A Machine Calibration Record Document Sample for Manufacturing provides a detailed log of the calibration activities performed on manufacturing equipment to ensure accuracy and consistency. This document includes essential information such as calibration dates, technician details, equipment identification, and measurement results. Maintaining precise calibration records is critical for quality control and regulatory compliance in manufacturing processes.

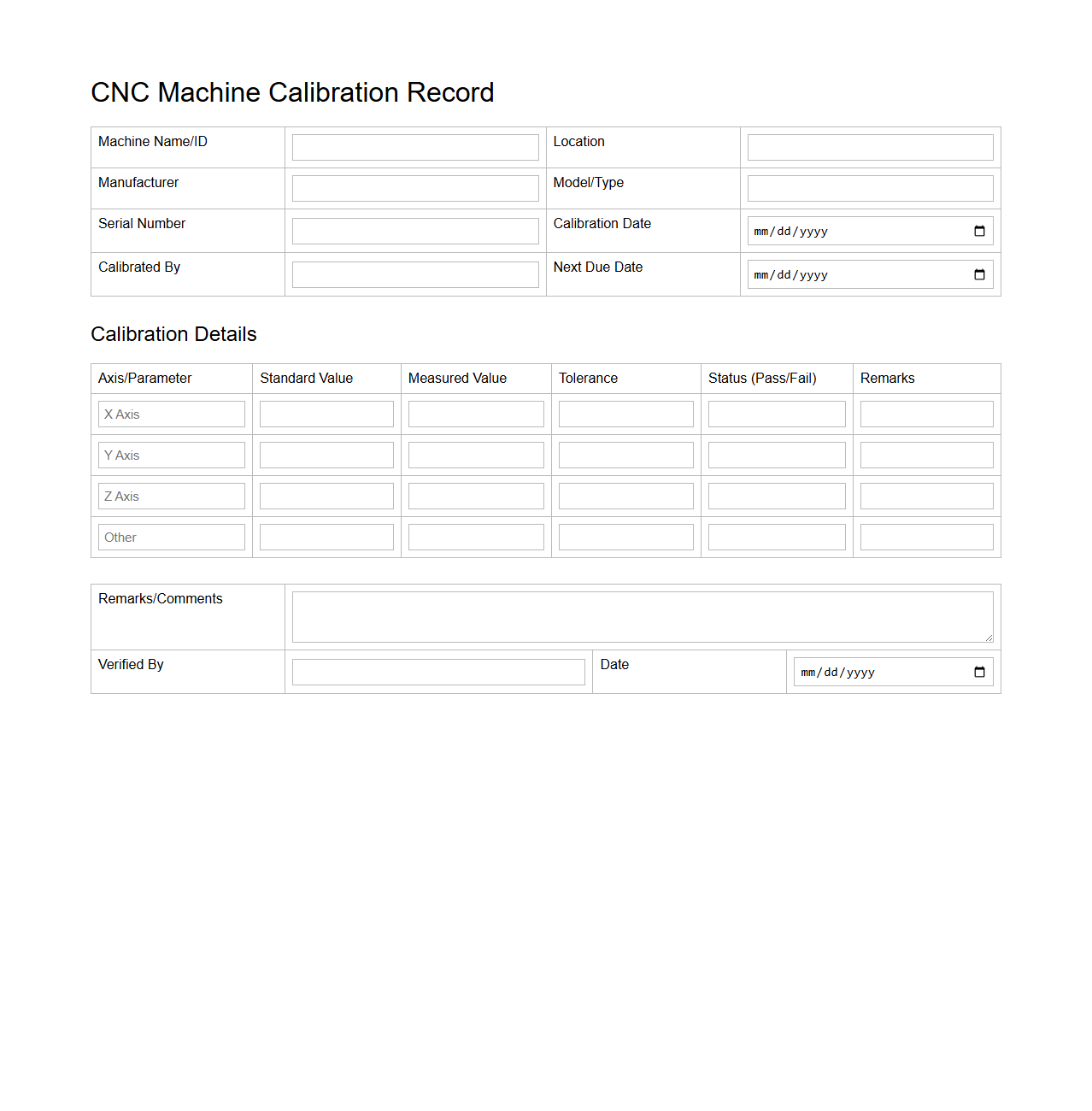

CNC Machine Calibration Record Template

A

CNC Machine Calibration Record Template document is a standardized form used to systematically record the calibration data and settings of CNC machines. It ensures accurate tracking of machine performance, alignment, and tool accuracy by documenting measurement results, calibration dates, and technician details. This template supports maintenance schedules and quality control processes, enhancing machine precision and operational reliability.

