A Assembly Line Inspection Document Sample for Manufacturing provides a structured template to systematically evaluate the quality and efficiency of production processes. It includes detailed checkpoints for equipment, materials, and worker performance to ensure adherence to industry standards. This document helps identify defects early, reducing downtime and improving overall product consistency.

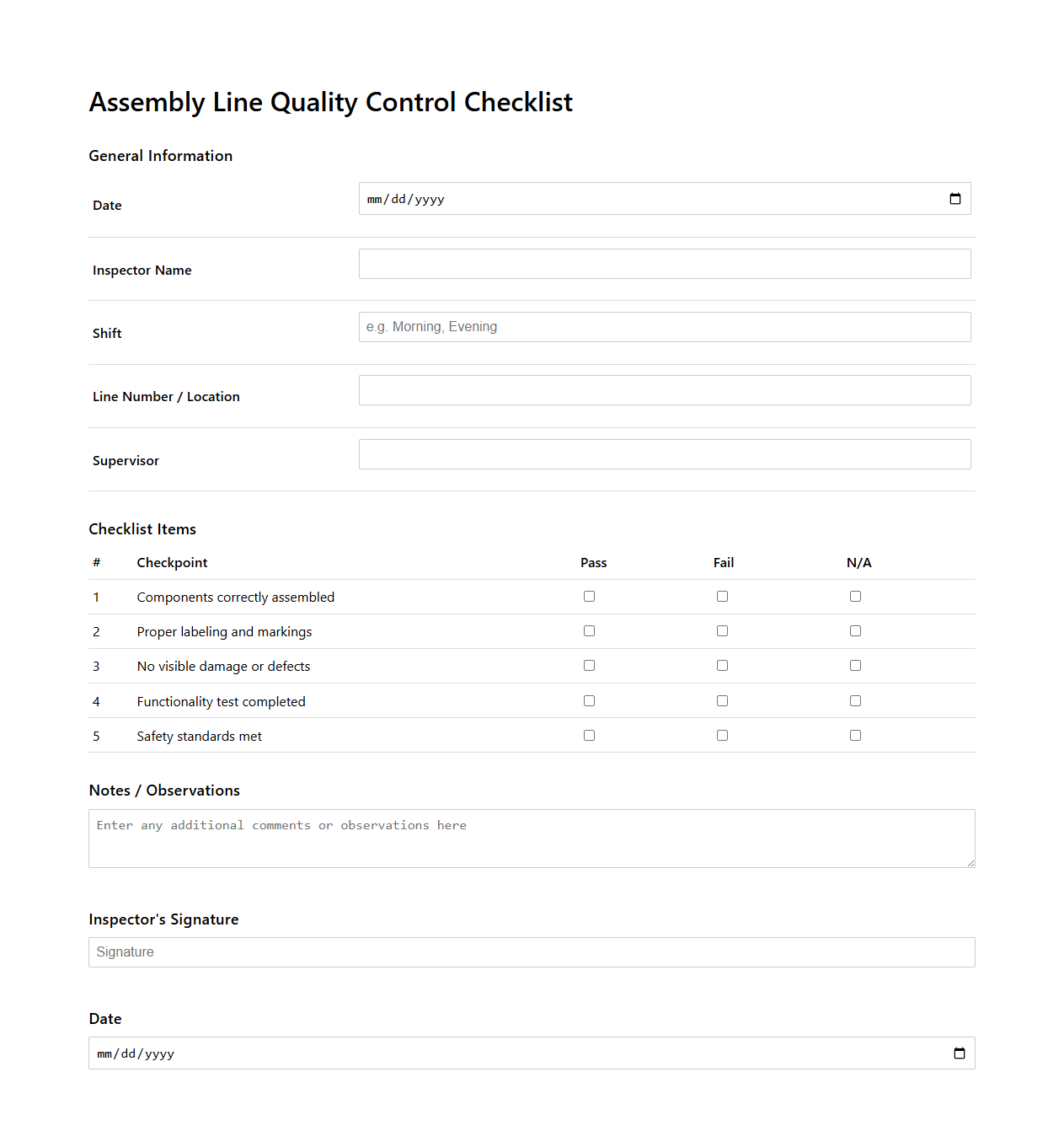

Assembly Line Quality Control Checklist Template

An

Assembly Line Quality Control Checklist Template document serves as a systematic tool used to monitor and ensure the quality standards of products during the manufacturing process. It provides a detailed list of inspection points, criteria, and procedures that workers or quality inspectors must verify at various stages of the assembly line. This template helps in identifying defects early, maintaining consistent product quality, and streamlining corrective actions to minimize production errors.

