A Finished Goods Dispatch Document Sample for Manufacturing outlines critical details such as product type, quantity, dispatch date, and destination to ensure accurate tracking and delivery. This document serves as proof of shipment and helps maintain inventory accuracy within the supply chain. Proper use of this sample enhances operational efficiency and minimizes errors during the dispatch process.

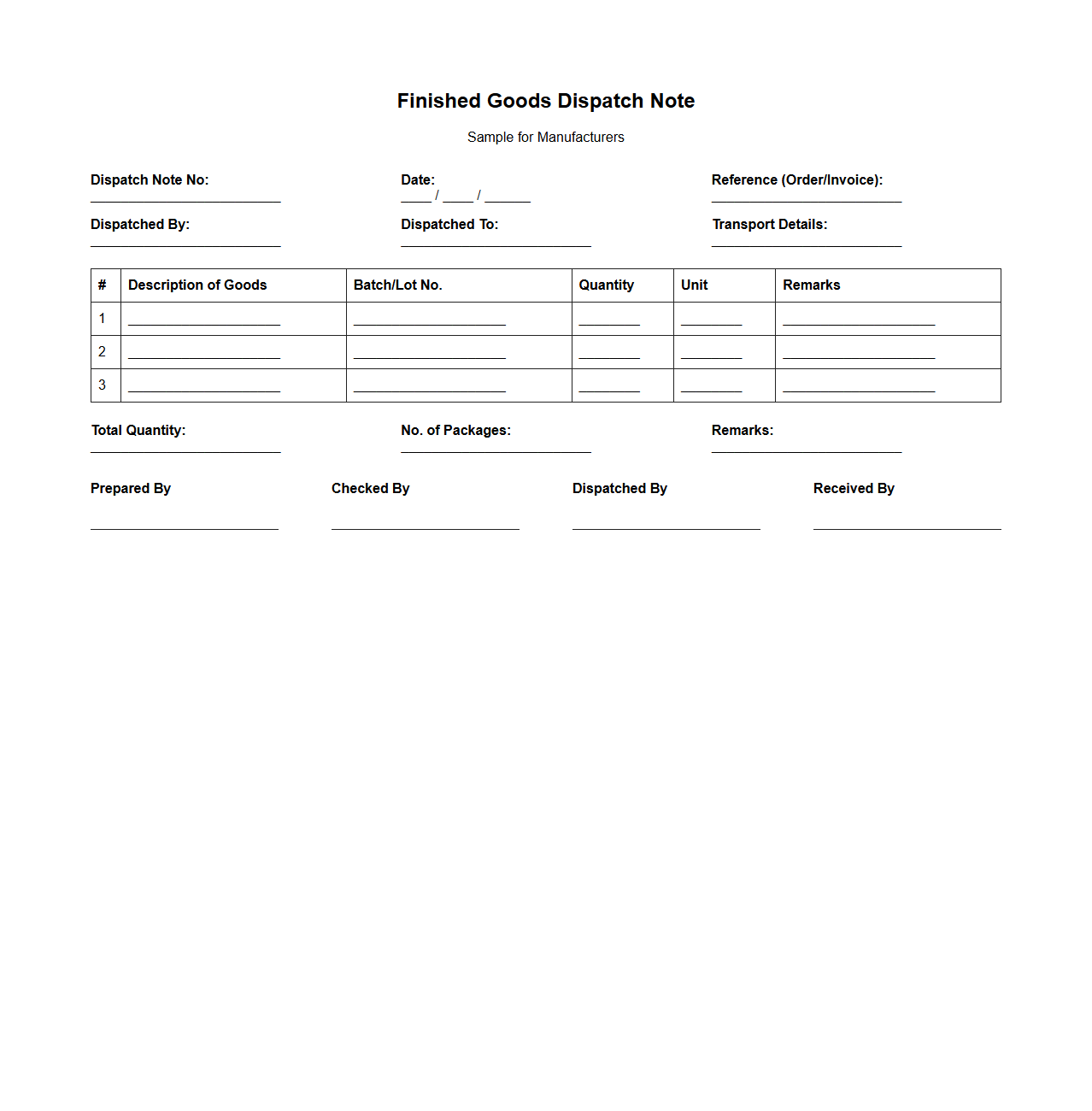

Finished Goods Dispatch Note Sample for Manufacturers

A

Finished Goods Dispatch Note Sample for manufacturers serves as a critical document that details the specifics of products being shipped from the production facility to clients or warehouses. It typically includes product description, quantity, batch numbers, and dispatch date, ensuring accurate tracking and inventory management. Manufacturers rely on this note to verify order fulfillment and maintain a transparent supply chain process.

