A First Article Inspection Document Sample for Manufacturing serves as a comprehensive report verifying that a produced item meets all specified design and quality standards. This document includes detailed measurements, material certifications, and inspection results to ensure compliance before mass production. It helps manufacturers identify defects early and maintain consistent product quality throughout the production process.

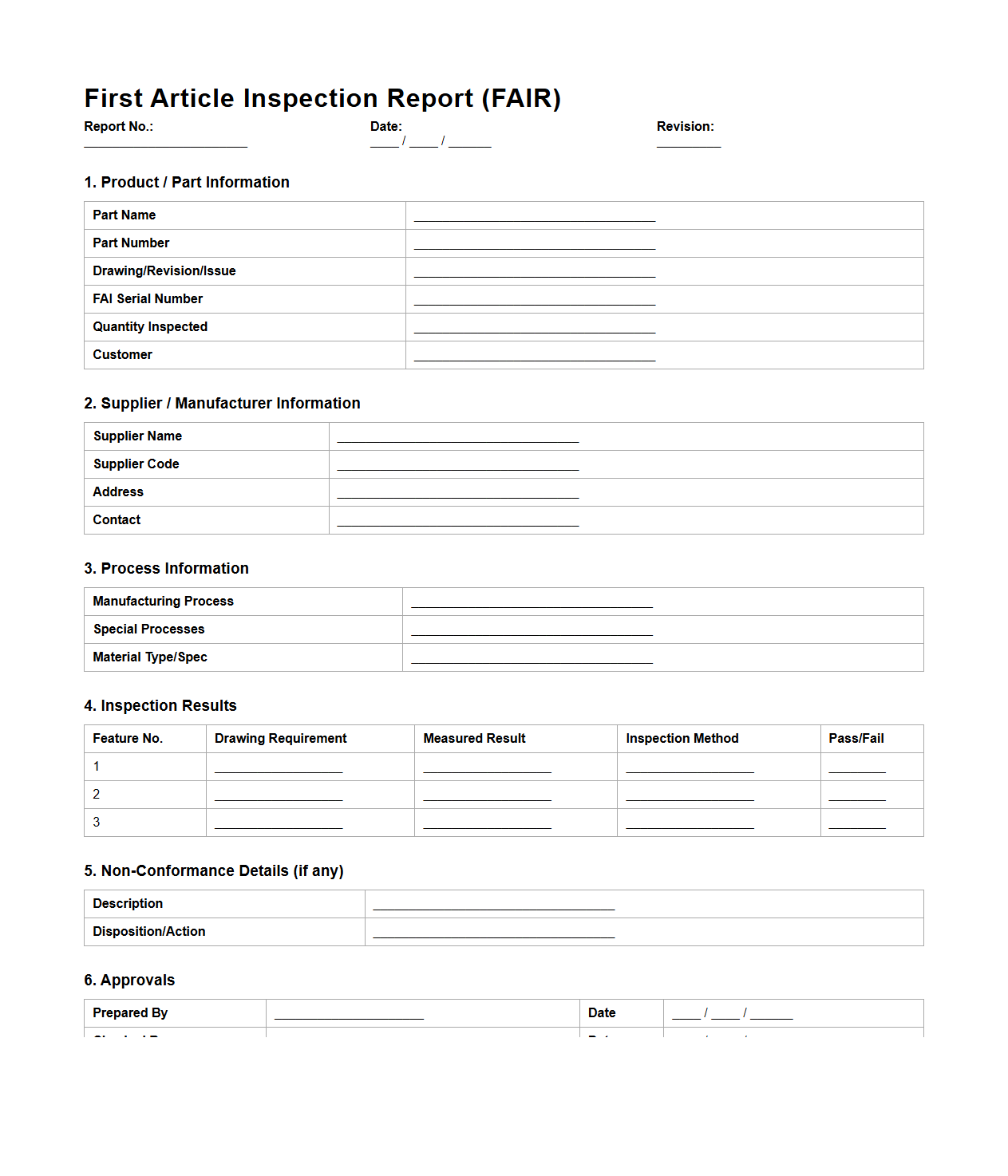

First Article Inspection Report Template for Aerospace Components

The

First Article Inspection Report Template for Aerospace Components is a critical quality assurance document used to verify that manufactured parts meet all specified design and engineering requirements. This template ensures thorough inspection of dimensions, materials, and performance characteristics, providing traceable documentation essential for compliance with aerospace industry standards such as AS9102. It facilitates consistent reporting and helps manufacturers and suppliers confirm part accuracy before full-scale production begins.

