A Tool Change Checklist Document Sample for Machining ensures all necessary steps are systematically followed to maintain precision and safety during tool replacement. It includes inspection points, calibration verification, and proper documentation to prevent downtime and machining errors. Using this checklist enhances operational efficiency and quality control in manufacturing processes.

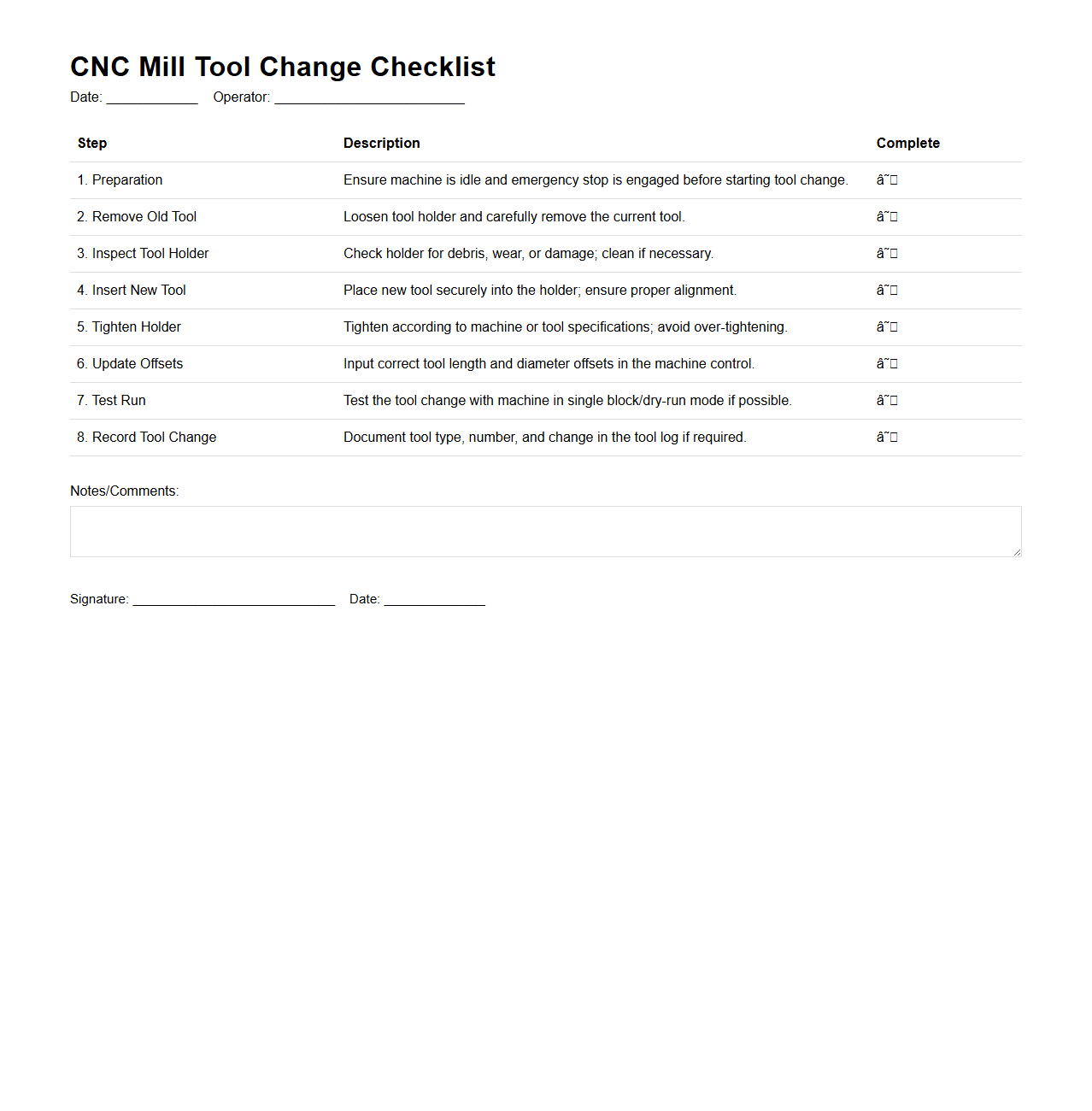

CNC Mill Tool Change Checklist Template

A

CNC Mill Tool Change Checklist Template document serves as a structured guide to ensure all essential steps and safety measures are followed when changing tools on a CNC milling machine. It helps operators verify tool alignment, calibration, and proper tool holding to maintain machining accuracy and prevent equipment damage. Using this checklist improves efficiency, reduces downtime, and supports consistent quality control in CNC milling operations.

