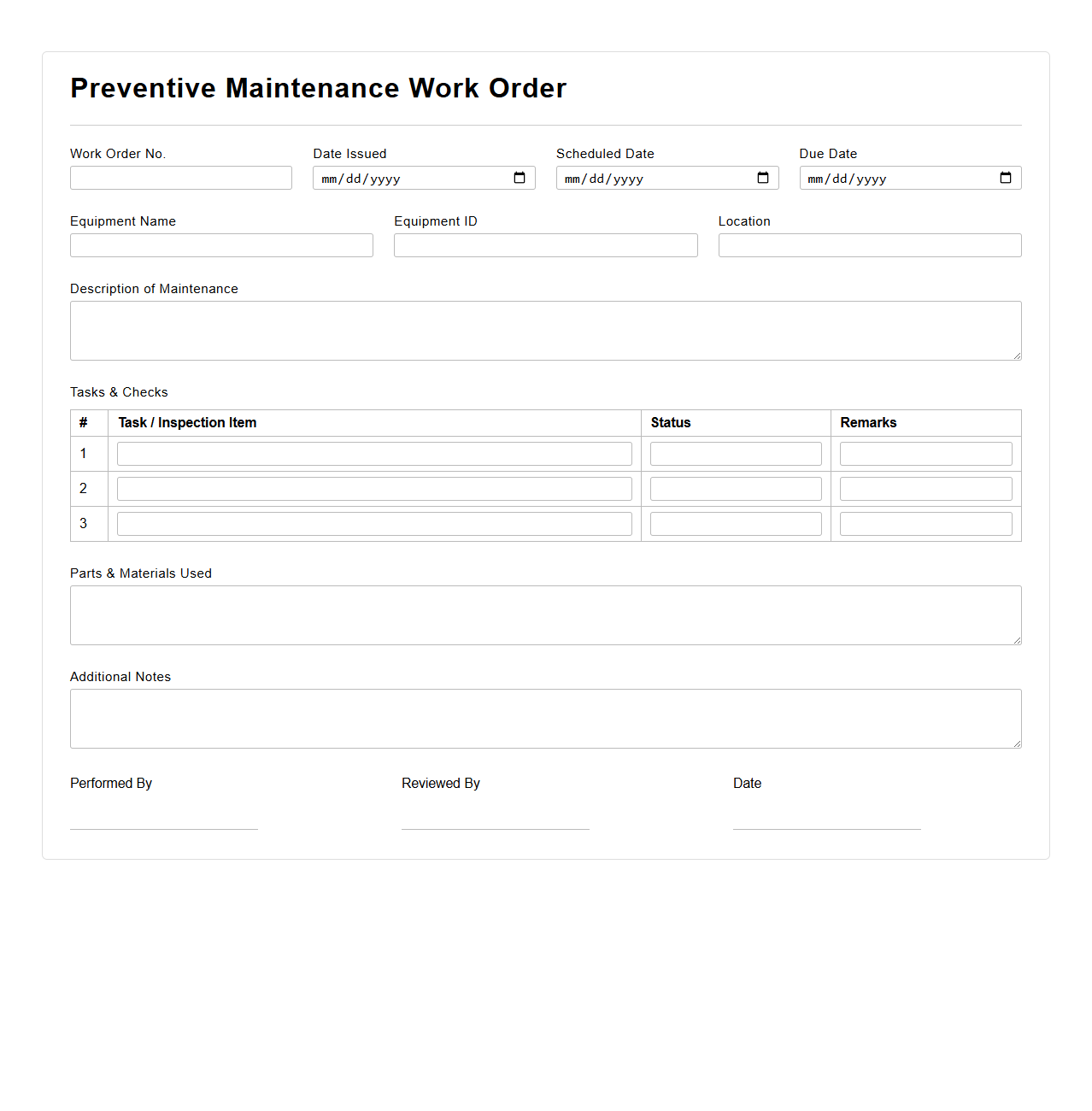

Preventive Maintenance Work Order Template for Manufacturing

A

Preventive Maintenance Work Order Template for manufacturing is a structured document designed to schedule, track, and document routine maintenance tasks for machinery and equipment. It ensures optimal operational efficiency by outlining specific maintenance activities, timelines, required tools, and responsible personnel, reducing unexpected downtime and extending equipment lifespan. This template supports compliance with safety standards and helps in systematic documentation for auditing and performance analysis in manufacturing processes.

