A Inventory Audit Document Sample for Manufacturing provides a structured template to accurately track and verify stock levels of raw materials, work-in-progress, and finished goods within a manufacturing facility. This document helps ensure compliance with internal controls and regulatory standards by detailing item descriptions, quantities, and audit dates. Regular use of this template improves inventory accuracy, reduces discrepancies, and supports efficient production planning.

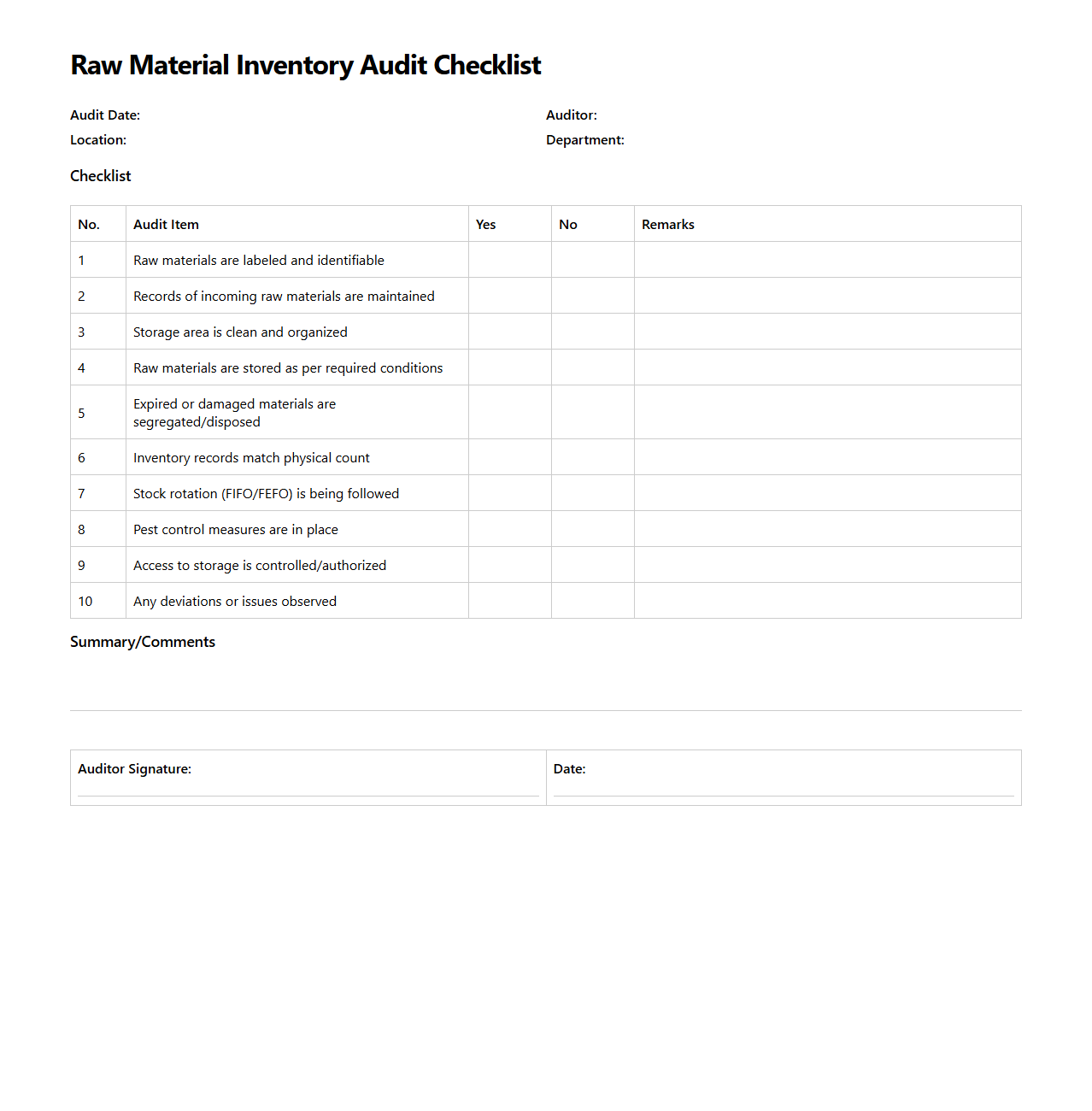

Raw Material Inventory Audit Checklist

A

Raw Material Inventory Audit Checklist document is a structured tool used to verify the accuracy and completeness of raw material stocks within a company's inventory. It ensures that quantities, storage conditions, and procurement records are thoroughly reviewed to maintain proper inventory control and prevent discrepancies. This checklist aids in compliance with industry standards, facilitates efficient supply chain management, and supports accurate financial reporting.