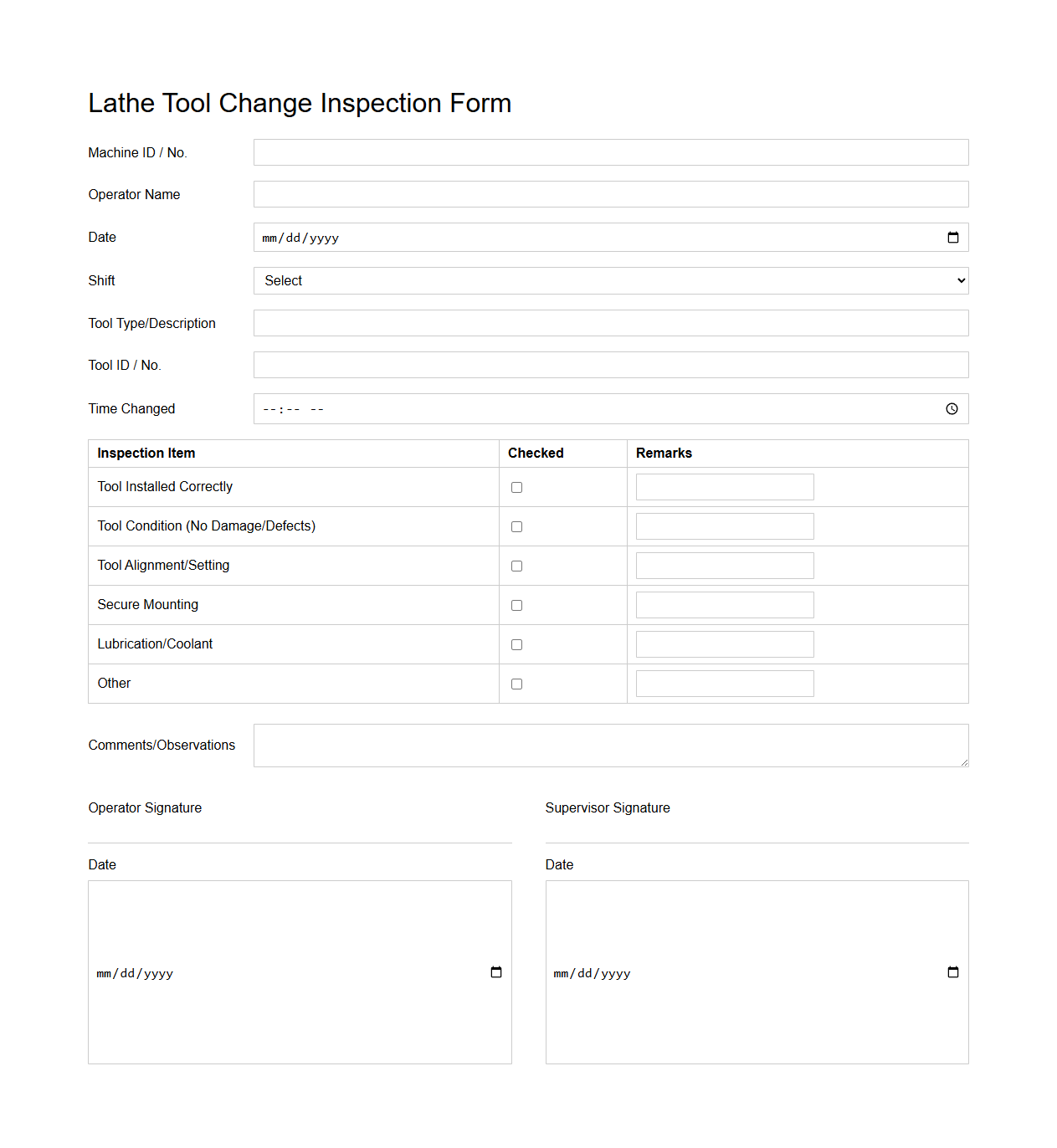

Lathe Tool Change Inspection Form

The

Lathe Tool Change Inspection Form document is used to systematically record and verify the details of tool replacements in lathe machinery, ensuring operational accuracy and safety. It captures essential data such as tool identification, change date, operator name, and inspection outcomes to maintain consistent machining quality. This form supports preventive maintenance and helps reduce downtime by facilitating prompt detection of tool wear or misalignment.

