A Machine Downtime Report Document Sample for Manufacturing provides a detailed record of equipment stoppages, capturing the duration and causes of downtime. This report helps identify patterns and inefficiencies, enabling maintenance teams to implement preventive measures and improve overall production efficiency. Accurate documentation supports informed decision-making and reduces production losses in manufacturing operations.

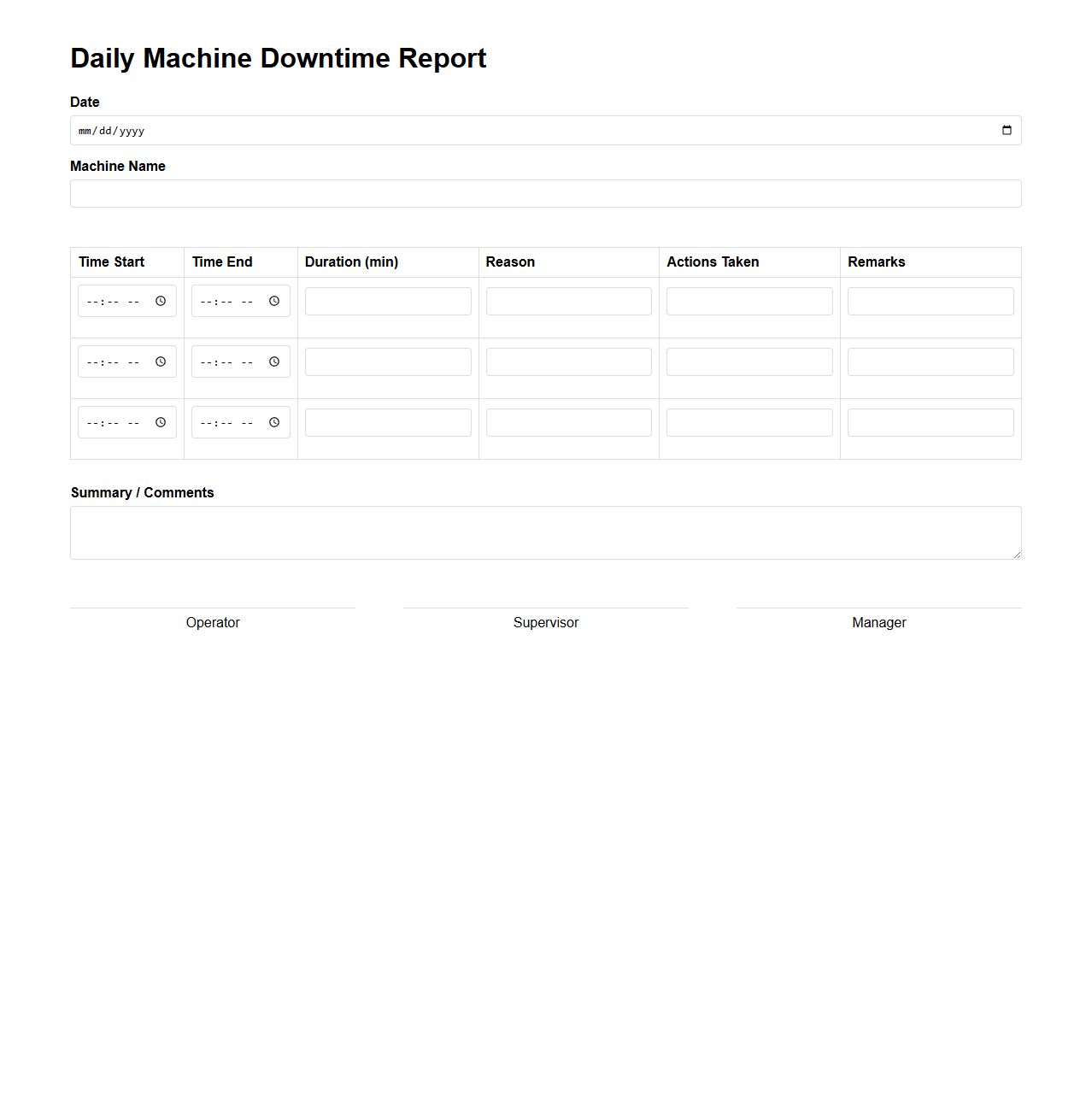

Daily Machine Downtime Report Template

The

Daily Machine Downtime Report Template document is a structured tool used to record and analyze the duration and causes of equipment inactivity within a manufacturing or production environment. It captures vital data such as machine ID, downtime start and end times, reasons for stoppage, and corrective actions taken, facilitating improved maintenance scheduling and operational efficiency. This report helps managers identify recurring issues, reduce unplanned downtime, and enhance overall productivity by providing actionable insights into machine performance.

