A Maintenance Log Document Sample for Industrial Automation Systems provides a standardized format to record routine inspections, repairs, and system updates, ensuring consistent tracking of equipment performance. This document helps in identifying patterns of failure, scheduling preventive maintenance, and improving system reliability. Proper documentation supports compliance with industry standards and enhances operational efficiency.

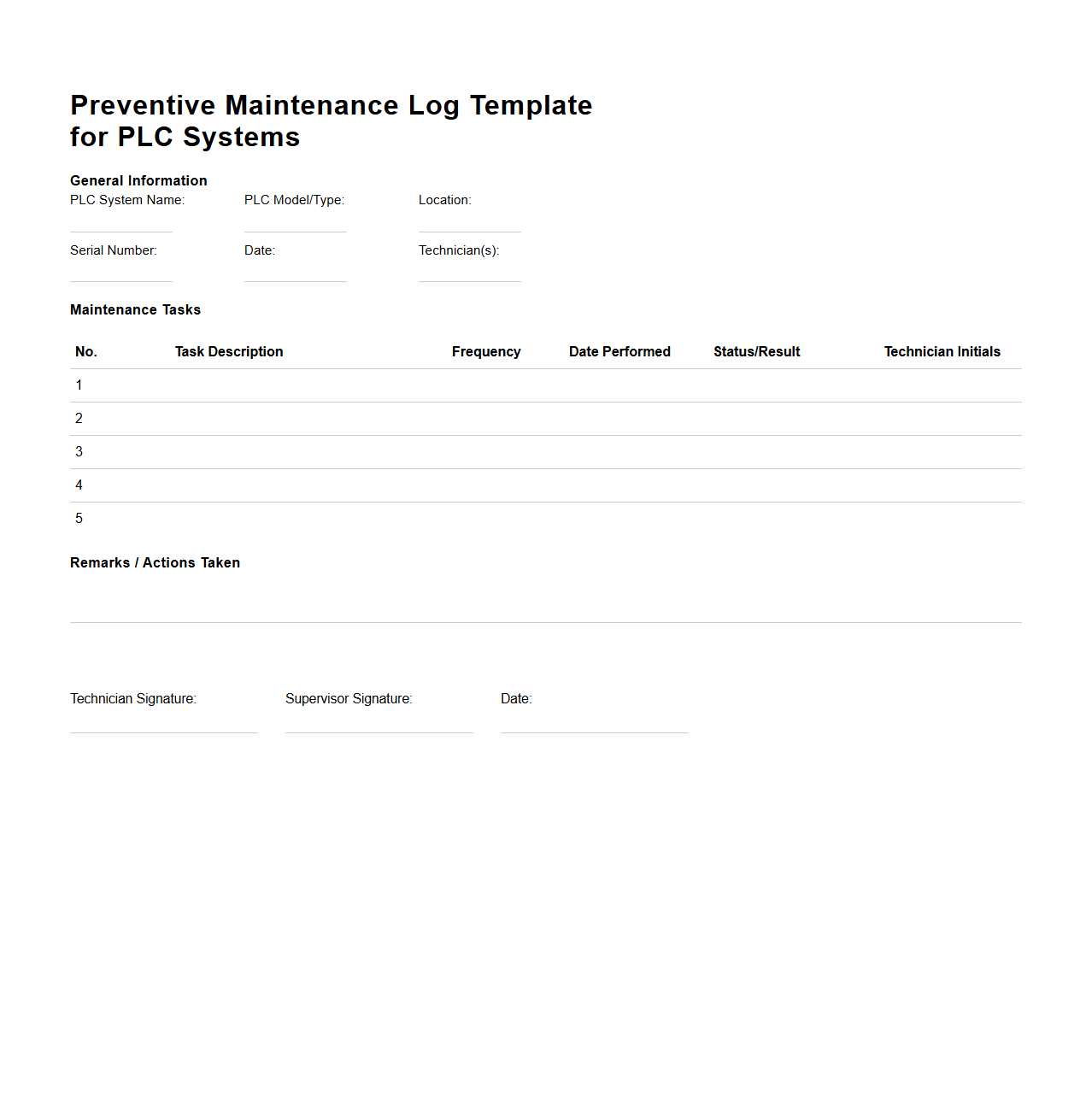

Preventive Maintenance Log Template for PLC Systems

A

Preventive Maintenance Log Template for PLC Systems document is designed to systematically track and record routine maintenance activities performed on Programmable Logic Controllers (PLC). This template helps ensure consistent inspection, cleaning, and testing of PLC components to prevent unexpected failures and extend equipment lifespan. By documenting maintenance tasks, dates, and technician observations, it supports operational efficiency and minimizes downtime in automated industrial processes.

