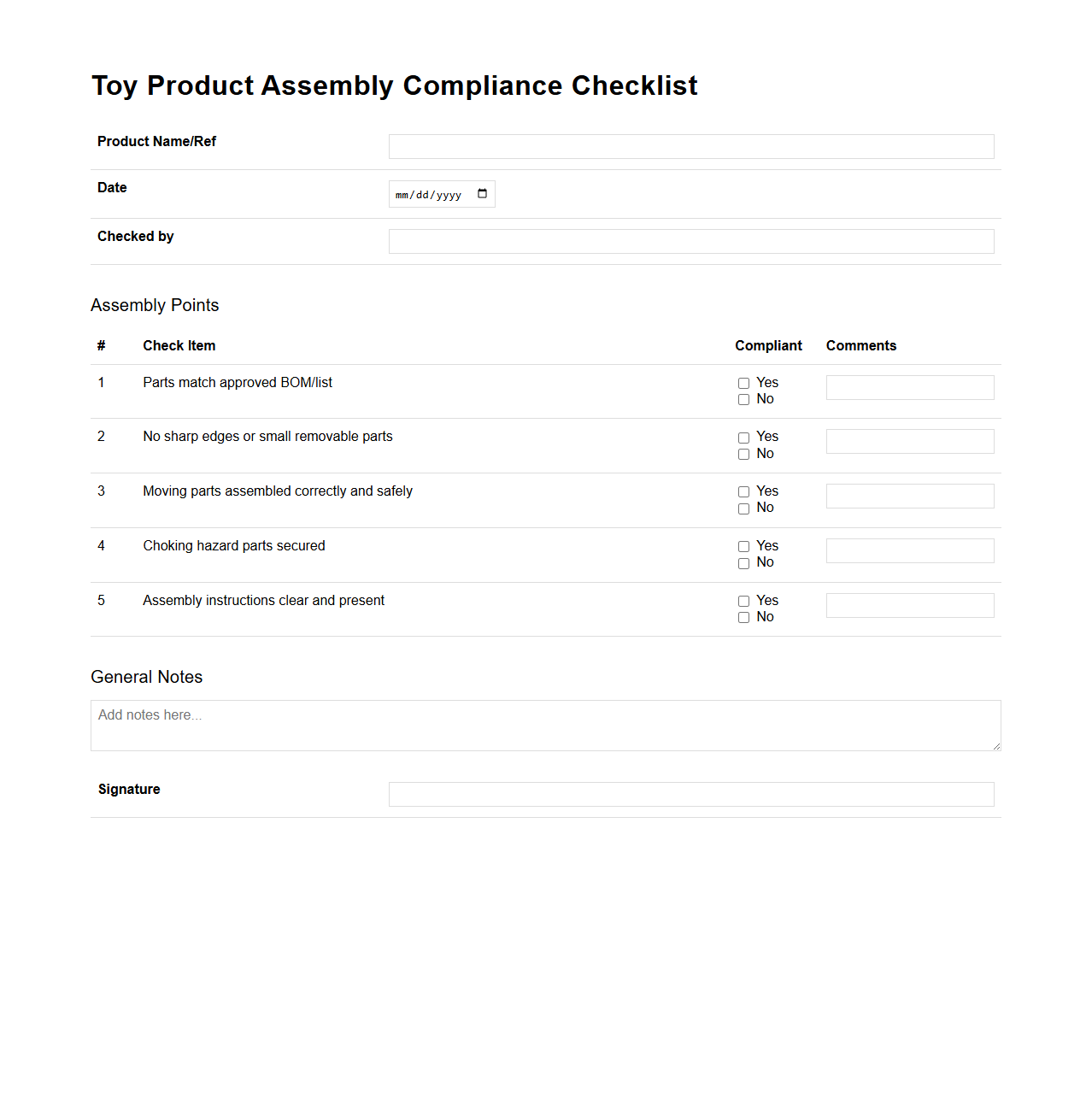

A Assembly Checklist Document Sample for Product Manufacturing provides a detailed list of steps and components required to ensure accurate and efficient assembly processes. This document helps maintain quality control by verifying that every part is correctly installed and tested before final product completion. It serves as a critical tool for minimizing errors and streamlining workflow in manufacturing environments.