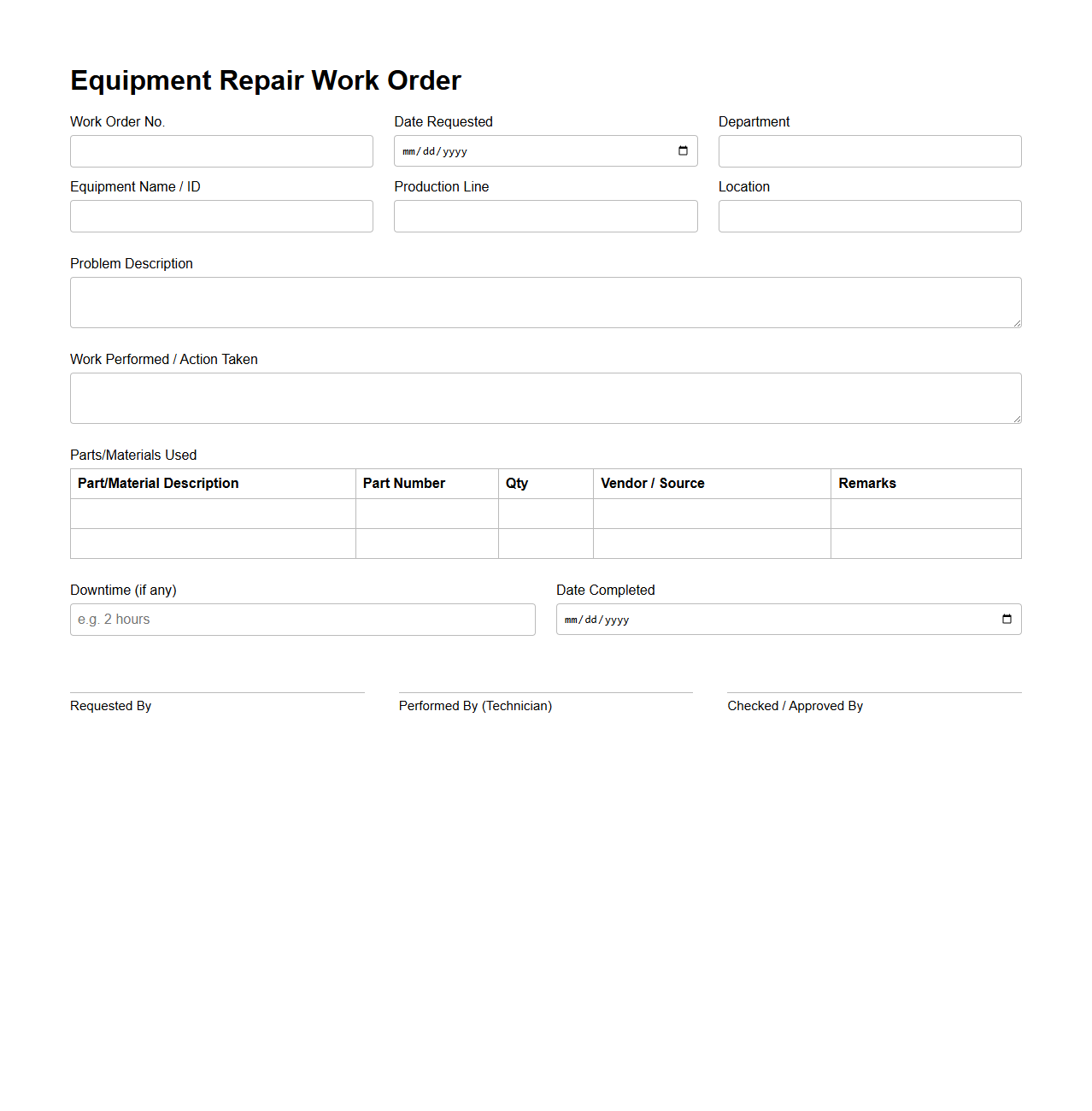

Equipment Repair Work Order for Production Lines

An

Equipment Repair Work Order for Production Lines document outlines the necessary details and instructions required to address maintenance and repair tasks on machinery within a manufacturing environment. It typically includes information such as the equipment identification, issue description, required parts, labor allocation, and timelines for completion. This document ensures efficient communication between maintenance teams and production managers, minimizing downtime and optimizing production line performance.

