The Employee Training Record Document Sample for Manufacturing tracks essential training details, including course names, completion dates, and employee signatures. This document ensures compliance with industry standards and helps maintain workforce skills for safety and efficiency. Keeping accurate records supports audits and continuous improvement within manufacturing operations.

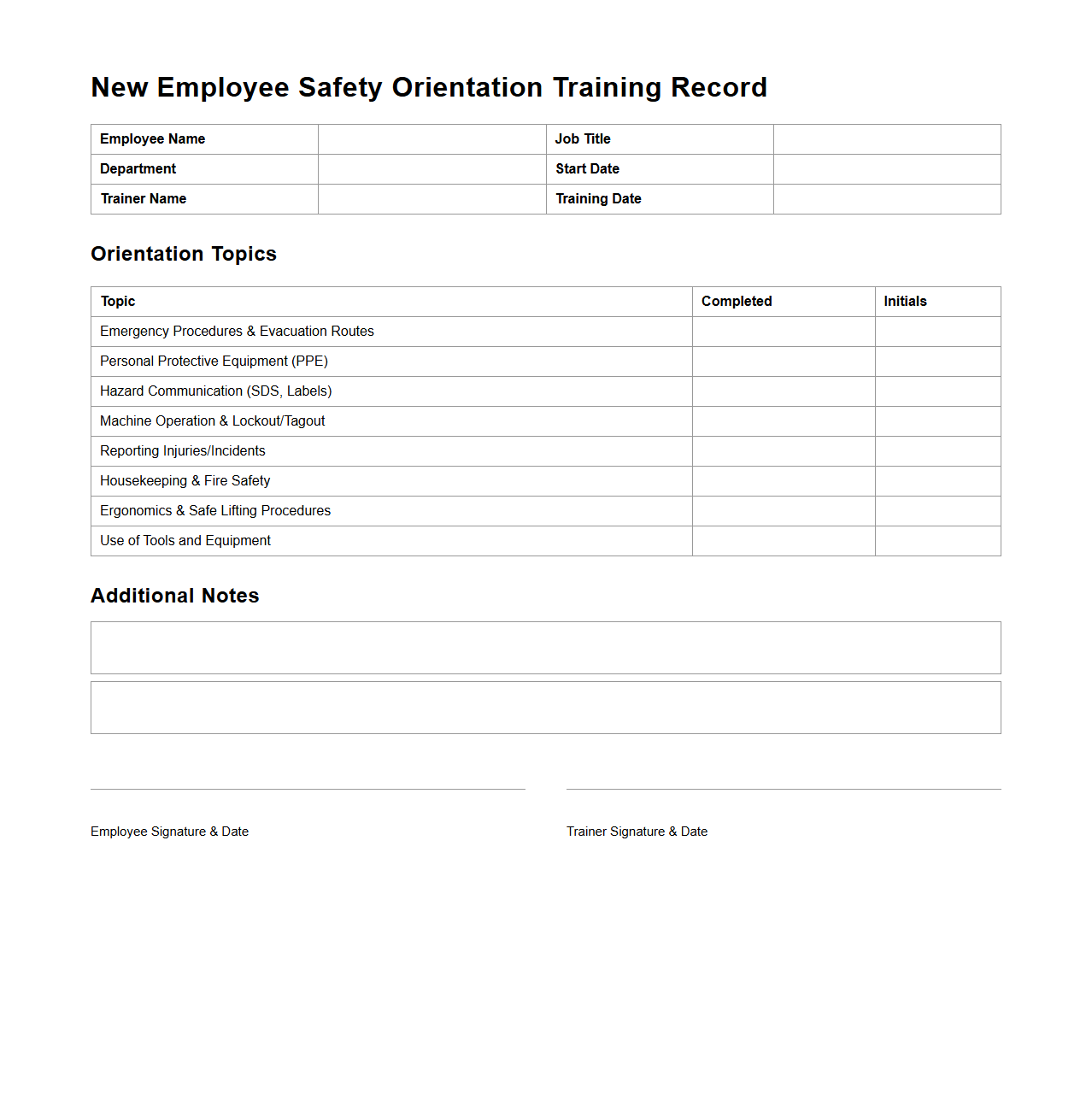

New Employee Safety Orientation Training Record for Manufacturing

The

New Employee Safety Orientation Training Record for Manufacturing is a documented proof that tracks the completion of safety training provided to newly hired workers in a manufacturing setting. This record ensures compliance with OSHA regulations by confirming employees understand workplace hazards, proper equipment use, and emergency procedures. Maintaining this document helps manufacturing companies mitigate risks and promotes a culture of safety from the start of employment.

