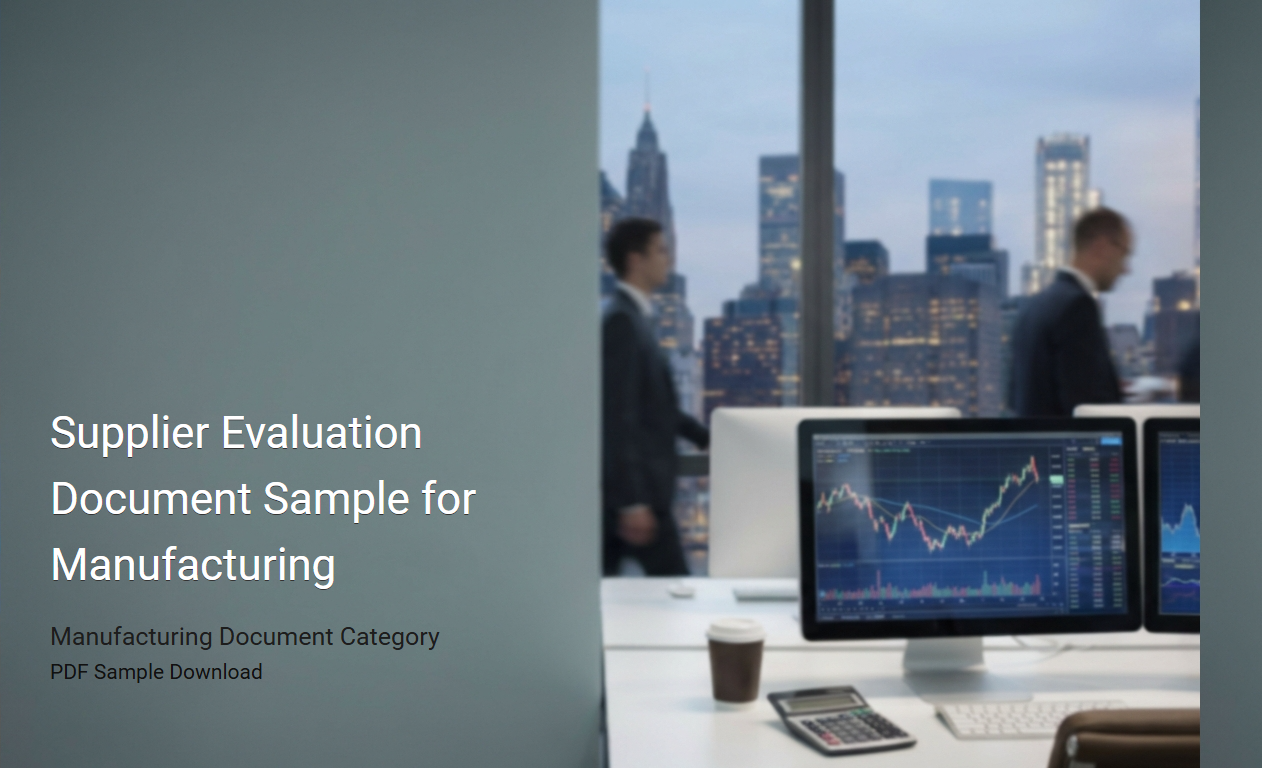

Supplier Quality Assessment Template for Manufacturing

A

Supplier Quality Assessment Template for manufacturing is a structured document used to evaluate and monitor the quality standards of suppliers providing raw materials, components, or services. It ensures that supplier processes comply with industry regulations and internal quality requirements, enhancing product consistency and reducing risks of defects. This template typically includes criteria such as supplier audit results, material certifications, process capabilities, and corrective action tracking.

