A Supply Chain Tracking Document Sample for Manufacturing Industry provides a detailed template to monitor the movement of raw materials, components, and finished goods throughout the production process. It enables manufacturers to enhance transparency, reduce delays, and ensure compliance with quality standards. Using this document helps streamline operations and improve overall supply chain efficiency.

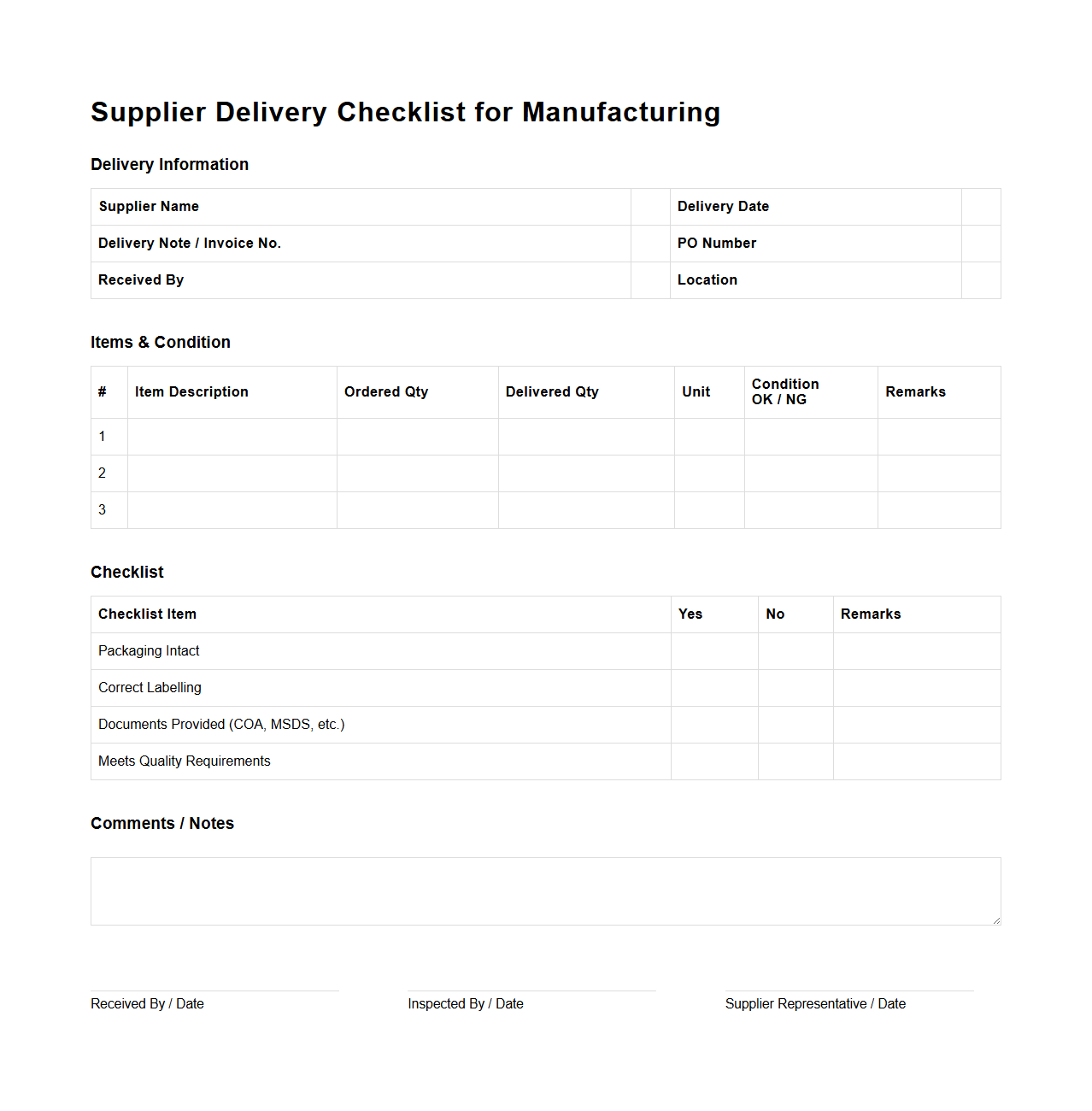

Supplier Delivery Checklist for Manufacturing

The

Supplier Delivery Checklist for manufacturing is a document that ensures all materials and components supplied meet quality, quantity, and specification requirements before acceptance. It serves as a verification tool for receiving teams to inspect delivery accuracy, packaging integrity, and compliance with purchase orders or contracts. This checklist helps manufacturers minimize production delays and maintain consistent product standards by systematically validating supplier shipments.