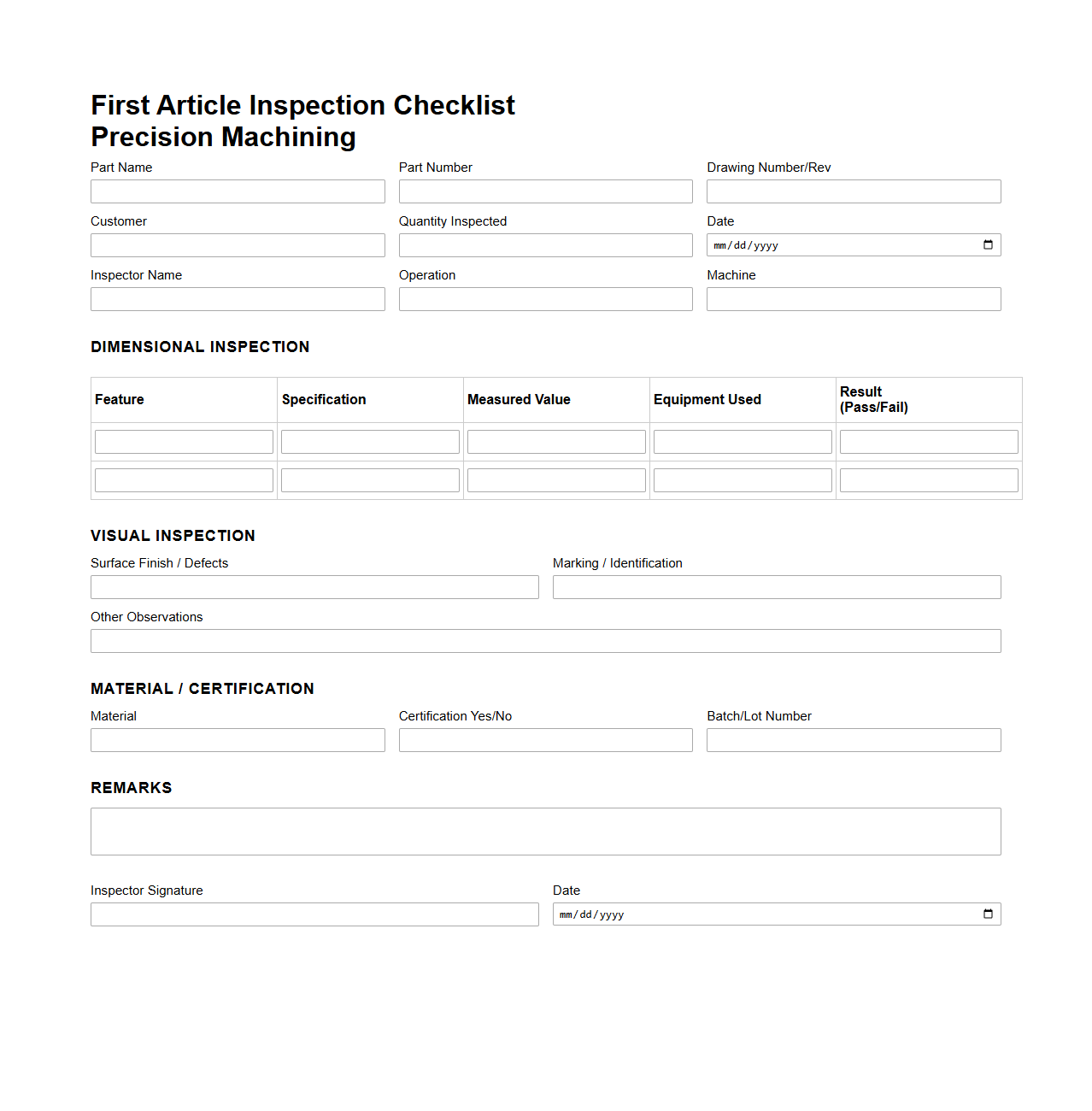

First Article Inspection Checklist for Precision Machining

The

First Article Inspection Checklist for precision machining is a detailed document used to verify that a manufactured part meets specified design requirements and tolerances. It ensures all critical dimensions, materials, and processes comply with engineering drawings and industry standards before full production begins. This checklist is essential for quality control and helps identify any discrepancies early in the manufacturing process, reducing errors and costly rework.