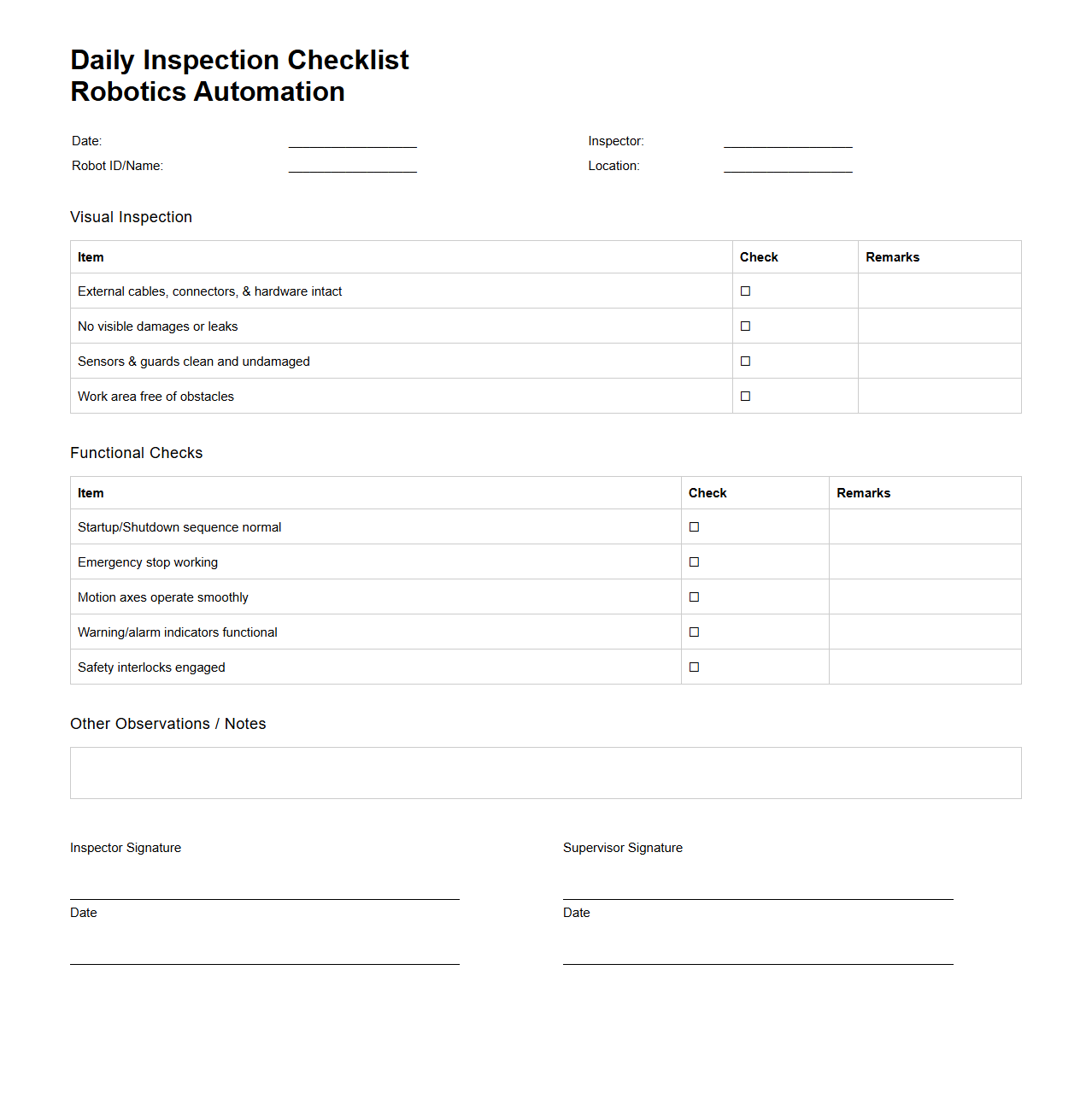

Daily Inspection Checklist for Robotics Automation

A

Daily Inspection Checklist for Robotics Automation document is a structured guide used to ensure the proper functioning and safety of robotic systems through routine evaluations. It includes critical inspection points such as mechanical integrity, sensor calibration, software performance, and safety interlocks, helping to identify potential issues before they lead to downtime or hazards. Maintaining this checklist supports operational efficiency and compliance with industry safety standards.