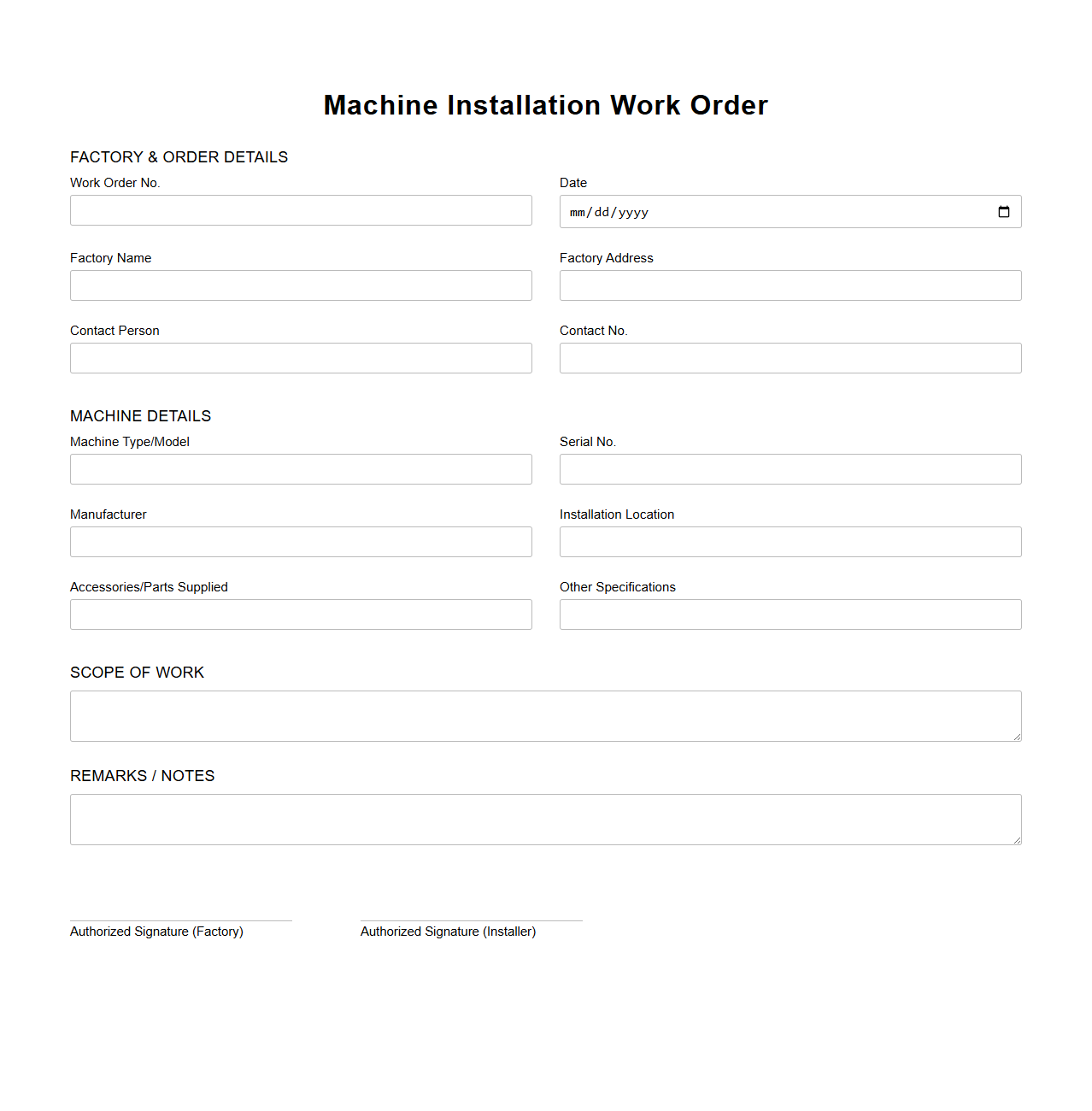

Machine Installation Work Order for Factories

A

Machine Installation Work Order for factories is a formal document outlining the specific tasks, materials, and timelines required for installing machinery on-site. It ensures proper coordination between technical teams, vendors, and management by detailing equipment specifications, installation procedures, safety protocols, and quality checks. This work order helps streamline project execution, minimize downtime, and guarantee compliance with industrial standards.

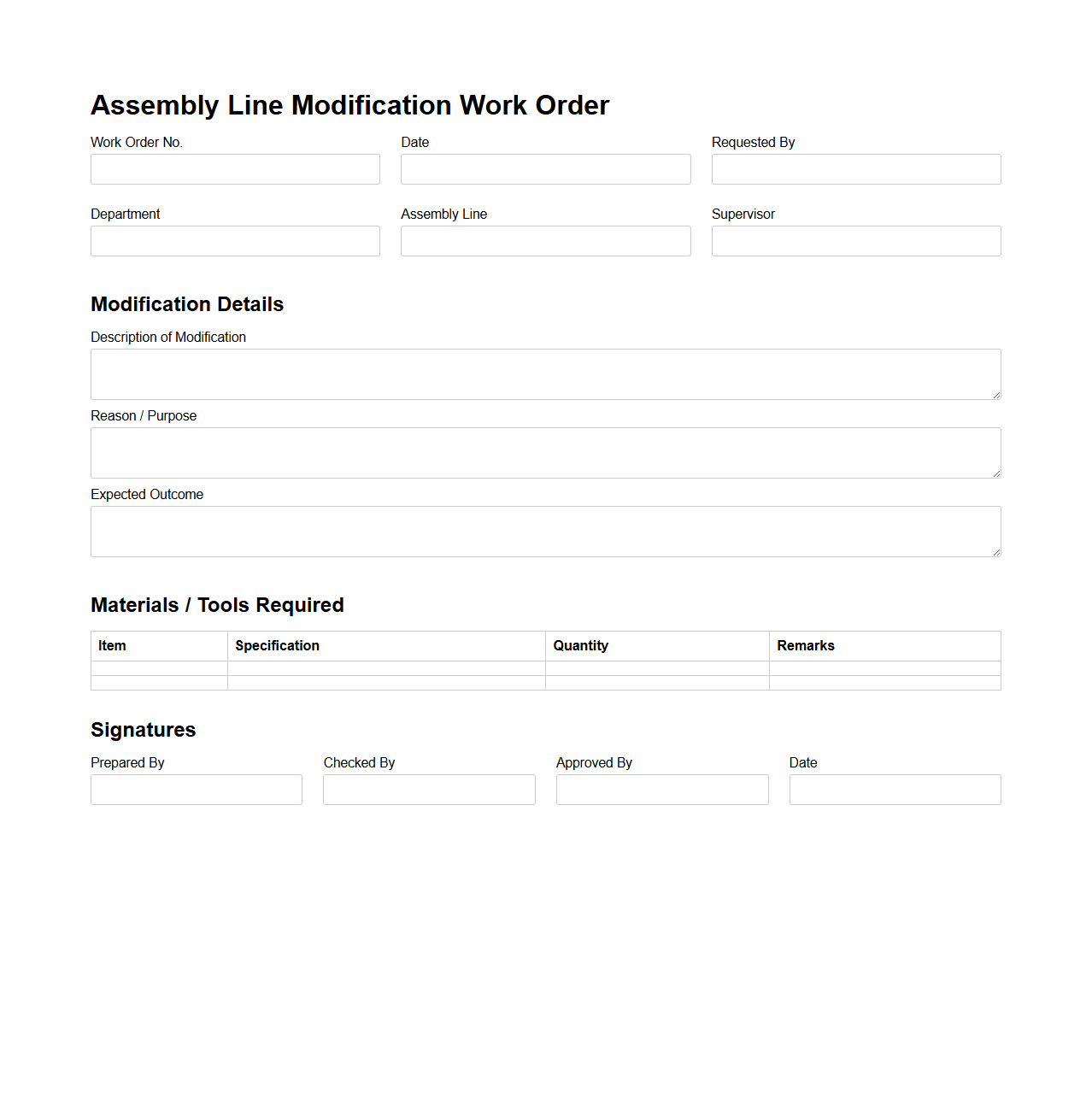

Assembly Line Modification Work Order Format

The

Assembly Line Modification Work Order Format document serves as a structured template used to detail necessary changes or upgrades to an assembly line in manufacturing. It specifies the scope of modifications, required materials, labor instructions, and timelines to ensure efficient implementation. This format helps maintain clarity, accountability, and traceability throughout the modification process.