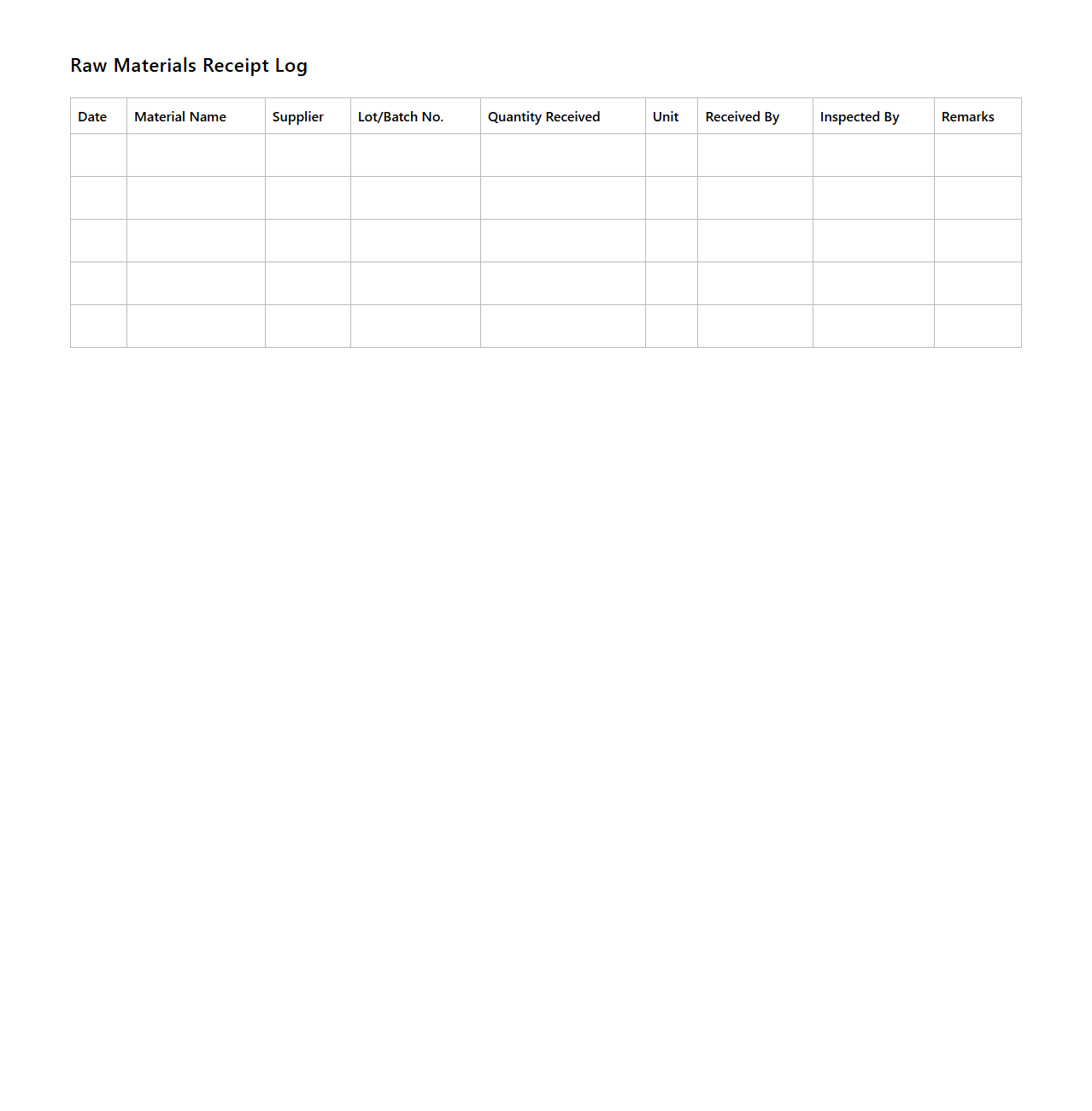

Raw Materials Receipt Log Template

A

Raw Materials Receipt Log Template document is used to systematically record the details of incoming raw materials, ensuring accurate tracking of quantities, supplier information, and delivery dates. It serves as a vital tool for quality control and inventory management, helping to verify that received materials meet specified requirements. This template enhances operational efficiency by providing a standardized format for documentation and audit purposes.

Production Batch Tracking Form

A

Production Batch Tracking Form is a critical document used in manufacturing to monitor and record the details of each production batch, ensuring traceability and quality control throughout the production process. It typically includes information such as batch number, production date, raw materials used, operator details, and inspection results. This form helps maintain compliance with industry standards and enables efficient identification of issues or recalls related to specific batches.