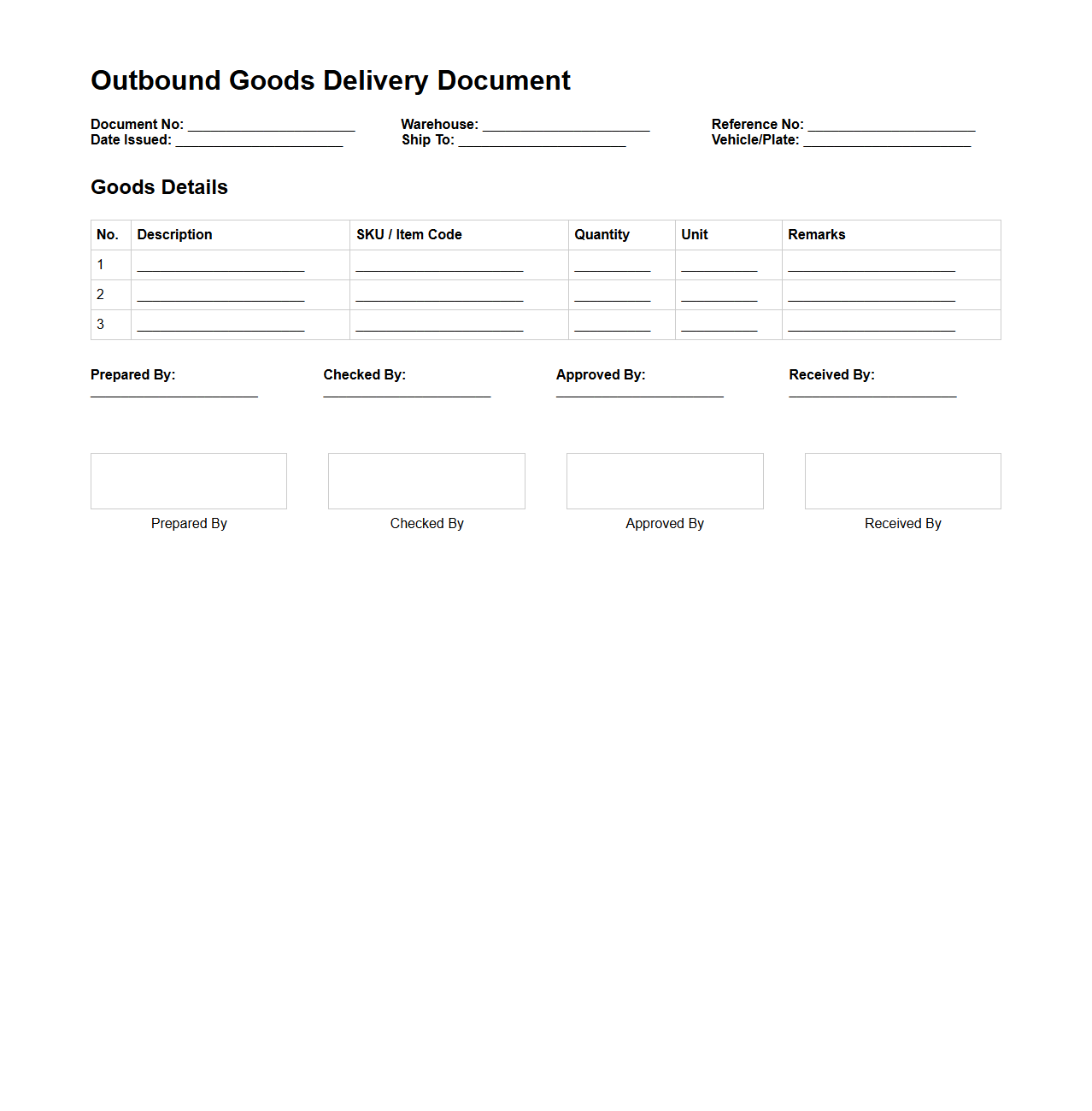

Outbound Goods Delivery Document Example

An

Outbound Goods Delivery Document example demonstrates the essential information required during the shipment of products from a warehouse to the customer, including delivery date, quantity, and item details. This document ensures accuracy in order fulfillment by tracking the physical dispatch of goods and confirming shipment status. It serves as a critical tool for inventory management, logistics coordination, and verifying delivery performance.