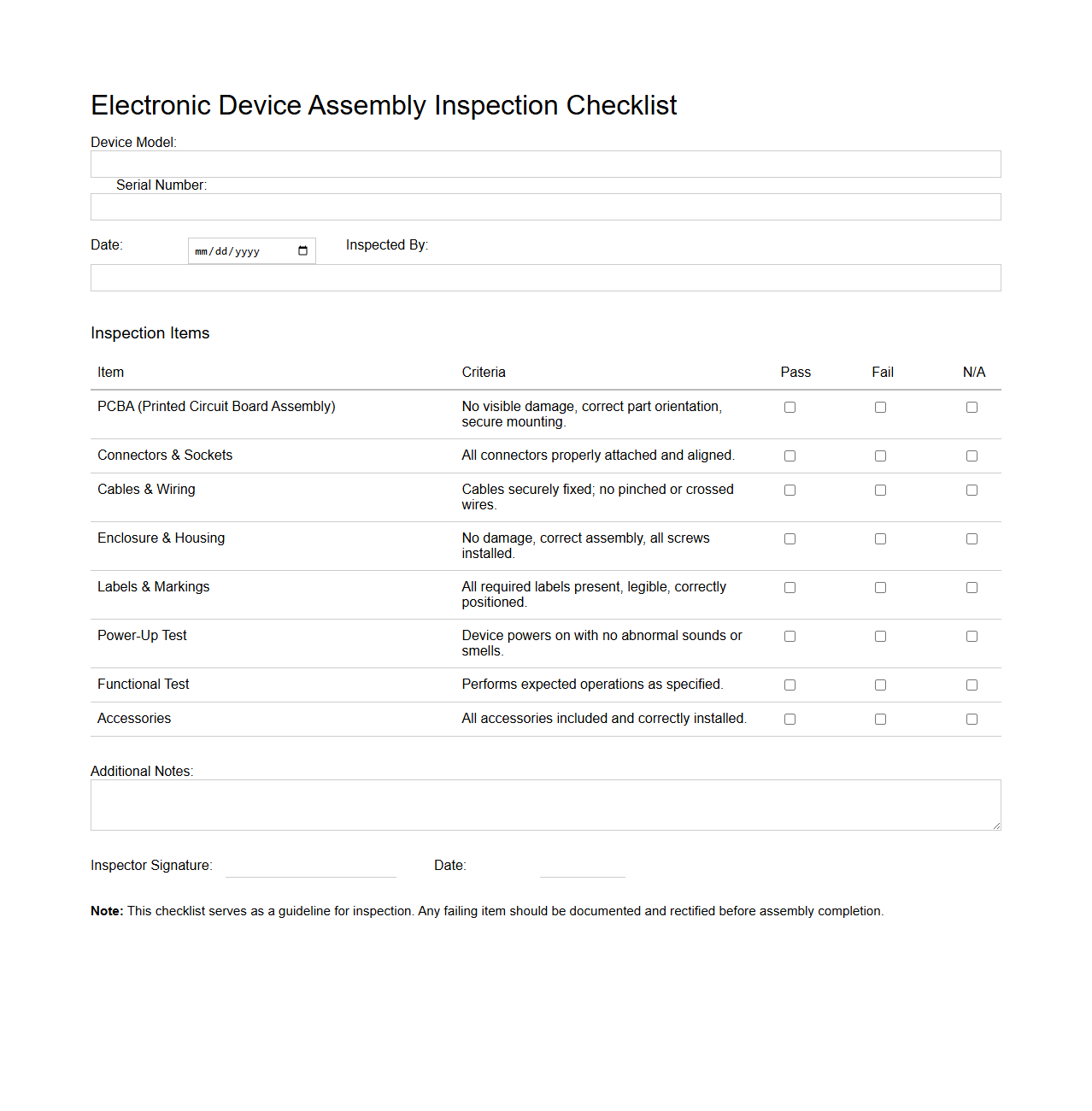

Electronic Device Assembly Inspection Checklist Template

The

Electronic Device Assembly Inspection Checklist Template is a structured document designed to ensure thorough quality control during the assembly process of electronic devices. It systematically guides inspectors through key verification points such as component placement, soldering quality, and functional testing to detect defects early. Utilizing this template helps maintain consistency, reduces errors, and enhances overall product reliability in electronics manufacturing.

Automotive Parts Assembly Quality Checklist Example

An

Automotive Parts Assembly Quality Checklist Example document is a structured tool designed to ensure every component in the assembly process meets specific quality standards. It outlines key inspection points, measurement criteria, and verification steps to prevent defects and maintain compliance with industry regulations. This checklist helps manufacturers improve product reliability, reduce rework costs, and enhance overall production efficiency.

