A Health and Safety Audit Document Sample for Manufacturing Site provides a comprehensive framework to evaluate workplace safety protocols and compliance. It includes detailed checklists, risk assessments, and corrective action plans tailored specifically for manufacturing environments. This document ensures systematic identification of hazards and promotes continuous improvement in occupational health and safety standards.

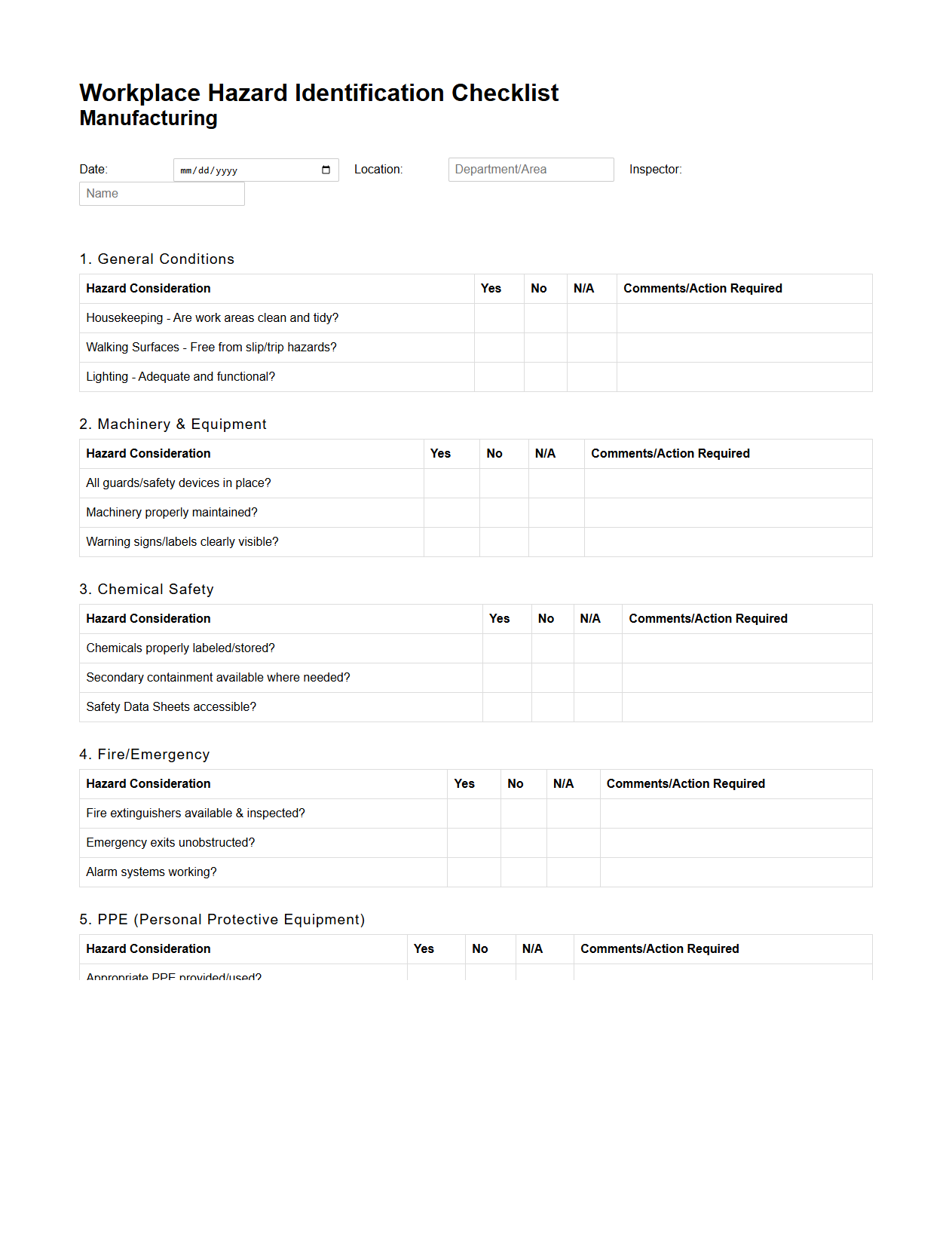

Workplace Hazard Identification Checklist for Manufacturing

A

Workplace Hazard Identification Checklist for Manufacturing document systematically outlines potential risks and hazards specific to manufacturing environments, ensuring thorough evaluation of machinery, chemicals, ergonomic factors, and safety protocols. This checklist aids organizations in proactively identifying safety issues to prevent accidents, comply with regulatory standards, and maintain a safe working environment. Regular use of this tool supports continuous monitoring and improvement of workplace safety practices.