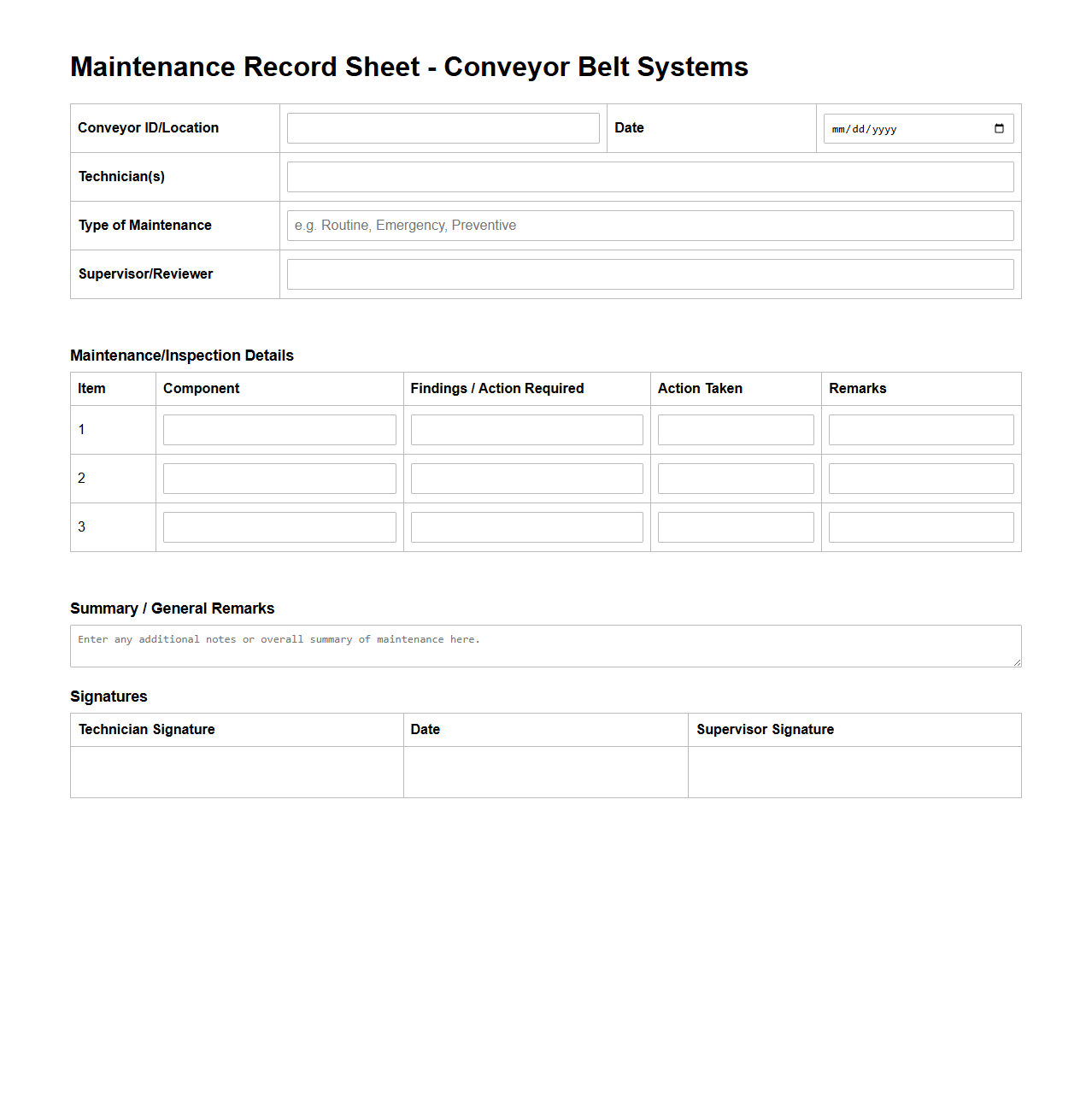

Maintenance Record Sheet for Conveyor Belt Systems

A

Maintenance Record Sheet for Conveyor Belt Systems documents all scheduled inspections, repairs, and upkeep activities to ensure optimal performance and longevity of the equipment. It includes detailed entries on component replacements, lubrication schedules, belt tension adjustments, and any identified issues to facilitate proactive maintenance. This record serves as a critical tool for tracking system health, minimizing downtime, and supporting compliance with safety and operational standards.