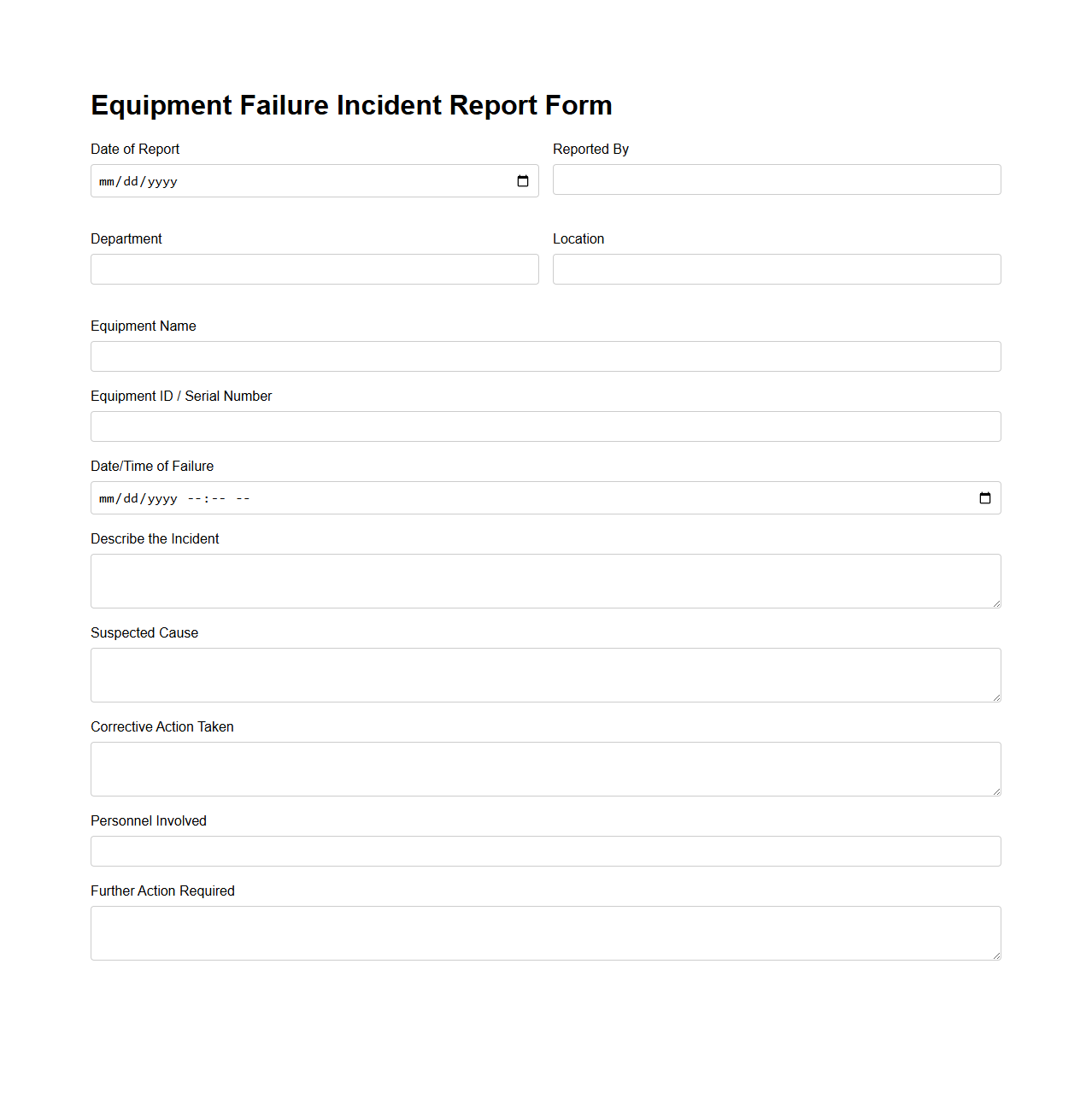

Equipment Failure Incident Report Form

The

Equipment Failure Incident Report Form document is used to systematically record details of malfunctions or breakdowns in machinery and equipment. It collects critical information such as the type of equipment, nature of the failure, time of occurrence, and immediate impact on operations. This documentation supports root cause analysis, preventive maintenance planning, and compliance with safety regulations.