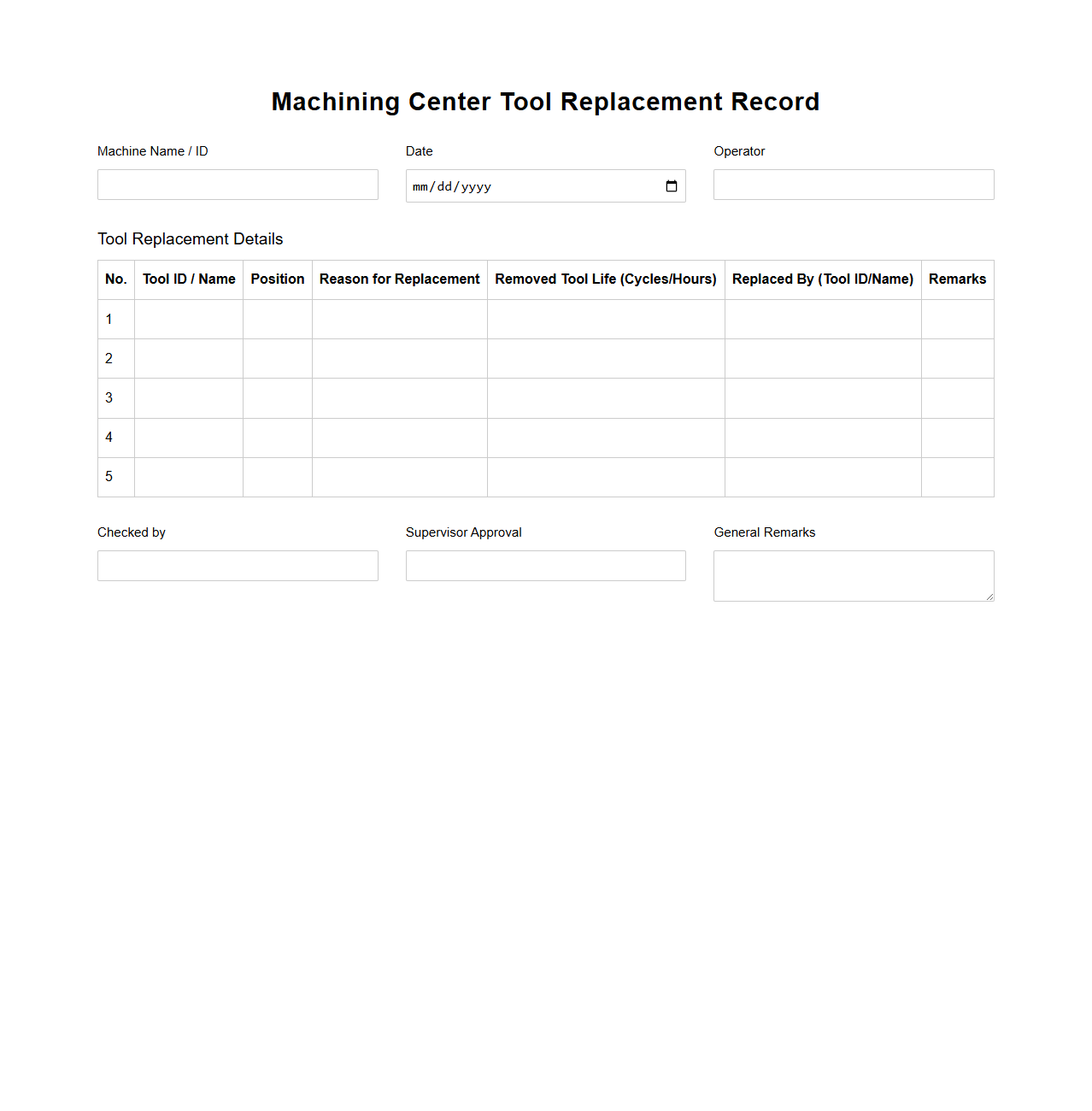

Machining Center Tool Replacement Record

A

Machining Center Tool Replacement Record document tracks the details of tool changes within a machining center, including tool identification, replacement date, and reason for replacement. This record ensures accurate maintenance history, helps optimize tool usage, and supports quality control by minimizing machining errors caused by worn or damaged tools. Maintaining this document is essential for operational efficiency and extending tool life in manufacturing processes.

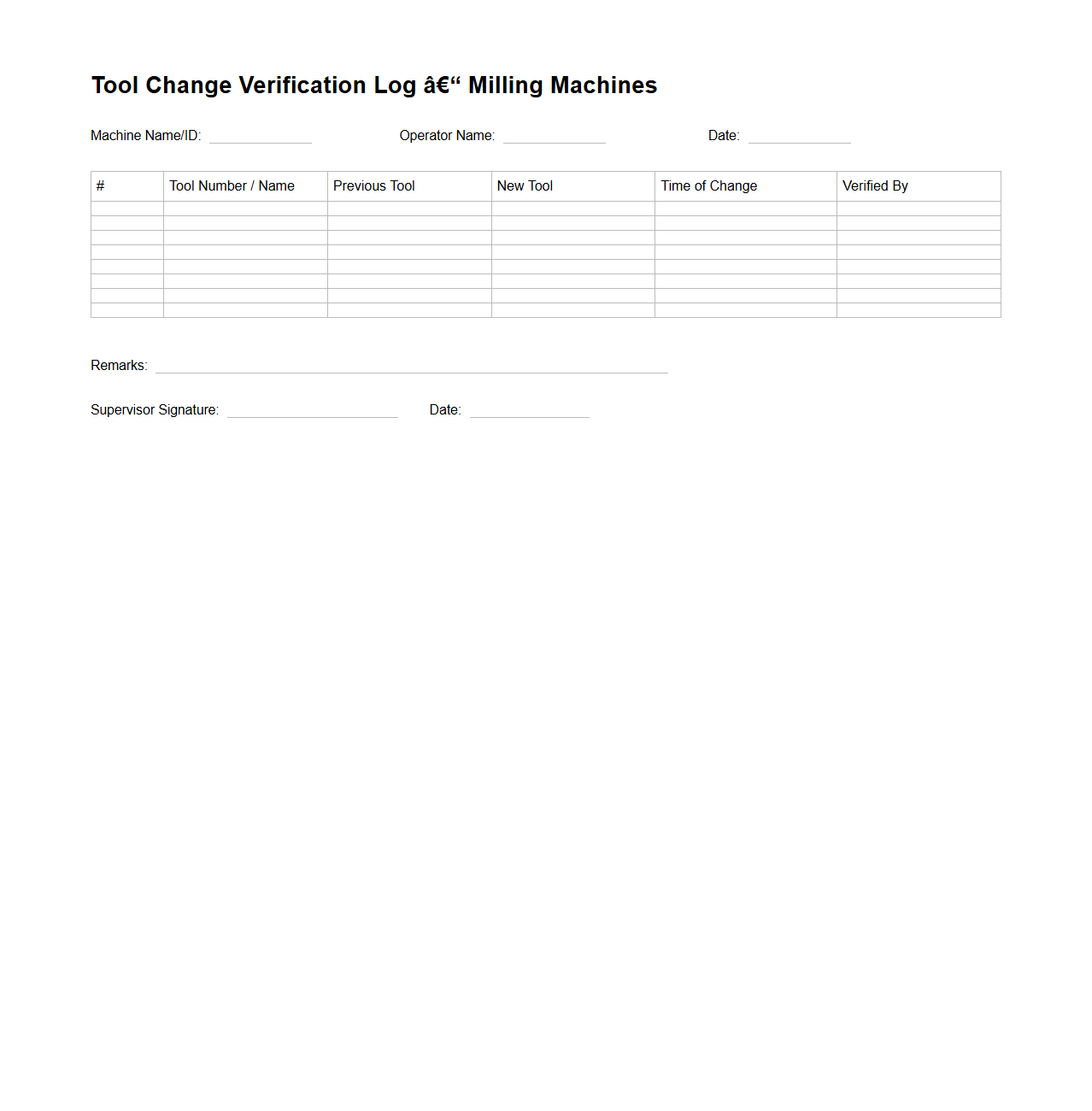

Tool Change Verification Log for Milling Machines

The

Tool Change Verification Log for milling machines is a critical document used to track and verify each tool change during machining processes, ensuring tool accuracy and preventing errors. It records details such as tool numbers, change times, operator initials, and any discrepancies observed, which helps maintain consistent production quality and reduces downtime. Proper use of this log enhances traceability and supports compliance with manufacturing standards.