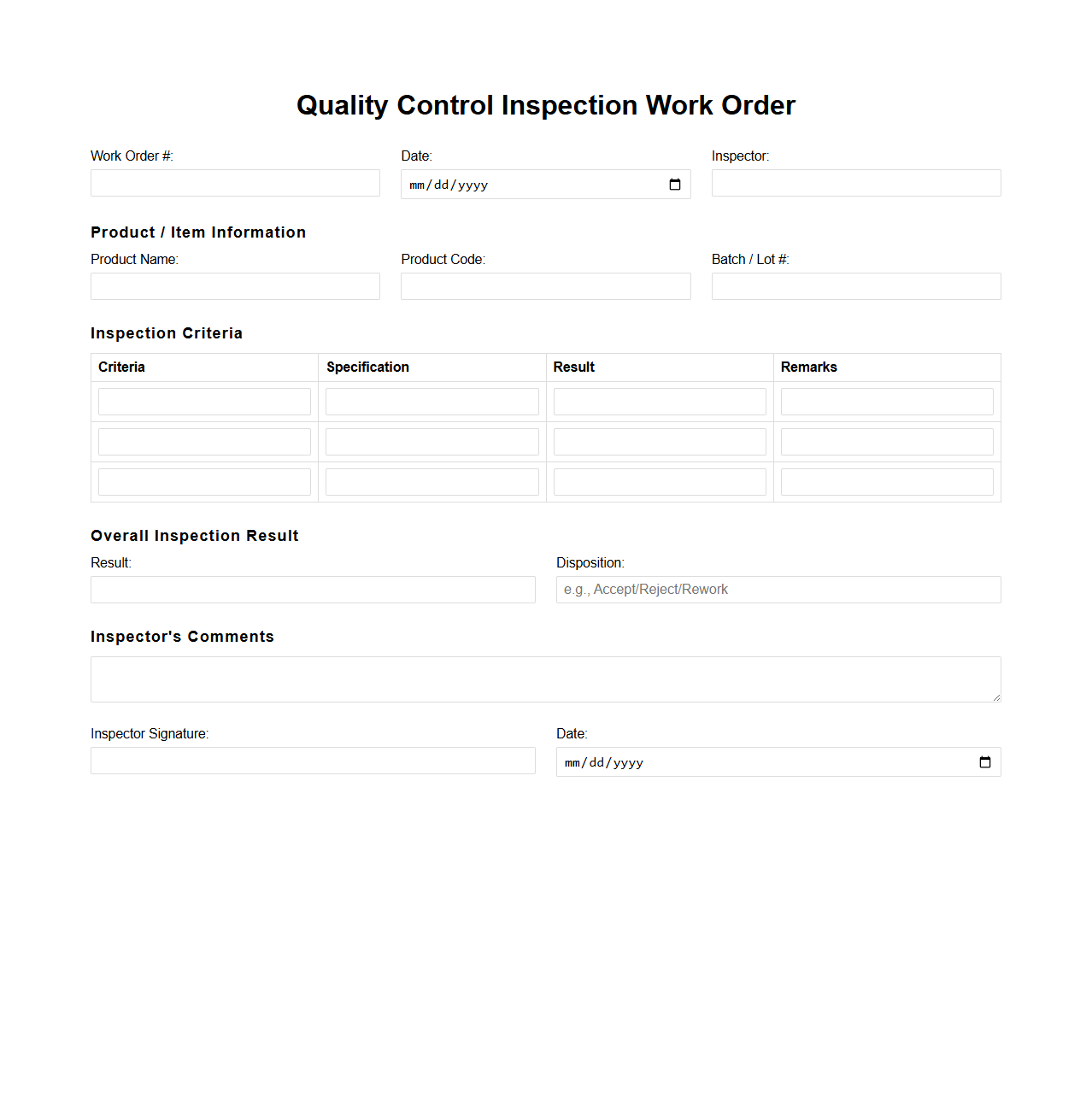

Quality Control Inspection Work Order Example

A

Quality Control Inspection Work Order Example document outlines specific instructions and criteria for performing quality inspections on products or processes to ensure compliance with set standards. It details inspection parameters, measurement methods, acceptance criteria, and documentation requirements to facilitate consistent and accurate quality assessments. This document serves as a critical tool for quality assurance teams to systematically verify product integrity and operational effectiveness.

