A Production Schedule Document Sample for Manufacturing Operations outlines the planned sequence of tasks and timelines to ensure efficient workflow and resource allocation. It helps manufacturers track progress, coordinate teams, and meet delivery deadlines. This document typically includes production dates, assigned personnel, equipment requirements, and batch quantities to optimize operational productivity.

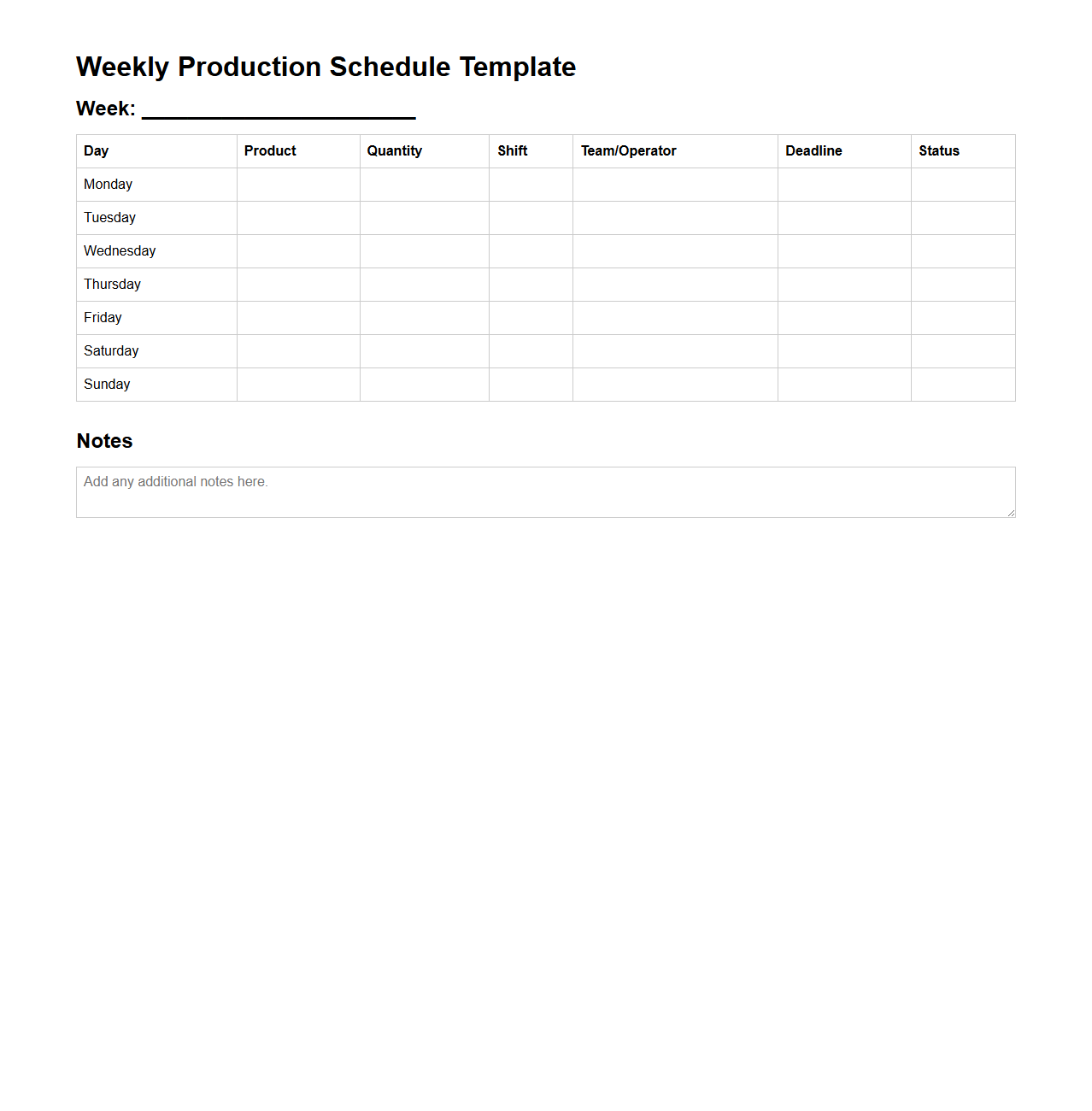

Weekly Production Schedule Template for Manufacturing

A

Weekly Production Schedule Template for manufacturing is a structured document that outlines the planned production activities, timelines, and resource allocation for each week. It helps manufacturers coordinate tasks, track progress, and optimize workflow to meet production targets efficiently. This template ensures clear communication across teams, minimizing downtime and enhancing overall productivity.

