A Preventive Maintenance Schedule Document Sample for Manufacturing outlines planned maintenance activities to ensure machinery and equipment operate efficiently and reduce downtime. It includes detailed timelines, tasks, and responsible personnel to systematically prevent unexpected breakdowns. This document helps manufacturing facilities maintain equipment reliability and optimize production processes.

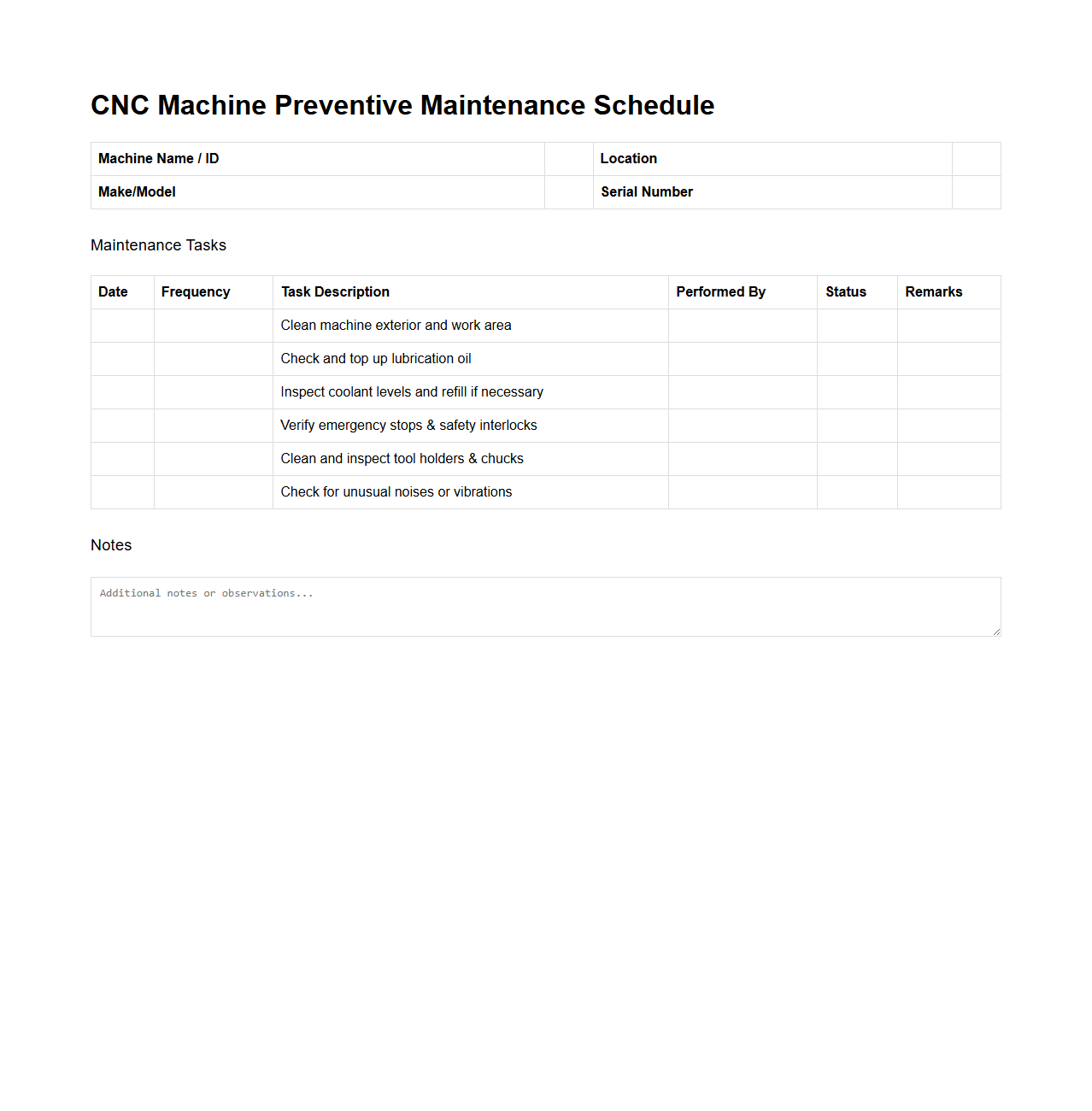

CNC Machine Preventive Maintenance Schedule Template

A

CNC Machine Preventive Maintenance Schedule Template document is a structured tool designed to systematically track and plan routine maintenance tasks for Computer Numerical Control (CNC) machines. It helps ensure timely inspections, lubrication, calibration, and part replacements, reducing unexpected downtime and enhancing machine longevity. This template improves operational efficiency by providing clear guidelines and timelines for maintenance activities tailored to specific CNC equipment requirements.