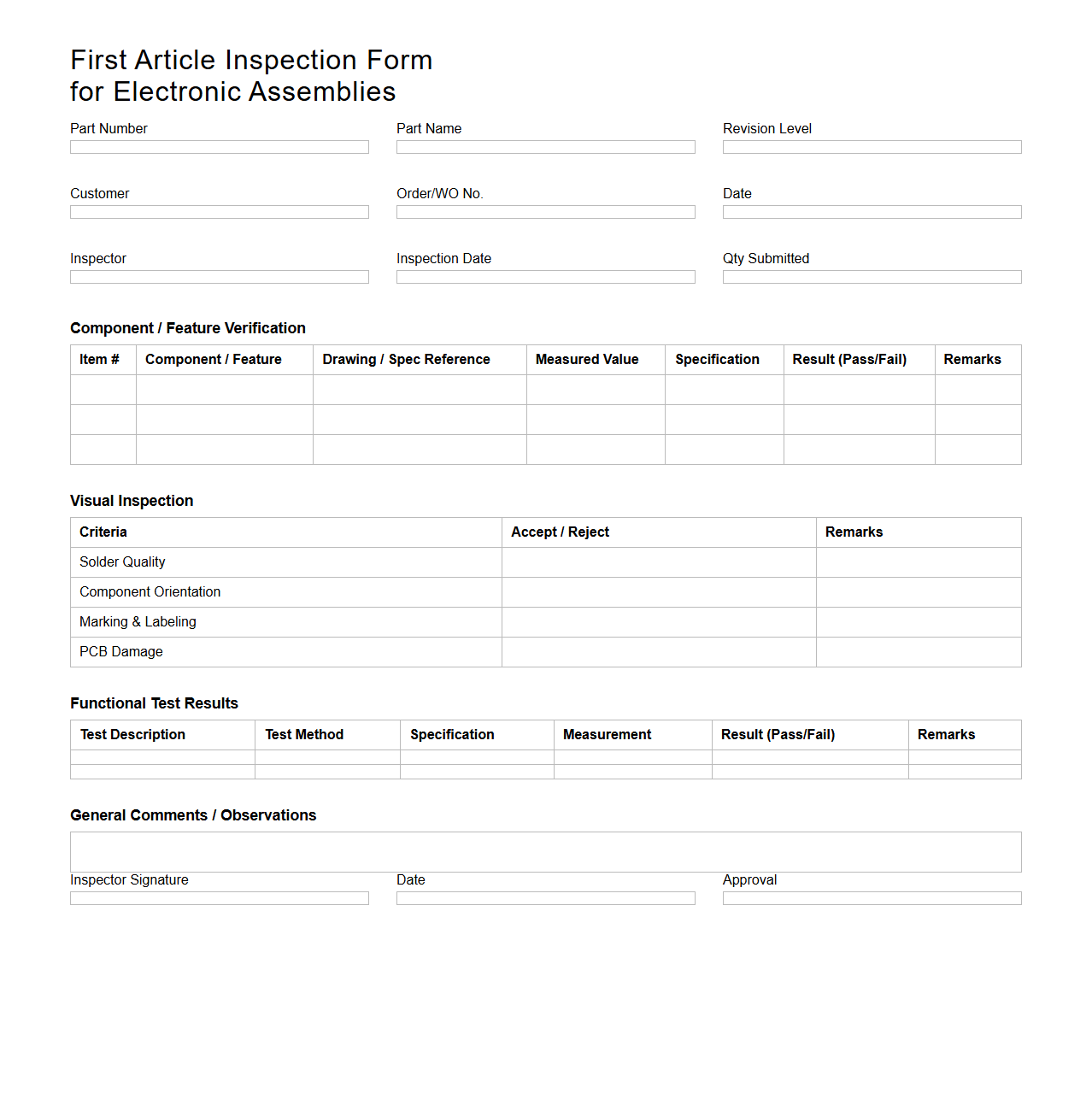

First Article Inspection Form for Electronic Assemblies

The

First Article Inspection Form for Electronic Assemblies is a critical document used to verify that the initial production units meet specified design and quality standards. It captures detailed inspection data on key characteristics such as component placement, soldering quality, and electrical functionality before mass production begins. This form ensures compliance with customer requirements and serves as a reference for continuous quality assurance throughout the manufacturing process.

