A Process Validation Document Sample for Manufacturing provides a detailed framework to ensure that production processes consistently yield products meeting predetermined quality standards. This document outlines critical parameters, test methods, and acceptance criteria essential for validating manufacturing efficiency and compliance. Utilizing this sample helps manufacturers streamline validation procedures and maintain regulatory adherence.

Process Validation Master Plan Template

The

Process Validation Master Plan Template document outlines the strategy, scope, and responsibilities for validating manufacturing processes to ensure consistent product quality and compliance with regulatory standards. It serves as a comprehensive guide that defines process validation activities, timelines, resources, and acceptance criteria for critical control points. This template is essential for maintaining thorough documentation and effective risk management throughout the product lifecycle in regulated industries.

Installation Qualification Protocol Example

An

Installation Qualification Protocol (IQP) Example document provides a structured template outlining the procedures and criteria for verifying that equipment or systems are installed according to manufacturer specifications and regulatory requirements. This document typically includes detailed installation steps, environmental conditions, material specifications, and acceptance criteria to ensure consistent compliance and traceability. It serves as a critical component in validation processes within industries such as pharmaceuticals, manufacturing, and quality assurance.

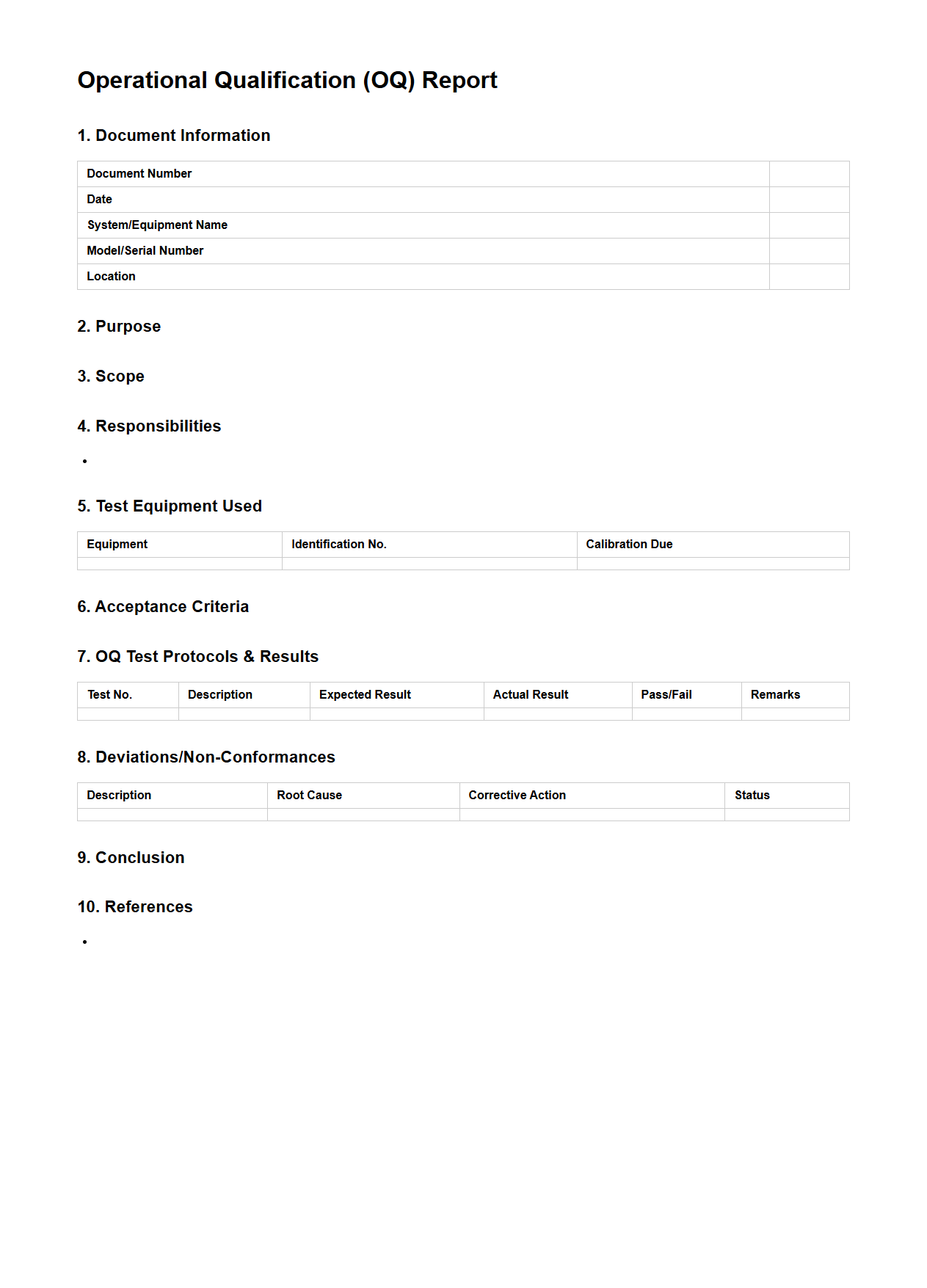

Operational Qualification Report Sample

An

Operational Qualification Report Sample document provides a detailed validation record demonstrating that equipment or systems operate according to predefined specifications under actual working conditions. This report includes test procedures, acceptance criteria, test results, and any deviations encountered to ensure compliance with regulatory standards such as FDA or GMP. It serves as a critical component in the overall validation lifecycle, facilitating quality assurance and operational reliability in manufacturing or laboratory environments.

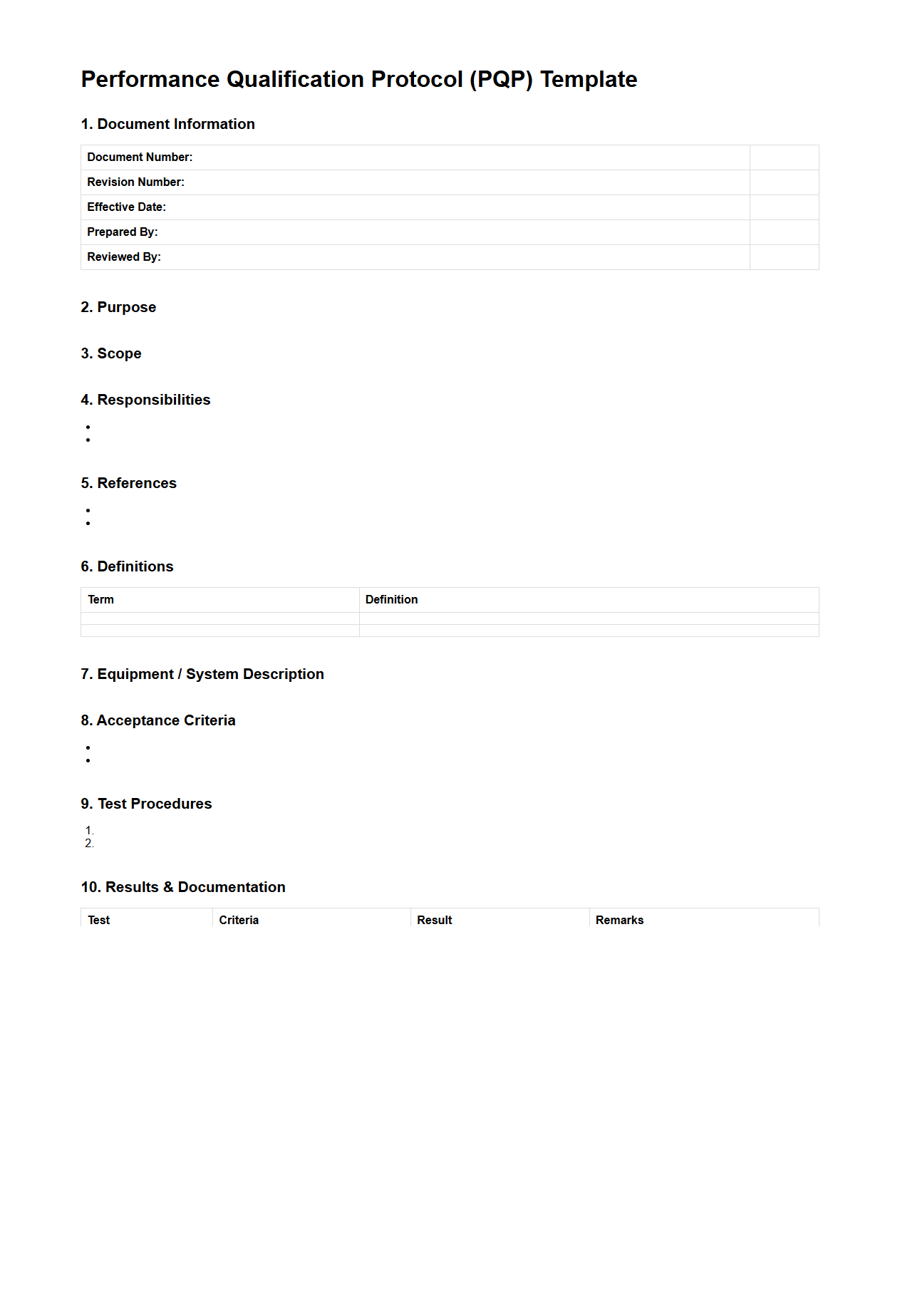

Performance Qualification Protocol Template

A

Performance Qualification Protocol Template document is a standardized framework used to verify that equipment, systems, or processes consistently operate according to predetermined specifications in a manufacturing or production environment. It includes detailed test procedures, acceptance criteria, and documentation requirements to ensure compliance with regulatory standards and quality assurance. This template facilitates consistent execution and validation, reducing risks and ensuring product reliability.

