The Equipment Downtime Log Document Sample for Maintenance provides a structured template to record and track periods when machinery is non-operational. This document helps maintenance teams identify downtime causes, schedule repairs efficiently, and improve overall equipment reliability. Regular use of the log supports proactive maintenance strategies and reduces unexpected operational interruptions.

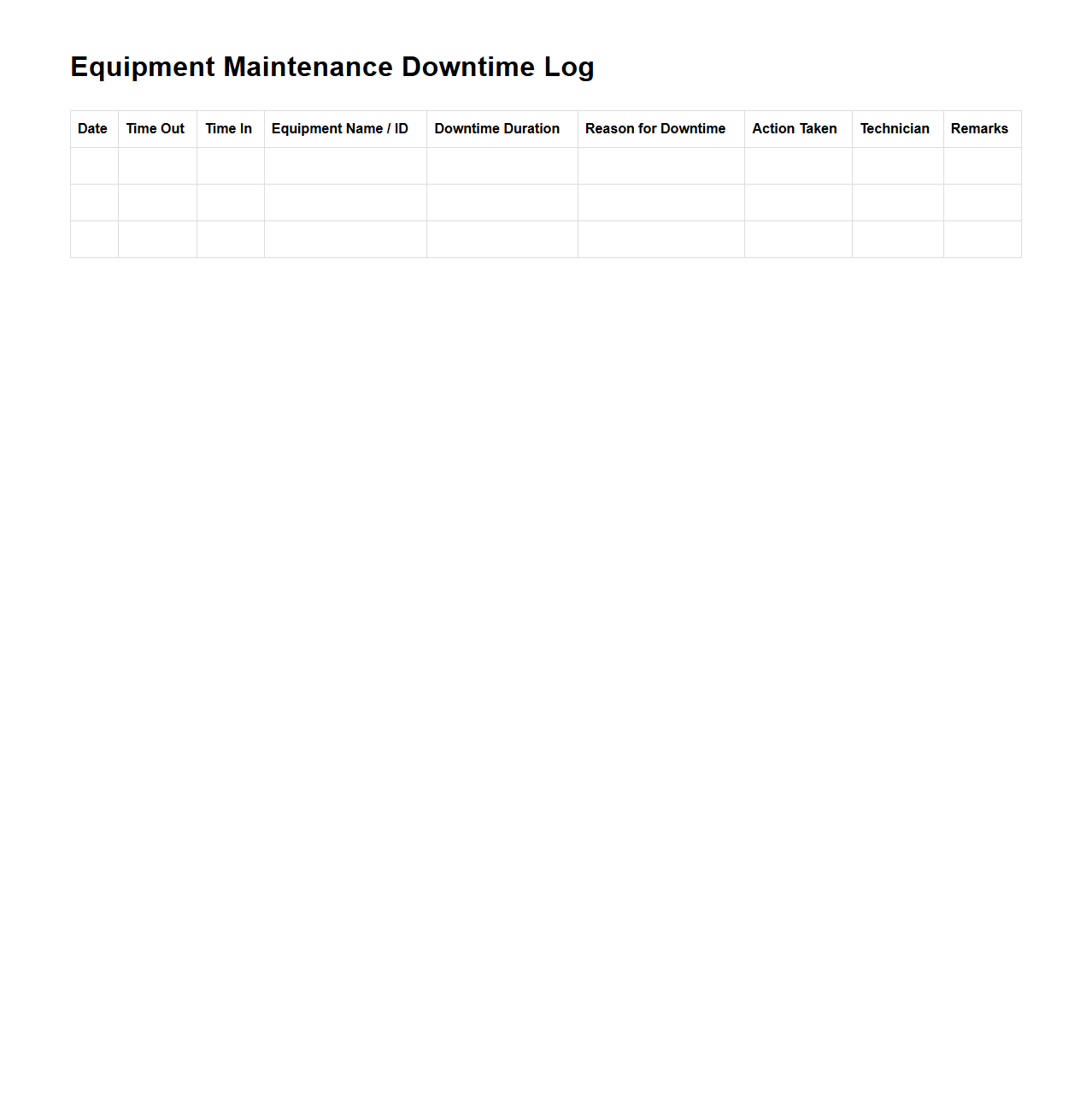

Equipment Maintenance Downtime Log Template

The

Equipment Maintenance Downtime Log Template document is designed to systematically record periods when machinery or equipment is non-operational due to maintenance activities. It enables tracking of downtime causes, durations, and impacts on production, facilitating data-driven decisions to improve maintenance efficiency and reduce operational disruptions. This template often includes fields for equipment ID, maintenance type, start and end times, and technician notes, ensuring accurate and consistent documentation across maintenance teams.

Machinery Downtime Tracking Sheet

A

Machinery Downtime Tracking Sheet is a vital document used to record and monitor periods when equipment or machinery is not operational. It captures key data such as the start and end times of downtime, reasons for stoppage, and responsible personnel, enabling accurate analysis of production losses. This tracking sheet helps maintenance teams identify patterns, optimize repair schedules, and improve overall equipment efficiency.

