An Inventory Adjustment Document Sample for Retail Store serves as a vital tool for accurately recording changes in stock levels due to discrepancies, damages, or theft. This document helps maintain precise inventory records by detailing adjustments with specific item information, quantities, and reasons for changes. Effective use of this sample ensures improved inventory control and operational efficiency in retail management.

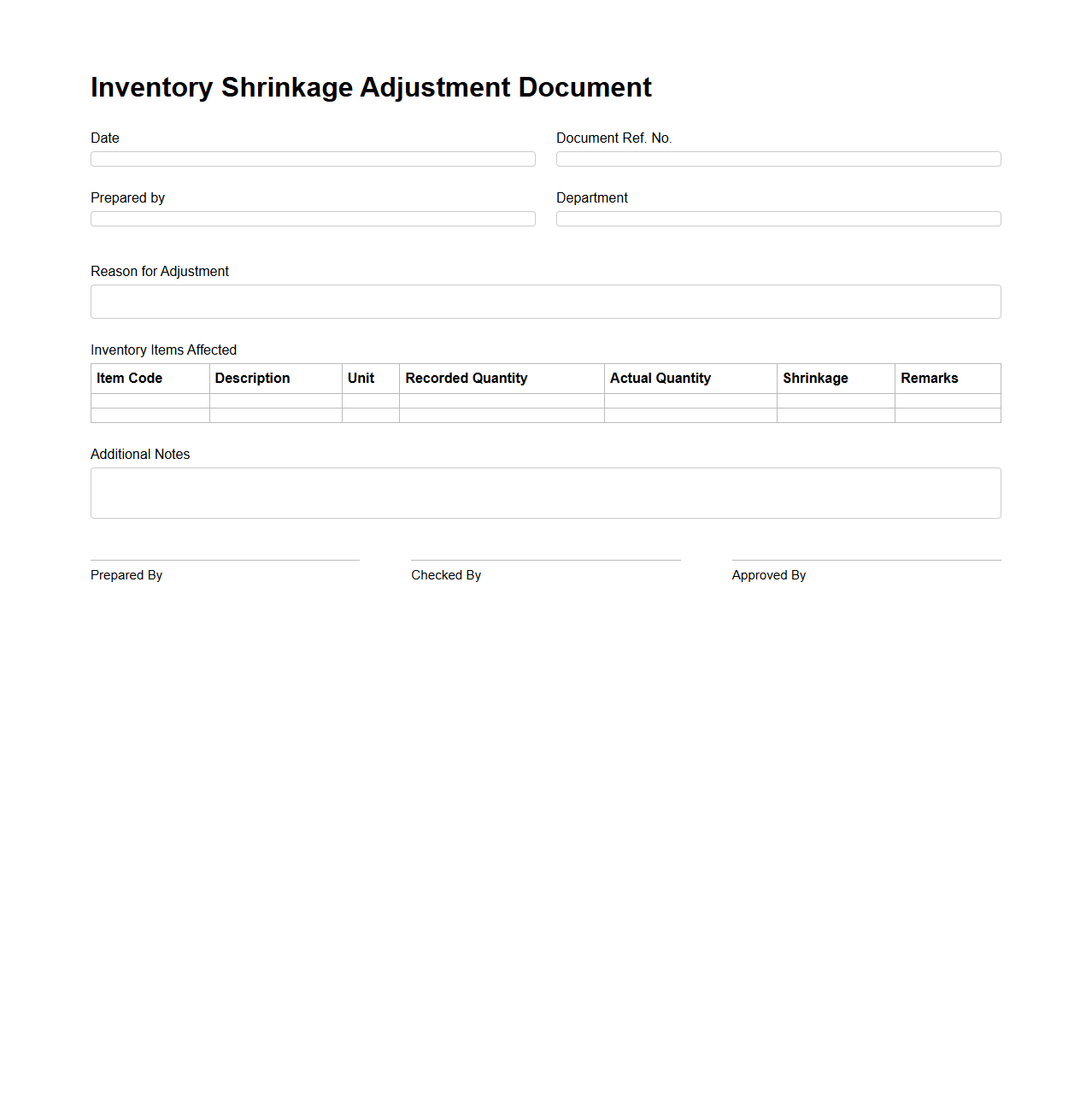

Sample Inventory Shrinkage Adjustment Document

The

Sample Inventory Shrinkage Adjustment Document serves as a formal record outlining discrepancies between recorded inventory levels and actual physical counts. It details the quantity and value adjustments necessary to reconcile inventory records, accounting for losses due to theft, damage, or errors. This document is essential for accurate financial reporting and maintaining inventory accuracy.

