A Inventory Control Document Sample for Manufacturing provides a structured template to track raw materials, work-in-progress, and finished goods efficiently. It helps maintain accurate stock levels, reduces waste, and ensures timely reordering to avoid production delays. This document is essential for optimizing inventory management and improving overall manufacturing workflow.

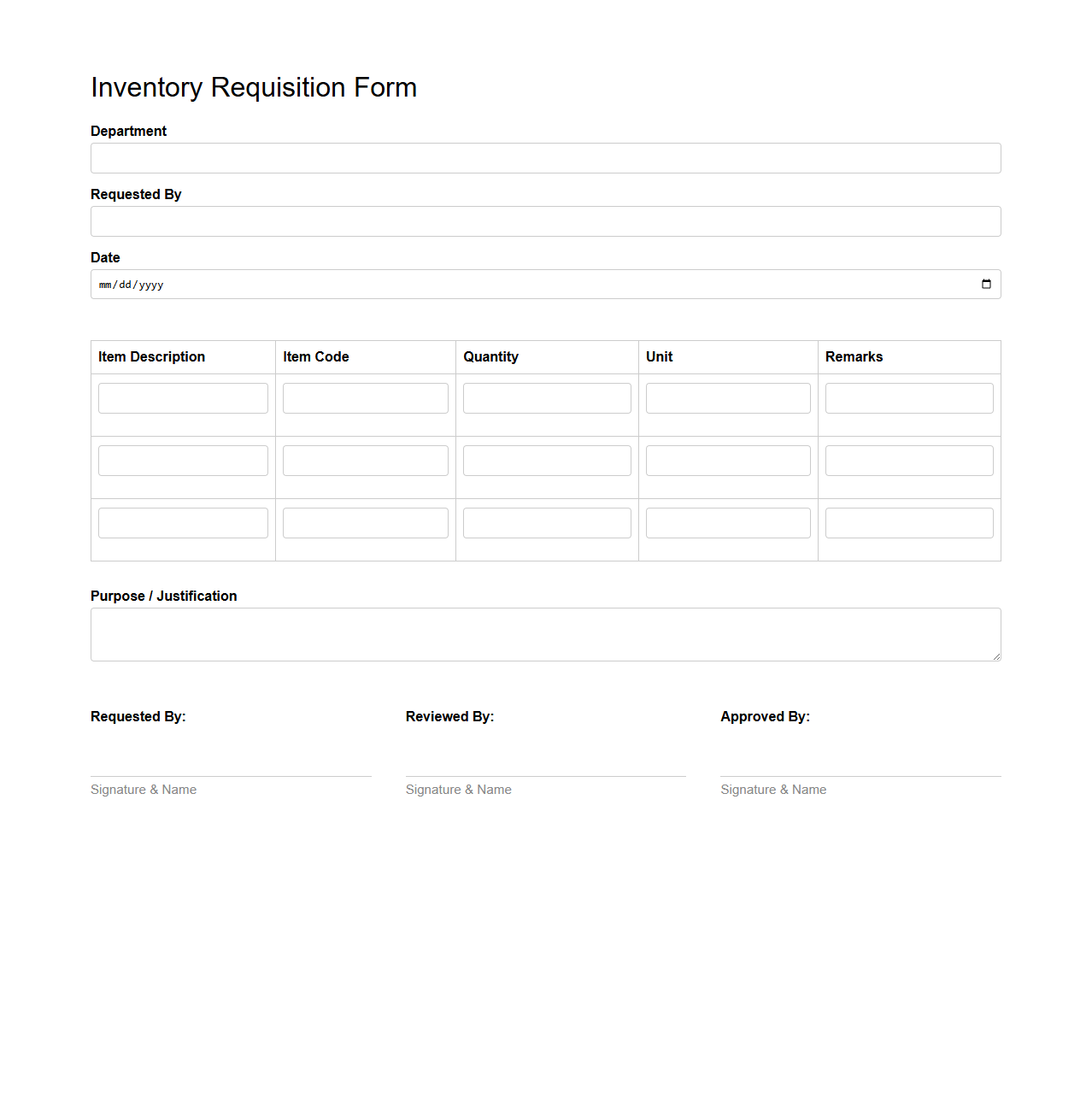

Inventory Requisition Form Template

An

Inventory Requisition Form Template is a standardized document used by organizations to request materials or supplies from their inventory. It helps track item quantities, requesters' details, and approval status to ensure efficient stock management and prevent shortages. Utilizing this template streamlines the procurement process and maintains accurate inventory records.