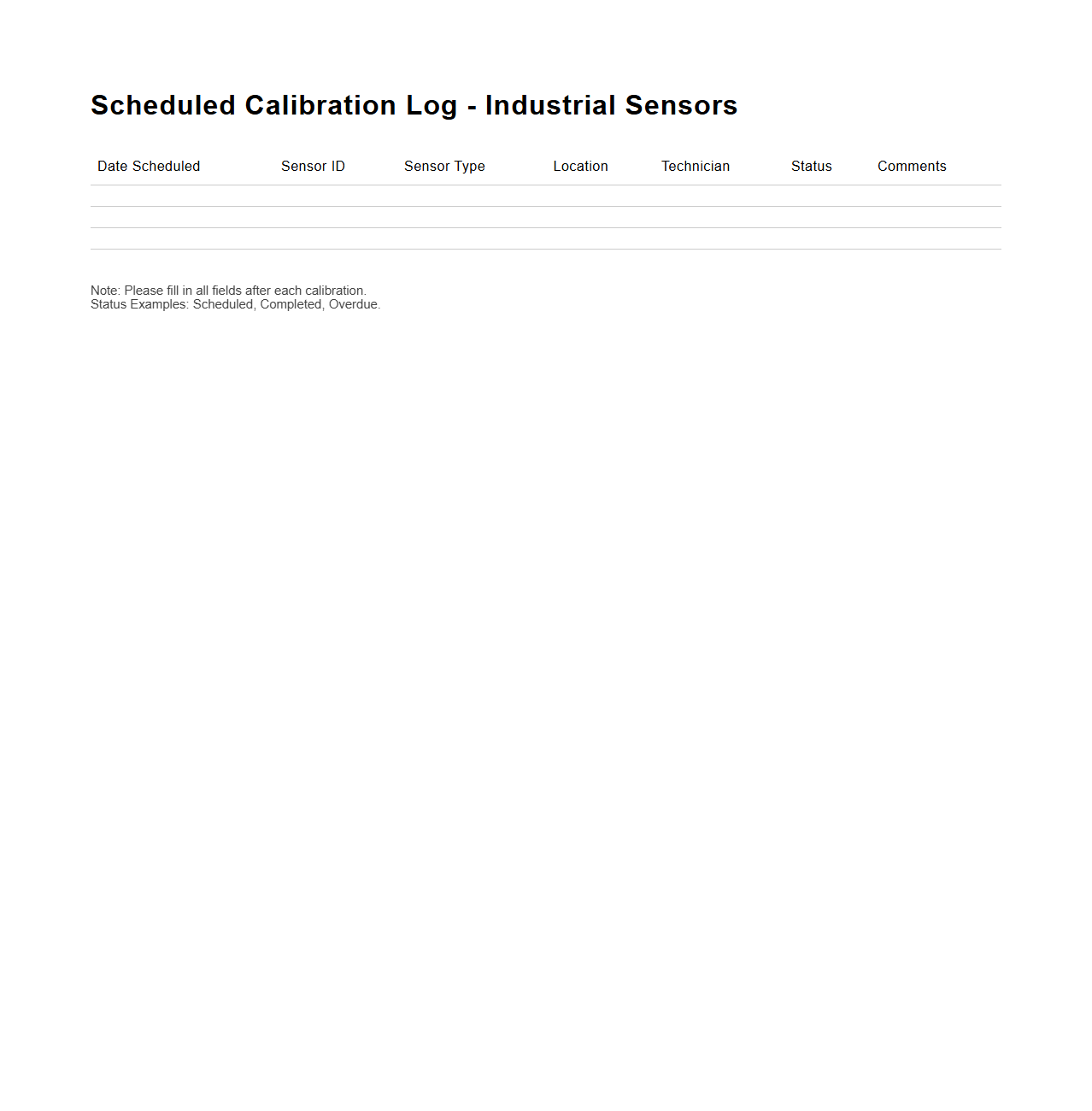

Scheduled Calibration Log for Industrial Sensors

The

Scheduled Calibration Log for Industrial Sensors document systematically records calibration activities, ensuring sensors maintain accuracy and reliability in industrial operations. It includes details such as calibration dates, sensor identification numbers, technician information, calibration results, and next scheduled calibration. This log supports regulatory compliance, quality control, and predictive maintenance planning in manufacturing environments.