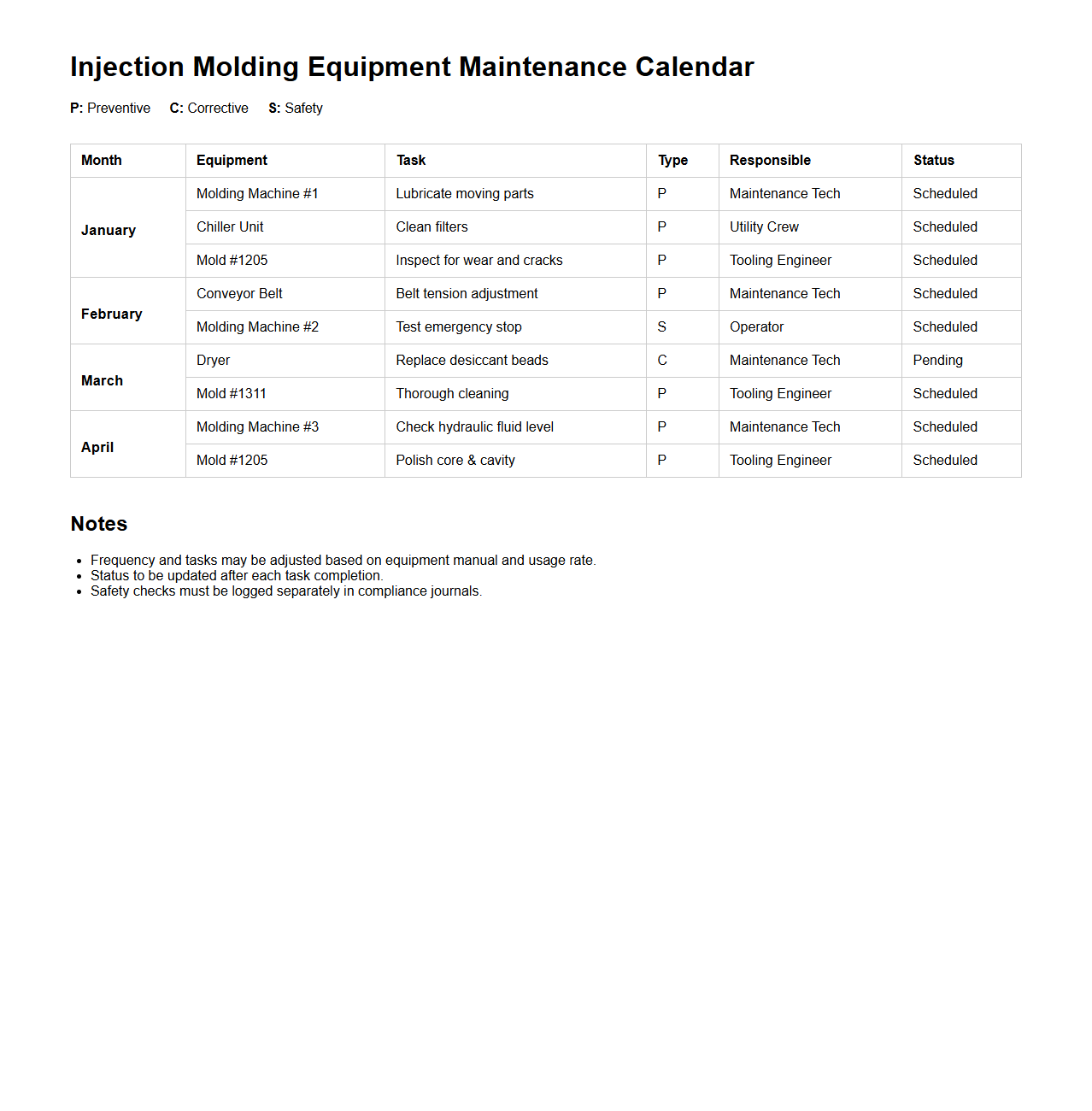

Injection Molding Equipment Maintenance Calendar Example

An

Injection Molding Equipment Maintenance Calendar Example document outlines a scheduled plan for routine inspections, servicing, and repairs of injection molding machines to ensure optimal performance and reduce downtime. It typically includes dates, specific maintenance tasks such as cleaning, lubrication, part replacement, and operational checks, along with assigned personnel and safety precautions. This organized approach helps in extending equipment lifespan, improving product quality, and maintaining consistent production efficiency.