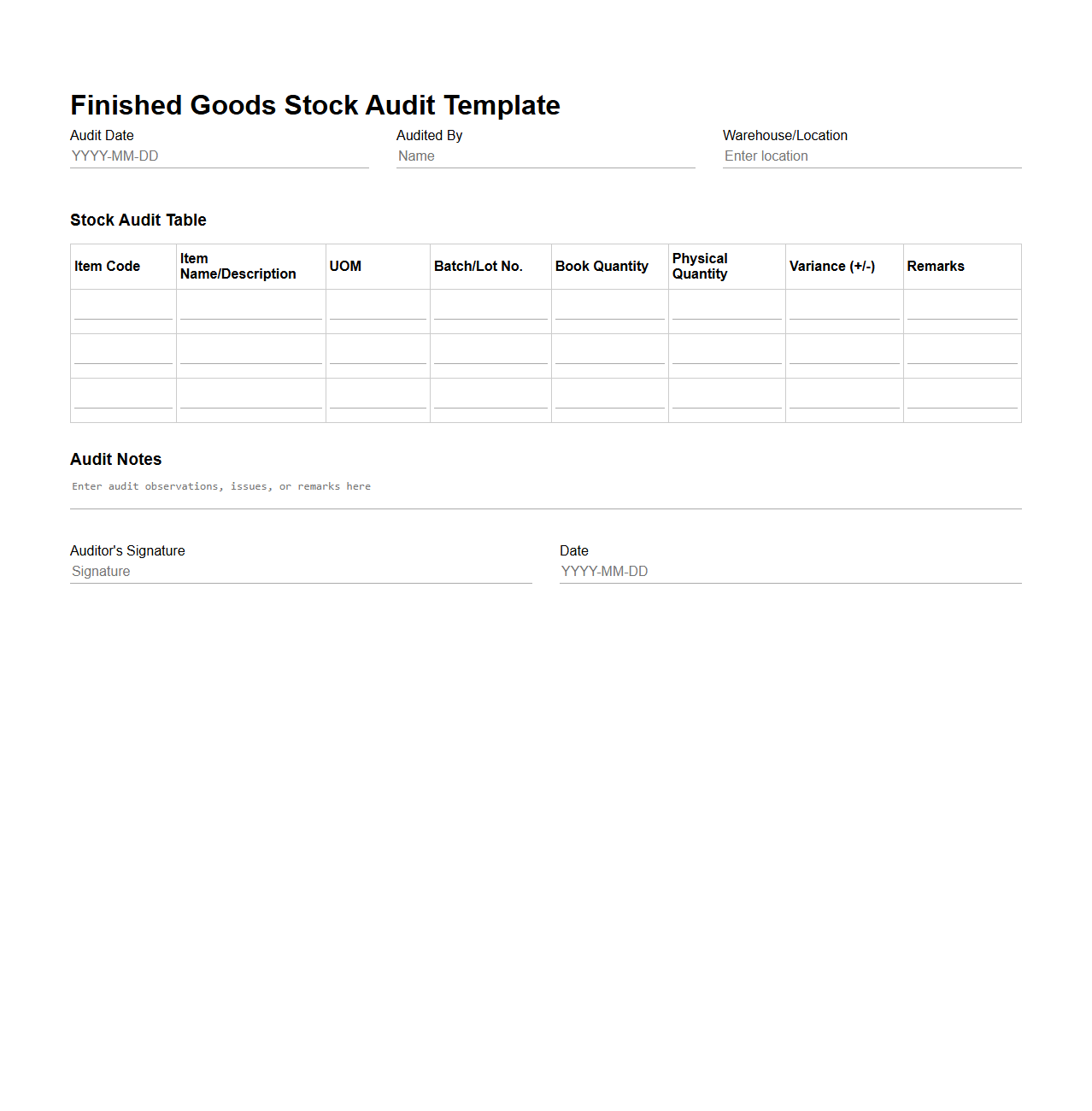

Finished Goods Stock Audit Template

A Finished Goods Stock Audit Template is a structured document designed to systematically verify and record the quantity and condition of finished goods inventory. It helps businesses ensure accuracy in stock levels, identify discrepancies, and maintain optimal inventory control for effective supply chain management. Using this

audit template enhances accountability and supports financial reporting by providing a clear, standardized process for stock verification.