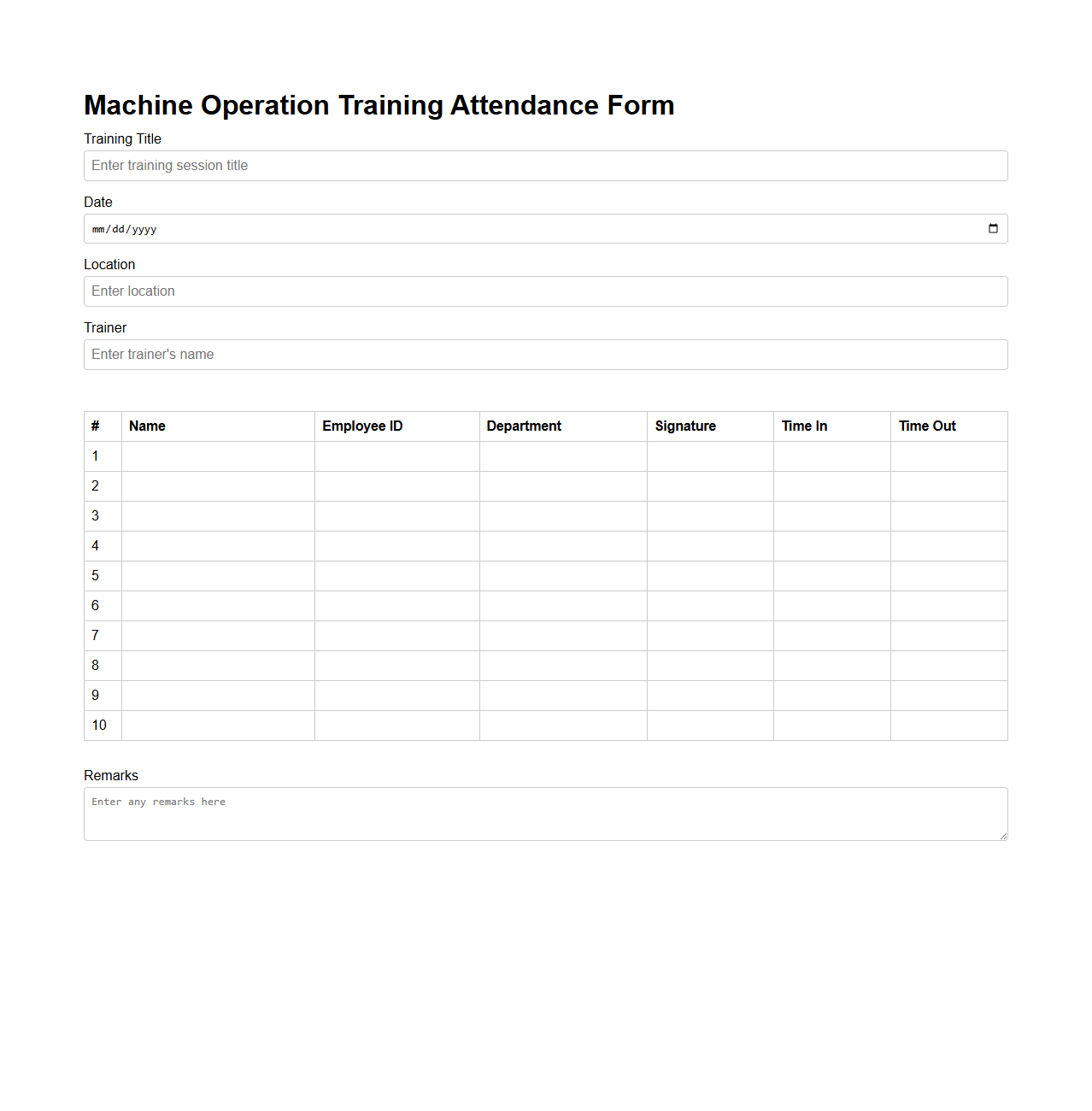

Machine Operation Training Attendance Form

The

Machine Operation Training Attendance Form is a document used to record the participation of employees in training sessions focused on operating machinery safely and efficiently. It captures essential details such as trainee names, training dates, topics covered, and instructor information to ensure compliance with workplace safety standards and regulatory requirements. Maintaining accurate attendance records helps organizations track skill development and verify that personnel are qualified to handle specific equipment.