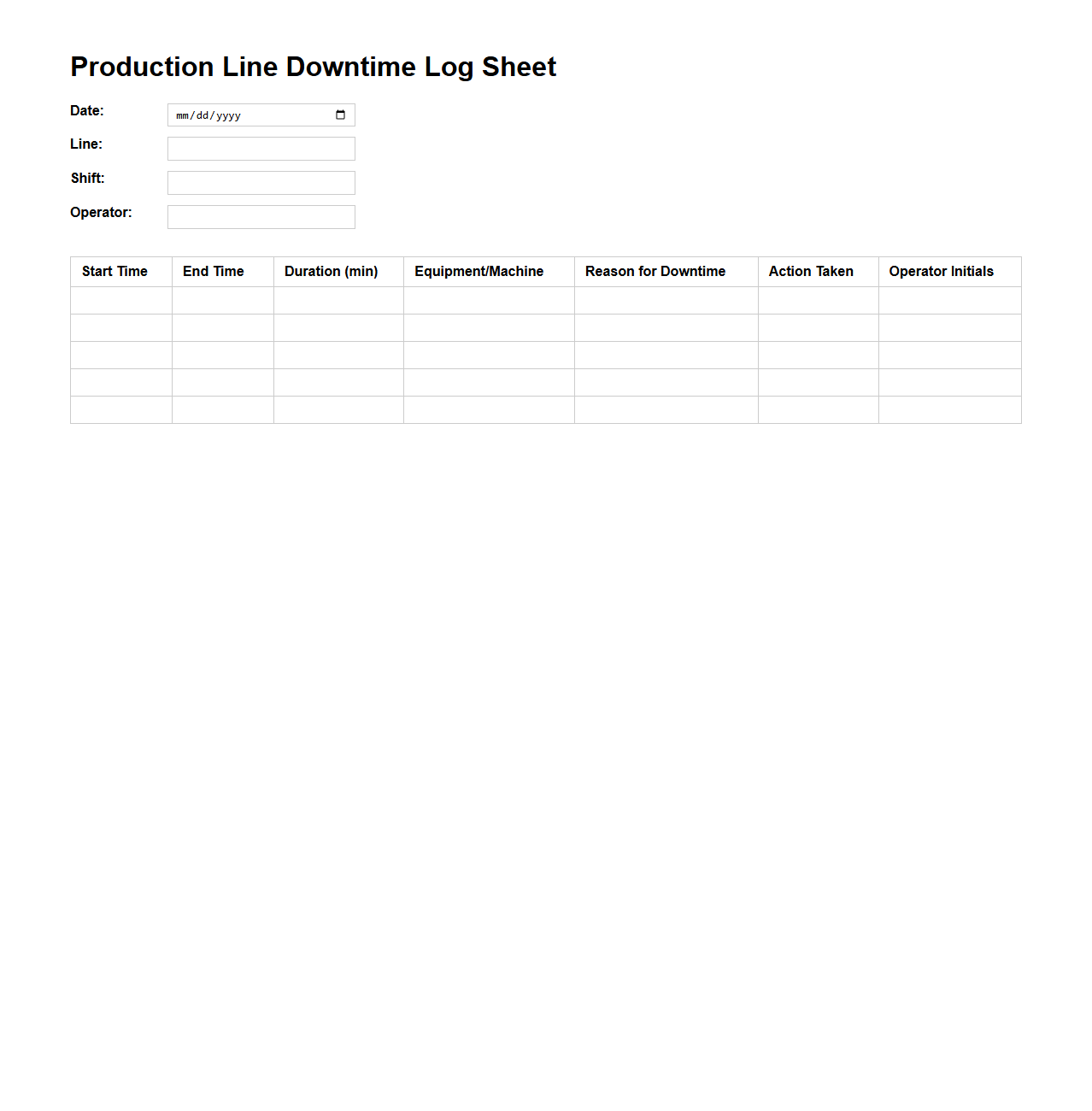

Production Line Downtime Log Sheet

A

Production Line Downtime Log Sheet document records instances when manufacturing equipment or production lines stop operating, capturing detailed information such as the start and end times of downtime, reasons for stoppage, and corrective actions taken. This log is essential for identifying patterns, minimizing disruptions, and improving overall equipment effectiveness (OEE). Maintaining accurate downtime records supports data-driven decisions for optimizing production efficiency and reducing operational costs.