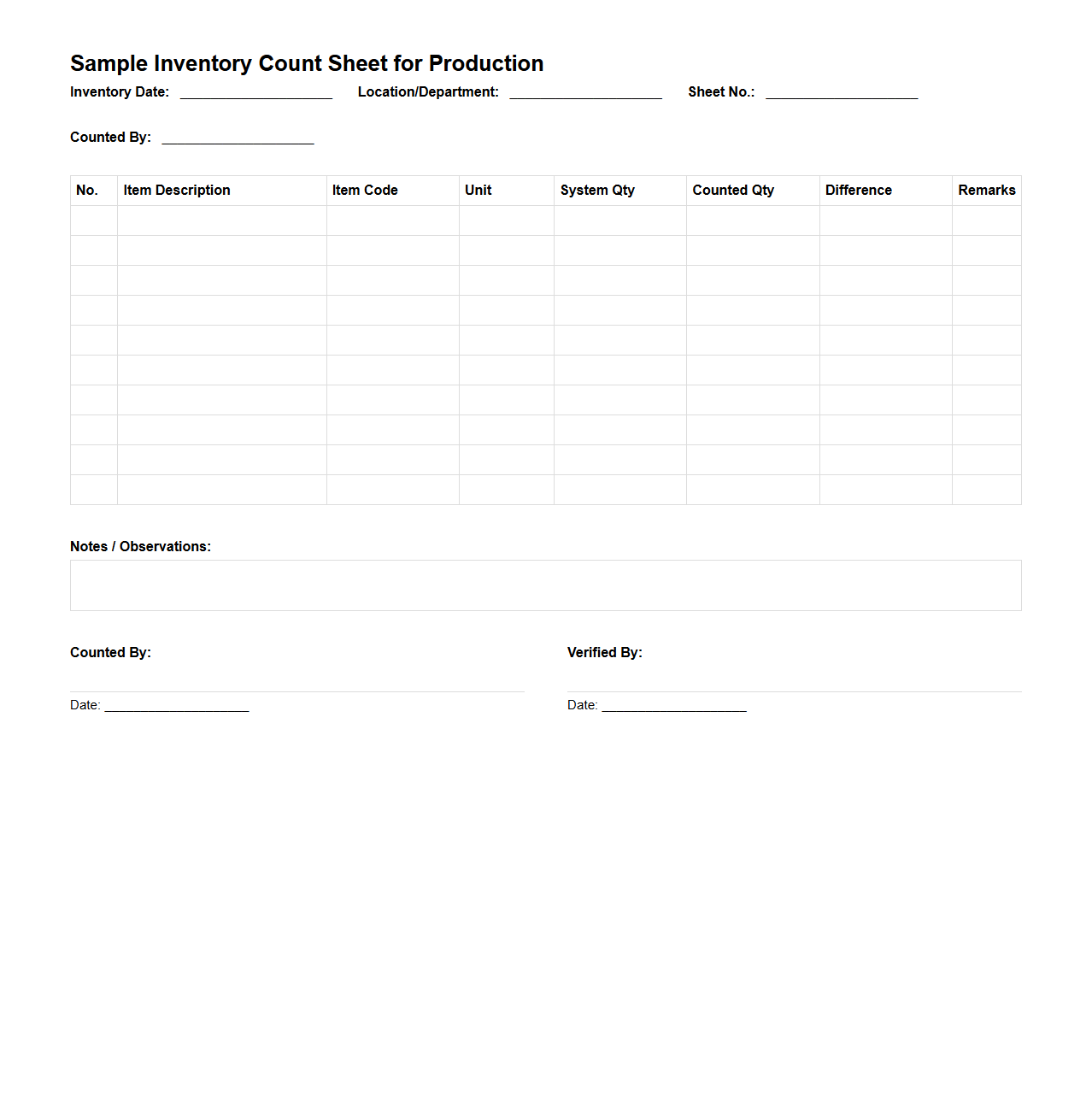

Sample Inventory Count Sheet for Production

A

Sample Inventory Count Sheet for Production is a crucial document used to accurately track raw materials, work-in-progress items, and finished goods during the manufacturing process. This sheet helps ensure inventory accuracy by recording quantities, item descriptions, and batch numbers, facilitating efficient stock management and minimizing discrepancies. Regular use of this tool supports production planning, cost control, and quality assurance within manufacturing operations.

Inventory Movement Tracking Form for Manufacturing

The

Inventory Movement Tracking Form for manufacturing is a critical document used to record and monitor the transfer of raw materials, work-in-progress items, and finished goods within production facilities. It provides accurate data on quantities moved, locations, timestamps, and responsible personnel to ensure real-time visibility and accountability in inventory management. This form supports streamlined operations, reduces errors, and enhances supply chain efficiency by maintaining precise control over asset flow.