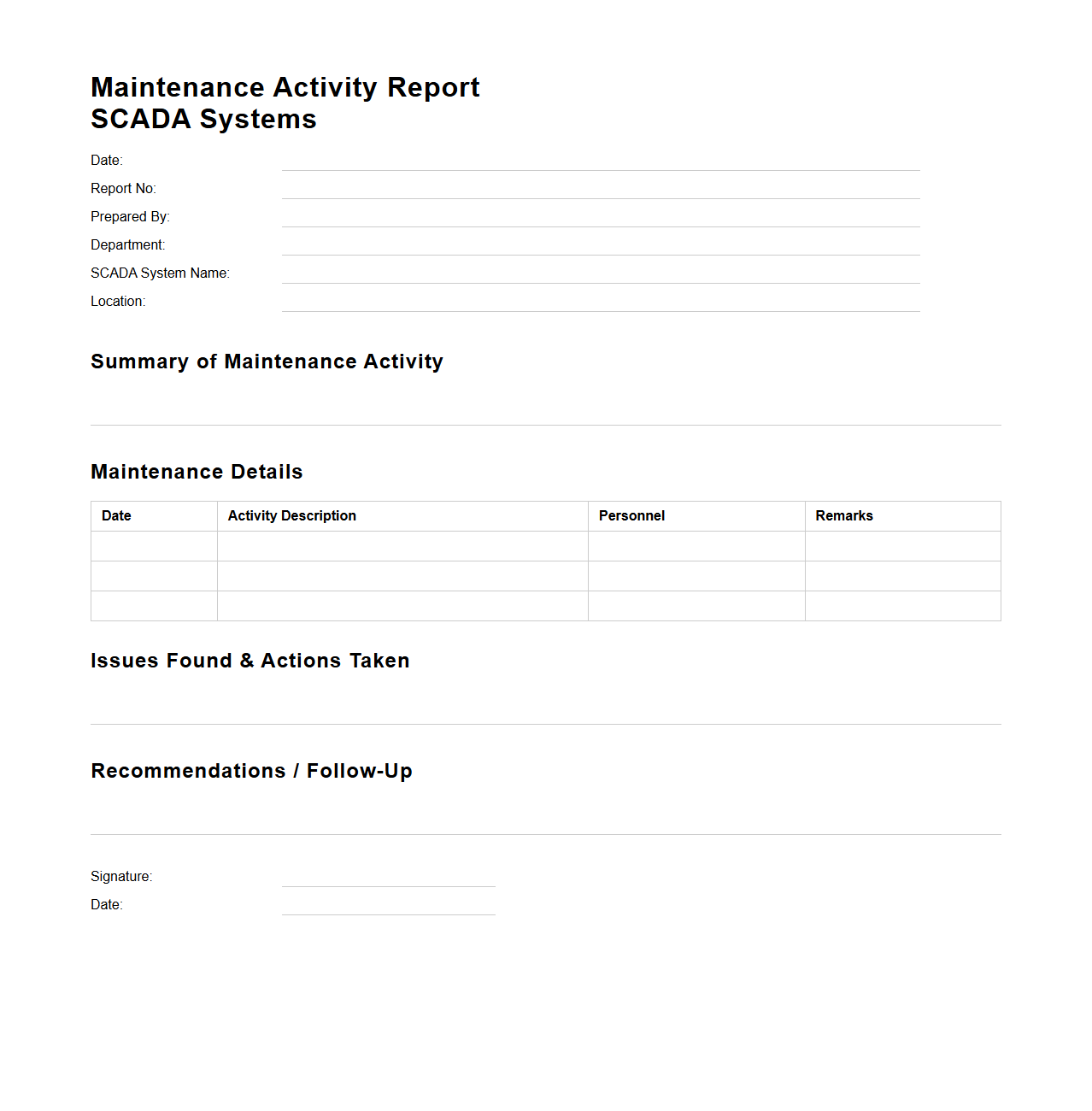

Maintenance Activity Report for SCADA Systems

The

Maintenance Activity Report for SCADA Systems document provides a detailed log of all maintenance tasks performed to ensure the reliability and efficiency of Supervisory Control and Data Acquisition (SCADA) systems. It includes records of system inspections, software updates, hardware repairs, and any corrective actions taken to prevent downtime. This report is essential for tracking system health, facilitating troubleshooting, and optimizing performance over time.

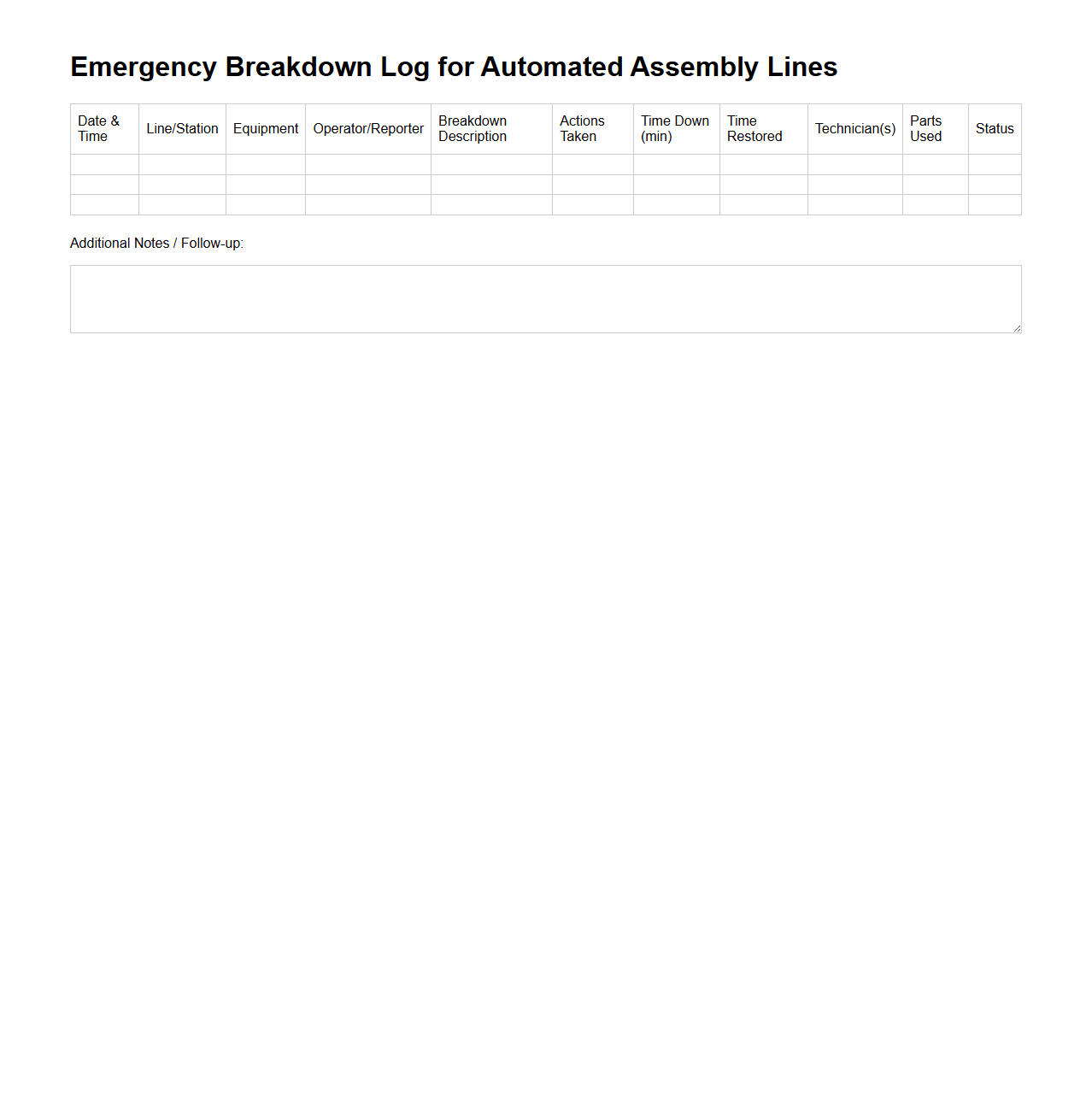

Emergency Breakdown Log for Automated Assembly Lines

The

Emergency Breakdown Log for Automated Assembly Lines document records detailed incidents of machine failures and operational disruptions, providing critical data for troubleshooting and maintenance scheduling. It includes timestamps, affected machinery, error codes, and immediate corrective actions taken to minimize downtime. This log enhances process reliability by facilitating quick response and root cause analysis in automated manufacturing environments.