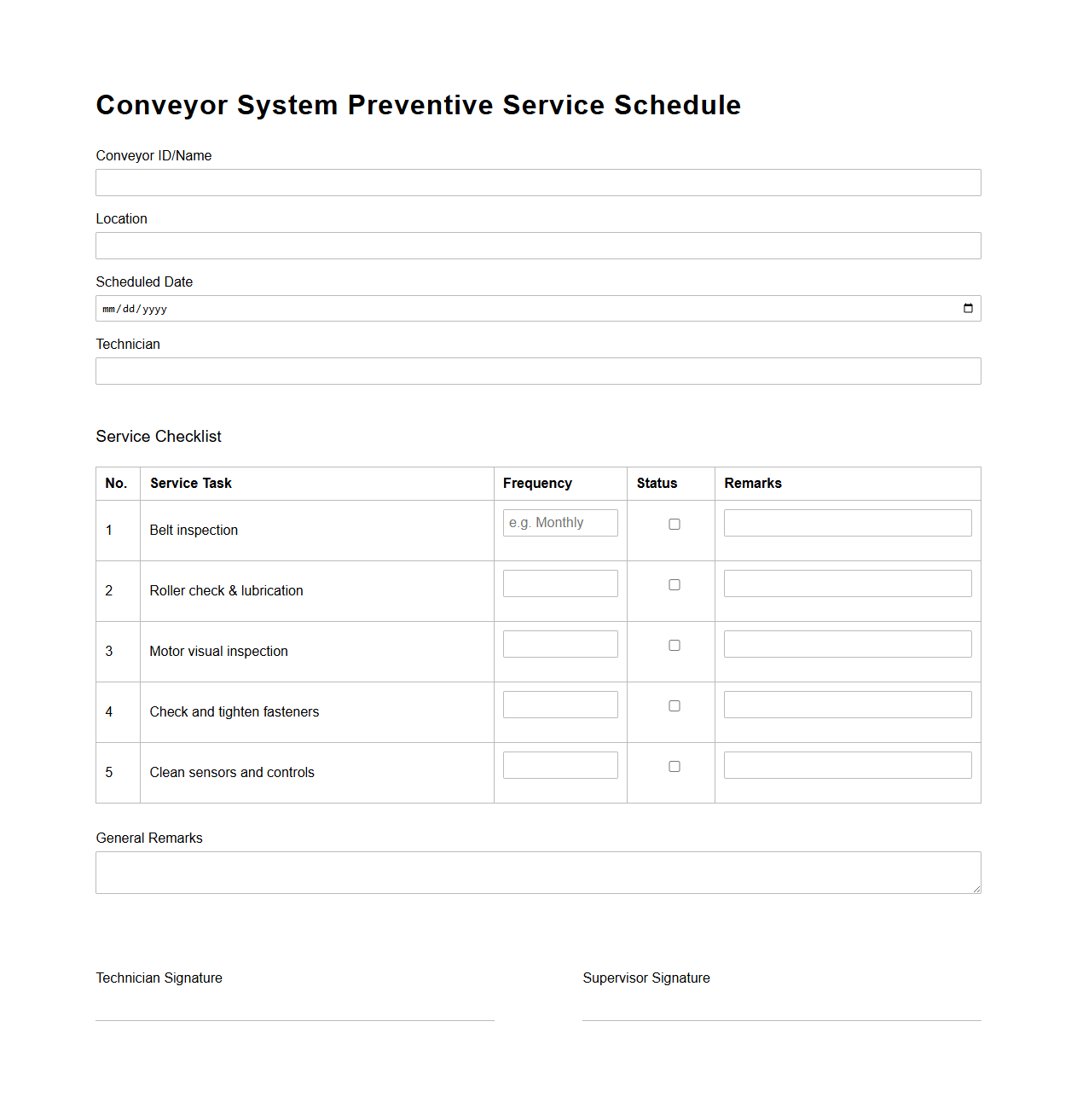

Conveyor System Preventive Service Schedule Format

The

Conveyor System Preventive Service Schedule Format document outlines a structured timetable for regular maintenance tasks to ensure optimal performance and longevity of conveyor systems. It details specific inspection points, service intervals, and maintenance activities essential for preventing unexpected breakdowns and minimizing downtime. This format serves as a critical tool for maintenance teams to systematically track and execute preventive measures, enhancing operational efficiency and safety.

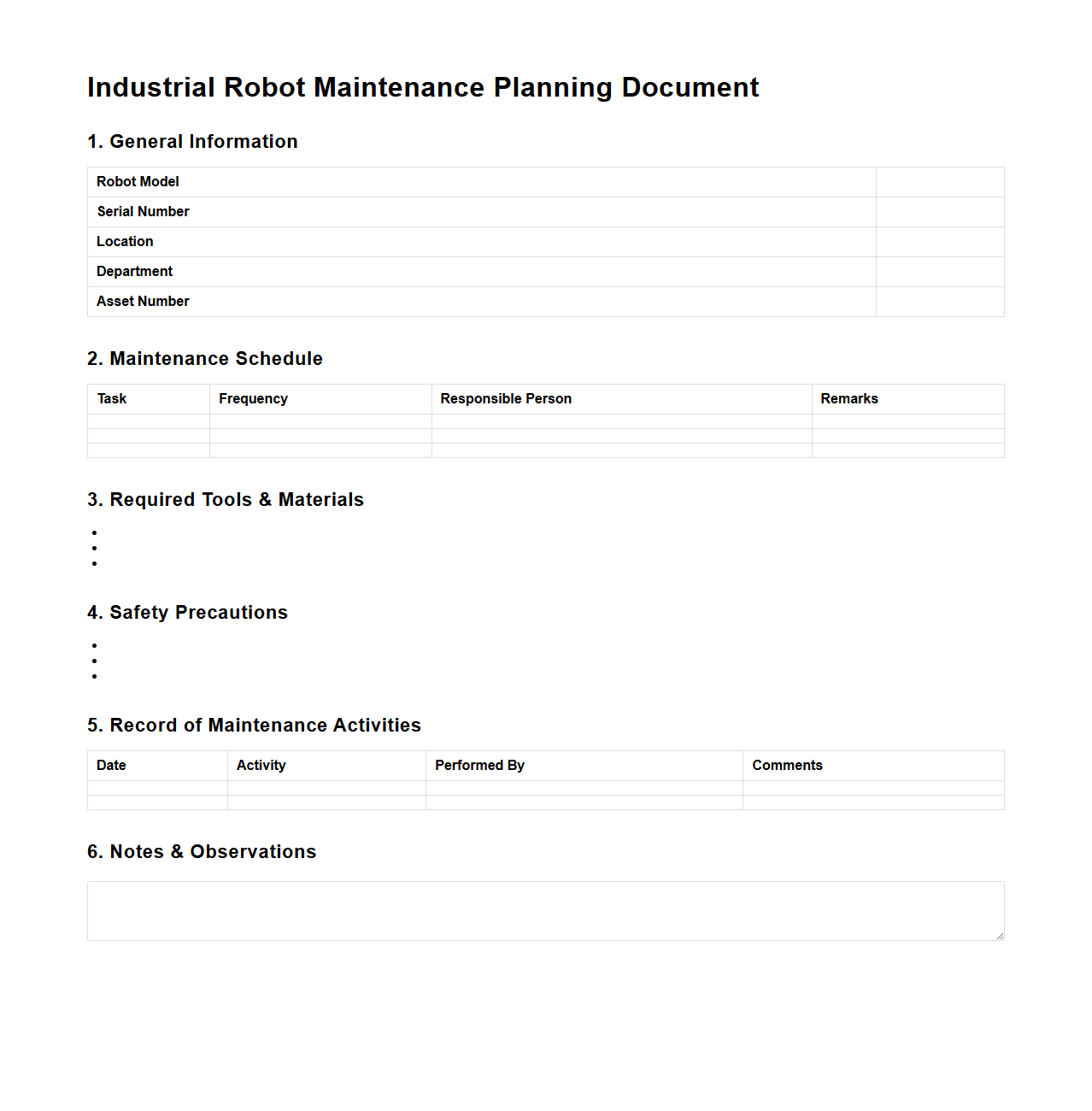

Industrial Robot Maintenance Planning Document

The

Industrial Robot Maintenance Planning Document outlines systematic procedures and schedules to ensure optimal performance and longevity of robots used in manufacturing and automation. It includes detailed maintenance tasks, timelines, resource allocation, and safety protocols tailored to specific robot models and operational environments. Effective planning minimizes downtime, reduces repair costs, and enhances overall production efficiency.