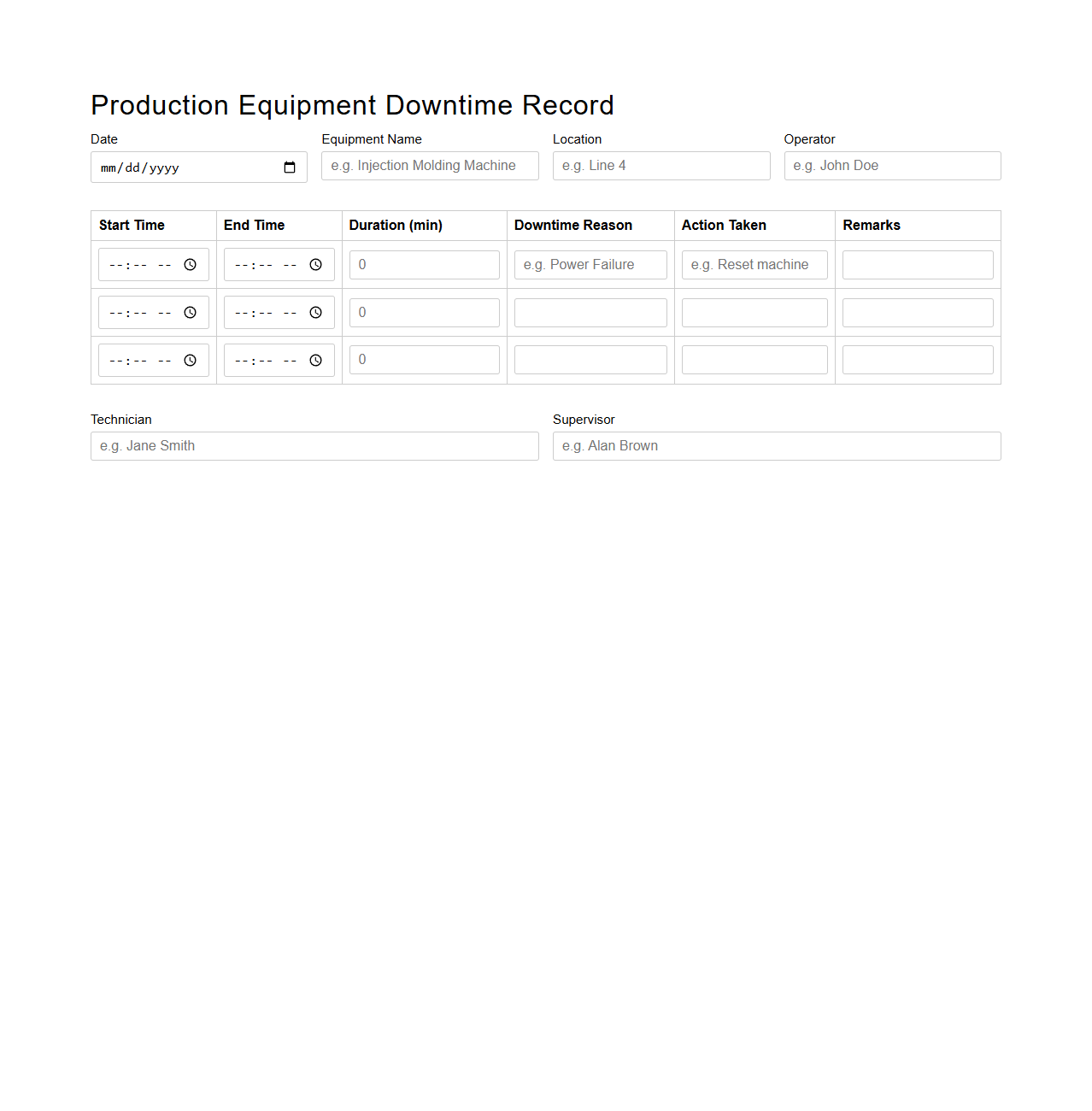

Production Equipment Downtime Record Sample

A

Production Equipment Downtime Record Sample document is a detailed log used to track periods when machinery or equipment is not operational during manufacturing processes. This record captures essential data such as start and end times of downtime, reasons for stoppage, affected equipment, and impact on production output. Maintaining this document helps identify recurring issues, optimize maintenance schedules, and improve overall equipment efficiency (OEE).