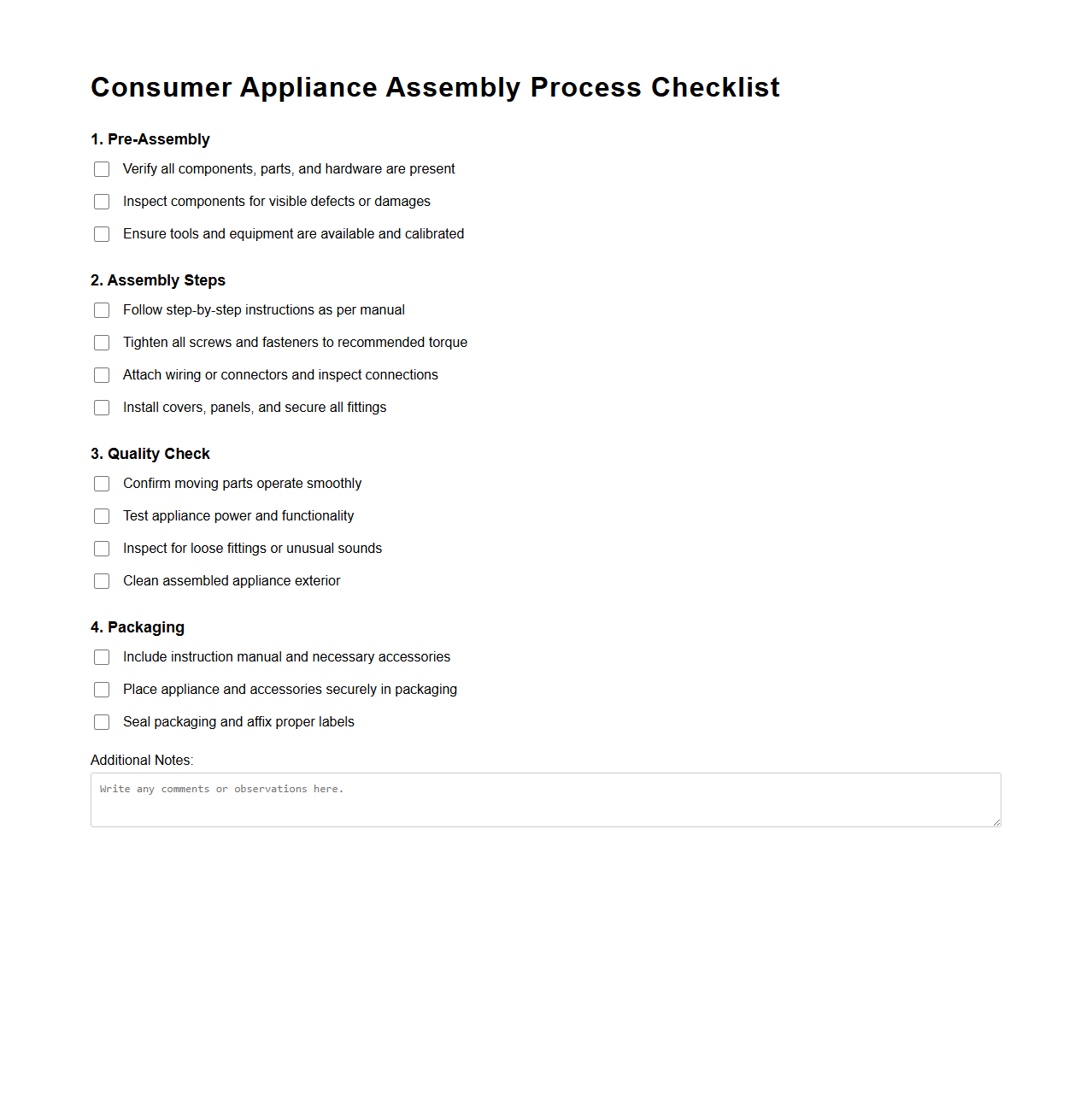

Consumer Appliance Assembly Process Checklist

The

Consumer Appliance Assembly Process Checklist document outlines a systematic series of steps to ensure accurate and efficient assembly of household appliances. It highlights critical tasks such as component verification, quality inspections, and safety compliance, helping manufacturers maintain consistent product standards. By using this checklist, assembly teams minimize errors and enhance overall production efficiency.