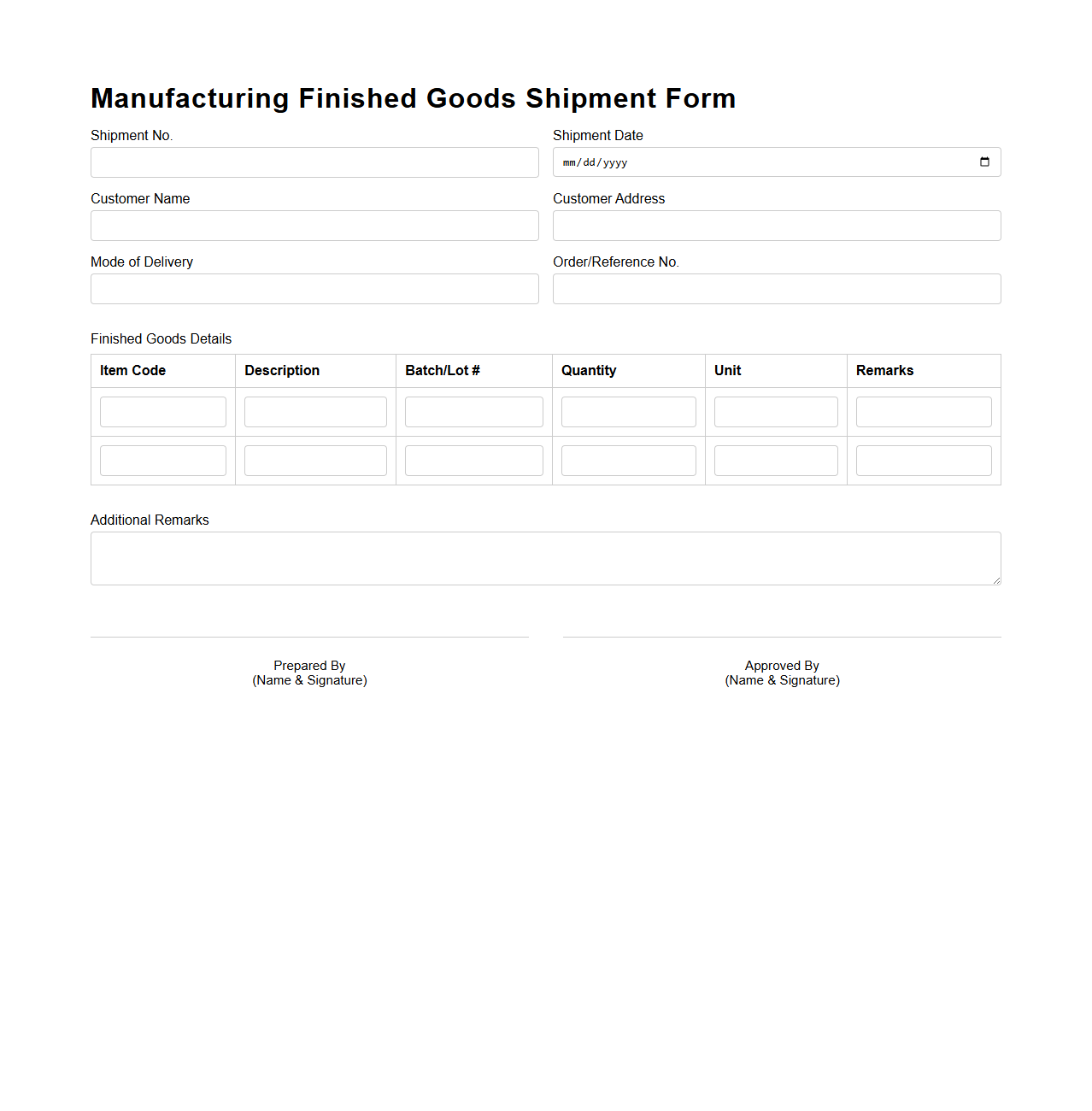

Manufacturing Finished Goods Shipment Form Sample

Manufacturing Finished Goods Shipment Form Sample document is a standardized template used by manufacturers to record comprehensive details of finished goods being shipped to customers or distribution centers. It typically includes essential information such as product descriptions, quantities, batch numbers, shipping dates, and destination addresses to ensure accurate tracking and inventory management. This form facilitates transparent communication between production, logistics, and sales departments, streamlining the shipment process and minimizing errors.

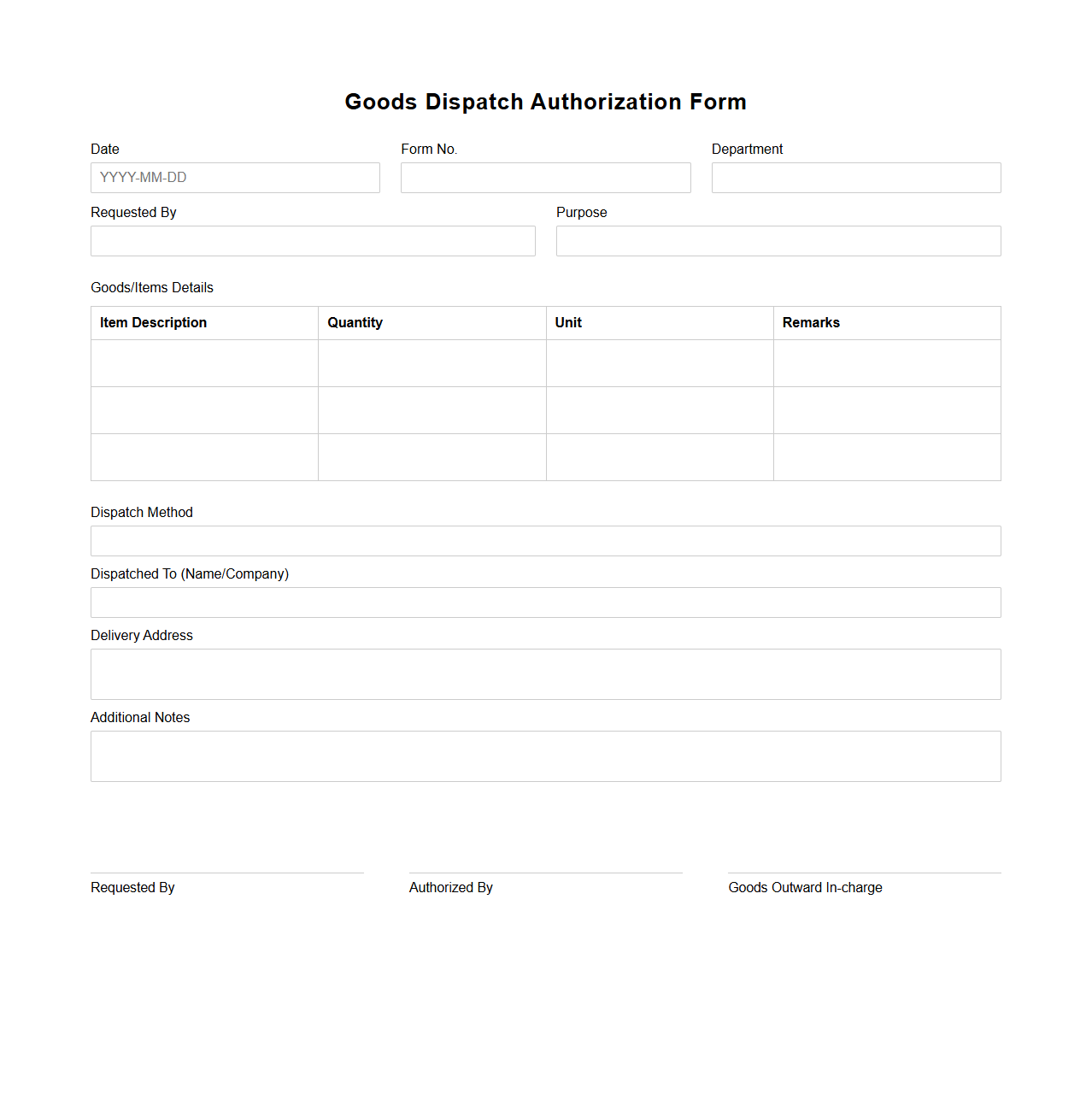

Goods Dispatch Authorization Form Template

The

Goods Dispatch Authorization Form Template is a standardized document used to approve and track the release of goods from inventory or storage. It ensures authorization by relevant personnel before dispatch, detailing item descriptions, quantities, destination, and dispatch date to maintain accurate inventory control. This form serves as a critical tool for logistics management, minimizing errors and preventing unauthorized shipments.