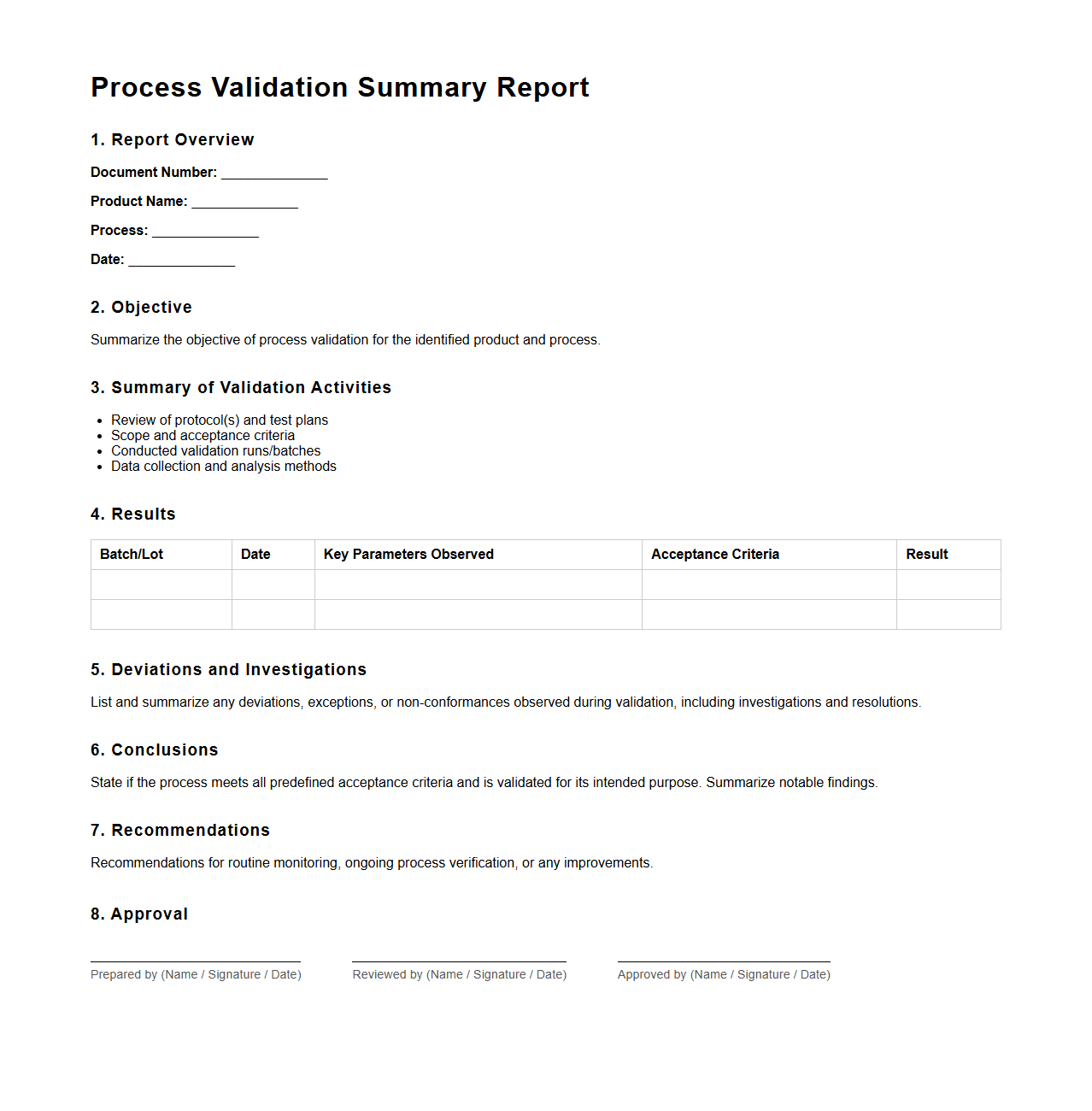

Process Validation Summary Report Example

A

Process Validation Summary Report Example document provides a detailed overview of the validation activities conducted to confirm that a manufacturing process consistently produces products meeting predetermined quality standards. It highlights critical parameters, test results, deviations, and corrective actions taken, ensuring compliance with regulatory requirements such as FDA or ISO guidelines. This document is essential for demonstrating process reliability and supporting product release decisions within quality management systems.

