A Safety Compliance Document Sample for Manufacturing outlines essential safety protocols and regulatory requirements specific to manufacturing environments. This document serves as a practical template to ensure workplace safety standards are met and hazards are effectively managed. Manufacturing companies use it to demonstrate adherence to OSHA regulations and promote a culture of safety among employees.

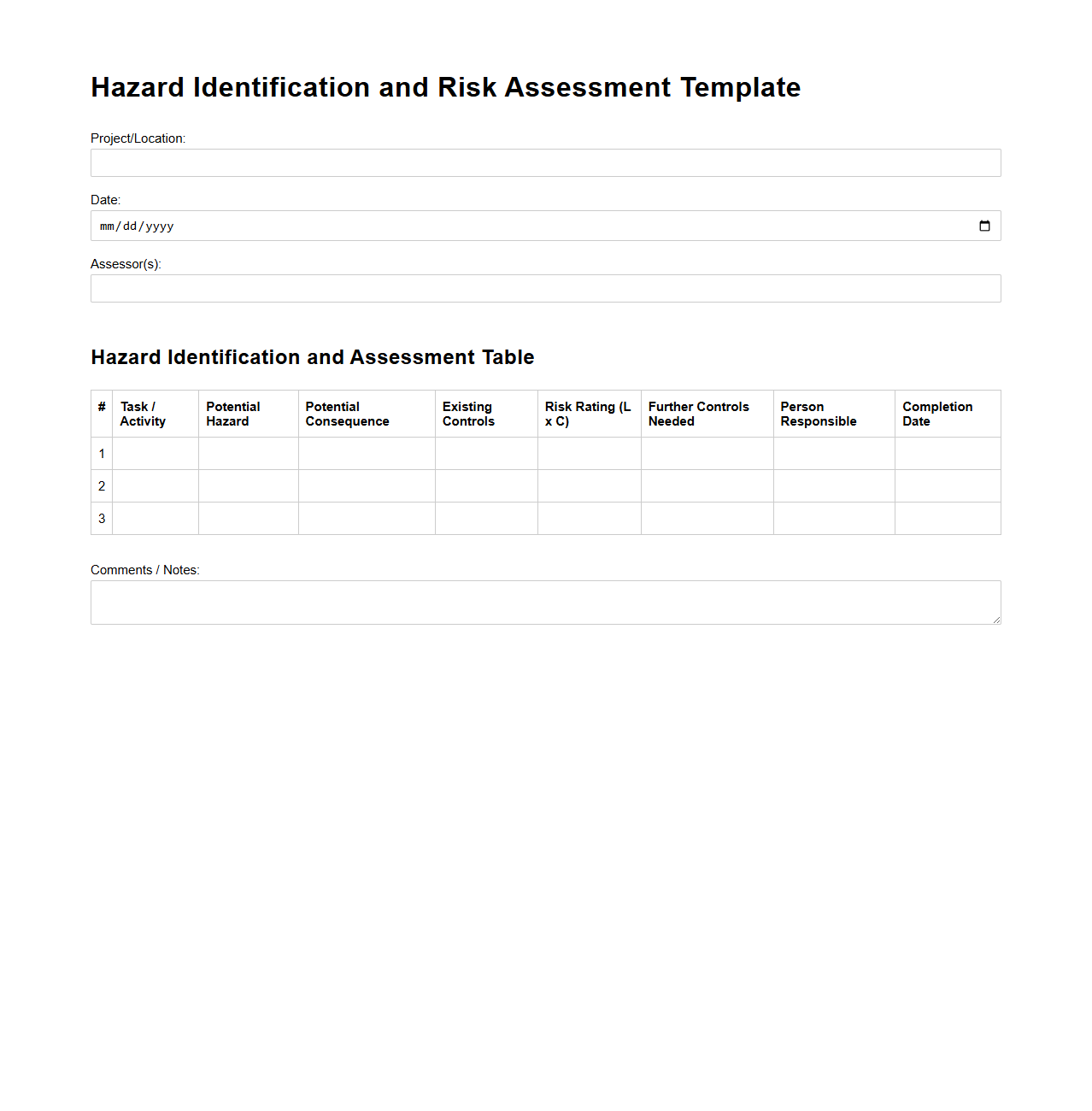

Hazard Identification and Risk Assessment Template

A

Hazard Identification and Risk Assessment Template document serves as a structured tool to systematically identify potential hazards and evaluate associated risks in a workplace or project environment. It helps organizations implement preventive measures by categorizing hazards based on severity and likelihood, ensuring compliance with safety regulations. This template facilitates clear communication among teams, enabling effective risk management and continuous improvement in health and safety protocols.