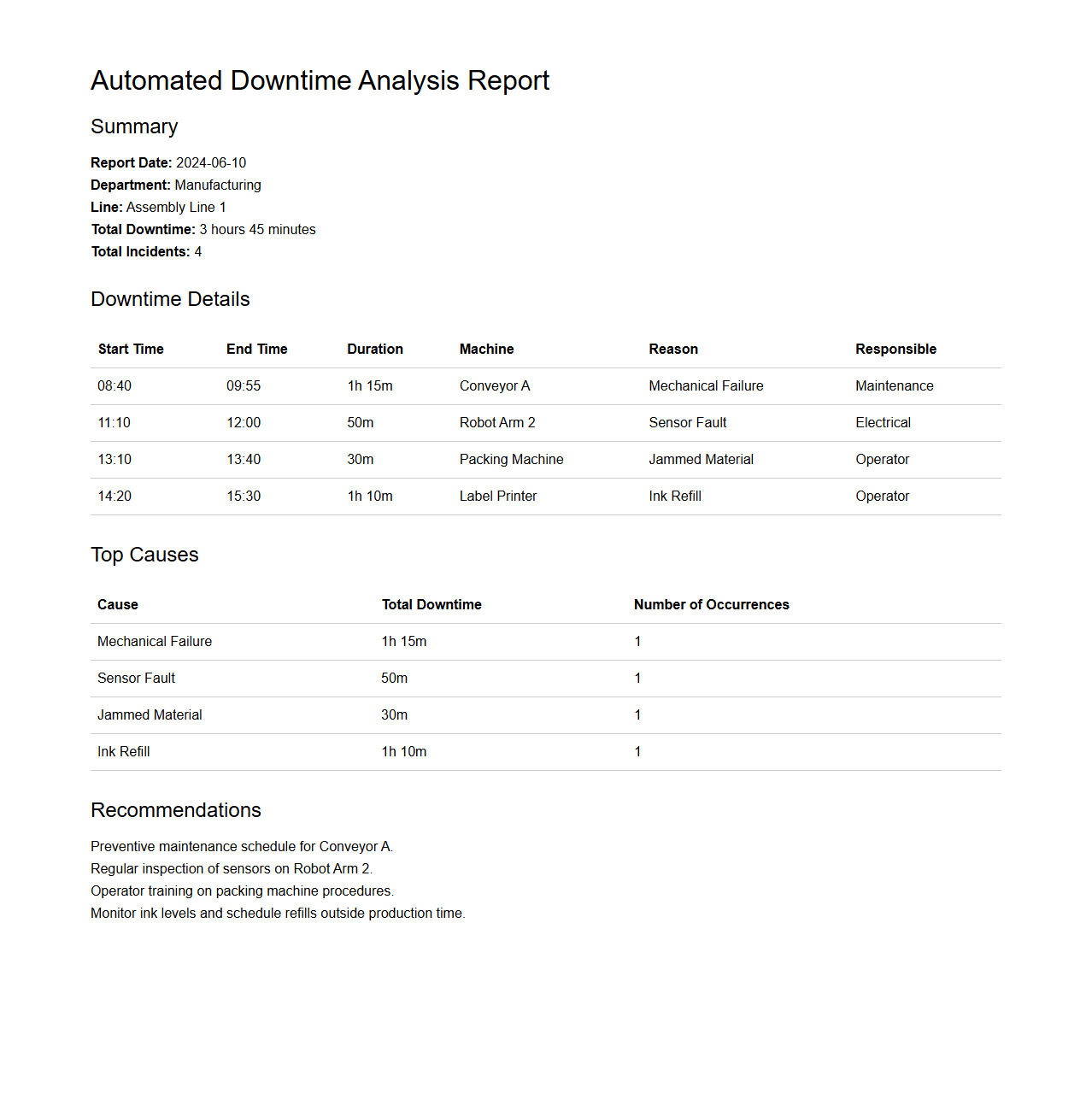

Automated Downtime Analysis Report Example

An

Automated Downtime Analysis Report Example document provides a detailed examination of equipment or system downtime by collecting and analyzing machine data automatically. It highlights key metrics such as downtime duration, causes of stoppages, and frequency, enabling organizations to identify patterns and root causes efficiently. This report supports maintenance teams in improving operational efficiency and minimizing production losses through data-driven insights.