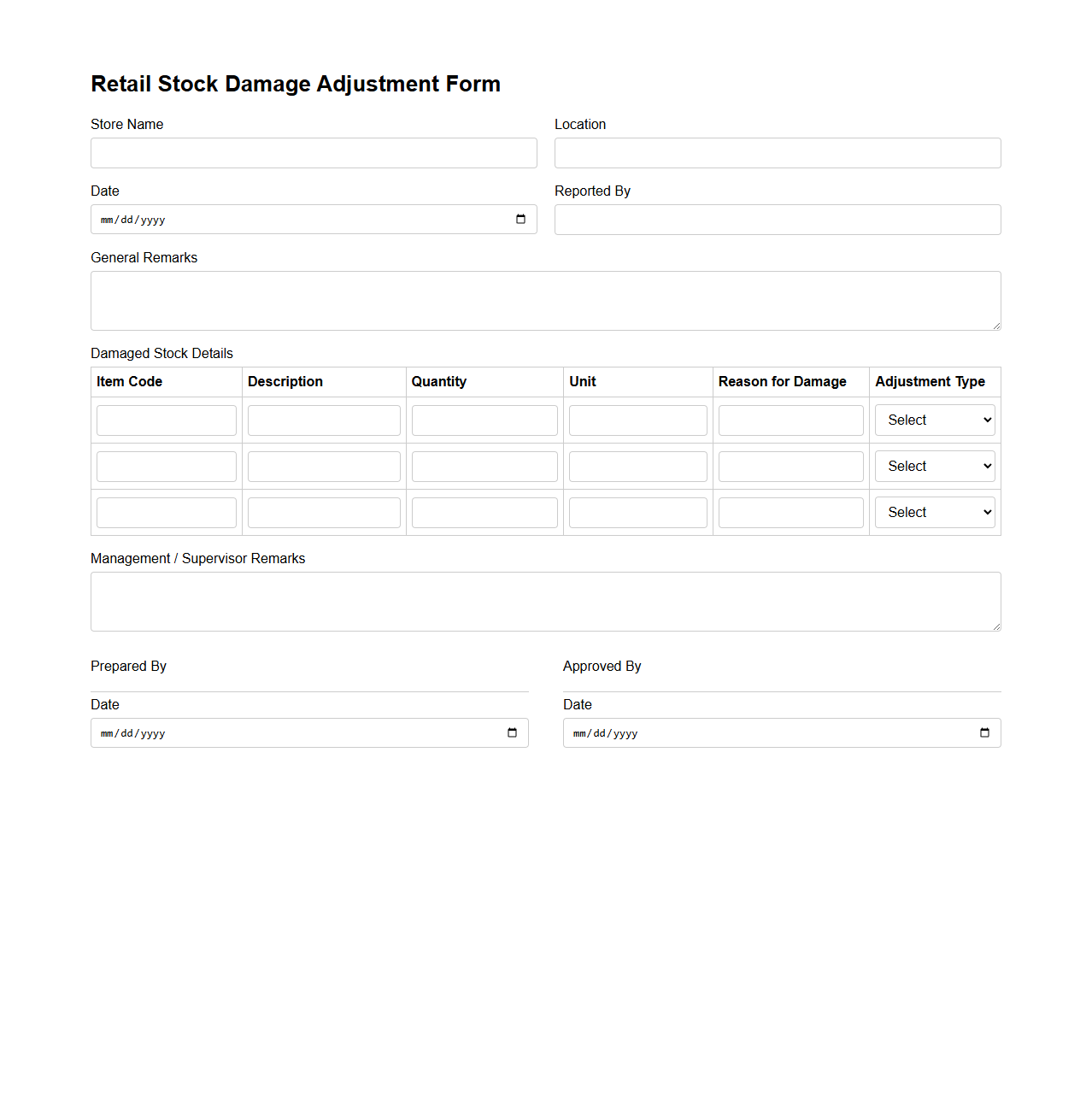

Retail Stock Damage Adjustment Form

The

Retail Stock Damage Adjustment Form is a document used by retail businesses to record and authorize adjustments for damaged inventory items. It details the type, quantity, and cause of damage, enabling accurate stock level updates and financial reporting. This form helps maintain inventory accuracy and supports accountability in loss management processes.