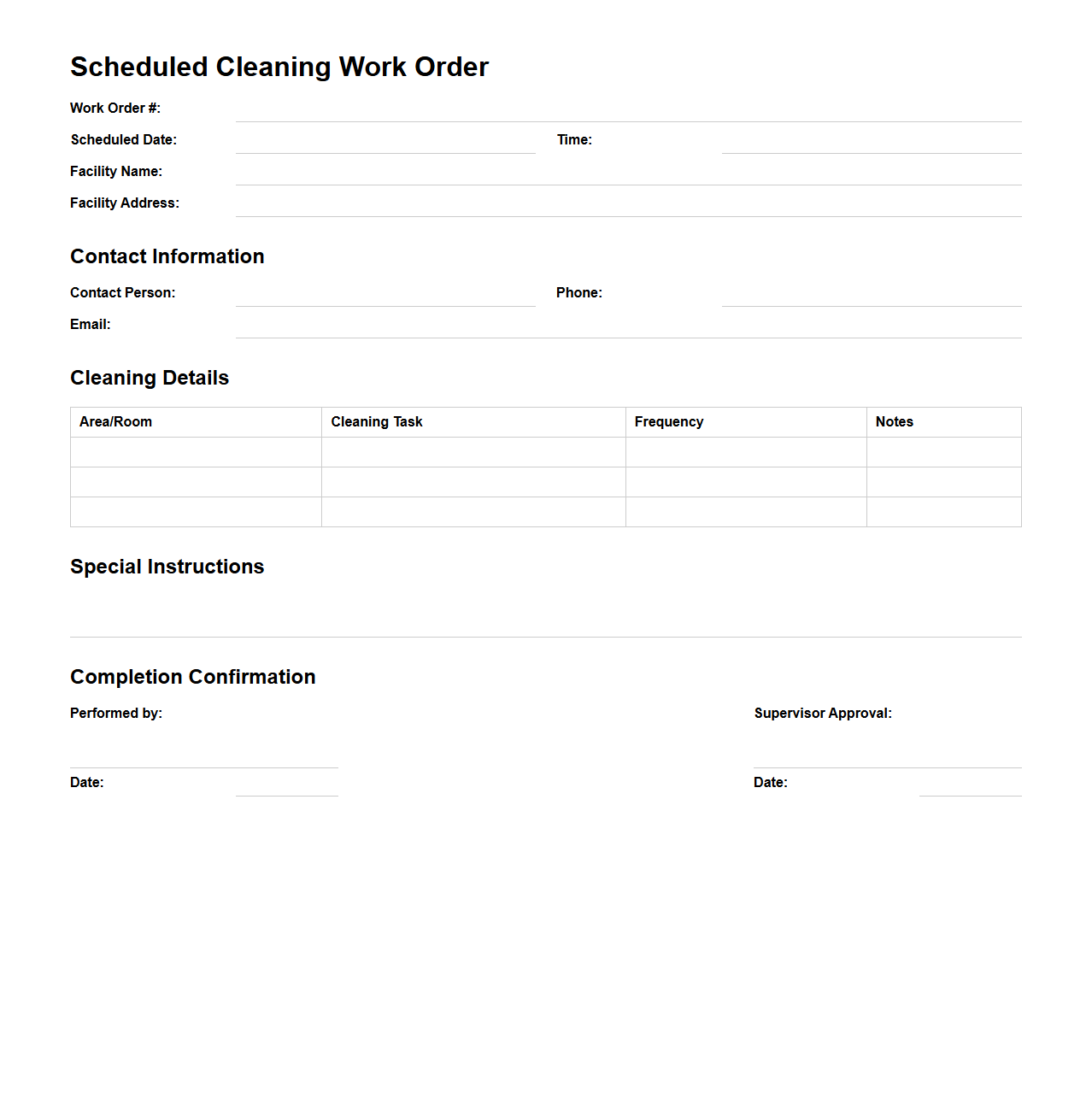

Scheduled Cleaning Work Order for Manufacturing Facilities

A

Scheduled Cleaning Work Order for manufacturing facilities is a detailed document outlining routine cleaning tasks to maintain hygiene and operational efficiency. It specifies the cleaning schedule, required materials, assigned personnel, and safety protocols to ensure compliance with industry standards. This work order helps prevent contamination, equipment malfunction, and ensures a safe working environment.