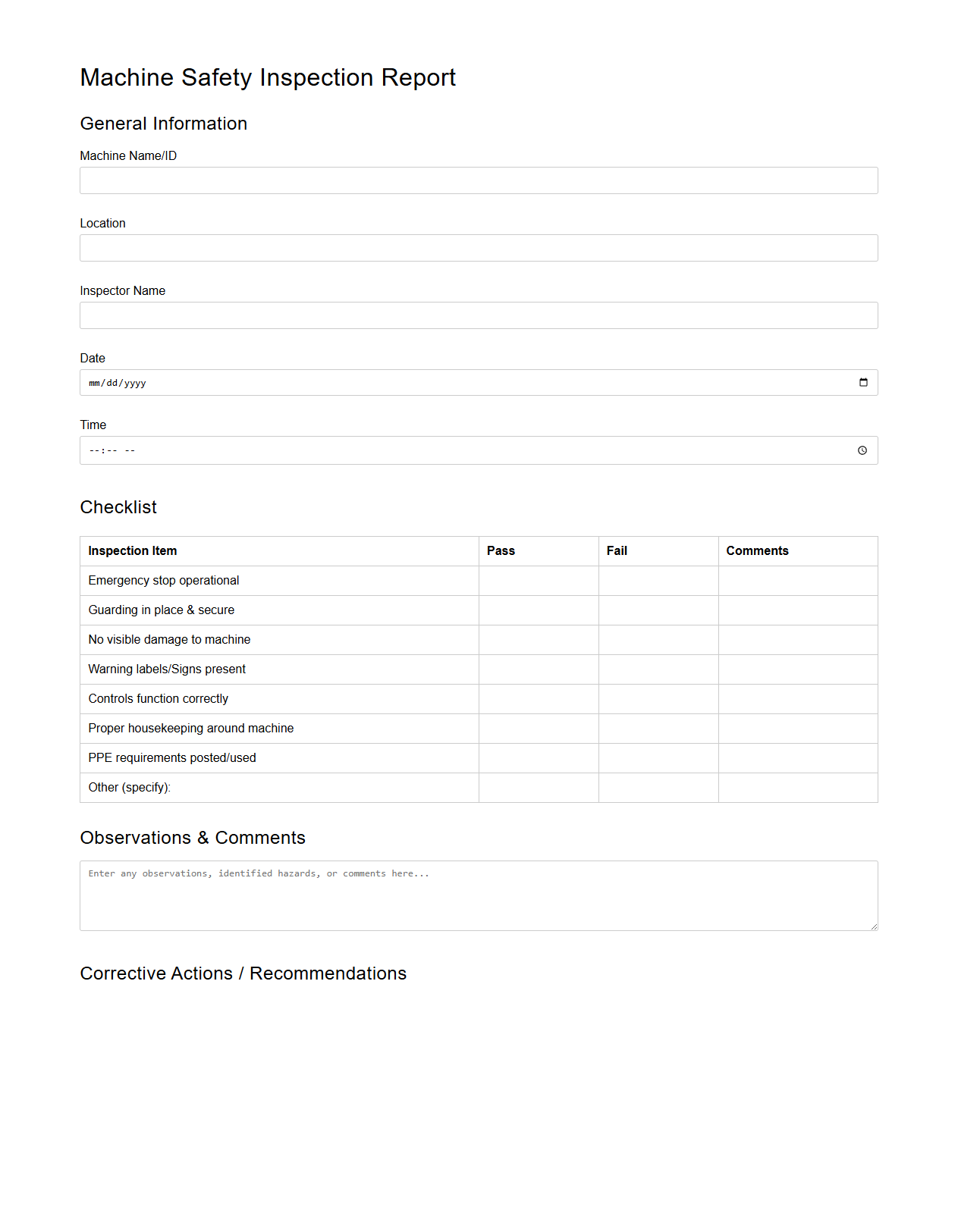

Machine Safety Inspection Report Template

A

Machine Safety Inspection Report Template document serves as a standardized tool for assessing and documenting the safety conditions of machinery in industrial or manufacturing settings. It includes sections for identifying equipment, listing safety checks, recording observations, and noting corrective actions to ensure compliance with safety regulations. This template helps organizations maintain a consistent approach to machine safety audits, reducing the risk of accidents and improving workplace safety standards.

