A Production Order Document Sample for Assembly Line provides a detailed blueprint for manufacturing processes, ensuring efficient workflow and resource allocation. This document outlines specific tasks, materials, and timelines necessary to complete each production stage. Clear documentation helps improve communication among team members and enhances overall production quality.

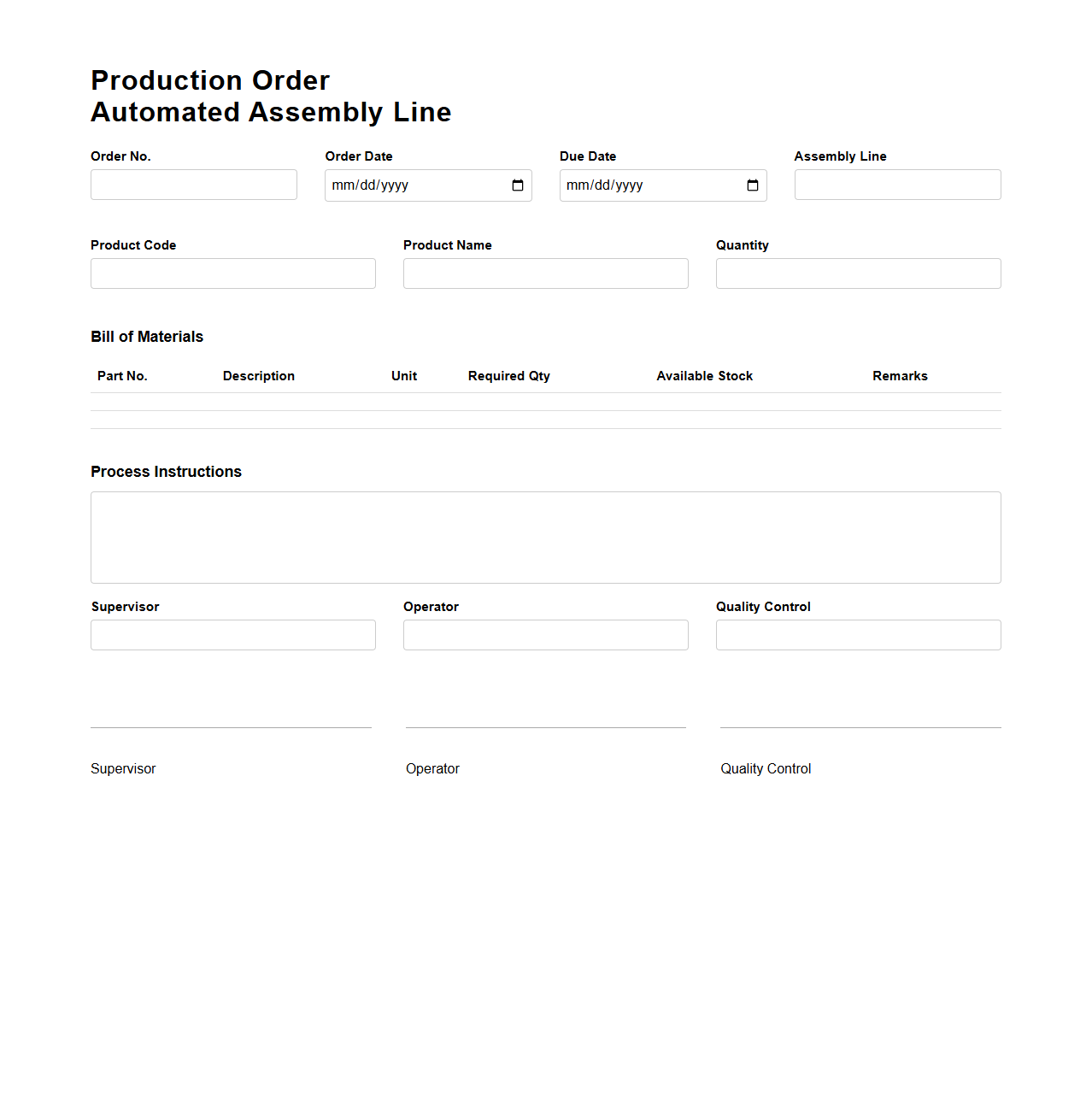

Production Order Template for Automated Assembly Line

A

Production Order Template for an Automated Assembly Line document serves as a standardized blueprint that outlines specific instructions, materials, and process steps required to execute manufacturing tasks efficiently. This template ensures consistency in production activities, reduces setup times, and enhances communication between departments by clearly defining roles, resources, and timelines. By automating the generation and use of these templates, factories can improve workflow precision and minimize errors in the assembly process.