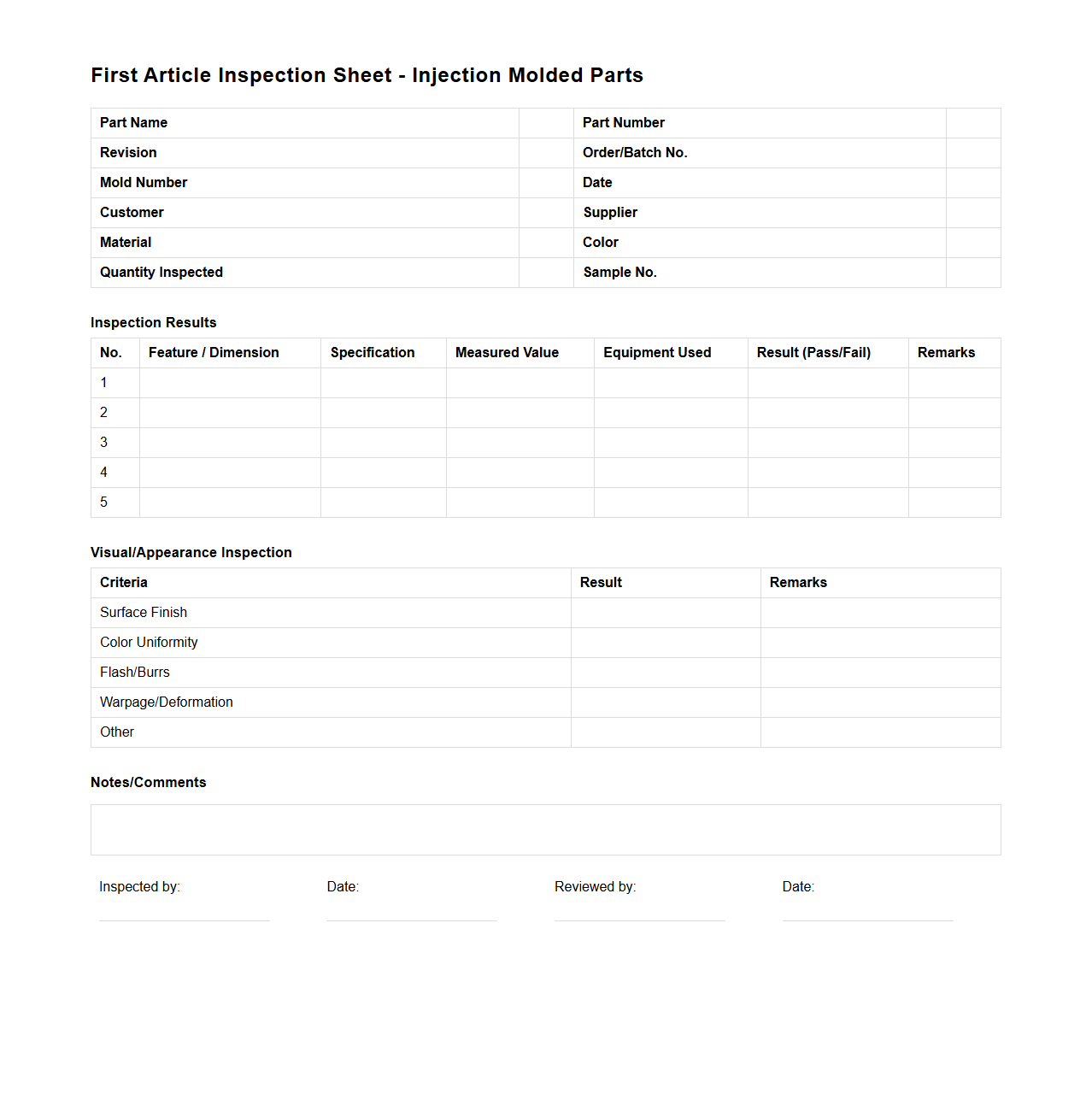

First Article Inspection Sheet for Injection Molded Parts

The

First Article Inspection Sheet for injection molded parts is a detailed document used to verify that the initial production run meets all specified design and quality requirements. It includes dimensional measurements, material specifications, and visual inspection results to ensure that the mold and manufacturing process produce parts conforming to engineering standards. This sheet serves as a critical quality control tool to identify discrepancies early and prevent defective parts from entering mass production.