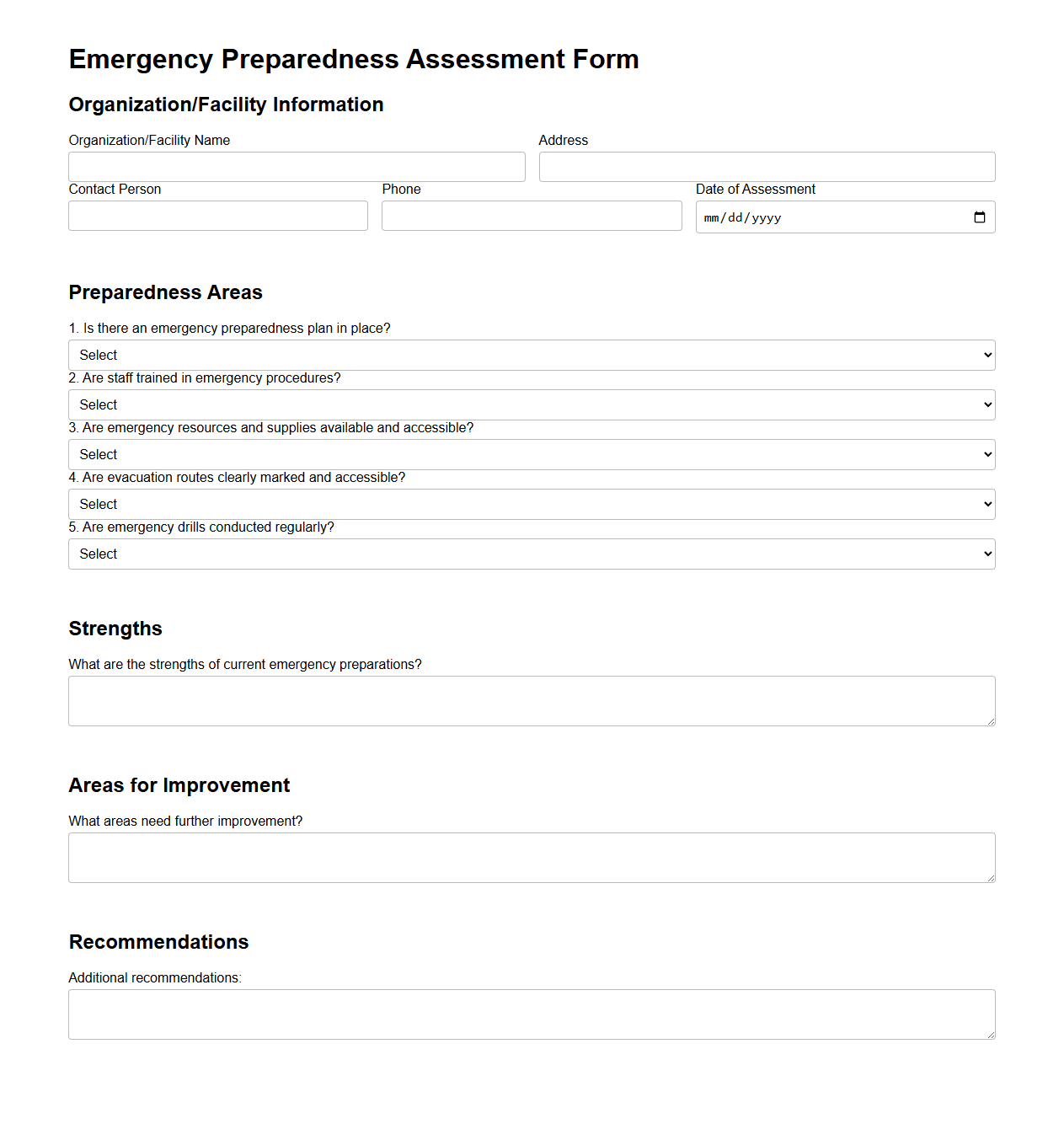

Emergency Preparedness Assessment Form

An

Emergency Preparedness Assessment Form document systematically evaluates an organization's readiness to respond to various emergencies, identifying potential risks, resource availability, and staff training levels. It facilitates the development of targeted action plans by highlighting vulnerabilities and ensuring compliance with safety regulations. Regular use of this form enhances overall resilience and minimizes the impact of disasters on operations and personnel.

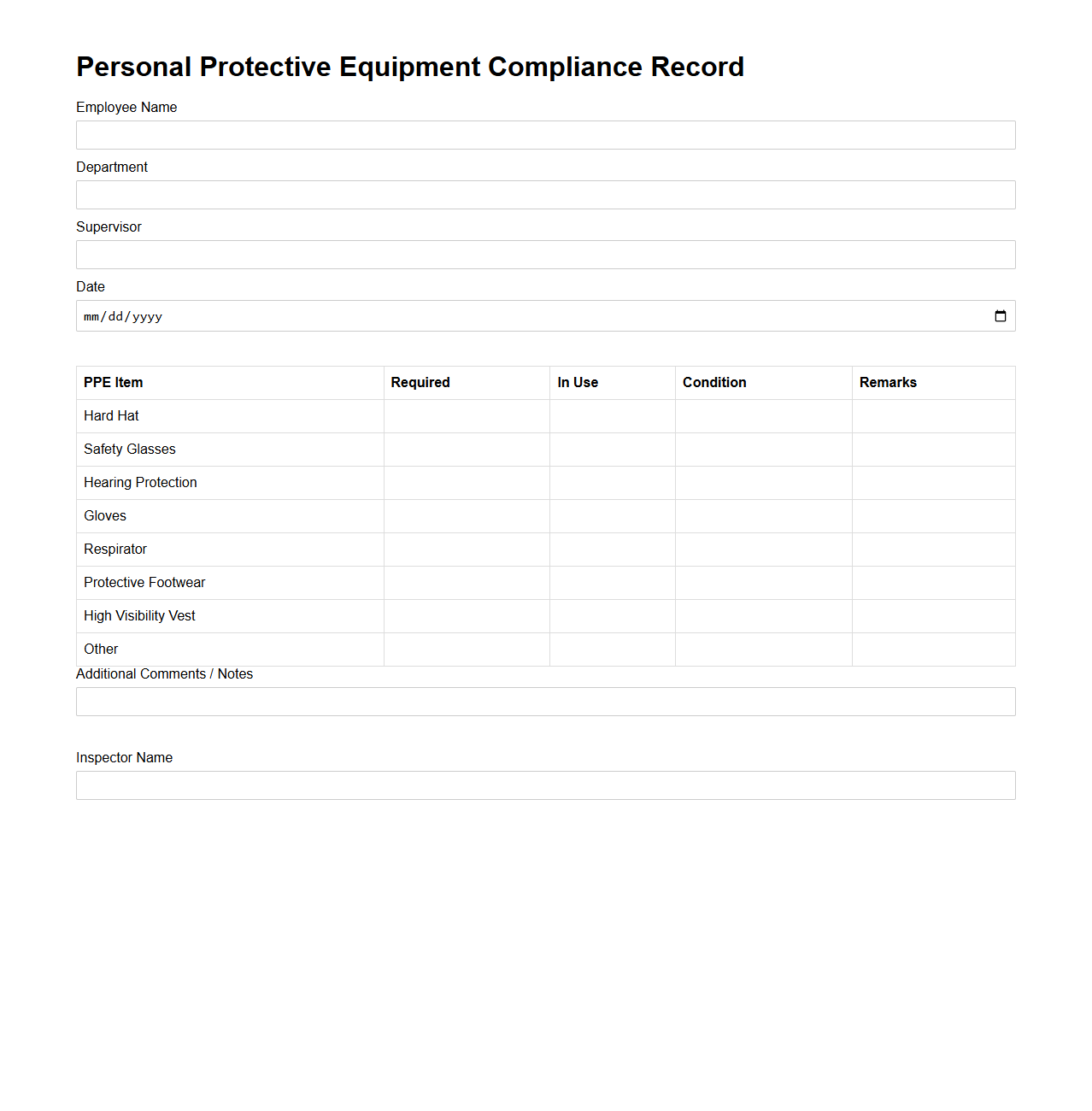

Personal Protective Equipment Compliance Record

A

Personal Protective Equipment Compliance Record document tracks and verifies the proper use, maintenance, and inspection of PPE in the workplace to ensure adherence to safety regulations. It serves as a crucial record for employers to demonstrate compliance with OSHA standards and other regulatory bodies, reducing the risk of workplace injuries and legal penalties. This document typically includes employee names, types of PPE issued, inspection dates, and notes on any defects or replacements.