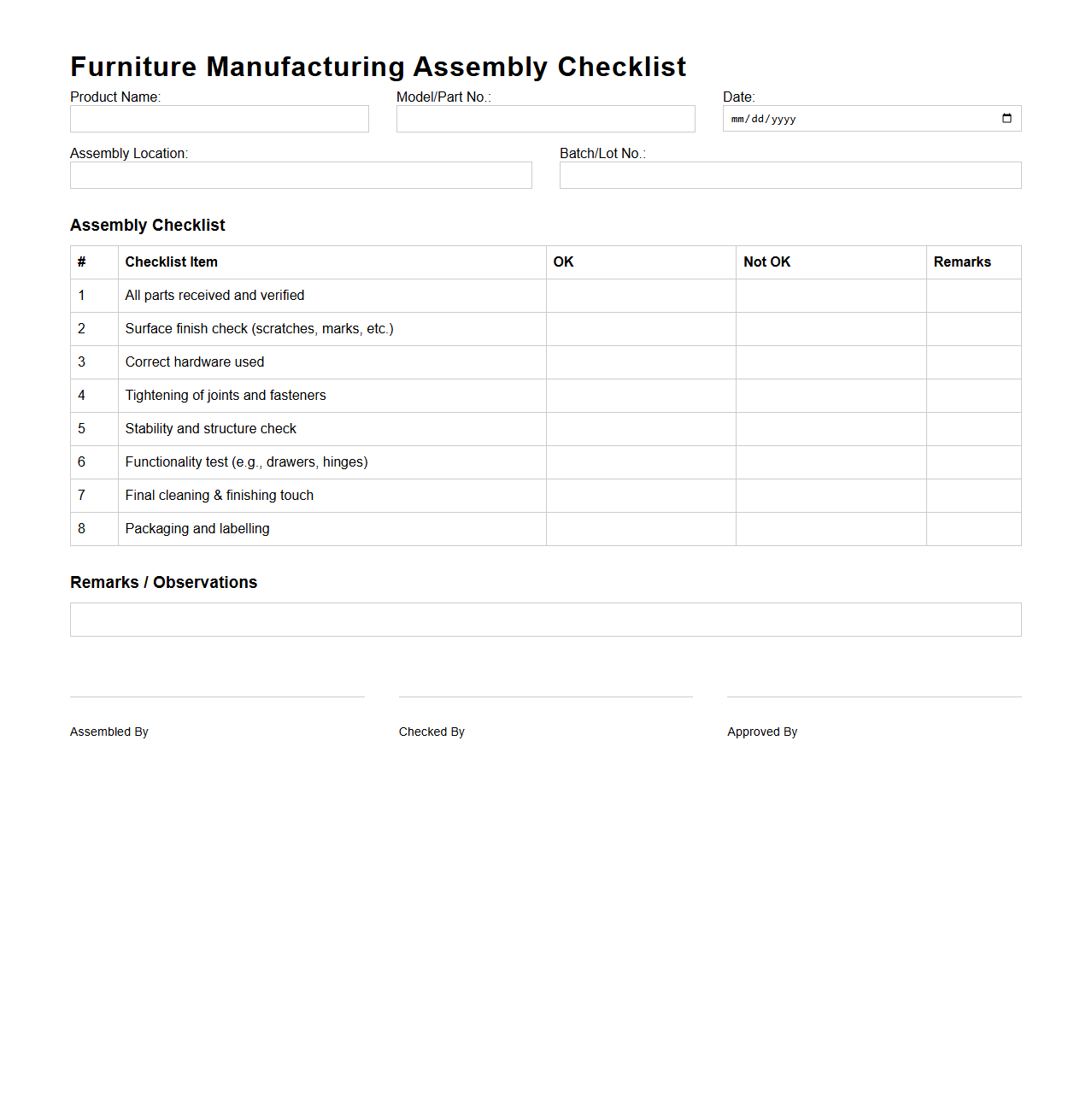

Furniture Manufacturing Assembly Checklist Format

A

Furniture Manufacturing Assembly Checklist Format document outlines step-by-step procedures and quality control measures for assembling furniture pieces efficiently and accurately. This format ensures all components are correctly installed, tools are properly used, and safety standards are maintained throughout the production process. By standardizing assembly tasks, the checklist helps reduce errors, improve productivity, and maintain consistent product quality.

Industrial Equipment Assembly Verification Checklist

The

Industrial Equipment Assembly Verification Checklist is a critical document used to ensure that all components of industrial machinery are correctly assembled according to design specifications and safety standards. It systematically verifies each step, from component fitting and alignment to functional testing, reducing the risk of operational failure and enhancing equipment reliability. This checklist supports quality control processes and helps maintain compliance with industry regulations.