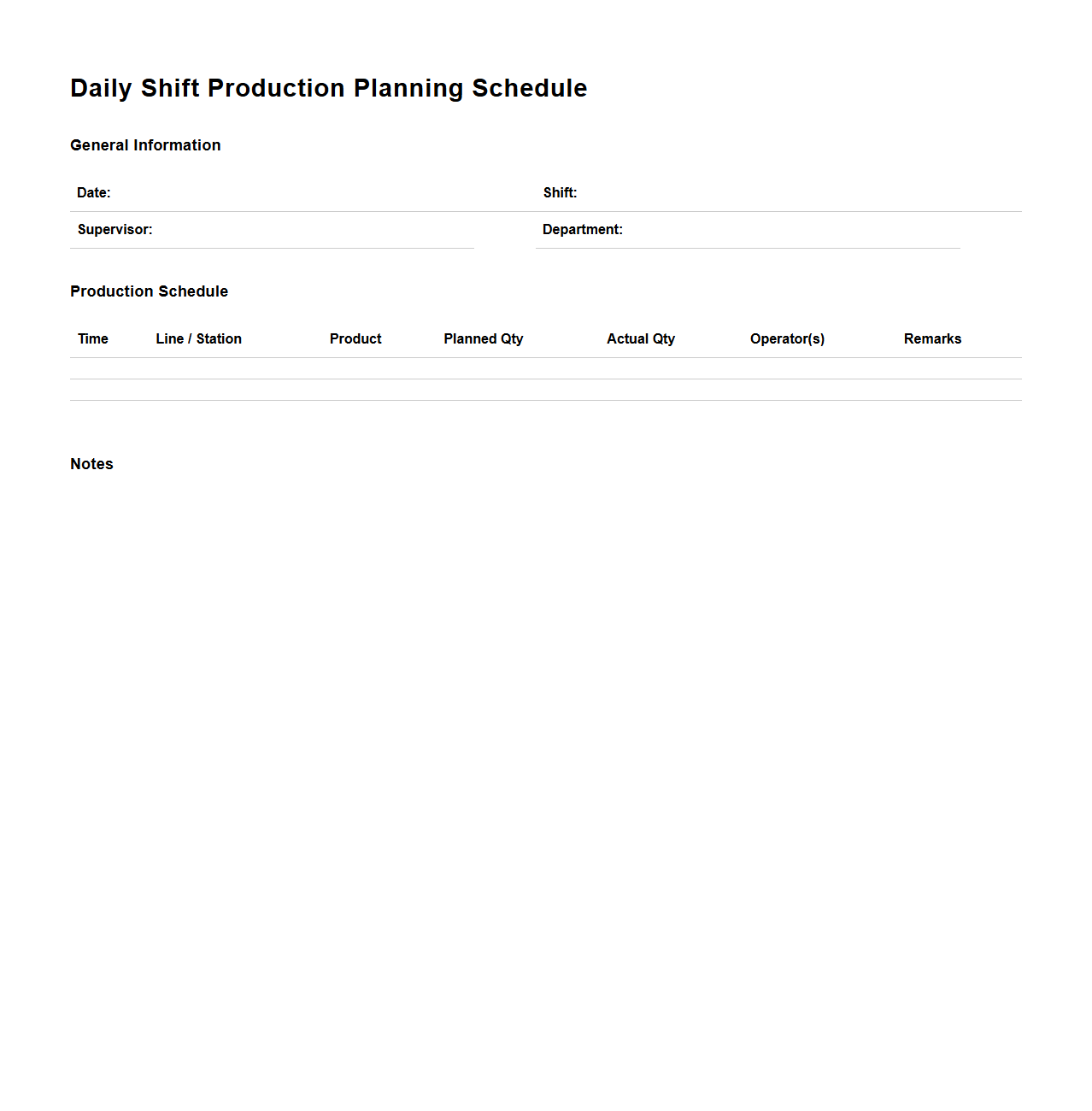

Daily Shift Production Planning Schedule Example

A

Daily Shift Production Planning Schedule Example document outlines the specific tasks, timelines, and resource allocation for each shift within a production cycle, ensuring efficient workflow and meeting output targets. It typically includes shift start and end times, assigned personnel, equipment usage, and production goals to optimize operational performance. This schedule is essential for maintaining consistency, minimizing downtime, and coordinating cross-functional teams in manufacturing or production environments.