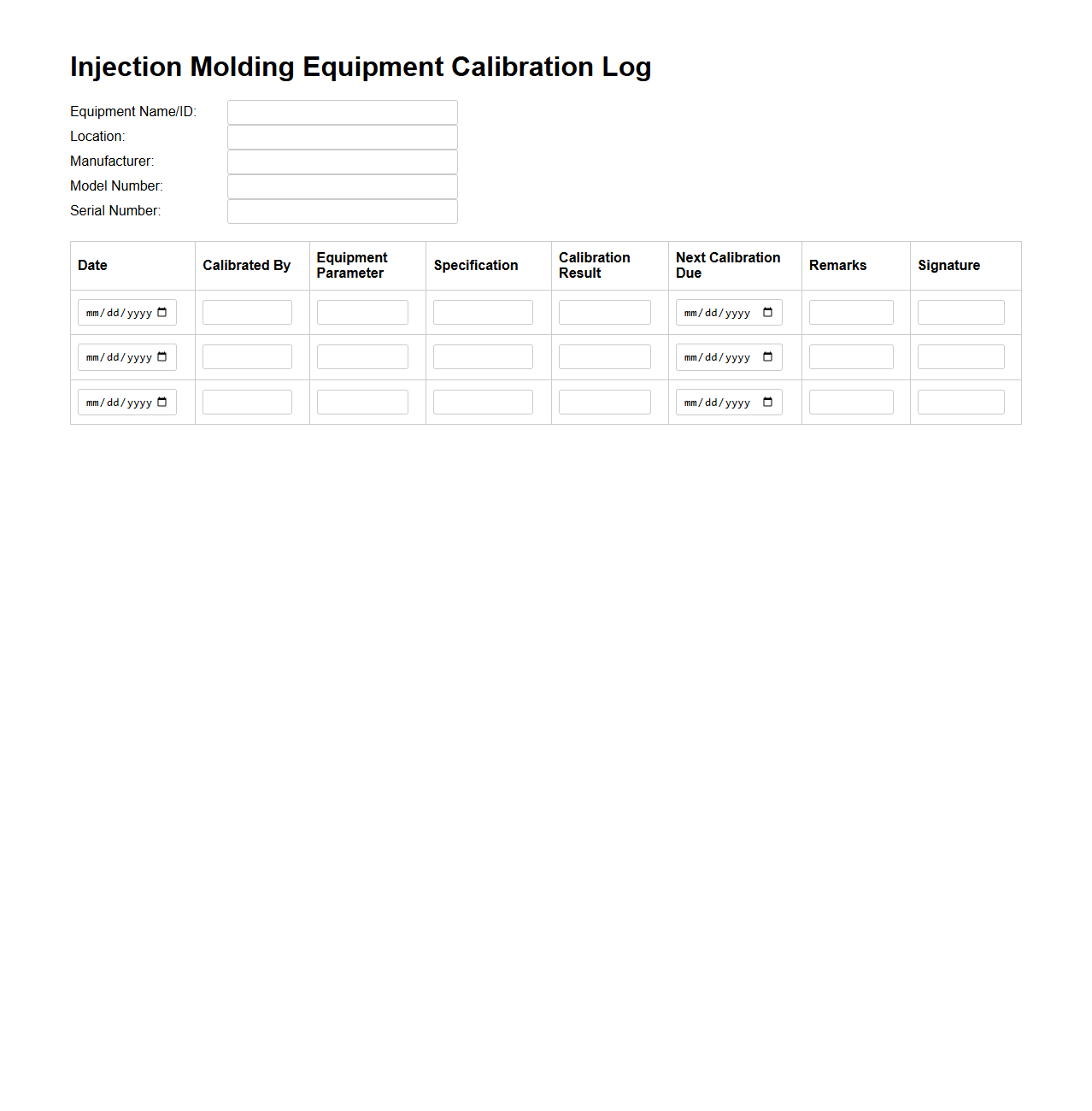

Injection Molding Equipment Calibration Log

An

Injection Molding Equipment Calibration Log document is a critical record used to track the calibration of machinery used in injection molding processes. It ensures that all equipment meets precise standards for temperature, pressure, and timing, which are essential for producing consistent, high-quality plastic parts. Maintaining this log helps prevent defects, supports compliance with industry regulations, and optimizes production efficiency.