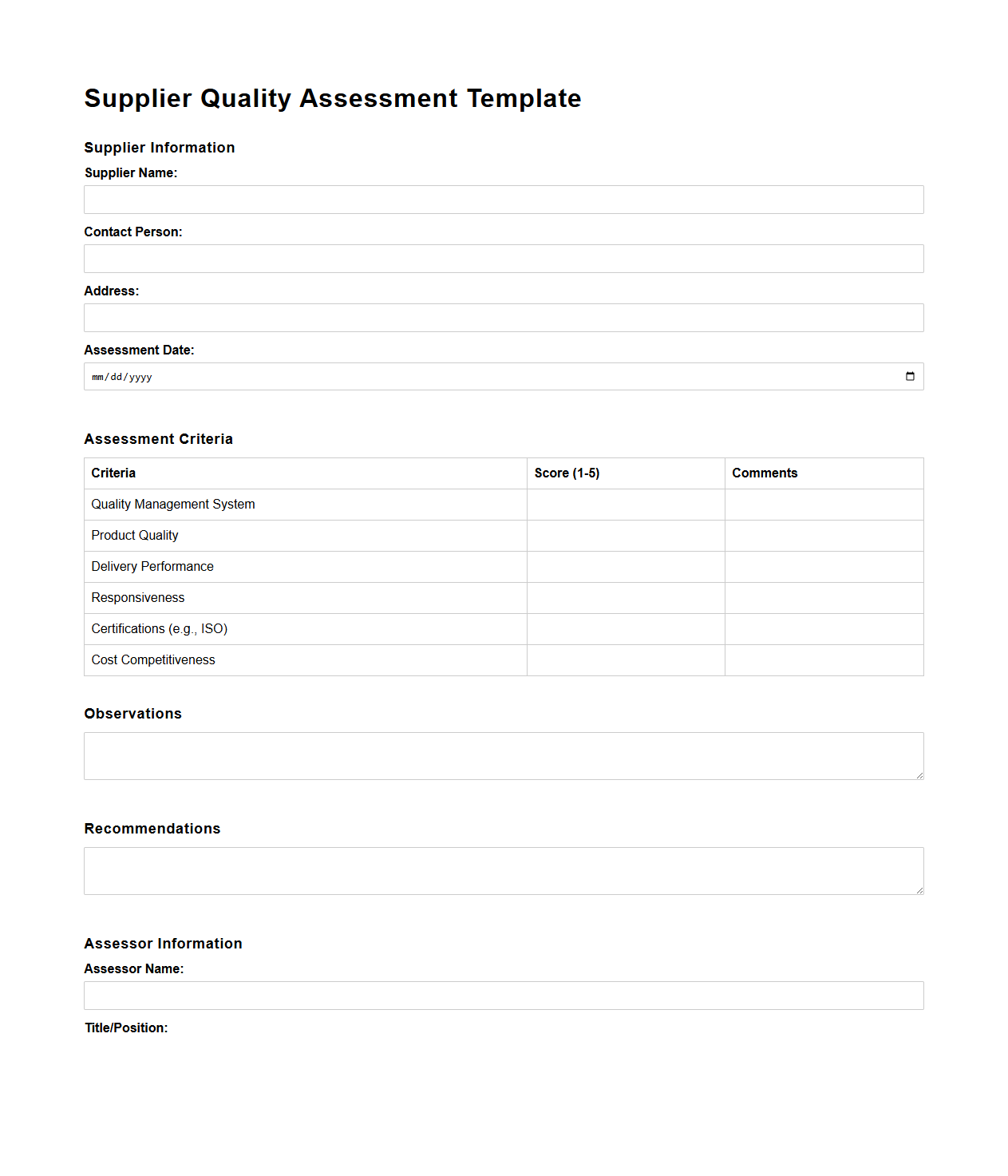

Manufacturing Supplier Performance Review Sample

A

Manufacturing Supplier Performance Review Sample document serves as a structured template to evaluate and analyze the efficiency, quality, and reliability of suppliers within the manufacturing process. It outlines key performance indicators such as delivery timeliness, defect rates, compliance with specifications, and communication effectiveness. This document helps organizations maintain high supplier standards, optimize procurement strategies, and drive continuous improvement in the supply chain.