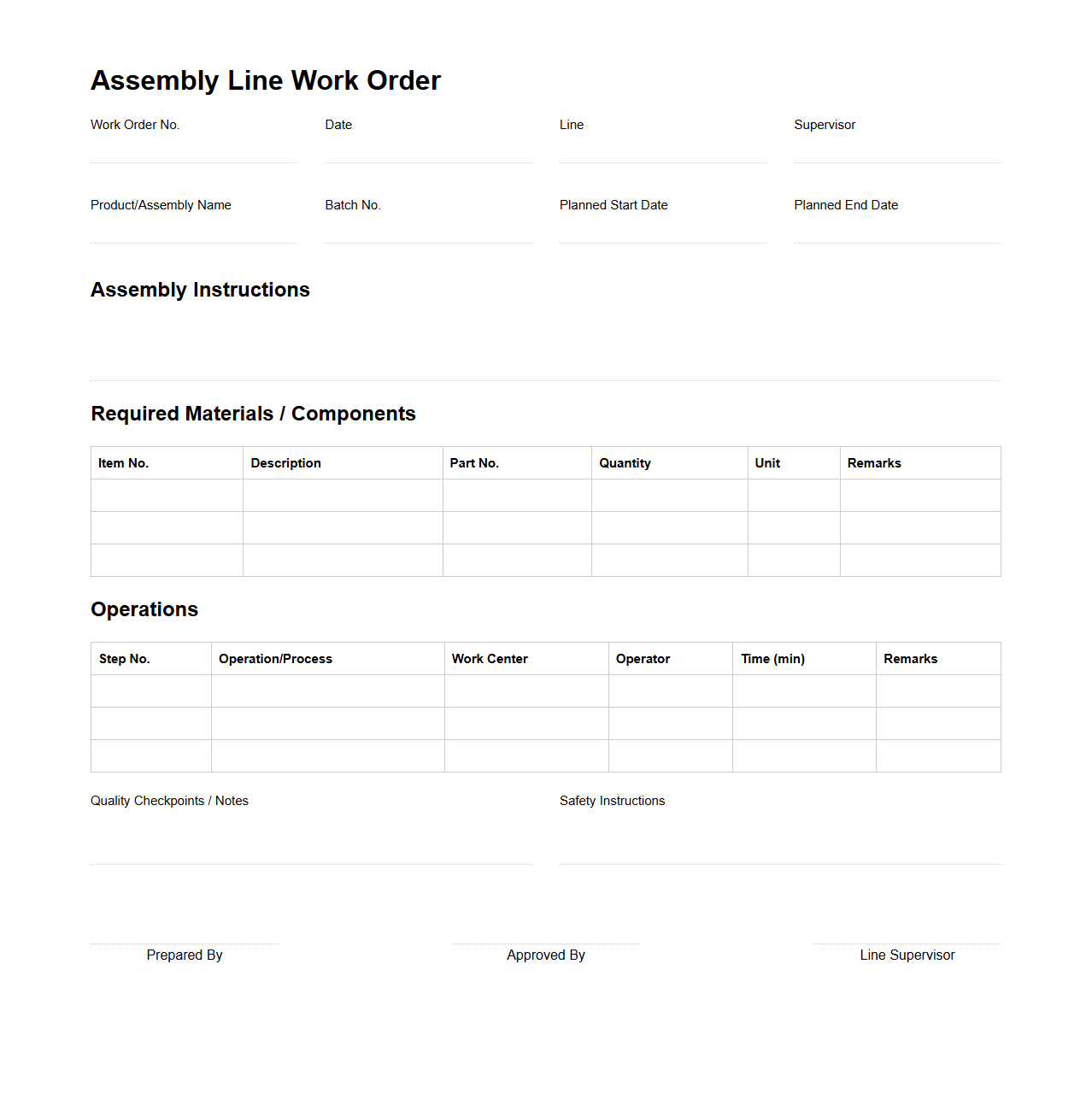

Standard Assembly Line Work Order Format

A

Standard Assembly Line Work Order Format document outlines the specific instructions, sequence of tasks, and materials required for assembly line operations to ensure consistent product quality and efficient workflow. It includes details such as part numbers, quantities, assembly steps, and quality control checkpoints to streamline production processes. This format serves as a crucial communication tool between production planners, line workers, and quality assurance teams.