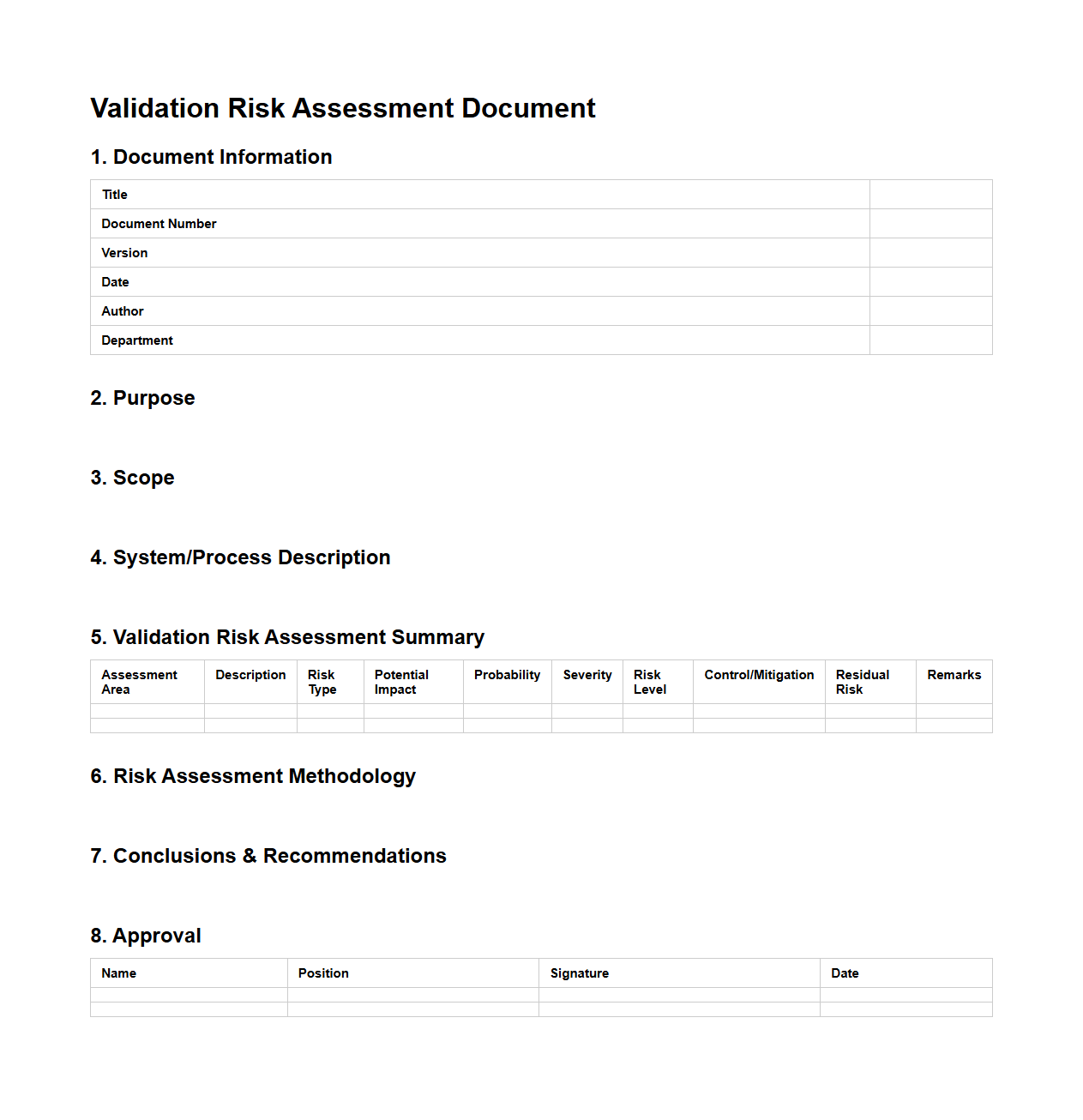

Validation Risk Assessment Document

A

Validation Risk Assessment Document identifies and evaluates potential risks associated with a process, system, or product to ensure compliance with regulatory standards and quality requirements. It systematically analyzes hazards, their likelihood, and potential impact to prioritize mitigation strategies effectively. This document supports decision-making by providing a clear risk management framework essential for validation activities in industries such as pharmaceuticals or manufacturing.

