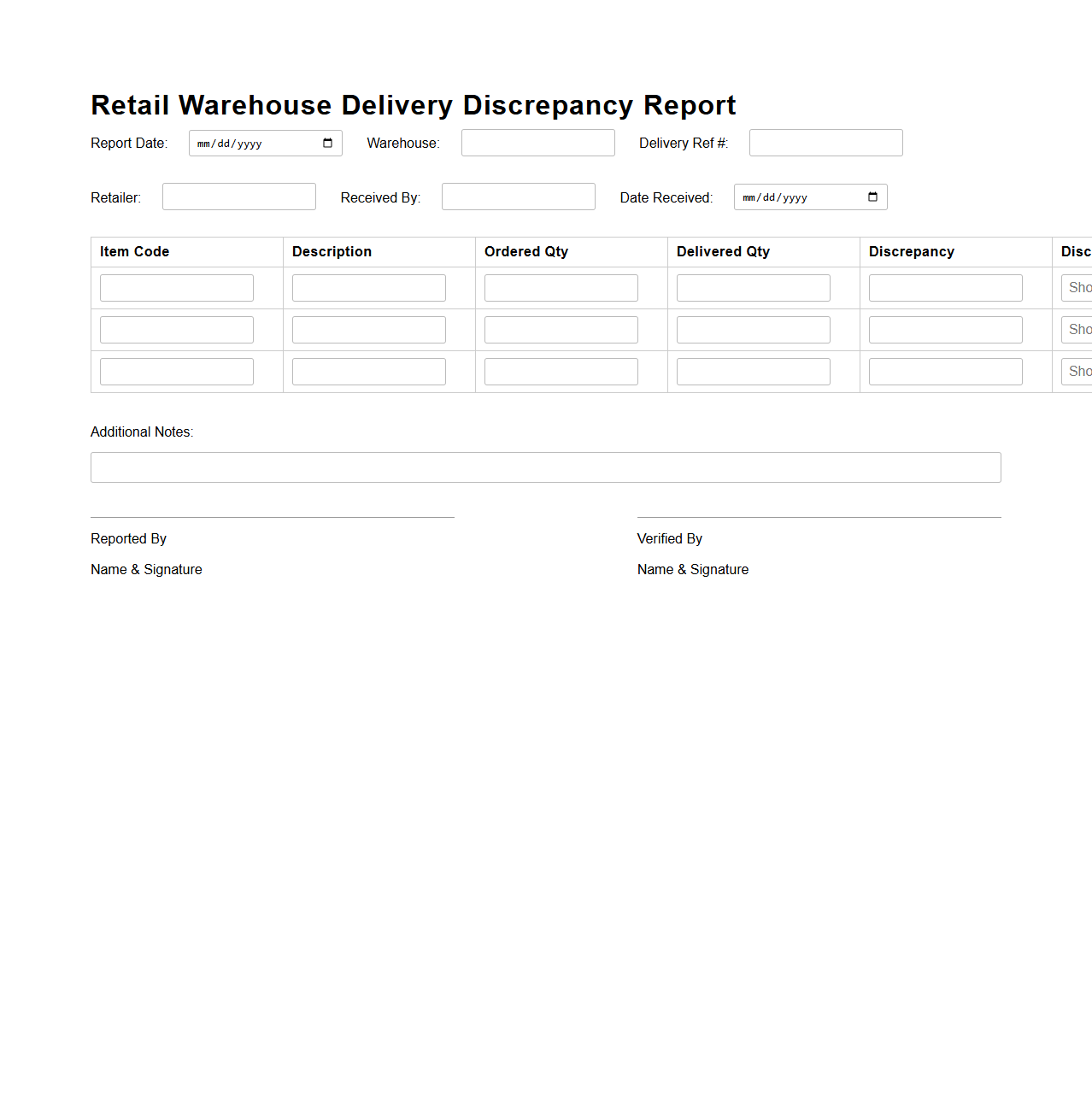

Retail Warehouse Delivery Discrepancy Report

The

Retail Warehouse Delivery Discrepancy Report document details inconsistencies between ordered and received goods at retail warehouses. It records variances in quantities, damaged items, or incorrect shipments to ensure accurate inventory management and supplier accountability. This report is essential for resolving delivery issues and maintaining supply chain efficiency.