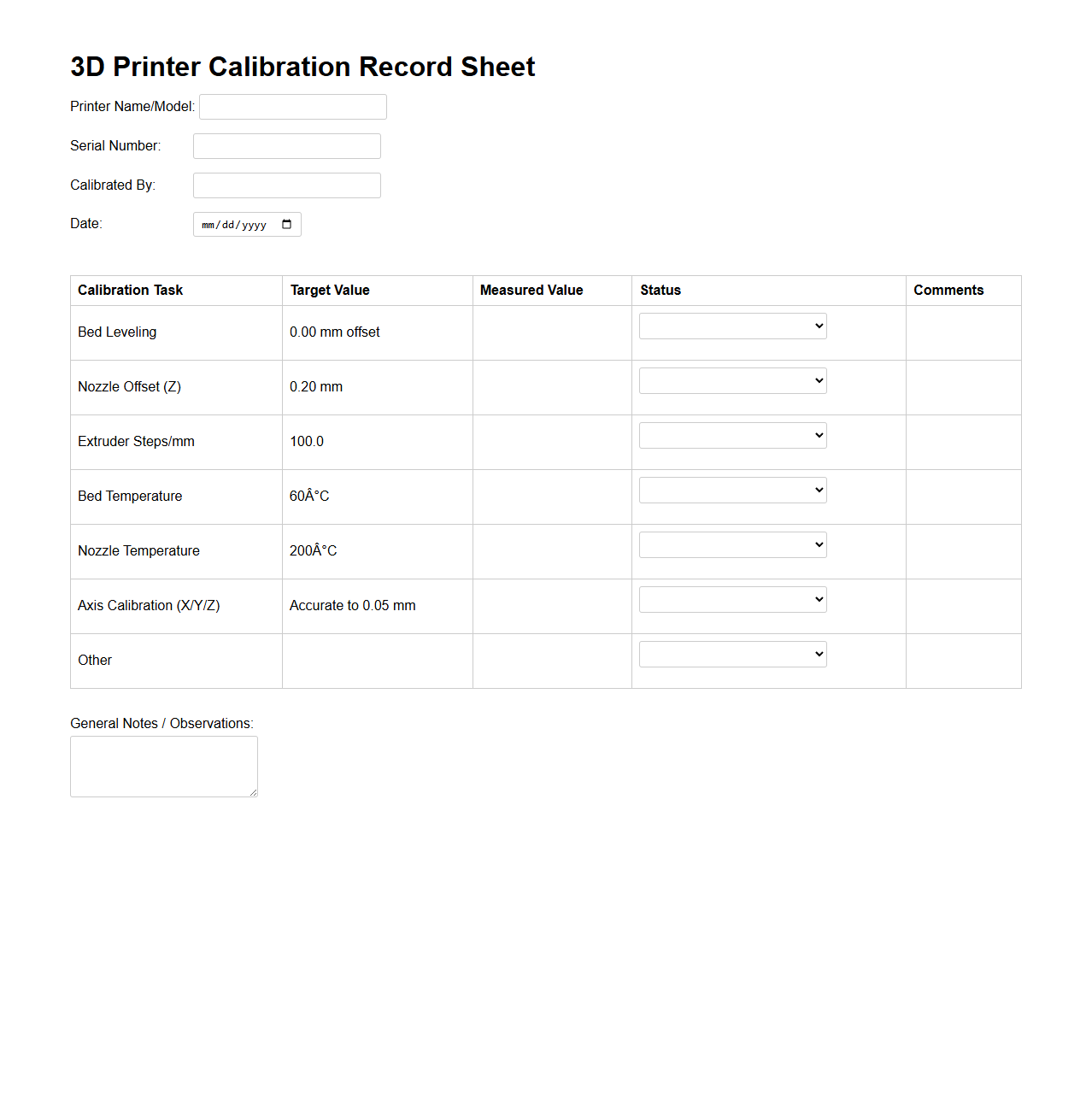

3D Printer Calibration Record Sheet

A

3D Printer Calibration Record Sheet is a document used to systematically track and record the adjustments and settings made to a 3D printer to ensure accurate and precise printing results. It includes detailed information such as calibration dates, printer model, filament type, temperature settings, bed leveling data, and test print outcomes. Maintaining this record sheet helps optimize printer performance, troubleshoot issues efficiently, and achieve consistent print quality over time.