Lubrication Maintenance Tracker for Industrial Machinery

The

Lubrication Maintenance Tracker for Industrial Machinery document is an essential tool designed to monitor and record lubrication schedules, types, and quantities used on various mechanical components. It helps ensure optimal machine performance, reduce wear and tear, and prevent unexpected breakdowns by maintaining consistent lubrication practices. This document supports maintenance teams in extending equipment lifespan and improving operational efficiency through systematic tracking and timely interventions.

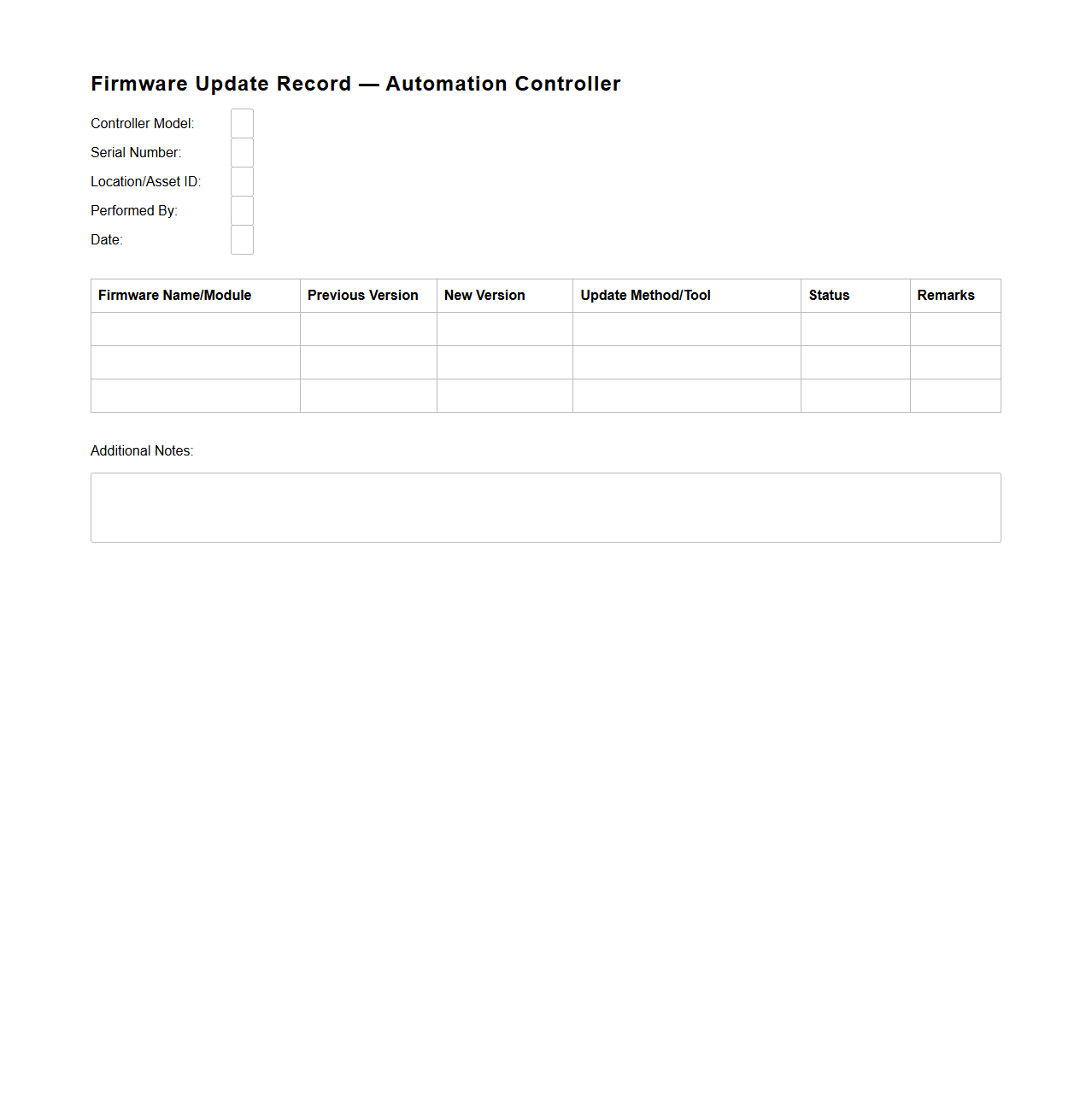

Firmware Update Record for Automation Controllers

The

Firmware Update Record for Automation Controllers document serves as a detailed log of all firmware revisions applied to a specific automation controller, including version numbers, update dates, and change summaries. This record is critical for ensuring traceability, maintaining system reliability, and supporting troubleshooting efforts in industrial automation environments. It provides engineers and technicians with a reliable reference to verify firmware integrity and compliance with operational standards.