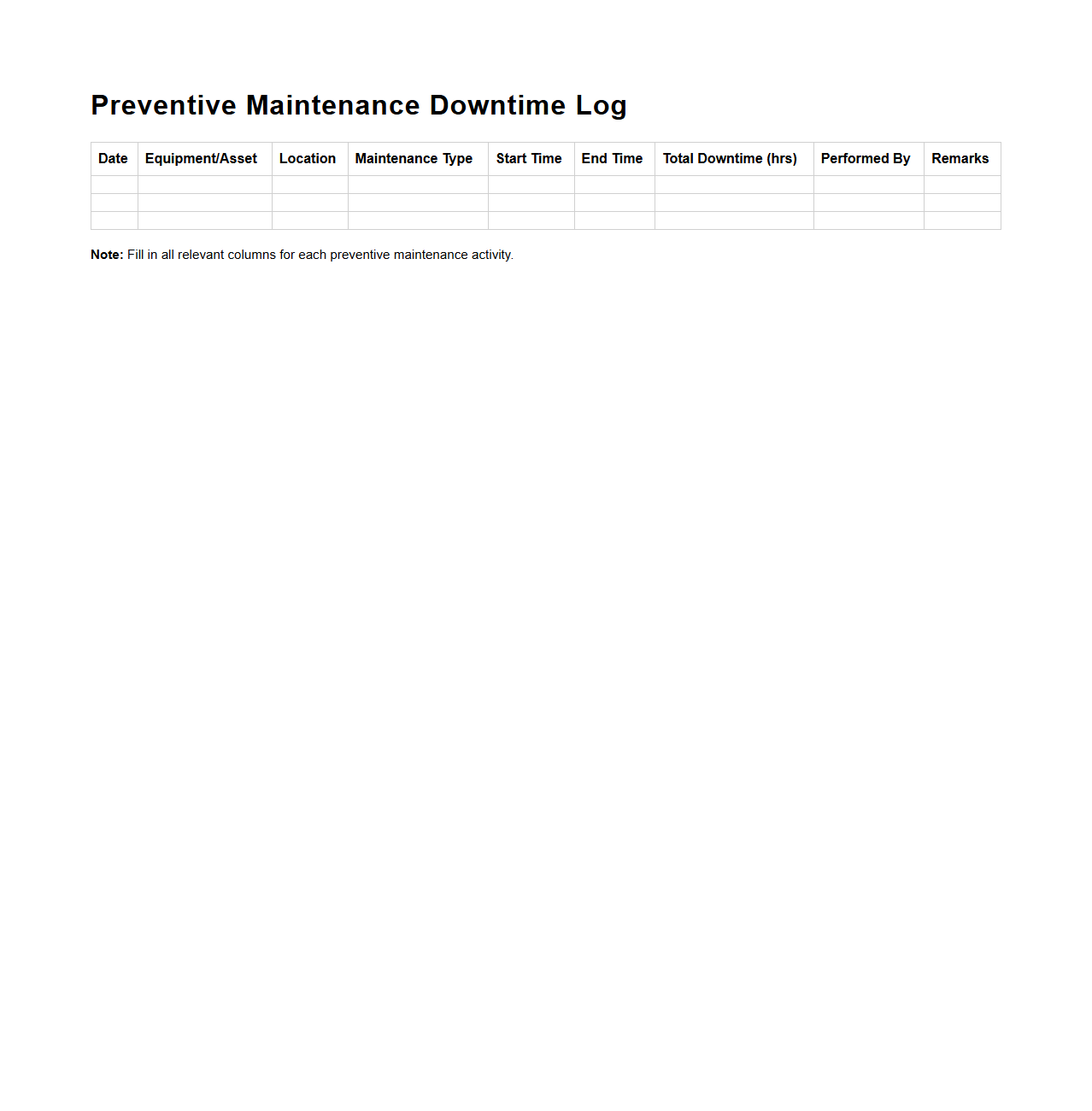

Preventive Maintenance Downtime Log Format

The

Preventive Maintenance Downtime Log Format document is designed to systematically record and track equipment downtime during scheduled preventive maintenance activities. It captures essential details such as the date, duration, reason for downtime, and maintenance actions performed, enabling organizations to analyze maintenance efficiency and identify recurring issues. This structured log format supports better planning, reduces unexpected breakdowns, and enhances overall equipment reliability.