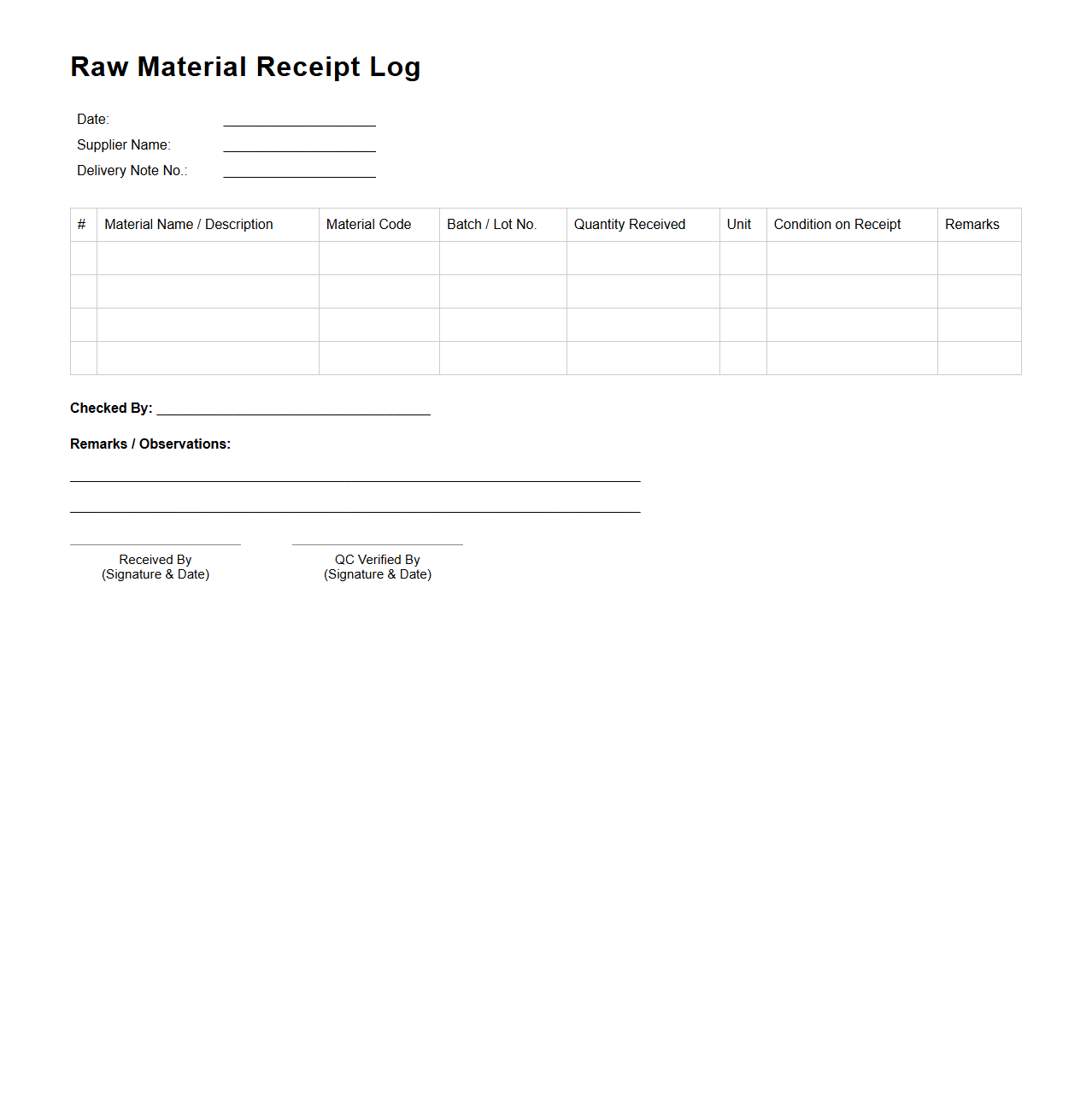

Raw Material Receipt Log Sample

A

Raw Material Receipt Log Sample document is a standardized record used to track the receipt of raw materials in manufacturing or production processes. It typically includes details such as date of receipt, supplier information, quantity, batch numbers, and quality inspection results to ensure transparency and accuracy in inventory management. This log is essential for maintaining traceability and verifying compliance with procurement and quality control standards.