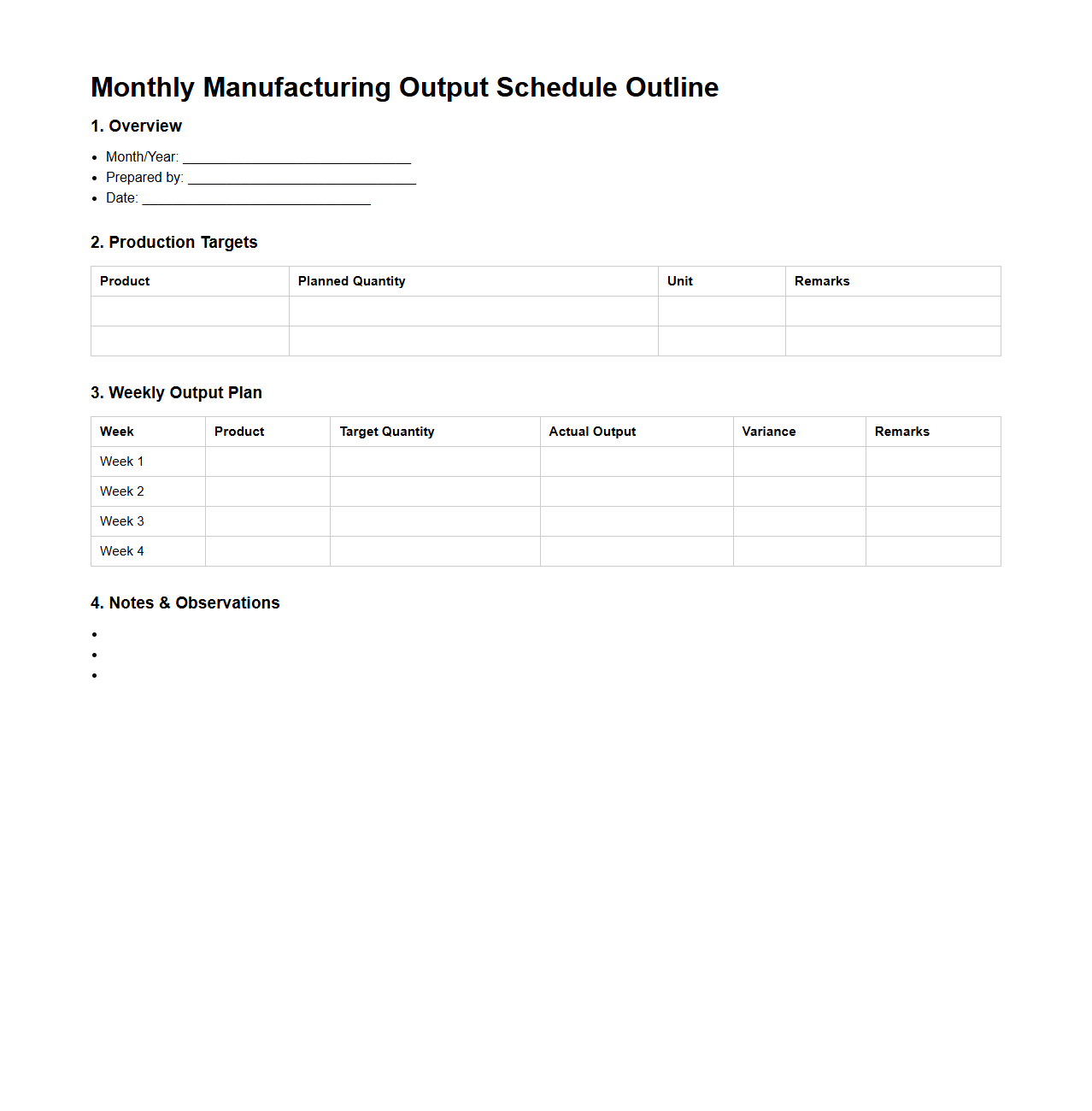

Monthly Manufacturing Output Schedule Outline

The

Monthly Manufacturing Output Schedule Outline document serves as a strategic plan that details production targets, timelines, and resource allocation for a manufacturing facility over a one-month period. It enables efficient tracking of output against goals, ensuring alignment with inventory demands and operational capacity. This document is critical for optimizing workflow, minimizing downtime, and enhancing overall manufacturing productivity.