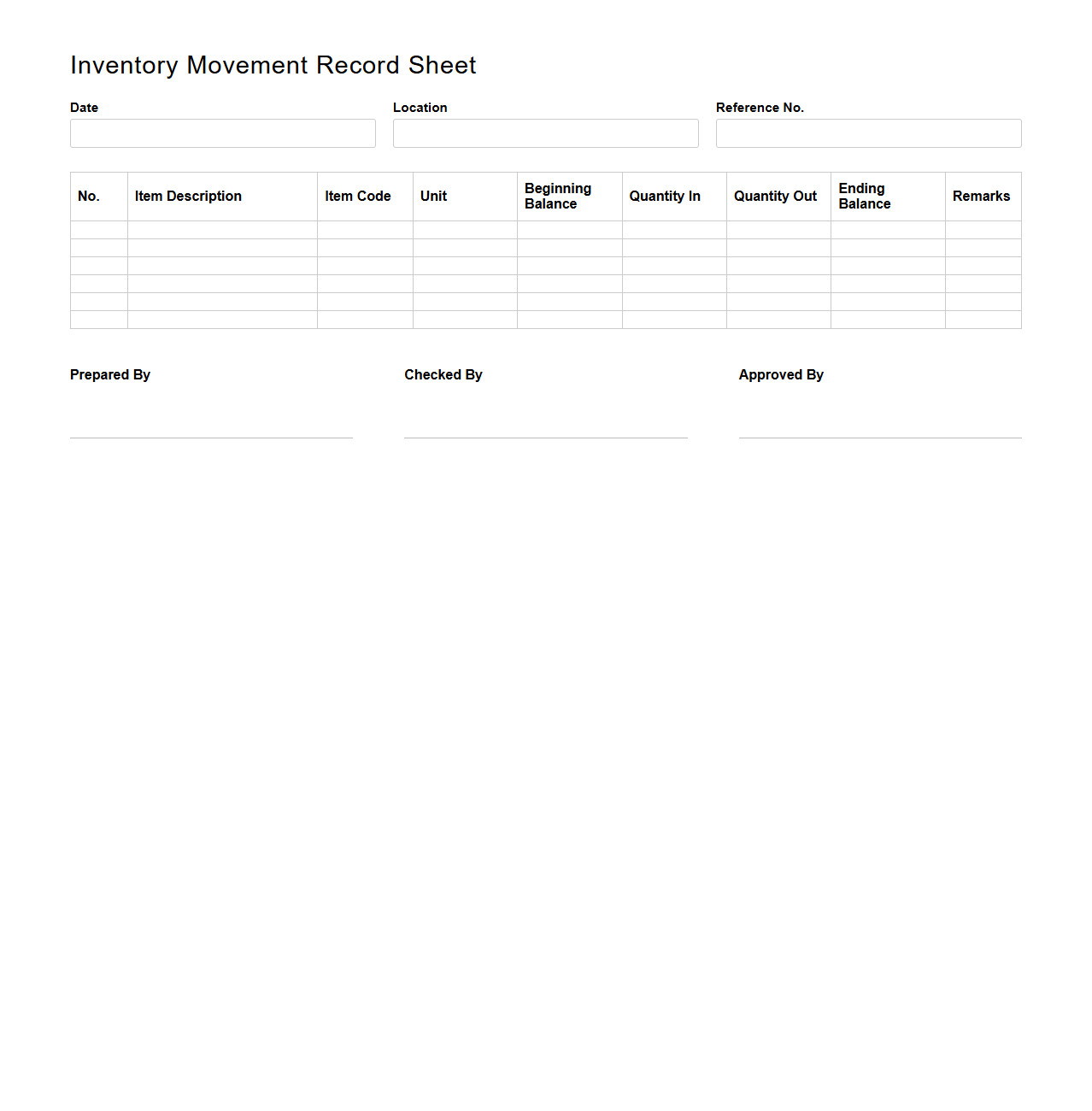

Inventory Movement Record Sheet

The

Inventory Movement Record Sheet is a document used to track the transfer, receipt, and issuance of inventory items within a warehouse or business operation. It records detailed information such as item descriptions, quantities, dates, and responsible personnel to ensure accurate inventory management and accountability. This sheet helps prevent stock discrepancies, supports audit trails, and enhances supply chain efficiency.