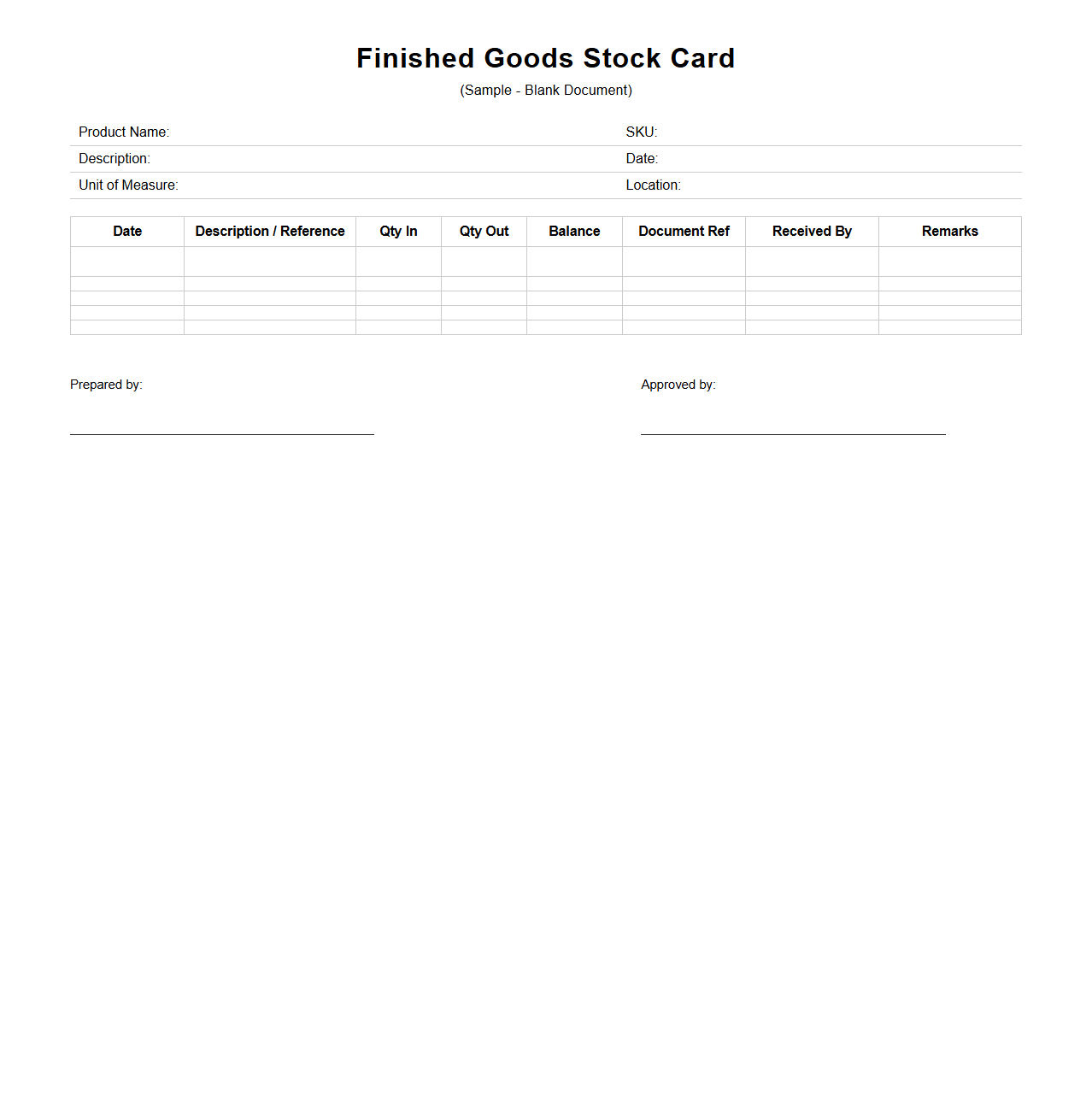

Finished Goods Stock Card Example

A

Finished Goods Stock Card Example document is a vital inventory management tool used to record details about finished products, including quantities received, issued, and on hand. It helps businesses track stock movements accurately, monitor inventory levels, and maintain proper control over finished goods for efficient order fulfillment. This document typically includes information such as product codes, dates, batch numbers, and balance quantities to ensure transparency and accountability in stock management.