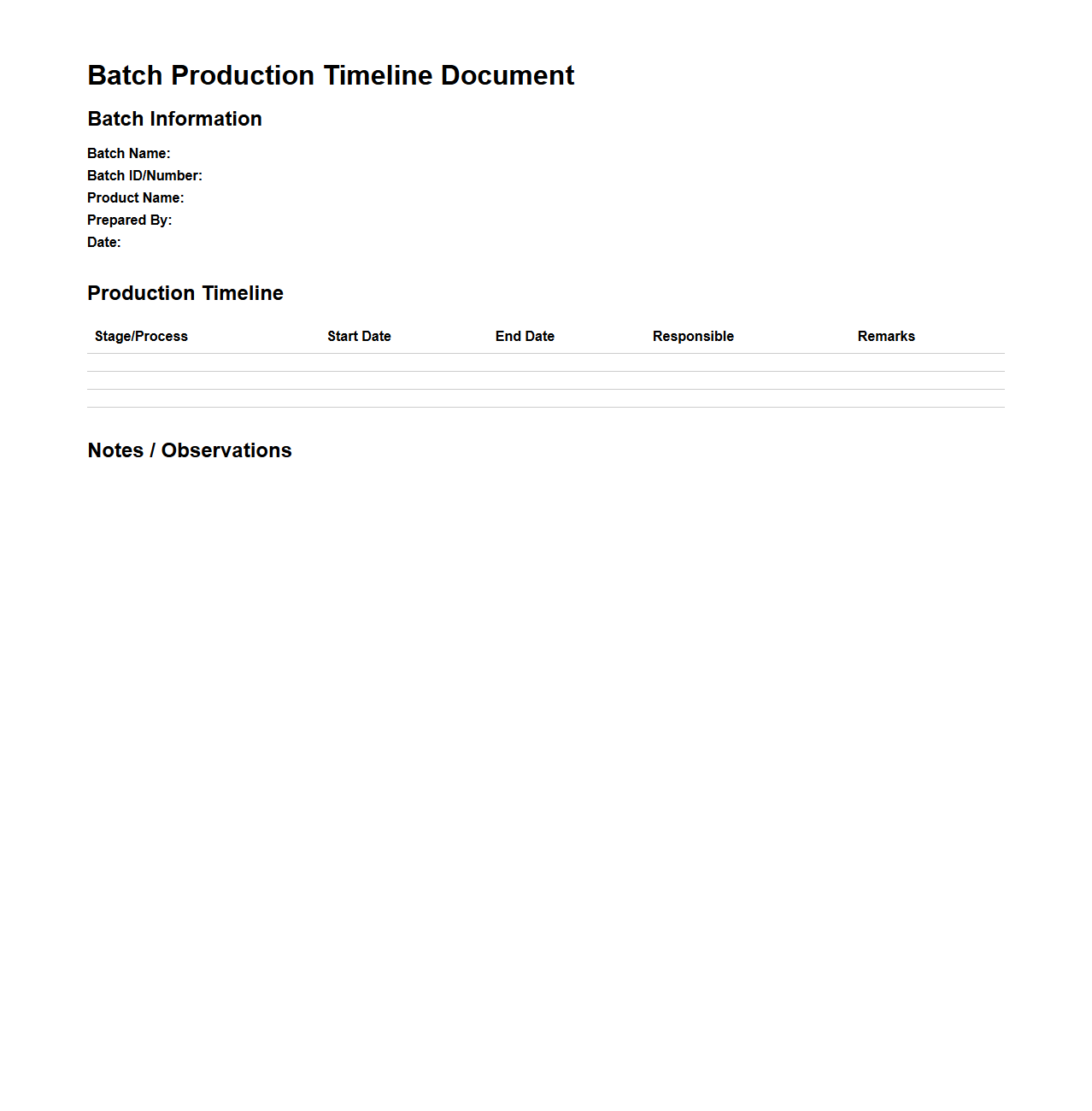

Batch Production Timeline Document Sample

A

Batch Production Timeline Document Sample outlines the scheduled sequence and duration of tasks involved in manufacturing a specific batch of products. It details key milestones, start and end dates, resource allocation, and quality control checkpoints to ensure timely and efficient production. This document serves as a critical tool for project management, helping teams coordinate activities and monitor progress within defined timeframes.