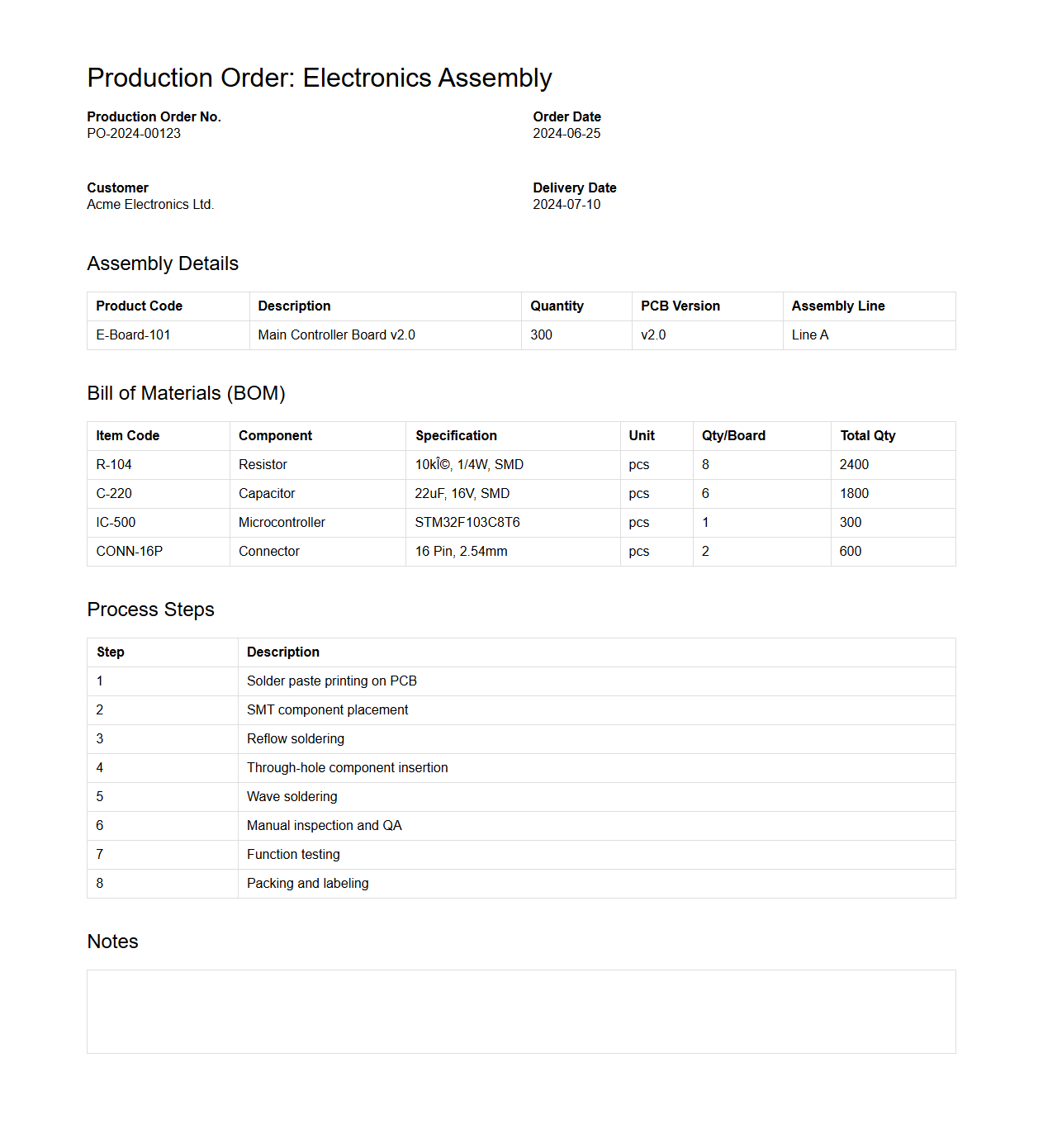

Manufacturing Production Order Example for Electronics Assembly

A

Manufacturing Production Order Example for Electronics Assembly document details the step-by-step instructions and specifications required to produce electronic components or devices. It includes critical data such as bill of materials (BOM), process steps, work center assignments, and quality checkpoints to ensure consistent and efficient production. This document serves as a vital reference for shop floor operators and production managers to streamline assembly workflows and maintain product standards.