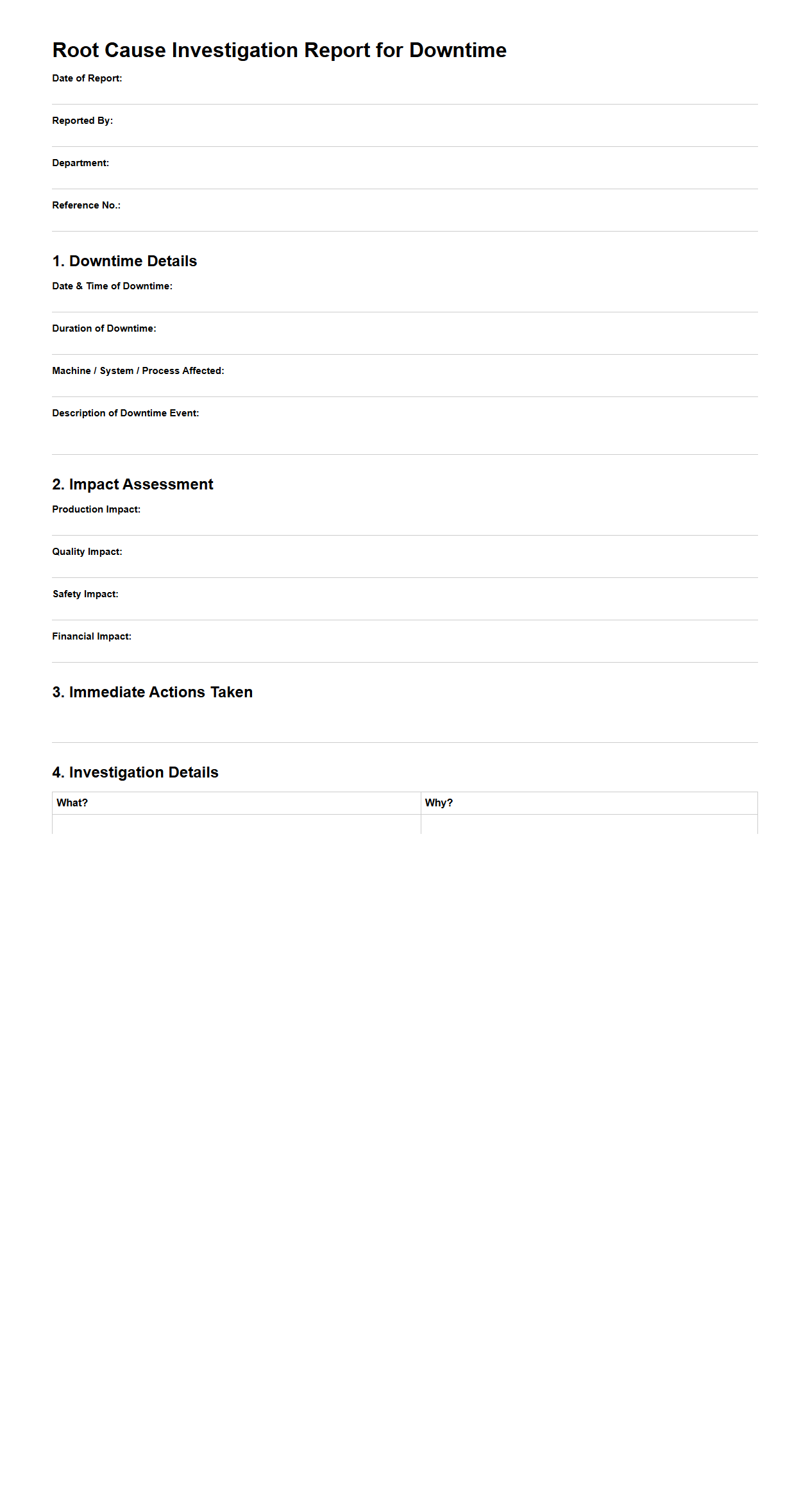

Root Cause Investigation Report for Downtime

A

Root Cause Investigation Report for Downtime document systematically analyzes the underlying causes of production or system outages to prevent recurrence. It details the timeline of events, identifies failure points, and recommends corrective actions based on data collected from monitoring tools and incident logs. This report enhances operational efficiency by enabling targeted maintenance and minimizing unplanned downtime.