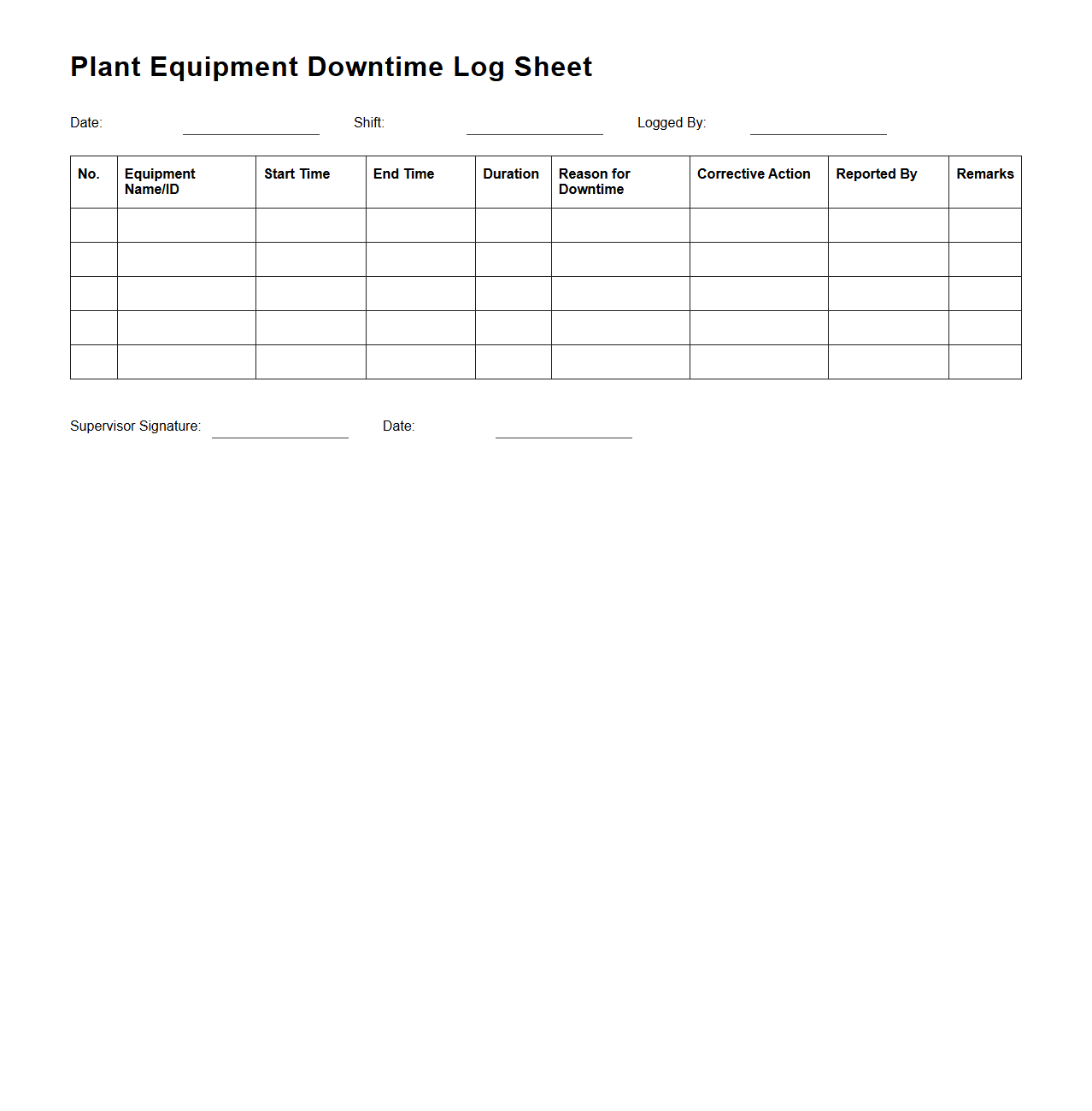

Plant Equipment Downtime Log Sheet

A

Plant Equipment Downtime Log Sheet document is used to accurately record instances when machinery or equipment within a manufacturing or industrial plant is non-operational. It captures essential data such as the duration of downtime, reasons for equipment failure, and the actions taken to resolve the issue, facilitating effective maintenance planning. This log sheet helps improve operational efficiency by identifying patterns and reducing unexpected equipment stoppages.