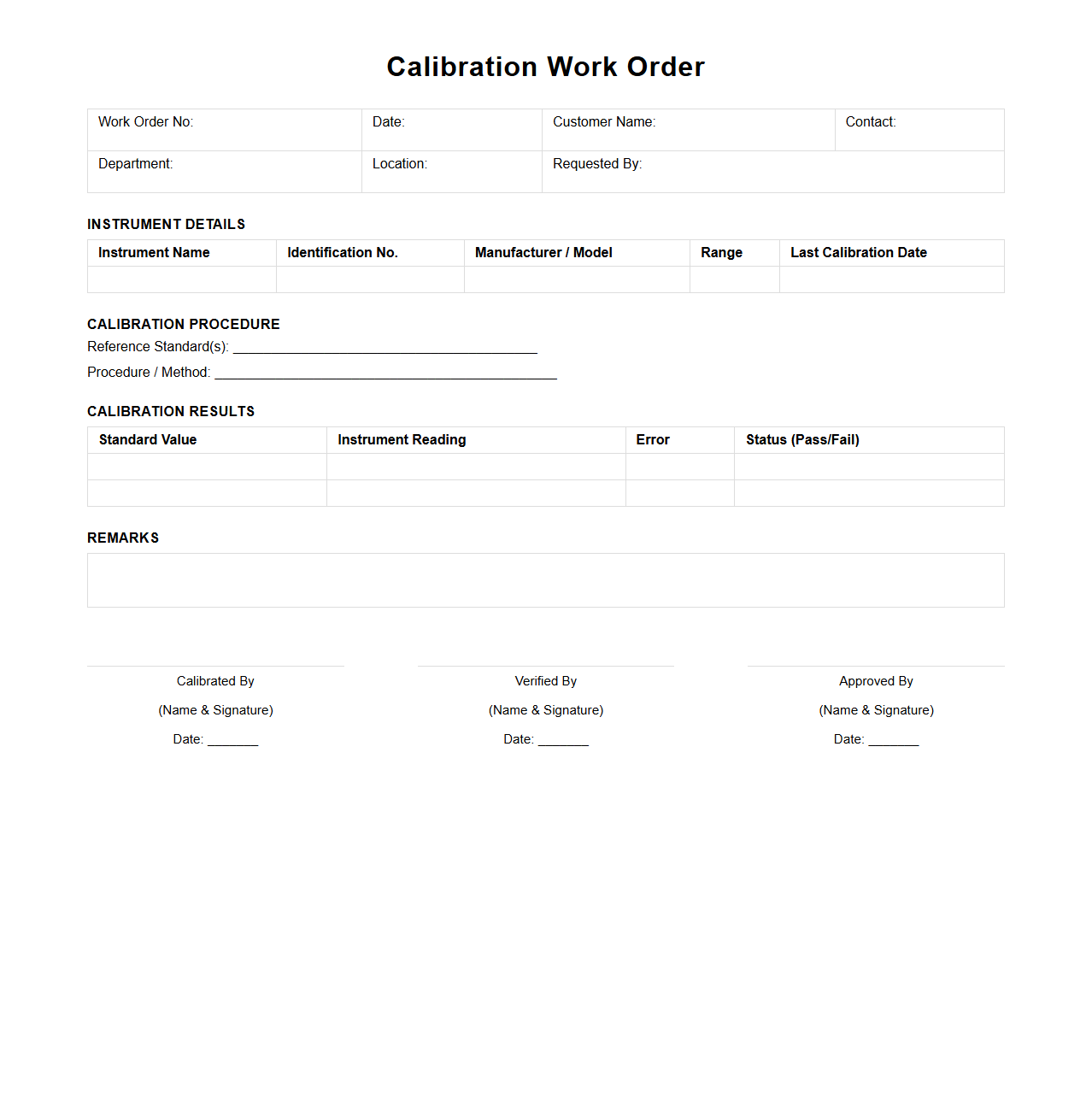

Calibration Work Order for Industrial Instruments

A

Calibration Work Order for industrial instruments is a formal document that outlines the specific tasks, procedures, and standards required for calibrating measurement devices to ensure their accuracy and reliability. It contains detailed information such as instrument identification, calibration methods, reference standards, scheduled dates, and assigned personnel to ensure consistent compliance with industry regulations. This document is essential for maintaining quality control, reducing downtime, and enhancing the precision of industrial processes.