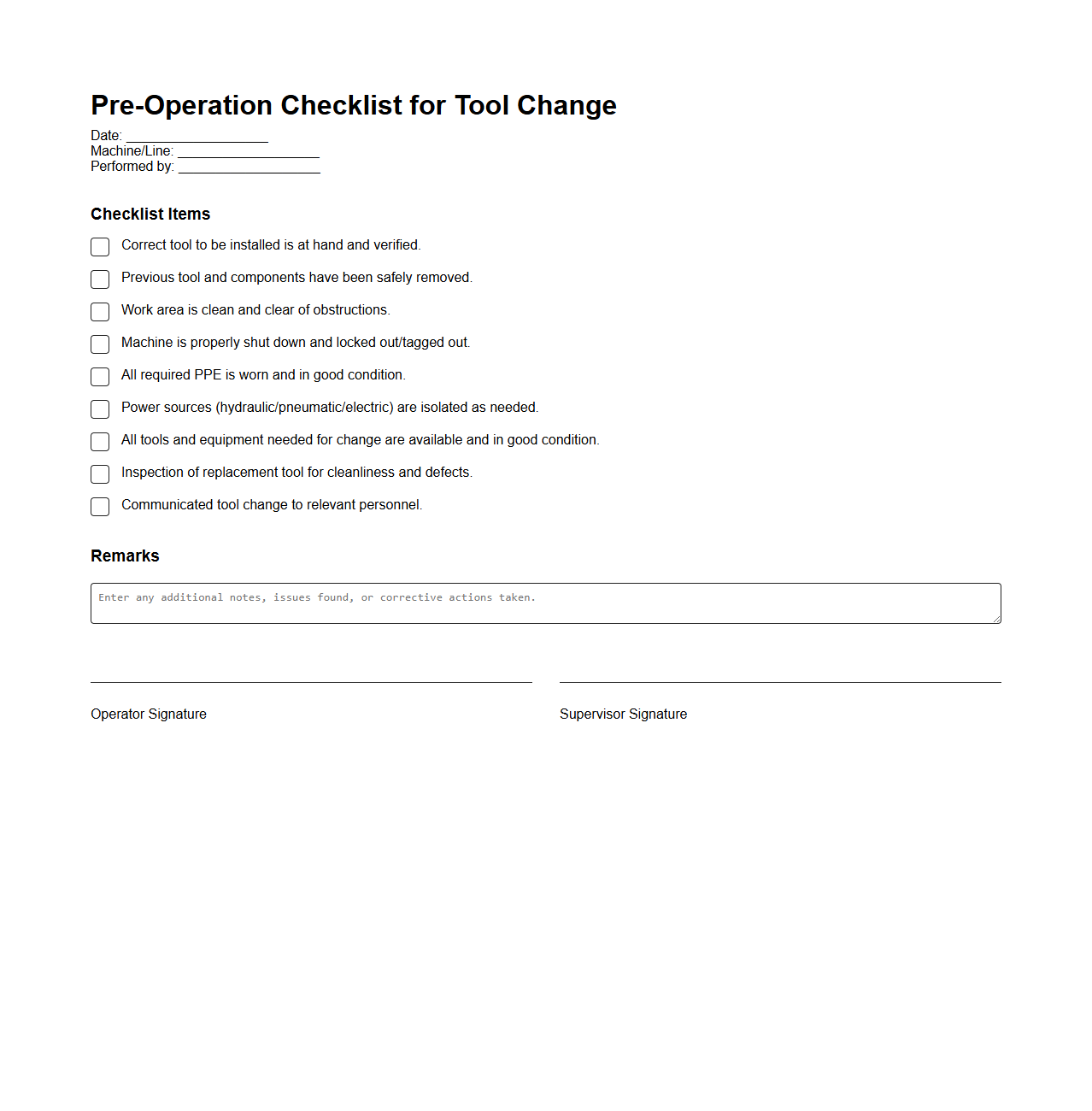

Pre-Operation Checklist for Tool Change

The

Pre-Operation Checklist for Tool Change document ensures all essential safety measures and procedural steps are followed before replacing or adjusting tools on machinery. It typically includes verification of machine shutdown status, confirmation of tool compatibility, and inspection of necessary equipment and personal protective gear. This checklist minimizes operational risks, improves efficiency, and maintains workplace safety standards.