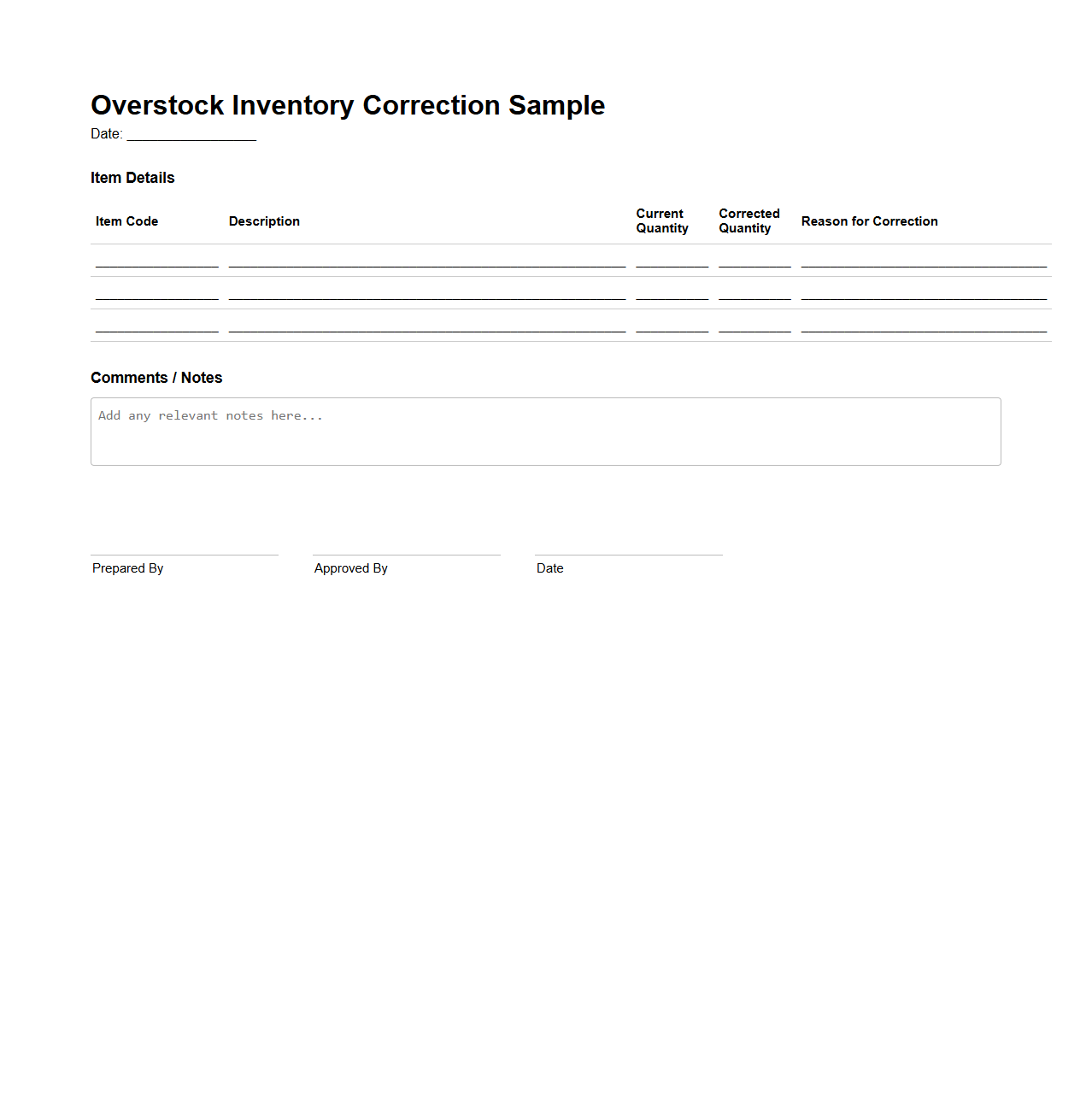

Overstock Inventory Correction Sample

An

Overstock Inventory Correction Sample document serves as a standardized template to record adjustments made to excess inventory levels in retail or warehouse management. It includes detailed information such as product identification, quantity corrected, reason for correction, and approval signatures to ensure accurate stock records. This document helps maintain inventory accuracy, minimize carrying costs, and improve supply chain efficiency.

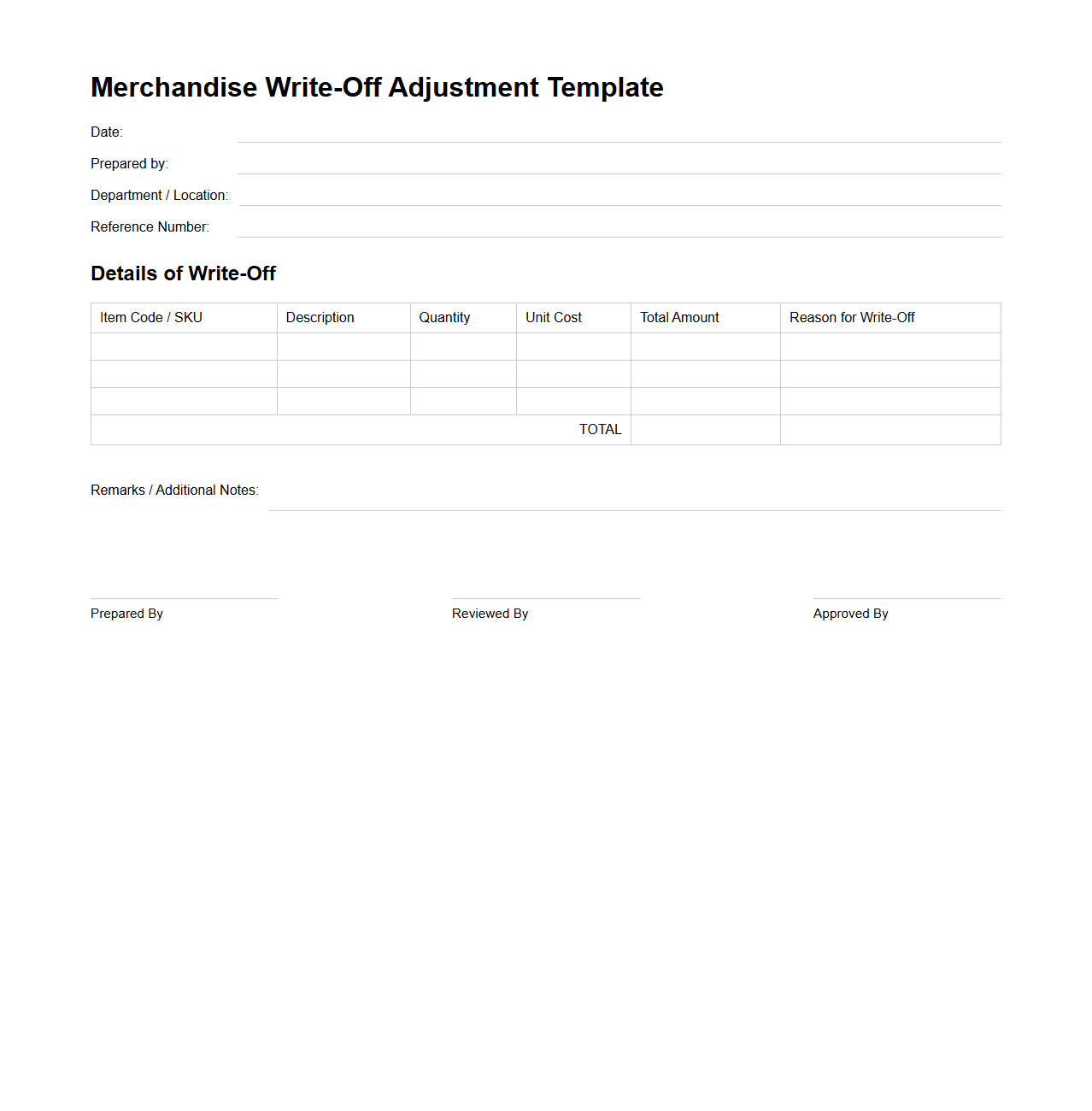

Merchandise Write-Off Adjustment Template

The

Merchandise Write-Off Adjustment Template document is used to systematically record and adjust inventory write-offs due to damage, theft, or obsolescence. It helps maintain accurate financial records by documenting the value and quantity of merchandise removed from inventory. This template ensures compliance with accounting standards and supports effective inventory management and auditing processes.