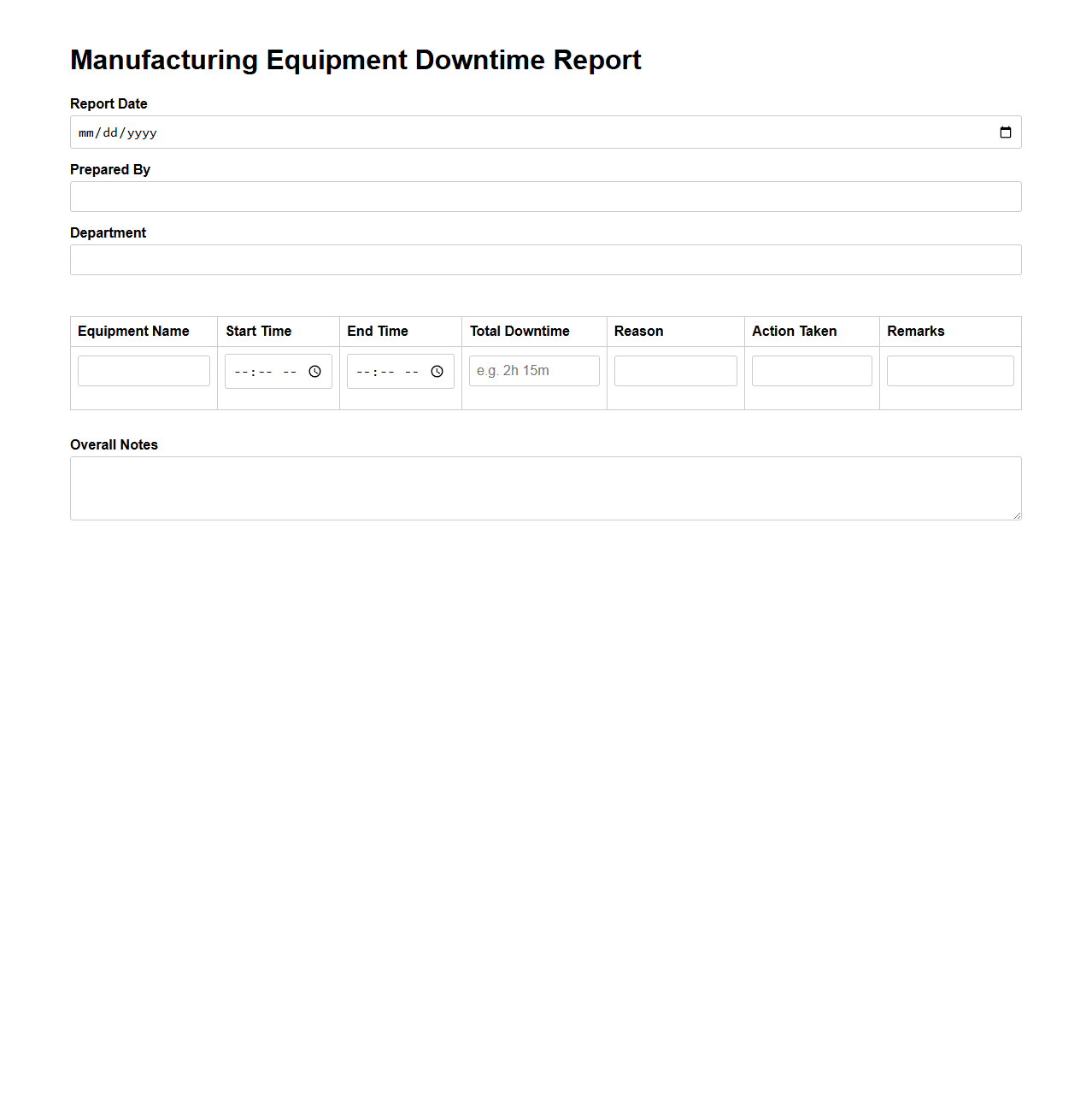

Manufacturing Equipment Downtime Report

A

Manufacturing Equipment Downtime Report document records periods when equipment is not operational, detailing causes such as mechanical failure, maintenance, or power outages. It helps identify patterns affecting production efficiency by tracking downtime duration, frequency, and impact on output. Organizations use this report to optimize maintenance schedules and improve overall equipment effectiveness (OEE).