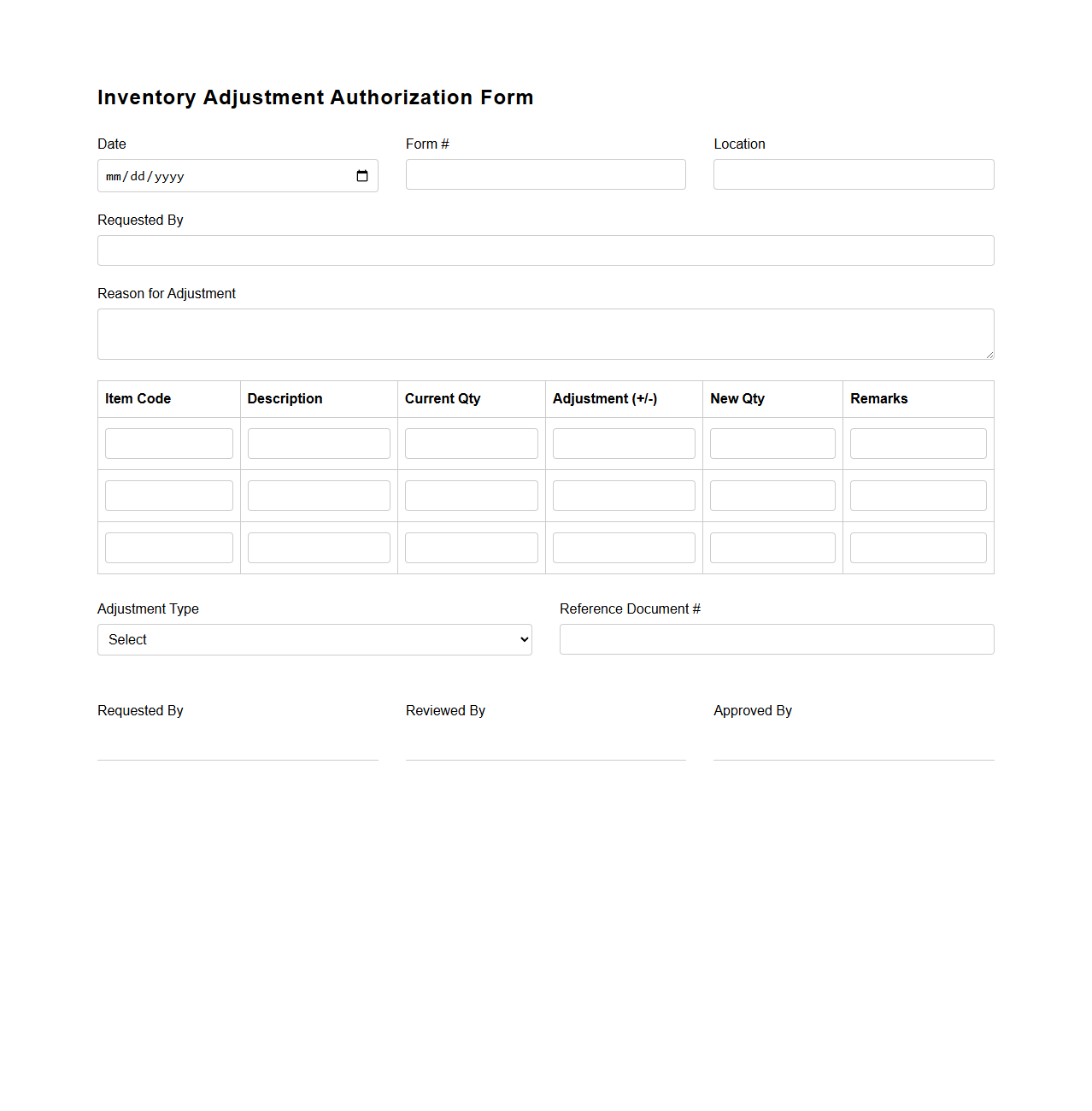

Inventory Adjustment Authorization Form

An

Inventory Adjustment Authorization Form is a critical document used to officially record and approve changes in inventory levels. It details reasons for adjustments such as discrepancies, damages, or losses, ensuring accurate stock control and preventing unauthorized modifications. This form supports transparency and accountability in inventory management processes within organizations.