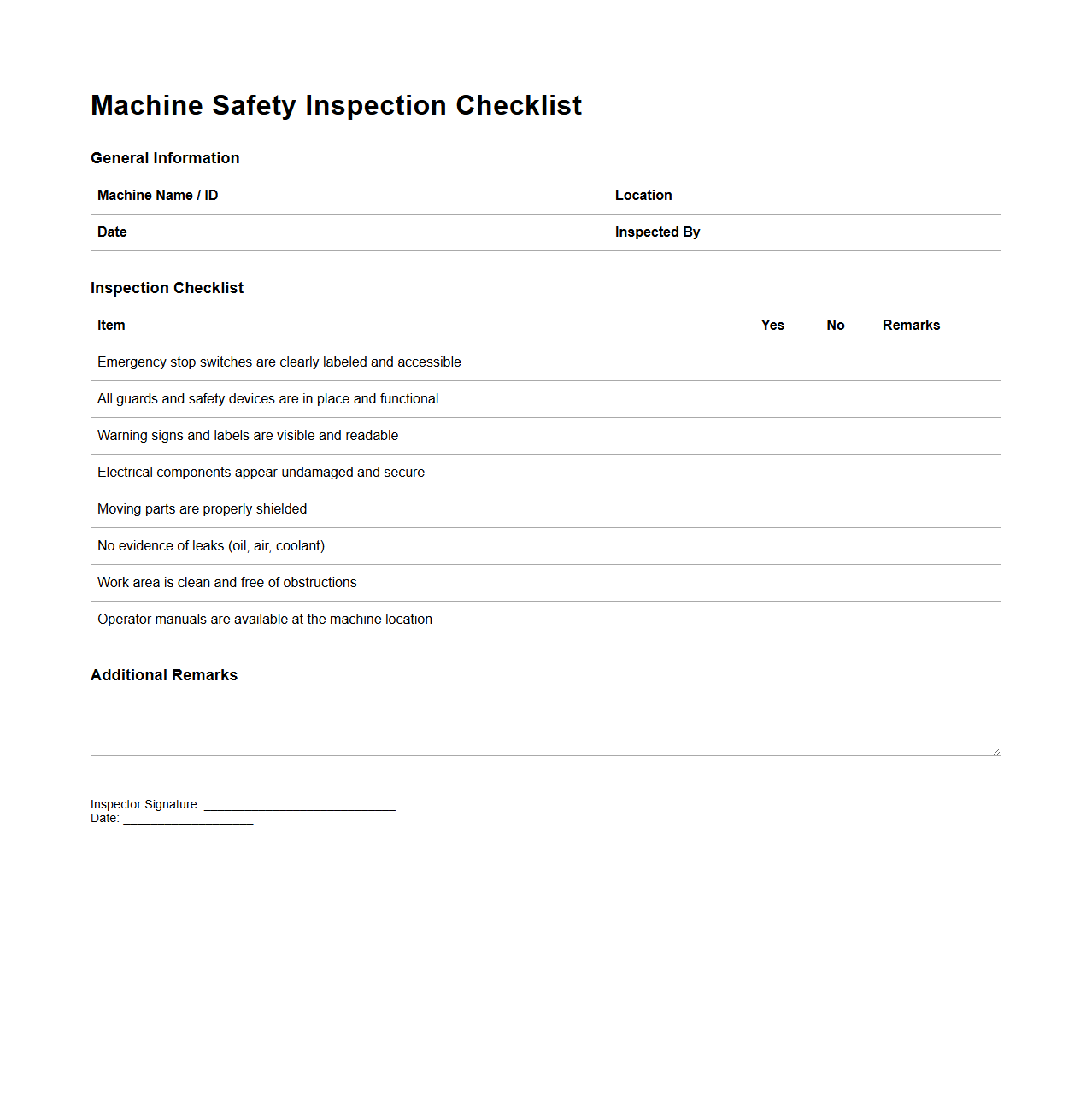

Machine Safety Inspection Checklist Sample

A

Machine Safety Inspection Checklist Sample document is a structured tool used to systematically evaluate the safety features and operational conditions of machinery. It helps identify potential hazards, ensure compliance with industry standards, and verify that all safety mechanisms, such as guards, emergency stops, and warning labels, are intact and functional. This checklist promotes workplace safety by providing a clear framework for regular inspections and maintenance of equipment.