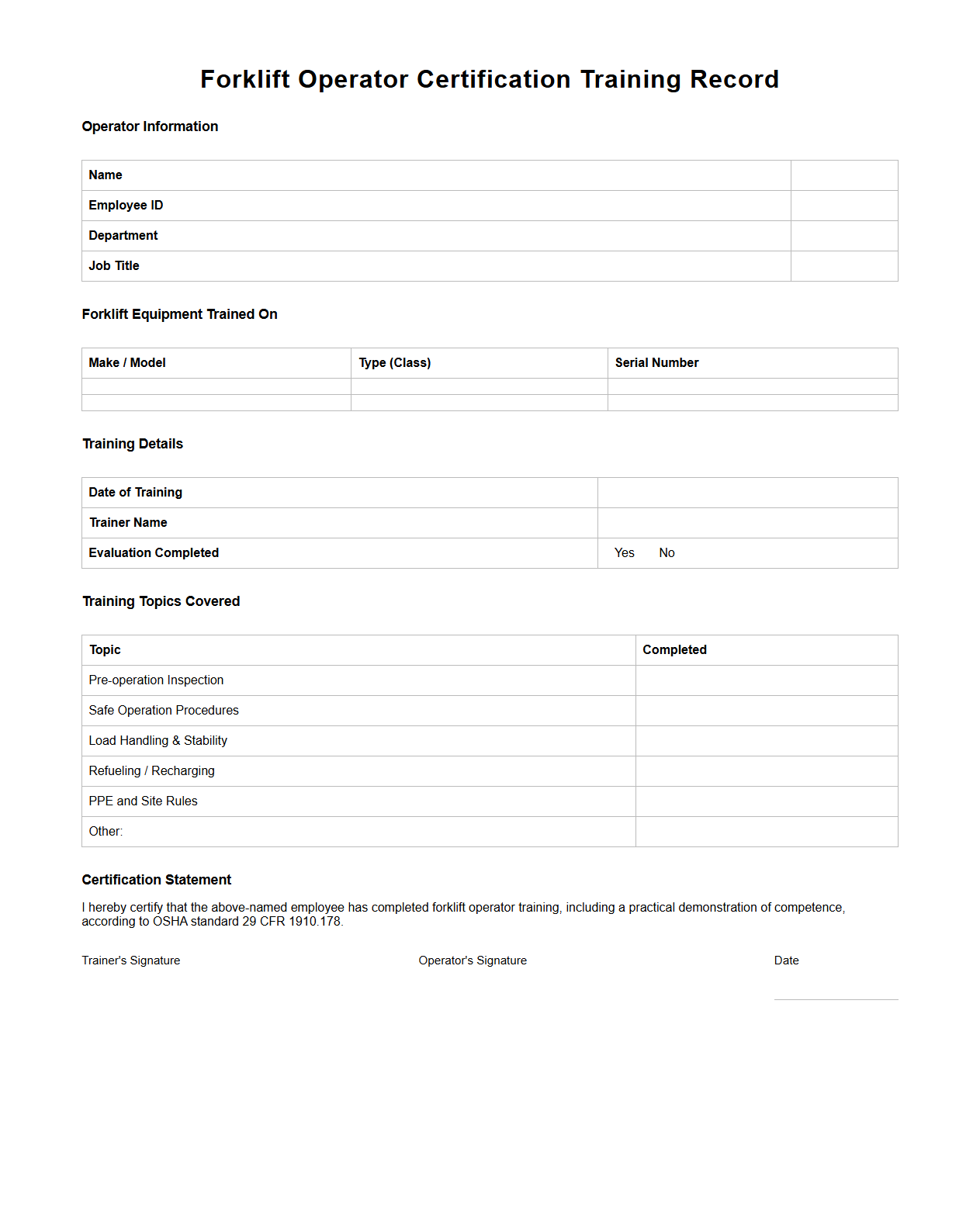

Forklift Operator Certification Training Record

A

Forklift Operator Certification Training Record document serves as official proof that an individual has successfully completed the necessary training and assessment to operate a forklift safely and efficiently. This record includes details such as the trainee's personal information, training dates, instructor credentials, and evaluation results. Maintaining this document ensures compliance with workplace safety regulations and supports risk management in industrial environments.