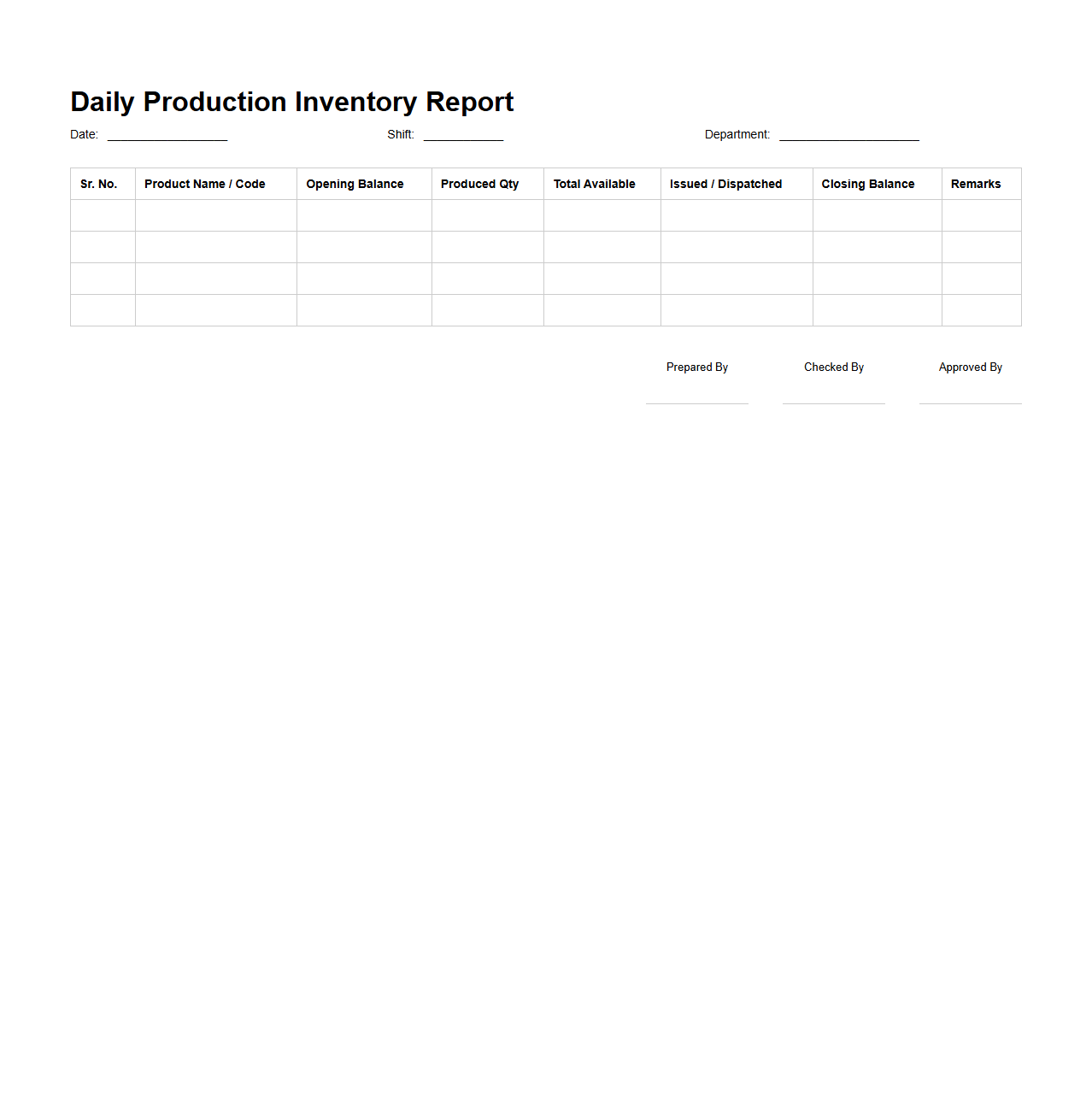

Daily Production Inventory Report Format

The

Daily Production Inventory Report Format document serves as a structured template to record and track the quantity of raw materials, work-in-progress, and finished goods produced each day. It facilitates accurate monitoring of production output, inventory levels, and resource utilization, enabling efficient decision-making and operational control. This format typically includes fields for date, item description, opening inventory, production quantity, closing inventory, and any discrepancies or notes.

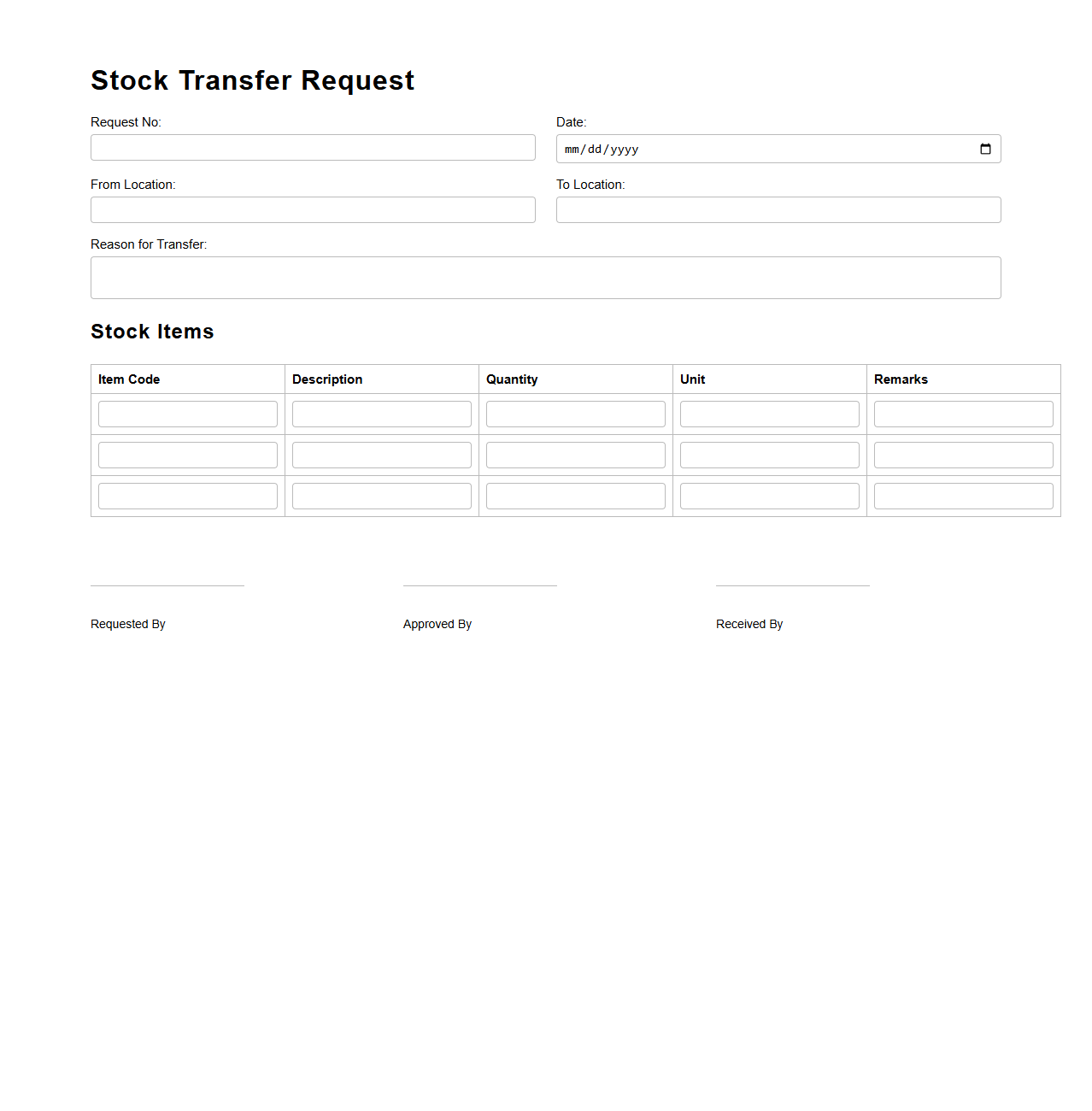

Stock Transfer Request Document

A

Stock Transfer Request Document is a formal record used within organizations to initiate the movement of inventory items from one location or warehouse to another. It details the specifics of the transfer, including item descriptions, quantities, source and destination points, and approval signatures, ensuring accurate tracking and accountability. This document plays a crucial role in inventory management systems by maintaining stock accuracy and supporting operational efficiency.