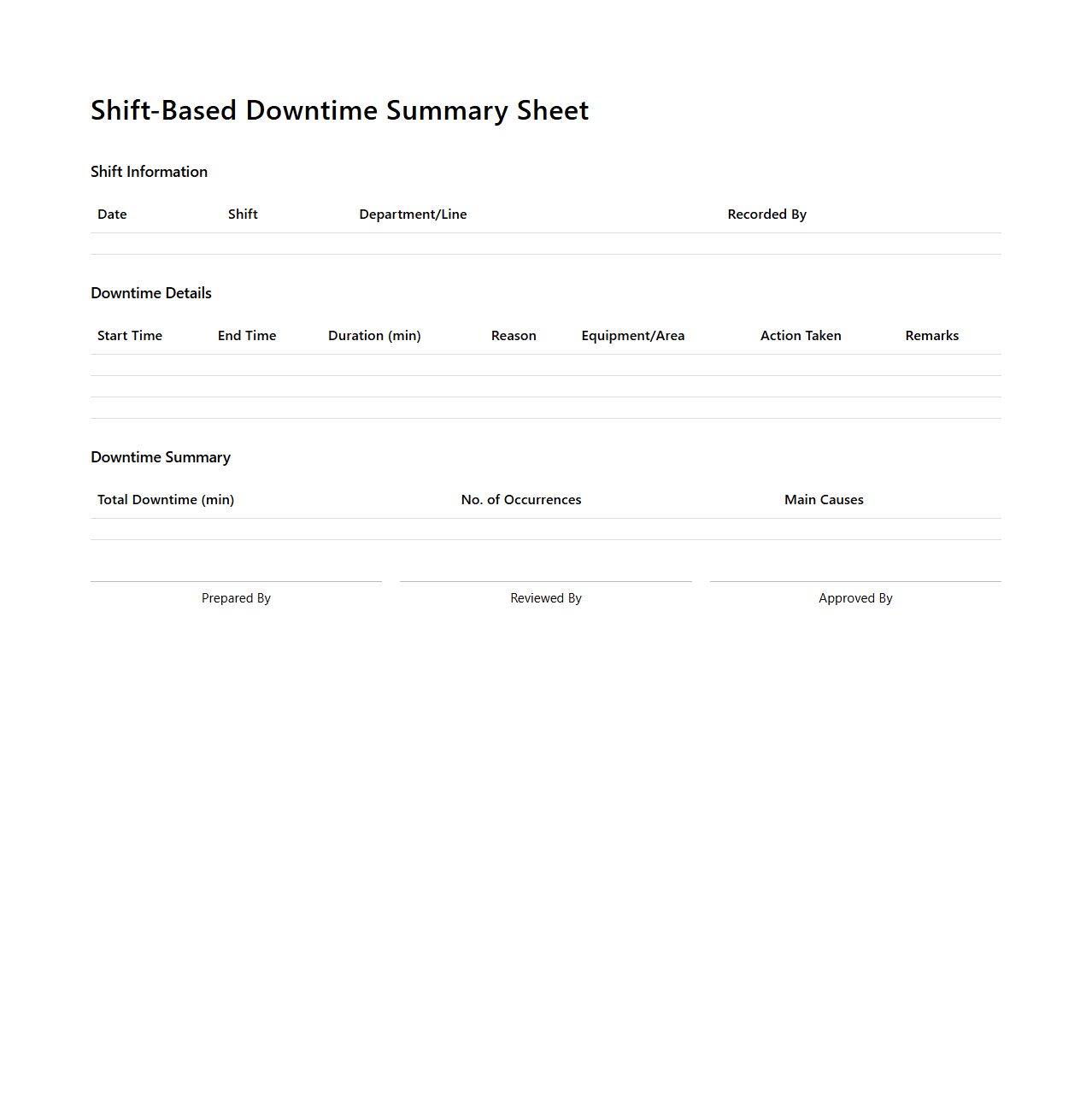

Shift-Based Downtime Summary Sheet

The

Shift-Based Downtime Summary Sheet document records detailed information about equipment or process downtime during specific work shifts, enabling accurate tracking and analysis of operational inefficiencies. It captures key metrics such as start and end times of downtime, reasons for interruptions, and the impact on production output, which supports data-driven decision-making for maintenance and process improvements. This document is essential for optimizing workforce allocation and minimizing productivity losses in manufacturing and industrial environments.

Maintenance Intervention Record for Machine Downtime

The

Maintenance Intervention Record for Machine Downtime document is a detailed log that tracks all maintenance activities performed during periods when machinery is not operational. It captures essential data such as the cause of downtime, duration, specific maintenance actions taken, and parts replaced, enabling a comprehensive analysis of machine performance and efficiency. This record supports predictive maintenance strategies and helps reduce future downtime by identifying recurring issues and improving repair processes.

Machine Downtime Cause Tracking Form

A

Machine Downtime Cause Tracking Form is a crucial document used in manufacturing and industrial operations to systematically record and analyze reasons for equipment stoppages. It captures detailed information such as the time of downtime, specific causes, duration, and responsible personnel to help identify patterns and areas for improvement. This form enables organizations to reduce unplanned interruptions, optimize maintenance schedules, and enhance overall equipment efficiency.