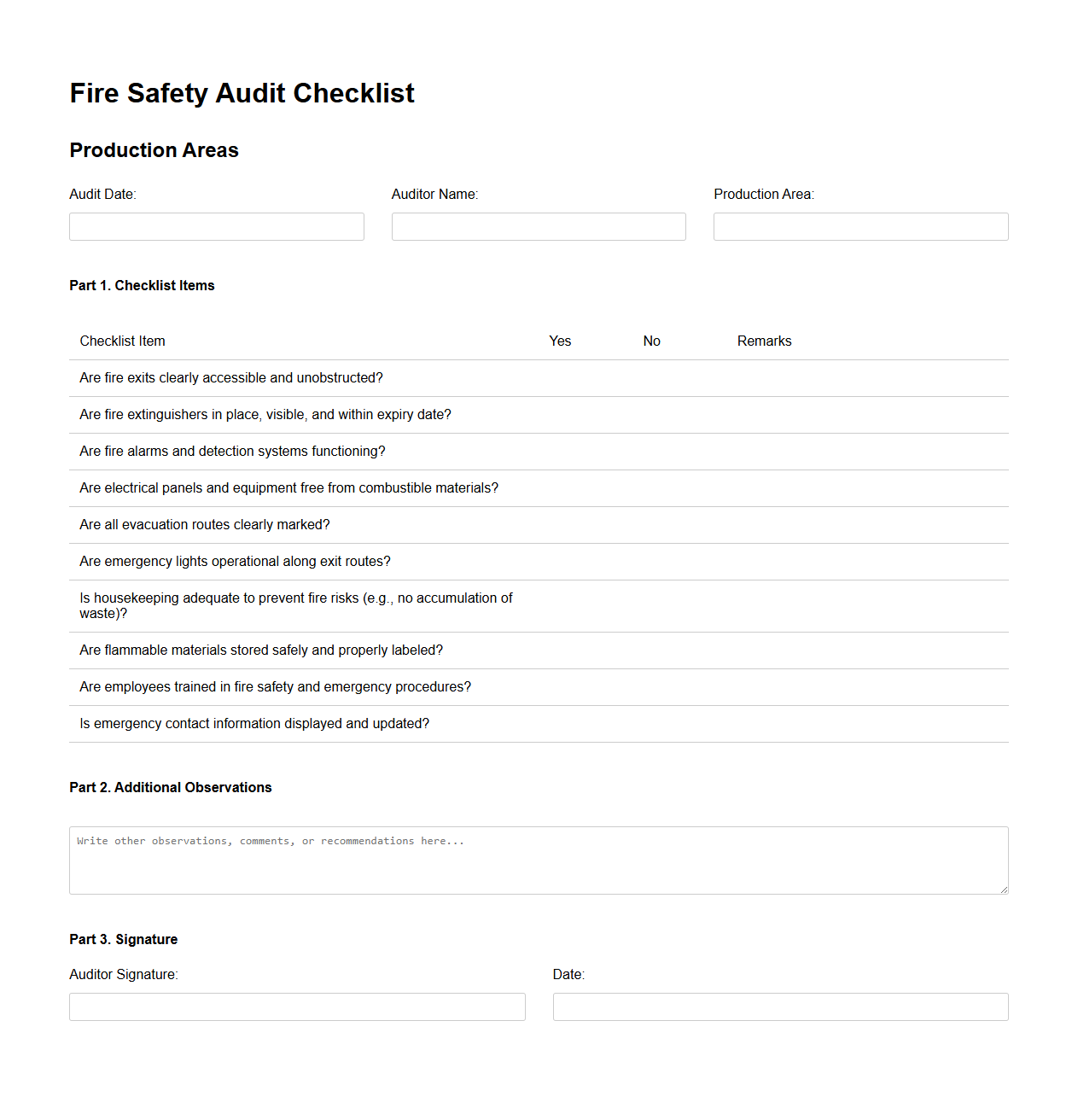

Fire Safety Audit Checklist for Production Areas

A

Fire Safety Audit Checklist for Production Areas document is a comprehensive tool designed to systematically evaluate all fire prevention and protection measures within manufacturing or production environments. It ensures compliance with safety standards by identifying potential fire hazards, verifying the functionality of fire detection and suppression systems, and assessing employee preparedness and training. Regular use of this checklist helps minimize fire risks, protect assets, and promote a safe workplace.