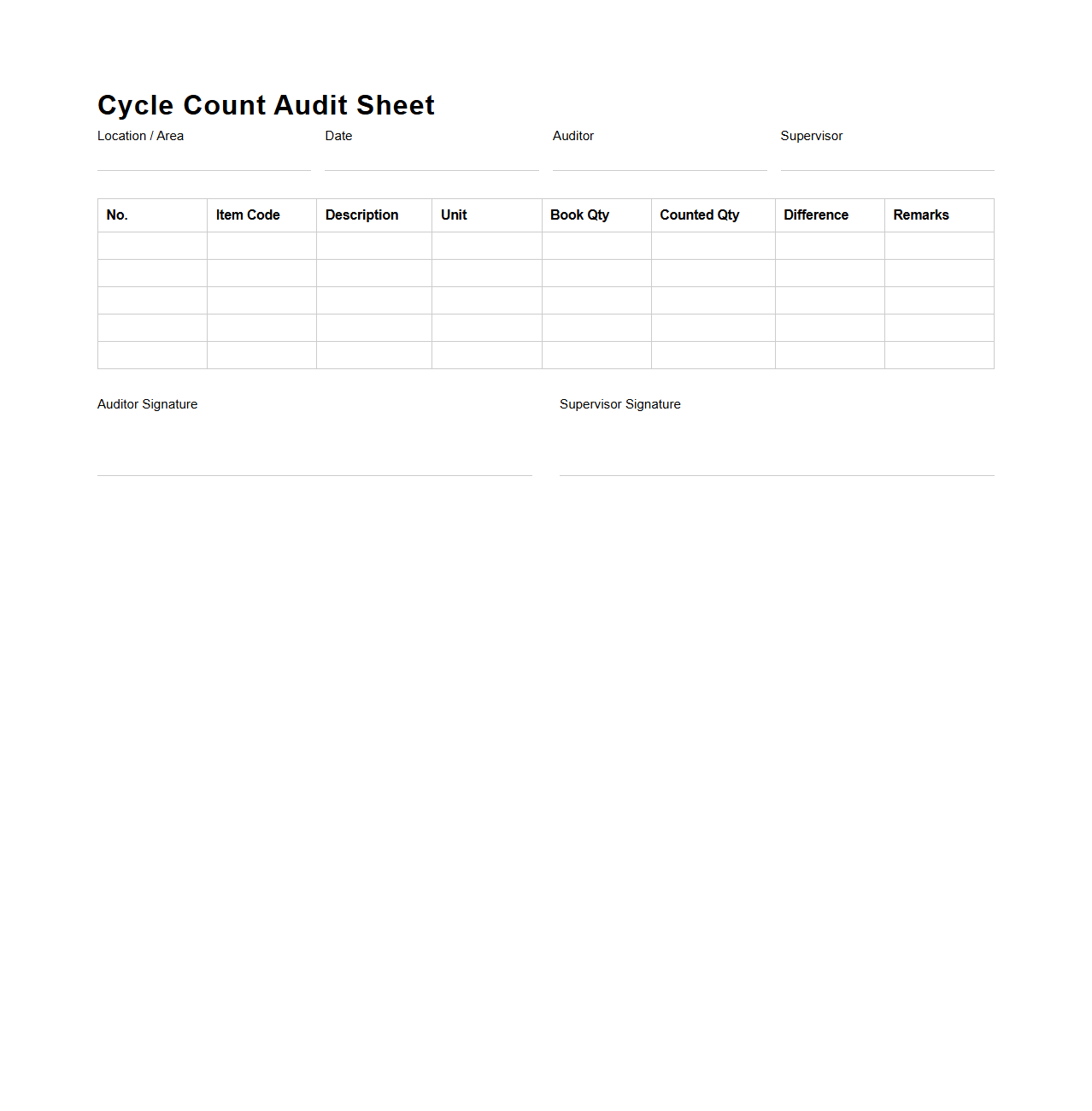

Cycle Count Audit Sheet

A

Cycle Count Audit Sheet is a detailed record used in inventory management to track and verify the accuracy of stock counts during periodic cycle counting. This document helps identify discrepancies between physical inventory and system records, ensuring data integrity and efficient inventory control. It typically includes item descriptions, quantities counted, location details, and auditor signatures to maintain accountability and support inventory reconciliation processes.