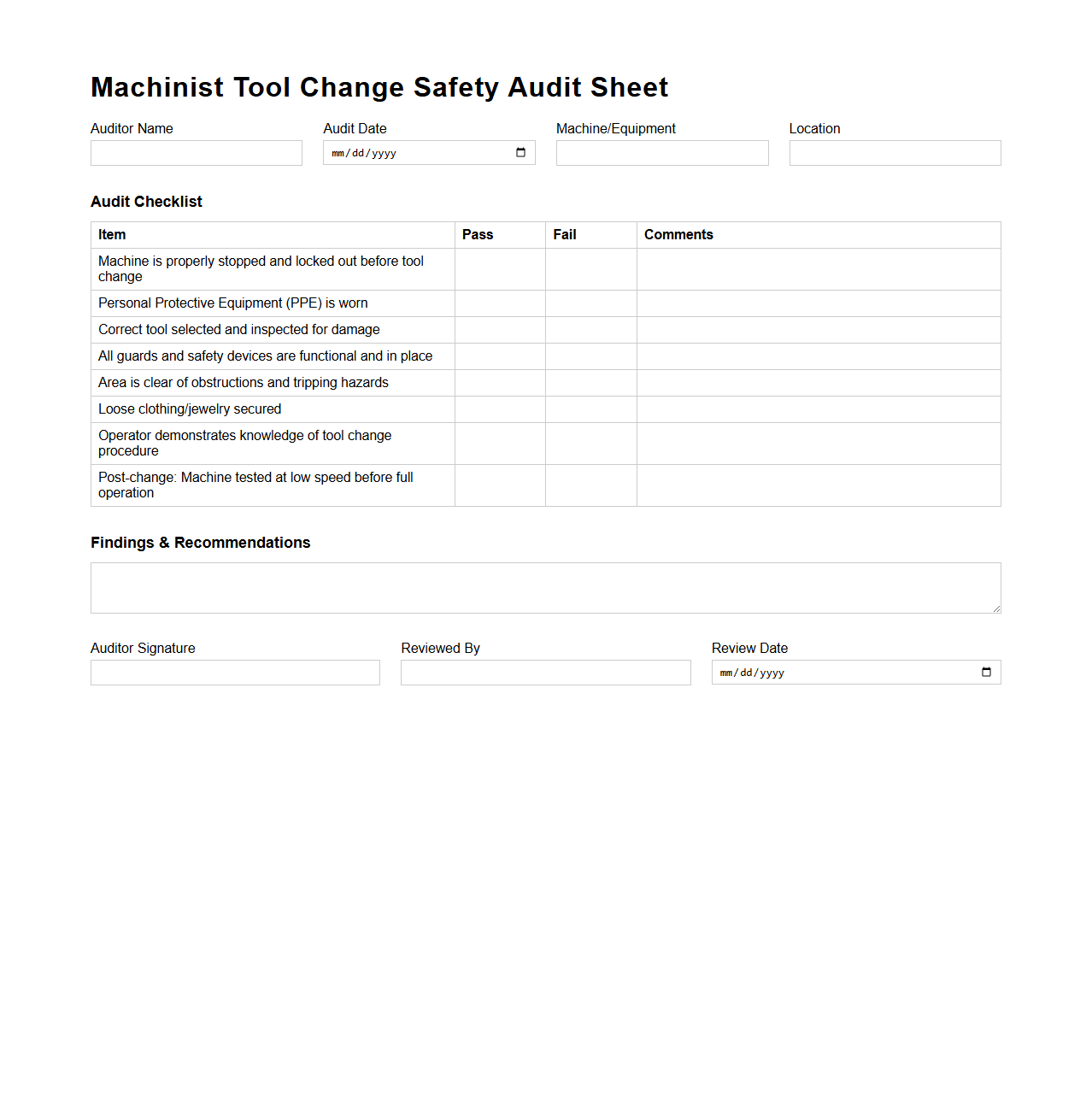

Machinist Tool Change Safety Audit Sheet

The

Machinist Tool Change Safety Audit Sheet is a critical document used to ensure safe and proper procedures during tool changes in machining operations. It systematically records compliance with safety standards, verifies correct tool installation, and monitors potential hazards to prevent accidents. This audit sheet helps maintain operational efficiency while enforcing workplace safety protocols in manufacturing environments.