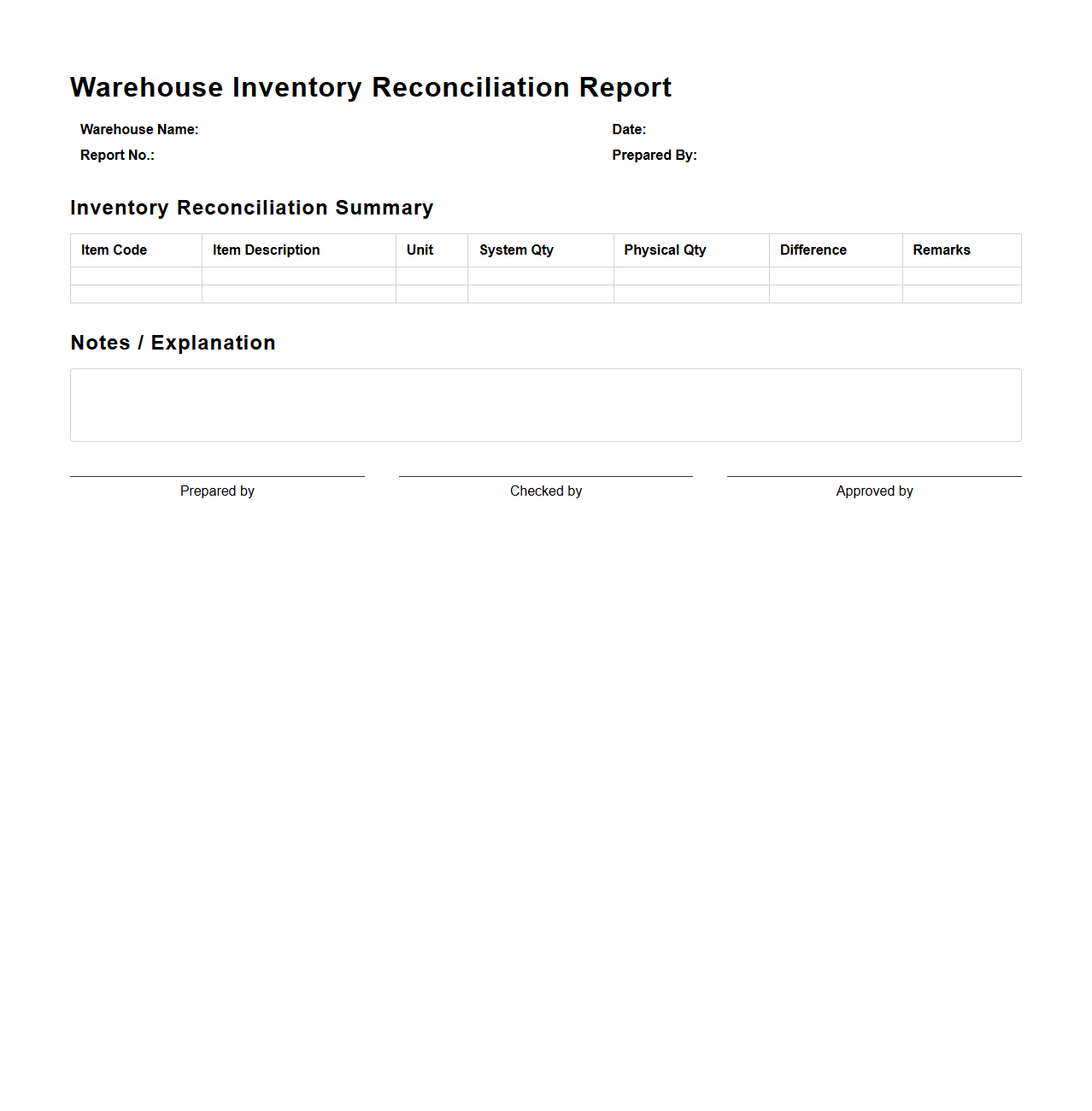

Warehouse Inventory Reconciliation Report

A

Warehouse Inventory Reconciliation Report is a crucial document that compares physical inventory counts with recorded stock levels to identify discrepancies. It helps businesses detect errors, theft, or loss, ensuring accurate inventory management and financial reporting. Regular reconciliation supports maintaining optimal stock levels and operational efficiency in warehouse management.