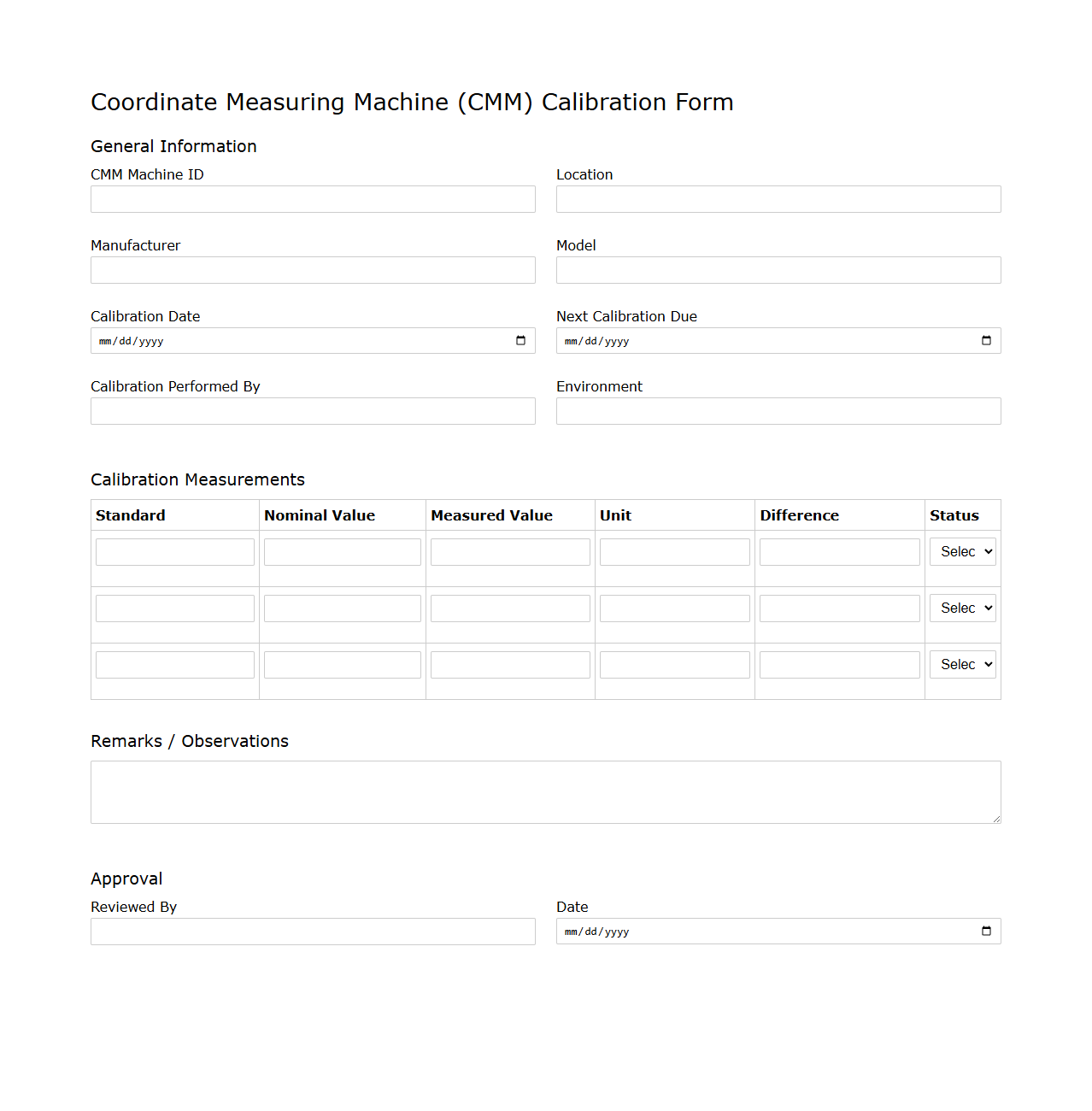

Coordinate Measuring Machine (CMM) Calibration Form

The

Coordinate Measuring Machine (CMM) Calibration Form document records the calibration data and status of a CMM, ensuring its measurement accuracy and reliability. It typically includes details such as calibration date, inspector information, calibration standards used, and measurement results compared to acceptable tolerances. Maintaining this document is essential for quality control and compliance with industry standards in manufacturing and inspection processes.

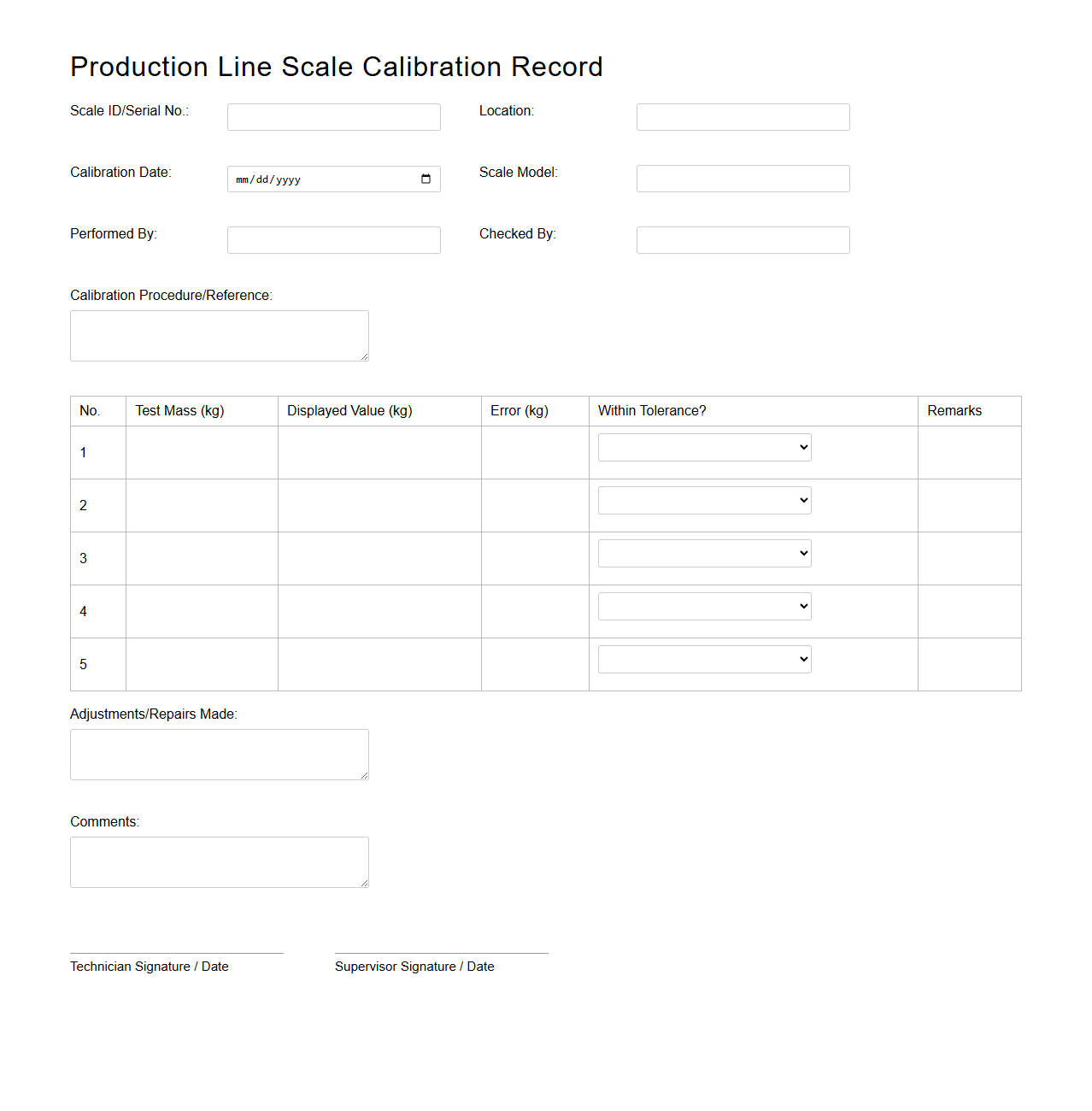

Production Line Scale Calibration Record

A

Production Line Scale Calibration Record document is a formal record that tracks the calibration of weighing scales used on production lines to ensure accuracy in measurement. It includes details such as calibration dates, results, technician information, and any adjustments made to maintain compliance with quality standards. This document is essential for maintaining traceability and ensuring product consistency in manufacturing processes.