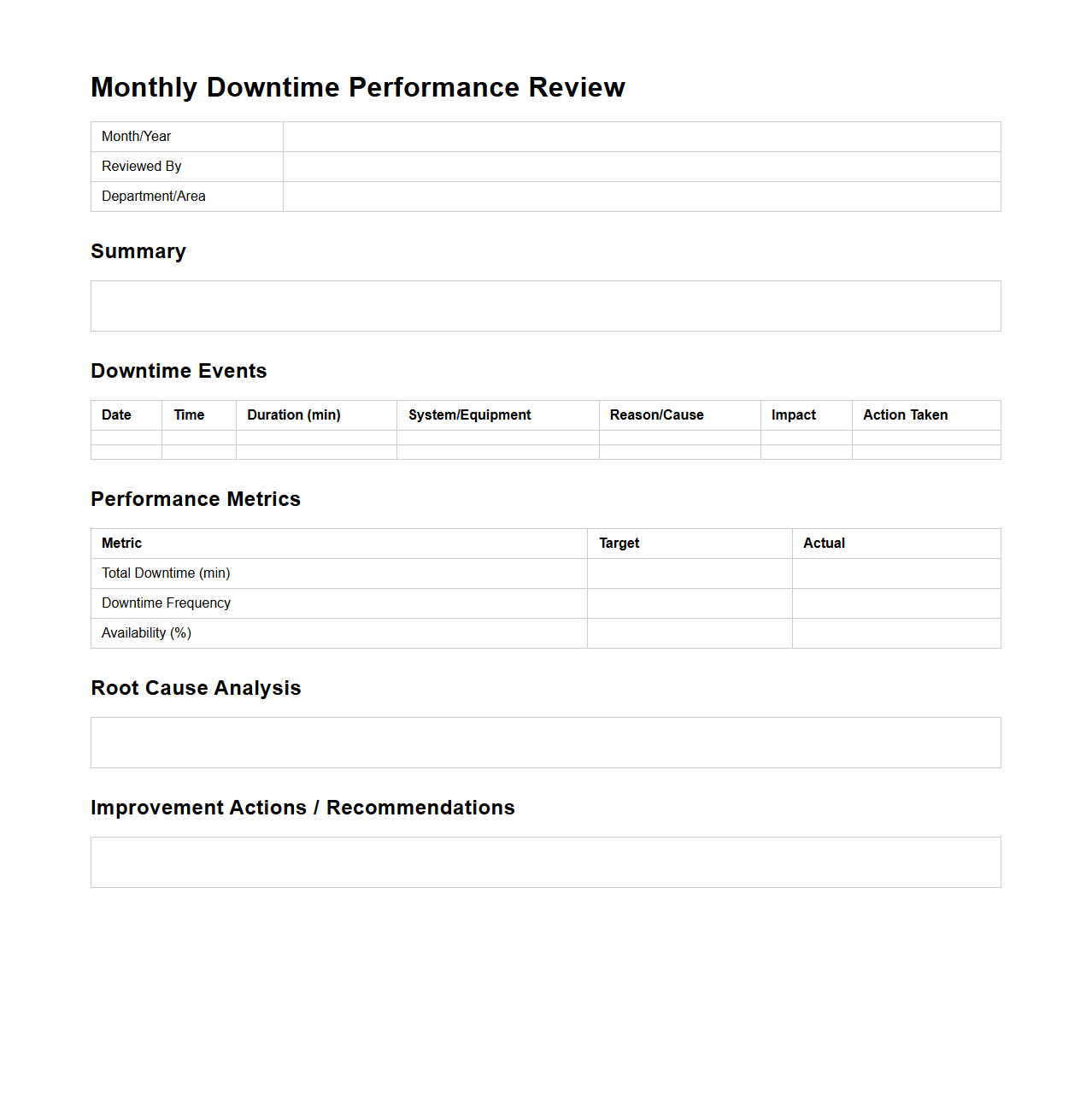

Monthly Downtime Performance Review Document

The

Monthly Downtime Performance Review Document systematically tracks and analyzes system or equipment downtime over a monthly period, providing critical insights into causes and durations. It serves as a vital tool for identifying recurring issues, assessing maintenance effectiveness, and driving continuous improvement in operational efficiency. By highlighting trends and key performance metrics, this document supports informed decision-making and reduces future downtime events.