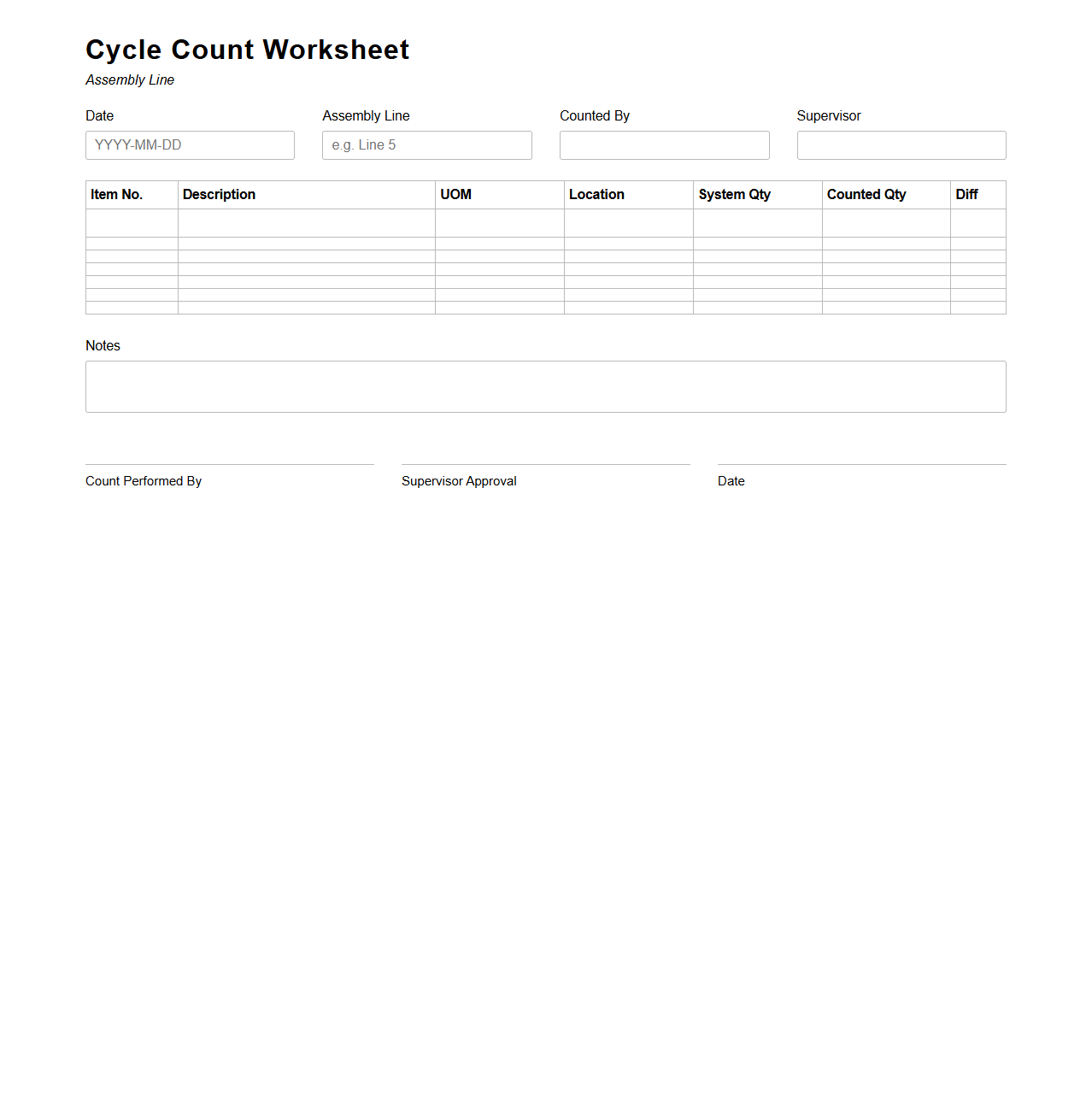

Cycle Count Worksheet for Assembly Line

A

Cycle Count Worksheet for Assembly Line document is a critical inventory management tool used to systematically verify and record the quantities of components and finished products at various stages of the assembly process. It helps maintain accurate inventory levels, reduce discrepancies, and ensure smooth production flow by identifying mismatches between recorded and actual stock. This worksheet supports continuous improvement efforts and minimizes production downtime caused by inventory errors.