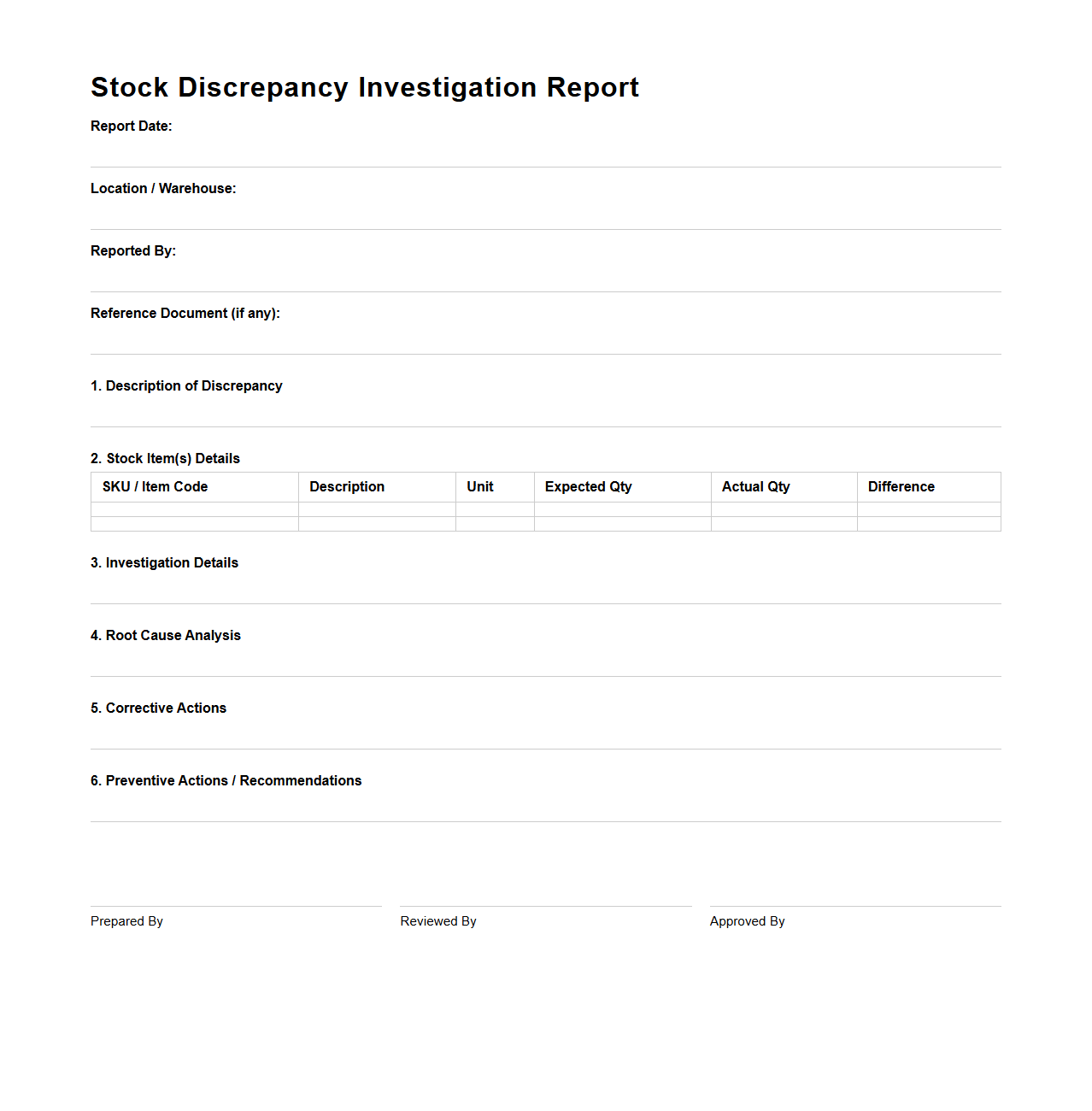

Stock Discrepancy Investigation Report

A

Stock Discrepancy Investigation Report document details the analysis and findings related to inconsistencies between recorded inventory levels and actual stock counts. It identifies causes such as theft, damage, misplacement, or data entry errors, providing actionable insights to rectify discrepancies. This report is essential for maintaining accurate inventory control and optimizing supply chain management.