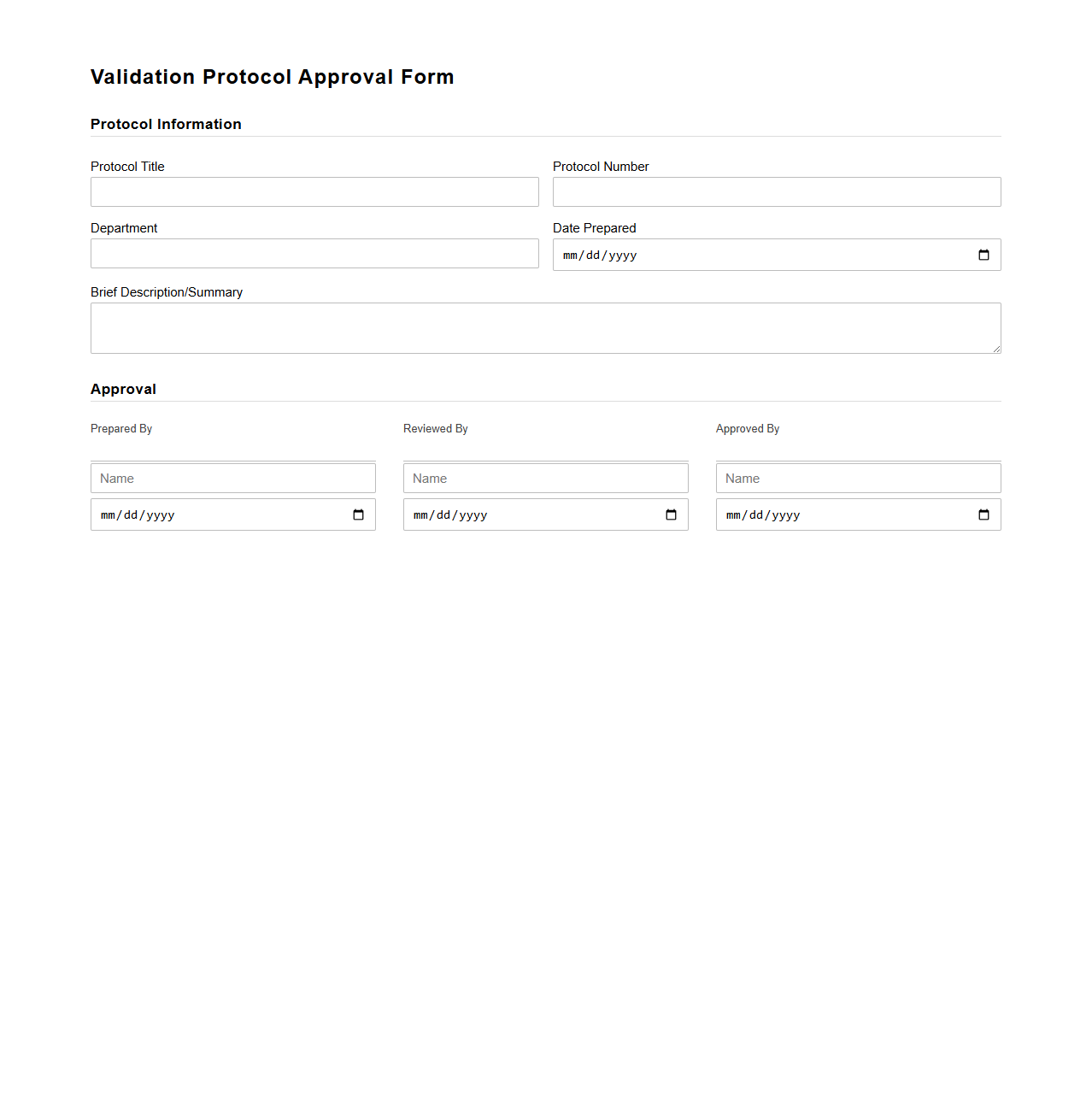

Validation Protocol Approval Form

The

Validation Protocol Approval Form document serves as a formal record confirming that a validation plan has been reviewed and authorized by qualified personnel. It ensures that the validation process meets regulatory standards and organizational requirements before execution. This approval is critical for maintaining compliance and quality assurance in industries like pharmaceuticals, manufacturing, and software development.