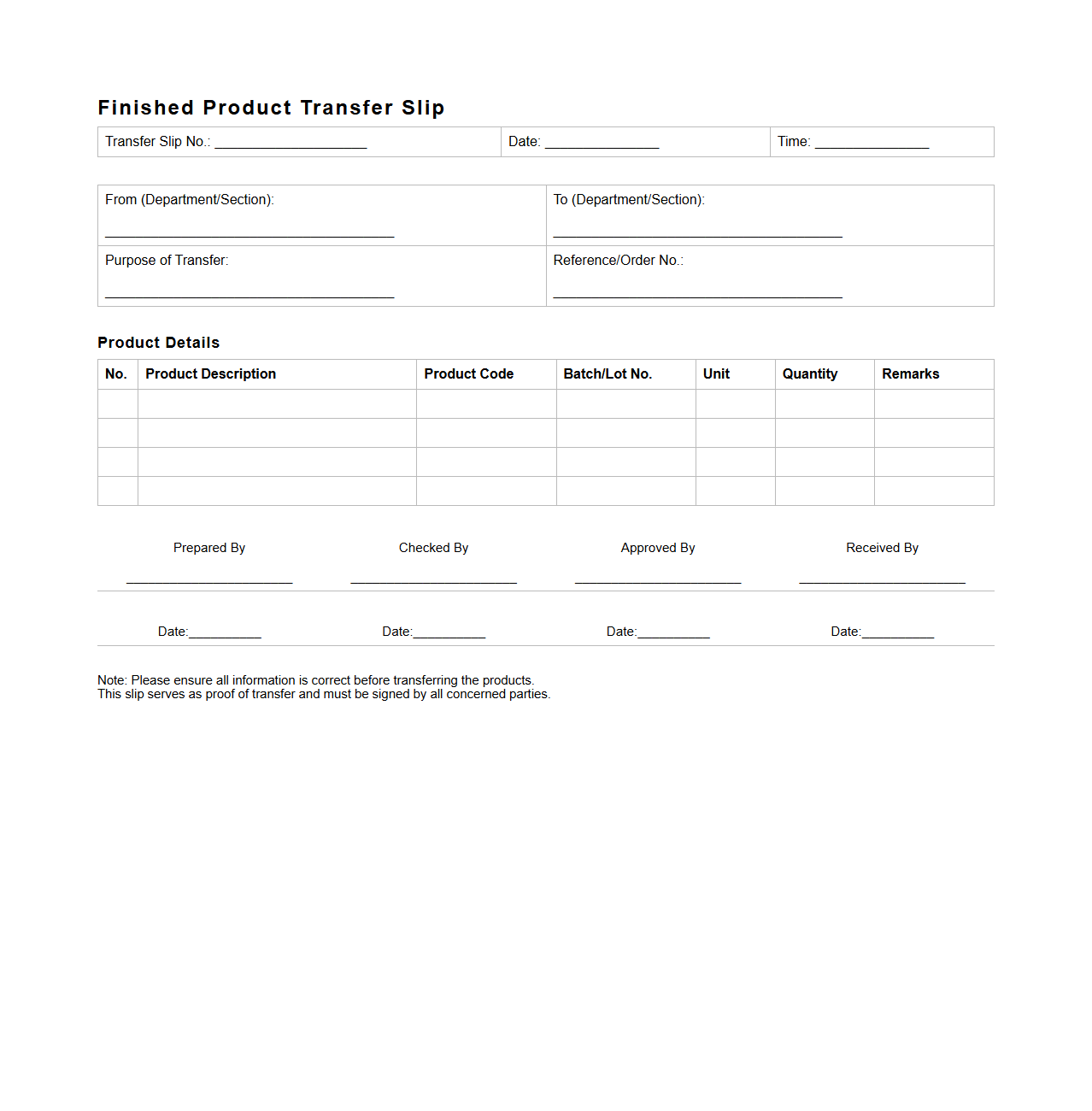

Finished Product Transfer Slip for Factory Operations

The

Finished Product Transfer Slip is a crucial document in factory operations, used to record the movement of completed goods from the production area to the warehouse or dispatch section. It details the product type, quantity, batch number, and transfer date, ensuring traceability and inventory accuracy. This slip facilitates smooth logistics coordination and helps maintain efficient inventory management within the manufacturing process.