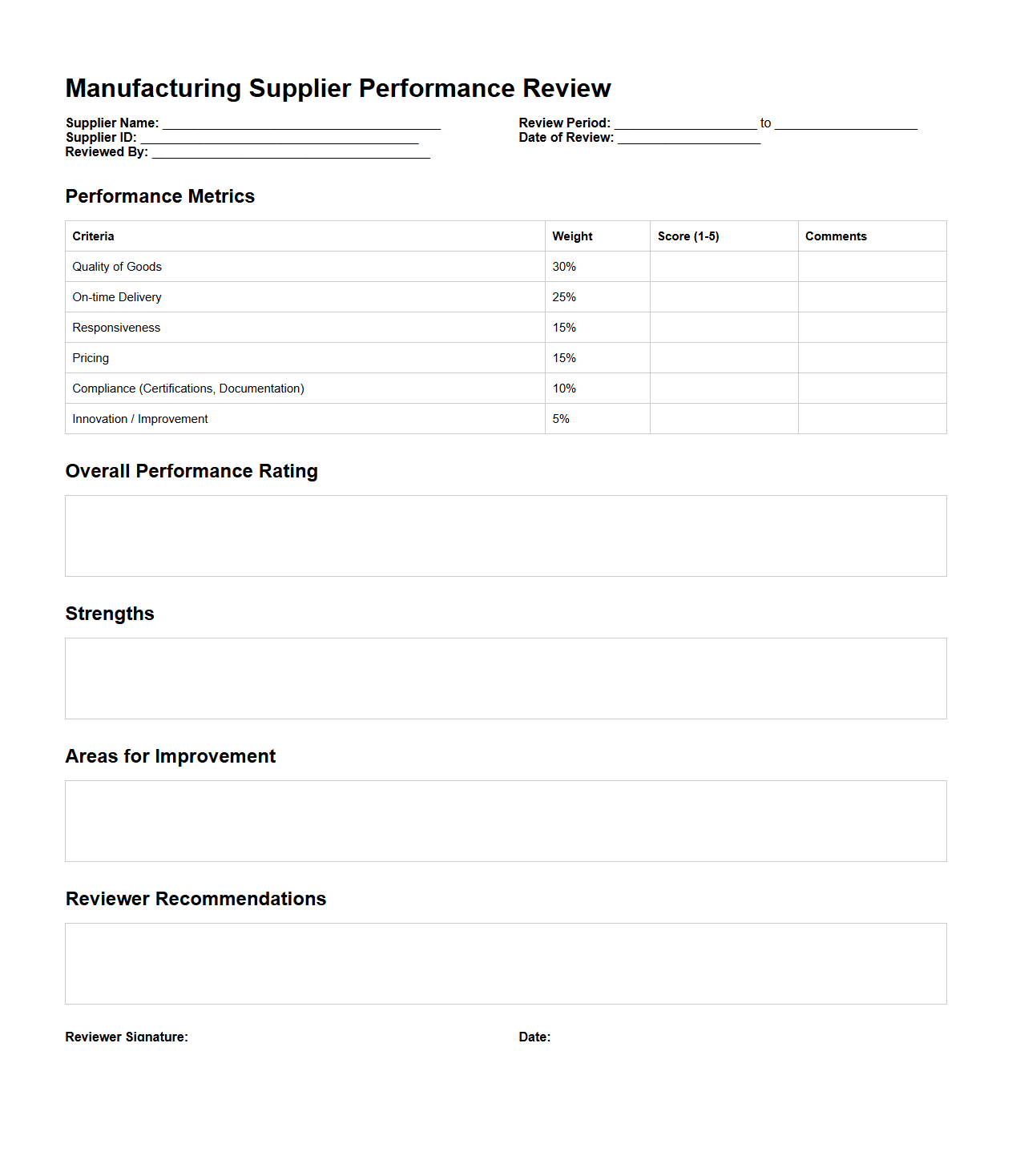

Supplier Capability Evaluation Form for Factories

The

Supplier Capability Evaluation Form for Factories is a comprehensive document designed to assess a supplier's operational efficiency, production capacity, and quality control measures. It collects detailed information on manufacturing processes, equipment condition, compliance with industry standards, and workforce skills. This evaluation ensures factories meet specific criteria to maintain product quality and supply chain reliability.