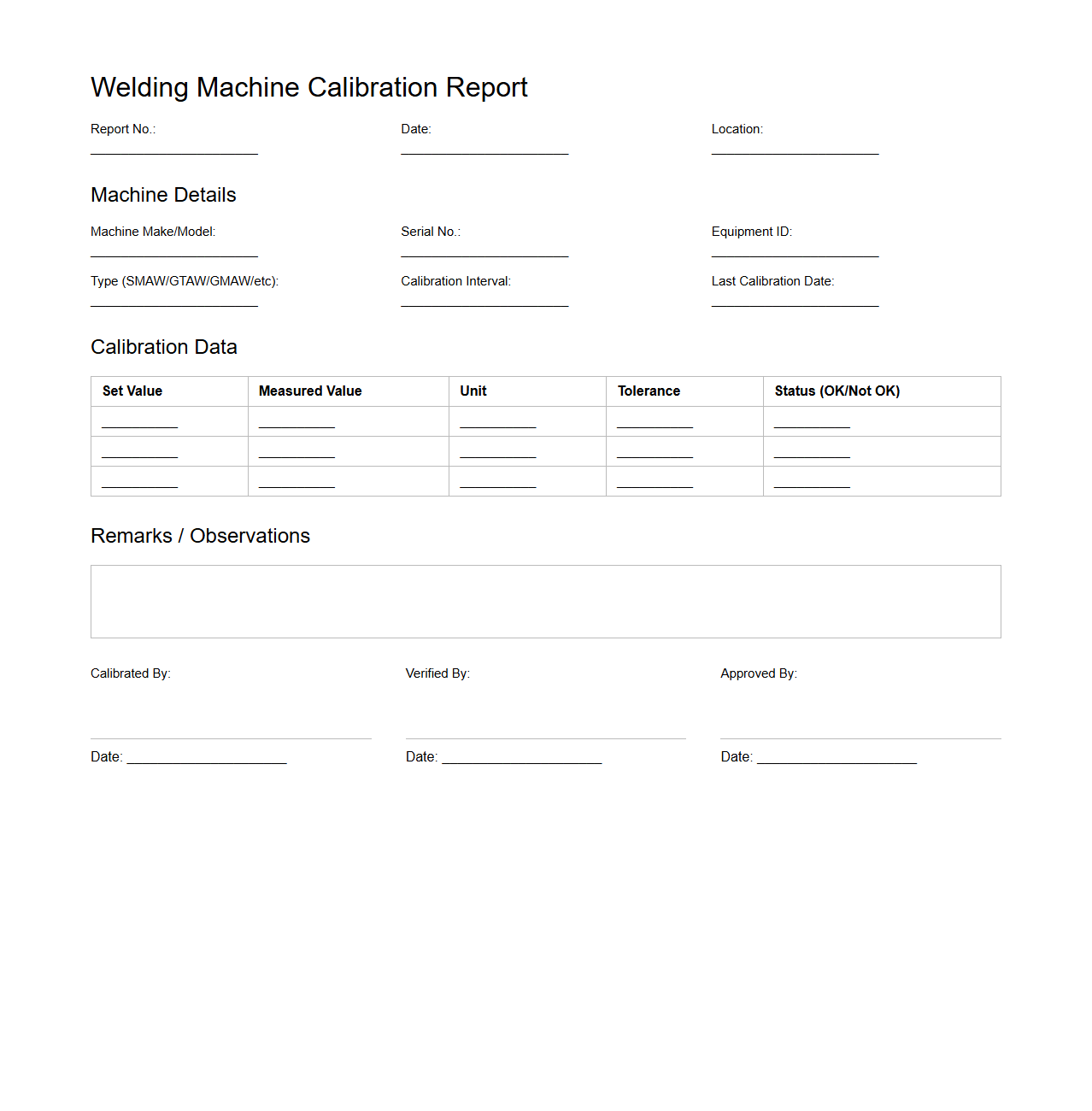

Welding Machine Calibration Report Format

A

Welding Machine Calibration Report Format document serves as a standardized template to record the calibration process, results, and compliance of welding equipment with industry standards. It typically includes details such as machine identification, calibration date, measured parameters, reference standards used, and technician's remarks. This format ensures accuracy, traceability, and quality assurance in maintaining welding machines for optimal performance and safety.