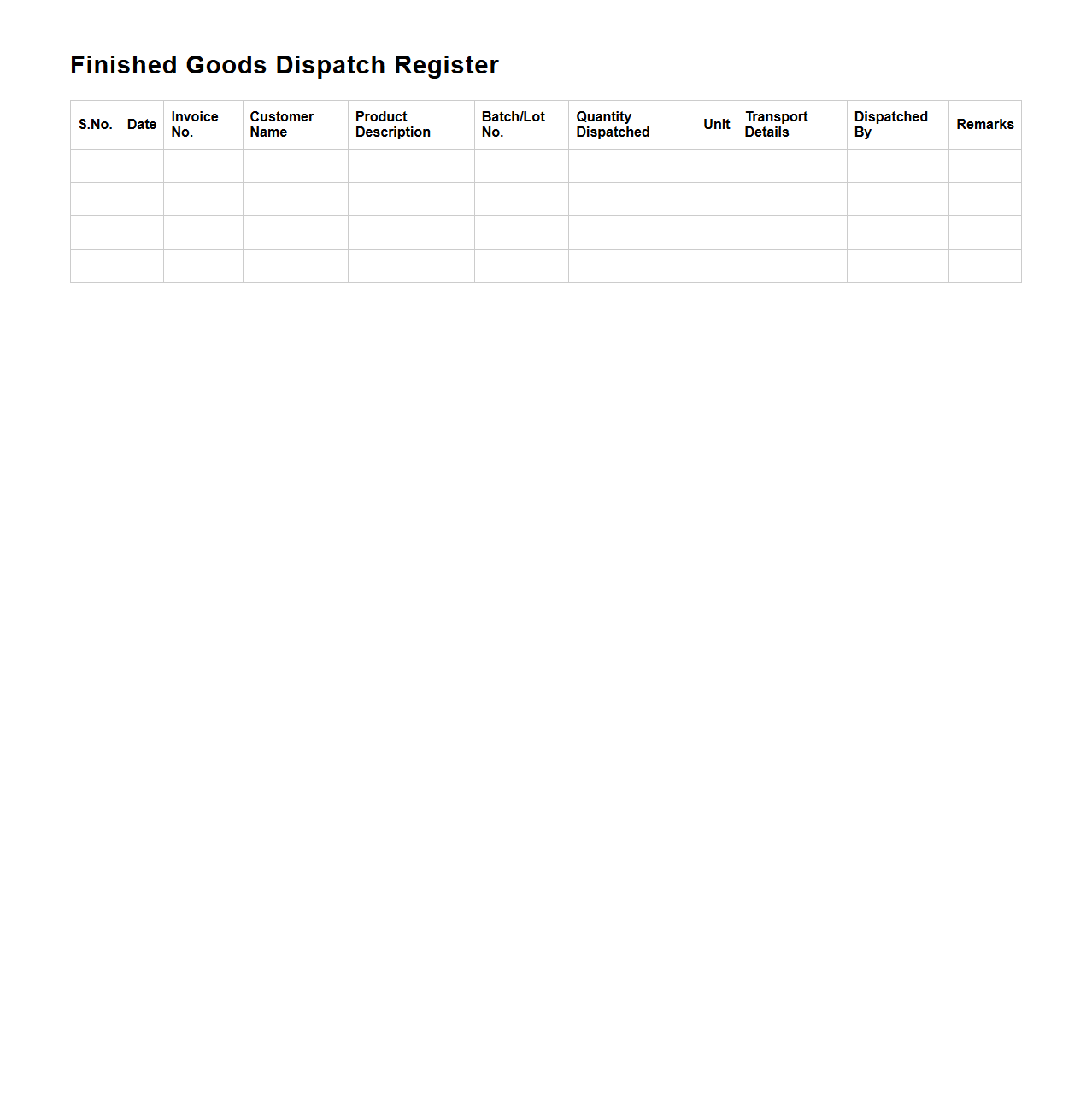

Finished Goods Dispatch Register

The

Finished Goods Dispatch Register is a vital document used to systematically record the details of goods dispatched from the manufacturing unit or warehouse. It tracks item descriptions, quantities shipped, dispatch dates, destination addresses, and transporter information, ensuring accurate inventory management and timely delivery verification. This register plays a crucial role in maintaining supply chain transparency, auditing processes, and resolving any shipment discrepancies.