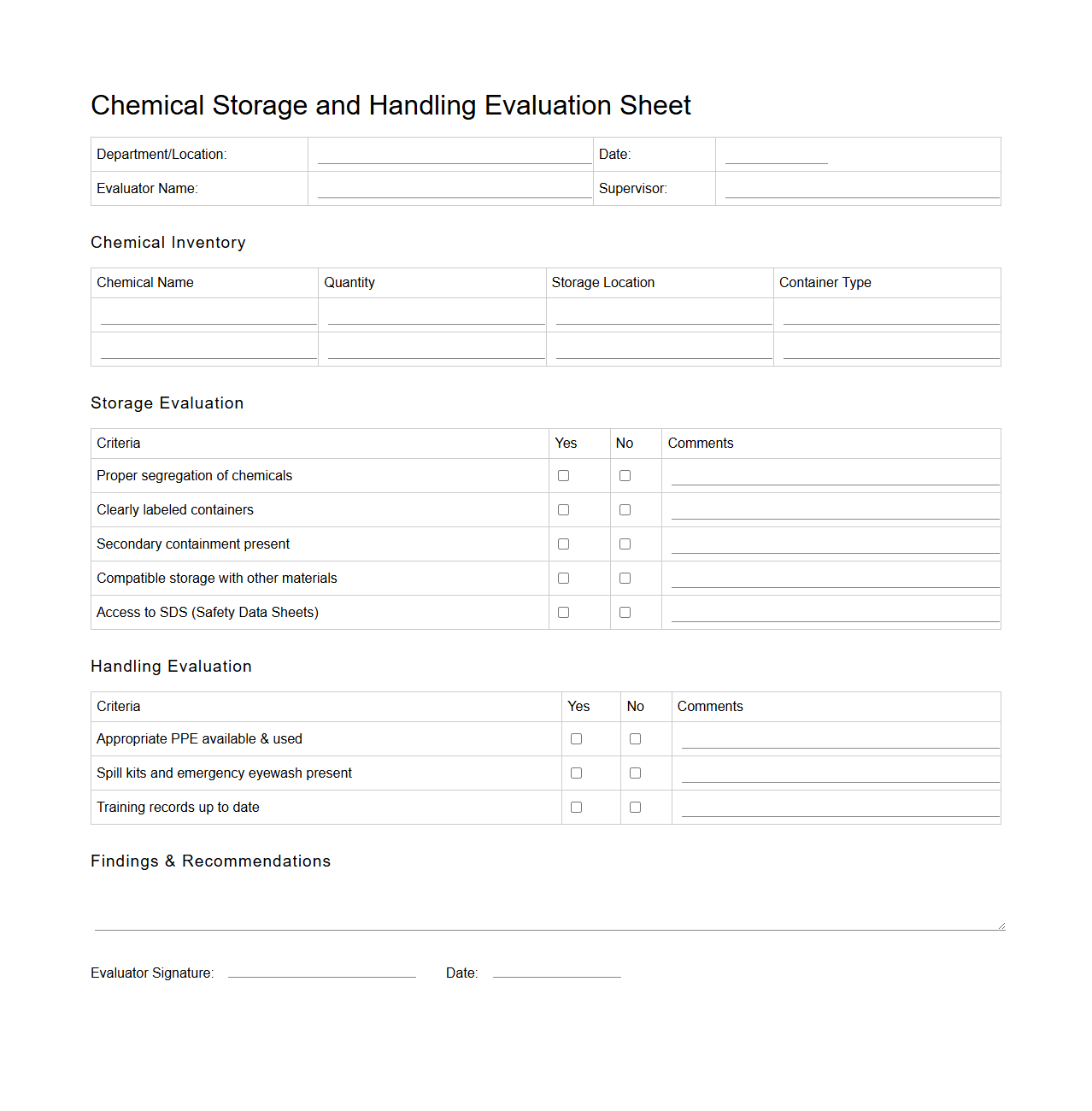

Chemical Storage and Handling Evaluation Sheet

A

Chemical Storage and Handling Evaluation Sheet is a structured document used to assess and ensure the safe management of chemicals within a facility. It systematically records information about chemical types, storage conditions, container integrity, labeling compliance, and potential hazards to minimize risks. This evaluation sheet supports regulatory compliance and promotes workplace safety by identifying necessary improvements and mitigating chemical-related incidents.