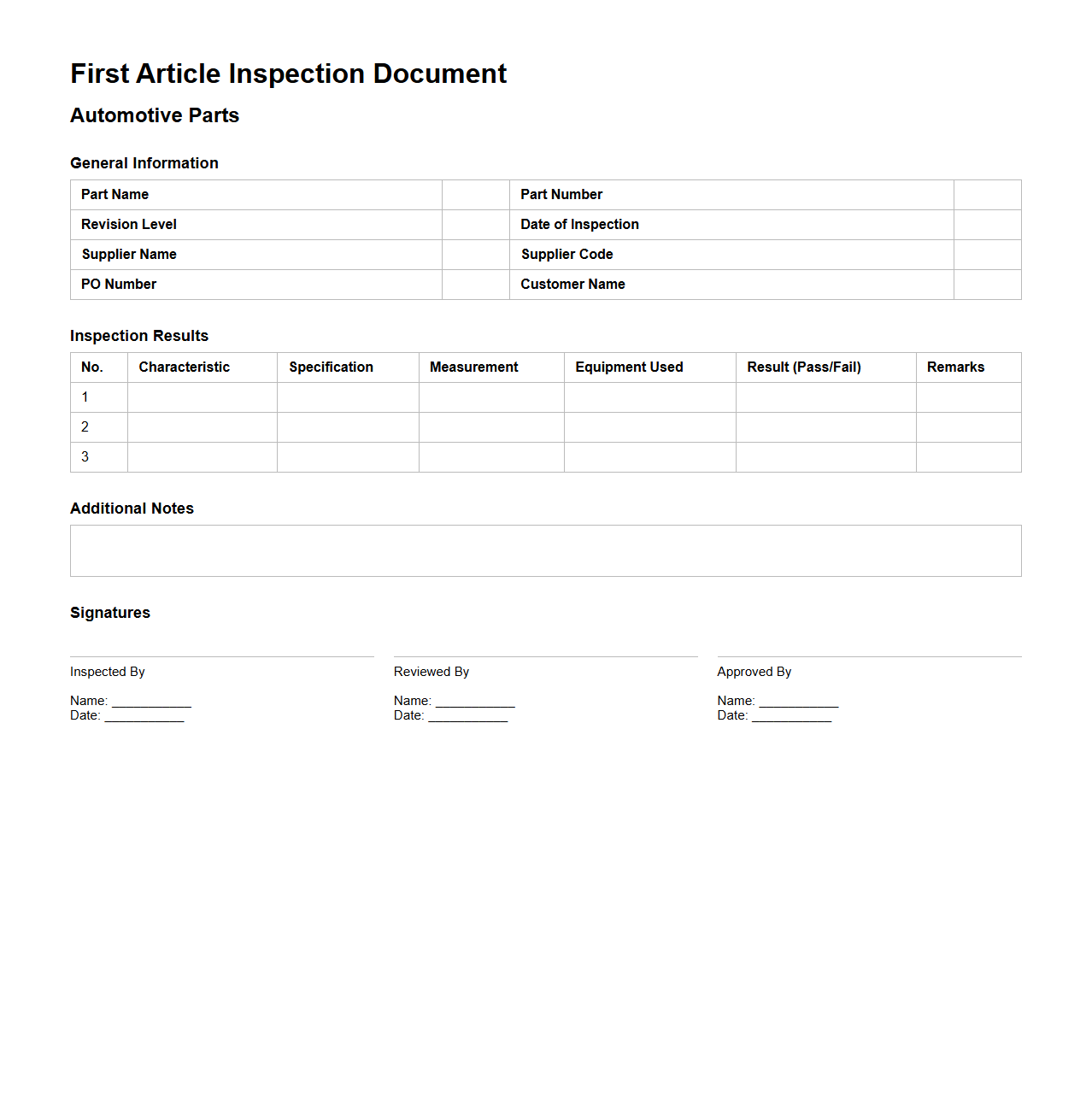

First Article Inspection Document for Automotive Parts

The

First Article Inspection Document for automotive parts is a detailed report that verifies a production sample meets all specified design and quality requirements before full-scale manufacturing begins. It includes precise measurements, material certifications, and process evidence to ensure compliance with industry standards such as ISO/TS 16949. This document plays a critical role in minimizing defects and ensuring the reliability and safety of automotive components.

First Article Inspection Certificate for Sheet Metal Fabrication

A

First Article Inspection Certificate for sheet metal fabrication is a formal document verifying that the initial manufactured part meets all specified engineering and quality standards. It includes detailed measurement data, material certifications, and compliance with design specifications to ensure the manufacturing process produces consistent, accurate results. This certificate serves as a critical quality assurance tool, preventing defects and ensuring customer requirements are fully satisfied.