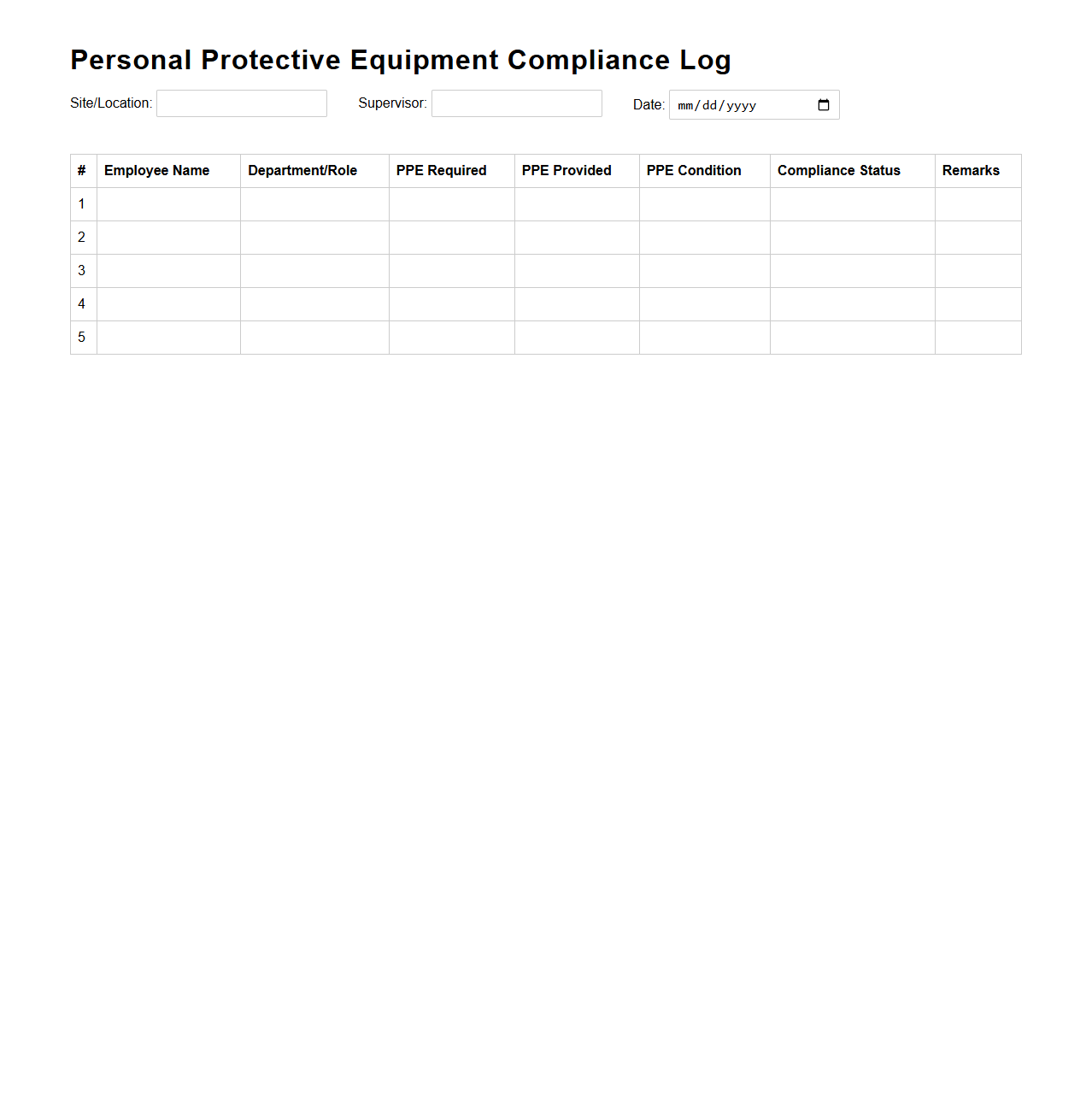

Personal Protective Equipment Compliance Log

A

Personal Protective Equipment Compliance Log document is a critical record used by organizations to track and verify the use of PPE by employees, ensuring adherence to safety regulations and workplace standards. This document helps monitor PPE distribution, maintenance, and employee training, reducing risks of injury and improving overall occupational health. Maintaining accurate compliance logs supports regulatory audits and enhances workplace safety culture.