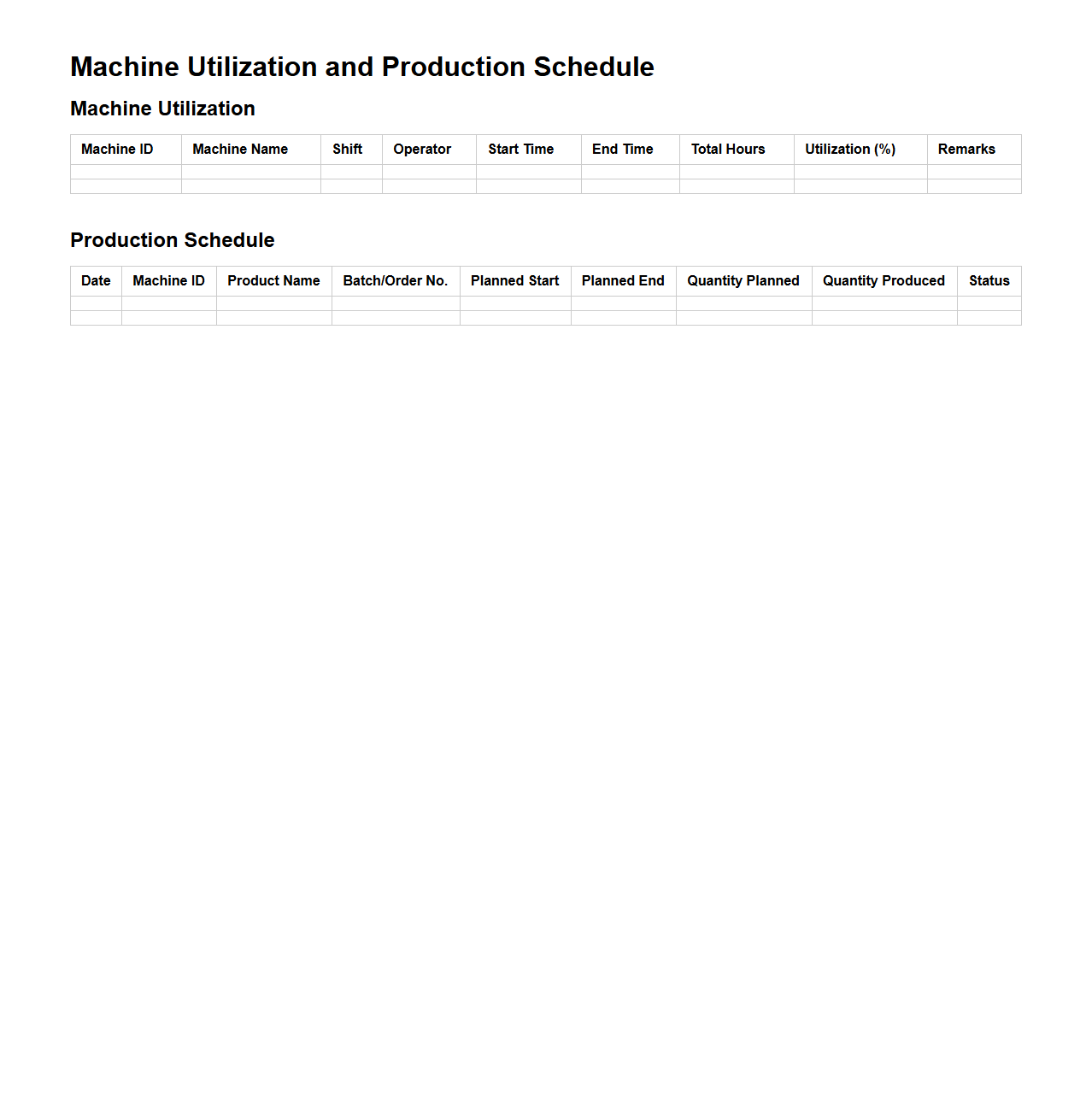

Machine Utilization and Production Schedule Format

Machine Utilization refers to the percentage of time a machine is actively used for production against the total available time, serving as a critical metric for operational efficiency. A Production Schedule Format document outlines a detailed plan that specifies the timing, sequence, and allocation of resources for manufacturing processes, ensuring optimal workflow and meeting delivery deadlines. Together, these tools enable manufacturers to maximize productivity, reduce downtime, and align production activities with overall business goals.

Assembly Line Work Schedule Template

An

Assembly Line Work Schedule Template document is a structured tool designed to organize and manage employee shifts and tasks within a manufacturing or production environment. It helps supervisors allocate work hours efficiently, track labor distribution, and ensure continuous workflow on the assembly line. By using this template, companies can improve productivity, reduce downtime, and maintain clear communication of daily responsibilities among the workforce.