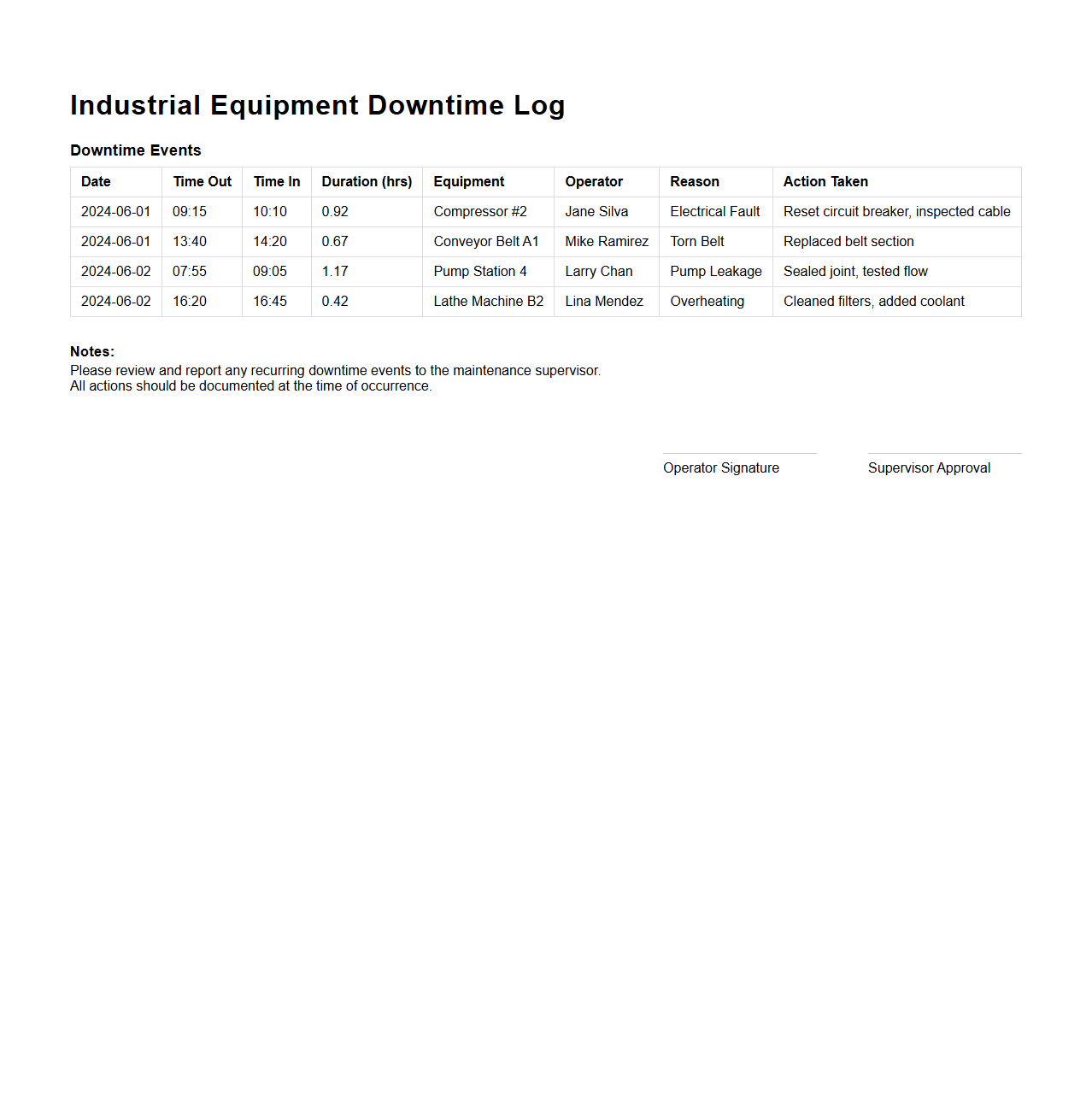

Industrial Equipment Downtime Log Example

An

Industrial Equipment Downtime Log Example document serves as a systematic record of machinery stoppages, capturing critical details such as duration, causes, and maintenance actions taken. This log helps manufacturers analyze patterns of equipment failure, improve operational efficiency, and reduce unscheduled downtime costs. Accurate documentation within the log supports data-driven decision-making for predictive maintenance and resource allocation.

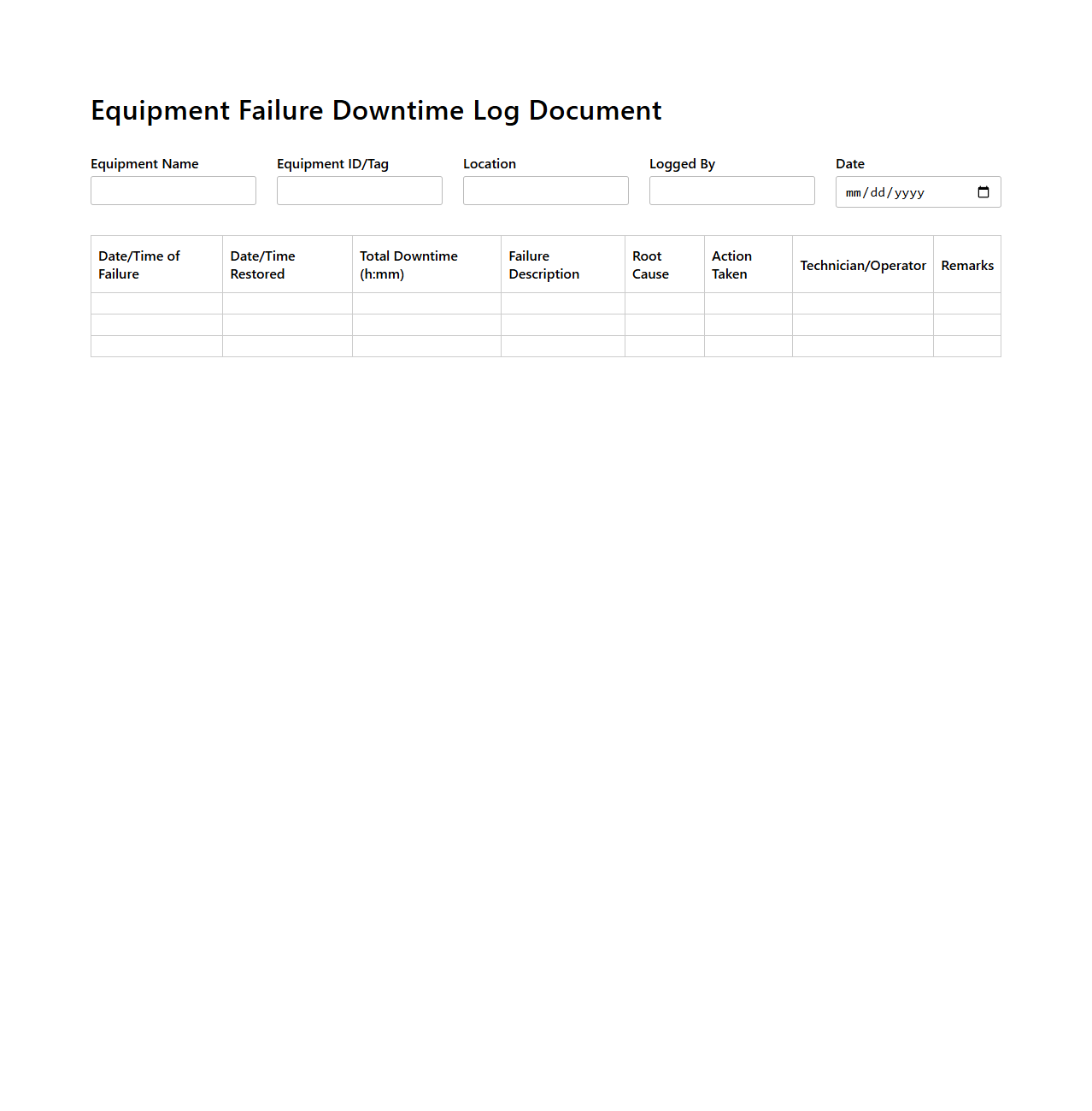

Equipment Failure Downtime Log Document

The

Equipment Failure Downtime Log Document is a critical tool used to record and track the instances of machinery or equipment malfunctions and the corresponding downtime periods. It captures essential data such as failure causes, start and end times of failure, repair actions taken, and the impact on production or operations. This document helps organizations identify patterns, reduce future failures, and improve maintenance efficiency by providing a detailed historical record of equipment performance issues.