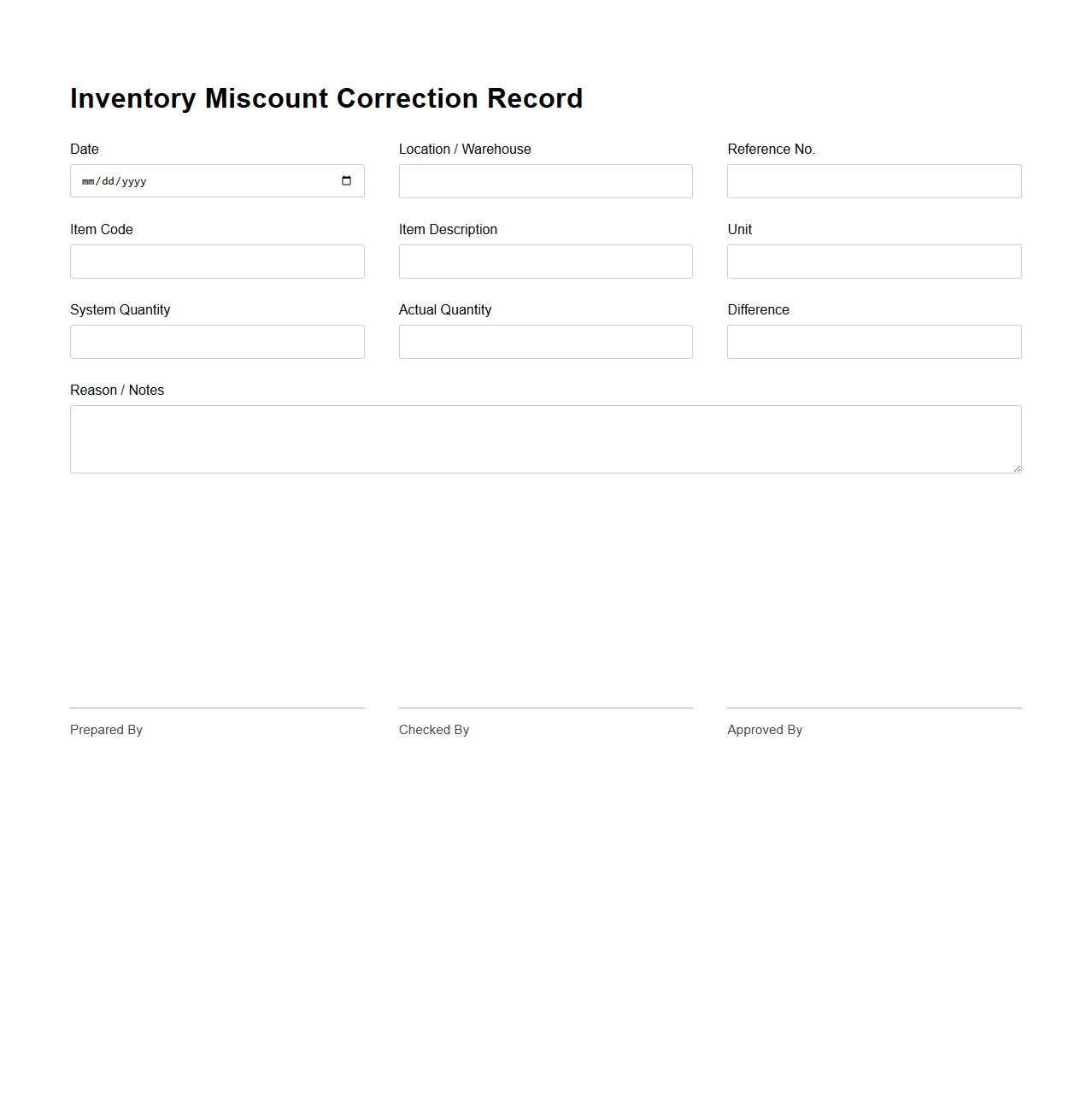

Inventory Miscount Correction Record

The

Inventory Miscount Correction Record document is a crucial tool used to identify and rectify discrepancies between physical inventory counts and recorded stock levels. It records detailed information about miscounts, including item descriptions, quantities corrected, reasons for discrepancies, and approval signatures, ensuring accurate inventory management. This document helps maintain data integrity, supports audit trails, and prevents potential financial losses due to inventory inaccuracies.