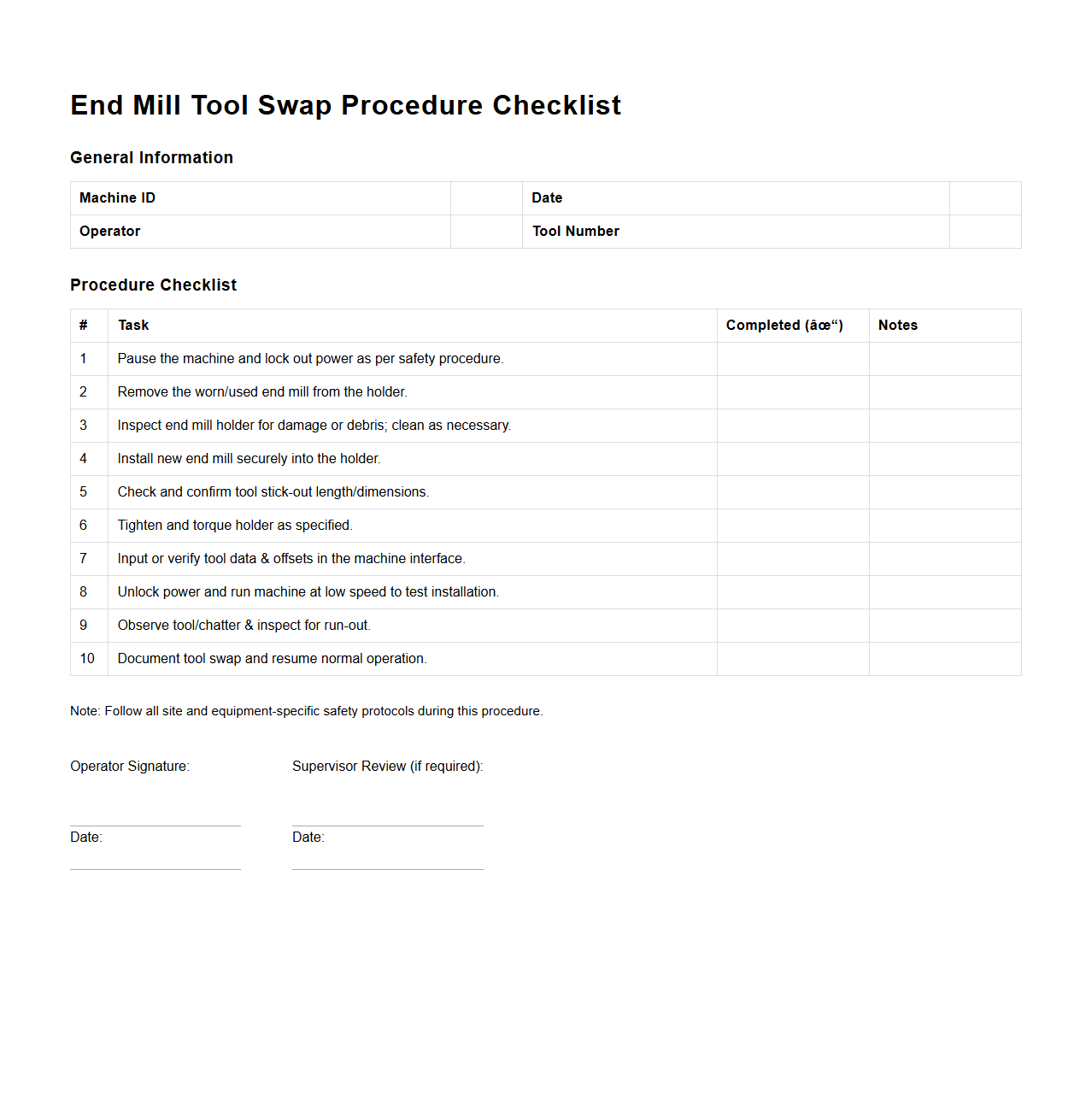

End Mill Tool Swap Procedure Checklist

The

End Mill Tool Swap Procedure Checklist document ensures the accurate and safe replacement of end mill tools in machining operations. It outlines critical steps such as verifying tool compatibility, proper tool handling, and calibration to maintain precision and prevent equipment damage. Following this checklist enhances operational efficiency and reduces downtime in CNC machining environments.