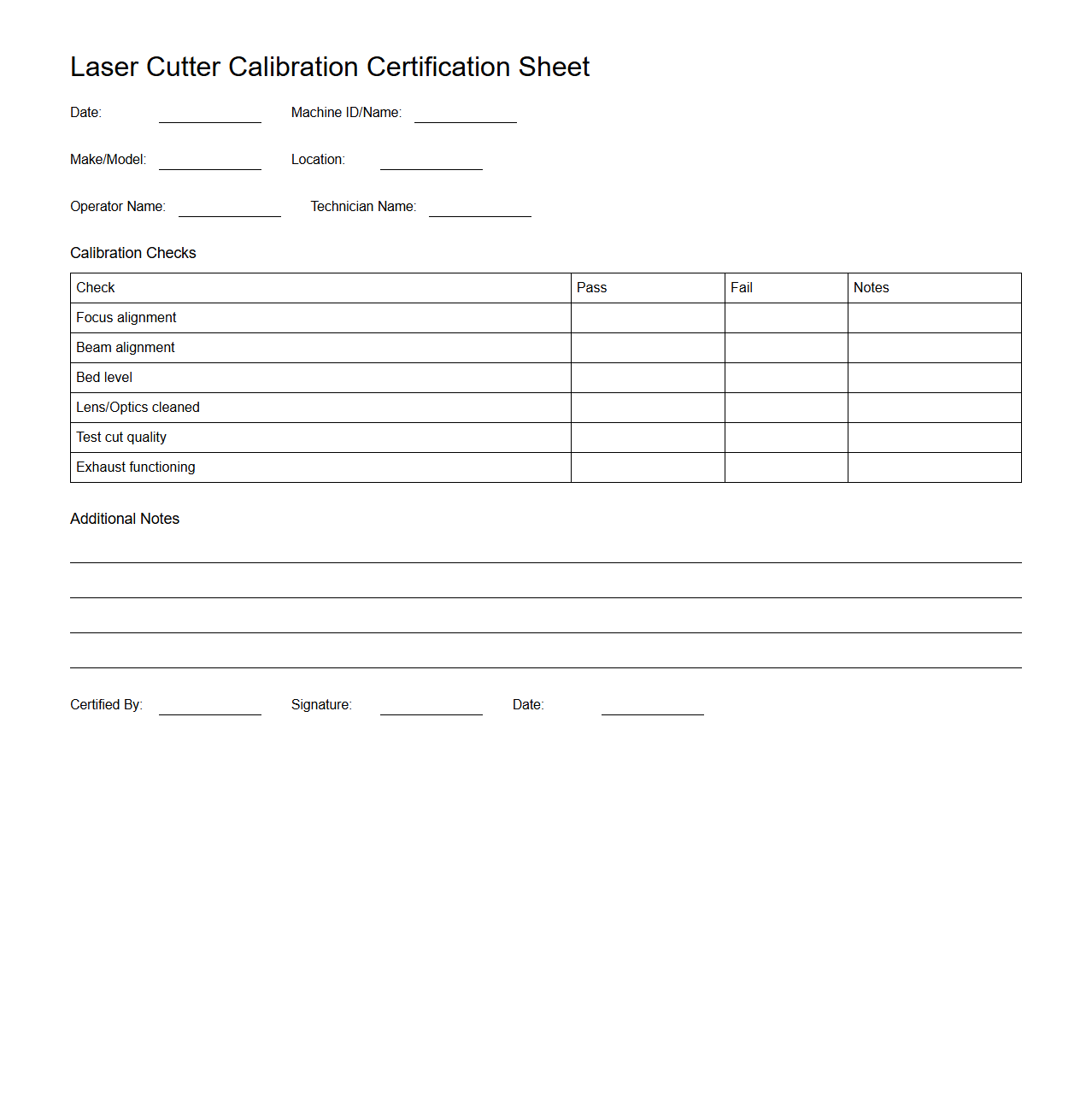

Laser Cutter Calibration Certification Sheet

The

Laser Cutter Calibration Certification Sheet document verifies that a laser cutter has undergone precise calibration to ensure optimal cutting accuracy and performance. It records essential calibration data, including power settings, alignment checks, and measurement tolerances. This certification is crucial for maintaining consistent quality and safety standards in laser cutting operations.