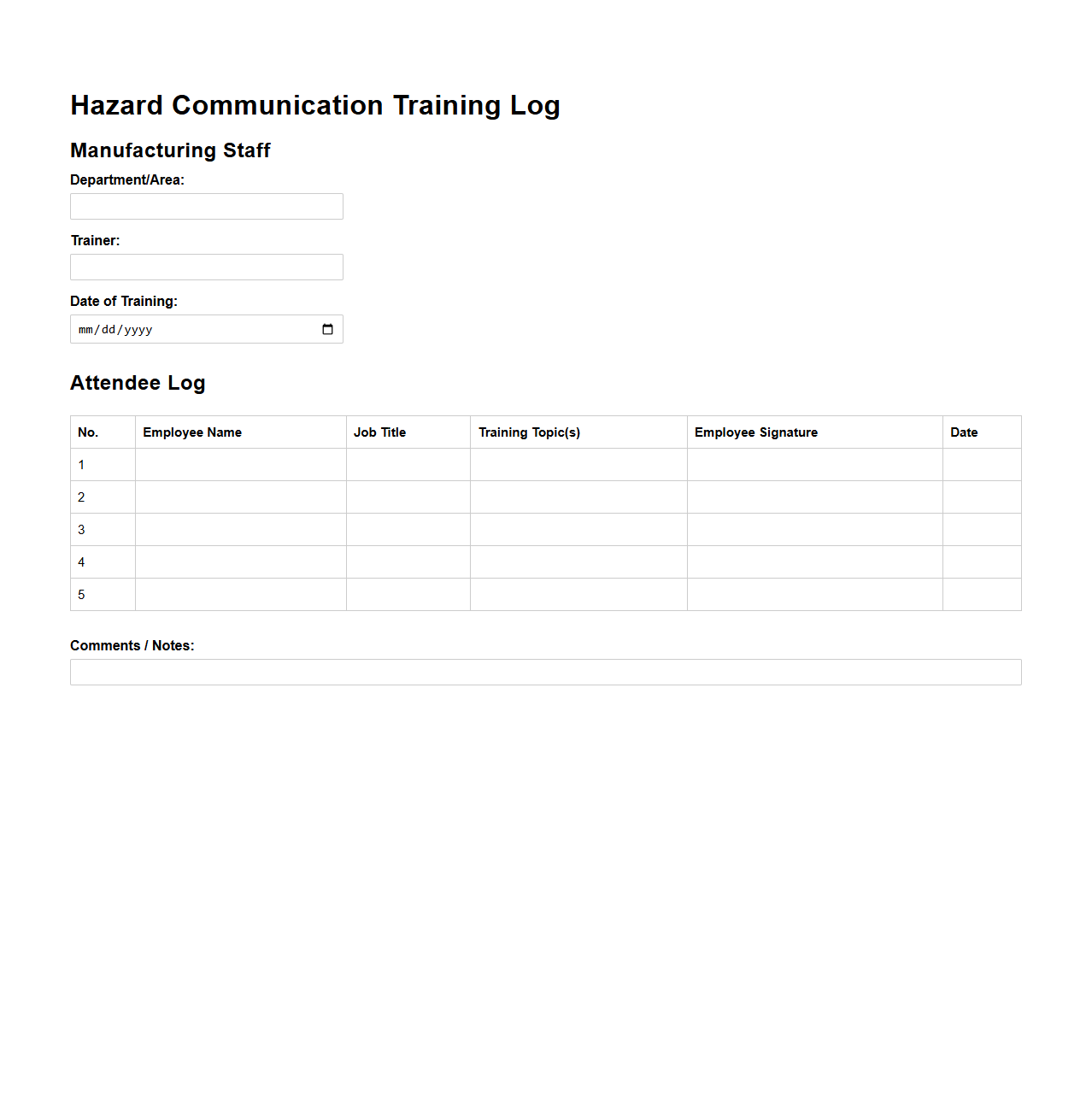

Hazard Communication Training Log for Manufacturing Staff

The

Hazard Communication Training Log for manufacturing staff is a critical document that records all training sessions related to workplace chemical safety and hazard awareness. It ensures compliance with OSHA standards by tracking employee participation, training dates, and the specific hazardous materials covered. Maintaining this log helps manufacturing facilities demonstrate due diligence in educating staff on proper handling, storage, and emergency response procedures for hazardous substances.

Lockout/Tagout Procedure Training Acknowledgment

The

Lockout/Tagout Procedure Training Acknowledgment document serves as a formal record that an employee has received and understood training on the lockout/tagout safety protocols, which prevent accidental machinery startup during maintenance or repair. This document ensures compliance with OSHA standards by confirming that workers are aware of the specific steps required to control hazardous energy sources. Employers use this acknowledgment to demonstrate due diligence in workplace safety and reduce the risk of injury related to energy control procedures.