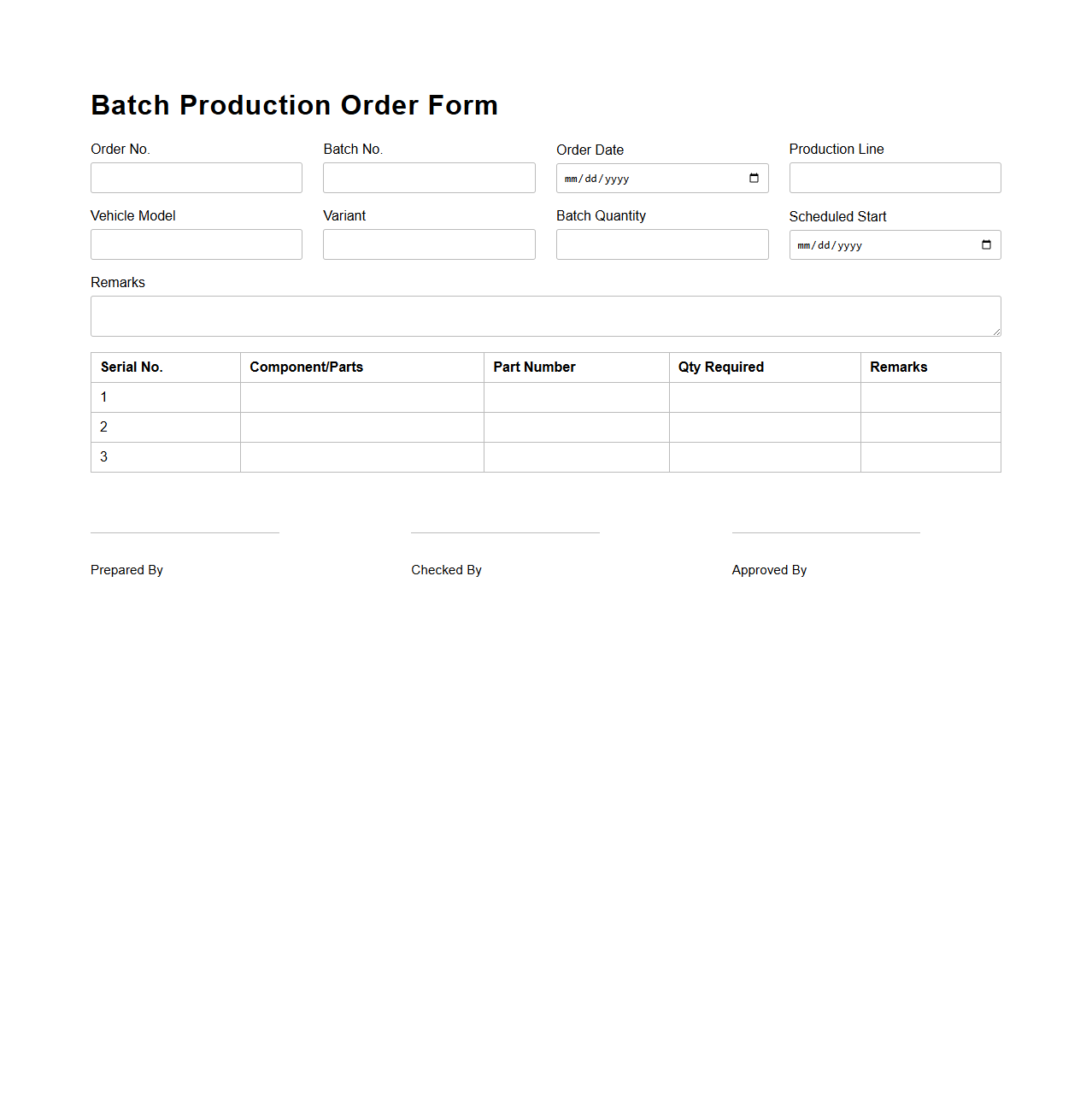

Batch Production Order Form for Automotive Assembly Line

A

Batch Production Order Form for an automotive assembly line is a critical document that outlines the specific details required to manufacture a set quantity of vehicle components or complete assemblies. It includes information such as part numbers, production quantities, material specifications, and scheduled start and end dates to ensure precise coordination and efficient workflow. This form helps maintain quality control, track inventory usage, and optimize resource allocation throughout the manufacturing process.

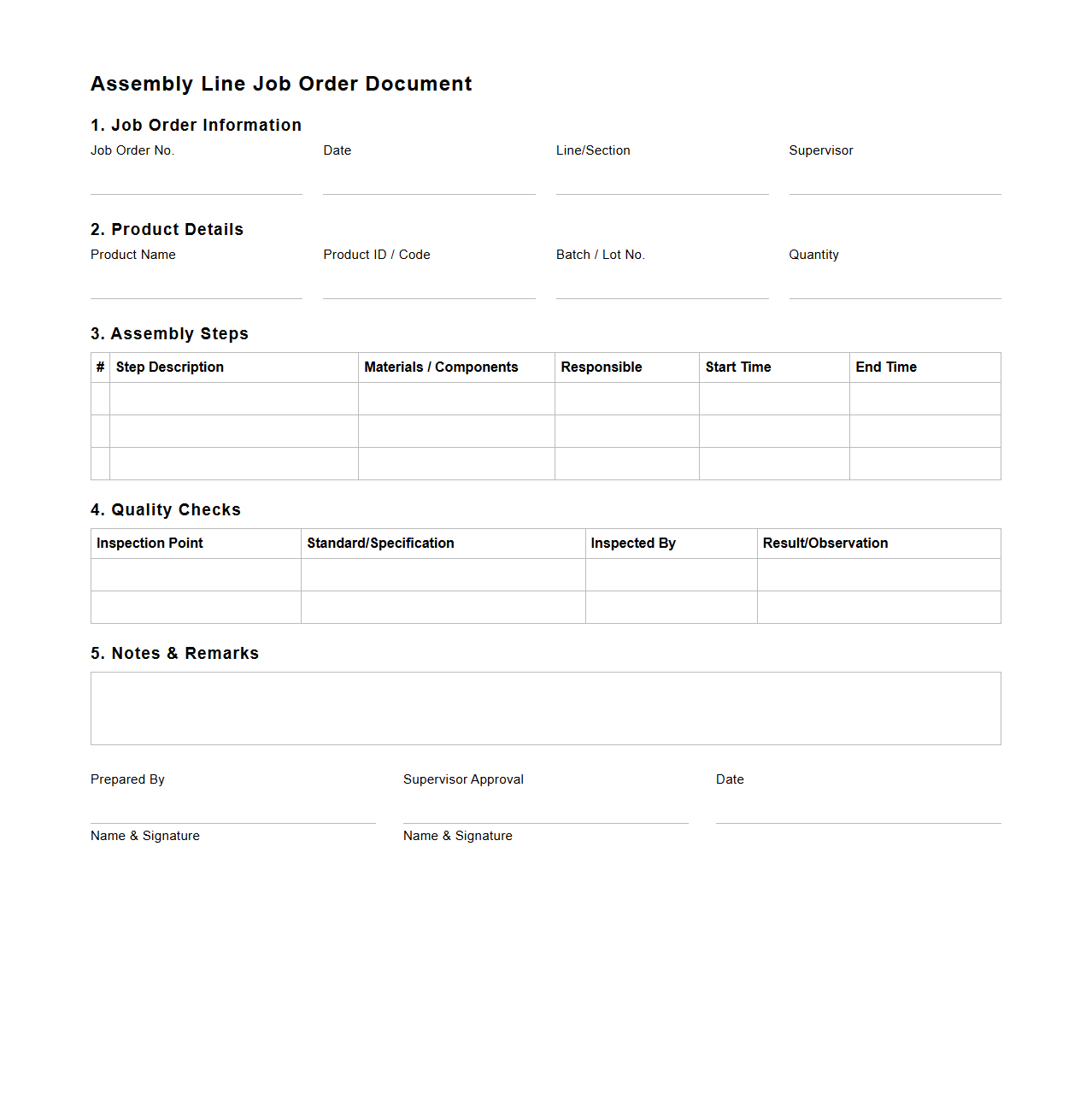

Detailed Assembly Line Job Order Document

A

Detailed Assembly Line Job Order Document serves as a comprehensive blueprint that outlines specific tasks, materials, and timelines required for each stage of the assembly line process. It ensures precise coordination and quality control by providing clear instructions and tracking production progress. This document plays a critical role in optimizing workflow efficiency and minimizing errors in manufacturing operations.