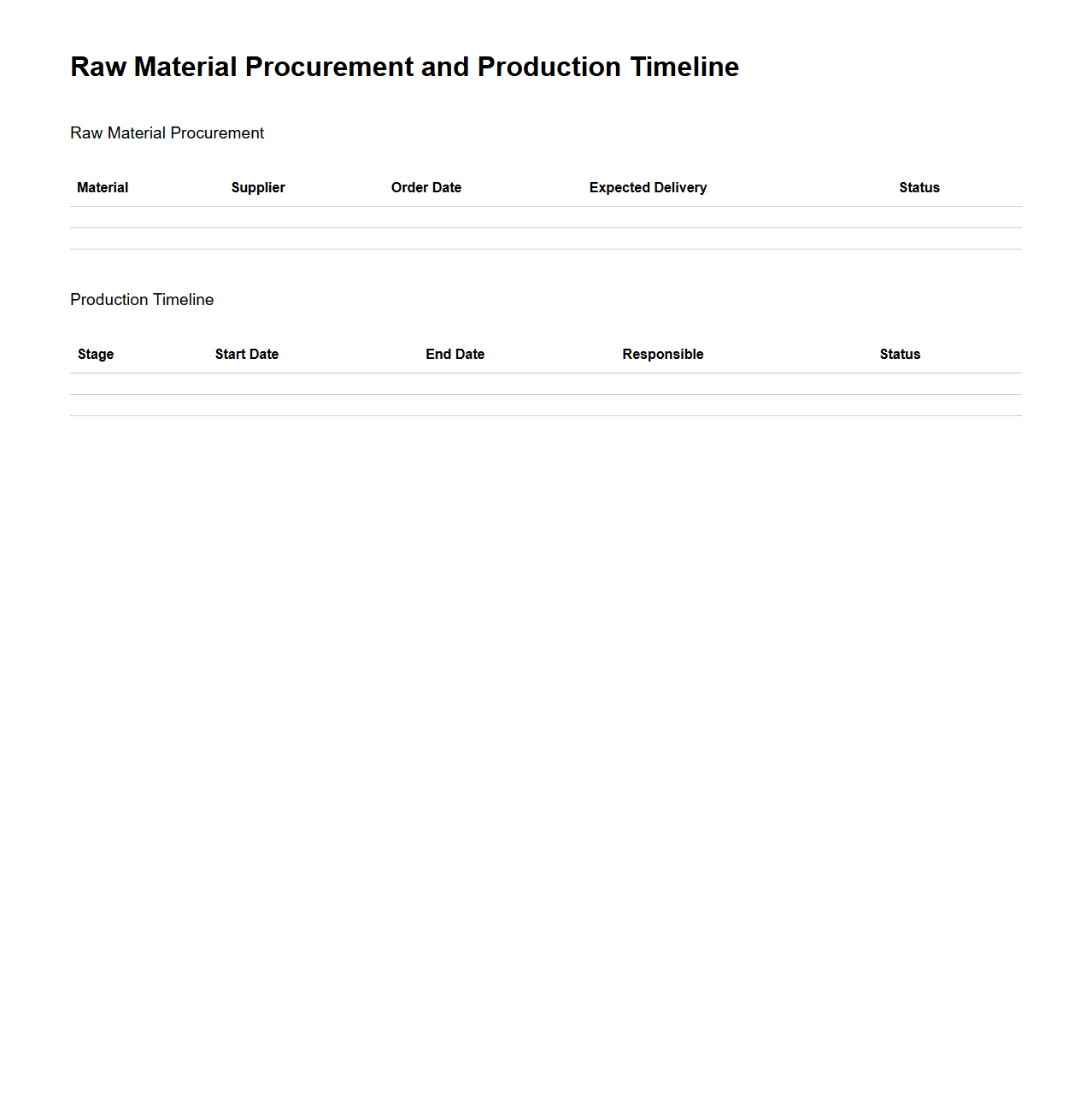

Raw Material Procurement and Production Timeline

The

Raw Material Procurement and Production Timeline document outlines the schedule and process for acquiring essential materials and managing their use throughout the manufacturing cycle. It helps coordinate supplier deliveries, monitor inventory levels, and align production stages to ensure timely completion of products. This document is critical for optimizing supply chain efficiency and minimizing production delays.

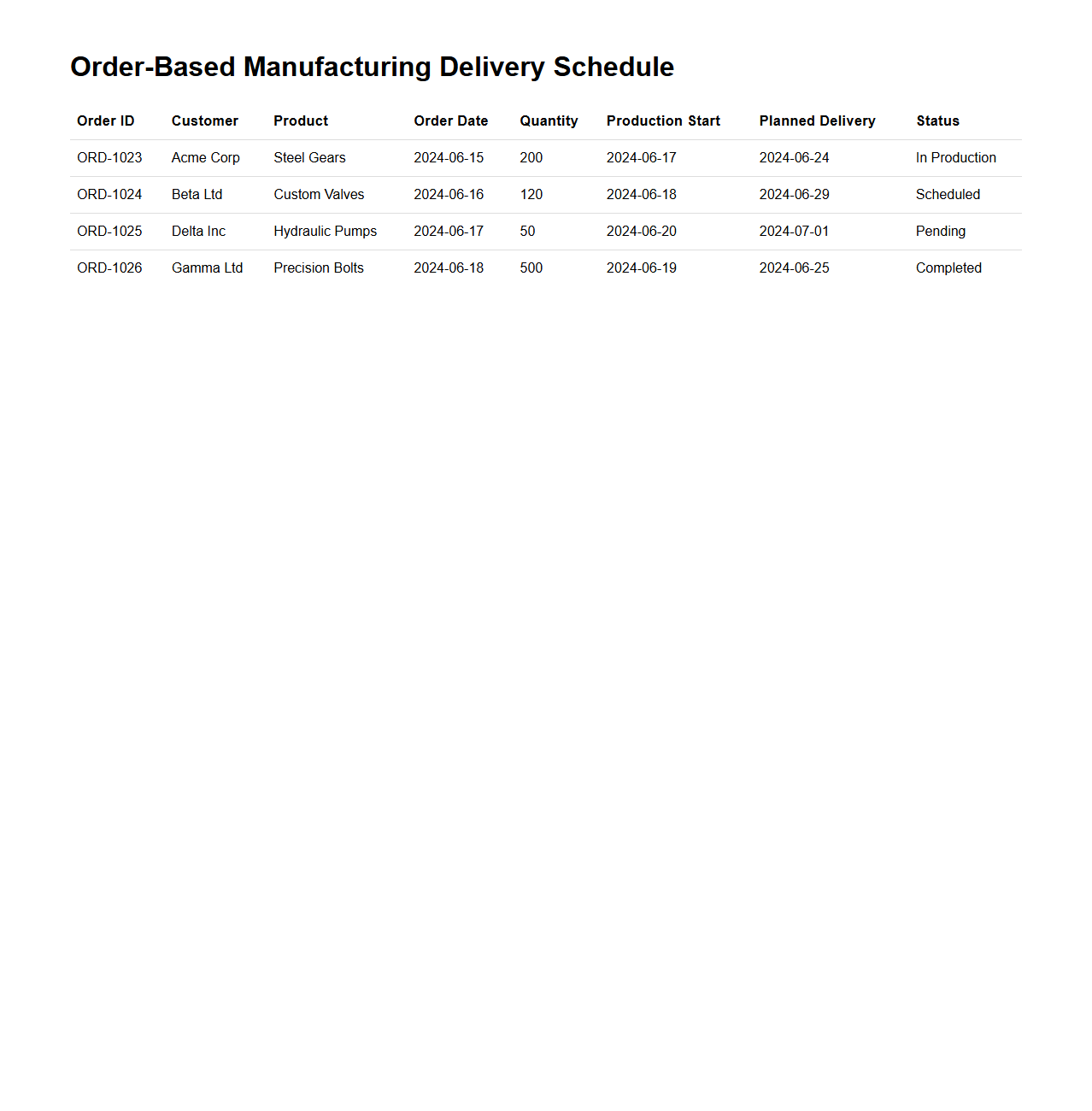

Order-Based Manufacturing Delivery Schedule

The

Order-Based Manufacturing Delivery Schedule document outlines the planned timeline and specific dates for producing and delivering products based on customer orders. It serves as a critical tool to coordinate production activities, manage inventory levels, and ensure timely shipment aligned with order requirements. This schedule helps manufacturers optimize resource allocation and meet delivery commitments effectively.