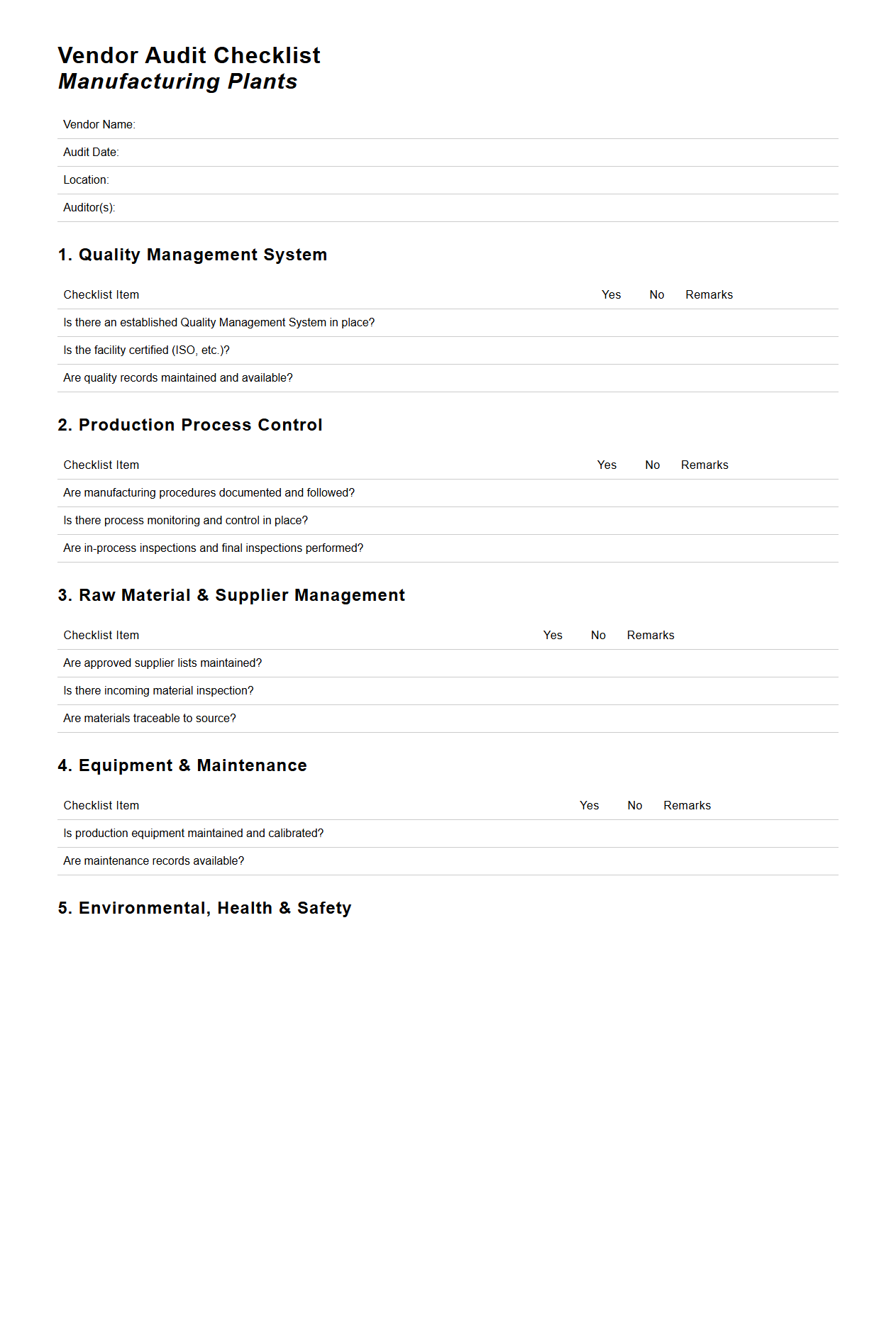

Vendor Audit Checklist for Manufacturing Plants

A

Vendor Audit Checklist for Manufacturing Plants document serves as a comprehensive tool to evaluate and ensure supplier compliance with industry standards, quality requirements, and regulatory guidelines. It systematically reviews aspects such as production processes, quality control systems, material handling, and safety protocols to mitigate risks and enhance supply chain reliability. This checklist supports manufacturing plants in maintaining consistent product quality and operational efficiency by identifying potential weaknesses in vendor performance.