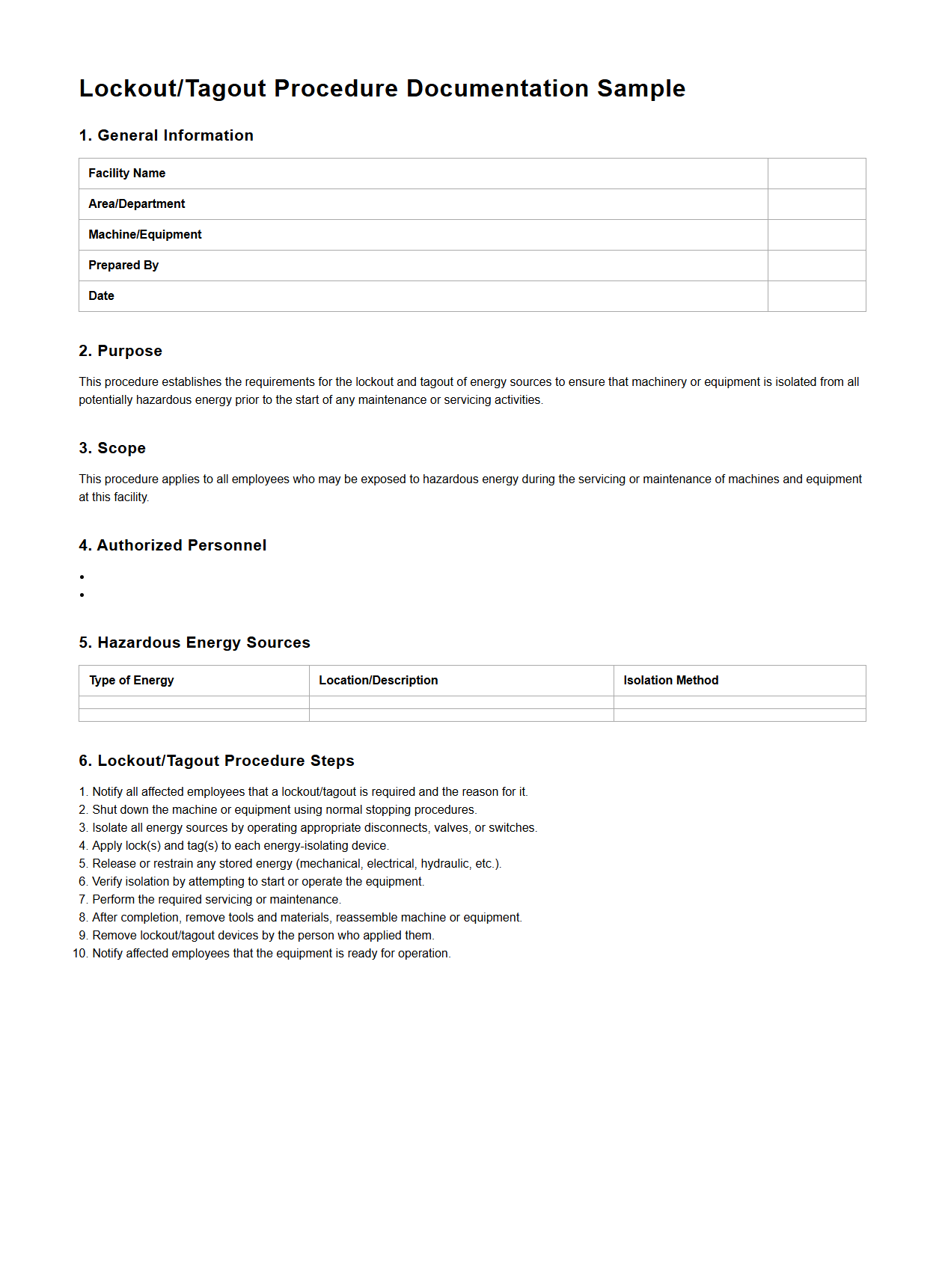

Lockout/Tagout Procedure Documentation Sample

A

Lockout/Tagout Procedure Documentation Sample document provides a detailed template outlining the steps required to safely disable machinery and equipment during maintenance or repair. It includes specific instructions on how to isolate energy sources, place lockout devices, and apply tags to prevent accidental startup, ensuring compliance with OSHA safety standards. This sample documentation is essential for training, auditing, and maintaining workplace safety protocols.