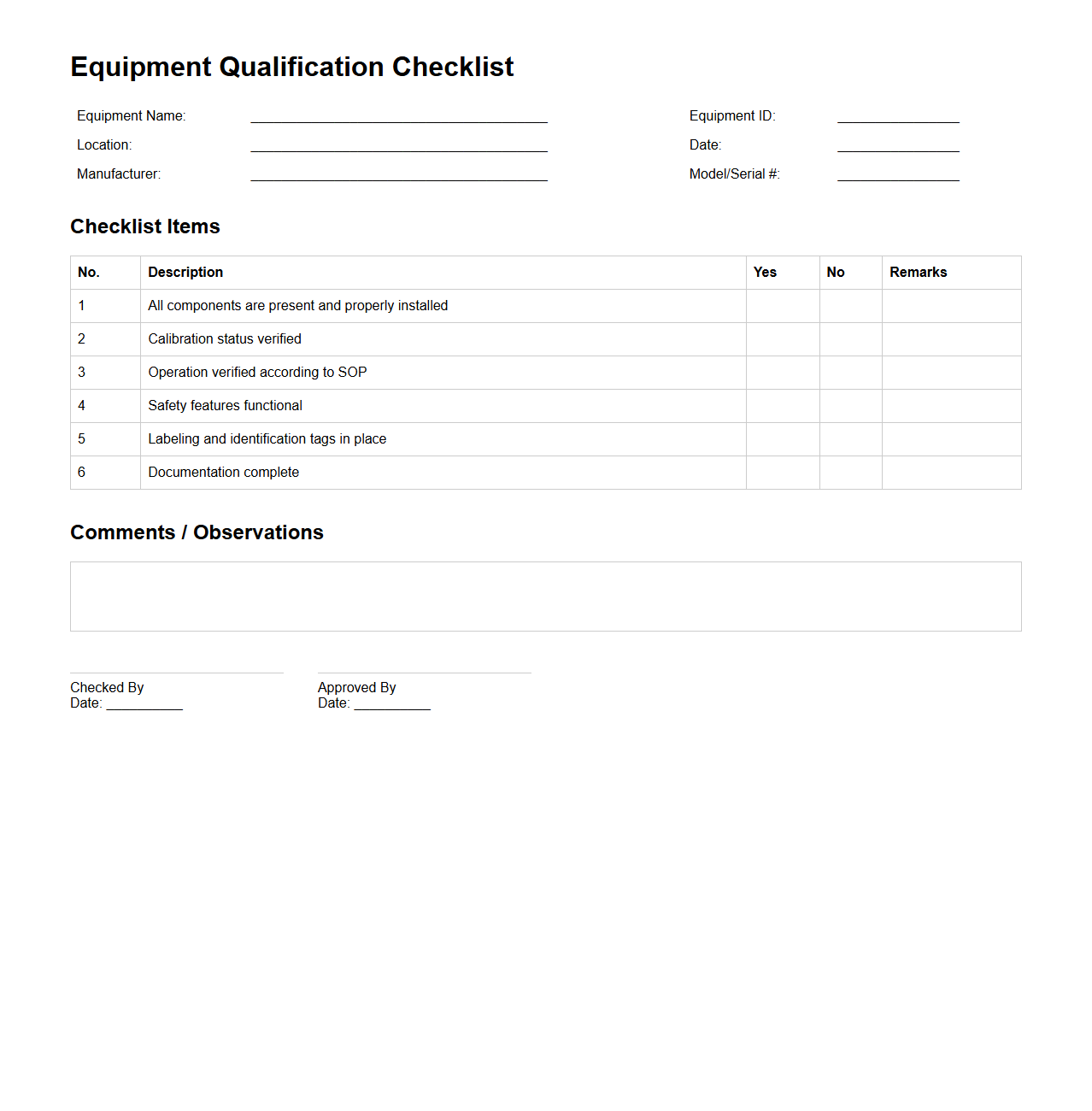

Equipment Qualification Checklist Sample

An

Equipment Qualification Checklist Sample document serves as a standardized tool to verify that equipment meets predefined criteria for proper functioning and compliance with industry standards. It outlines essential parameters such as calibration status, operational performance, maintenance history, and validation protocols to ensure reliability and safety. Using this checklist enhances consistency during installation, operational, and performance qualification processes within regulated environments.