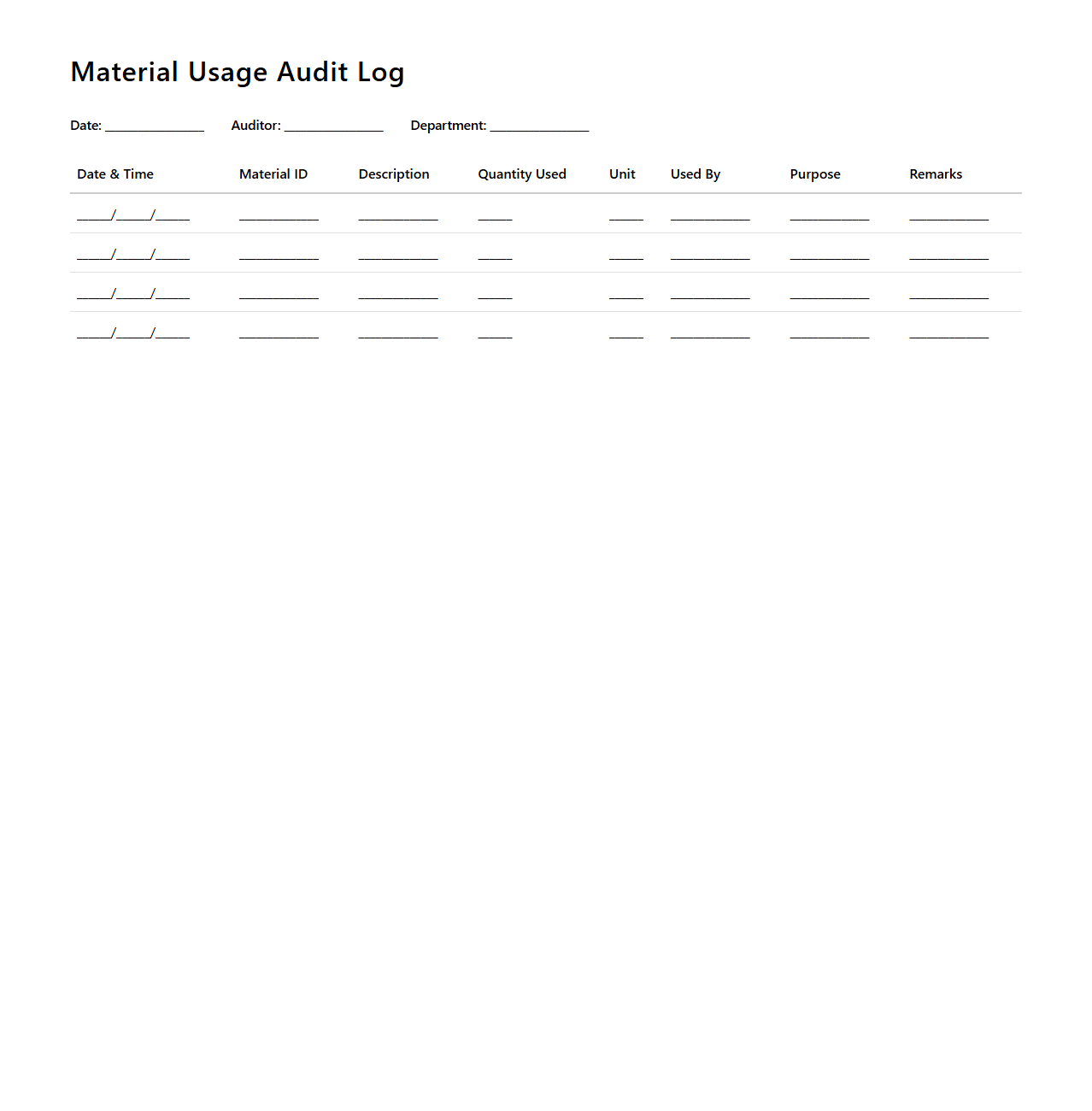

Material Usage Audit Log

The

Material Usage Audit Log document systematically records the consumption and tracking of materials within a project or manufacturing process. It provides detailed entries on quantities used, dates, responsible personnel, and any discrepancies or adjustments made. This log ensures transparency, supports inventory management, and facilitates compliance with auditing standards.

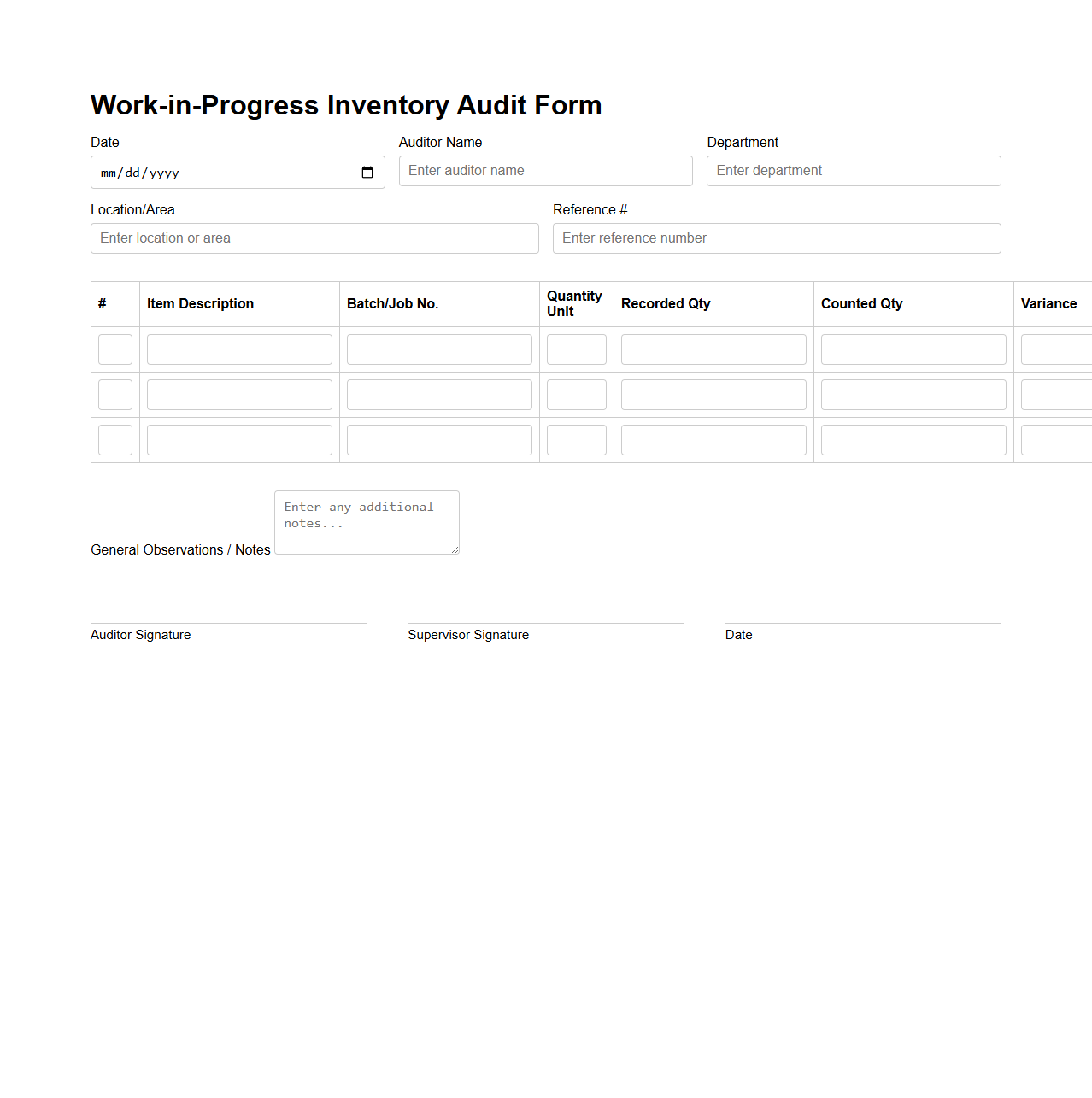

Work-in-Progress Inventory Audit Form

The

Work-in-Progress Inventory Audit Form document is used to systematically track and evaluate partially completed products within a manufacturing or production process. This form helps ensure accurate accounting of inventory levels, supporting effective cost control and workflow management. Regular audits using this form minimize discrepancies, optimize resource allocation, and improve overall production efficiency.