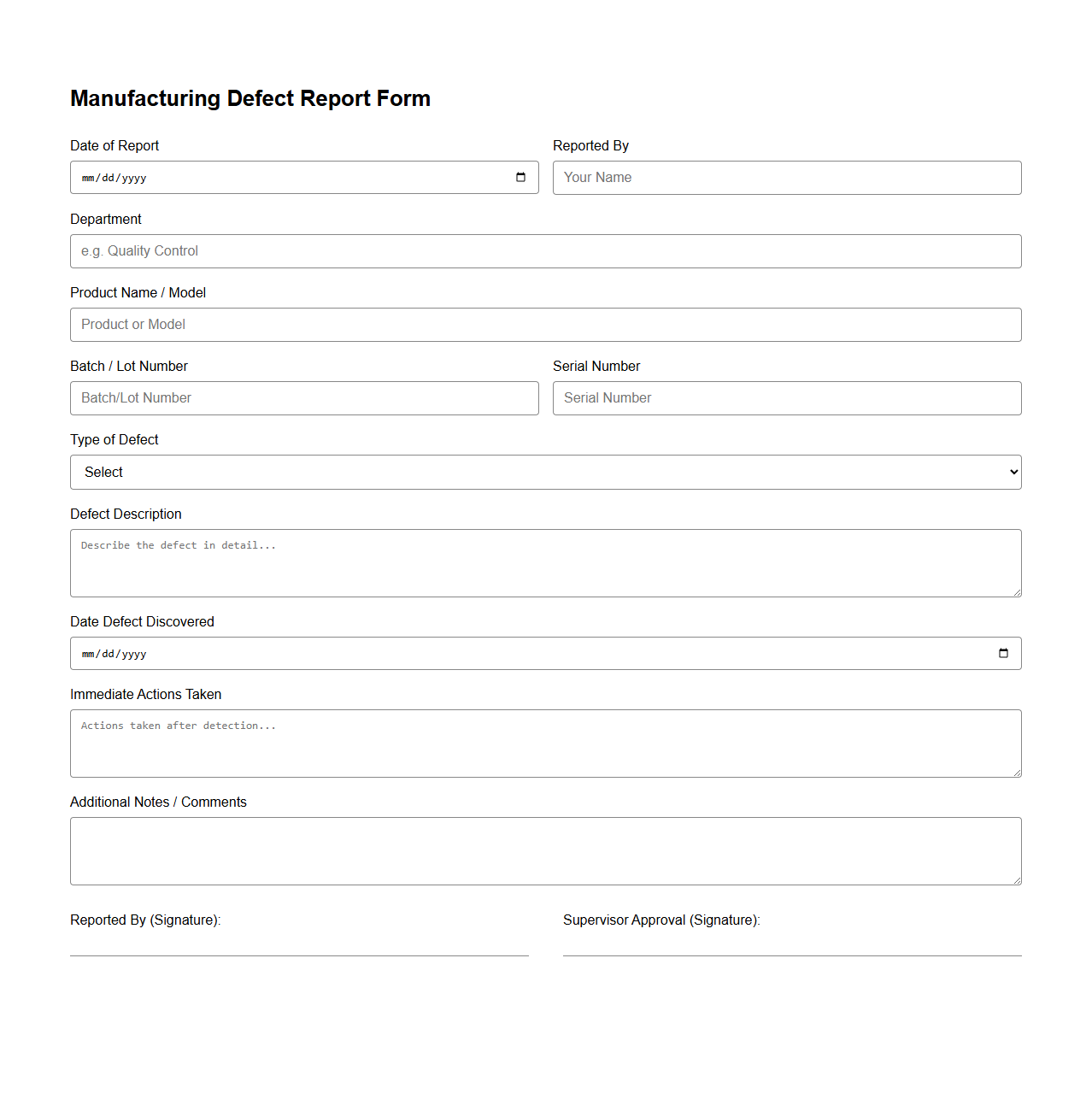

Manufacturing Defect Report Form Example

A

Manufacturing Defect Report Form Example document is a standardized template used to record and communicate details about defects identified during the production process. It typically includes fields for defect description, location, severity, root cause analysis, and corrective actions, ensuring consistent documentation and tracking. This form helps manufacturers maintain quality control, reduce errors, and facilitate continuous improvement in production workflows.