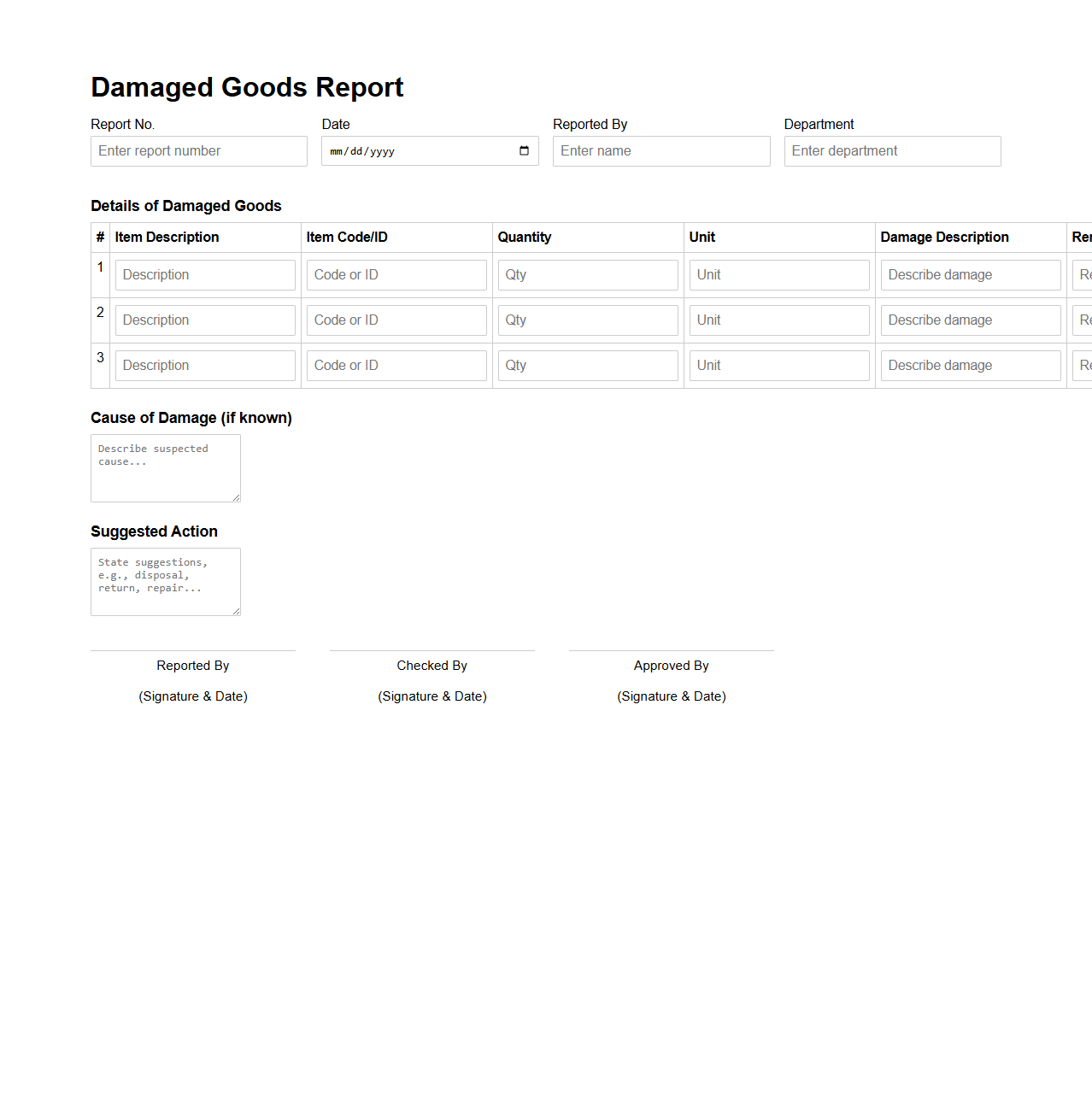

Damaged Goods Report Sample

A

Damaged Goods Report Sample document serves as a standardized template for recording details about products that arrive damaged or defective. It typically includes sections for item description, extent of damage, date of receipt, and actions taken, ensuring accurate communication between suppliers and buyers. This report helps streamline the claims process, prevent inventory discrepancies, and maintain quality control in supply chain management.