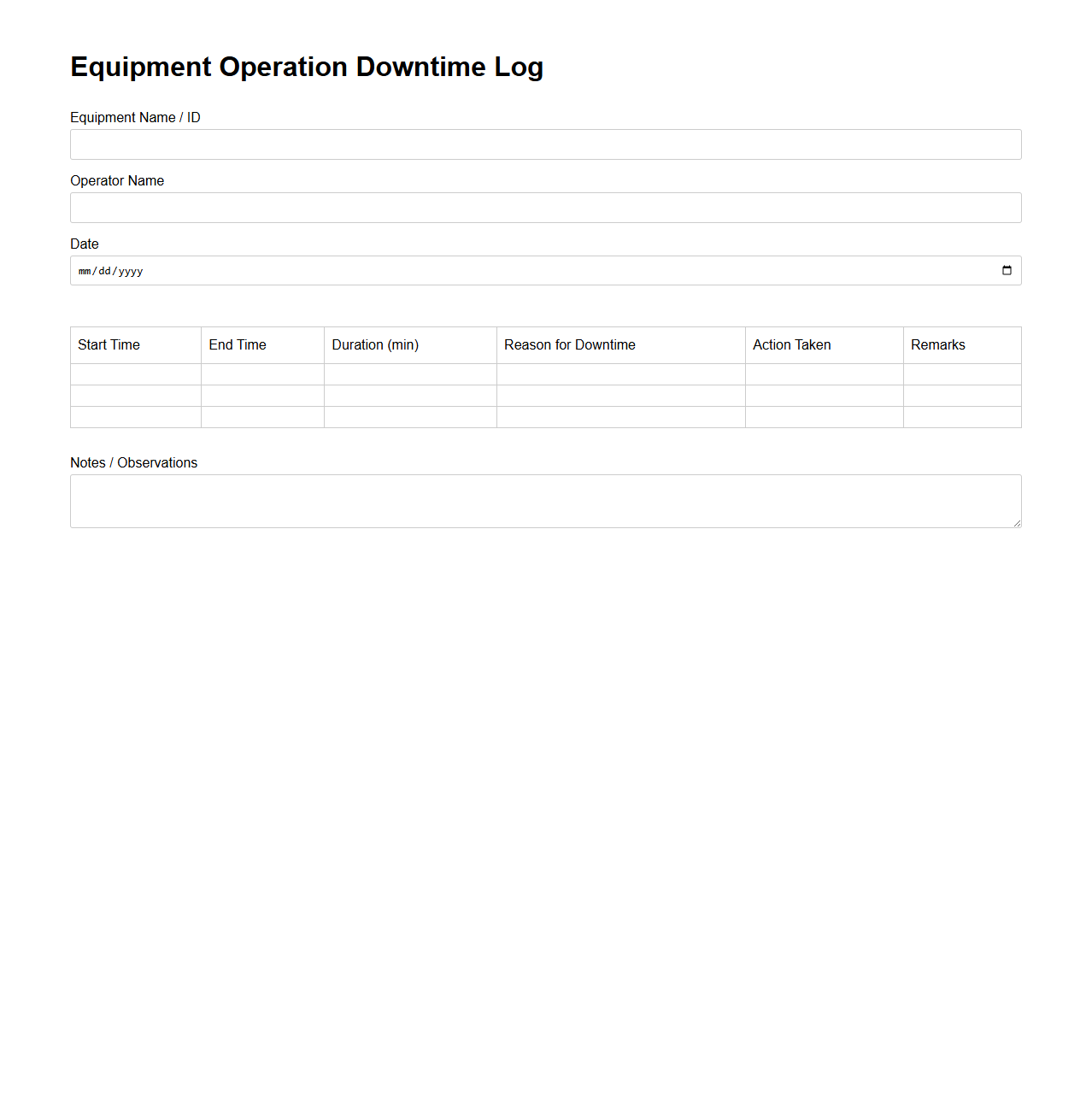

Equipment Operation Downtime Log Template

The

Equipment Operation Downtime Log Template document is a structured tool designed to record and track instances of equipment failures, maintenance, or inactivity during production processes. It details the start and end times of downtime events, reasons for the stoppage, and actions taken to resolve issues, enabling comprehensive analysis of equipment performance. This template enhances operational efficiency by identifying patterns and facilitating proactive maintenance planning.