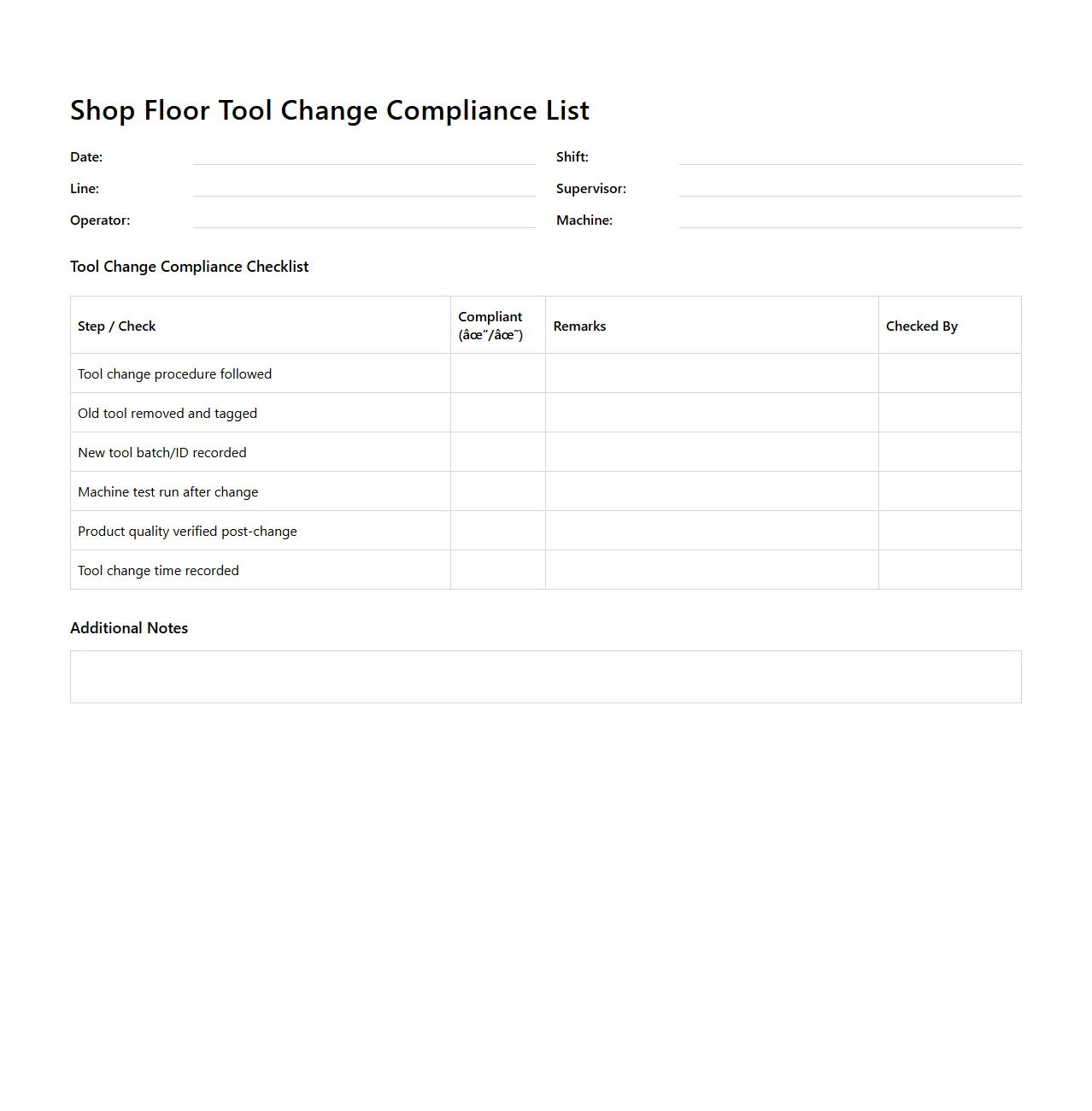

Shop Floor Tool Change Compliance List

The

Shop Floor Tool Change Compliance List document is a critical record that ensures all tool changes on the production floor meet established safety, quality, and operational standards. It tracks scheduled and completed tool changes, confirming adherence to compliance protocols to minimize downtime and prevent defects. This document facilitates efficient tool management, supports regulatory audits, and enhances overall manufacturing process reliability.

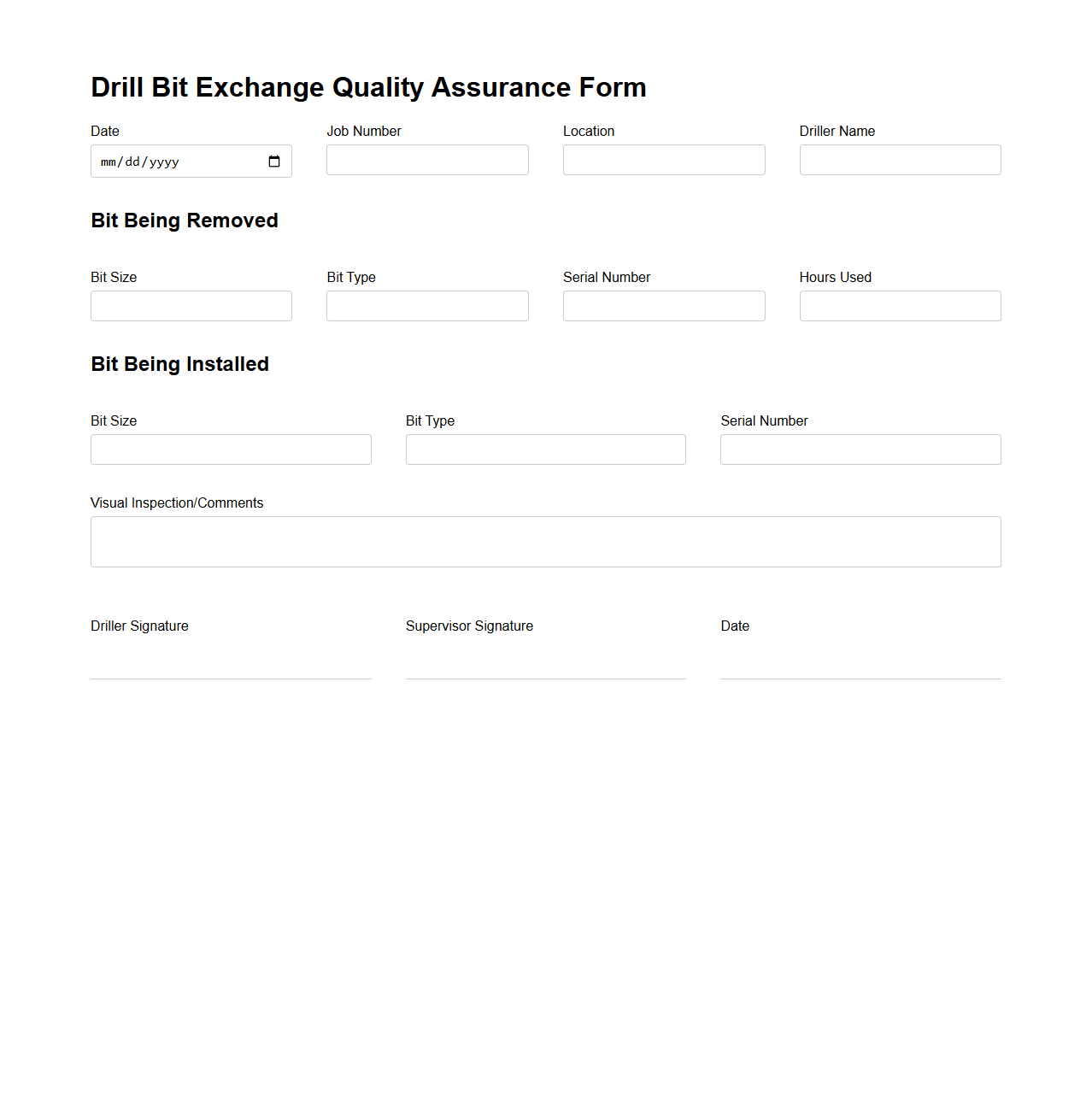

Drill Bit Exchange Quality Assurance Form

The

Drill Bit Exchange Quality Assurance Form is a critical document used to ensure the integrity and performance of drill bits during replacement processes. It systematically records inspection data, compliance with quality standards, and verification of bit condition before and after exchange. This form helps maintain operational efficiency and reduces downtime by preventing the use of defective or substandard drill bits.