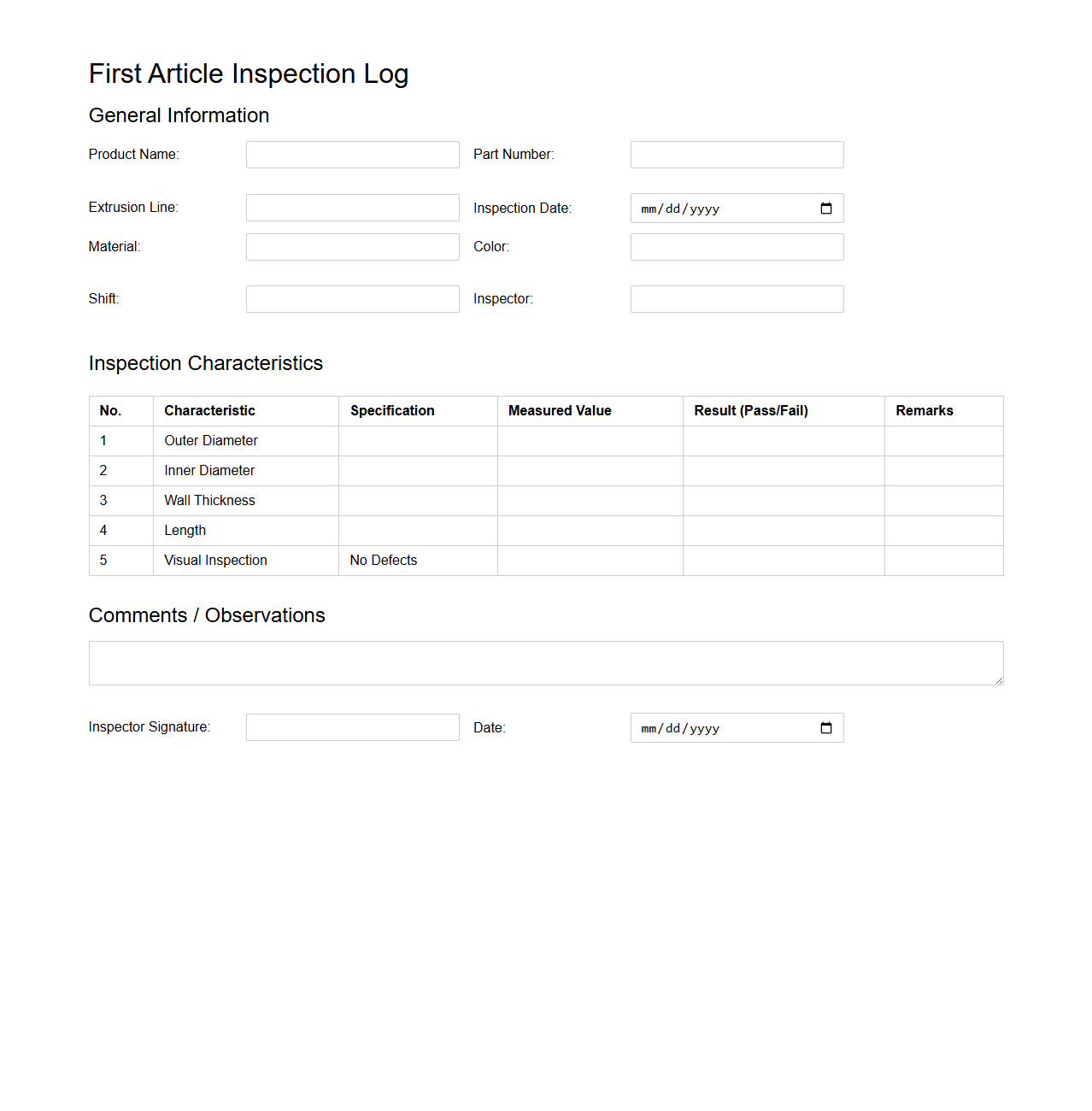

First Article Inspection Log for Plastic Extrusion

The

First Article Inspection Log for Plastic Extrusion document records the detailed inspection results of the initial production run of plastic extrusion parts, ensuring they meet specified design and quality standards. It systematically captures dimensional measurements, material properties, and process parameters to verify compliance with manufacturing requirements. This log is essential for identifying discrepancies early, facilitating quality control, and supporting traceability in production workflows.

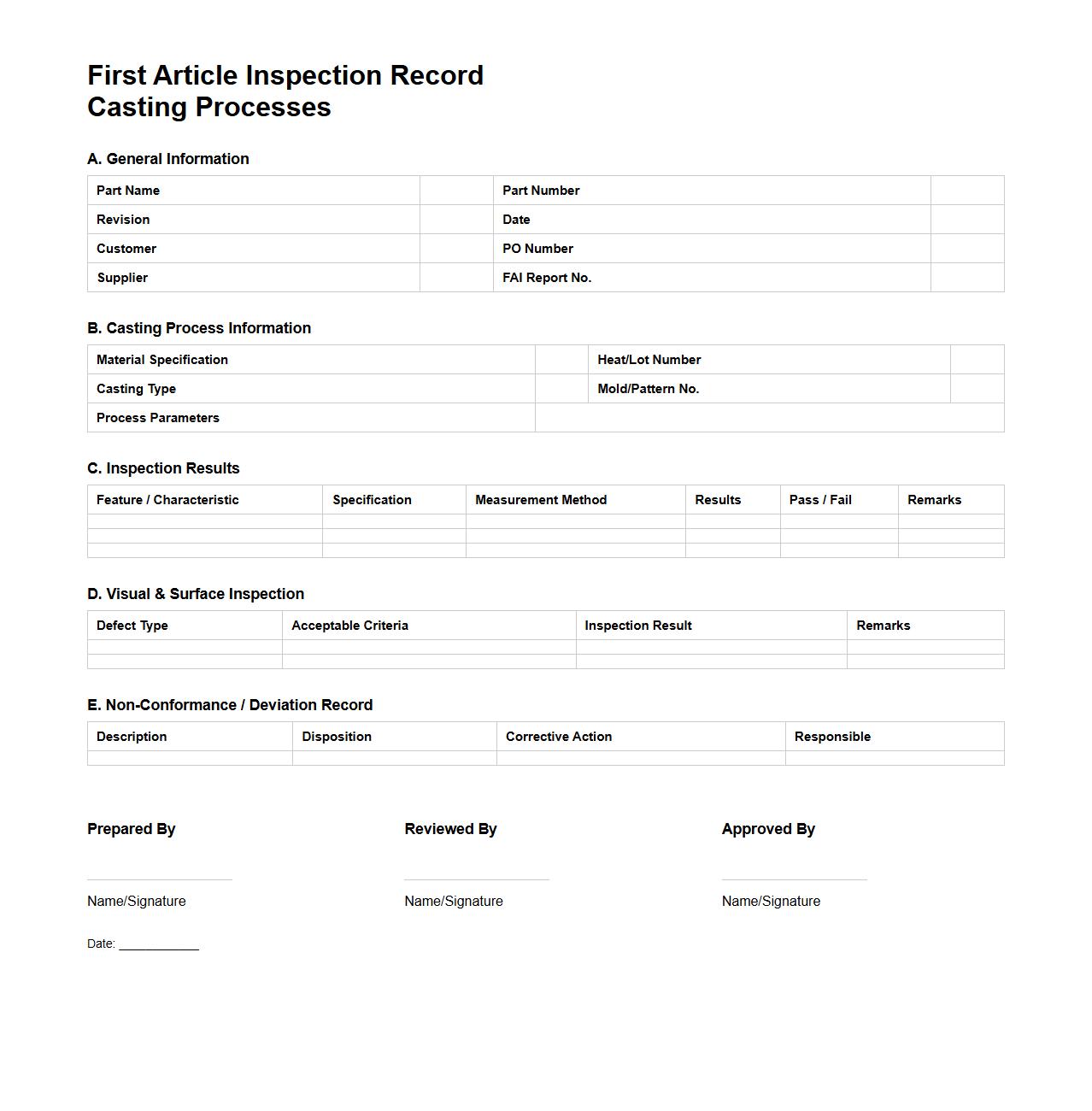

First Article Inspection Record for Casting Processes

The

First Article Inspection Record for Casting Processes document is a detailed report that verifies the dimensional and material compliance of a cast part against engineering specifications and standards. It captures critical measurements, visual inspections, and test results to ensure the casting meets quality requirements before mass production begins. This document serves as a formal approval and traceability tool for manufacturers and quality assurance teams.