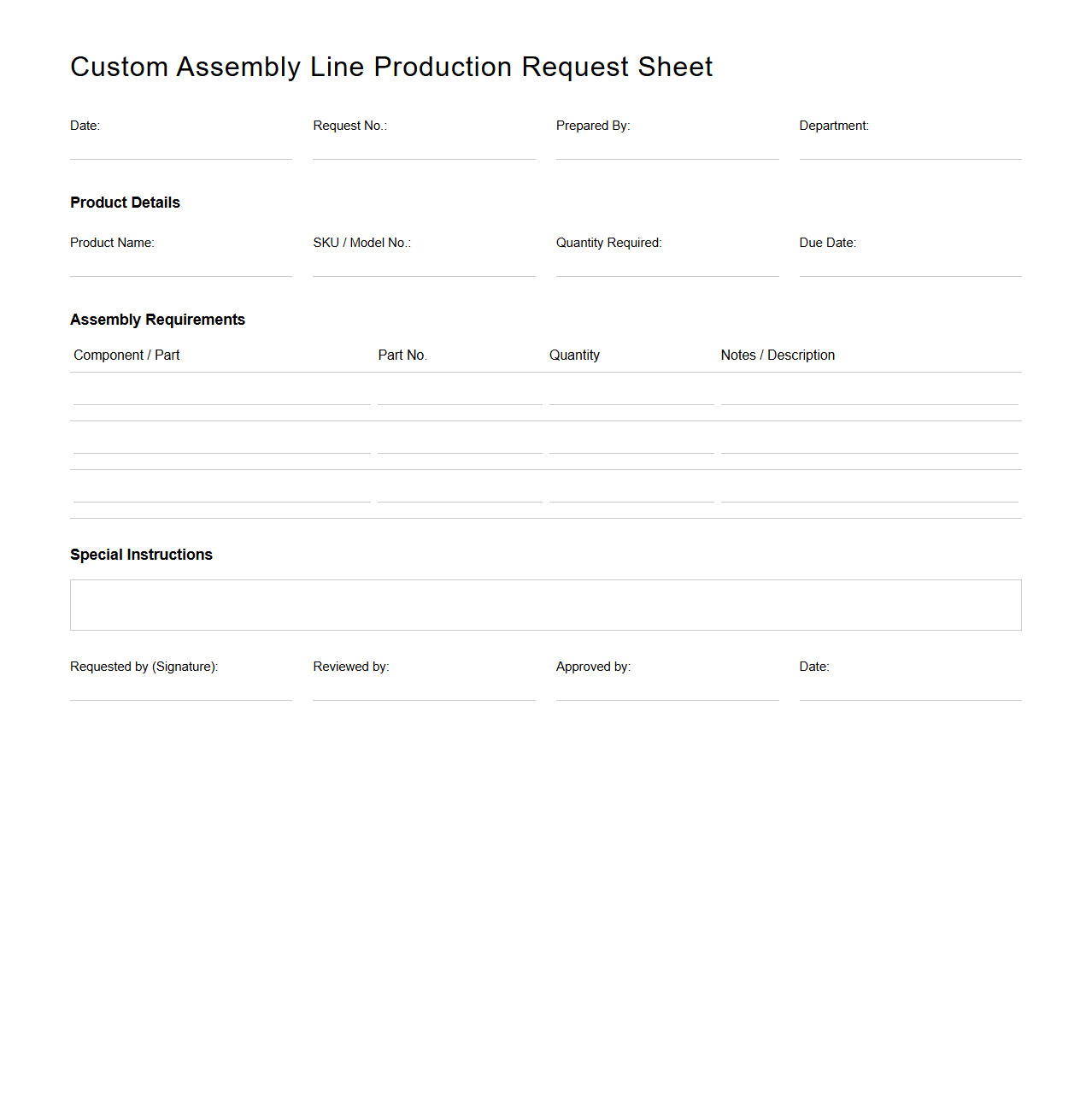

Custom Assembly Line Production Request Sheet

A

Custom Assembly Line Production Request Sheet is a detailed document used to specify requirements for tailored manufacturing processes on an assembly line. It outlines essential information such as product specifications, quantity, materials, and production timelines to ensure precise execution. This sheet facilitates clear communication between design, procurement, and production teams to optimize efficiency and quality.