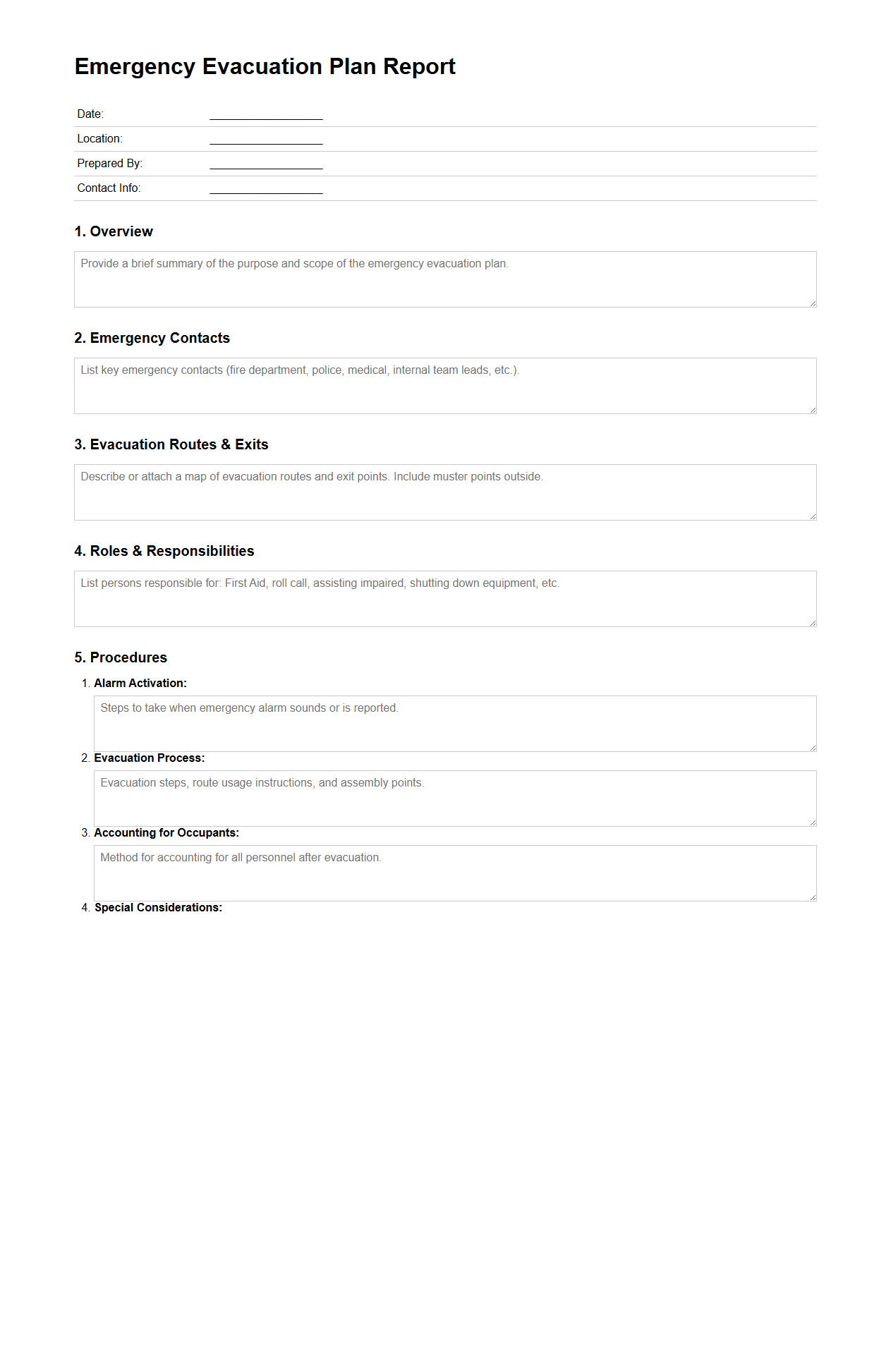

Emergency Evacuation Plan Report Template

An

Emergency Evacuation Plan Report Template document provides a structured framework for detailing procedures and routes to safely evacuate individuals during emergencies. It typically includes sections for identifying hazards, assigned responsibilities, communication protocols, and designated assembly points to ensure an organized response. This template is essential for organizations to create clear, actionable evacuation strategies that comply with safety regulations and minimize risks.

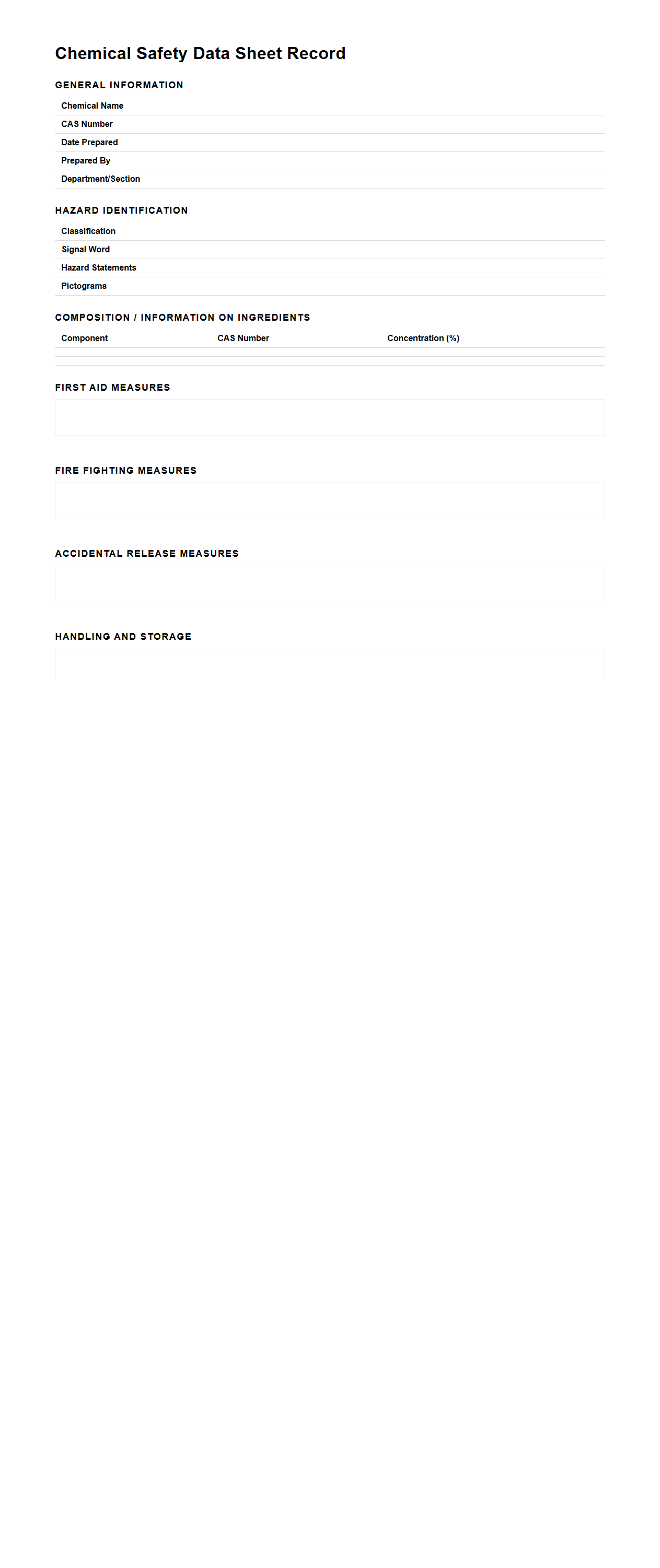

Chemical Safety Data Sheet Record Sample

A

Chemical Safety Data Sheet Record Sample document provides detailed information about the properties, hazards, safe handling, and emergency measures related to a specific chemical substance. It includes critical data such as physical and chemical characteristics, toxicity, first aid instructions, and storage requirements to ensure workplace safety and regulatory compliance. This document is essential for employers, safety officers, and workers to minimize risks and manage chemical exposures effectively.