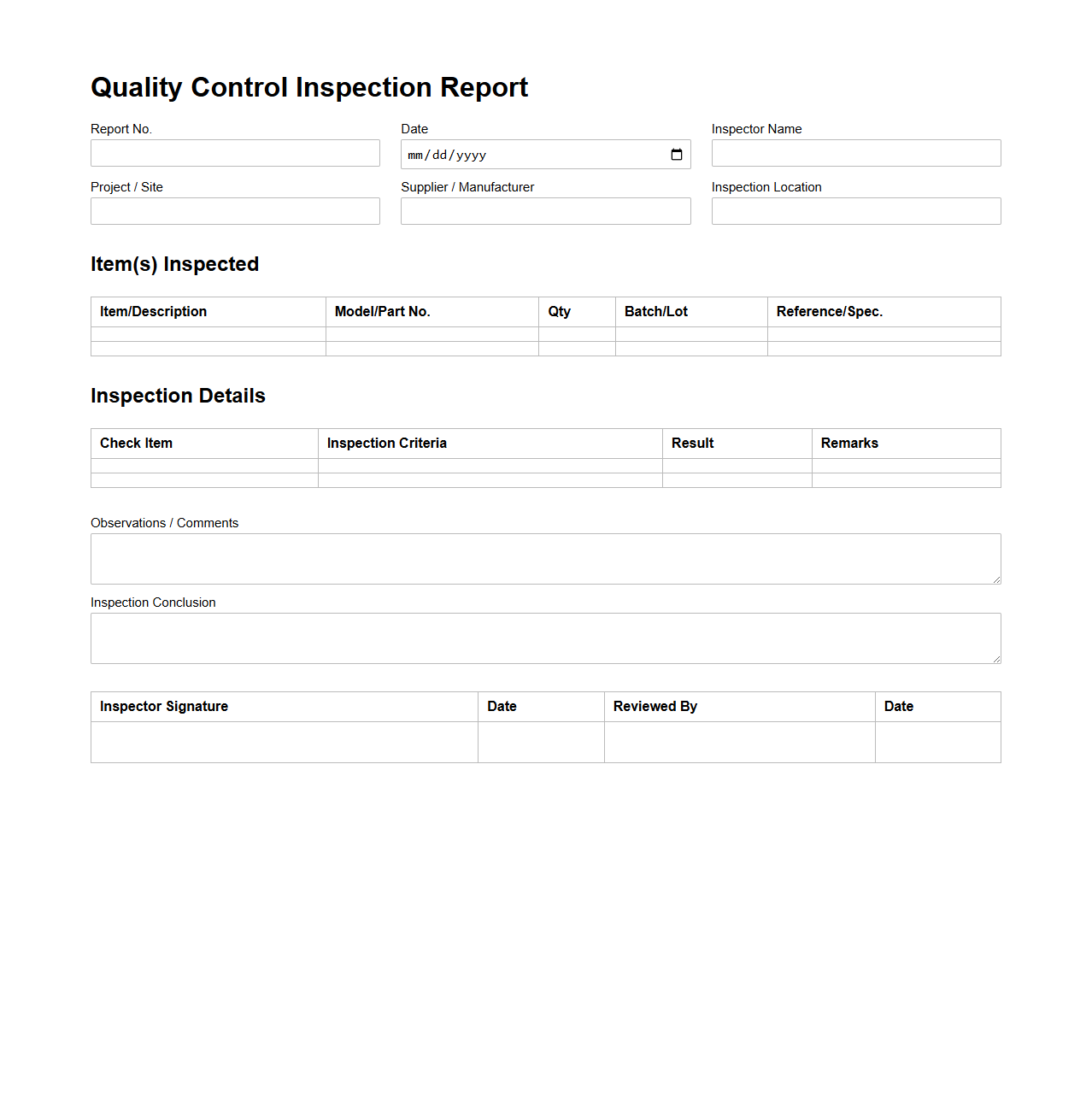

Quality Control Inspection Report

A

Quality Control Inspection Report document records the results of quality assessments conducted on products or processes to ensure compliance with specified standards. It details inspection methods, measured parameters, defects found, and corrective actions recommended. This report serves as a critical tool for maintaining product quality and facilitating continuous improvement in manufacturing or service delivery.

Inbound Shipment Tracking Template

An

Inbound Shipment Tracking Template document is a structured tool used by businesses to monitor and manage the arrival of goods from suppliers. It captures critical details such as shipment dates, carrier information, tracking numbers, and expected delivery timelines to ensure accurate inventory management. This template enhances transparency and helps prevent delays by providing a centralized reference for all inbound logistics.