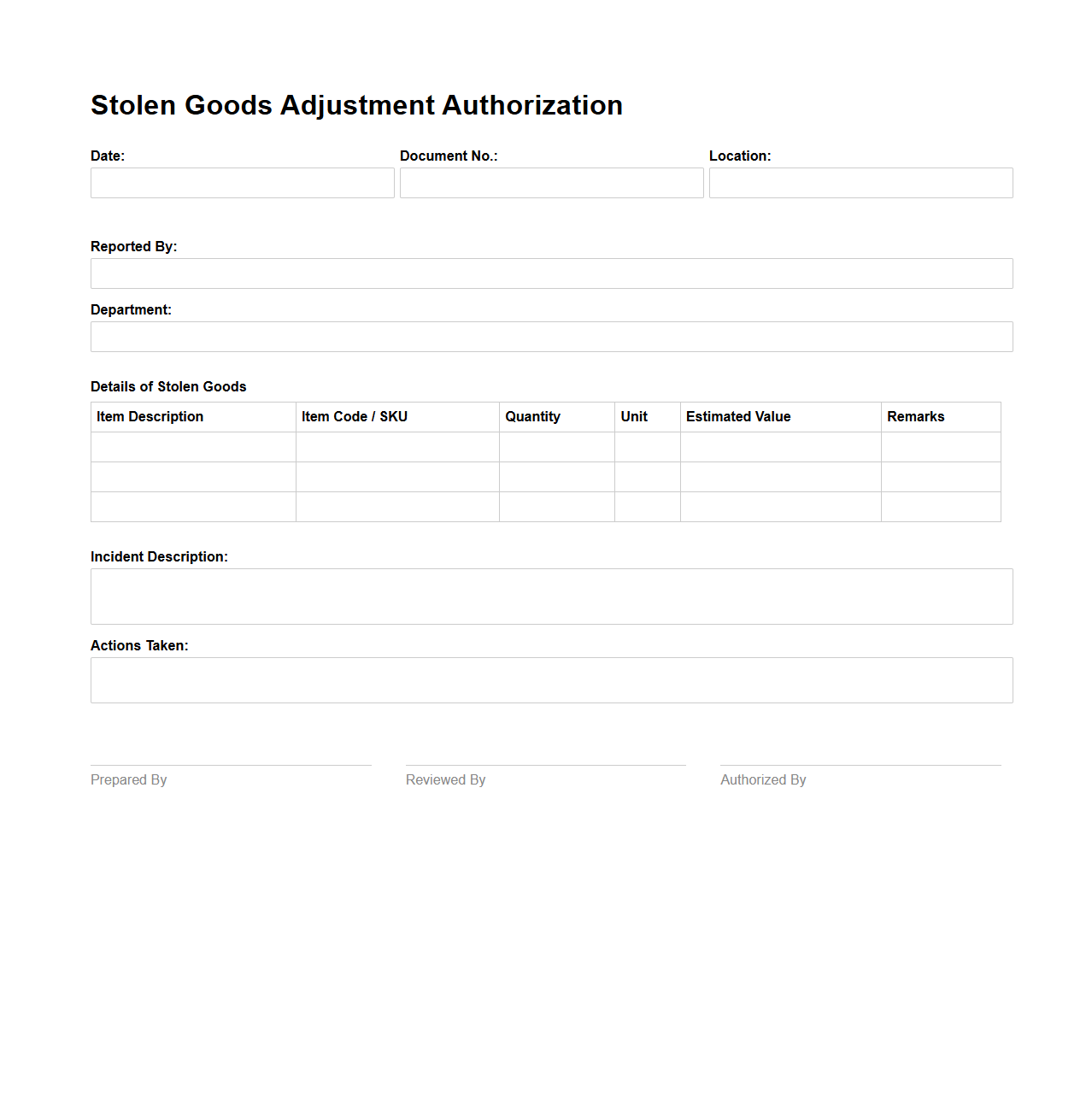

Stolen Goods Adjustment Authorization

A

Stolen Goods Adjustment Authorization document is an official form used by businesses to approve and process adjustments related to inventory items reported as stolen. It serves as proof for accounting departments to validate write-offs or corrections in financial records, ensuring accurate tracking of losses. This document typically includes details such as item descriptions, quantities, estimated values, and approval signatures.