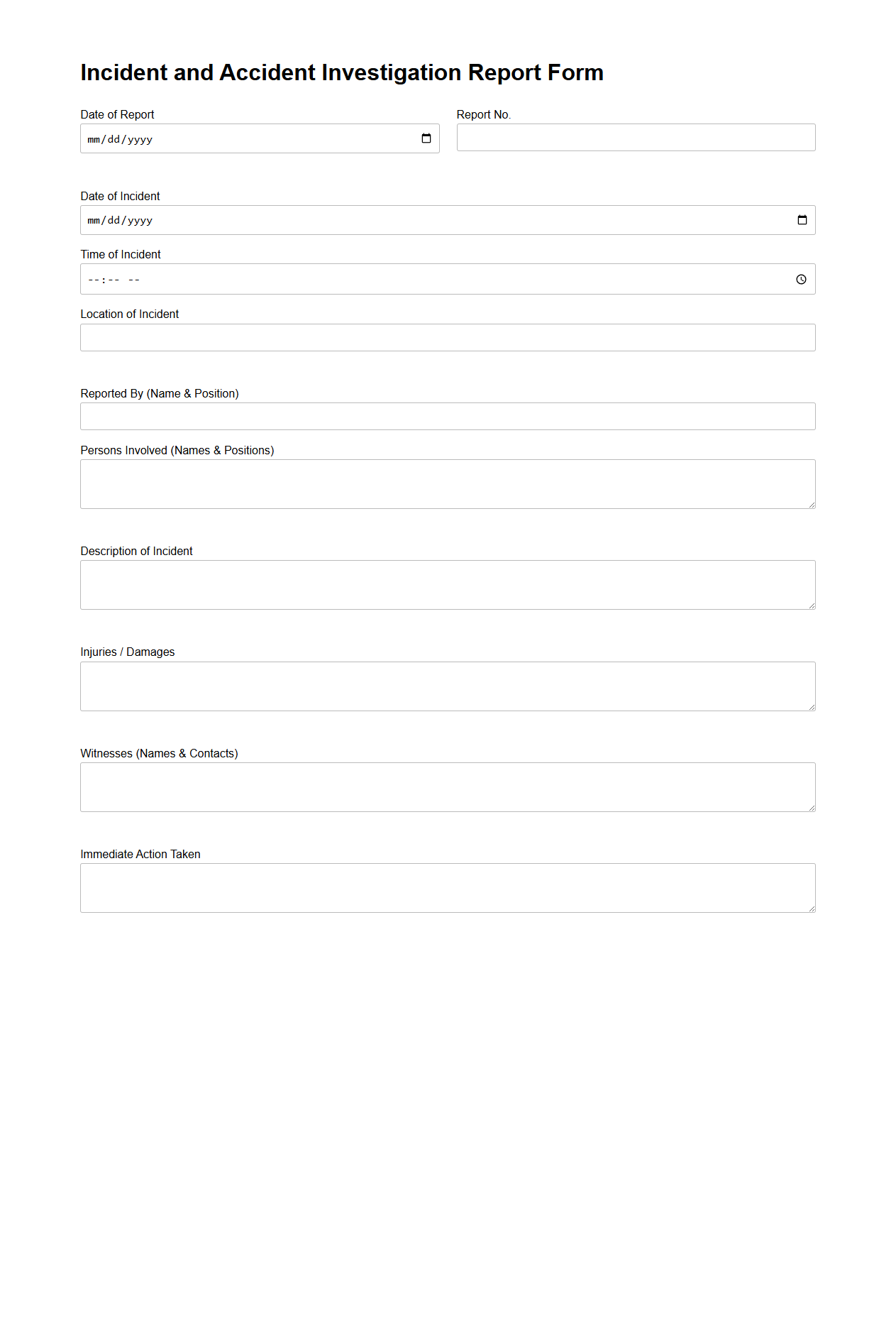

Incident and Accident Investigation Report Form

An

Incident and Accident Investigation Report Form is a structured document used to record detailed information about workplace incidents and accidents, facilitating thorough analysis. It captures essential data such as the date, location, people involved, cause, and consequences to identify root causes and prevent recurrence. Employers and safety professionals rely on these reports to comply with regulatory standards and improve occupational health and safety measures.