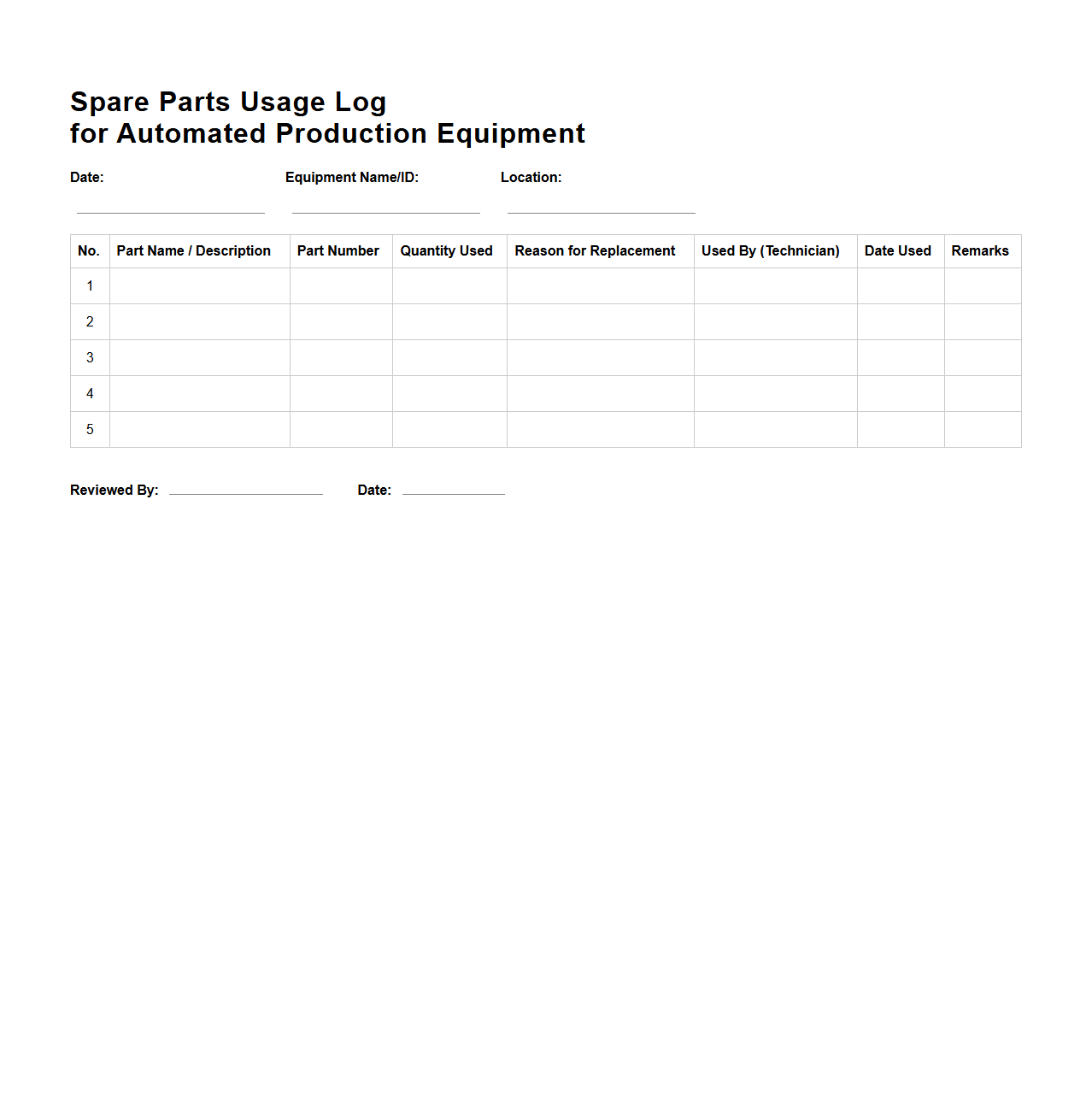

Spare Parts Usage Log for Automated Production Equipment

A

Spare Parts Usage Log for Automated Production Equipment is a detailed record that tracks the consumption and replacement of parts used in machinery. This document ensures efficient inventory management, helping to prevent production downtime by maintaining an accurate account of parts usage patterns. Regularly updating the log supports predictive maintenance and optimizes procurement processes.