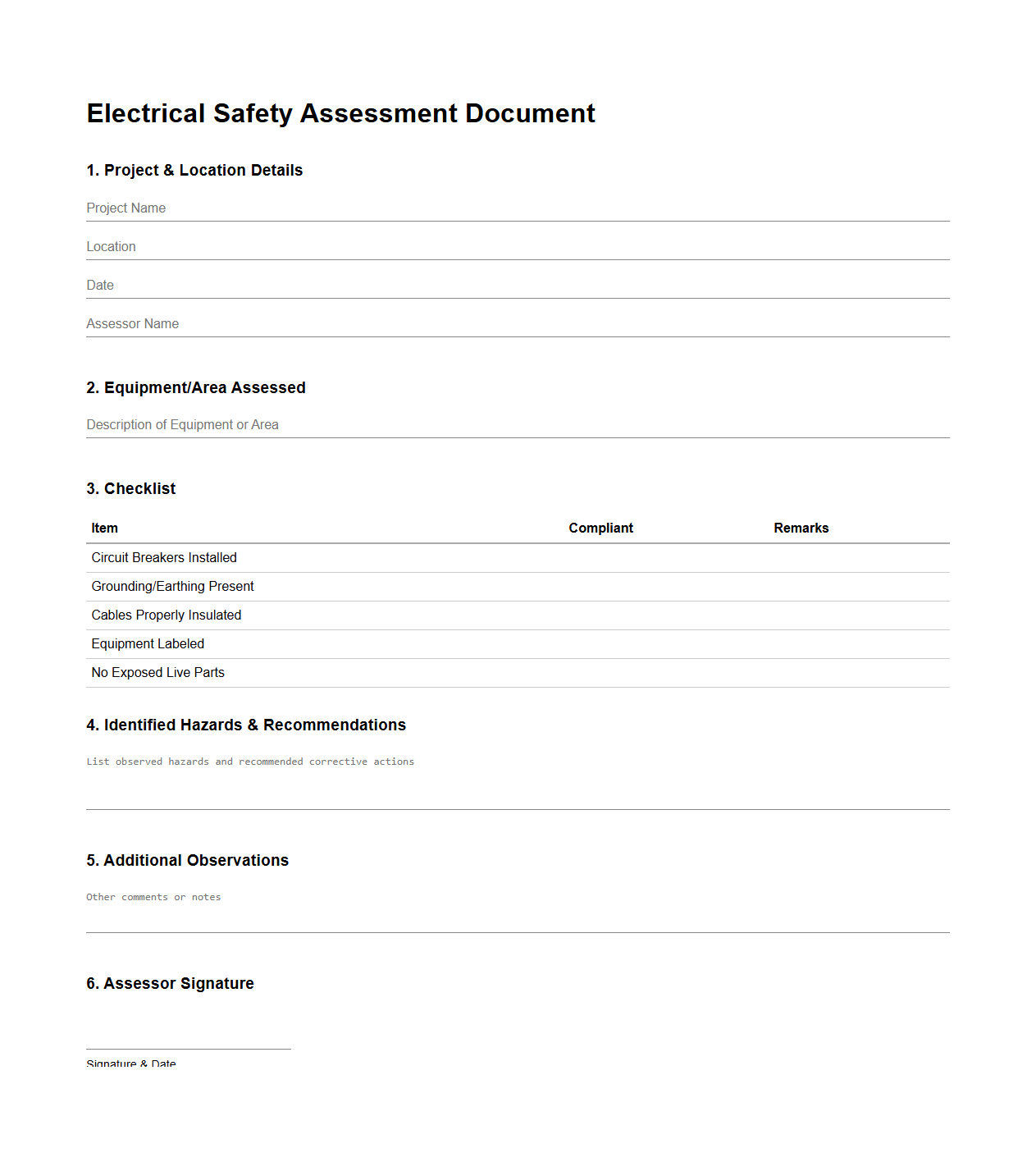

Electrical Safety Assessment Document

An

Electrical Safety Assessment Document is a comprehensive report that evaluates the safety protocols and compliance of electrical systems within a building or facility. It identifies potential hazards, assesses risks, and provides recommendations to ensure electrical installations meet regulatory standards and prevent accidents. This document is essential for maintaining workplace safety and adhering to industry guidelines.