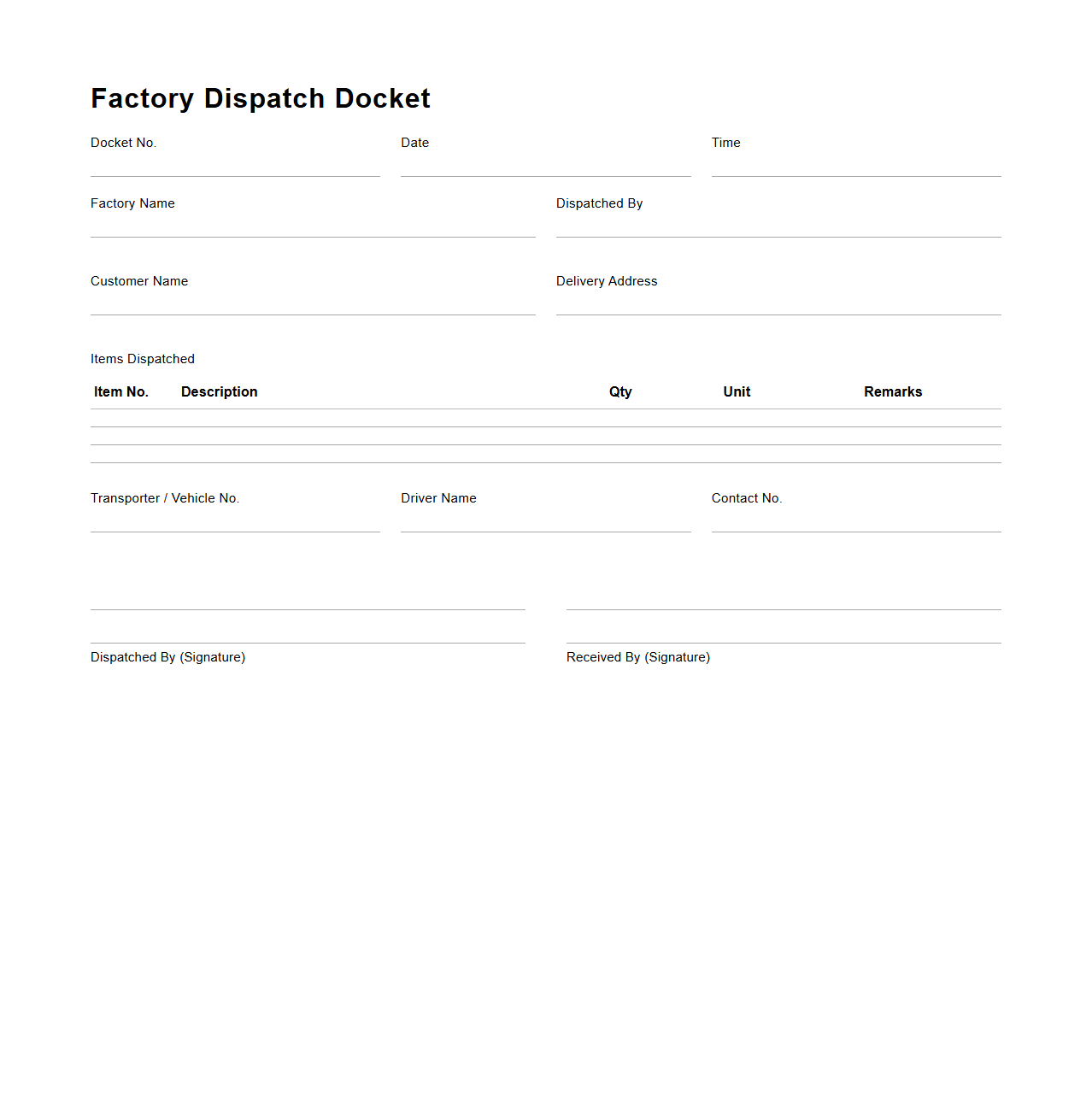

Factory Dispatch Docket Example

A

Factory Dispatch Docket Example document serves as an official record detailing the shipment of goods from a manufacturing facility. It includes key information such as product descriptions, quantities, batch numbers, dispatch dates, and recipient details to ensure accurate tracking and accountability. This document plays a critical role in inventory management, quality control, and verifying delivery compliance between the factory and clients.