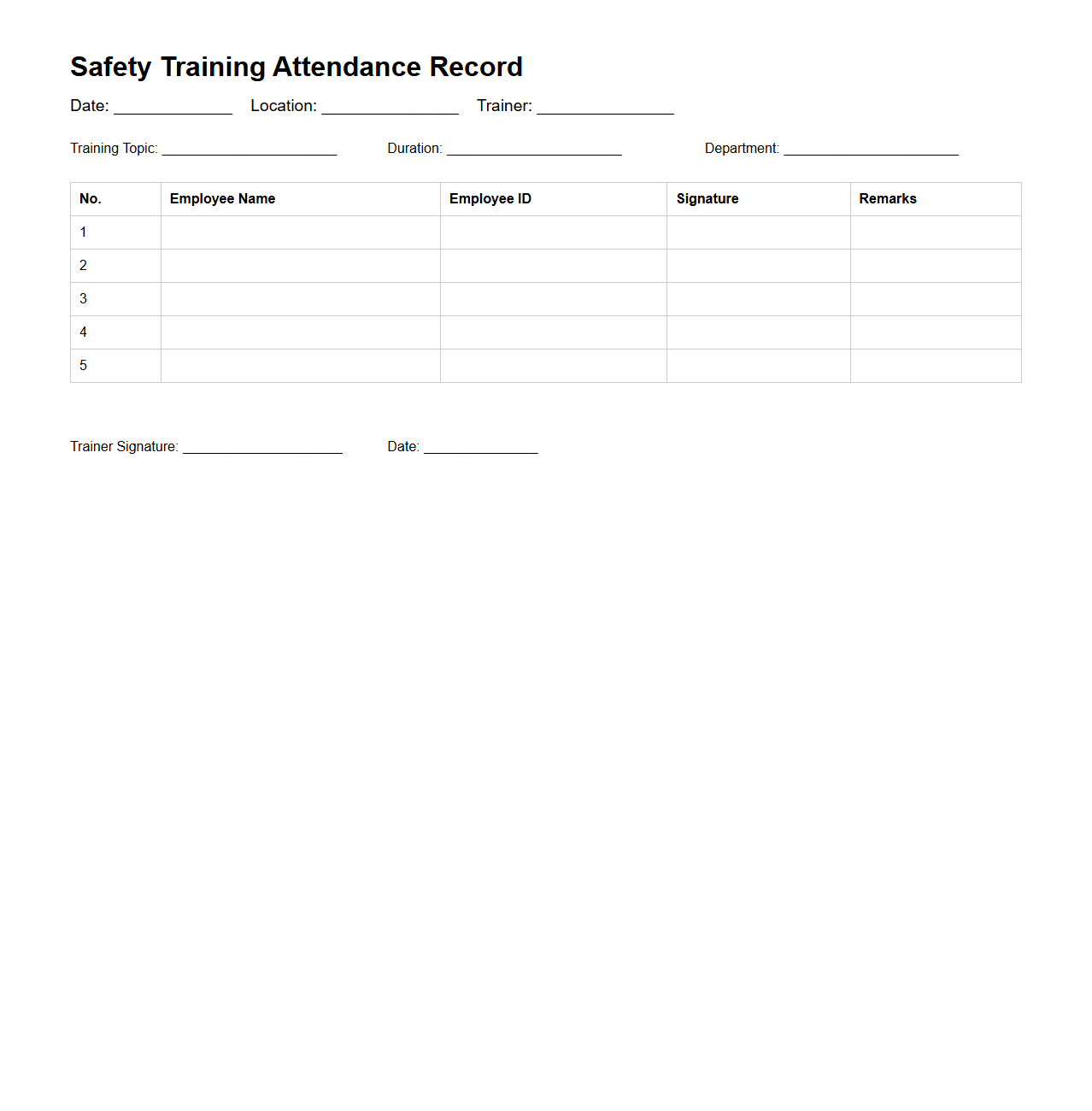

Safety Training Attendance Record Template

A

Safety Training Attendance Record Template document is designed to systematically capture and track employee participation in workplace safety training sessions. It includes essential fields such as employee names, training dates, topics covered, and signatures to ensure compliance with safety regulations. This template helps organizations maintain accurate records for audits and enhance overall workplace safety management.