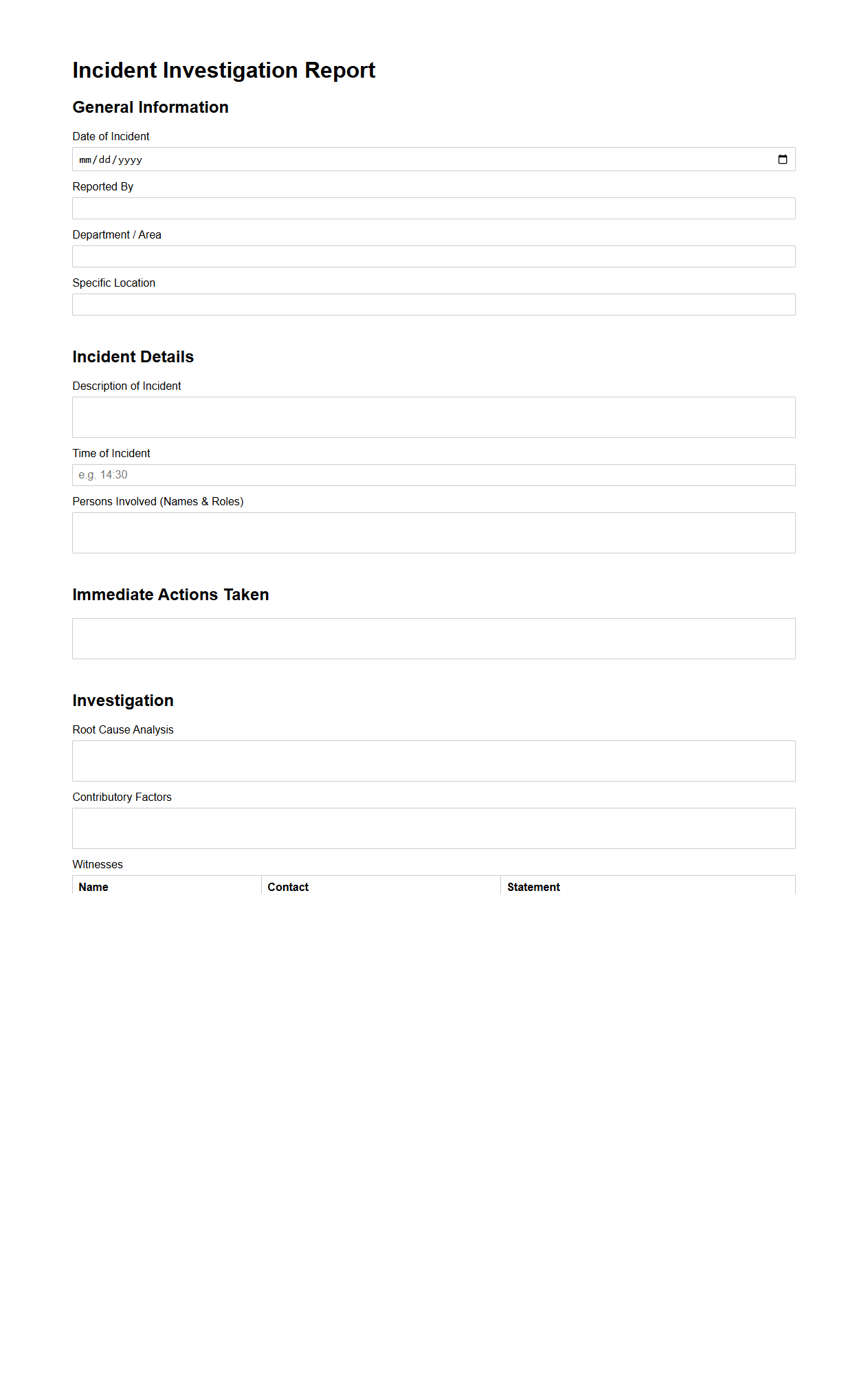

Incident Investigation Report for Manufacturing Sites

An

Incident Investigation Report for manufacturing sites is a detailed document that records the analysis of workplace incidents, including accidents, near misses, or equipment failures. It identifies root causes, contributing factors, and corrective actions to prevent recurrence, ensuring compliance with safety regulations and improving operational efficiency. This report serves as a critical tool for risk management, regulatory audits, and continuous safety improvement in industrial environments.

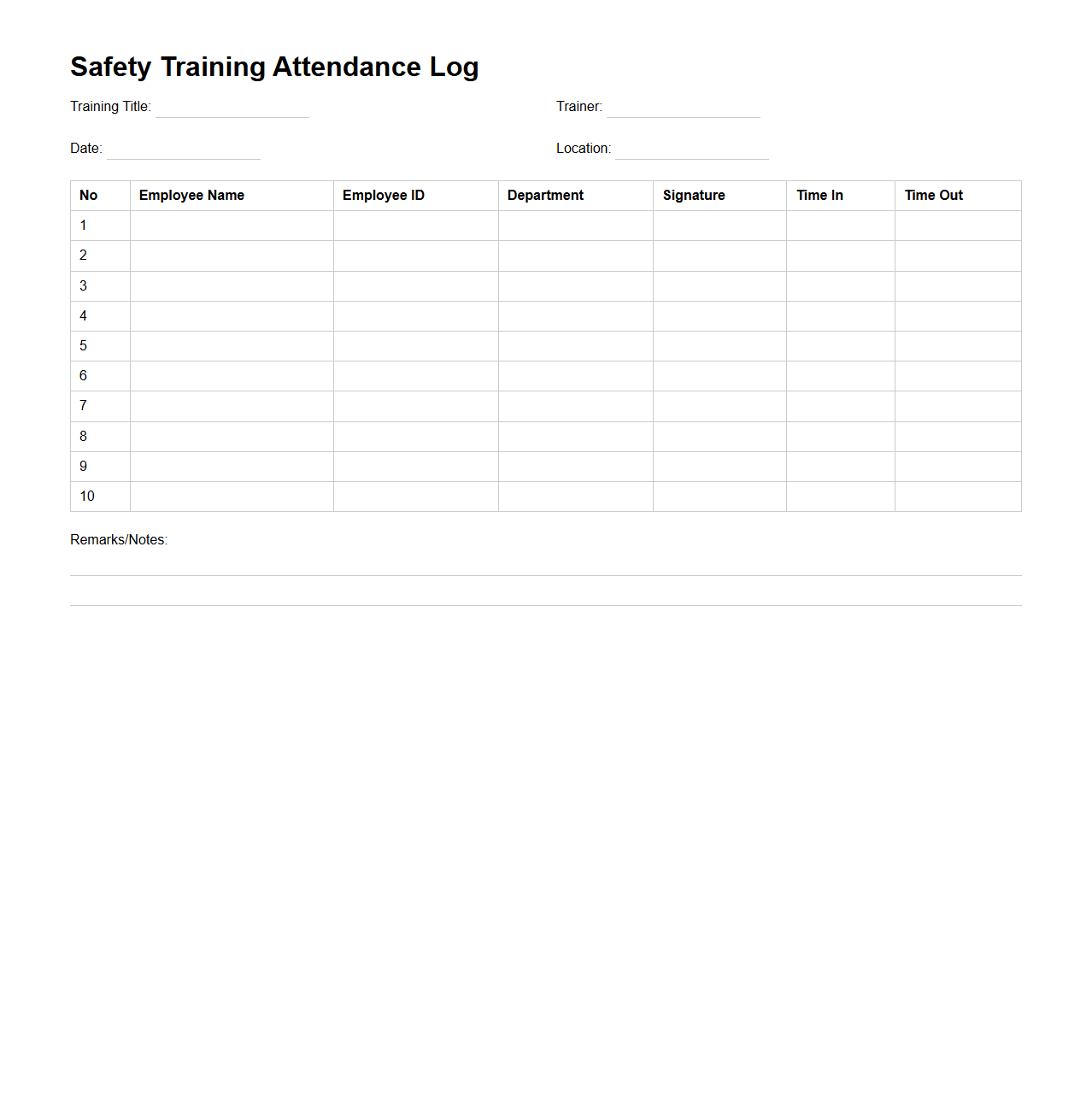

Safety Training Attendance Log

A

Safety Training Attendance Log document records the names, dates, and participation status of employees attending safety training sessions. It serves as a critical compliance tool for regulatory agencies such as OSHA, ensuring that all personnel have received mandatory safety instruction. Maintaining accurate logs helps organizations track training progress, identify gaps, and support workplace safety initiatives.