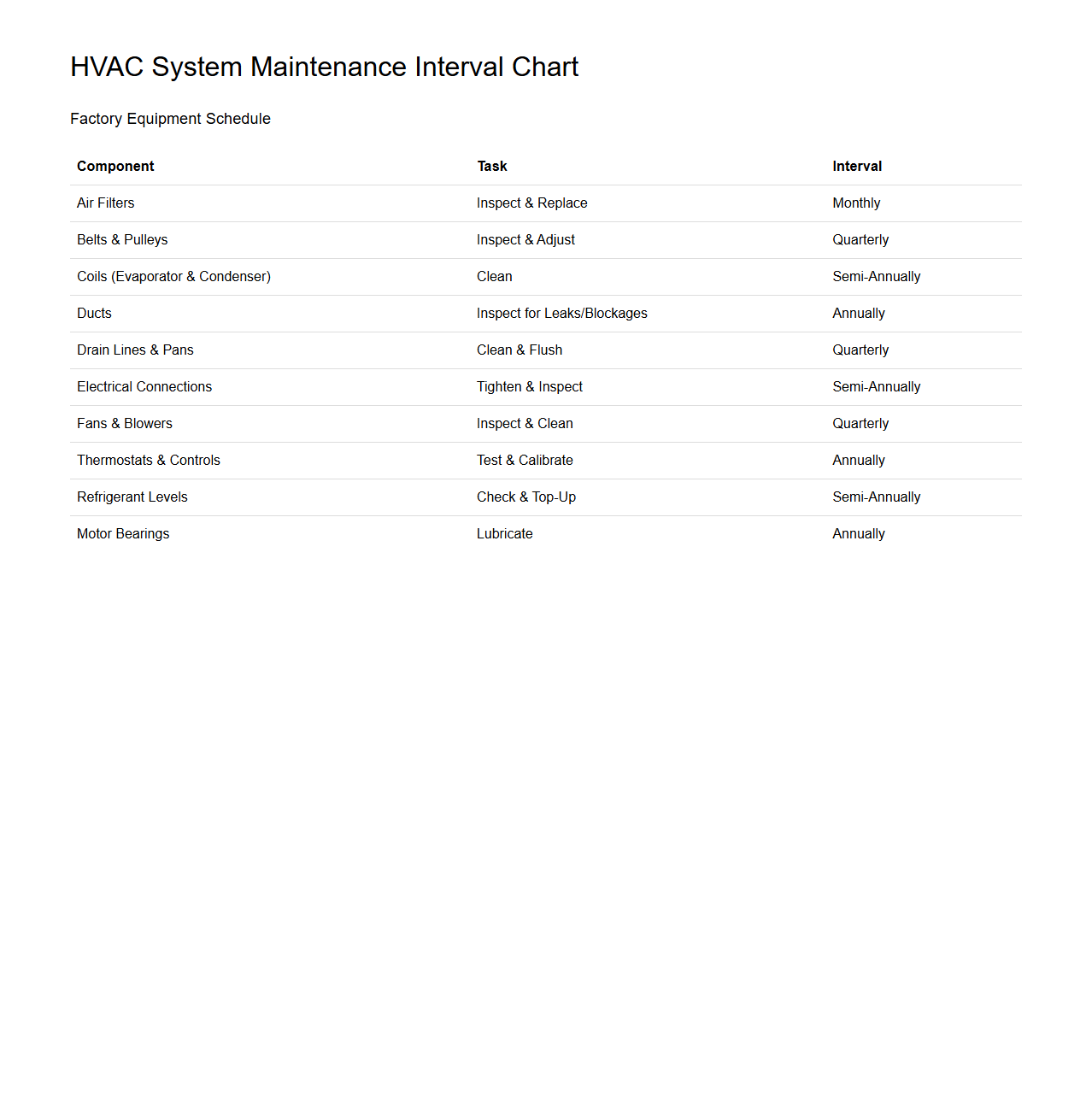

HVAC System Maintenance Interval Chart for Factories

The

HVAC System Maintenance Interval Chart for Factories document outlines scheduled maintenance tasks and recommended timeframes to ensure optimal performance of heating, ventilation, and air conditioning systems in industrial environments. It serves as a critical reference for factory facility managers to prevent equipment failures, enhance energy efficiency, and maintain indoor air quality. Regular adherence to these intervals minimizes downtime and extends the lifespan of HVAC components.