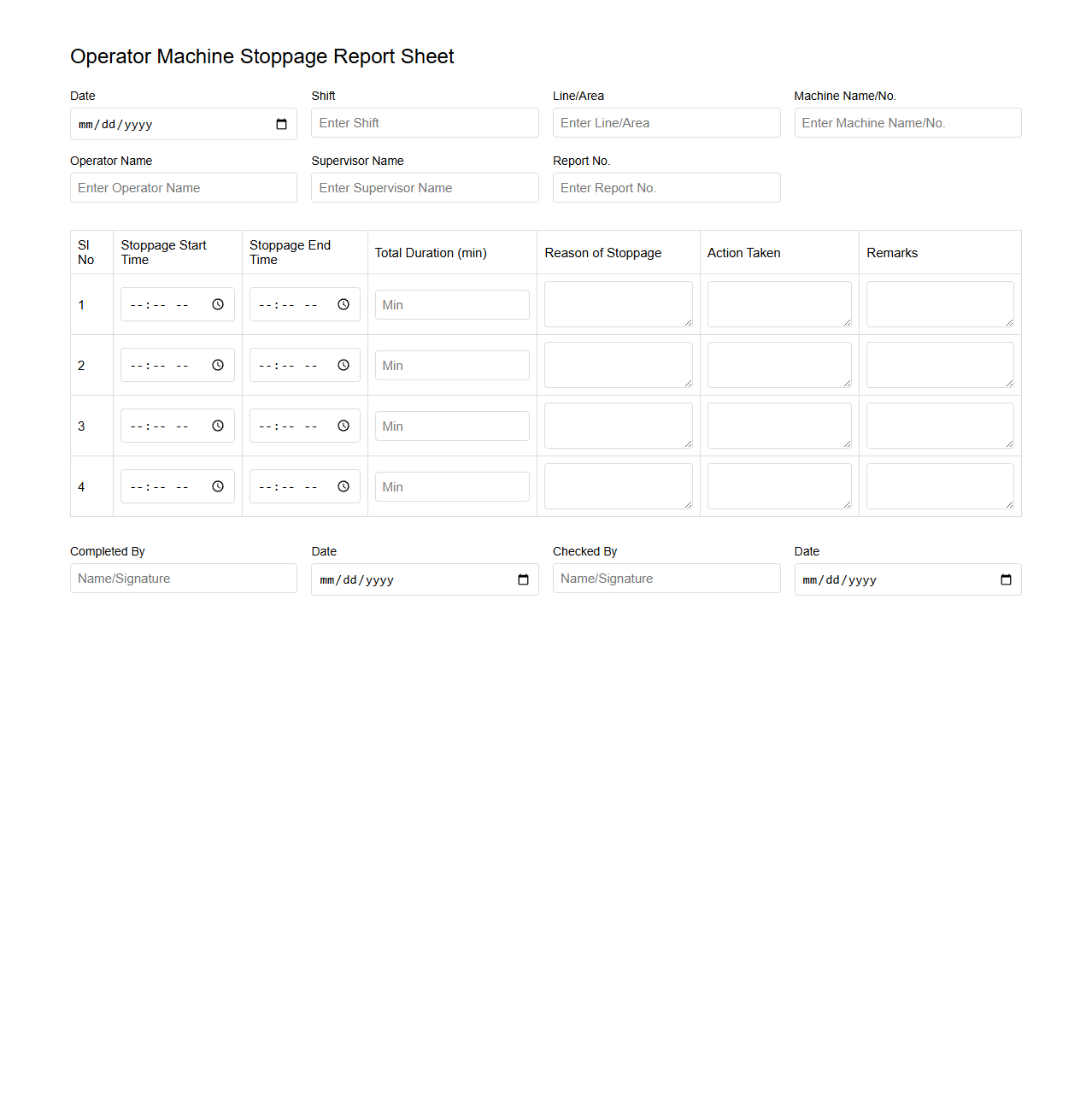

Operator Machine Stoppage Report Sheet

The

Operator Machine Stoppage Report Sheet document is used to systematically record instances when machinery halts during production operations. It captures essential data such as time of stoppage, duration, reason codes, and operator details to facilitate accurate downtime analysis. This report supports maintenance teams and management in identifying recurring issues, improving machine efficiency, and minimizing production losses.

What essential data fields are commonly included in a Machine Downtime Report for manufacturing?

The essential data fields in a Machine Downtime Report typically include machine ID, date and time of downtime events, and the duration of each incident. Additionally, operator details and department or production line information are recorded for analysis. These fields provide a comprehensive overview to track and understand machine performance over time.

How does the document categorize the causes of machine downtime?

The report categorizes downtime causes by grouping them into mechanical failure, electrical issues, operational errors, and external factors. Each cause is clearly documented to identify recurring problems and facilitate targeted improvements. This systematic classification aids in prioritizing maintenance and process adjustments.

What timeframes or periods does the report sample track for downtime events?

Typically, the report tracks downtime events over daily, weekly, and monthly periods to identify patterns and trends. This timeframe sampling allows manufacturers to correlate downtime with shifts, production schedules, and maintenance cycles. Regular tracking ensures timely interventions and resource allocation.

How are the impacts of downtime quantified or measured in the report?

The impacts of downtime are quantified using metrics such as total downtime duration, production loss, and cost implications. These measurements help to assess the operational and financial effects of machine stoppages. Quantifying impact supports data-driven decision-making for process optimization.

What corrective actions or follow-up steps are documented in the sample report?

The sample report documents corrective actions like maintenance requests, operator training sessions, and schedule adjustments. Follow-up steps often include root cause analysis and preventive measures to avoid recurrence. This documentation ensures accountability and continuous improvement.

More Manufacturing Templates