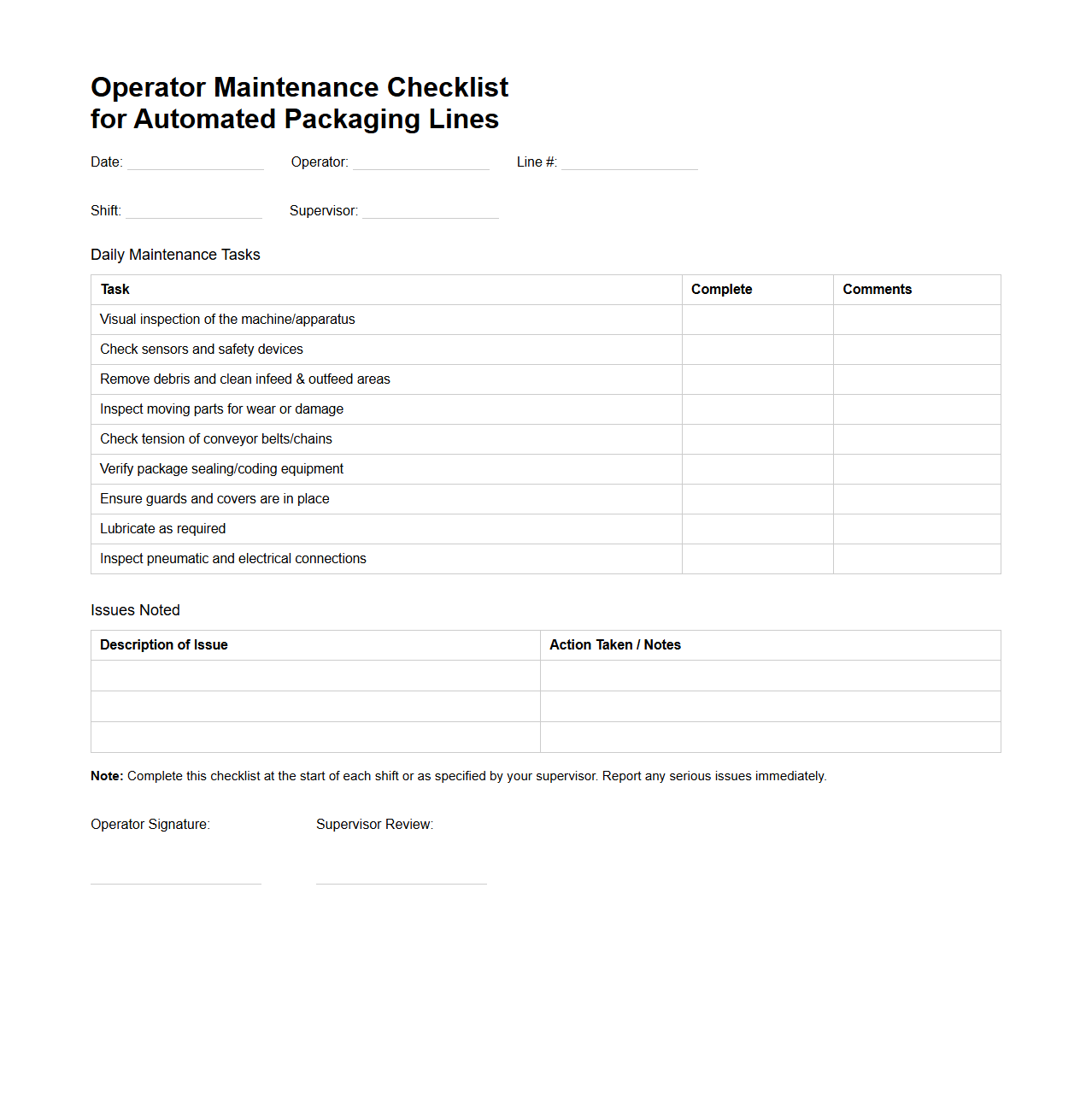

Operator Maintenance Checklist for Automated Packaging Lines

The

Operator Maintenance Checklist for Automated Packaging Lines document is a structured tool designed to guide operators through routine inspection and upkeep tasks to ensure optimal functioning of packaging machinery. It details critical maintenance activities such as lubrication, cleaning, and component checks to prevent downtime and extend equipment lifespan. Accurate and consistent use of this checklist supports operational efficiency and reduces the risk of costly mechanical failures in automated packaging environments.

What critical data fields should a maintenance log document capture for PLC troubleshooting?

A maintenance log for PLC troubleshooting must capture essential data fields like the date and time of the issue, the specific PLC module involved, and detailed error codes. Including the technician's name and actions taken during troubleshooting enhances accountability and traceability. Capturing these fields ensures efficient diagnostics and historical reference for future maintenance activities.

How does version control work in maintenance logs for firmware updates?

Version control in maintenance logs for firmware updates records the firmware version number and the exact date and time of the update. It also tracks who performed the update and any associated change notes or rollback procedures. This systematic documentation helps maintain consistency and traceability during system upgrades and troubleshooting phases.

Which standardized formats optimize traceability in industrial automation maintenance logs?

Standardized formats such as ISO 55000 and ISA-95 optimize traceability by providing consistent, structured maintenance log templates. These formats facilitate clear documentation of asset history, maintenance activities, and system status. Adopting such standards improves interoperability and audit readiness across industrial automation systems.

How can predictive maintenance triggers be documented within log entries?

Documenting predictive maintenance triggers in log entries involves recording sensor data trends, alert conditions, and predictive analytics results that signal potential failures. Logs should clearly note the trigger criteria, timestamps, and any preventive actions taken. Proper documentation enables proactive maintenance and reduces unexpected downtime.

What compliance requirements affect recorded procedures in automation system maintenance logs?

Compliance requirements such as FDA 21 CFR Part 11 and IEC 62304 mandate secure, timestamped, and tamper-evident maintenance log records. These standards ensure data integrity, traceability, and accountability in automation system procedures. Meeting these requirements is crucial for regulatory audits and maintaining system certification.

More Technology Templates