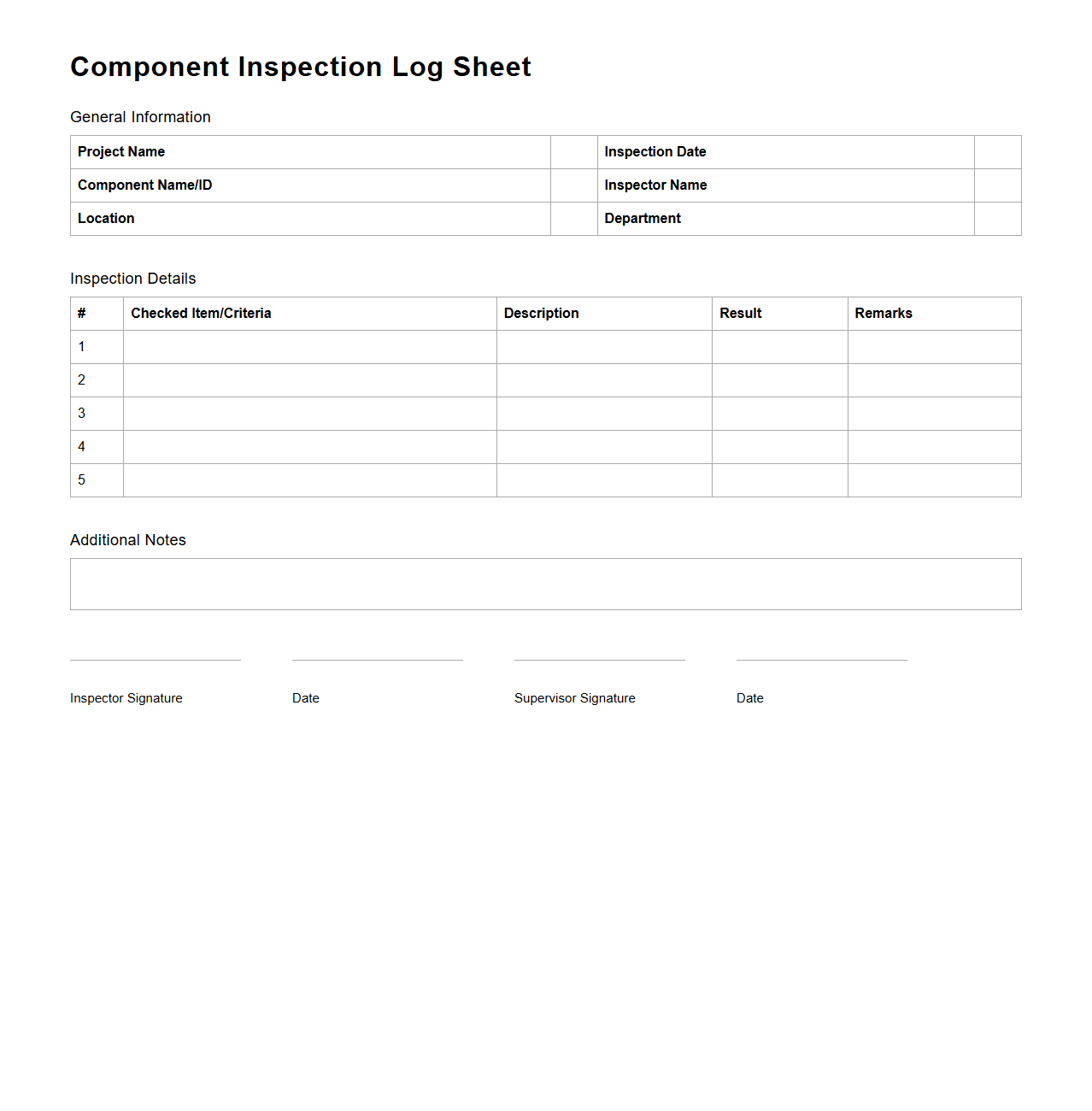

Component Inspection Log Sheet Sample

A

Component Inspection Log Sheet Sample document is a detailed record used to track the inspection results of individual components in manufacturing or quality control processes. It captures essential data such as component identification, inspection date, inspector name, measurement readings, and pass/fail status, ensuring traceability and compliance with quality standards. This document helps organizations maintain consistent quality, identify defects early, and support audits or certifications.

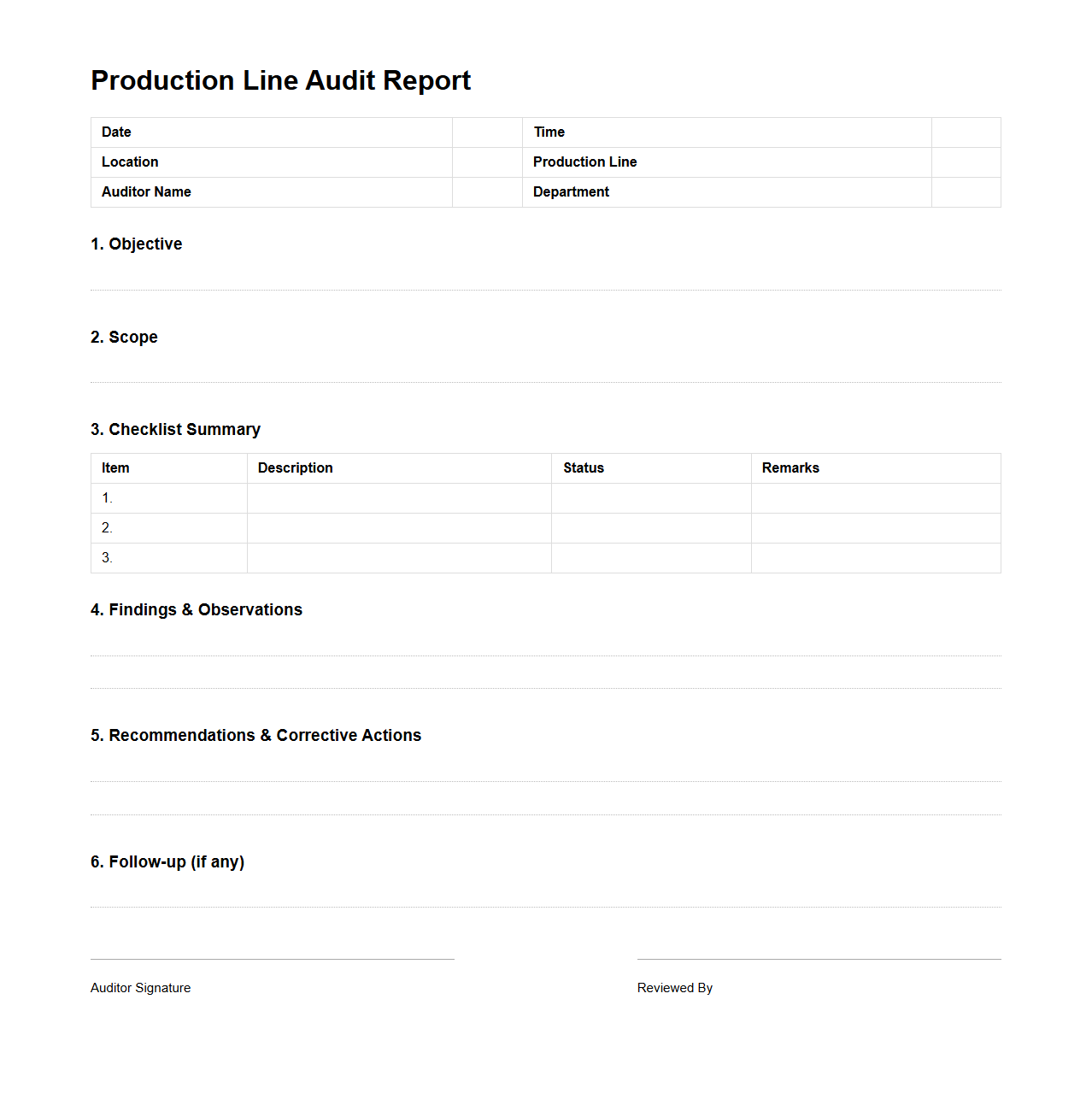

Production Line Audit Report Format

A

Production Line Audit Report Format document is a standardized template used to systematically evaluate the efficiency, compliance, and quality control of a manufacturing production line. It captures detailed observations, identifies deviations from established protocols, and recommends corrective actions to enhance operational performance. This report format ensures consistent documentation and facilitates continuous improvement in production processes.