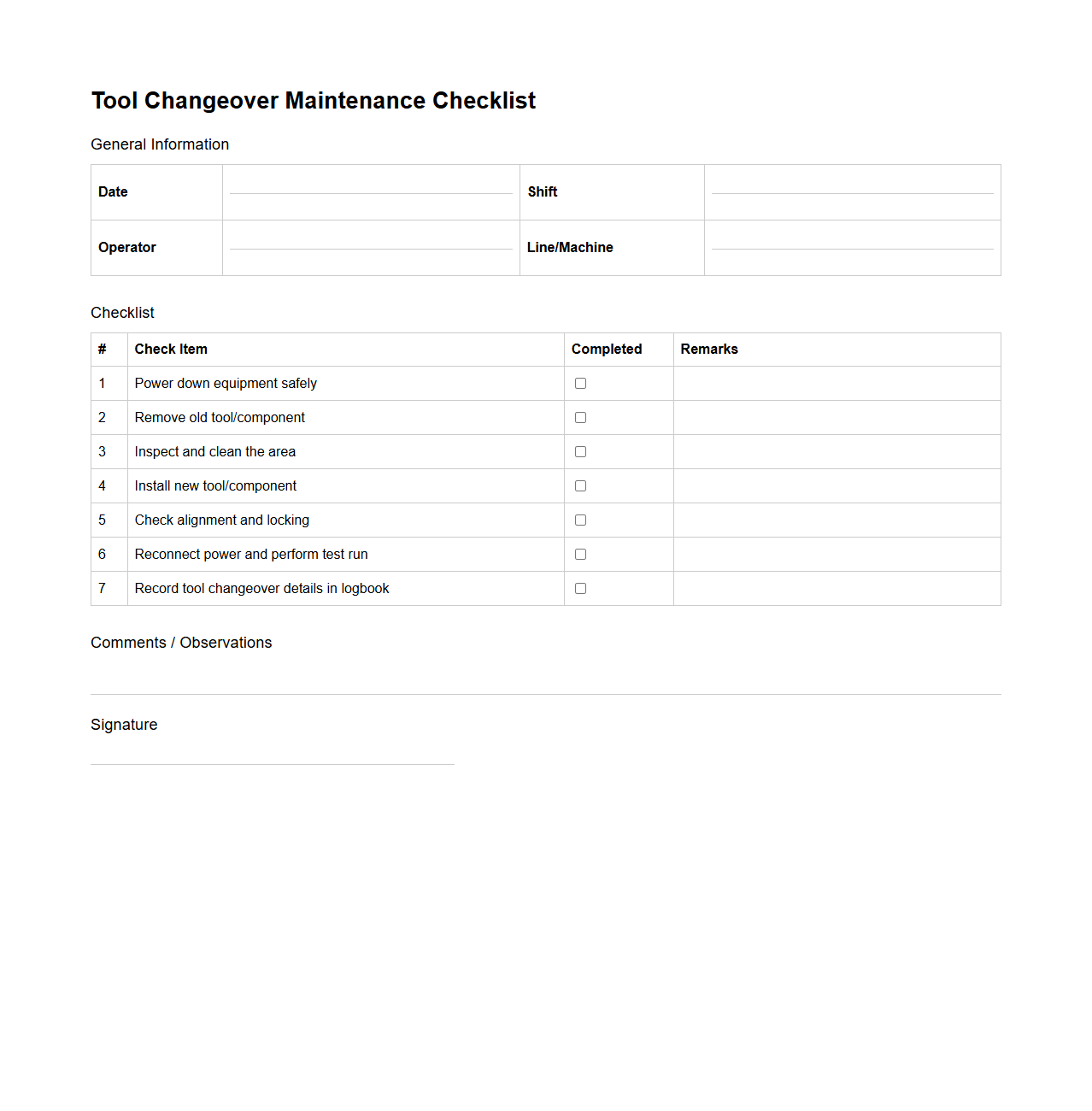

Tool Changeover Maintenance Checklist

The

Tool Changeover Maintenance Checklist document is a structured guide used to ensure all necessary steps and inspections are completed during the transition between different tools or equipment in a manufacturing or production environment. It helps maintain equipment efficiency, reduces downtime, and prevents errors by outlining specific maintenance tasks, safety checks, and calibration procedures required for each changeover. This checklist supports consistent quality control and operational reliability by standardizing changeover practices across teams.

What is the primary purpose of the Tool Change Checklist Document in machining operations?

The primary purpose of the Tool Change Checklist Document is to ensure a systematic and error-free process during tool changes in machining operations. It serves as a guide to maintain consistency and precision, reducing the risk of mistakes that could impact product quality or machine performance. By following this document, operators can uphold safety standards and operational efficiency.

Which critical steps are included in the checklist for safe and accurate tool changes?

The checklist includes critical steps such as verifying the correct tool type and size, safely securing the machine before tool removal, and properly aligning and installing the new tool. It also covers inspection of the tool condition and calibration settings to ensure accuracy. These steps are essential for maintaining machining precision and avoiding tool misplacement or damage.

How does the document ensure traceability of tool changes and operator accountability?

The document assigns responsibility by requiring operators to record their identification and the time of the tool change. It includes fields for logging tool serial numbers and machine status to create a traceable record. This traceability fosters accountability and simplifies troubleshooting or audits related to tool management.

What safety measures are highlighted in the checklist to prevent machine damage or injury?

The checklist emphasizes safety measures such as powering down the machine, using protective equipment, and verifying the machine's readiness before restarting. It also mandates checks for clear tool paths and secure tool mounting to prevent accidental tool ejection. These precautions protect both the operator and the machinery from potential harm.

Which verification processes does the checklist require after completing a tool change?

Post tool change, the checklist requires verifying tool alignment and tightness, conducting a test run to check machine function, and confirming the tool's operational parameters. It ensures that the tool is functioning properly and that no errors occurred during installation. This final verification step is critical for maintaining production quality and machine safety.

More Manufacturing Templates