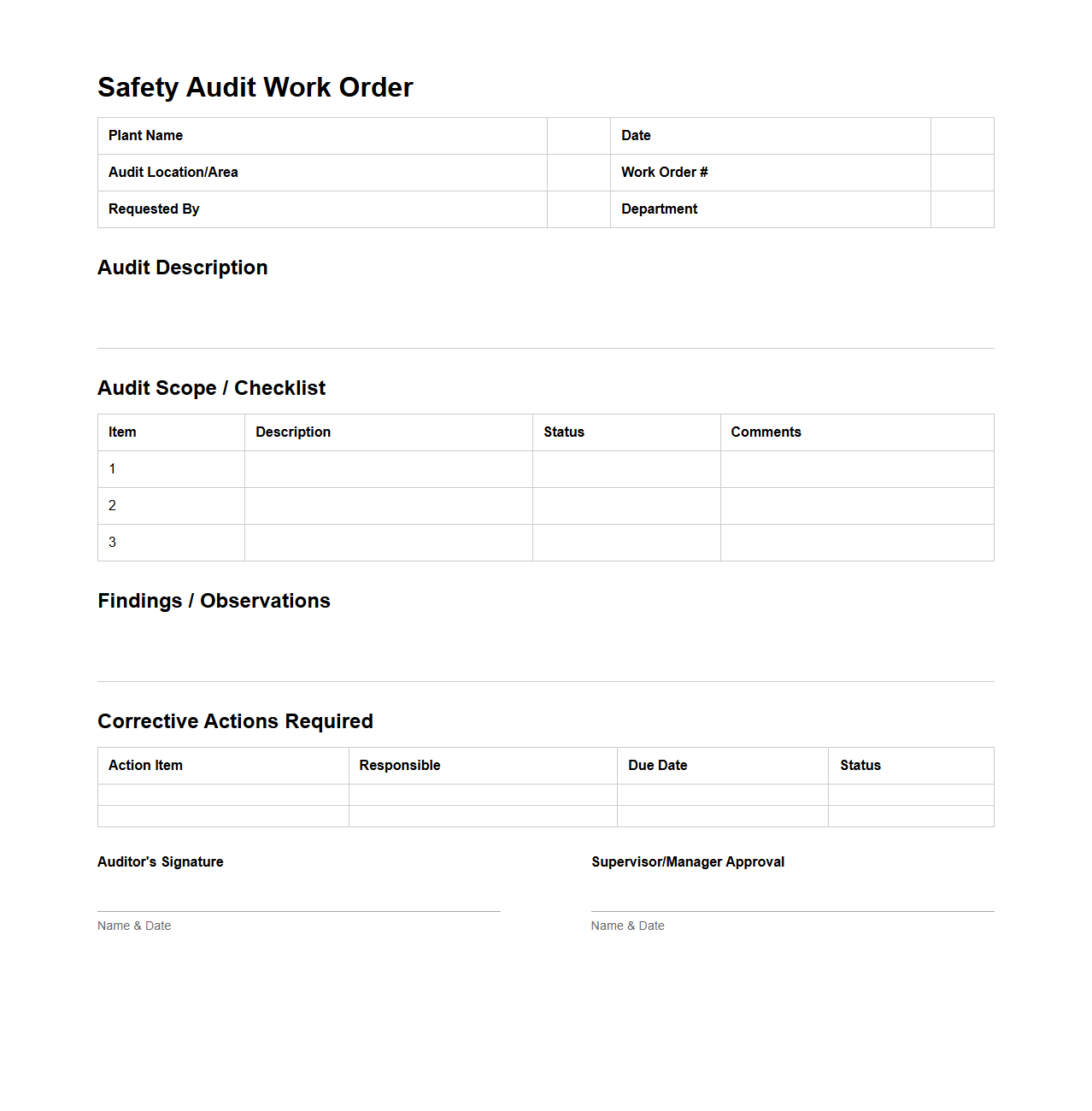

Safety Audit Work Order for Manufacturing Plants

A

Safety Audit Work Order for manufacturing plants is a formal document that outlines the specific tasks, criteria, and schedule for conducting a systematic evaluation of safety protocols and compliance within the facility. It ensures that all safety standards, such as OSHA regulations and internal policies, are checked to identify hazards, mitigate risks, and improve overall workplace safety. This document serves as a critical tool for coordinating audit activities, assigning responsibilities, and maintaining a record of safety assessments and corrective actions.

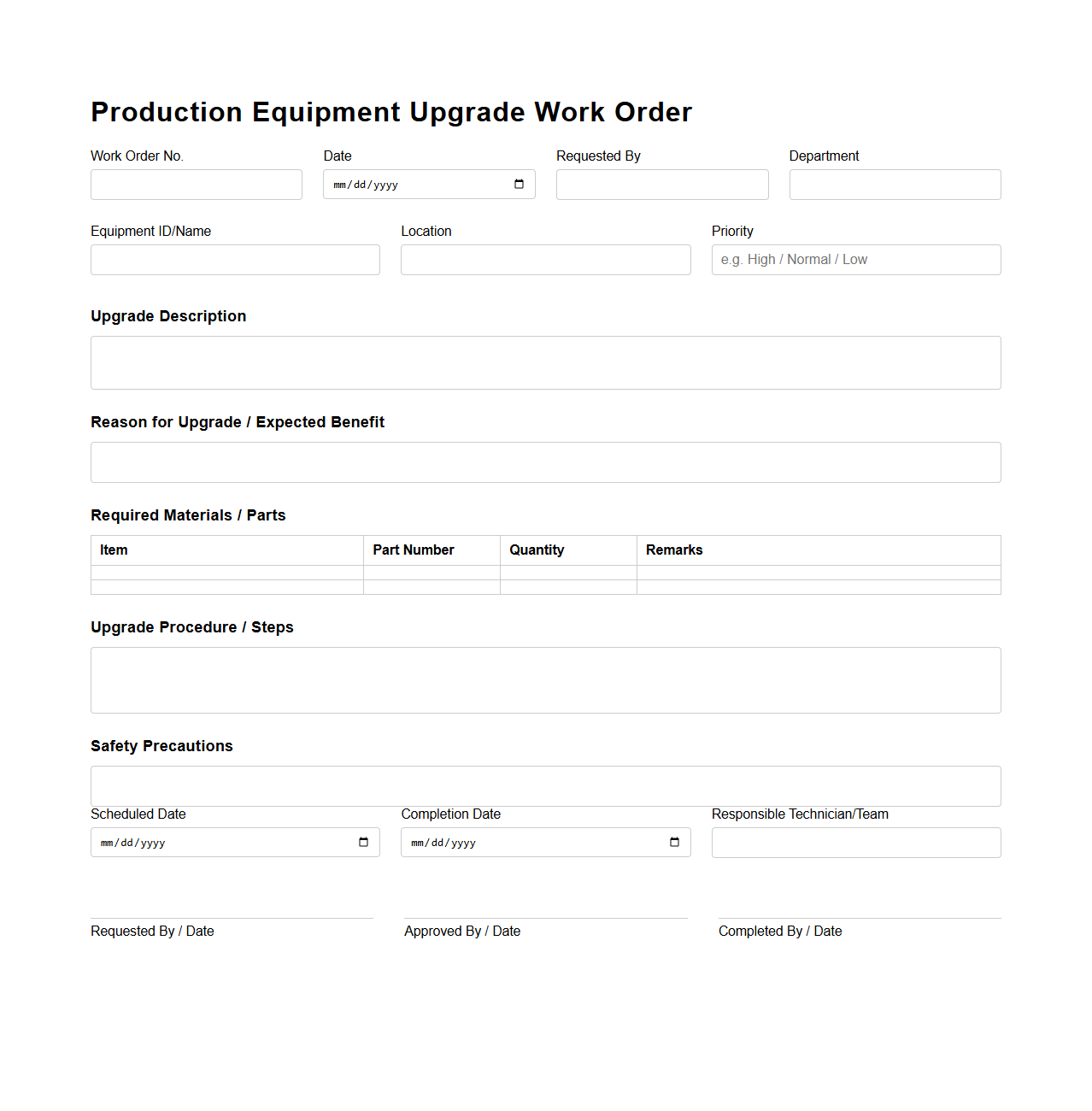

Production Equipment Upgrade Work Order Template

A

Production Equipment Upgrade Work Order Template document standardizes the process of requesting and tracking equipment enhancements within manufacturing environments. It includes fields for equipment identification, upgrade specifications, required materials, and estimated labor time to ensure clear communication and efficient workflow management. This template helps maintain operational continuity by minimizing downtime and optimizing production capacity during equipment upgrades.