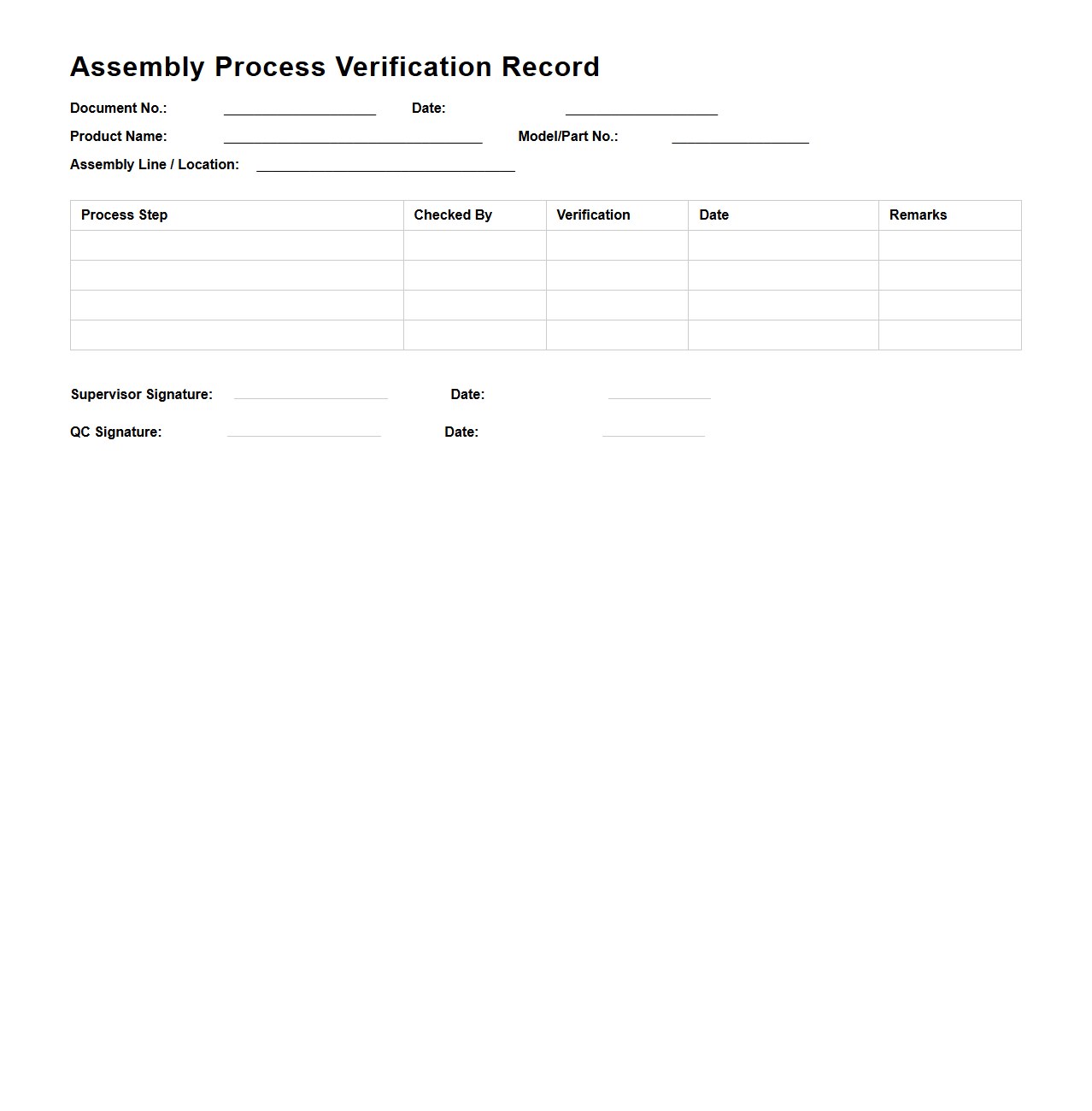

Assembly Process Verification Record Example

An

Assembly Process Verification Record Example document provides a detailed account of the verification activities performed during the assembly process to ensure compliance with design specifications and quality standards. It typically includes data such as assembly steps, inspection results, measurement data, and operator signatures to validate that each stage meets established criteria. This document serves as a critical tool for quality control, traceability, and regulatory compliance in manufacturing environments.