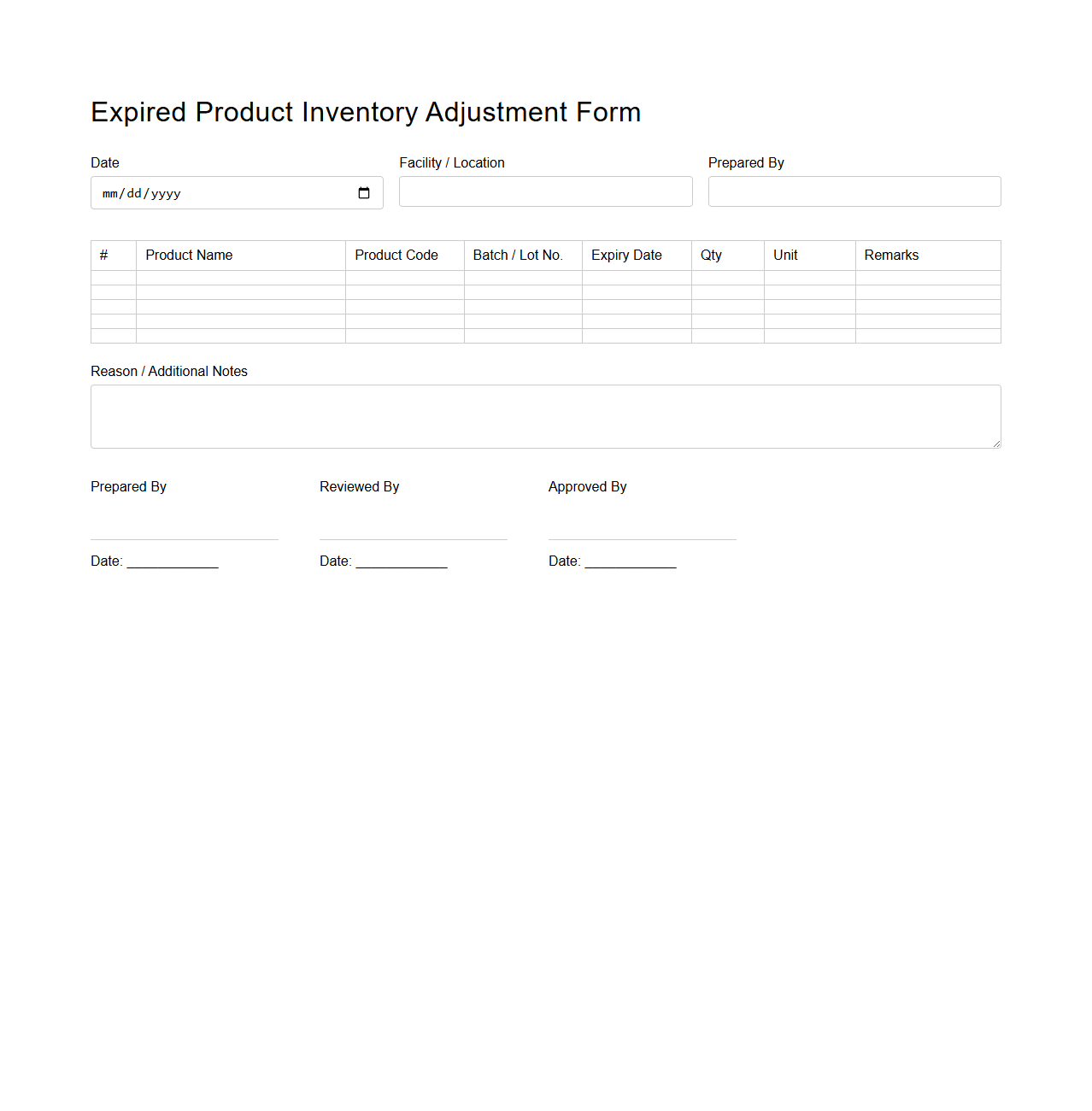

Expired Product Inventory Adjustment Form

The

Expired Product Inventory Adjustment Form is a critical document used to record and authorize the removal or adjustment of inventory items that have passed their expiration date. It ensures accurate inventory management by reflecting changes in stock levels due to expired goods, helping prevent the sale or distribution of unsafe products. This form supports compliance with regulatory standards and internal auditing processes by providing a traceable record of expired product handling.

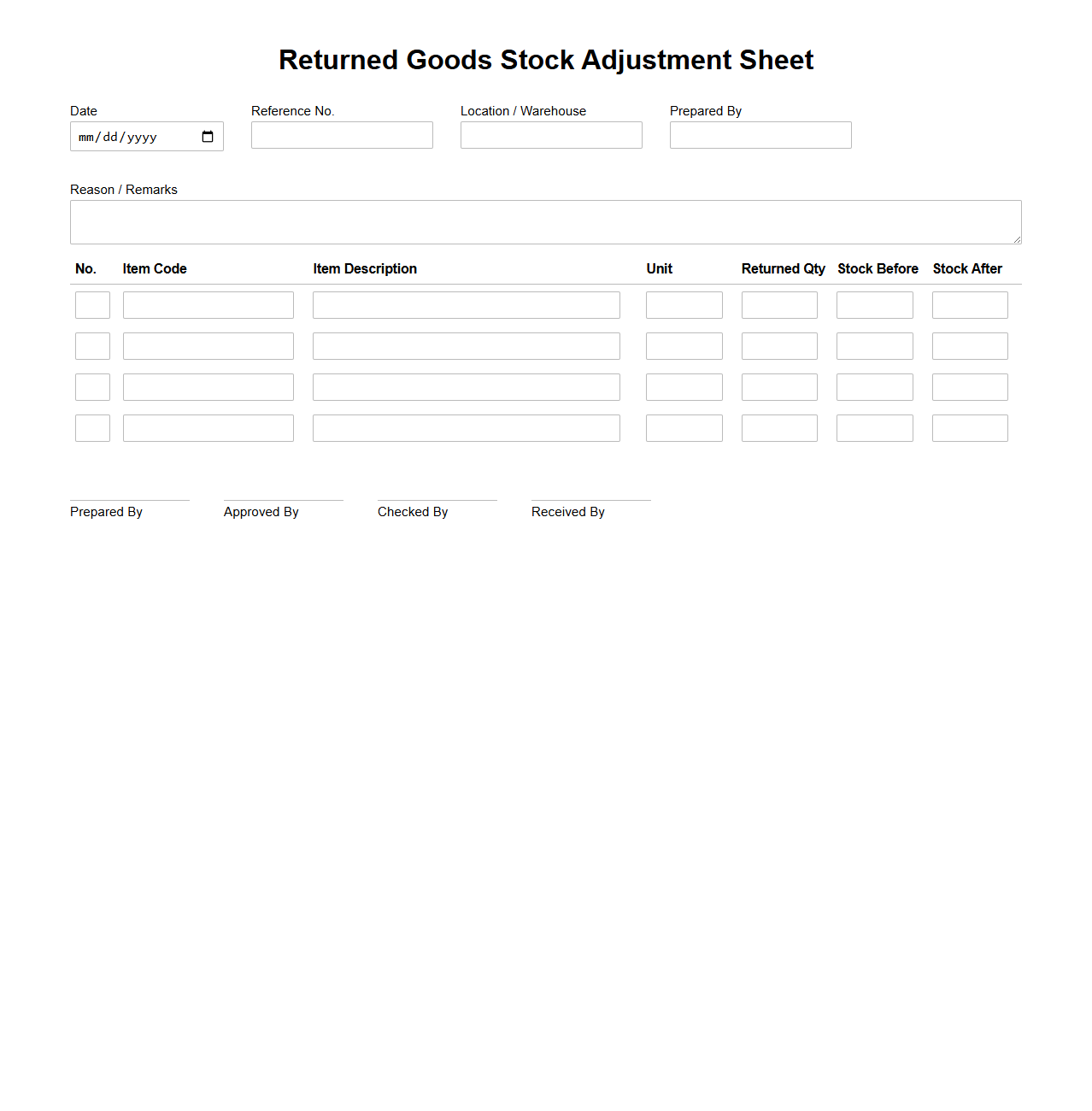

Returned Goods Stock Adjustment Sheet

The

Returned Goods Stock Adjustment Sheet document is used to record and track inventory changes when goods are returned by customers or suppliers, ensuring accurate stock levels are maintained. It details the quantities, reasons for return, and any necessary adjustments to inventory records, aiding in effective stock management and financial reconciliation. This document plays a crucial role in minimizing discrepancies and improving inventory accuracy in supply chain operations.