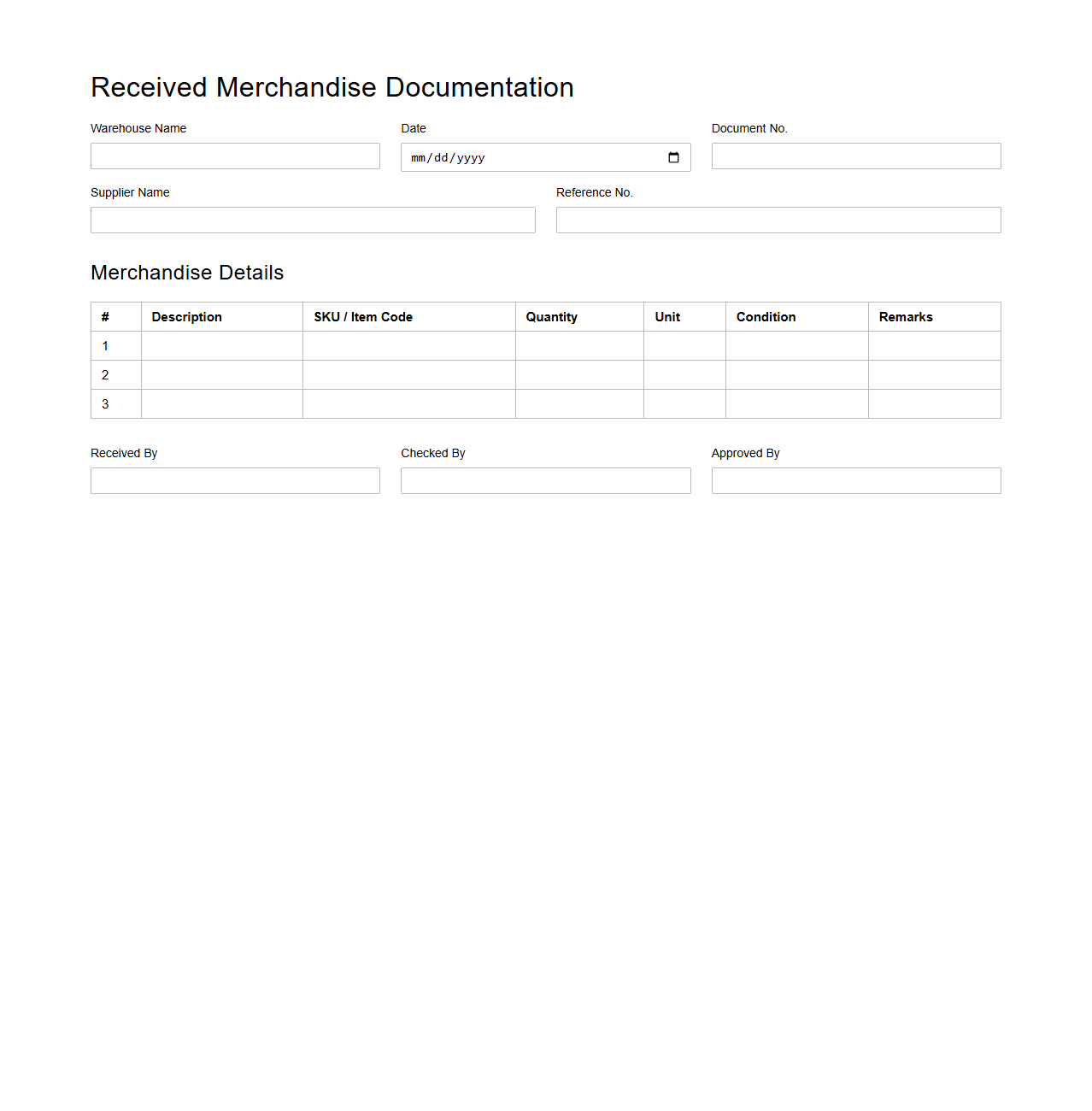

Received Merchandise Documentation for Retail Warehouse

Received Merchandise Documentation for Retail Warehouse is a critical record that verifies the acceptance and inspection of goods delivered to a warehouse, ensuring accuracy in inventory management. This document includes detailed information such as product descriptions, quantities received, shipment dates, and condition notes to facilitate seamless tracking and accountability. Maintaining accurate

Received Merchandise Documentation helps prevent discrepancies, supports audit compliance, and streamlines reorder processes.

What key information must be included in a retail warehouse goods receiving document?

The goods receiving document must include detailed product descriptions, quantities, and unit measures for accurate inventory management. It should clearly list the purchase order number and supplier details for verification purposes. Additionally, the date and time of the receipt are critical for maintaining precise records.

How does the sample document verify the quantity and condition of received goods?

The document uses a systematic counting and inspection process to verify quantities against purchase orders. It includes specific sections to record any physical condition notes such as damages or defects upon arrival. This ensures that discrepancies between expected and received items are identified immediately.

What fields or sections are present for documenting discrepancies or damages?

There are dedicated fields labeled "Discrepancies" and "Damages" to record any irregularities during the receiving process. These sections allow staff to note the nature and extent of any issues with the shipment. This documentation is essential for resolving claims and supplier communication.

How does the sample ensure traceability of suppliers and delivery dates?

The document includes fields for the supplier's name, contact details, and delivery date to maintain full traceability. It often includes a unique reference number that links the received goods back to the original purchase order. This traceability supports efficient audit trails and accountability.

What signatures or authorizations are required to complete the goods receiving process?

The goods receiving document typically requires signatures from the warehouse receiver and a supervisor or quality control manager to authorize receipt. These signatures confirm that the goods have been inspected and accepted as per standards. Additionally, the supplier's delivery personnel may also sign to acknowledge handover.