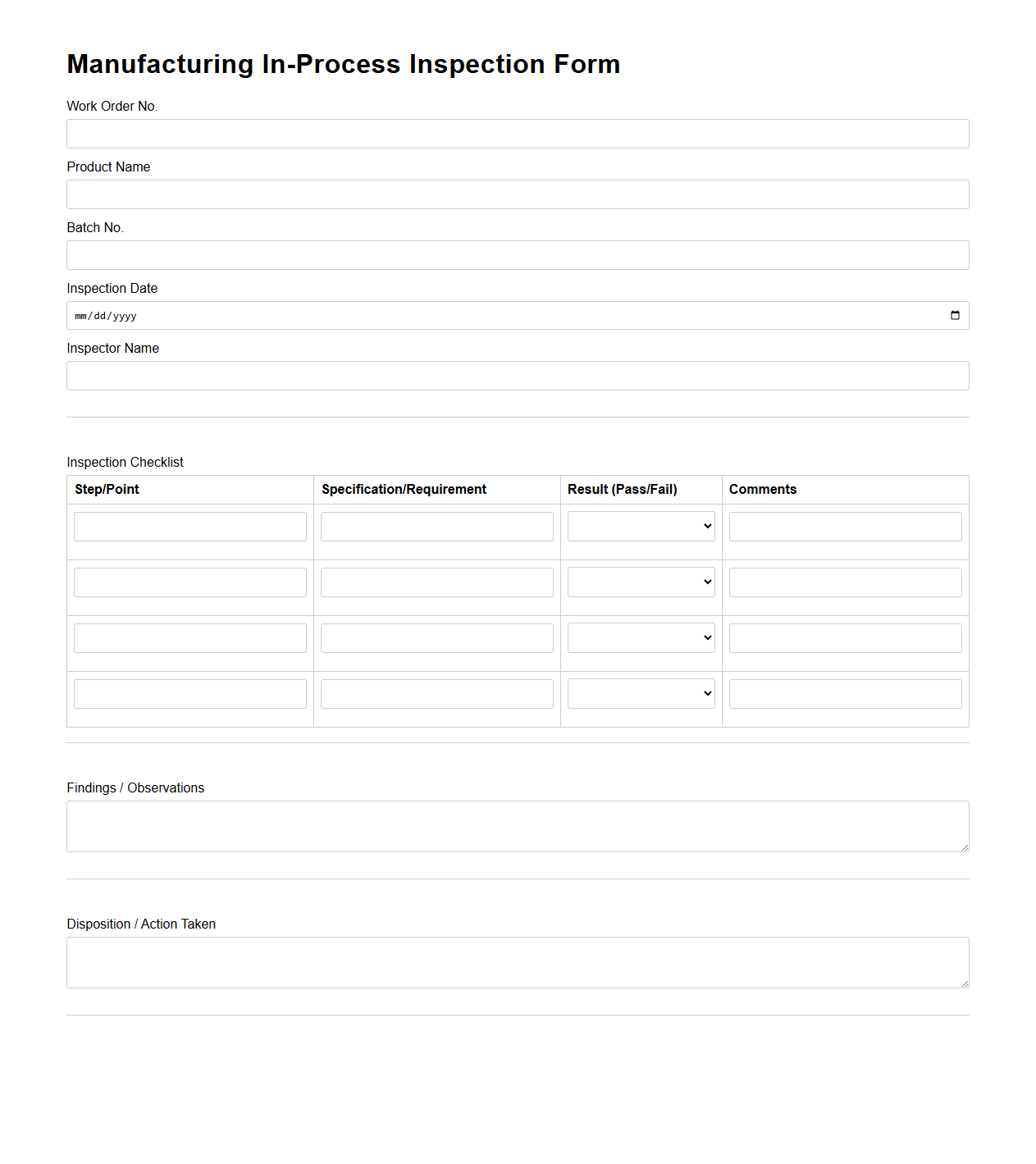

Manufacturing In-Process Inspection Form Sample

A

Manufacturing In-Process Inspection Form Sample document is used to systematically record the quality checks conducted during various stages of the manufacturing process. It helps identify defects early, ensuring product specifications and standards are consistently met before final assembly. This form improves traceability, reduces waste, and supports compliance with industry quality management systems.