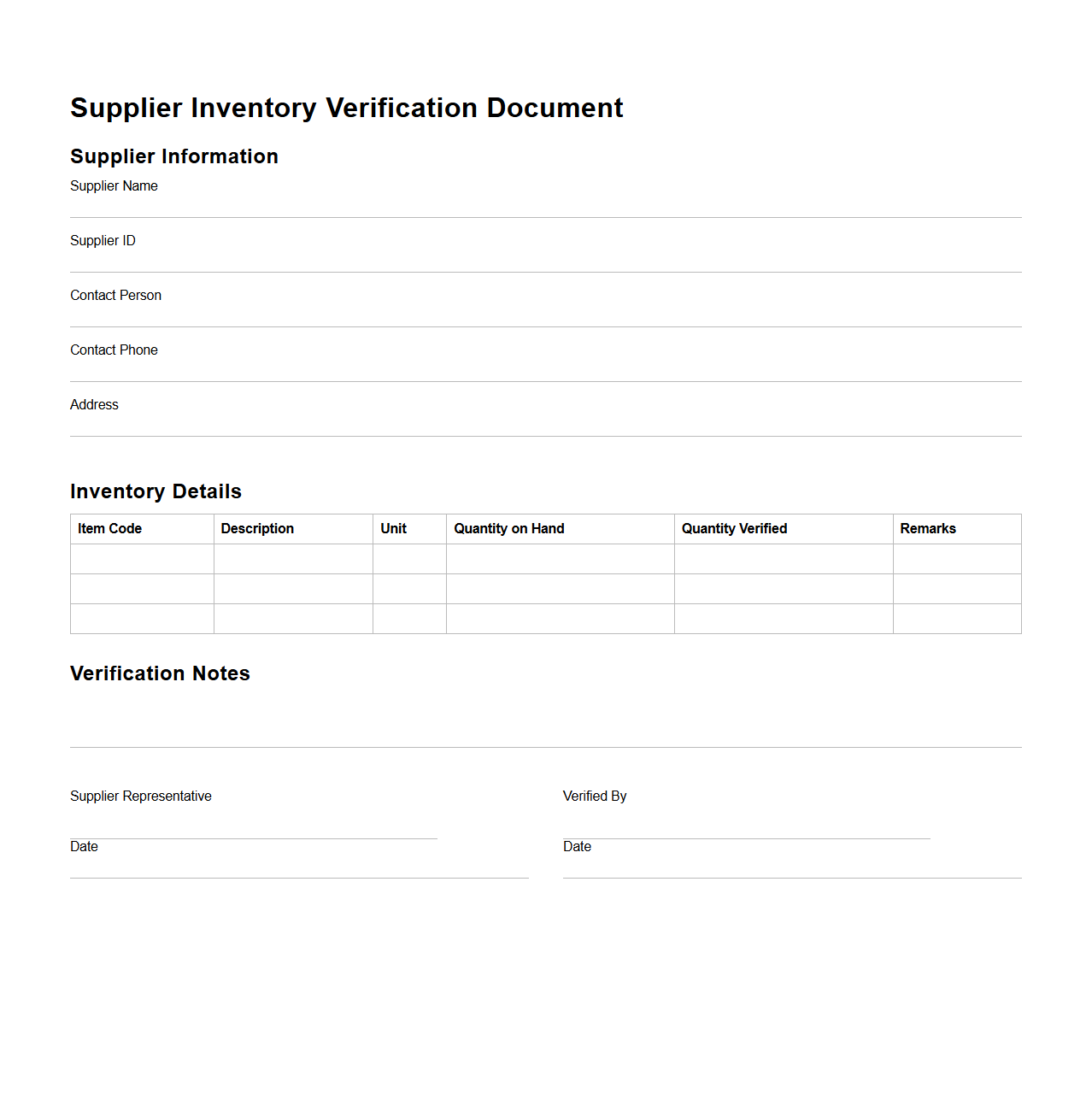

Supplier Inventory Verification Document

Supplier Inventory Verification Document serves as a crucial record that confirms the accuracy and integrity of inventory supplied by vendors. This document details item quantities, descriptions, and condition assessments, ensuring alignment with purchase orders and contractual agreements. Maintaining a

Supplier Inventory Verification Document helps prevent discrepancies, supports audit compliance, and facilitates effective inventory management.