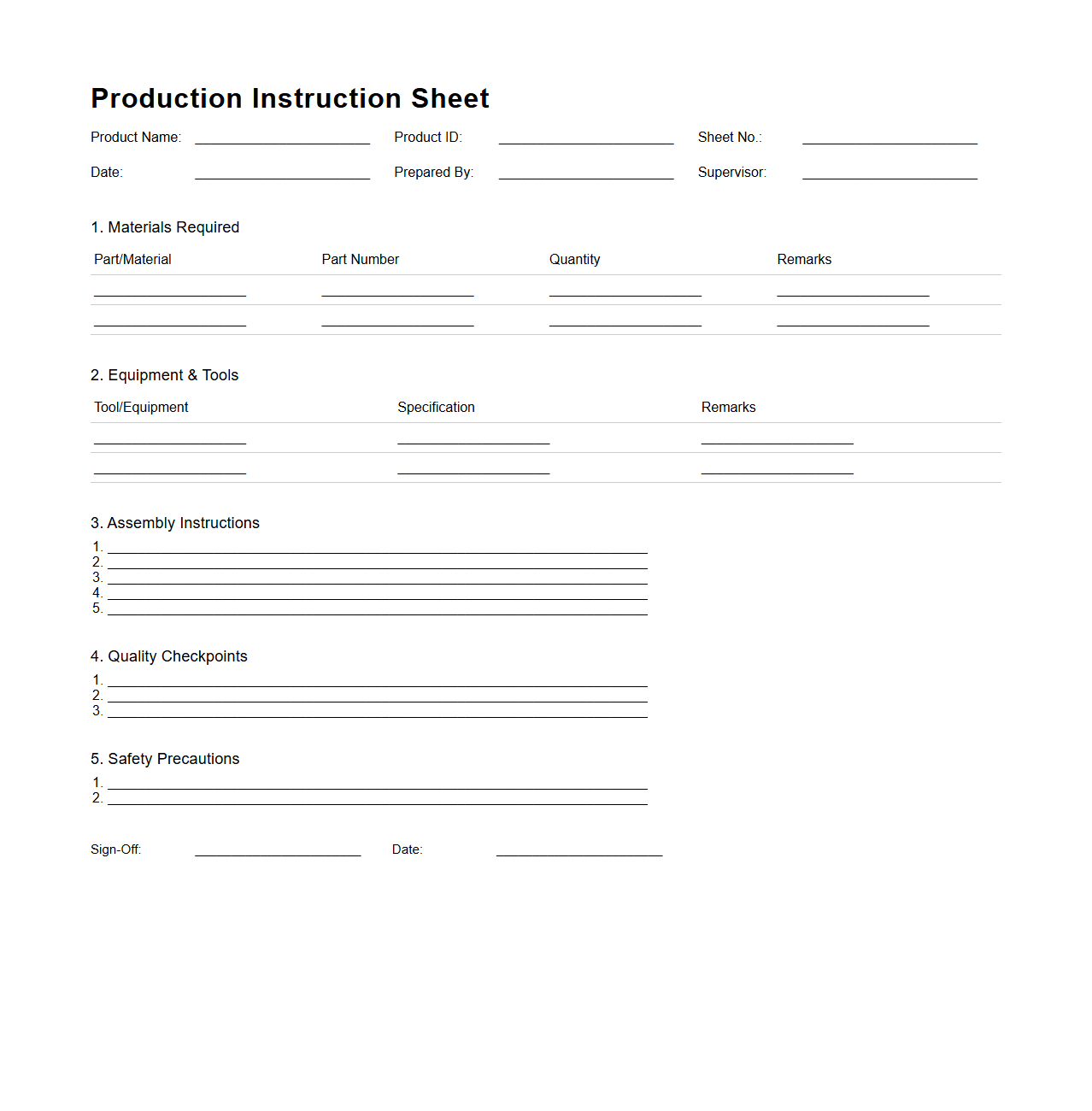

Production Instruction Sheet for Assembly Line Operations

A

Production Instruction Sheet for Assembly Line Operations is a detailed document that outlines step-by-step procedures, tools required, and quality standards necessary for efficient product assembly. It serves as a crucial reference to ensure consistency, accuracy, and compliance with manufacturing specifications across the assembly line. By standardizing operations, this sheet helps reduce errors, optimize workflow, and maintain production timelines.