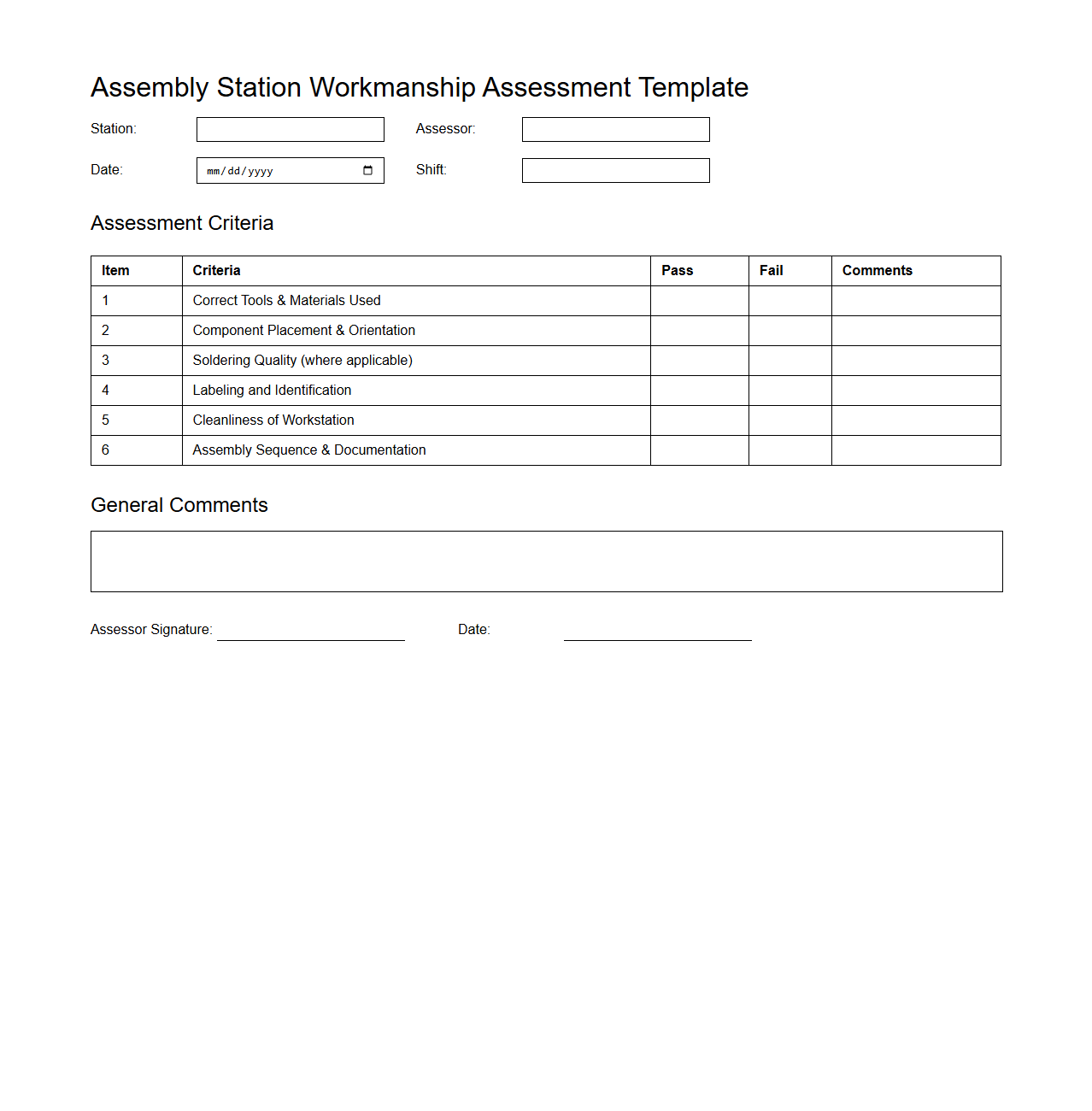

Assembly Station Workmanship Assessment Template

The

Assembly Station Workmanship Assessment Template document serves as a standardized tool to evaluate the quality and consistency of workmanship at assembly stations. It outlines specific criteria and metrics used to assess the accuracy, completeness, and compliance of assembly tasks with established manufacturing standards. This template helps ensure product reliability and supports continuous improvement in production processes.