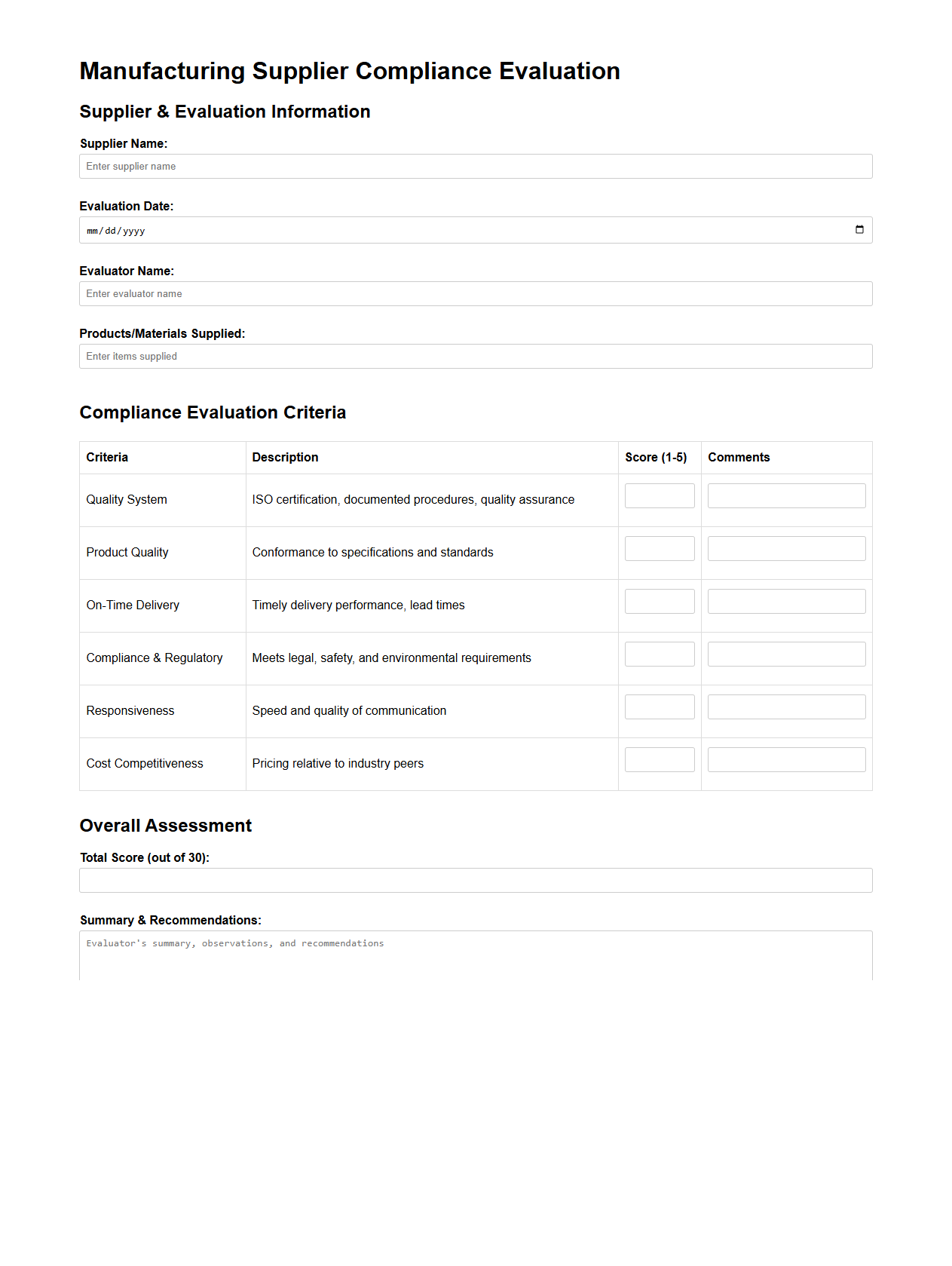

Manufacturing Supplier Compliance Evaluation Example

A

Manufacturing Supplier Compliance Evaluation Example document serves as a critical tool to assess and verify a supplier's adherence to industry standards, regulatory requirements, and contractual obligations. It typically includes criteria such as quality control processes, safety standards, delivery performance, and environmental compliance, providing a structured framework to measure supplier reliability and risk. Utilizing this document helps manufacturers ensure consistent product quality, reduce supply chain disruptions, and maintain compliance with legal and ethical guidelines.

Supplier Risk Assessment Report for Manufacturing

A

Supplier Risk Assessment Report for manufacturing is a detailed document that evaluates the potential risks associated with a supplier's ability to deliver quality materials or components on time. It includes analysis of factors such as financial stability, compliance with industry standards, supply chain reliability, and past performance to identify vulnerabilities that could impact production. This report helps manufacturers make informed decisions, ensuring supply chain resilience and minimizing disruptions.

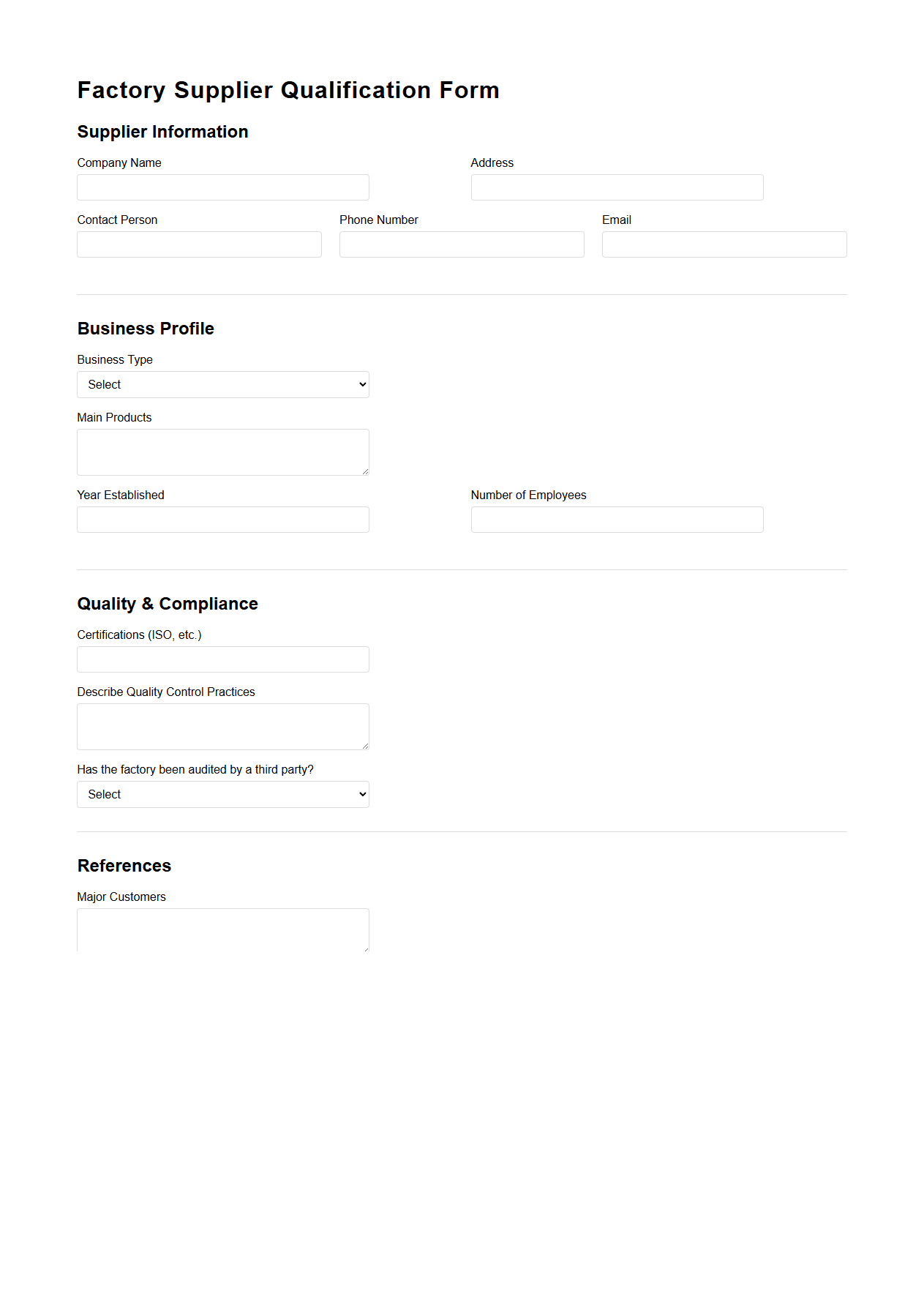

Factory Supplier Qualification Form Sample

A

Factory Supplier Qualification Form sample document is a standardized template used by companies to evaluate and verify the capabilities, compliance, and quality standards of potential suppliers or manufacturers. It typically includes sections for factory details, production capacity, certifications, quality control measures, and adherence to industry regulations. This document ensures systematic supplier assessment, minimizing risks and facilitating informed procurement decisions.