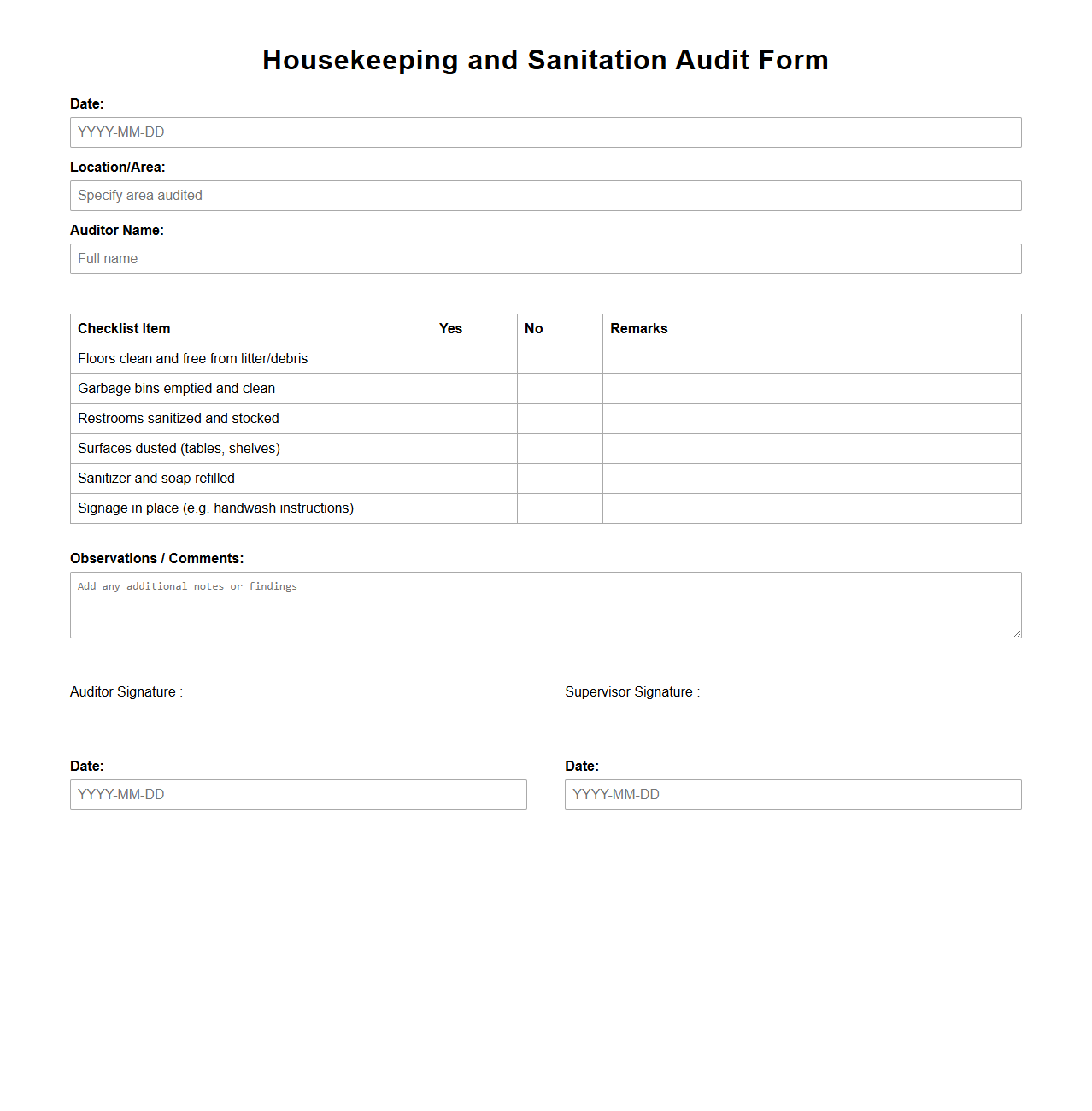

Housekeeping and Sanitation Audit Form

A

Housekeeping and Sanitation Audit Form is a structured document used to systematically evaluate cleanliness, hygiene practices, and overall maintenance standards in various facilities. It helps organizations identify areas needing improvement by recording observations against predefined criteria related to sanitation, waste management, and workplace organization. This form ensures compliance with health and safety regulations while promoting a clean, safe, and efficient environment.

What key safety protocols are documented for machinery operation in the audit?

The audit details machinery operation safety protocols including mandatory lockout/tagout procedures to prevent accidental startup. It emphasizes routine inspection and maintenance schedules to ensure equipment remains in safe working condition. Operator training requirements are clearly outlined to maintain competency and reduce workplace incidents.

How does the audit sample address hazardous material storage and handling procedures?

The audit sample highlights hazardous material storage and handling protocols that comply with regulatory standards. It ensures that all materials are properly labeled, segregated, and stored in designated areas to mitigate risks. Procedures for safe handling, including the use of appropriate containment measures, are strictly enforced to prevent spills and exposure.

What emergency response measures are outlined in the audit document?

The audit document outlines comprehensive emergency response measures including clearly defined evacuation routes and assembly points. It details the availability and accessibility of emergency equipment such as fire extinguishers, first aid kits, and eyewash stations. Regular drills and employee training are mandated to ensure preparedness in the event of an emergency.

Which sections of the audit assess personal protective equipment (PPE) compliance?

Sections dedicated to personal protective equipment (PPE) compliance evaluate usage, availability, and condition of required gear. The audit checks for proper PPE training, storage, and enforcement of policies in high-risk areas. Documentation of PPE inspections and employee adherence is carefully reviewed to maintain safety standards.

How is employee health and safety training documented and verified in the sample?

Employee health and safety training is documented through detailed records including attendance logs, training content, and competency assessments. Verification processes include periodic evaluations and refresher courses to ensure ongoing compliance. The audit emphasizes the importance of maintaining up-to-date training files for all personnel.

More Manufacturing Templates