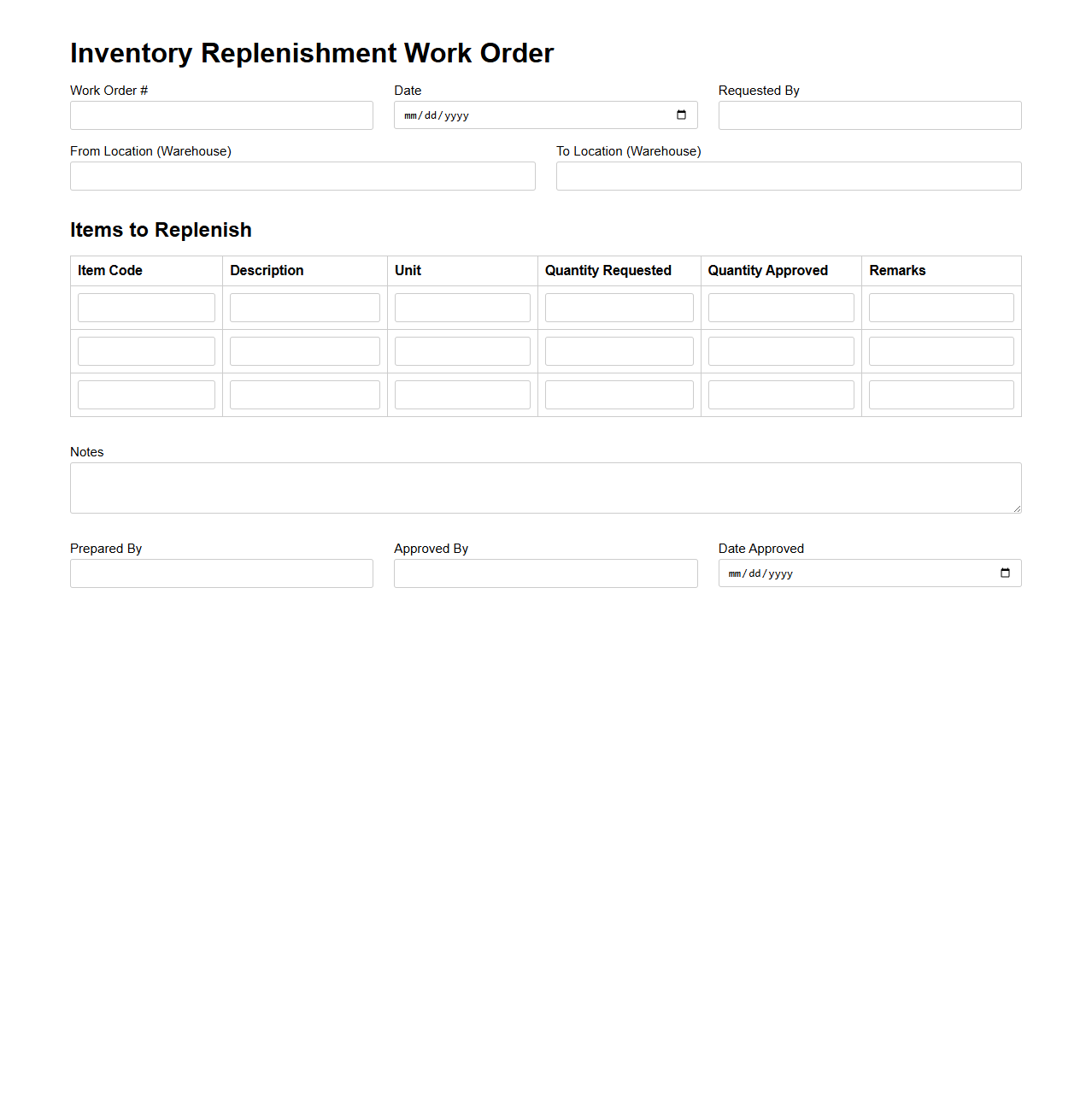

Inventory Replenishment Work Order for Warehouses

An

Inventory Replenishment Work Order for warehouses is a detailed document that outlines the specific instructions for restocking inventory items to maintain optimal stock levels. It includes information such as item descriptions, quantities to be replenished, locations within the warehouse, and timing requirements. This document ensures efficient inventory management by reducing stockouts and streamlining the replenishment process.

What is the primary purpose of a Work Order Document in manufacturing tasks?

The primary purpose of a Work Order Document in manufacturing is to provide detailed instructions and authorization for specific production tasks. It acts as a formal communication tool between different departments to ensure smooth workflow. This document helps in coordinating labor, materials, and equipment usage effectively.

Which key sections should be included in a standard manufacturing Work Order Document?

A standard manufacturing Work Order Document includes several key sections such as job description, materials required, task schedules, and labor assignments. It also contains information about the quantities to be produced and quality standards. These sections ensure that all aspects of the manufacturing process are clearly defined and tracked.

How does the document specify task assignments and responsible personnel?

The Work Order Document specifies task assignments by listing each task alongside the name or designation of the responsible personnel. This ensures accountability and clarifies who is in charge of each part of the process. Clear assignment of duties also helps prevent delays and miscommunication in production.

What information must be recorded regarding materials and resources required for each task?

The document records details of materials such as quantity, type, and specifications needed for each manufacturing task. It also includes equipment and resource requirements to ensure that everything is available at the right time. Accurate recording of these details supports inventory management and reduces production downtime.

How does the Work Order Document track completion status and quality control for manufacturing activities?

The Work Order Document includes sections for completion status updates and quality control checks for each phase of production. This allows supervisors to monitor progress and ensure products meet the required standards. Proper tracking helps in identifying issues early and maintaining overall manufacturing efficiency.