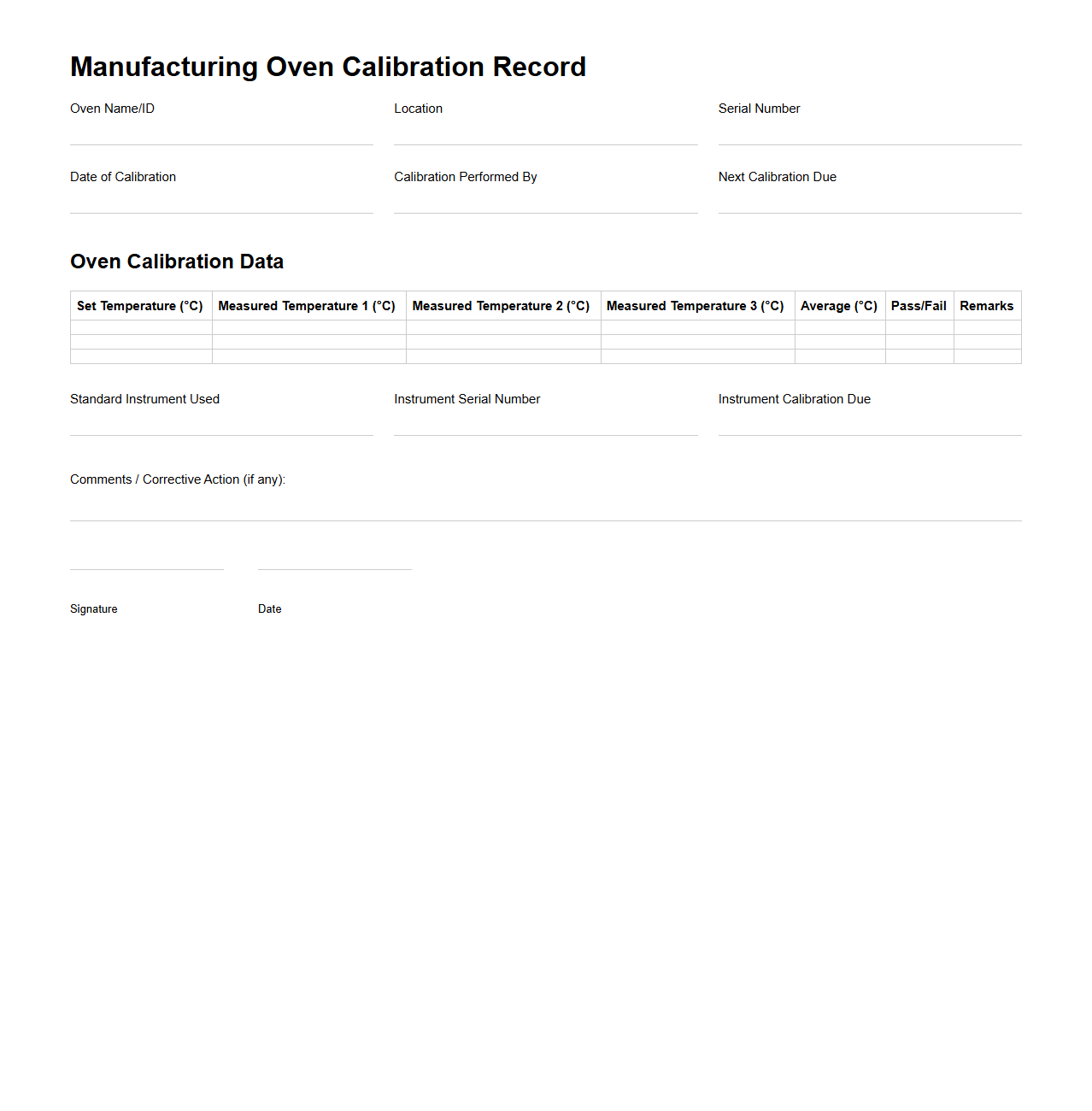

Manufacturing Oven Calibration Record Template

A

Manufacturing Oven Calibration Record Template document is used to systematically log and track the calibration data of industrial ovens to ensure they operate within specified temperature ranges. It includes fields for recording date, equipment ID, calibration results, technician details, and any deviations from standard settings. This template supports regulatory compliance, quality control, and equipment maintenance efficiency in manufacturing processes.

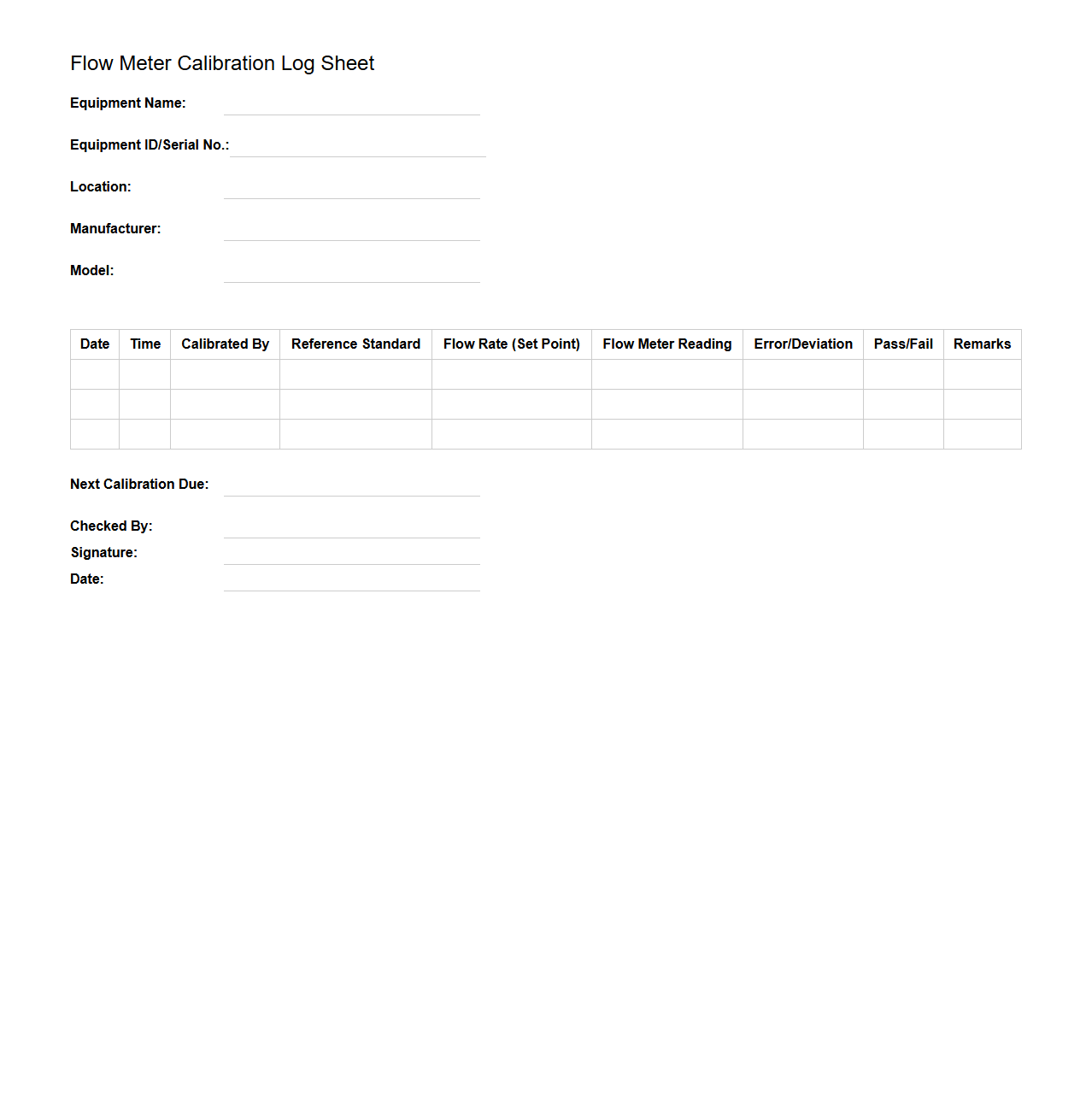

Flow Meter Calibration Log Sheet

A

Flow Meter Calibration Log Sheet document records the calibration data of flow meters, ensuring accuracy and reliability in fluid measurement systems. It tracks essential information such as calibration date, instrument identification, calibration results, and technician details, facilitating compliance with industry standards. Maintaining this log helps detect measurement deviations early and supports scheduled maintenance activities.