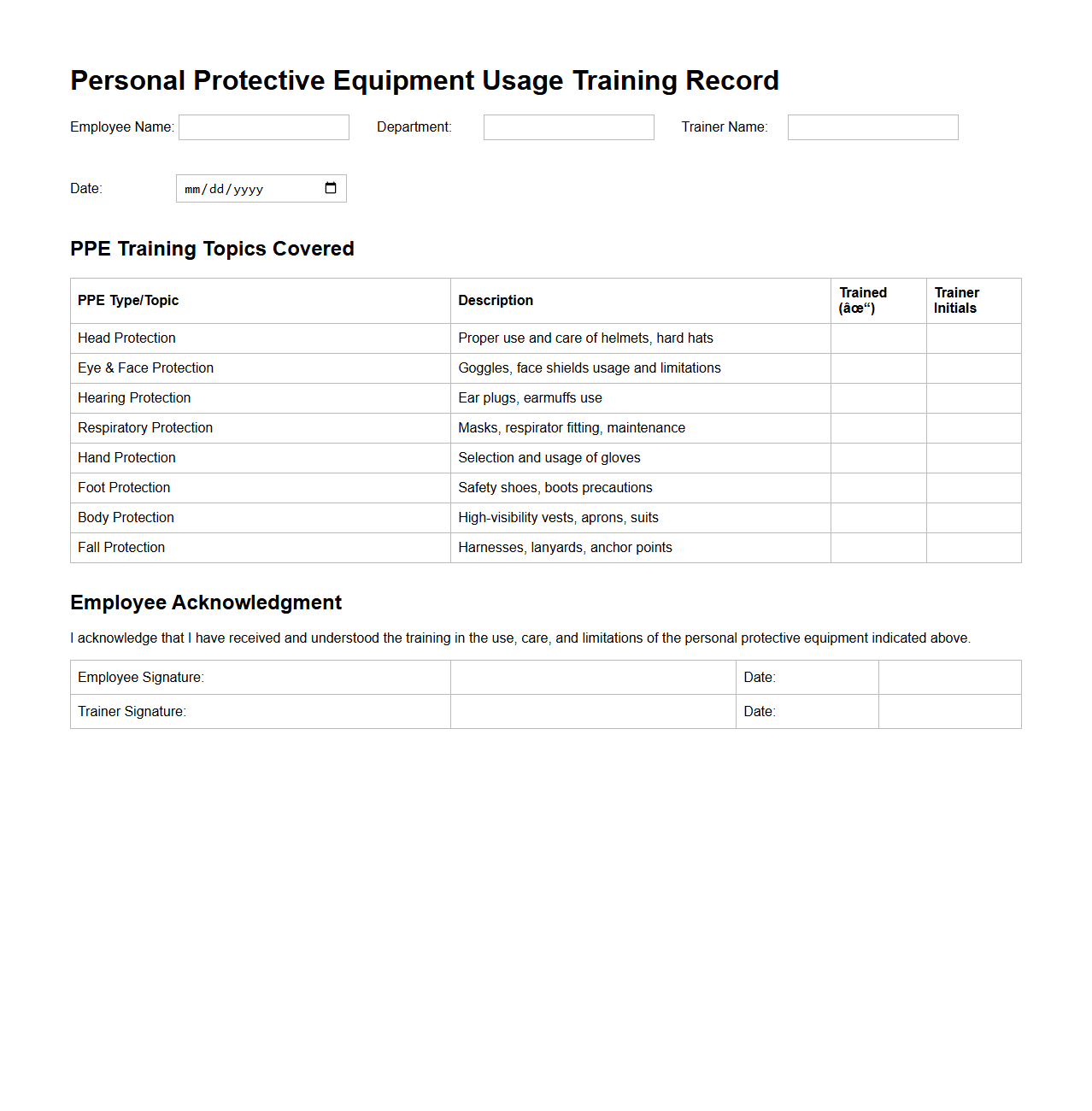

Personal Protective Equipment Usage Training Record

A

Personal Protective Equipment Usage Training Record document systematically tracks employees' completion of safety training programs related to the proper use of PPE. This record ensures compliance with occupational health and safety regulations by documenting the type of PPE covered, training dates, and employee acknowledgment. Maintaining this document supports workplace safety audits and enhances risk management by verifying that personnel are adequately trained to use protective gear effectively.