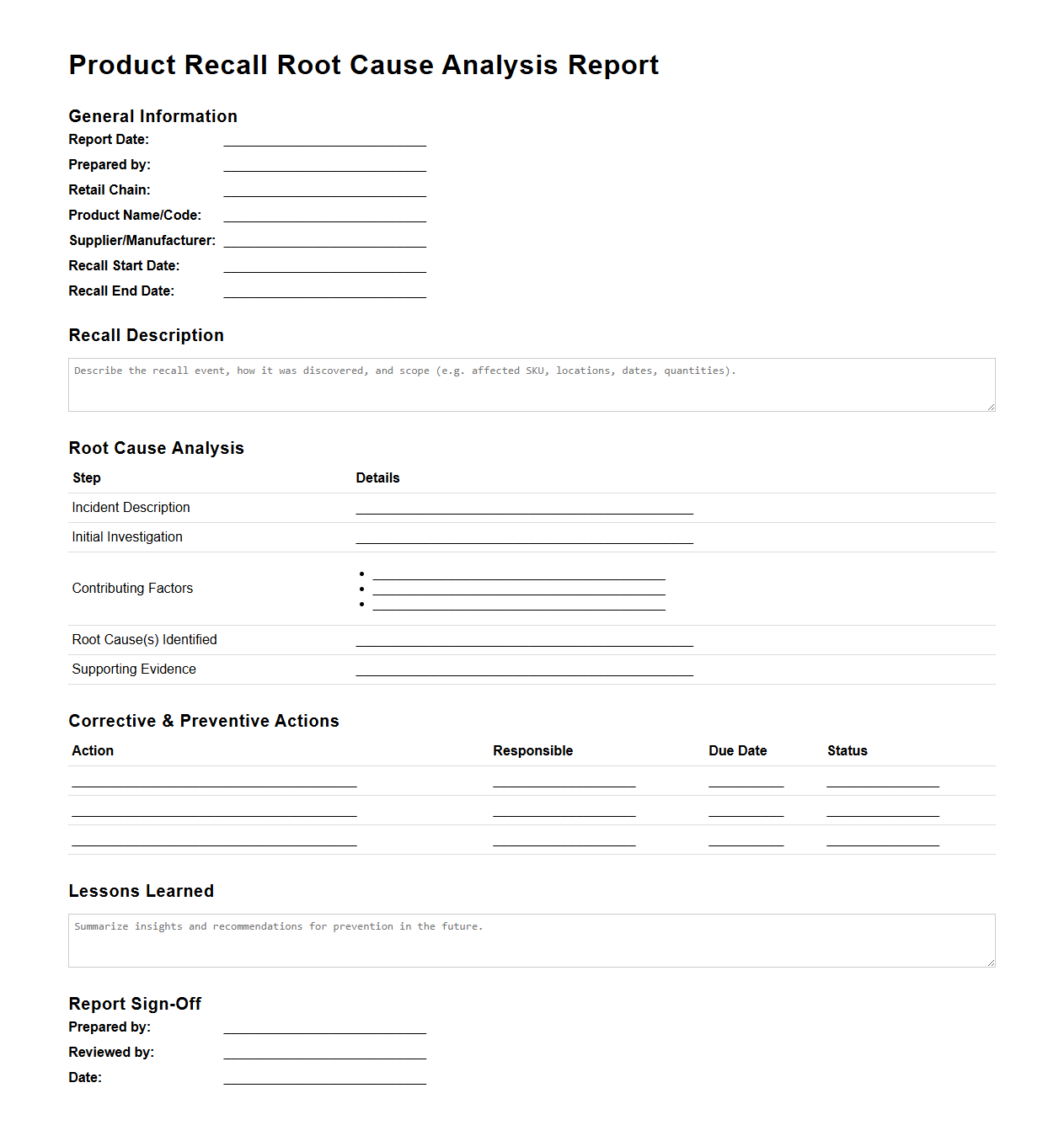

Medical Device Assembly Audit Checklist

A

Medical Device Assembly Audit Checklist document systematically evaluates the assembly process to ensure compliance with regulatory standards such as ISO 13485 and FDA requirements. It includes criteria for verifying component integrity, proper labeling, adherence to assembly procedures, and validation of functional testing. This checklist helps identify non-conformities and supports continuous improvement in medical device manufacturing quality control.