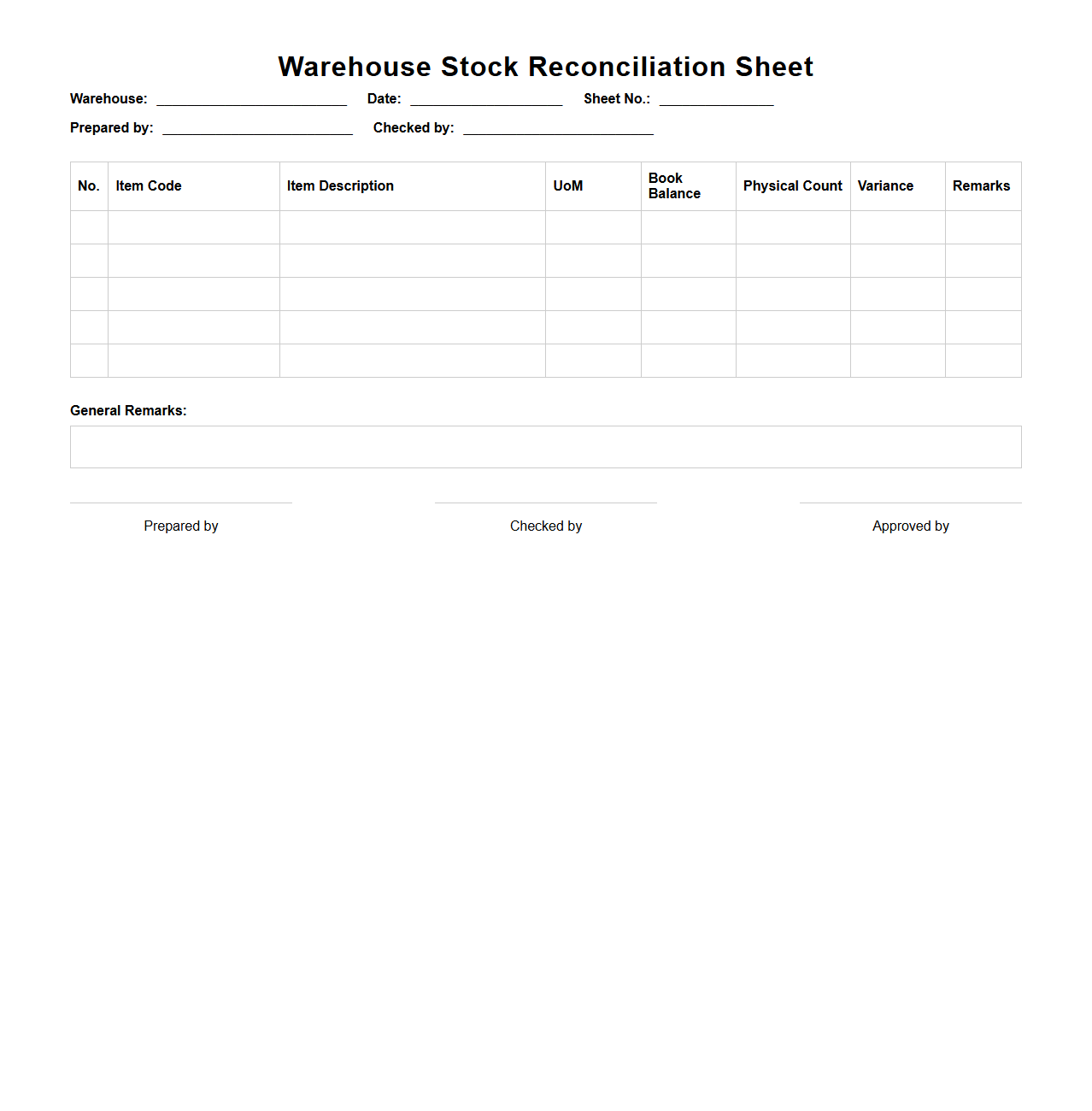

Warehouse Stock Reconciliation Sheet

A

Warehouse Stock Reconciliation Sheet document is used to accurately track and verify inventory levels by comparing physical stock counts with recorded data. It helps identify discrepancies caused by errors, theft, or damage, ensuring inventory records remain precise and reliable. This document is essential for maintaining efficient warehouse management and supporting accurate financial reporting.

Manufacturing Order Progress Tracker

The

Manufacturing Order Progress Tracker document is a critical tool used to monitor the status of production orders throughout the manufacturing process. It provides real-time updates on each stage, from raw material procurement to final assembly, ensuring efficiency and timely completion. This document helps identify bottlenecks, manage resources effectively, and improve overall workflow transparency in manufacturing operations.