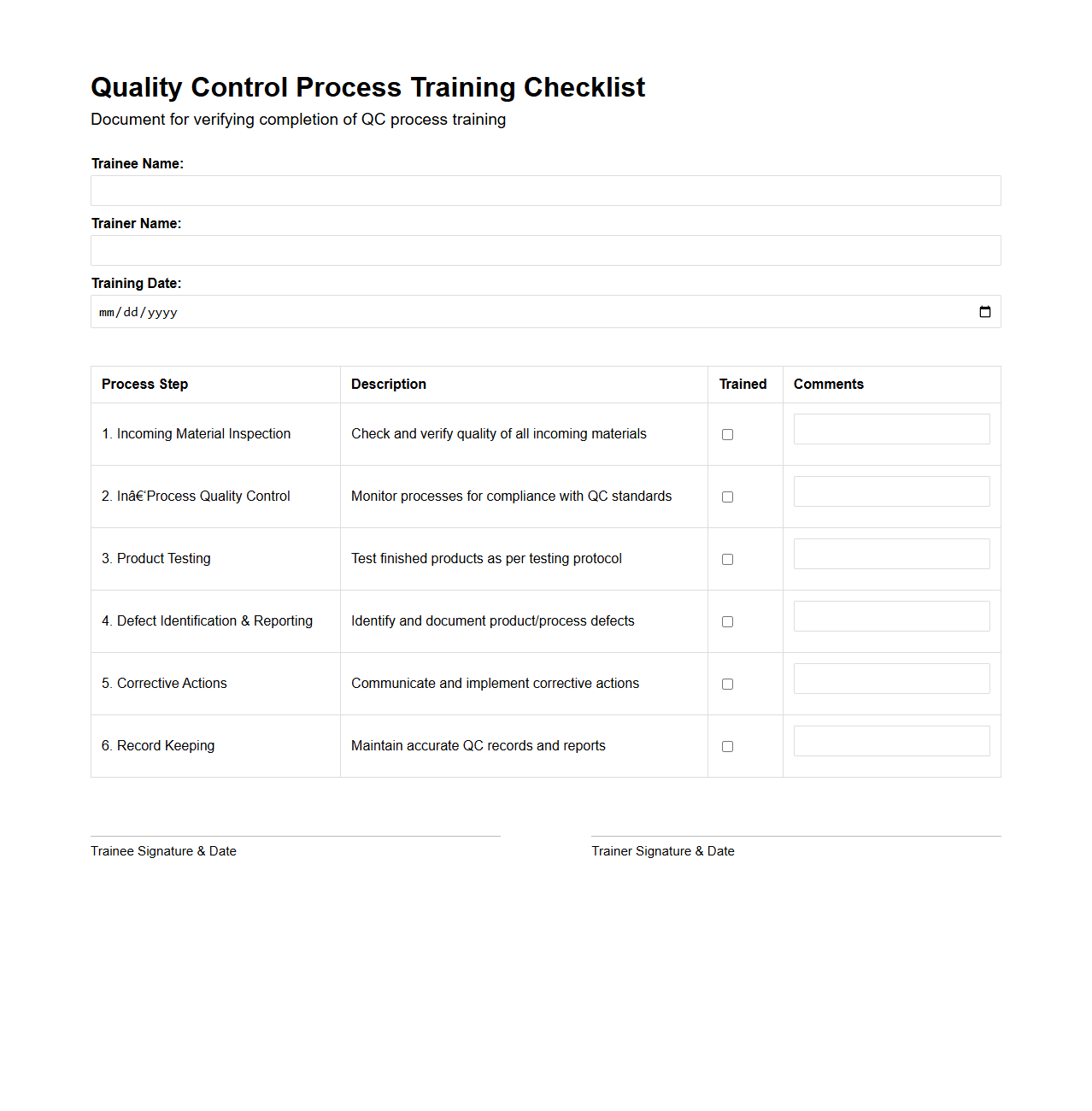

Quality Control Process Training Checklist

A

Quality Control Process Training Checklist document outlines essential steps, criteria, and standards for effectively training employees in quality control procedures. It ensures consistent understanding and application of quality protocols, minimizing errors and enhancing product reliability. This checklist serves as a practical guide to monitor progress and verify competency in quality control tasks.

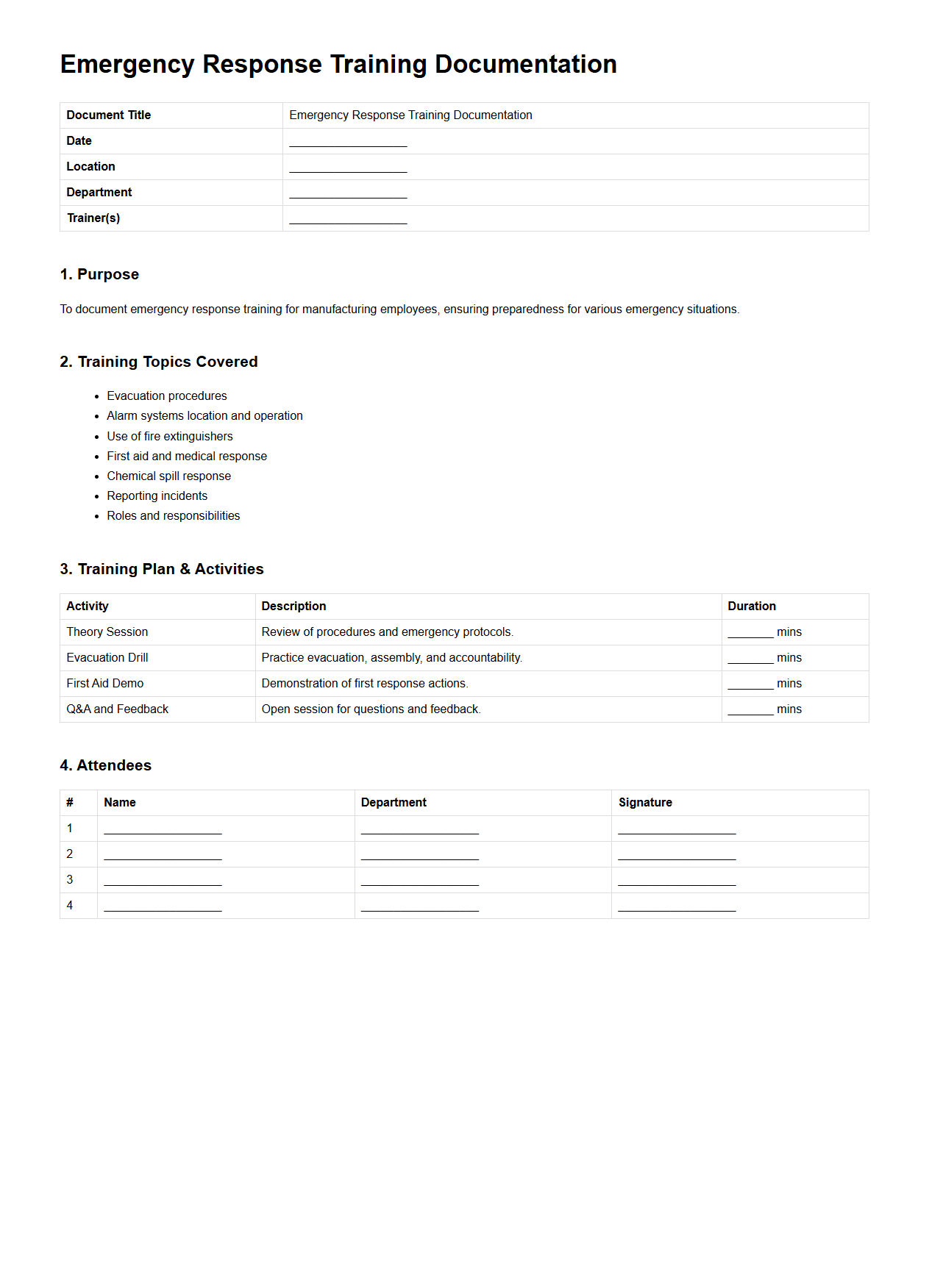

Emergency Response Training Documentation for Manufacturing

Emergency Response Training Documentation for Manufacturing is a detailed record that captures all training activities related to handling emergencies in a manufacturing environment. This document ensures compliance with industry safety standards by tracking employee participation, specific training modules, and assessment outcomes. Maintaining

comprehensive emergency response records helps improve workplace safety, facilitates audits, and supports continuous improvement in risk management protocols.