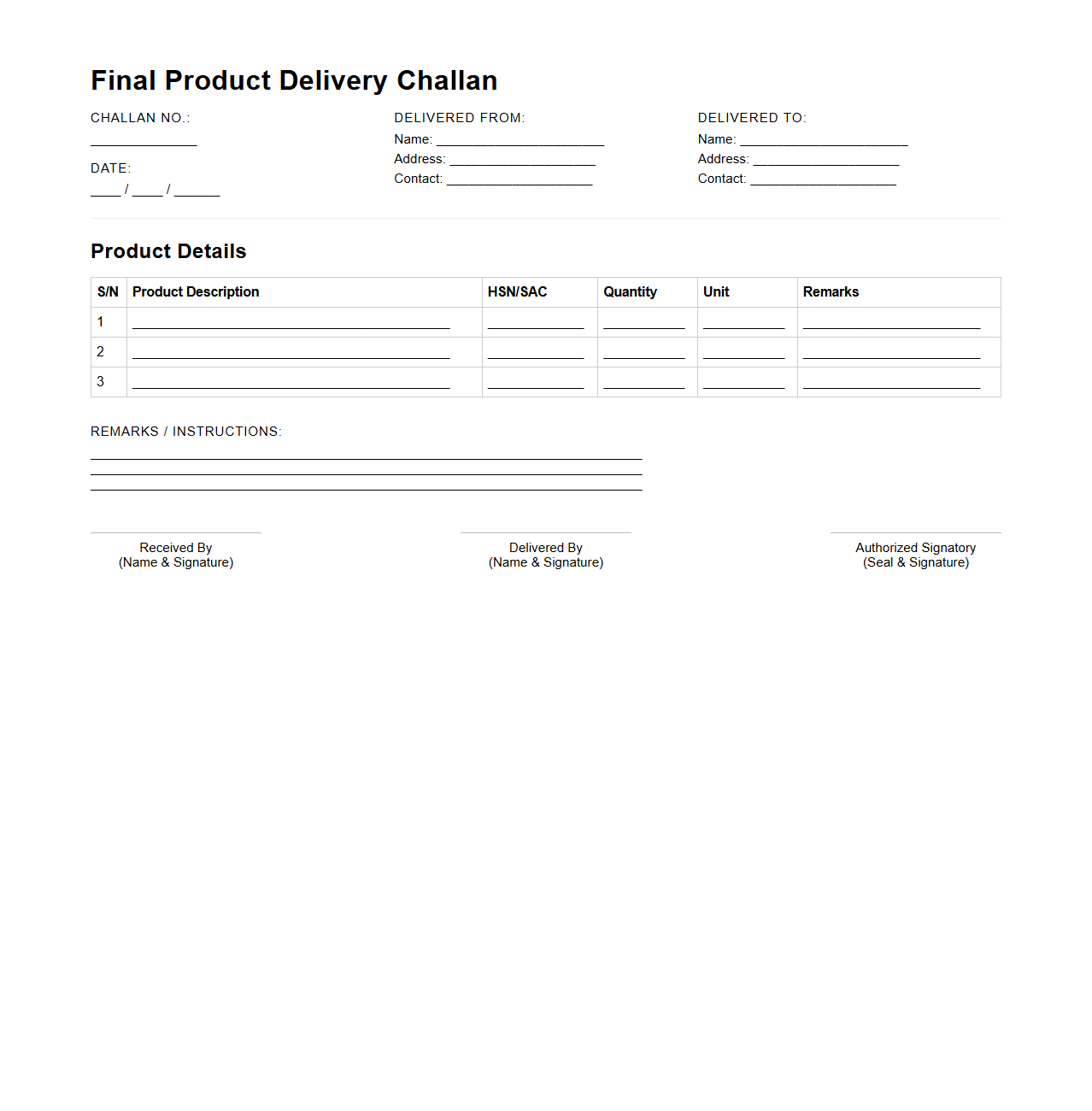

Final Product Delivery Challan Sample

A

Final Product Delivery Challan Sample document serves as proof of the transfer of goods from the seller to the buyer, detailing the quantity, description, and condition of the products delivered. It includes essential information such as product serial numbers, delivery date, and signatures of both parties to ensure accountability and verification. This document plays a crucial role in the logistics and inventory processes by confirming the receipt of goods and facilitating smooth payment or further processing.