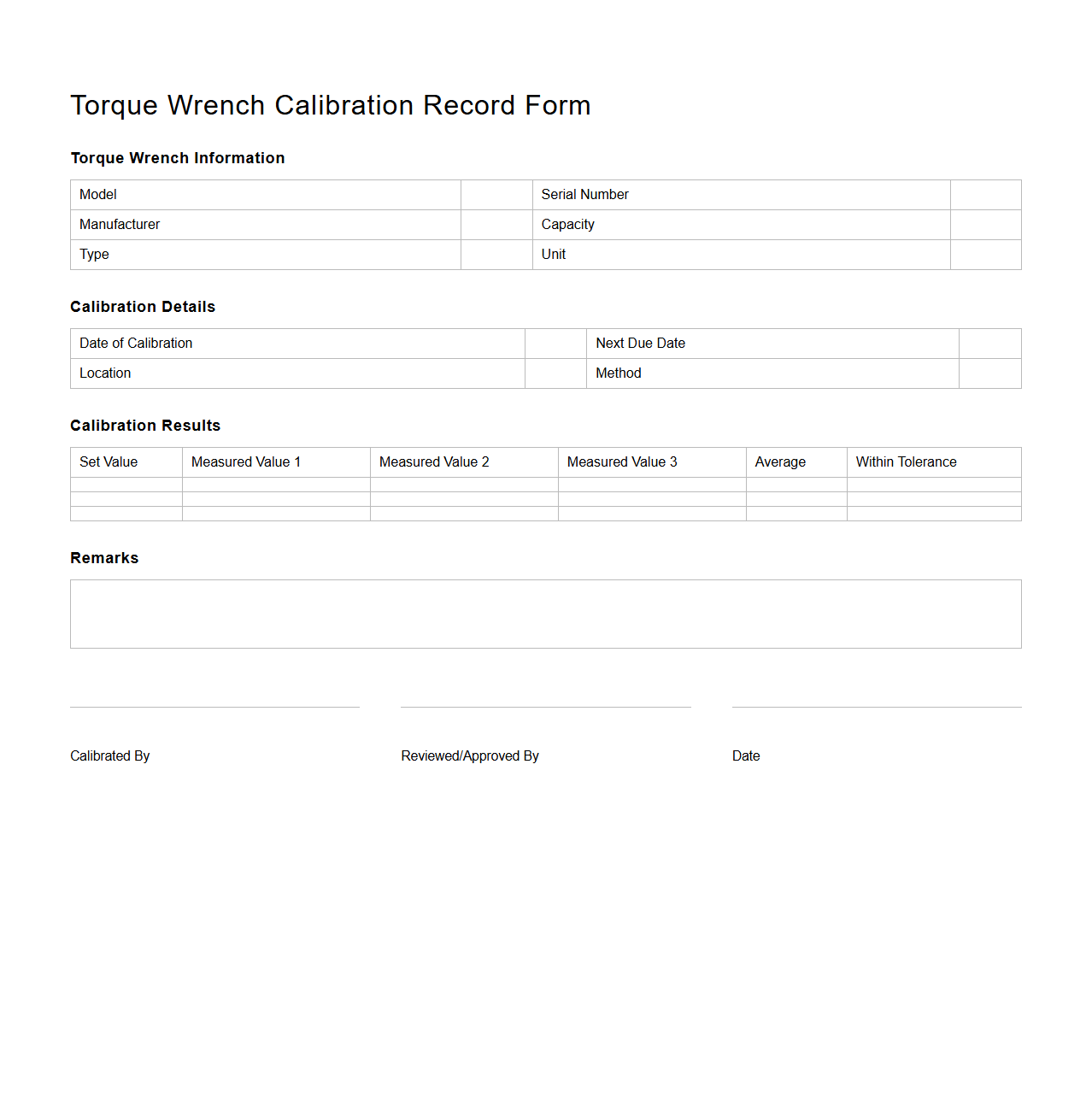

Torque Wrench Calibration Record Form

A

Torque Wrench Calibration Record Form document is essential for tracking the accuracy and performance of torque wrenches used in mechanical and industrial applications. It records calibration dates, settings, measurement results, and technician details to ensure tools meet required specifications and maintain quality control. Proper documentation helps prevent equipment failure and ensures compliance with industry standards like ISO and ANSI.

What key parameters must be recorded during machine calibration for compliance?

During machine calibration, it is essential to record measured values, environmental conditions, and the calibration date. These parameters ensure the machine operates within specified tolerances. Accurate recording guarantees compliance with industry standards and audit requirements.

How is traceability to calibration standards documented in the record?

Traceability is documented by referencing calibration standards that are linked to national or international standards. The record includes the standard's identification number and the calibration lab details. This process assures the legitimacy and accuracy of the calibration performed.

What information is required to identify the calibrated equipment uniquely?

Unique identification requires recording the equipment's serial number, model number, and manufacturer. Including a physical description or barcode enhances traceability. This information prevents confusion and ensures the correct equipment is tracked throughout its lifecycle.

Which section of the document details the calibration procedure and outcomes?

The Calibration Procedure section outlines step-by-step methods used and the criteria followed. It also includes the results or outcomes of the calibration process. This section is critical for transparency and validation of compliance efforts.

How does the document capture approval and verification by authorized personnel?

The document features a dedicated Approval and Verification section containing signatures, names, and dates from authorized individuals. This confirms the calibration was reviewed and meets required standards. Such validation ensures accountability and audit readiness.

More Manufacturing Templates