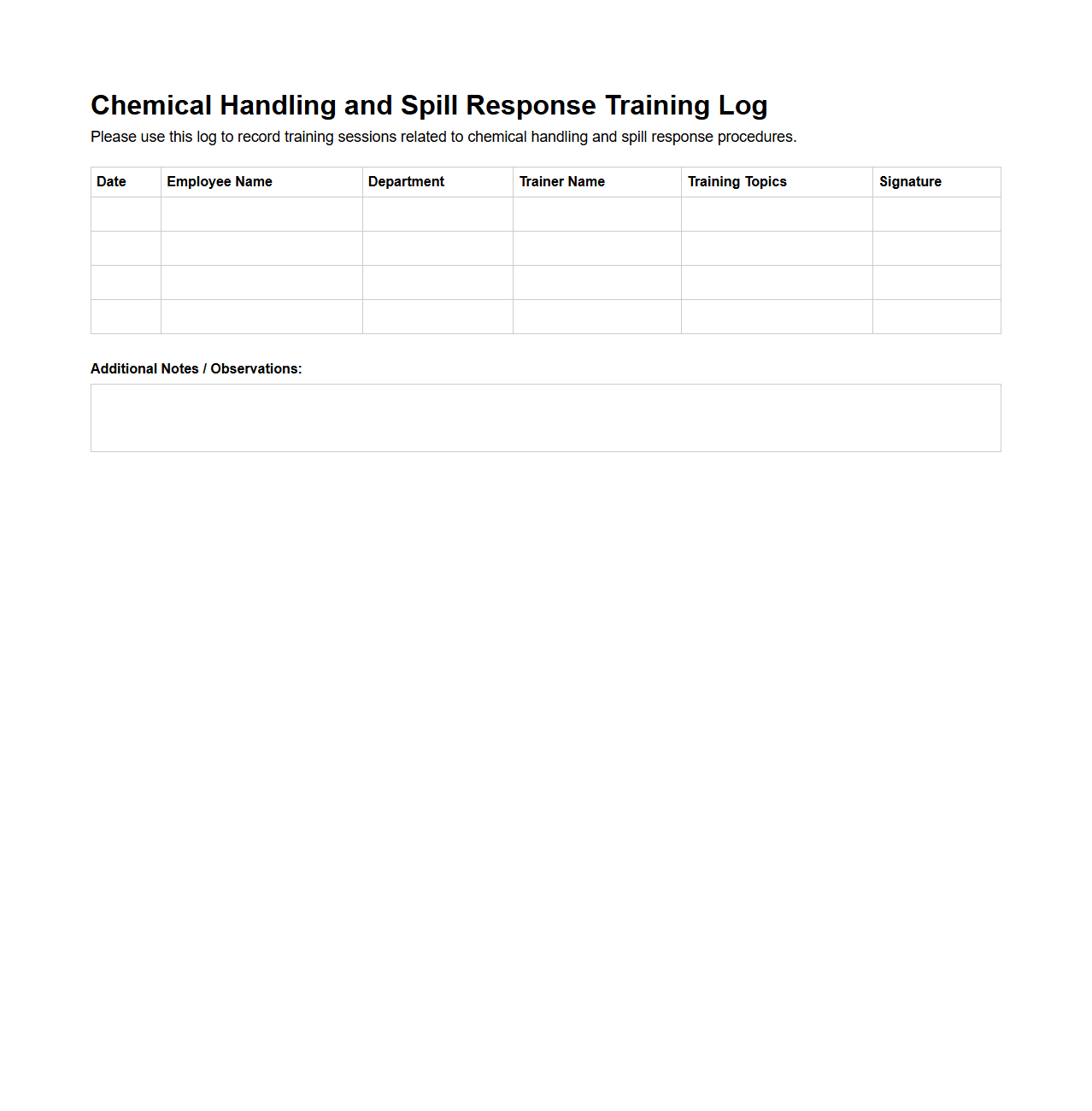

Chemical Handling and Spill Response Training Log

A

Chemical Handling and Spill Response Training Log document records employee training related to the safe management of hazardous substances and procedures for addressing chemical spills. It ensures compliance with safety regulations by tracking who has completed training, the dates of sessions, and the specific topics covered. Maintaining this log supports workplace safety by documenting readiness to prevent and respond to chemical incidents effectively.