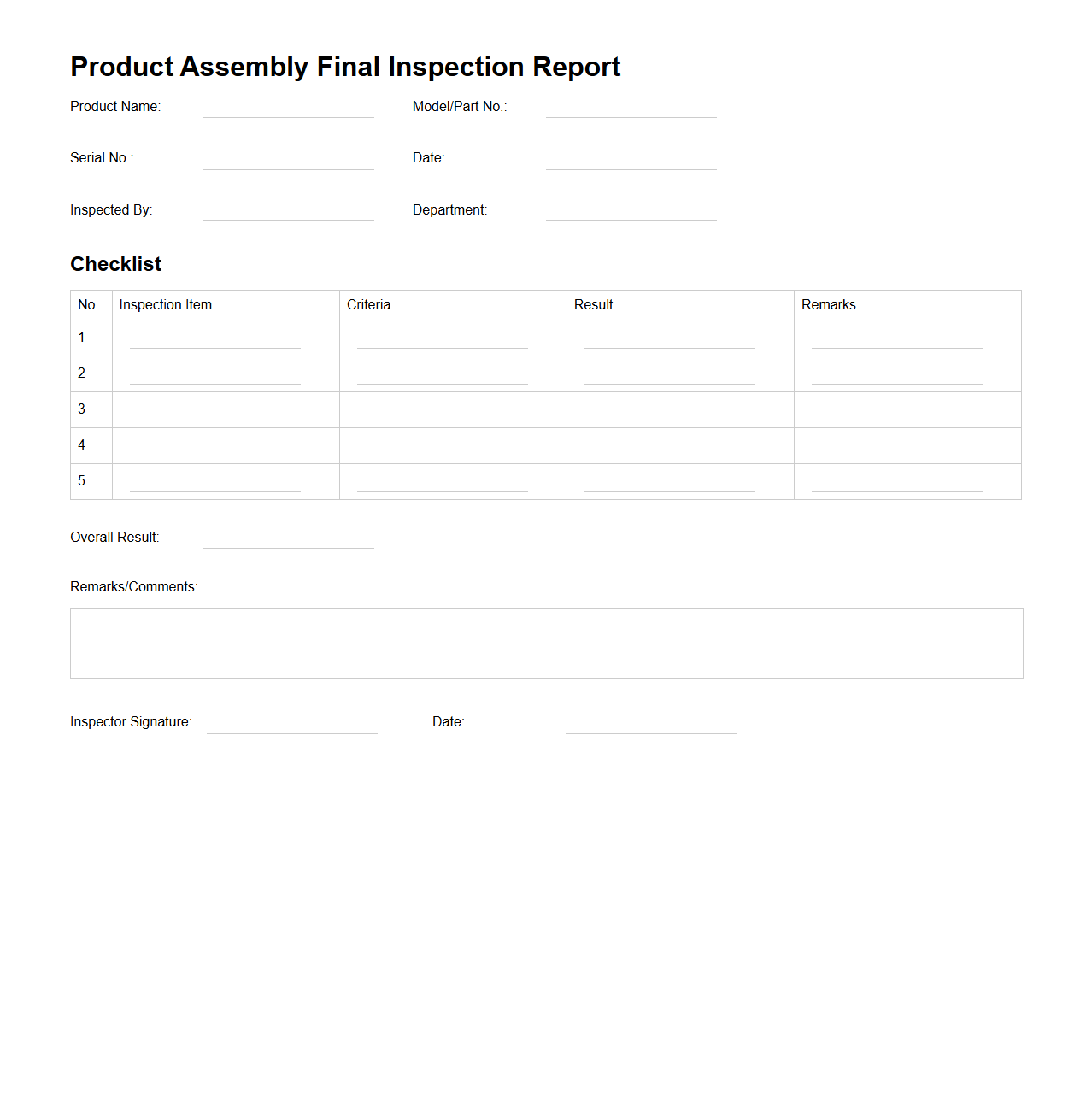

Product Assembly Final Inspection Report

A

Product Assembly Final Inspection Report document serves as a comprehensive record detailing the results of the final quality check performed on a product after assembly. It includes critical information such as inspection criteria, measurement data, defect identification, and compliance status to ensure the product meets design and safety standards. This report is essential for verifying that the assembled product is ready for shipment or further processing.

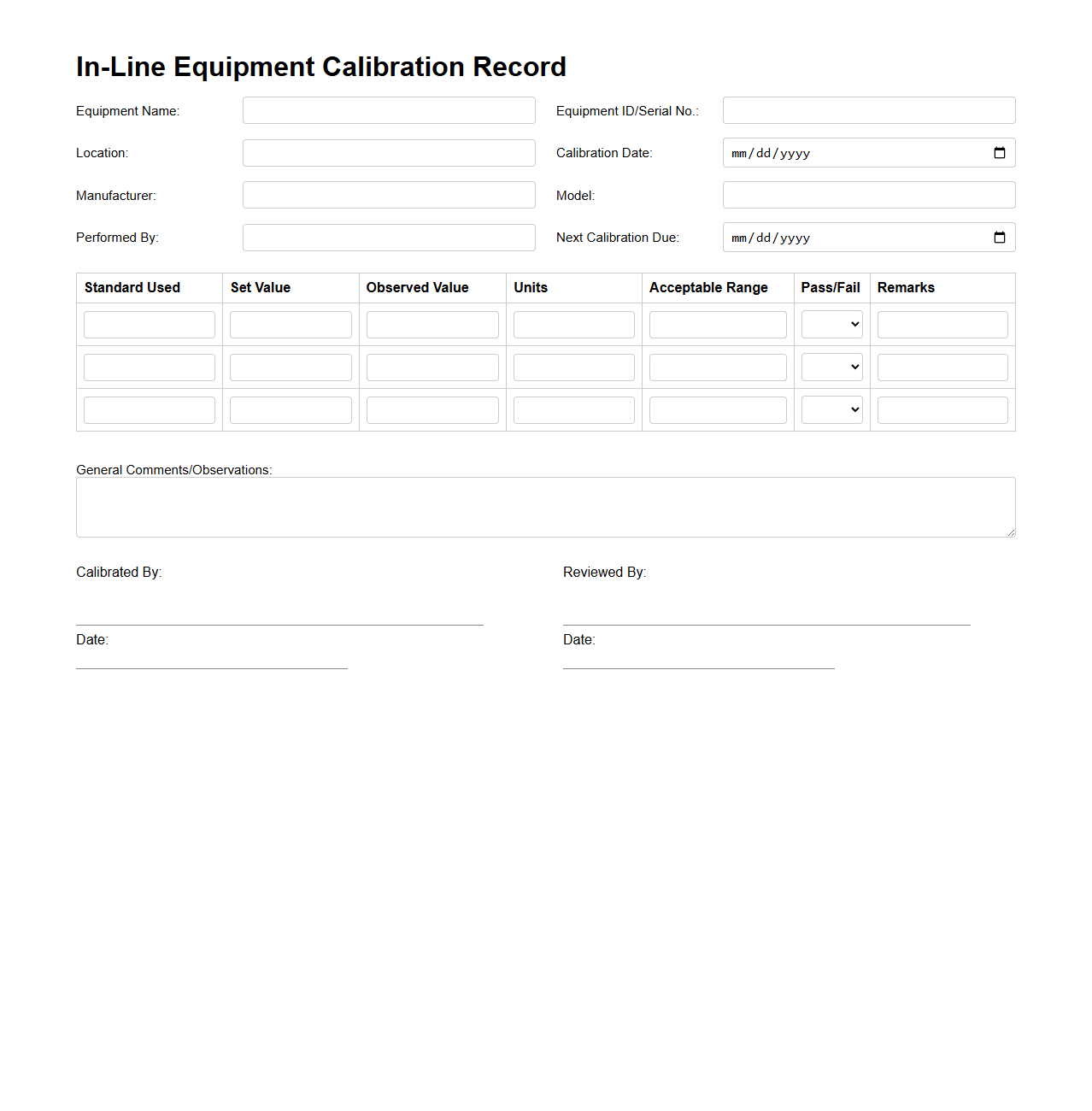

In-Line Equipment Calibration Record Example

An

In-Line Equipment Calibration Record Example document provides a detailed log of calibration activities performed directly on equipment without removal from its operational setting. It includes essential data such as calibration date, technician details, equipment identifiers, and measurement results to ensure accuracy and compliance with quality standards. This record helps maintain traceability and supports equipment reliability in regulated industries.