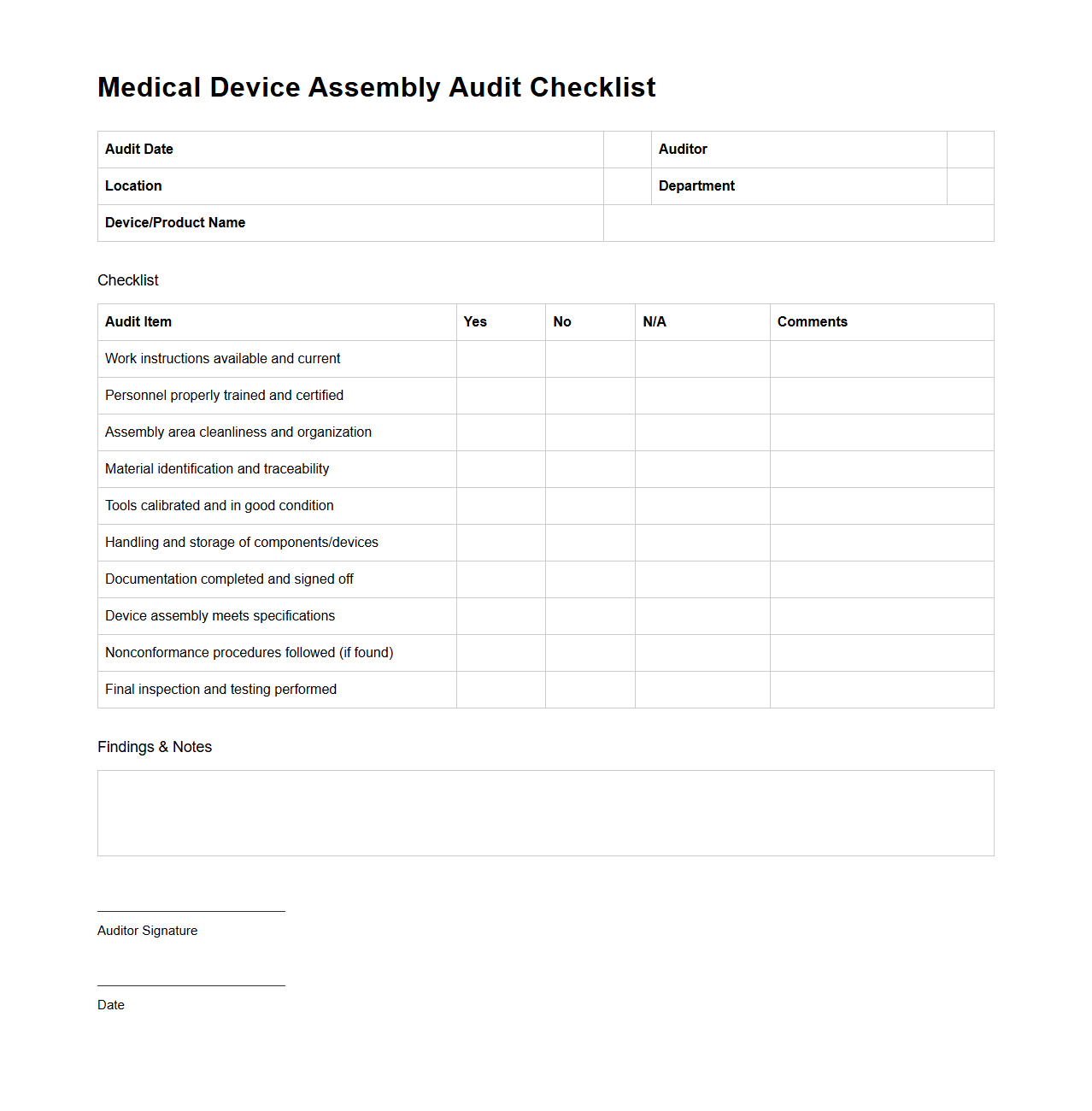

Electrical Panel Assembly Procedure Checklist

The

Electrical Panel Assembly Procedure Checklist document serves as a comprehensive guide to ensure all steps in assembling electrical panels are accurately followed, improving safety and quality standards. It outlines detailed tasks such as component installation, wiring verification, and compliance with electrical codes and industry regulations. This checklist minimizes errors, facilitates quality control, and guarantees reliable operation of electrical systems.

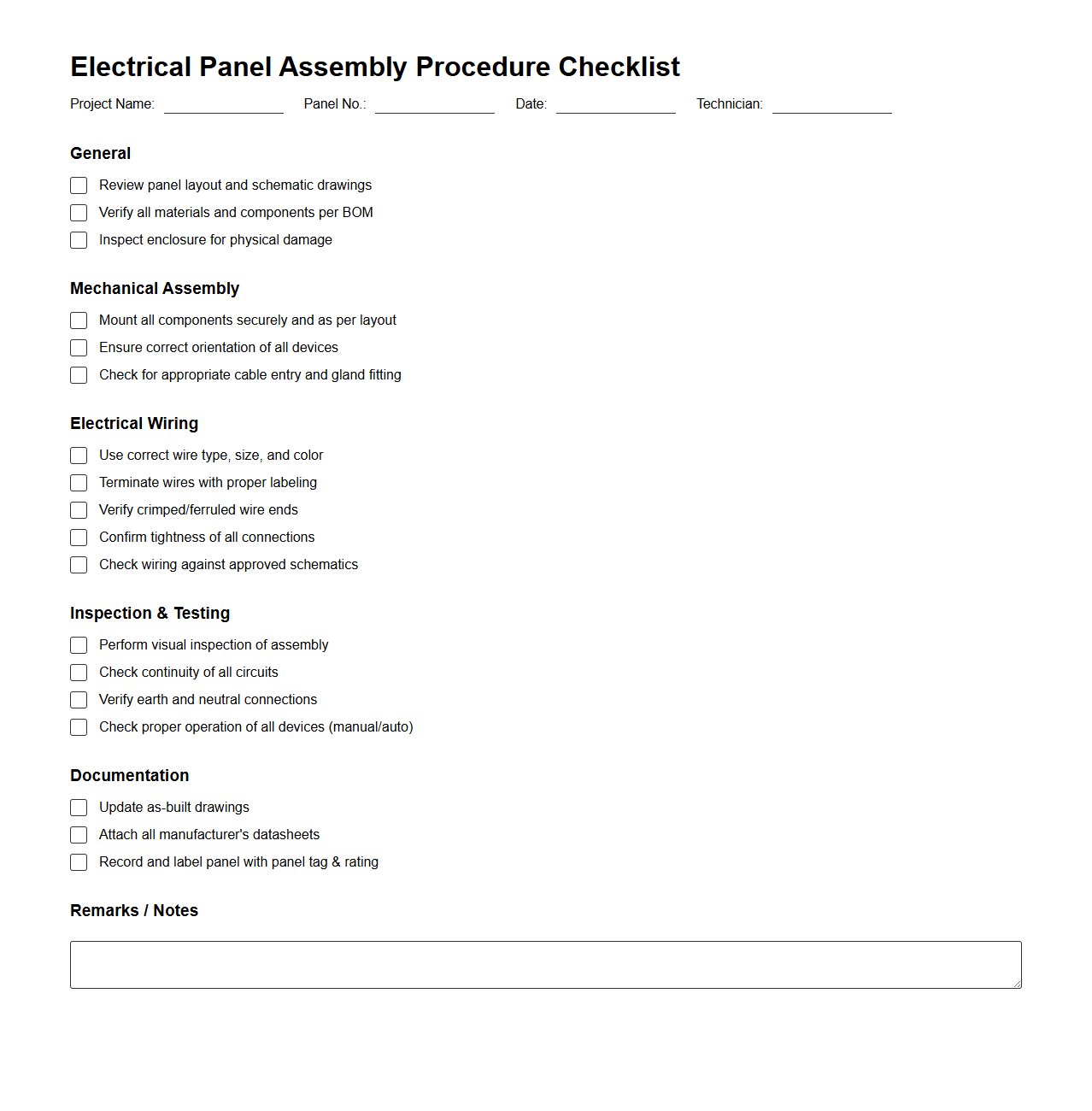

Toy Product Assembly Compliance Checklist

The

Toy Product Assembly Compliance Checklist document ensures all components of a toy meet safety and regulatory standards before final assembly. It outlines specific criteria such as material safety, choking hazard prevention, and proper labeling requirements to maintain product integrity. Manufacturers use this checklist to verify compliance with industry regulations and avoid potential recalls or legal issues.