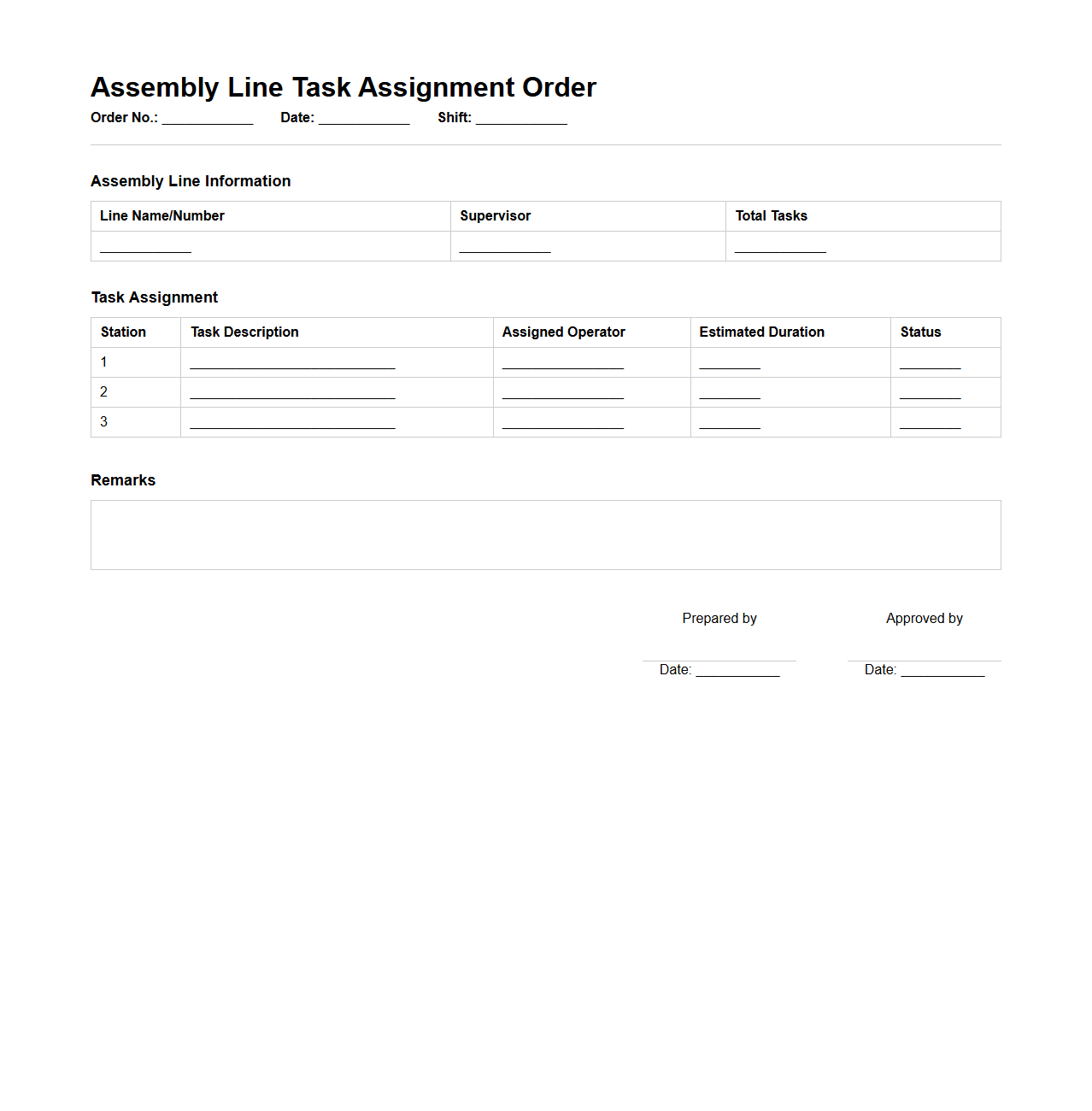

Assembly Line Task Assignment Order Layout

The

Assembly Line Task Assignment Order Layout document specifies the sequence and arrangement of tasks assigned to each workstation on a production line. It ensures efficient workflow by detailing the order in which components are assembled, minimizing bottlenecks and balancing workload across stations. This document is essential for optimizing production speed, maintaining quality, and improving overall operational efficiency.

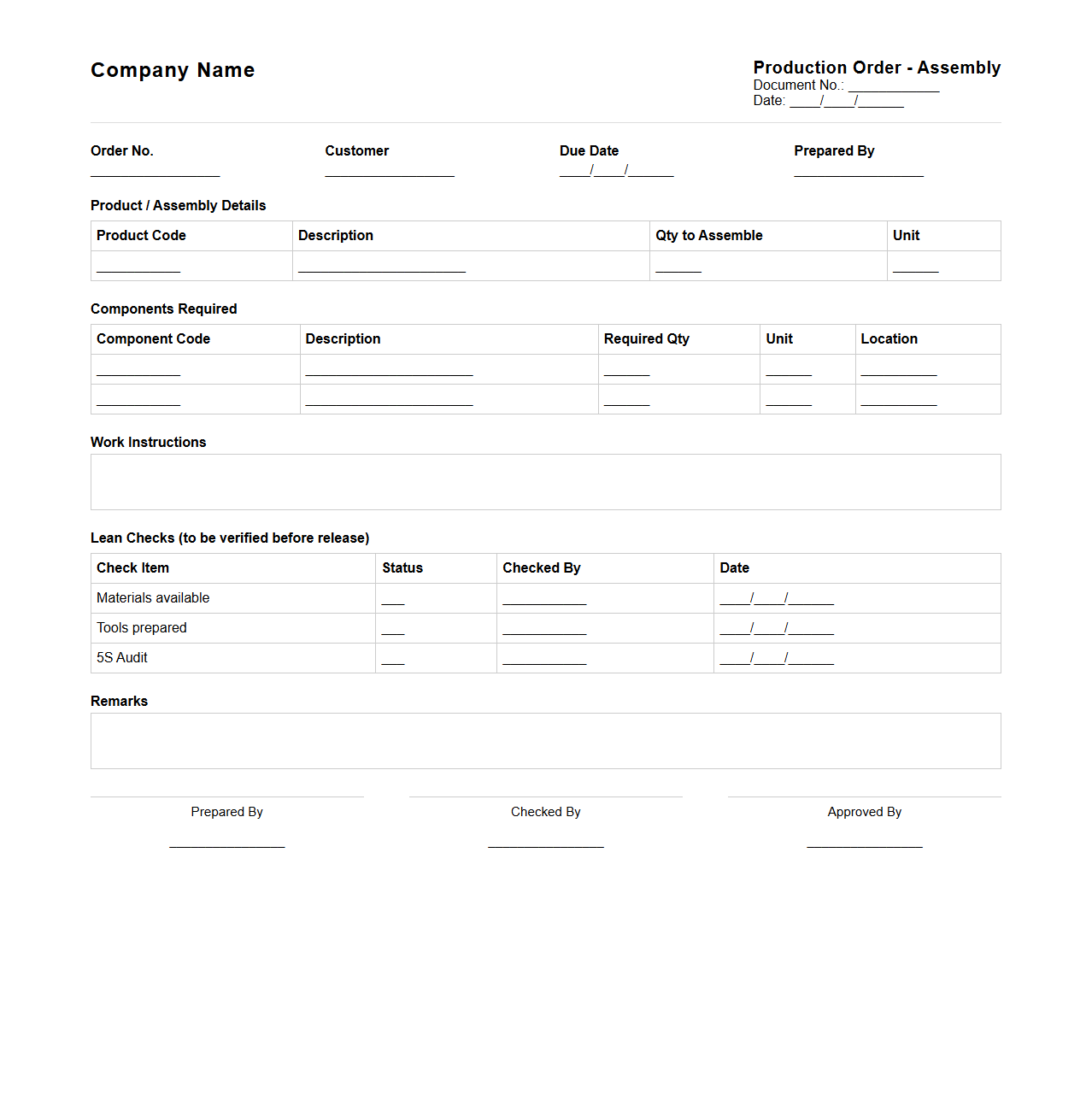

Lean Manufacturing Production Order for Assembly Process

A

Lean Manufacturing Production Order for Assembly Process document outlines the specific instructions and workflow required to efficiently assemble products while minimizing waste and maximizing value. It includes detailed steps, resource allocation, and timing to ensure smooth, just-in-time production aligned with lean principles. This document helps streamline operations, reduce downtime, and improve overall assembly quality.