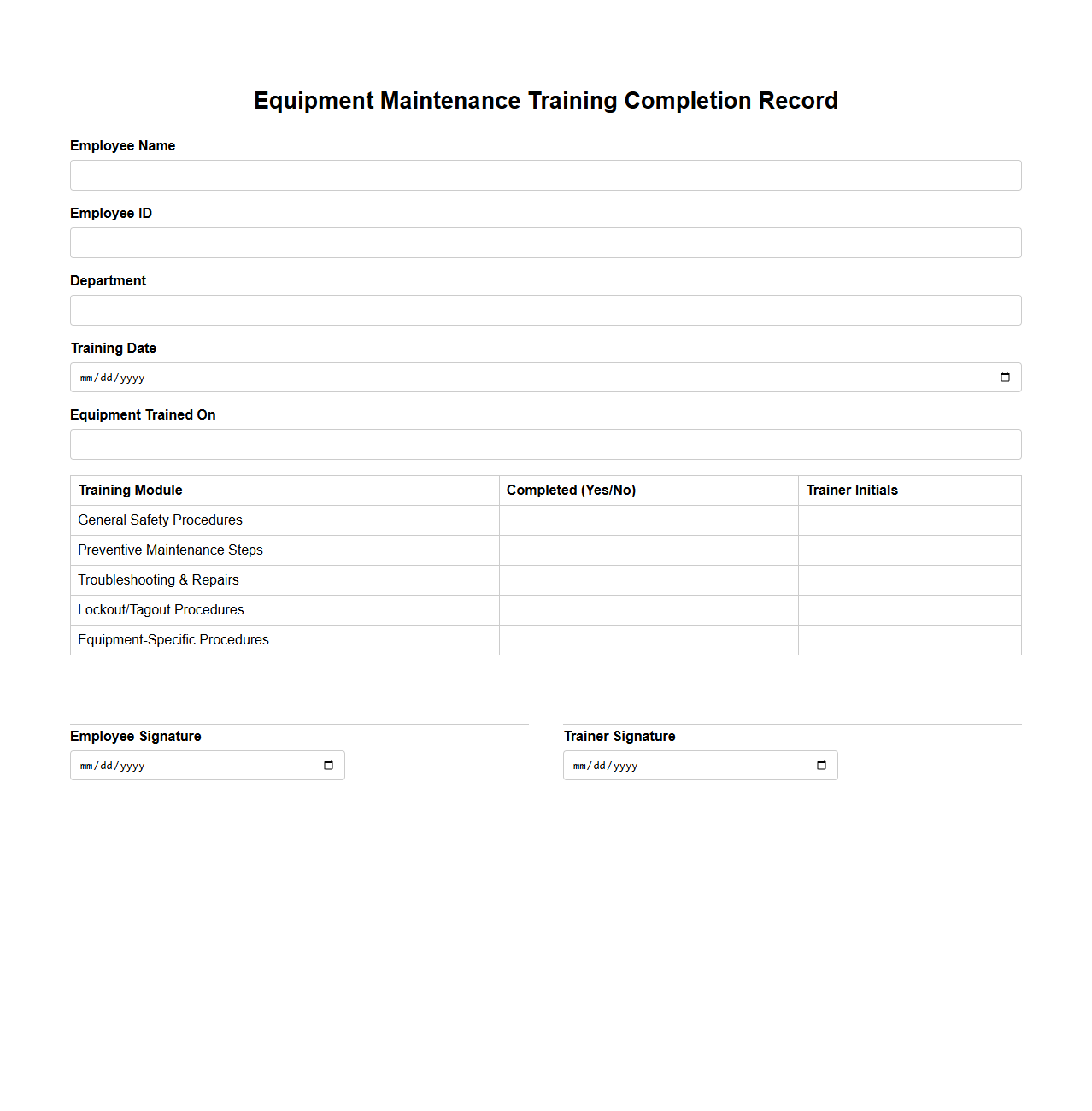

Equipment Maintenance Training Completion Record

The

Equipment Maintenance Training Completion Record document serves as an official record verifying that individuals have successfully completed training on the proper maintenance procedures for specific equipment. It captures essential details such as trainee names, dates of training, and the scope of the maintenance skills covered, ensuring compliance with safety and operational standards. This document is crucial for tracking workforce competency and supporting audit requirements in industrial and technical environments.

What essential employee information should be included in a manufacturing training record document?

The employee's full name and unique identification number must be clearly documented for accurate record-keeping. Job title and department help contextualize the training and its relevance to their role. Additionally, including hire date and supervisor details ensures the record's completeness.

How does the document record the specific training topics or modules completed by each employee?

The document lists each training topic or module with detailed titles and codes for easy reference. Completion dates are logged alongside each topic to track training timelines. Certificates or assessment scores related to each module are often attached for verification.

What methods are used to verify completion and comprehension of each training session?

Assessments and quizzes are commonly administered at the end of training to confirm understanding. Supervisors or trainers provide signatures or digital acknowledgments as proof of attendance. In some cases, practical demonstrations or job performance reviews further validate comprehension.

How is training compliance regularly tracked and updated within the record?

The record is routinely reviewed and updated through automated tracking systems or manual audits to ensure compliance with company standards. Notifications and reminders are set for upcoming refresher courses or expiry of certifications. This proactive approach prevents lapses in mandatory training requirements.

What procedures are in place for documenting re-training or corrective training activities?

Re-training sessions are recorded with updated dates and reasons for remediation clearly noted in the document. Corrective actions include detailed descriptions of the issues and the steps taken to resolve them. All involved personnel, including trainers and supervisors, sign off to acknowledge completion and effectiveness.

More Manufacturing Templates