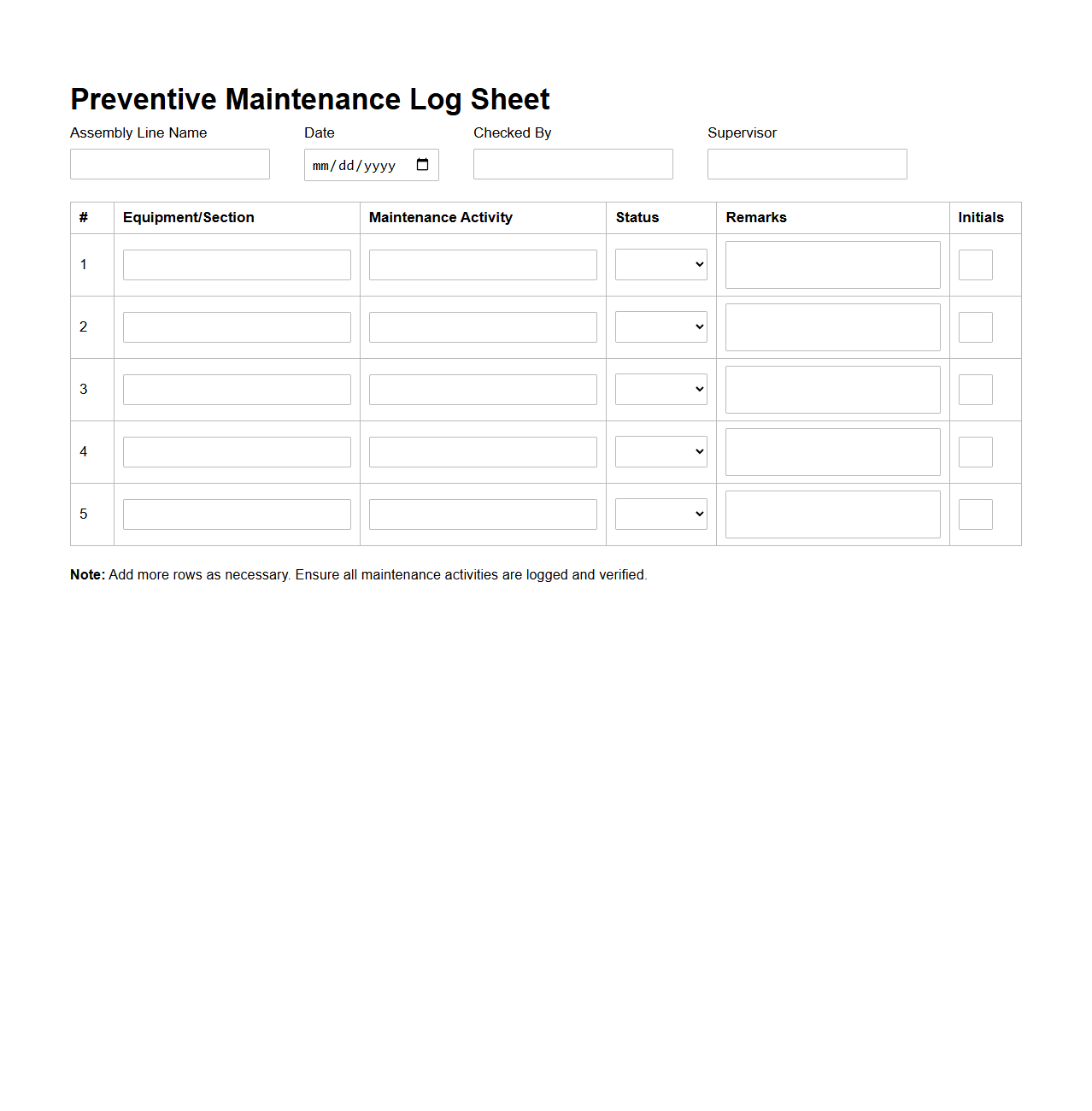

Preventive Maintenance Log Sheet for Assembly Lines

A

Preventive Maintenance Log Sheet for assembly lines is a detailed record used to track routine maintenance tasks designed to prevent equipment breakdowns and ensure smooth production flow. This document includes data on inspection dates, maintenance activities performed, parts replaced, and any anomalies detected, enabling timely interventions. Consistent use of this log enhances equipment reliability, reduces downtime, and supports compliance with safety standards.