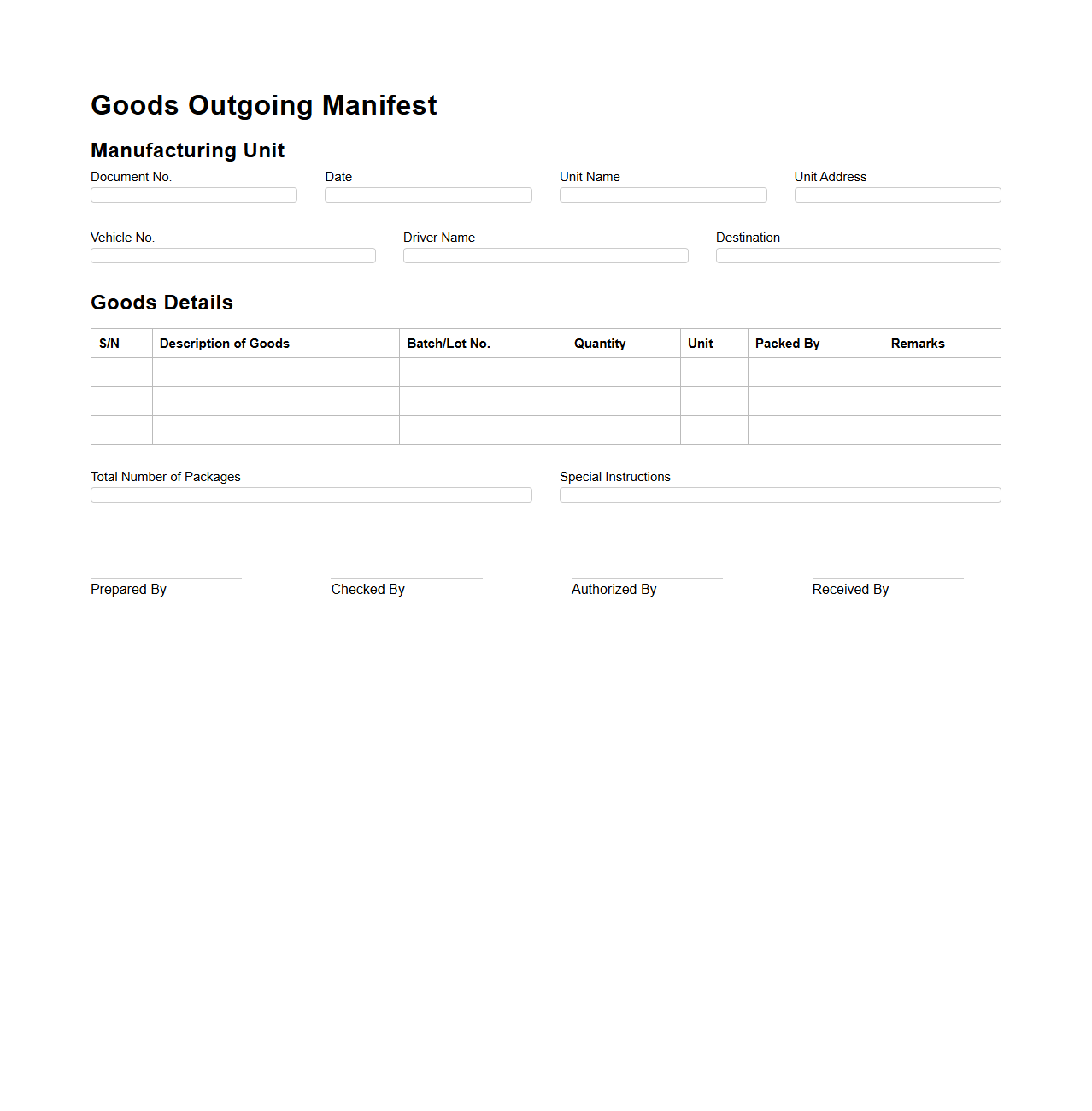

Goods Outgoing Manifest for Manufacturing Units

The

Goods Outgoing Manifest for manufacturing units is a critical document that details all products dispatched from the facility to various destinations. It typically includes information such as product descriptions, quantities, batch numbers, and shipping dates, ensuring accurate tracking and accountability. This manifest facilitates seamless logistics coordination and compliance with inventory management protocols.

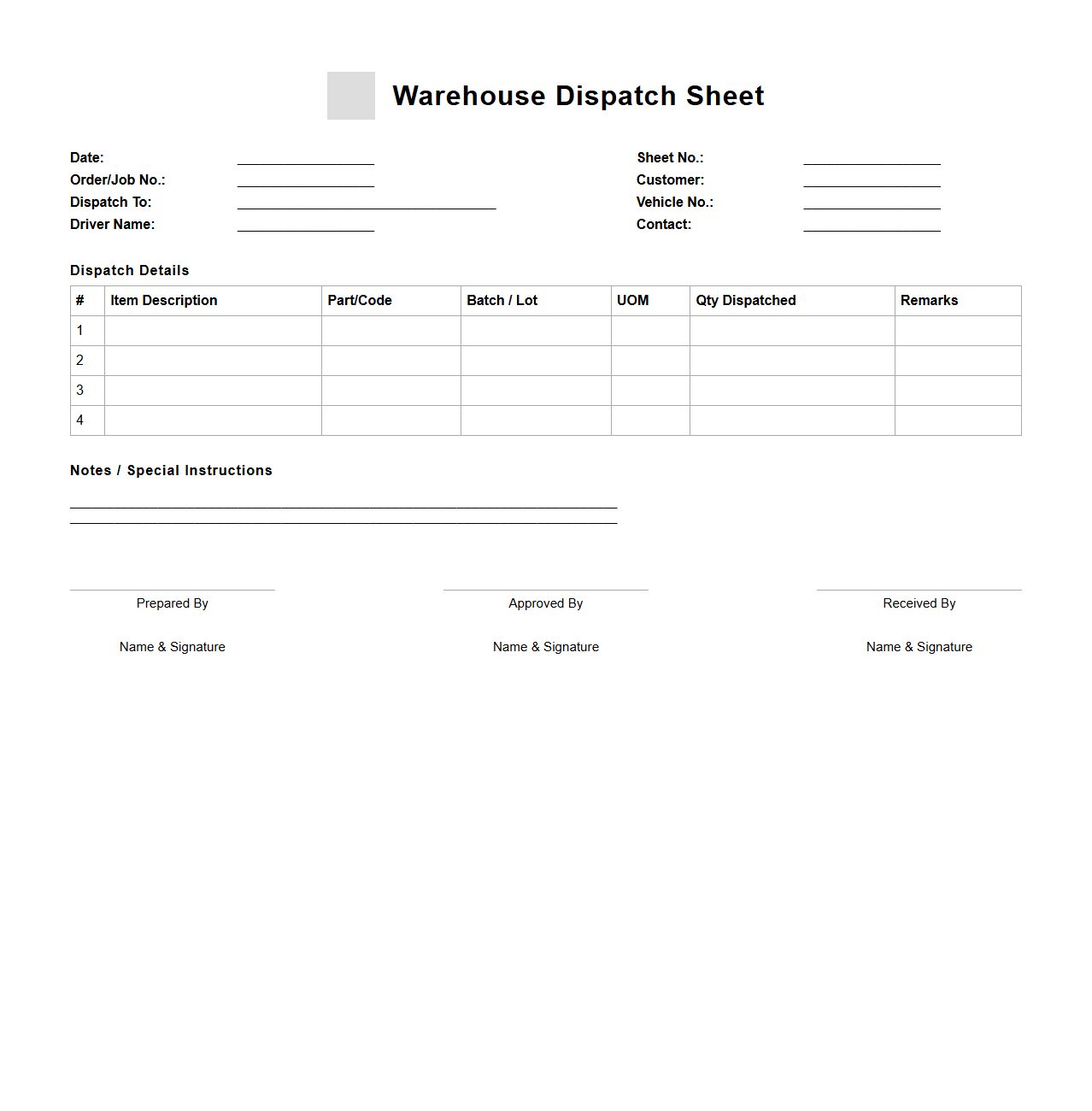

Manufacturing Warehouse Dispatch Sheet Sample

A

Manufacturing Warehouse Dispatch Sheet Sample document serves as a critical tool for tracking the movement of raw materials and finished goods from the warehouse to the production floor or delivery point. It includes key information such as item descriptions, quantities, batch numbers, dispatch dates, and recipient details to ensure accuracy and accountability during inventory transfer. This document enhances operational efficiency by minimizing errors and enabling real-time inventory management in manufacturing environments.