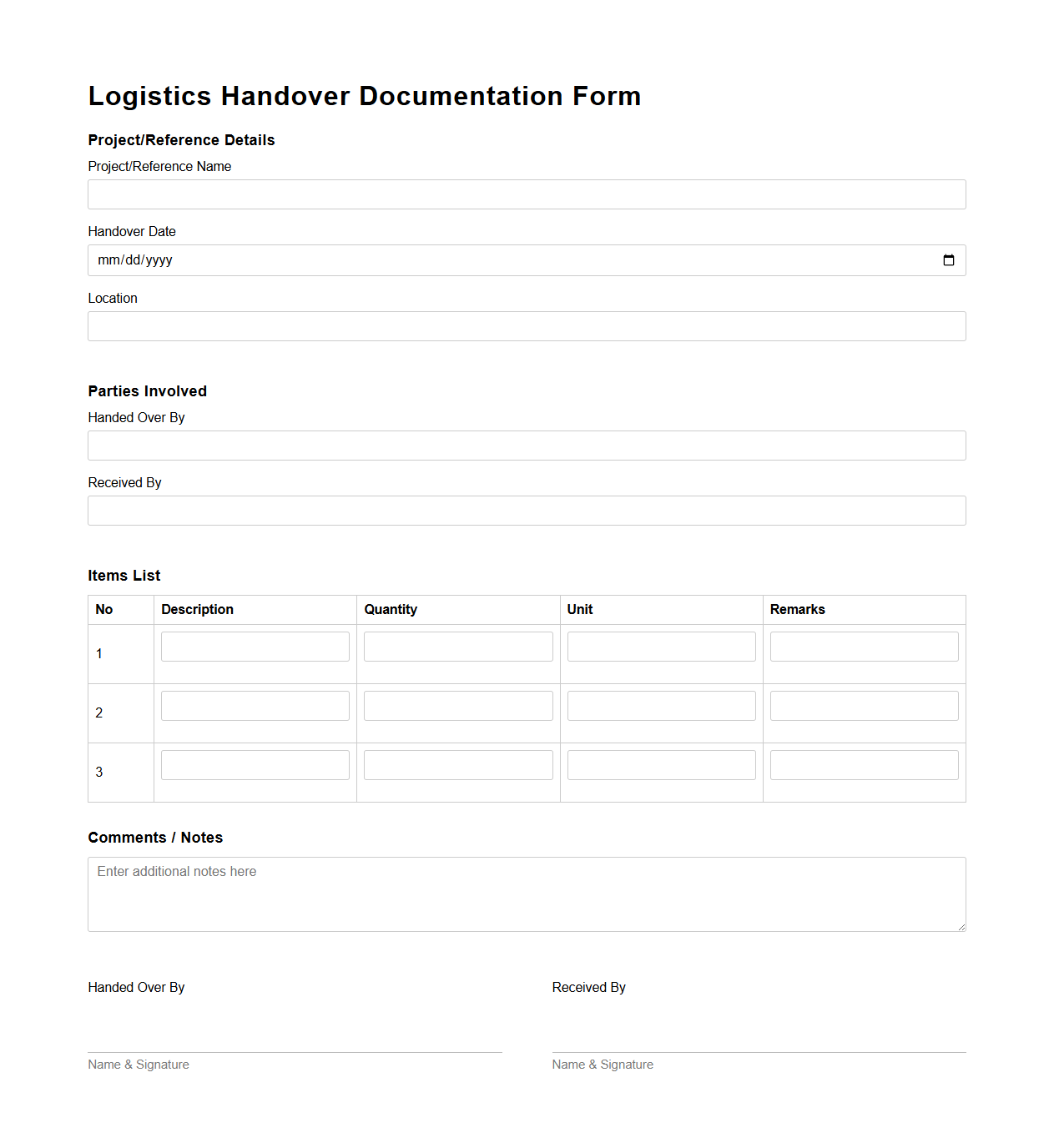

Logistics Handover Documentation Form

The

Logistics Handover Documentation Form is a critical document used to record the transfer of responsibilities, materials, and information between logistics teams or shifts. It ensures accurate tracking of inventory, equipment status, and delivery schedules, minimizing errors and downtime. This form enhances accountability and smooth operational continuity within supply chain management.

What key data fields are essential for effective supply chain tracking in this document template?

The document template includes product identification numbers, batch or lot numbers, and shipment dates as essential data fields. It also captures supplier details and destination information to ensure comprehensive tracking. These fields enable accurate monitoring and quick retrieval of supply chain status.

How does the document ensure traceability of materials and components throughout the supply chain?

Traceability is maintained by linking each material and component to a unique tracking code within the document. Detailed records of origin, processing stages, and transit checkpoints are systematically logged. This structure guarantees that every step from supplier to end customer is transparently recorded.

What procedures are outlined for updating and maintaining the accuracy of the tracking information?

The document mandates regular data verification and timestamped updates by authorized personnel to maintain accuracy. It includes protocols for immediate recording of any changes or discrepancies identified during inspections. Continuous monitoring ensures the integrity of tracking information throughout the supply process.

How does the document facilitate supplier and logistics partner collaboration?

The document incorporates designated fields for input from both suppliers and logistics partners, promoting real-time communication and data sharing. It supports standardized reporting formats to align all parties on key logistics milestones. This collaborative approach enhances coordination and reduces supply chain delays.

What mechanisms for issue reporting and resolution are included in the tracking document?

There are structured fields for incident documentation and immediate notification protocols embedded in the document. It specifies escalation procedures and assigned responsible personnel for efficient problem resolution. These mechanisms ensure timely response and minimize impact on supply chain continuity.

More Manufacturing Templates

![]()