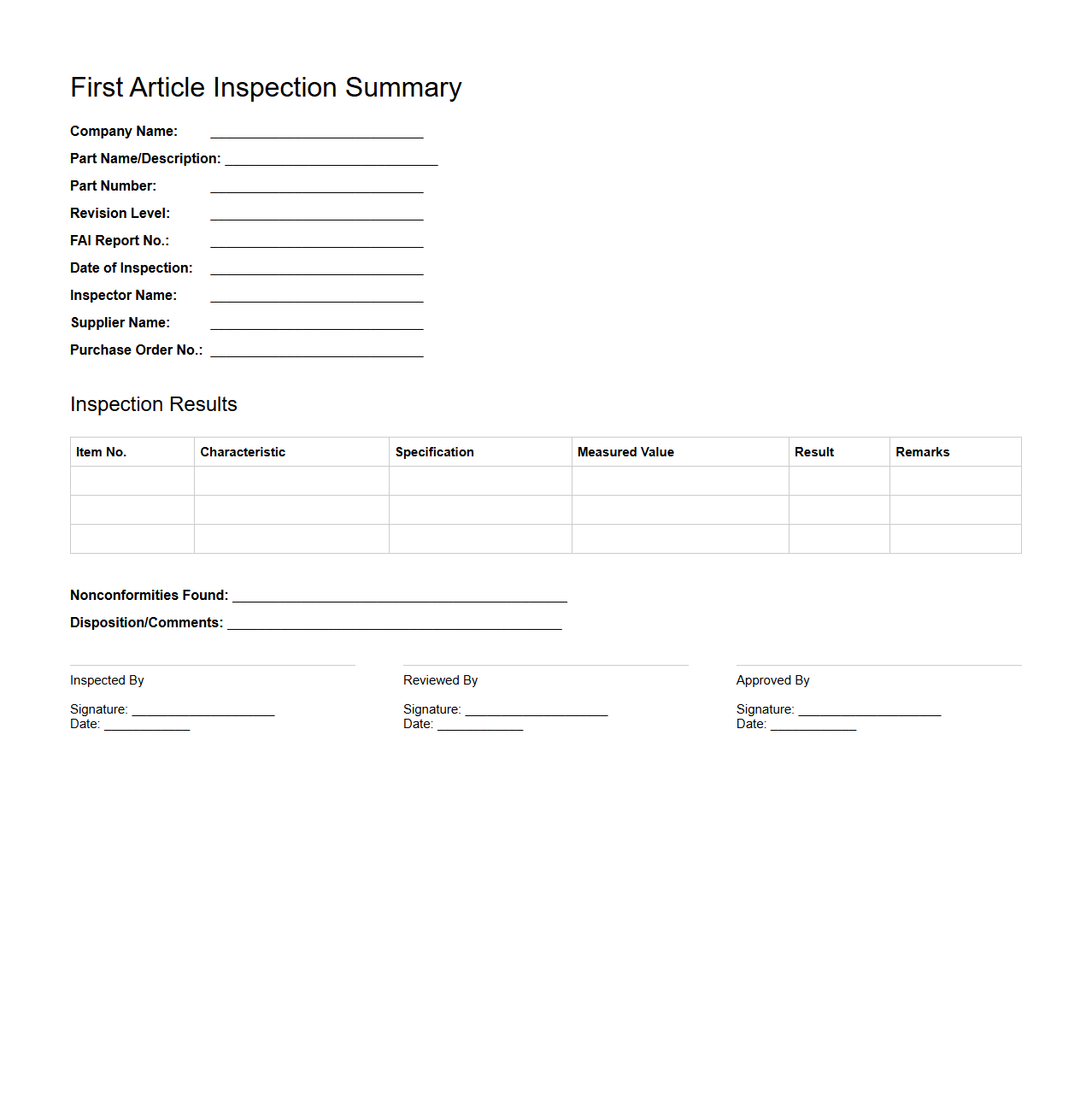

First Article Inspection Summary for Medical Device Manufacturing

The

First Article Inspection Summary in medical device manufacturing is a detailed report verifying that the initial production run of a device meets all specified design and quality requirements. This document compiles inspection results, dimensional data, and compliance confirmations to ensure the manufacturing process consistently produces devices within stringent regulatory standards. It serves as a critical quality control step to prevent defects and guarantee patient safety before full-scale production begins.