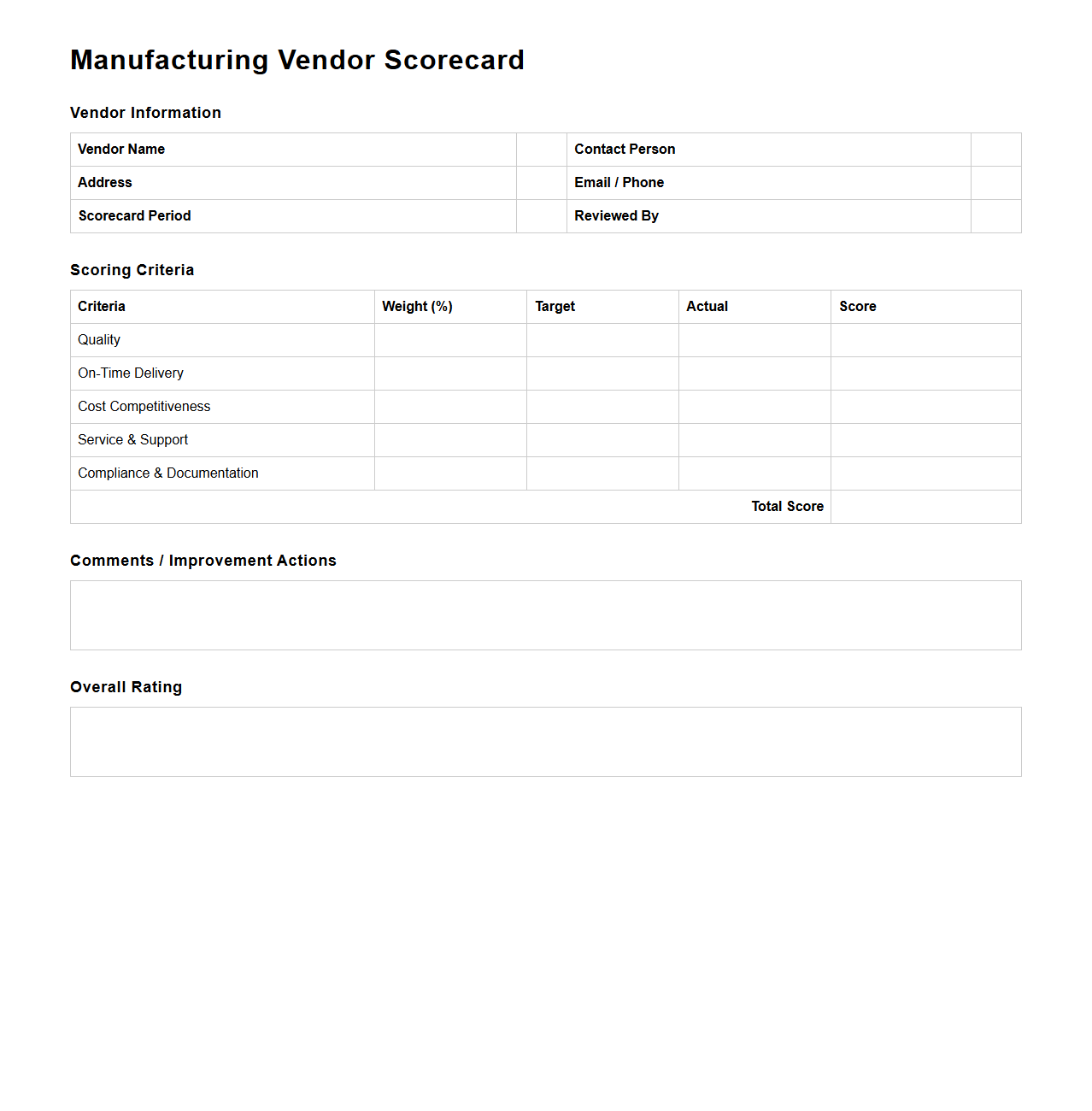

Manufacturing Vendor Scorecard Template

A

Manufacturing Vendor Scorecard Template document is a structured tool used to evaluate and track the performance of suppliers in the manufacturing process. It measures key criteria such as quality, delivery timeliness, cost efficiency, and compliance with industry standards, enabling companies to maintain consistent supplier quality and improve procurement decisions. This template facilitates clear communication between manufacturers and vendors, fostering accountability and continuous improvement.