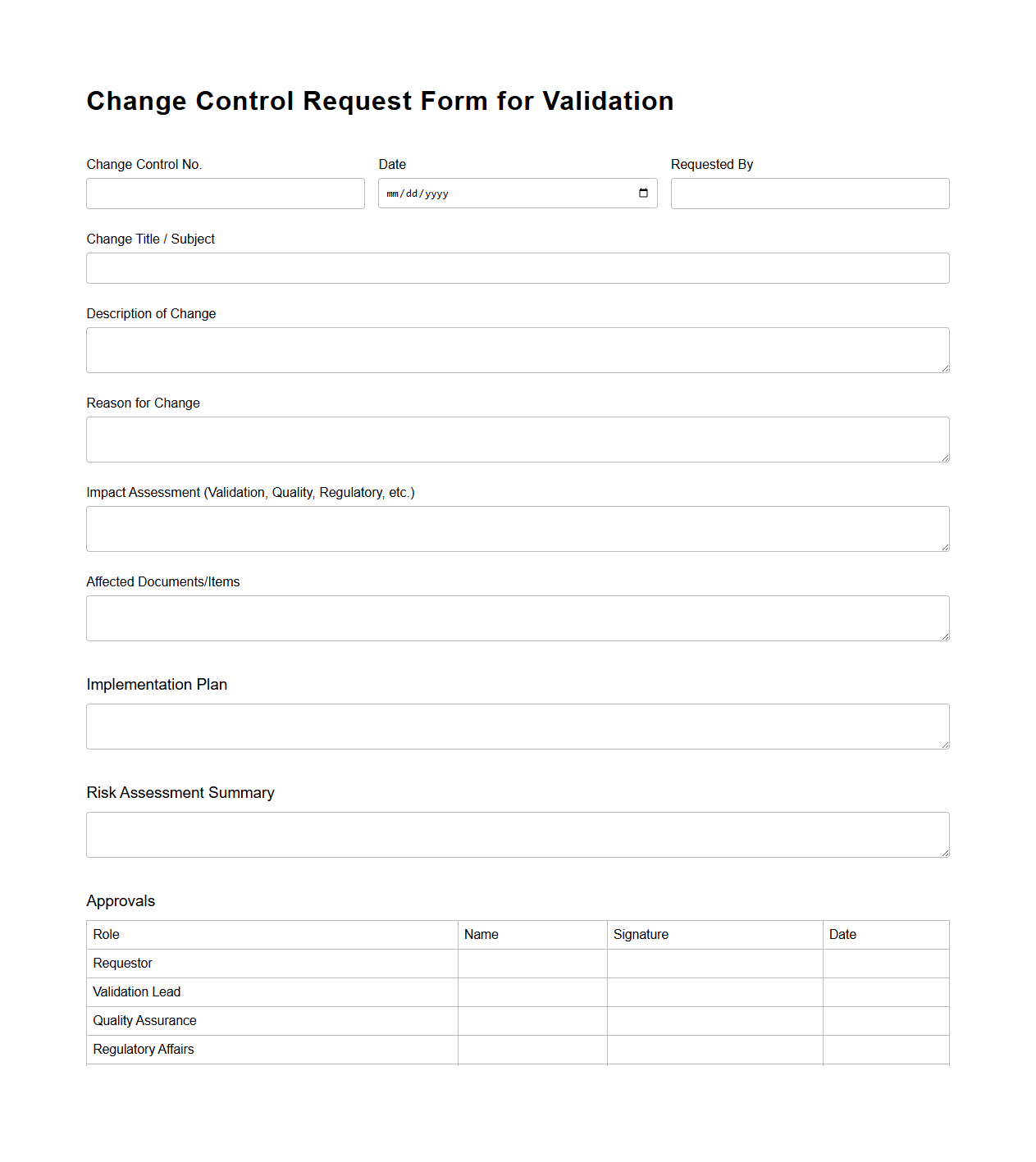

Change Control Request Form for Validation

A

Change Control Request Form for Validation documents is a formal document used to propose, evaluate, and authorize changes to validated systems or processes within regulated environments. It ensures that all modifications undergo thorough assessment for potential impact on compliance, functionality, and quality before implementation. This process helps maintain regulatory adherence and product integrity by documenting change rationale, risk analysis, and approval status.