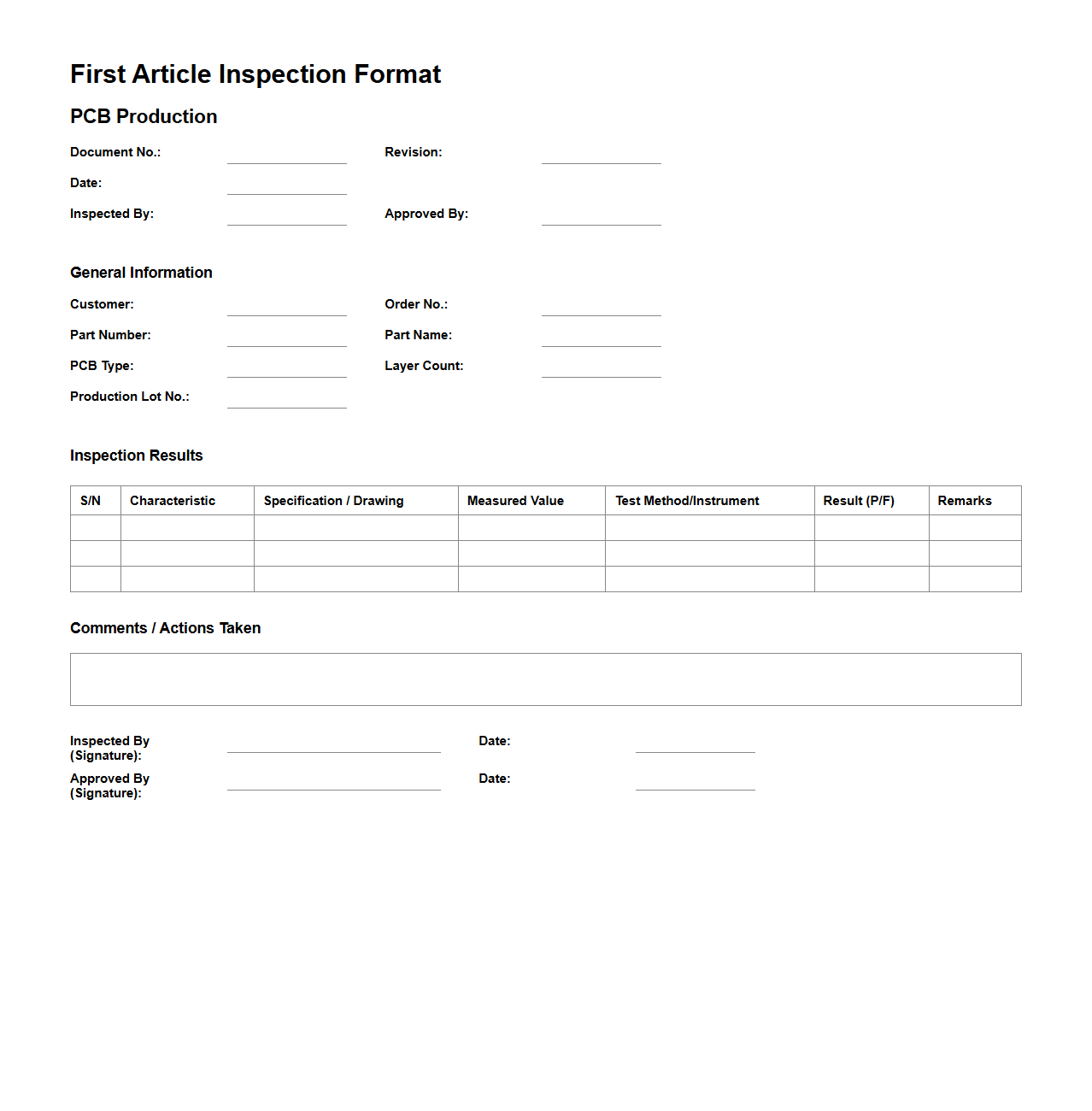

First Article Inspection Format for PCB Production

The

First Article Inspection (FAI) Format for PCB production is a standardized document that verifies the initial printed circuit board meets specified design and quality requirements before mass manufacturing begins. It includes detailed measurements, inspection criteria, and test results for critical PCB features such as layer alignment, plating thickness, solder mask accuracy, and electrical connectivity. This format ensures consistency, identifies potential defects early, and facilitates communication between design and production teams to maintain high-quality PCB outputs.

What critical dimensions and tolerances are verified in the First Article Inspection Document?

The First Article Inspection Document verifies critical dimensions such as length, width, height, and diameter that are essential for component functionality. These dimensions are measured against specified tolerances to ensure the part meets design requirements. Precise verification ensures product quality and conformity to engineering standards.

Which material specifications are documented for the inspected component?

The inspected component's material specifications include grade, type, and any relevant standards like ASTM or ISO. This documentation confirms the raw materials used comply with engineering and customer requirements. Proper recording of these specs ensures traceability and quality assurance throughout production.

How are measurement methods and inspection tools recorded in the sample document?

The sample document details the specific measurement methods used, such as calipers, micrometers, or CMM (Coordinate Measuring Machine). It also lists the inspection tools with calibration status and identification to ensure accuracy. This recording guarantees repeatability and reliability of the inspection process.

What traceability information (e.g., batch numbers, part identification) is included in the inspection record?

The inspection record includes critical traceability information such as batch numbers, serial numbers, and part identification codes. This data links each inspected component back to its production history for accountability. Traceability is vital for tracking, quality control, and addressing any future issues.

How are nonconformances and corrective actions documented in the First Article Inspection sample?

Nonconformances are documented by describing the deviation from specifications and its impact on the part's functionality. Corrective actions are recorded, detailing the steps taken to resolve the issue and prevent recurrence. This documentation ensures continuous improvement and compliance with quality standards.

More Manufacturing Templates