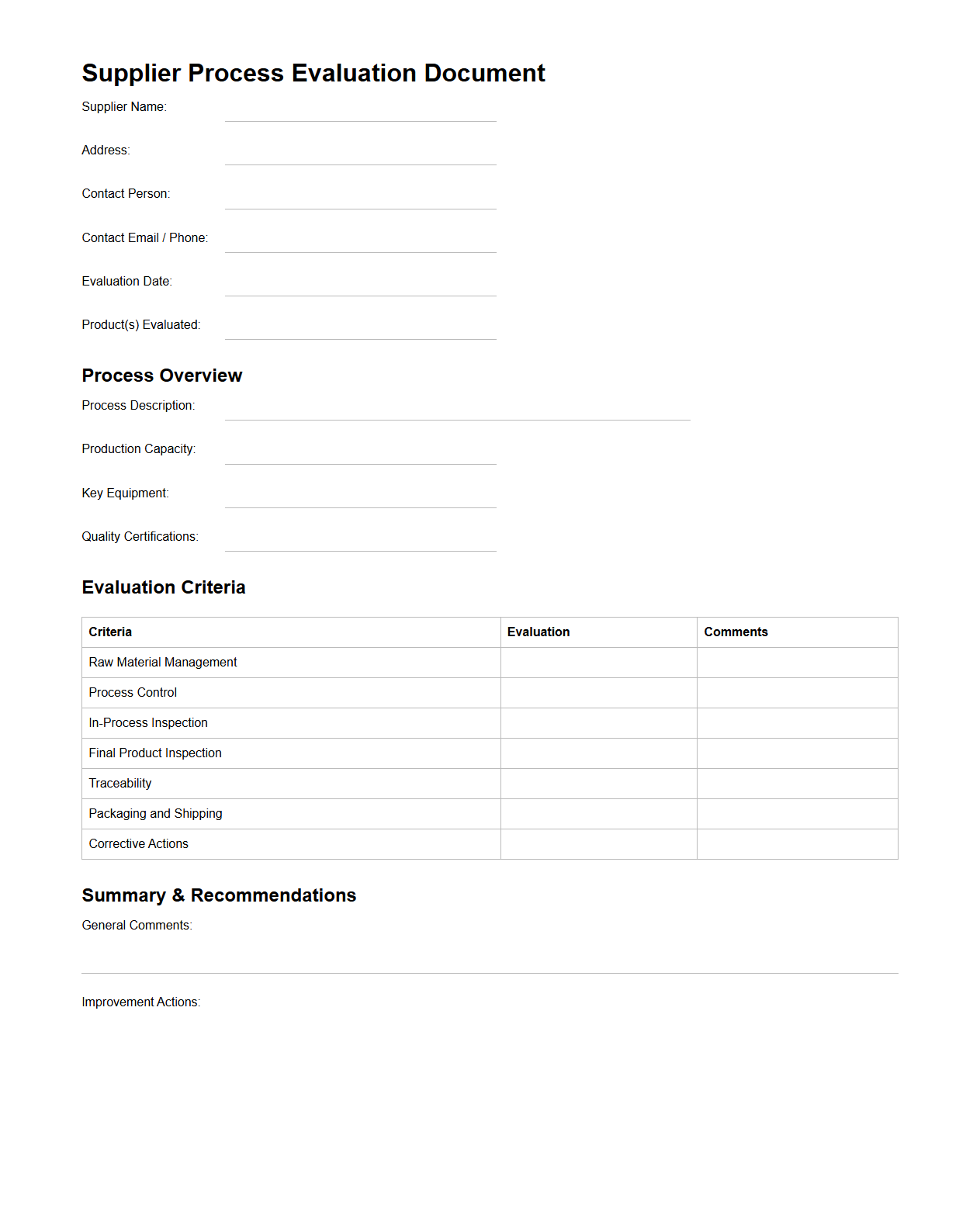

Supplier Process Evaluation Document for Manufacturing

The

Supplier Process Evaluation Document in manufacturing is a critical tool used to assess and verify a supplier's production capabilities, quality control measures, and compliance with industry standards before partnership. It includes detailed criteria such as process flow, equipment used, certifications, and risk mitigation strategies to ensure the supplier can consistently meet product specifications. This documentation helps manufacturers maintain high standards, reduce defects, and secure reliable supply chain performance.