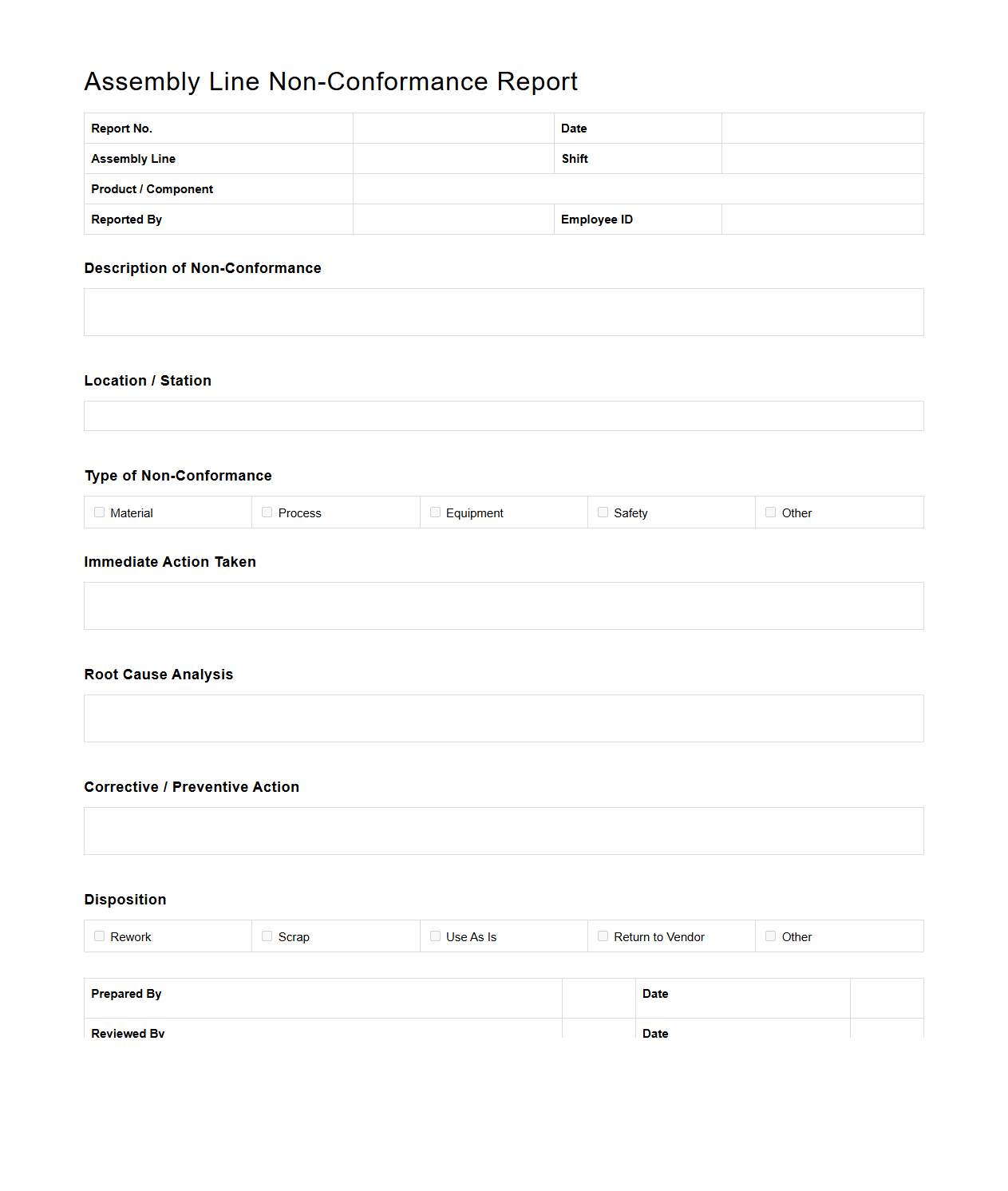

Assembly Line Non-Conformance Report Sample

An

Assembly Line Non-Conformance Report Sample document captures detailed information about defects or deviations identified during the manufacturing process on an assembly line. It helps track the nature, cause, and corrective actions for quality issues, ensuring compliance with industry standards and continuous improvement. This sample serves as a template for consistent reporting and facilitates effective communication among production, quality control, and management teams.

What are the key inspection criteria outlined in this assembly line inspection document?

The assembly line inspection document emphasizes critical quality standards such as dimensional accuracy, component functionality, and safety compliance. Inspectors must verify that each part meets the specified tolerance levels and operates as designed. Additionally, visual inspections for defects like cracks, misalignments, or surface imperfections are mandatory.

Which stages of the manufacturing process are covered by the inspection procedures?

The inspection procedures encompass multiple manufacturing stages including initial material receipt, in-process assembly checks, and final product evaluation. Each stage has tailored inspection tasks to ensure consistency and quality throughout the production cycle. This comprehensive approach helps identify issues early and maintain high standards.

What documentation or records must be completed during assembly line inspections?

Inspectors are required to complete detailed inspection checklists and record all findings in standardized forms or digital systems. These documents capture measurement results, defect reports, and verification signatures to maintain traceability. Accurate and thorough documentation supports accountability and facilitates quality audits.

Who is responsible for conducting and verifying inspection tasks according to this document?

The document assigns responsibility primarily to trained quality inspectors and assembly line supervisors who perform verification tasks. Additionally, designated quality assurance managers oversee the overall inspection process and ensure compliance with standards. This clear role division guarantees thoroughness and accountability.

How are non-conformances or defects to be reported and managed per the inspection guidelines?

Non-conformances must be immediately documented in a defect report and escalated to the quality control team for assessment. The guidelines mandate prompt corrective actions, including root cause analysis and rework or scrap decisions. Continuous monitoring of defect trends is essential to prevent recurrence and enhance manufacturing quality.

More Manufacturing Templates