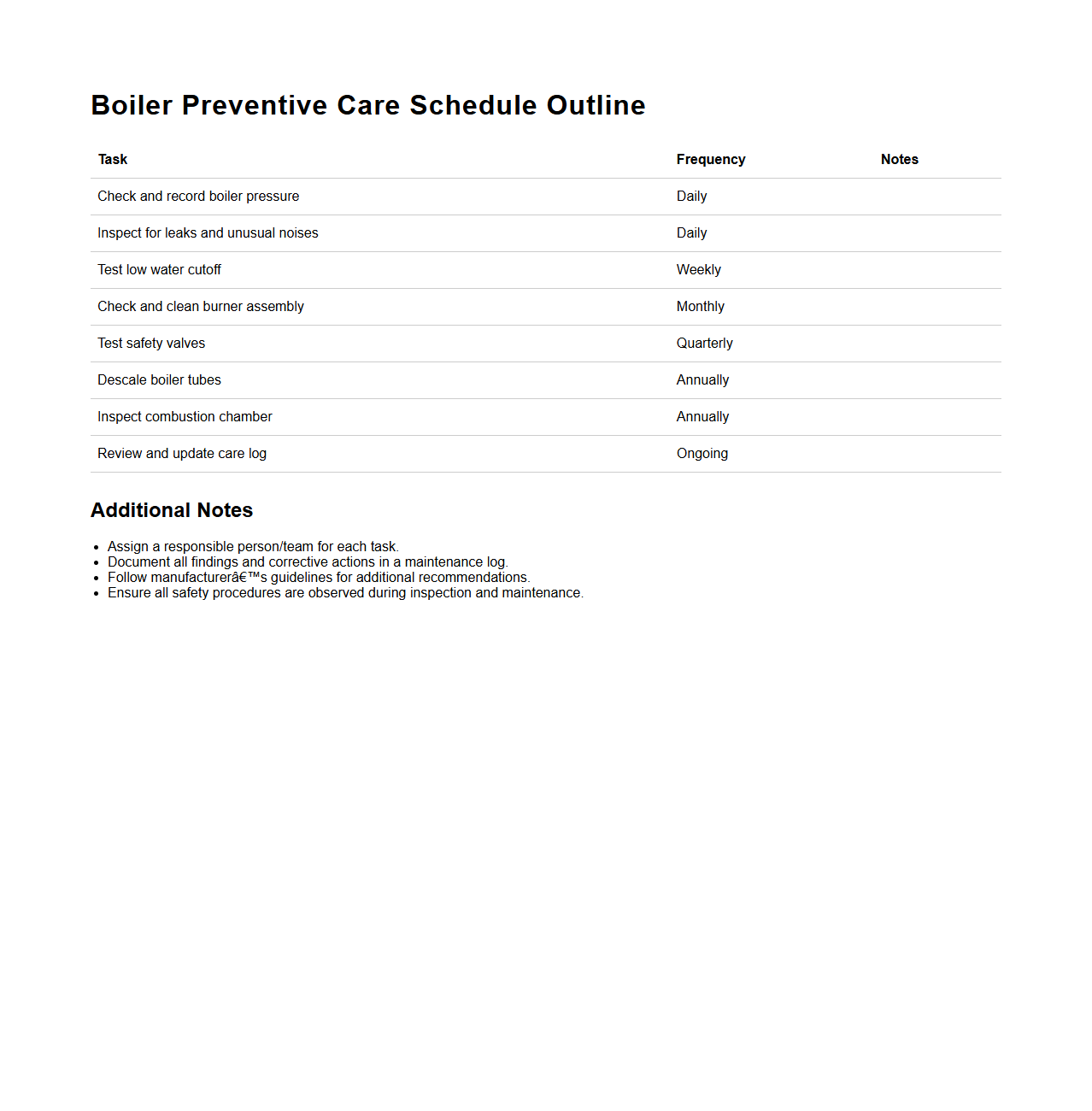

Boiler Preventive Care Schedule Outline

A

Boiler Preventive Care Schedule Outline document provides a detailed plan for regular maintenance and inspection activities designed to ensure optimal boiler performance and longevity. It includes timelines for routine checks, cleaning, safety inspections, and component replacements to prevent unexpected breakdowns and improve operational efficiency. This schedule enhances safety compliance and minimizes costly repairs by addressing potential issues proactively.