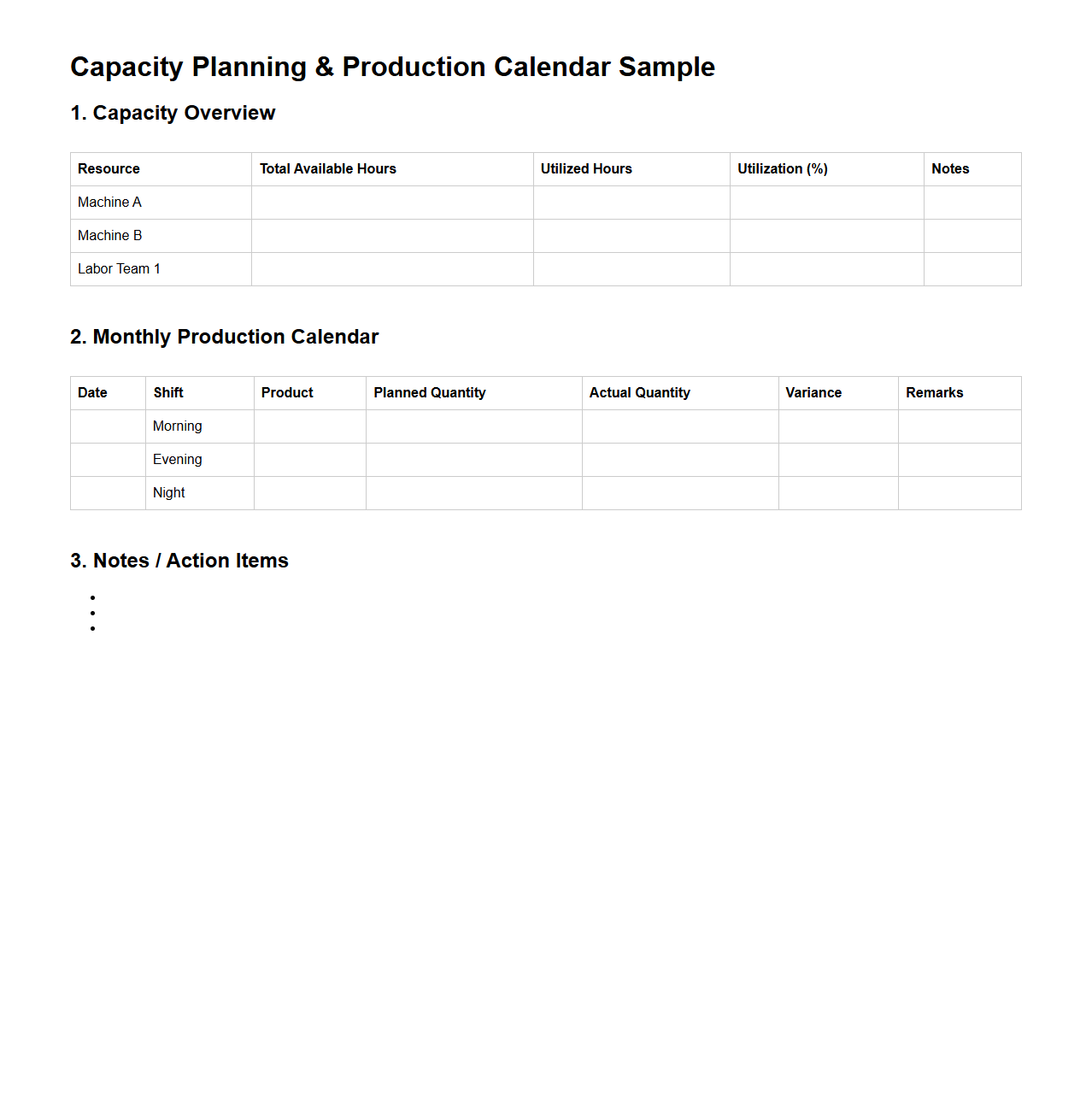

Capacity Planning and Production Calendar Sample

Capacity Planning ensures optimal resource allocation by analyzing production capabilities to meet demand forecasts, preventing bottlenecks and overutilization. A Production Calendar Sample document visually schedules production activities, deadlines, and maintenance periods, facilitating efficient workflow management and timely delivery. Both tools are essential for streamlining operations and enhancing overall manufacturing efficiency.