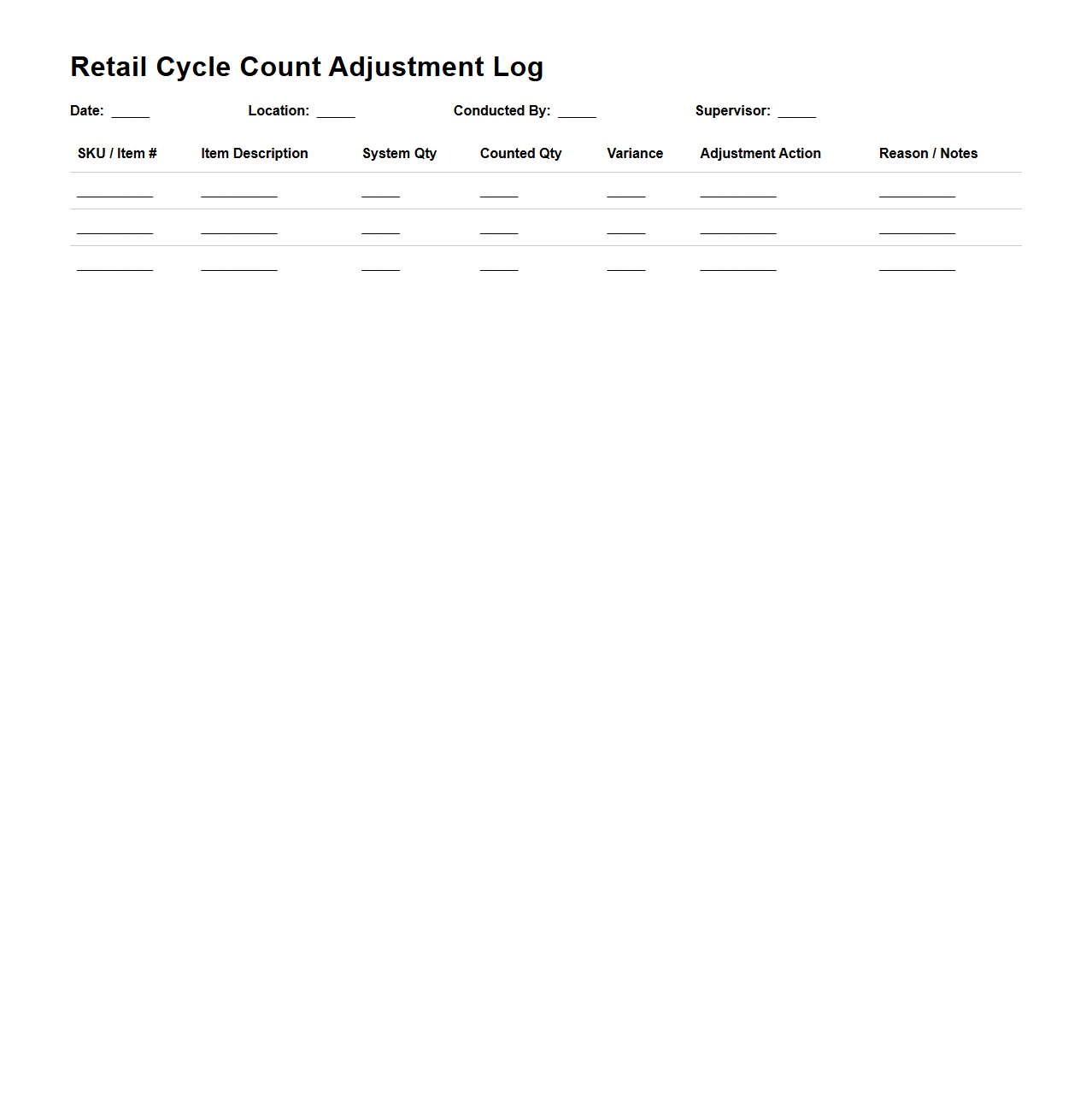

Retail Cycle Count Adjustment Log

The

Retail Cycle Count Adjustment Log document records discrepancies identified during inventory cycle counts in retail environments, tracking any adjustments made to stock levels for accuracy. It provides a detailed audit trail of count dates, item details, quantity variances, and reasons for changes, ensuring inventory integrity and accountability. This log is essential for maintaining precise stock data, facilitating effective inventory management, and minimizing shrinkage in retail operations.

What is the primary purpose of an Inventory Adjustment Document in a retail store?

The primary purpose of an Inventory Adjustment Document is to accurately record changes made to inventory levels. It helps ensure that stock counts are updated in real-time, reflecting loss, damage, or surplus. This document is essential for maintaining inventory accuracy and financial integrity in retail operations.

Which key data fields are typically included in a sample Inventory Adjustment Document?

A sample Inventory Adjustment Document usually includes item identification, quantity adjusted, and reason for adjustment. Additional fields often cover date, location, and the personnel responsible for the change. These fields provide a comprehensive record to track adjustments effectively.

How does the document classify the reasons for inventory adjustments (e.g., damage, loss, overage)?

The document uses predefined categories such as damage, loss, overage, or theft to classify the reasons for adjustments. These classifications help in analyzing inventory discrepancies and improving future stock management. Proper categorization ensures that the root causes of adjustments are identified clearly.

Who has the authority to approve and finalize inventory adjustments in the document sample?

The inventory manager or supervisor typically holds the authority to approve and finalize adjustments. This approval process adds a layer of accountability and validation. It ensures that all changes are verified before updating the inventory records officially.

How does the document track the before-and-after quantities of adjusted inventory items?

The document records both the original quantity and the updated quantity post-adjustment for each item. This comparison allows for clear tracking of stock changes over time. Maintaining these records supports audit trails and inventory reconciliation processes.