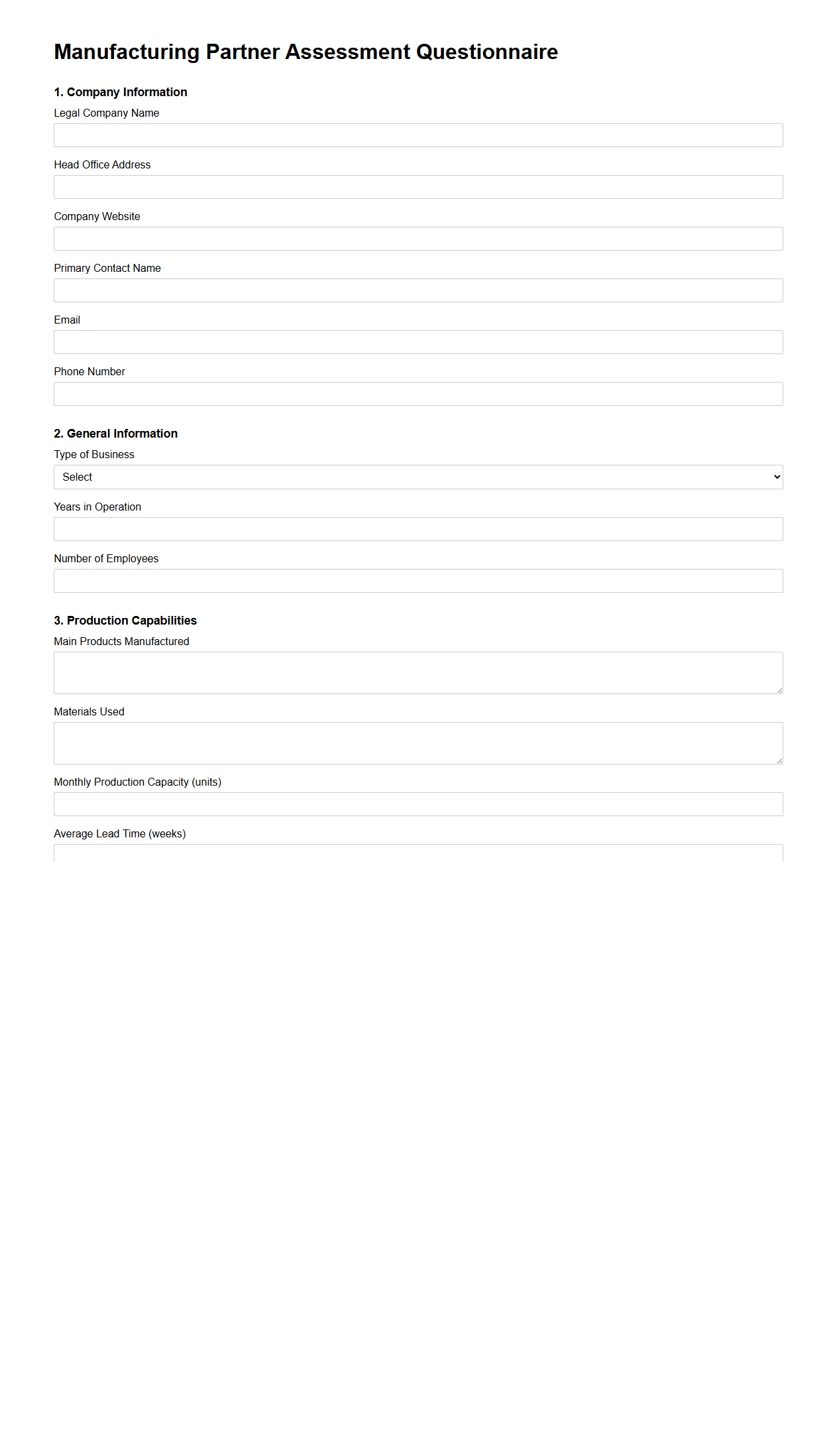

Manufacturing Partner Assessment Questionnaire

The

Manufacturing Partner Assessment Questionnaire is a critical tool used to evaluate the capabilities, quality standards, and compliance of potential or existing manufacturing partners. It collects detailed information on production processes, certifications, risk management, and supply chain transparency to ensure alignment with company requirements. This document helps mitigate risks, improve collaboration, and maintain consistent product quality across the manufacturing network.

What are the primary criteria used for supplier evaluation in this document?

The primary criteria for supplier evaluation include quality of products or services, delivery reliability, and compliance with agreed specifications. Cost competitiveness and financial stability are also critical factors to ensure long-term partnership viability. Additionally, suppliers are assessed on their environmental and social responsibility practices.

How is supplier performance measured and scored within this sample?

Supplier performance is measured using a scorecard system that quantifies key metrics such as on-time delivery, product quality, and responsiveness. Each category is assigned specific weights reflecting its importance, allowing for a composite performance score. Regular performance reviews help identify trends and areas needing improvement.

What documentation or evidence is required from suppliers during evaluation?

Suppliers must provide certificates of compliance, quality assurance reports, and delivery records as part of their evaluation package. Additionally, audit reports and corrective action documentation are required to verify adherence to standards. This ensures transparency and verification of supplier claims.

How does the document address corrective actions and follow-up for underperforming suppliers?

The document outlines a structured corrective action process including root cause analysis and action plans with defined timelines. Regular follow-up meetings monitor the progress of these corrective measures to ensure improvements. Continuous underperformance may lead to supplier probation or termination.

What frequency and review process are outlined for periodic supplier evaluations?

Supplier evaluations are conducted on a quarterly or biannual basis depending on the supplier's strategic importance. The review process involves cross-functional teams to provide comprehensive feedback. Results are communicated to suppliers, promoting ongoing dialogue and improvement.