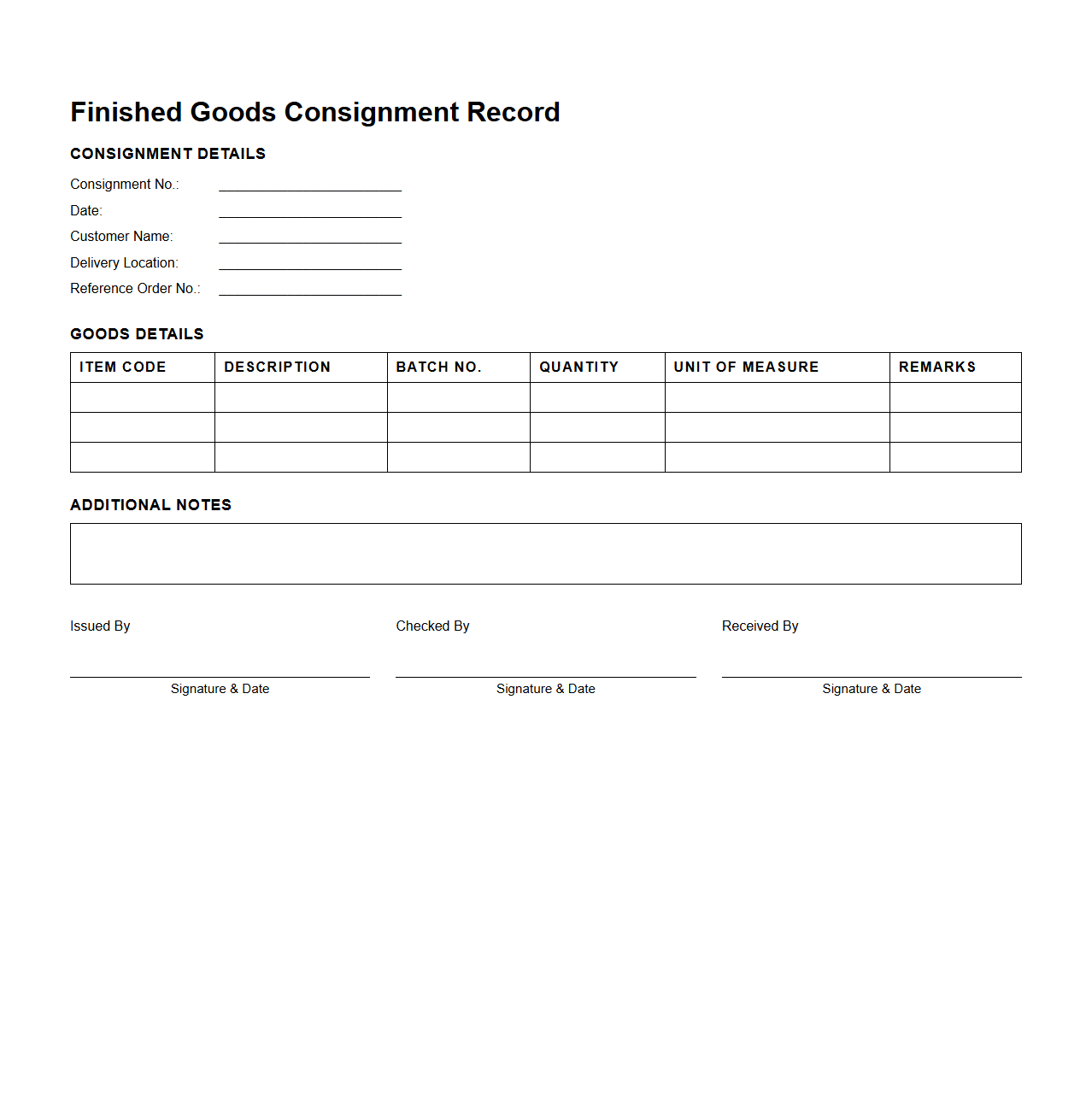

Finished Goods Consignment Record Example

A

Finished Goods Consignment Record Example document is used to track inventory that has been sent to a consignee but remains the property of the consignor until sold. It details product descriptions, quantities shipped, delivery dates, and sales status to ensure accurate monitoring and accountability. This record supports inventory management and financial reconciliation between suppliers and consignees.

What essential information should a Finished Goods Dispatch Document contain for manufacturing workflows?

A Finished Goods Dispatch Document should include critical details such as product description, quantity, batch or lot numbers, and packaging information. It must also specify the destination address and delivery instructions to ensure accurate shipment. Additionally, the document should record the dispatch date and carrier information for effective logistics coordination.

How does the dispatch document ensure traceability of finished goods in the supply chain?

The dispatch document incorporates unique batch numbers and serial numbers which are crucial for tracking the product through various stages of the supply chain. This traceability allows manufacturers and distributors to monitor the movement and status of goods in real-time. It also facilitates quick identification and resolution of any issues related to quality or delivery.

Which stakeholders are responsible for verifying and authorizing the dispatch document before shipping?

Key stakeholders include the warehouse manager, quality control personnel, and logistics coordinator who collectively verify the accuracy and completeness of the dispatch document. The warehouse manager confirms stock availability and packaging compliance. Quality control ensures the products meet standards, while logistics coordinates the shipping schedule and authorization.

What are the compliance and regulatory requirements addressed within a finished goods dispatch sample document?

The dispatch document must comply with industry standards such as product labeling regulations, safety guidelines, and export/import controls relevant to the manufacturing sector. It ensures adherence to legal documentation requirements, including certificates of origin and hazardous material declarations if applicable. Compliance safeguards reduce risk and maintain smooth customs clearance.

How does the dispatch document facilitate inventory updates and reconciliation in manufacturing operations?

The dispatch document serves as an official record to update inventory systems by reflecting the removal of finished goods from stock. It enables real-time inventory adjustments, preventing discrepancies between physical and recorded quantities. This reconciliation process supports accurate inventory management and aids in forecasting and production planning.

More Manufacturing Templates