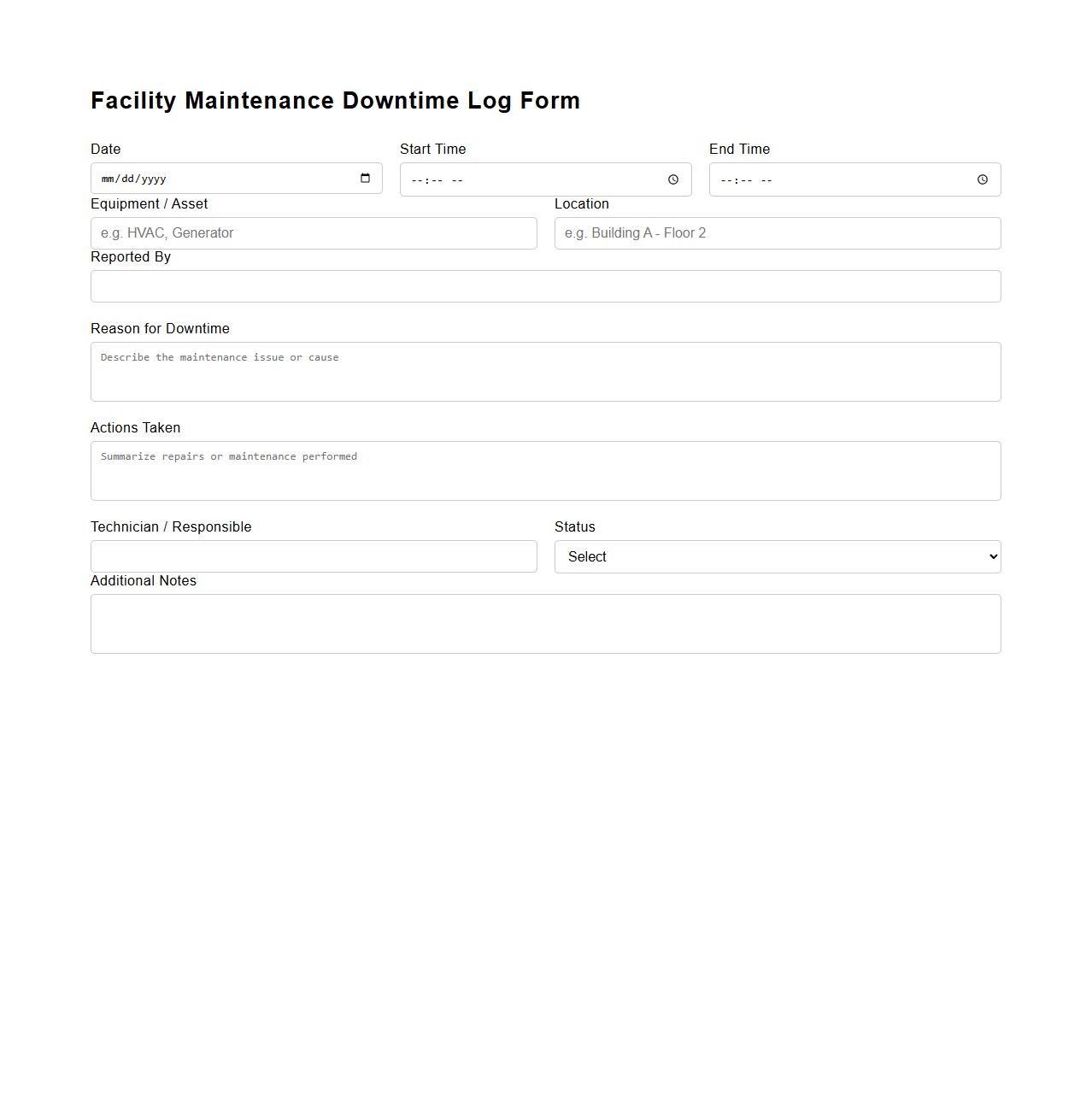

Facility Maintenance Downtime Log Form

A

Facility Maintenance Downtime Log Form is a critical document used to accurately record periods when equipment or systems within a facility are non-operational due to maintenance activities. It tracks the start and end times of downtime, the reason for the interruption, and the personnel involved, enabling detailed analysis of maintenance efficiency. This log supports proactive facility management by identifying patterns that may require process improvements or preventive measures.

What key data fields are essential in an Equipment Downtime Log for effective maintenance tracking?

Essential data fields in an Equipment Downtime Log include equipment identification, date and time of downtime, and duration of the downtime event. It is crucial to capture detailed cause descriptions and the specific maintenance actions taken. Additionally, fields for reporting personnel and status updates ensure comprehensive tracking of each incident.

How does the document categorize causes and durations of equipment downtime?

The log categorizes downtime causes into mechanical, electrical, operational, and external factors to streamline root cause analysis. Duration of downtime is typically segmented into immediate, short-term, and long-term categories for clear prioritization. This structured approach facilitates targeted maintenance planning and resource allocation.

What process is outlined in the log for reporting and resolving maintenance issues?

The log outlines a process starting with initial reporting by operators, followed by verification and prioritization by maintenance teams. It emphasizes timely documentation of corrective actions and verification of equipment functionality after repairs. Finally, resolution details and downtime impact assessments are recorded to close the maintenance loop.

How is equipment availability and performance measured and recorded within the log?

Equipment availability is measured by calculating the ratio of operational time to total scheduled time, noted in the log. Performance is tracked through metrics like mean time between failures (MTBF) and mean time to repair (MTTR). Recording these metrics in the log supports ongoing reliability and productivity assessments.

What methods are suggested in the document for analyzing downtime trends and prevention strategies?

The document suggests using statistical analysis and trend charts to identify recurring issues and patterns in downtime data. Preventive maintenance schedules and failure mode effects analysis (FMEA) are recommended strategies documented within the log. These methods collectively enhance proactive maintenance and minimize future equipment interruptions.

More Manufacturing Templates