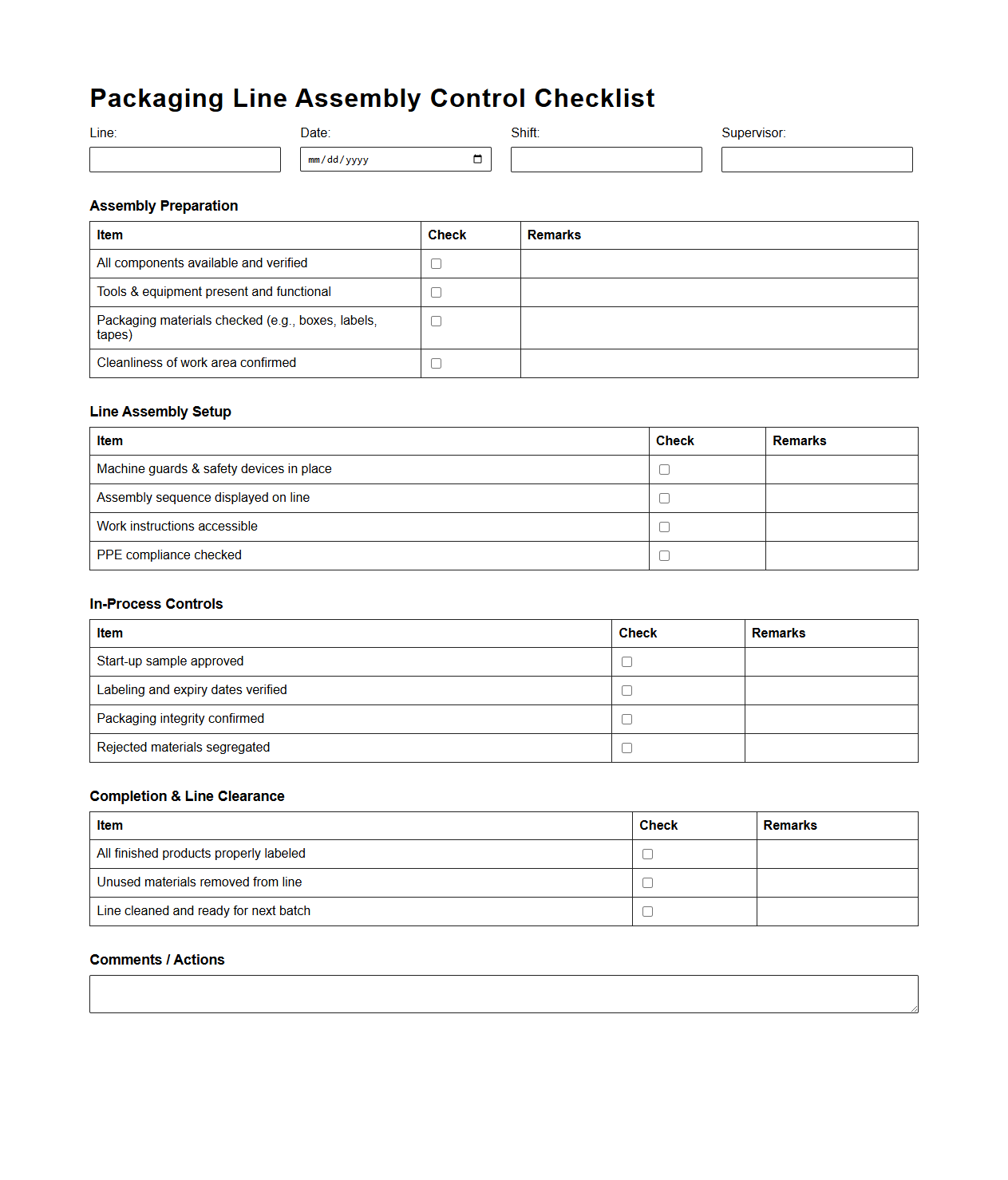

Packaging Line Assembly Control Checklist

The

Packaging Line Assembly Control Checklist document is a critical tool used to ensure all components and equipment on a packaging line are correctly installed and functioning before production begins. It systematically verifies assembly steps, alignment, safety features, and operational parameters to prevent errors and downtime. This checklist enhances quality control, compliance with industry standards, and smooth workflow integration in manufacturing environments.