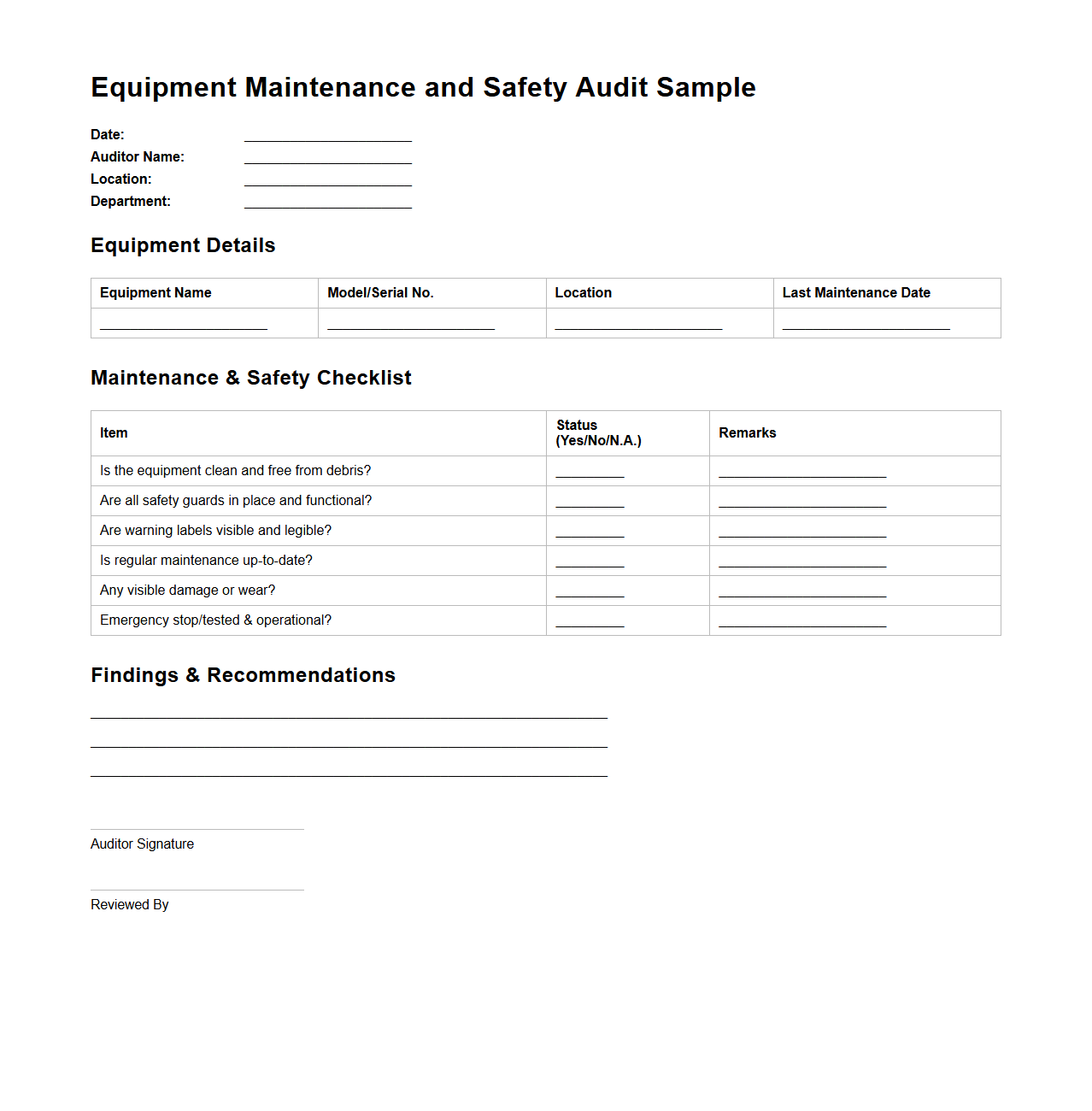

Equipment Maintenance and Safety Audit Sample

An

Equipment Maintenance and Safety Audit Sample document serves as a comprehensive template designed to systematically evaluate the condition and safety compliance of machinery and equipment in a workplace. It outlines specific criteria and checklists for inspecting operational efficiency, identifying potential hazards, and ensuring adherence to safety standards. This document is essential for minimizing downtime, preventing accidents, and maintaining regulatory compliance.

Workplace Safety Policy Statement Example

A

Workplace Safety Policy Statement Example document outlines an organization's commitment to maintaining a safe and healthy work environment. It serves as a formal declaration of safety priorities, responsibilities, and protocols designed to prevent accidents and ensure compliance with occupational health regulations. This statement typically highlights management's dedication to continuous safety improvement and employee well-being.

What personal protective equipment (PPE) requirements are outlined in the safety compliance document?

The safety compliance document mandates the use of essential personal protective equipment (PPE) such as helmets, gloves, eye protection, and steel-toed boots in all designated areas. It specifies that PPE must meet industry standards and be properly maintained to ensure maximum safety. Employees are required to wear the prescribed PPE at all times to minimize the risk of injury.

How does the document address emergency response procedures within the manufacturing facility?

The document outlines detailed emergency response procedures including clear evacuation routes, designated assembly points, and the roles of emergency response teams. It emphasizes regular drills and training to prepare employees for various types of emergencies such as fires or chemical spills. Additionally, it mandates the availability of emergency equipment like fire extinguishers and first aid kits throughout the facility.

What protocols are established for reporting workplace hazards according to the document?

The document establishes a formal hazard reporting protocol requiring immediate notification of supervisors or safety officers upon identification of any workplace risk. It encourages a no-retaliation policy to ensure employees feel safe reporting potential dangers. All reported hazards must be documented and addressed promptly to prevent accidents.

Which routine safety training and certification standards does the document mandate for employees?

The document requires employees to complete routine safety training and certification, including OSHA standards and site-specific hazard awareness programs. It mandates refresher courses at regular intervals to maintain compliance and reinforce safety best practices. Documentation of all completed certifications must be kept on file for auditing purposes.

How does the document define the process for conducting regular safety audits and inspections?

The process for regular safety audits and inspections is clearly defined, requiring scheduled evaluations by qualified safety personnel. The document stresses thorough reporting of findings, with corrective actions tracked until resolution. These audits help ensure ongoing compliance with safety standards and continuous improvement of workplace conditions.

More Manufacturing Templates