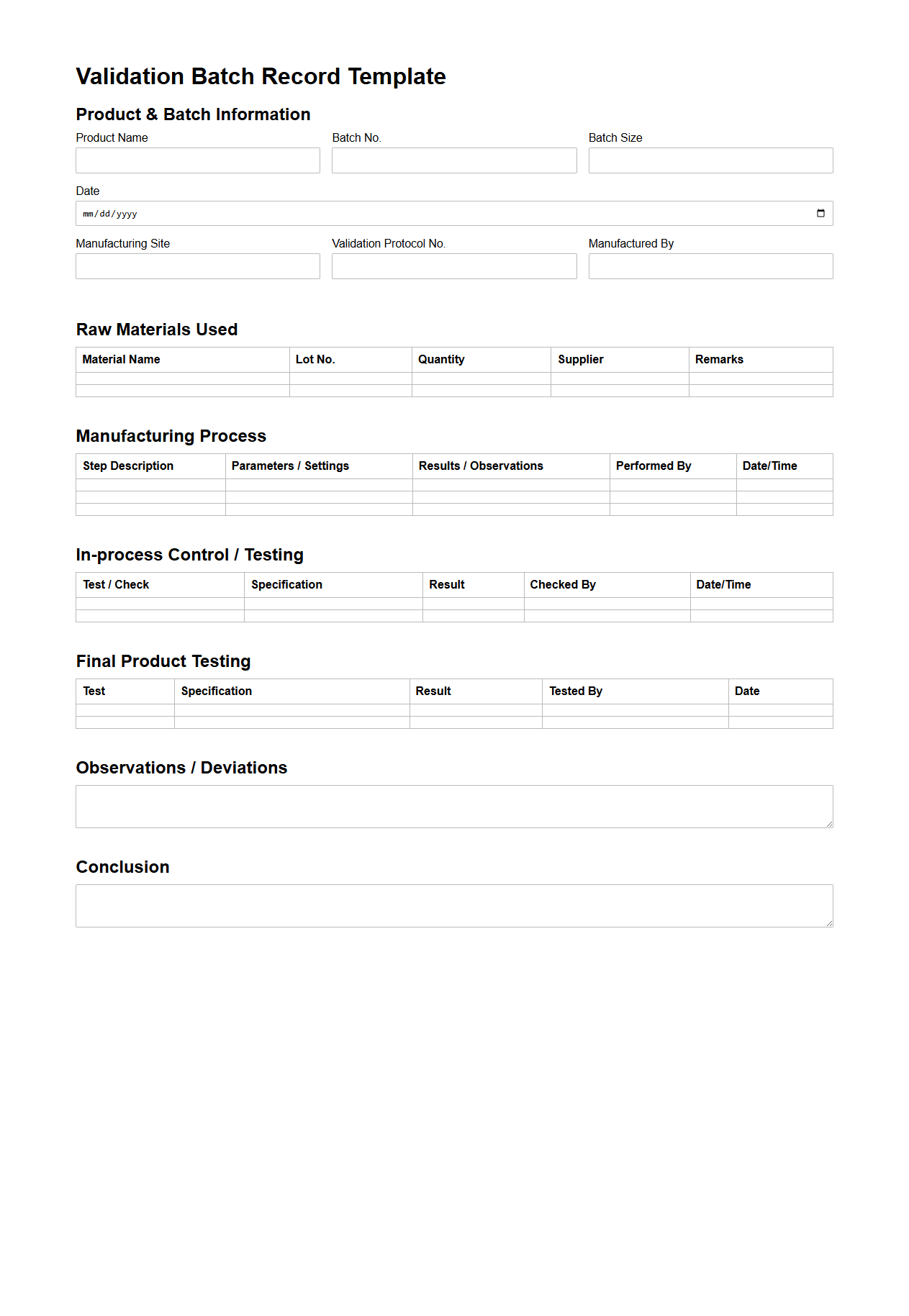

Validation Batch Record Template

A

Validation Batch Record Template document serves as a standardized framework for recording comprehensive details of production batches during the validation phase. It ensures consistent documentation of critical process parameters, materials used, equipment settings, and results to verify that manufacturing processes meet regulatory and quality requirements. This template is essential for maintaining compliance with Good Manufacturing Practices (GMP) and supports traceability and audit readiness.

What is the primary objective of the process validation documented in this sample?

The primary objective of the process validation documented in this sample is to ensure that the manufacturing process consistently produces products that meet predetermined quality standards. It aims to demonstrate reproducibility and control over the process variables. This validation establishes confidence in the overall process capability and product reliability.

Which critical process parameters are identified and justified within the document?

The document identifies critical process parameters (CPPs) such as temperature, pressure, and mixing time that directly impact product quality. Each parameter is justified based on scientific rationale and empirical data linking it to key quality attributes. This identification helps prioritize control efforts to maintain consistent process performance.

How does the document define and verify acceptance criteria for product quality?

The acceptance criteria are defined based on regulatory requirements, industry standards, and product specifications, focusing on critical quality attributes. Verification involves comprehensive testing and analysis to confirm that products consistently meet these predefined thresholds. This systematic approach ensures product safety, efficacy, and compliance.

What sampling and testing strategies are outlined for ongoing process monitoring?

The document outlines a robust sampling and testing strategy that includes random and periodic sampling to capture process variability. It specifies analytical methods and frequency for testing, ensuring timely detection of deviations. This ongoing monitoring facilitates proactive quality control and continuous process improvement.

How are deviations and corrective actions documented and managed in this sample?

Deviations are meticulously documented with detailed descriptions, root cause analyses, and impact assessments. The document emphasizes structured corrective actions that are tracked and verified for effectiveness. This rigorous management approach fosters regulatory compliance and enhances process robustness.

More Manufacturing Templates