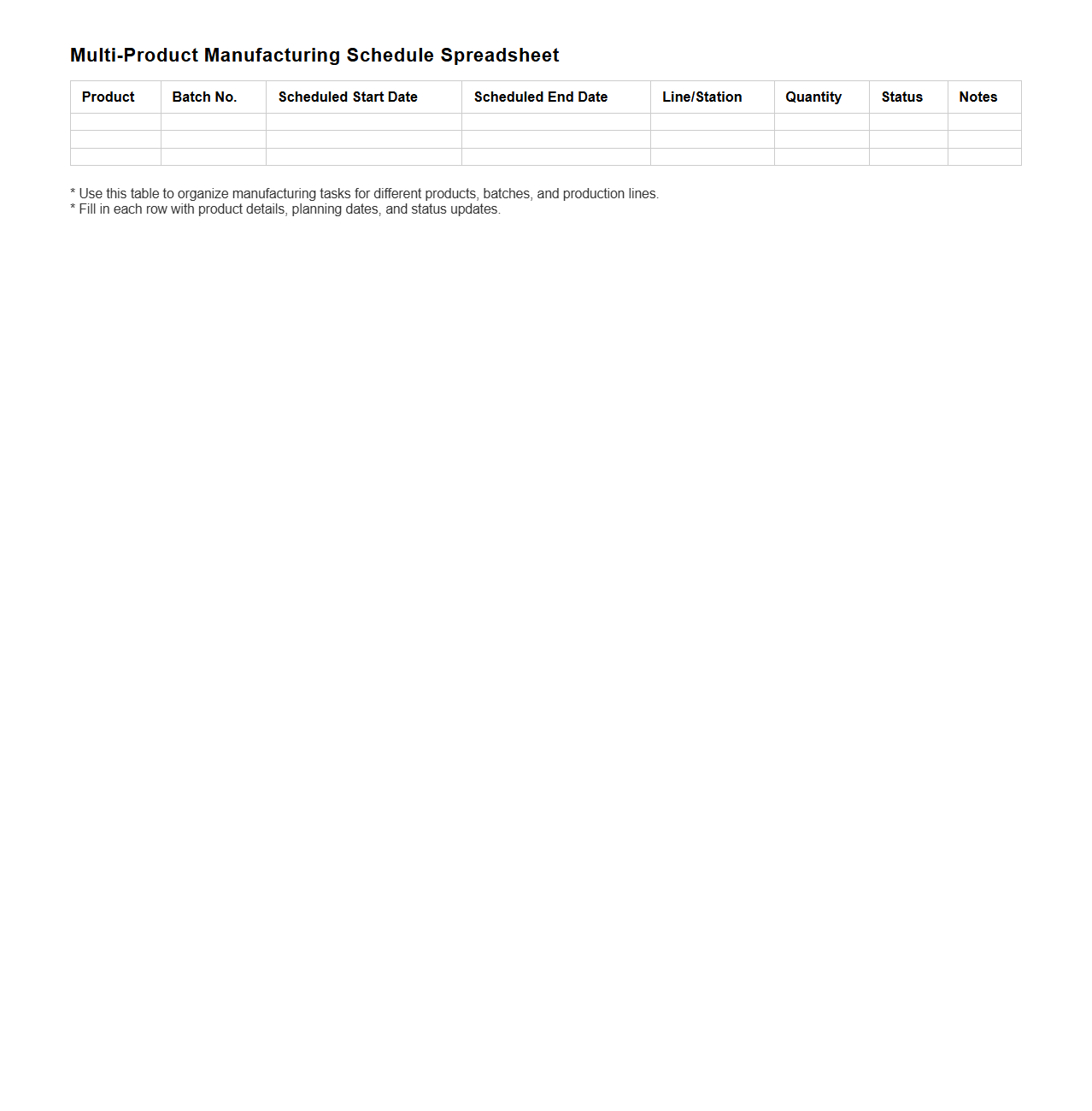

Multi-Product Manufacturing Schedule Spreadsheet

A

Multi-Product Manufacturing Schedule Spreadsheet is a comprehensive document used to plan, track, and optimize production timelines for multiple products simultaneously. It integrates key data such as production stages, resource allocation, lead times, and inventory levels to ensure efficient workflow and timely delivery. This tool enhances coordination across departments, minimizes downtime, and supports data-driven decision-making in manufacturing operations.

Key Components of a Production Schedule Document

A comprehensive production schedule document must include production phases, detailed timelines, resource allocation, and responsible personnel. It should also outline material requirements, machinery usage, and backup plans for unexpected obstacles. A clear overview of tasks and milestones ensures efficient manufacturing operations.

Outlining Timelines and Deadlines

The document specifies start and end dates for each production phase, creating a structured timeline. Critical deadlines are highlighted to maintain momentum and prevent bottlenecks. These timelines facilitate smooth transitions between stages, optimizing workflow efficiency.

Coordinating Resource Allocation

The schedule integrates the allocation of labor, materials, and machinery to maximize productivity. It ensures that resources are assigned when and where they are needed, avoiding downtime. Effective coordination reduces waste and supports continuous production progress.

Tracking Progress and Managing Delays

An essential feature is the ability to monitor real-time progress through checkpoints within the document. It provides mechanisms to identify delays early and initiate corrective actions. This proactive approach helps maintain the overall production schedule and minimize disruptions.

Quality Control and Compliance Provisions

The schedule includes dedicated stages for quality inspections and compliance checks to uphold manufacturing standards. It allocates time for testing, validation, and documentation to ensure adherence to regulations. Incorporating these provisions guarantees a high standard of the final product.

More Manufacturing Templates