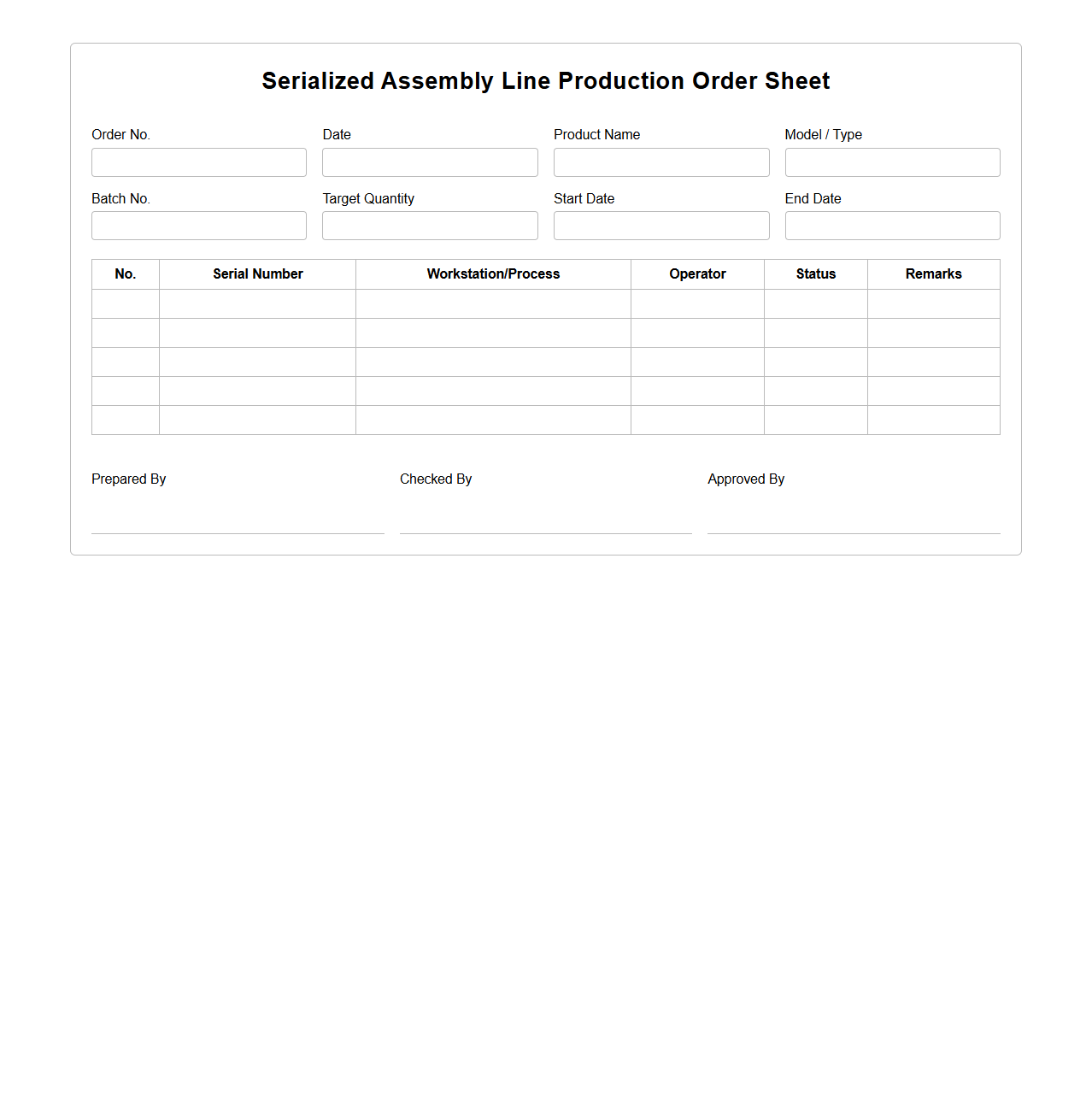

Serialized Assembly Line Production Order Sheet

A

Serialized Assembly Line Production Order Sheet document is used to organize and track the sequential manufacturing process of products through an assembly line. It details each step, assigns serial numbers, and monitors progress to ensure quality control and efficient workflow. This document is essential for maintaining production consistency and traceability in complex manufacturing environments.

Key Components of a Production Order Document

A standard Production Order Document must include sections such as order identification, detailed task instructions, and resource allocation. It outlines specific steps required in the assembly line to ensure process consistency. Additionally, labor and machine scheduling details must be incorporated for efficient workflow management.

Specification of Bill of Materials (BOM)

The document clearly lists the Bill of Materials (BOM) by specifying each component and quantity required for an assembly order. It includes part numbers, descriptions, and sourcing information to streamline material preparation. This ensures that all necessary materials are accounted for before production begins.

Tracking Production Deadlines and Delivery Schedules

Production deadlines and delivery schedules are tracked using dedicated sections within the document that specify start dates, completion targets, and shipping timelines. These timelines are monitored to maintain adherence to production plans. Alerts or status updates may also be included to identify any potential delays promptly.

Documentation of Quality Control Checkpoints

Quality control checkpoints are documented by listing inspection stages and required approvals at each critical phase. The document includes fields for recording tester names, results, and corrective actions if necessary. This ensures compliance with quality standards throughout the production process.

Identification and Traceability Codes

The document contains traceability codes such as batch numbers, serial numbers, or QR codes to link production orders to specific products. These identifiers facilitate tracking and recall management if needed. Proper coding supports transparency and accountability in the manufacturing workflow.

More Manufacturing Templates