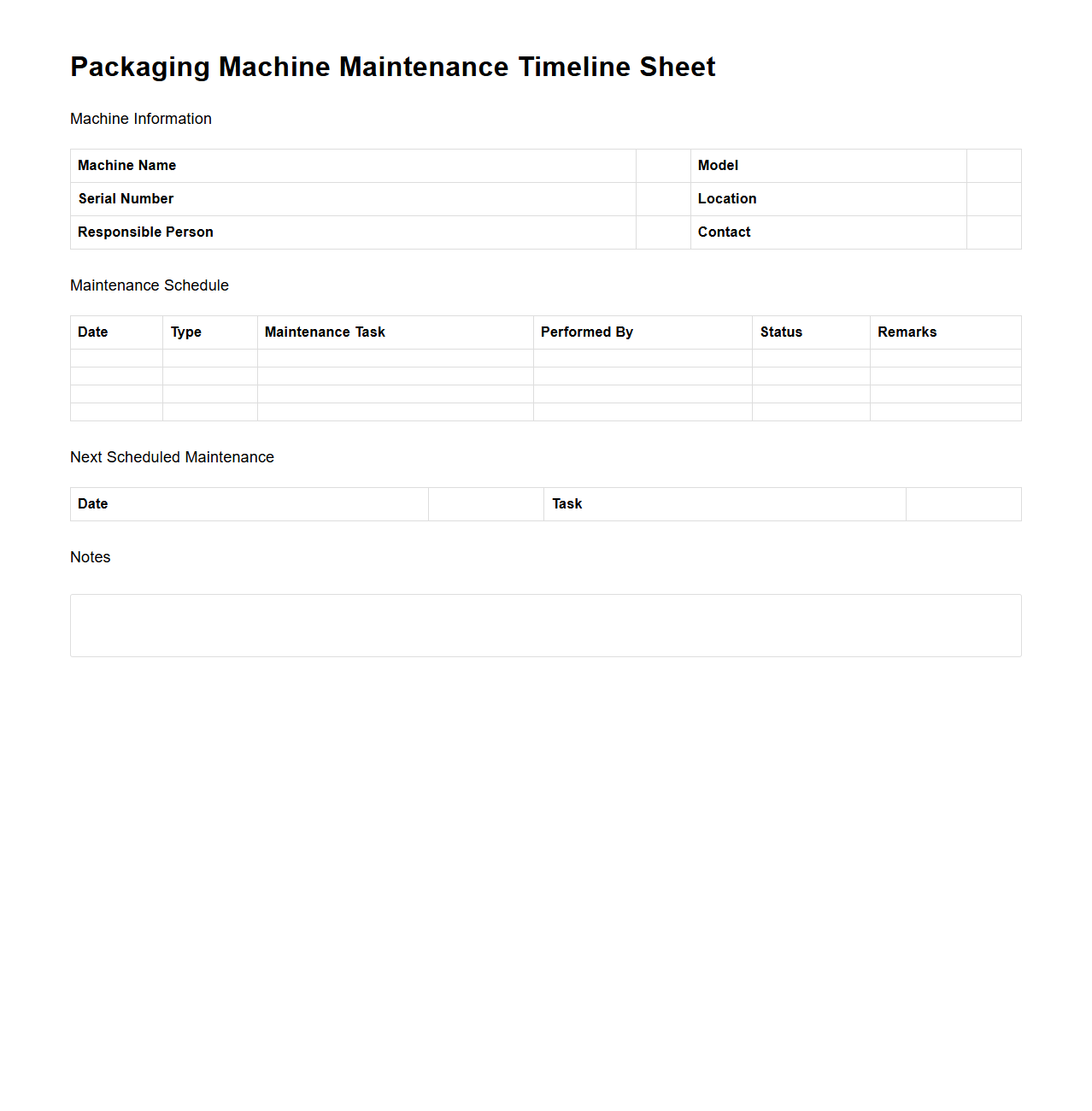

Packaging Machine Maintenance Timeline Sheet

A

Packaging Machine Maintenance Timeline Sheet is a detailed document that tracks all scheduled maintenance activities for packaging equipment, ensuring machinery operates efficiently and reduces downtime. It records dates, types of maintenance performed, and any repairs or inspections conducted, facilitating proactive upkeep and compliance with operational standards. Regularly updated, this document helps maintenance teams prioritize tasks and extend the lifespan of packaging machines.

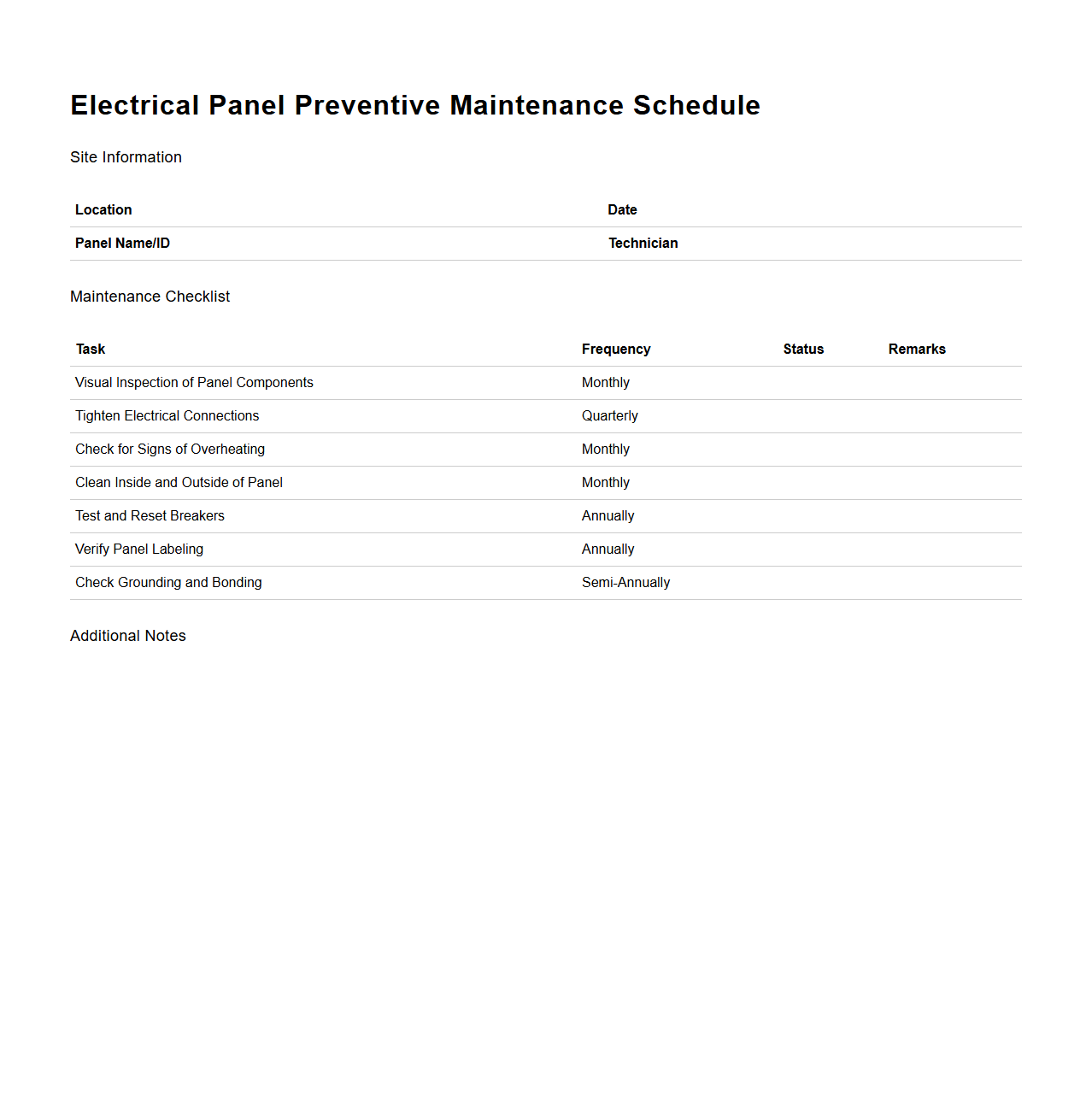

Electrical Panel Preventive Maintenance Schedule

The

Electrical Panel Preventive Maintenance Schedule document outlines a systematic plan for routine inspections, testing, and servicing of electrical panels to ensure optimal performance and safety. It details specific maintenance tasks, recommended frequencies, and essential safety checks to prevent equipment failure, reduce downtime, and extend the lifespan of electrical components. This schedule helps facilities comply with industry standards and enhances reliability by proactively addressing potential electrical issues before they escalate.