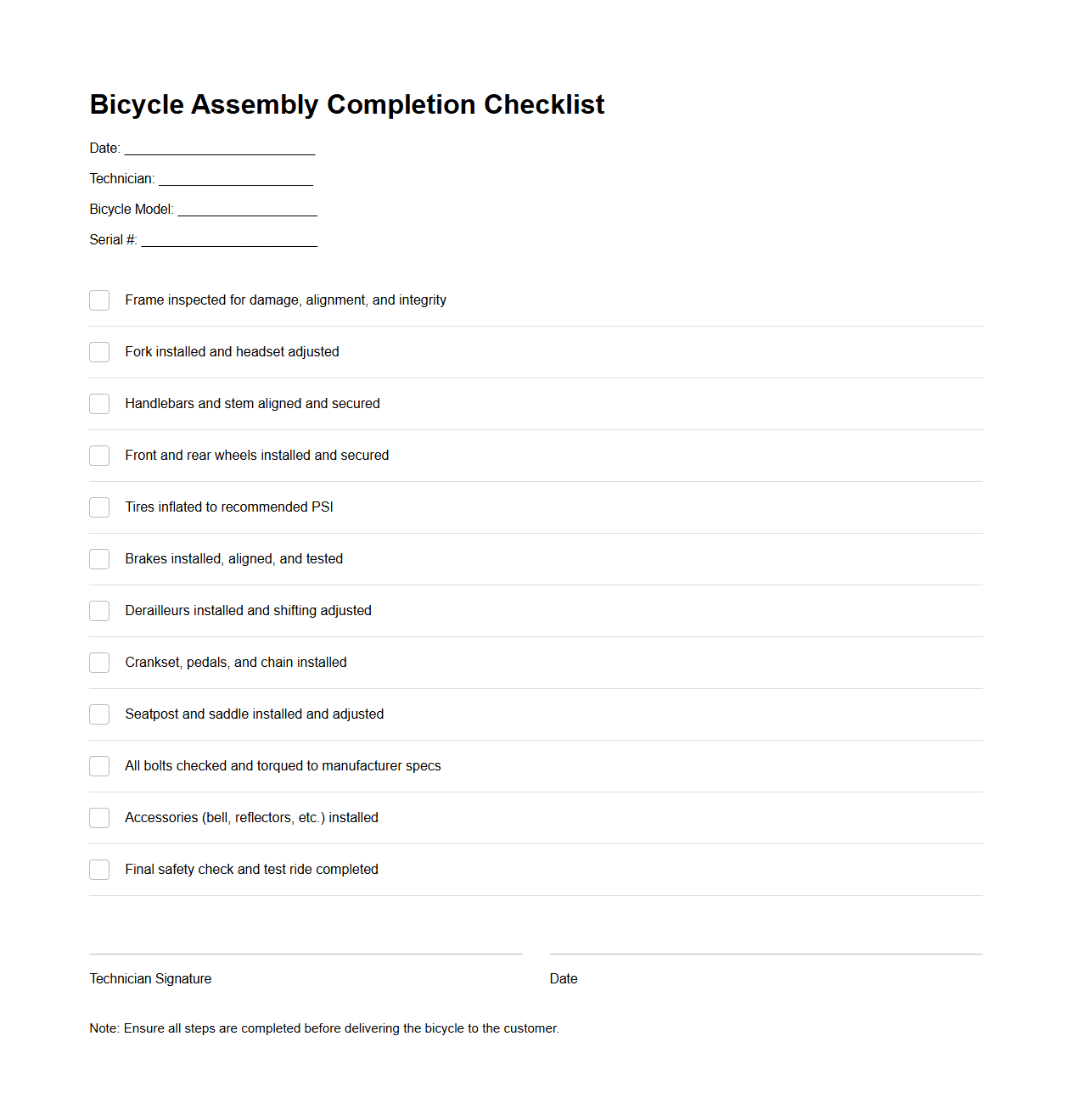

Bicycle Assembly Completion Checklist

The

Bicycle Assembly Completion Checklist document is a detailed guide used to ensure all components of a bicycle are correctly installed and inspected before use. It includes verification of critical parts such as brakes, gears, tires, and frame alignment to guarantee safety and functionality. This checklist helps prevent assembly errors and ensures compliance with quality standards in bicycle manufacturing or retail environments.

What key components must be verified in the assembly checklist for this product?

The assembly checklist must verify all essential components such as screws, bolts, and electronic parts are present and correctly installed. Each component should match the specified product model requirements to ensure compatibility. Proper functionality and alignment of these components are critical for product performance and safety.

How does the document ensure traceability for each assembly step?

Traceability is ensured by documenting the serial numbers and batch codes for each part used in the assembly. Each step is recorded with timestamps and operator identification to track responsibility. This systematic documentation allows for easy auditing and quality control throughout the production process.

What quality control measures are documented in the checklist?

The checklist includes inspection criteria such as dimensional checks, torque verification, and functional testing. Any deviations or defects found during inspections are recorded immediately for corrective action. This process guarantees that quality standards are consistently met before moving to the next stage.

Which safety protocols are included and checked during assembly?

Safety protocols require operators to use personal protective equipment (PPE), such as gloves and goggles, during assembly. The checklist ensures proper handling of hazardous materials and adherence to safety guidelines specific to the product. Regular safety audits documented in the checklist help prevent accidents and ensure a safe work environment.

How is completion of each stage documented and authorized in the checklist?

Completion is documented by having the operator and supervisor sign off each assembly step in the checklist. Dates and times are recorded to maintain an accurate assembly timeline. This authorization process validates that each stage meets all requirements before progressing further in production.

More Manufacturing Templates