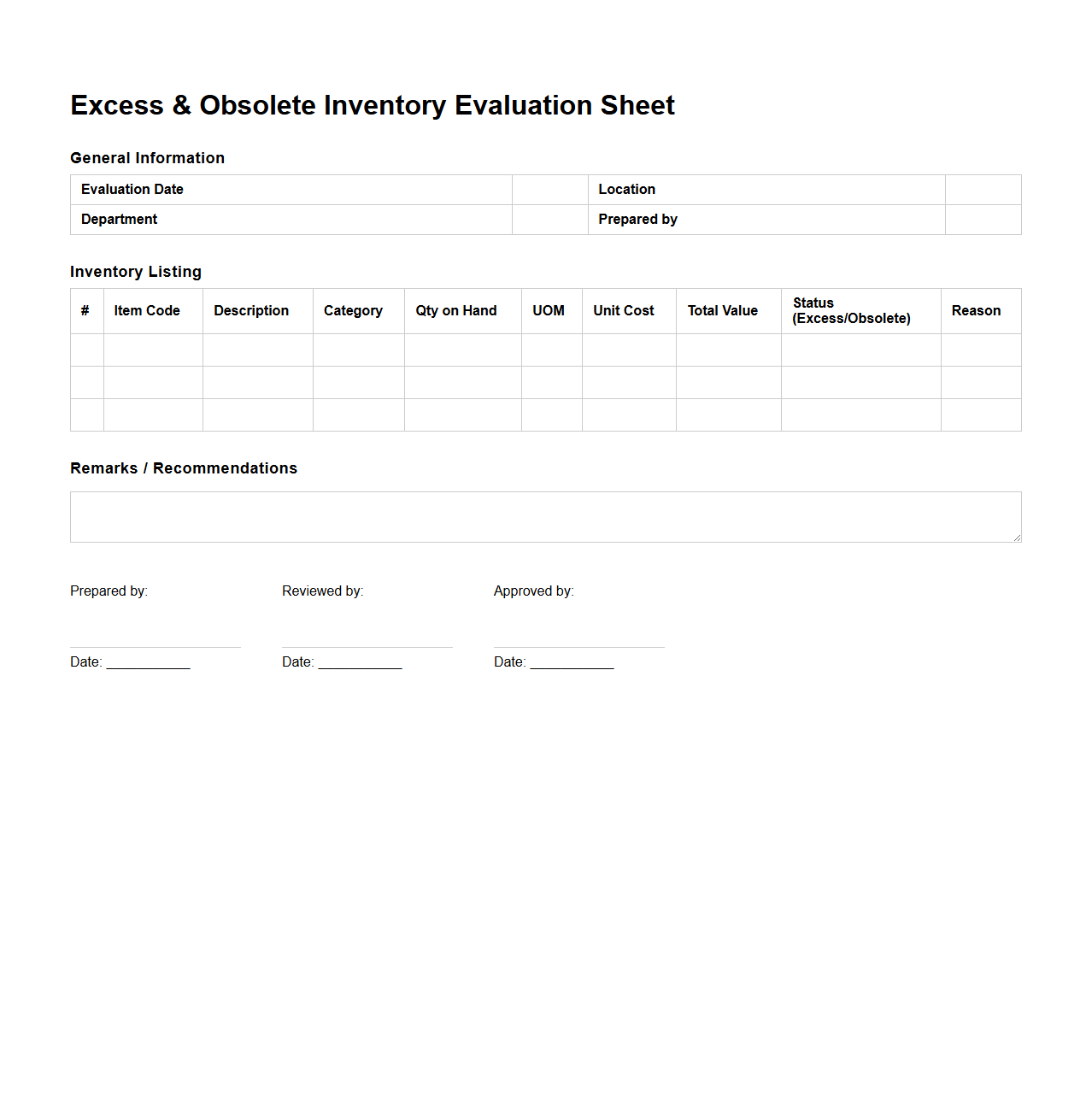

Excess and Obsolete Inventory Evaluation Sheet

The

Excess and Obsolete Inventory Evaluation Sheet is a critical document used by businesses to identify, categorize, and quantify surplus or outdated stock that no longer meets current demand or production needs. This evaluation tool helps in assessing financial impacts, optimizing inventory levels, and developing strategies for disposal, liquidation, or write-offs. By systematically documenting excess and obsolete inventory, companies improve asset management and reduce carrying costs.

What key inventory valuation methods are documented in the sample?

The sample primarily documents the FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) methods of inventory valuation. These are critical for accurately reflecting the cost flow assumptions in financial statements. Additionally, the sample mentions the weighted average cost approach to smooth out price fluctuations over periods.

Which procedures ensure the accuracy of physical inventory counts?

Physical inventory counts are ensured accurate through regular cycle counts and comprehensive year-end stocktaking events. The process involves dual verification by independent teams to eliminate counting errors. Furthermore, any discrepancies found trigger immediate recounts and reconciliations with system records.

How does the document address discrepancies between recorded and actual inventory?

The document mandates a thorough investigation and documentation of all inventory variances. It prescribes reconciliation procedures including variance analysis and approval by management before adjustments. These steps guarantee transparency and maintain the integrity of inventory records.

What controls are detailed for safeguarding raw materials and finished goods?

The sample outlines strict physical access controls, including locked storage and surveillance systems. Segregation of duties ensures no single individual has unchecked access to inventory. Additionally, routine inspections and inventory audits are implemented to prevent theft or loss.

Which audit trails are maintained for inventory movement and adjustments?

Comprehensive audit trails include timestamped logs for all inventory movements, reflecting quantities and responsible personnel. Adjustment entries require authorization with detailed notes explaining reasons. These trails help in identifying irregularities and ensure accountability in inventory management.

More Manufacturing Templates