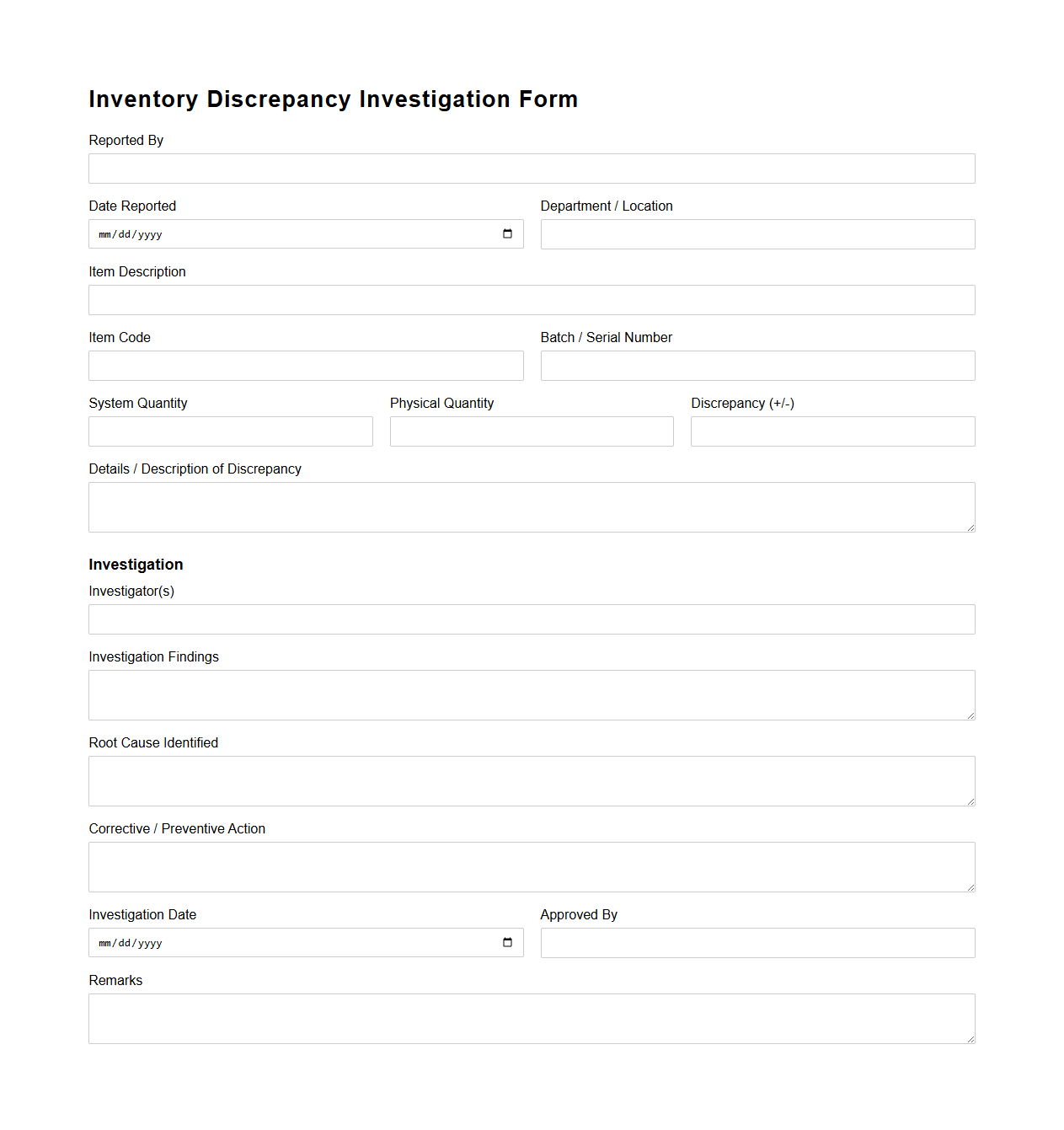

Inventory Discrepancy Investigation Form

The

Inventory Discrepancy Investigation Form is a crucial document used to identify and resolve inconsistencies between recorded inventory levels and actual stock counts. It helps businesses track discrepancies, determine their causes, and implement corrective actions to maintain accurate inventory records. This form supports inventory management processes by enhancing accountability and reducing errors in stock control.

Work-in-Progress Inventory Ledger

The

Work-in-Progress Inventory Ledger document tracks the value and status of partially completed goods within the production process, providing detailed records of raw materials, labor, and overhead costs accumulated. It serves as a crucial accounting tool to ensure accurate cost allocation and inventory management during manufacturing cycles. This ledger helps businesses monitor production efficiency and supports financial reporting by reflecting real-time work-in-progress inventory levels.

What key data fields are essential in an Inventory Control Document for manufacturing?

Essential data fields in an Inventory Control Document include item code, description, quantity, unit of measure, and location. Additional critical fields are batch or lot number, supplier details, and date of transaction. These fields ensure precise tracking and identification of inventory within the manufacturing process.

How does the document track and record stock levels of raw materials and finished goods?

The document tracks stock levels by recording all inflows and outflows with timestamps and quantities. It maintains real-time updates to inventory quantities, reflecting current stock levels for raw materials and finished goods. This enables accurate monitoring and effective stock management throughout production cycles.

Which inventory movement types (e.g., receipt, issue, adjustment) are documented and how are they categorized?

Inventory Control Documents categorize movements into types such as receipt, issue, transfer, and adjustment. Each movement type is logged with details like date, quantity, and reason to provide clear audit trails. Proper categorization ensures transparency and facilitates comprehensive inventory management.

What process is outlined for authorization and verification of inventory transactions in the document?

The document outlines a strict authorization process requiring approval from designated personnel before transactions are recorded. Verification includes cross-checking physical counts with recorded data to ensure accuracy. This authorization and verification process prevents errors and unauthorized inventory changes.

How does the document facilitate regular inventory audits and reconciliation?

The document provides structured records that support scheduled physical counts and automatic reconciliation with system data. It highlights discrepancies for prompt investigation and correction during audits. By maintaining detailed logs, the document streamlines inventory audits and ensures data integrity.

More Manufacturing Templates