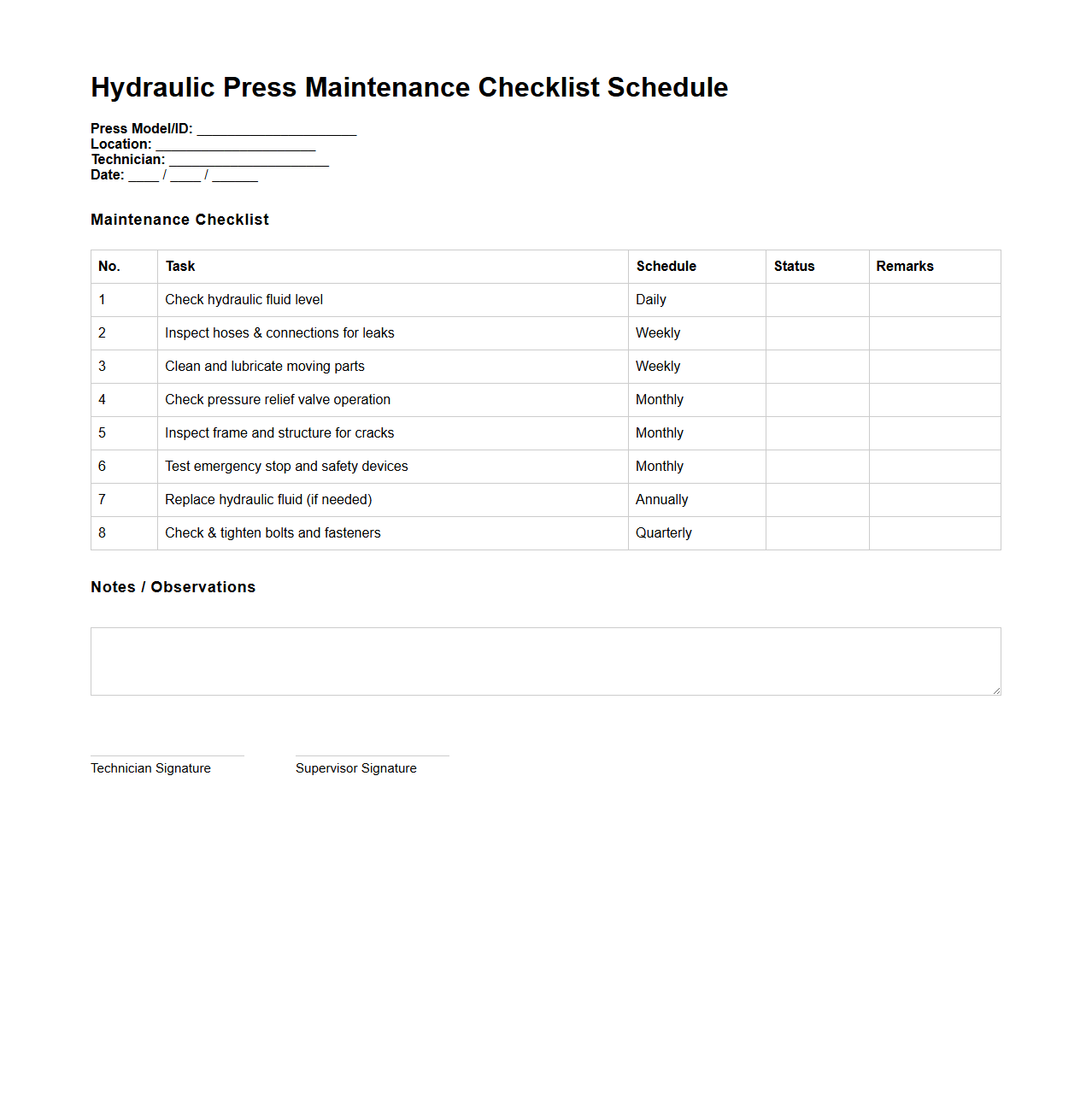

Hydraulic Press Maintenance Checklist Schedule

The

Hydraulic Press Maintenance Checklist Schedule document is a systematic guide designed to ensure regular inspection, servicing, and upkeep of hydraulic press machinery. It outlines critical maintenance tasks such as oil level checks, filter replacements, and hydraulic hose inspections with specified intervals to prevent equipment failure and prolong operational life. Regular use of this checklist enhances machine reliability, safety, and efficiency by addressing potential issues before they lead to costly downtime.

What is the primary objective of the preventive maintenance schedule outlined in this document?

The primary objective of the preventive maintenance schedule is to ensure all equipment operates efficiently and reliably. It aims to minimize downtime by predicting and addressing potential failures before they occur. This proactive approach enhances safety, extends asset lifespan, and reduces costly repairs.

Which critical equipment or machinery does this maintenance schedule specifically cover?

This maintenance schedule specifically covers critical equipment such as HVAC systems, manufacturing machinery, and power generators. It targets assets essential to operational continuity and safety compliance. The focus is on machinery with high wear and tear or significant operational impact.

What are the recommended maintenance intervals for each asset described in the document?

The document recommends maintenance intervals based on asset type and usage intensity. For example, HVAC systems require quarterly inspections, while manufacturing machinery needs monthly servicing. Power generators are scheduled for biannual checks to ensure readiness during emergencies.

How does the document define roles and responsibilities for maintenance tasks?

The document clearly assigns roles and responsibilities to maintenance personnel, supervisors, and management. Technicians are responsible for executing tasks, supervisors oversee quality control, and management ensures resource allocation. This structured framework promotes accountability and efficient task completion.

What procedures are in place for documenting completed maintenance activities?

The document mandates comprehensive documentation of all completed maintenance activities through logs and digital records. It requires detailed entries including date, task performed, personnel involved, and any observed issues. This ensures transparency, facilitates audits, and supports continuous improvement.

More Manufacturing Templates