A Packaging Inspection Document Sample for Finished Goods outlines the critical criteria for evaluating the packaging quality before product shipment. It includes inspection checkpoints such as label accuracy, package integrity, and compliance with safety standards to ensure customer satisfaction. This document serves as a quality control tool to minimize defects and maintain consistency in finished goods packaging.

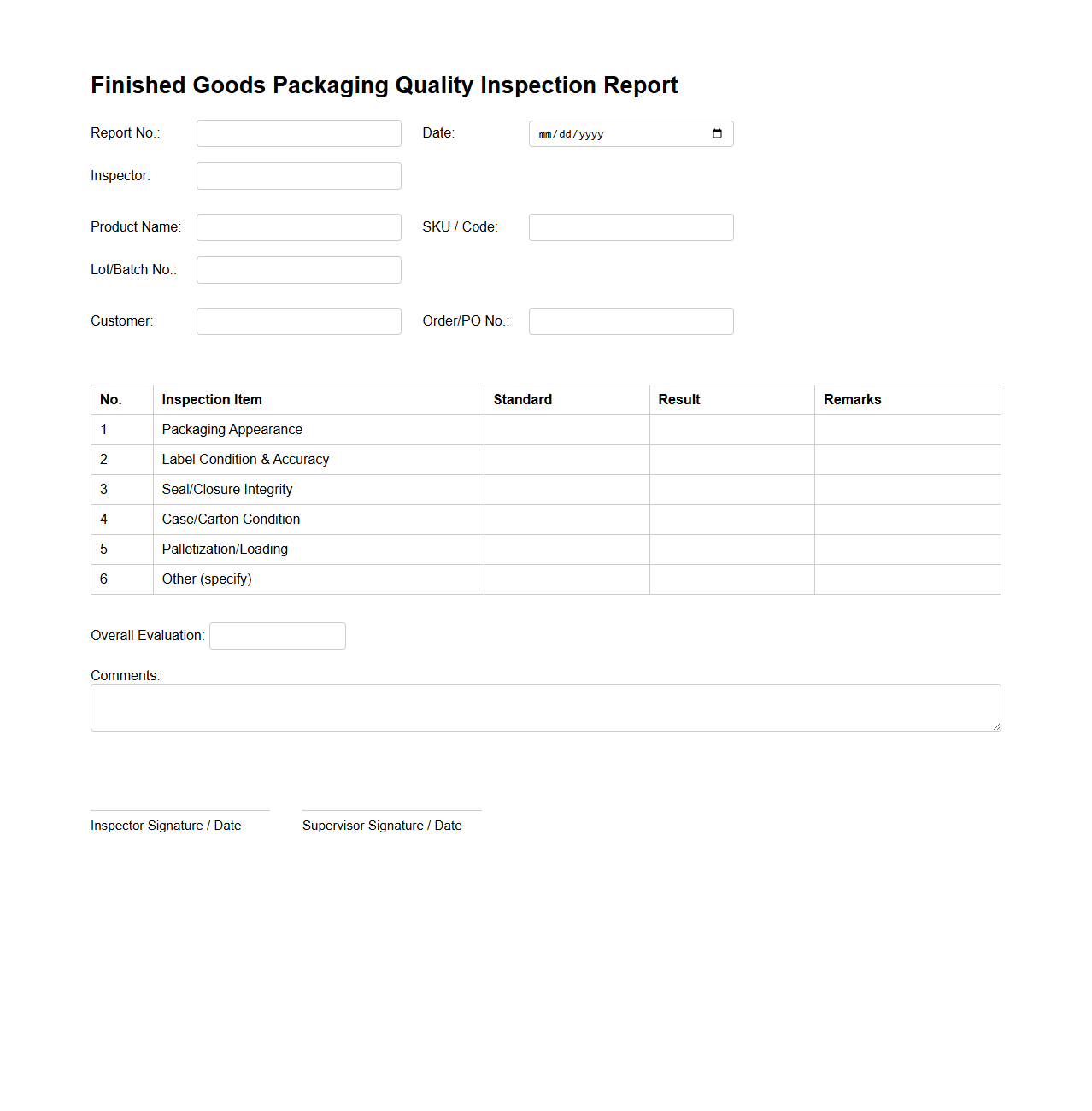

Finished Goods Packaging Quality Inspection Report Template

The Finished Goods Packaging Quality Inspection Report Template is a standardized document used to assess and record the quality of packaging for final products before shipment. It includes detailed criteria such as packaging integrity, labeling accuracy, and compliance with safety standards to ensure customer satisfaction and regulatory adherence. This template helps manufacturers maintain

consistent packaging quality and reduce the risk of damage during transportation.

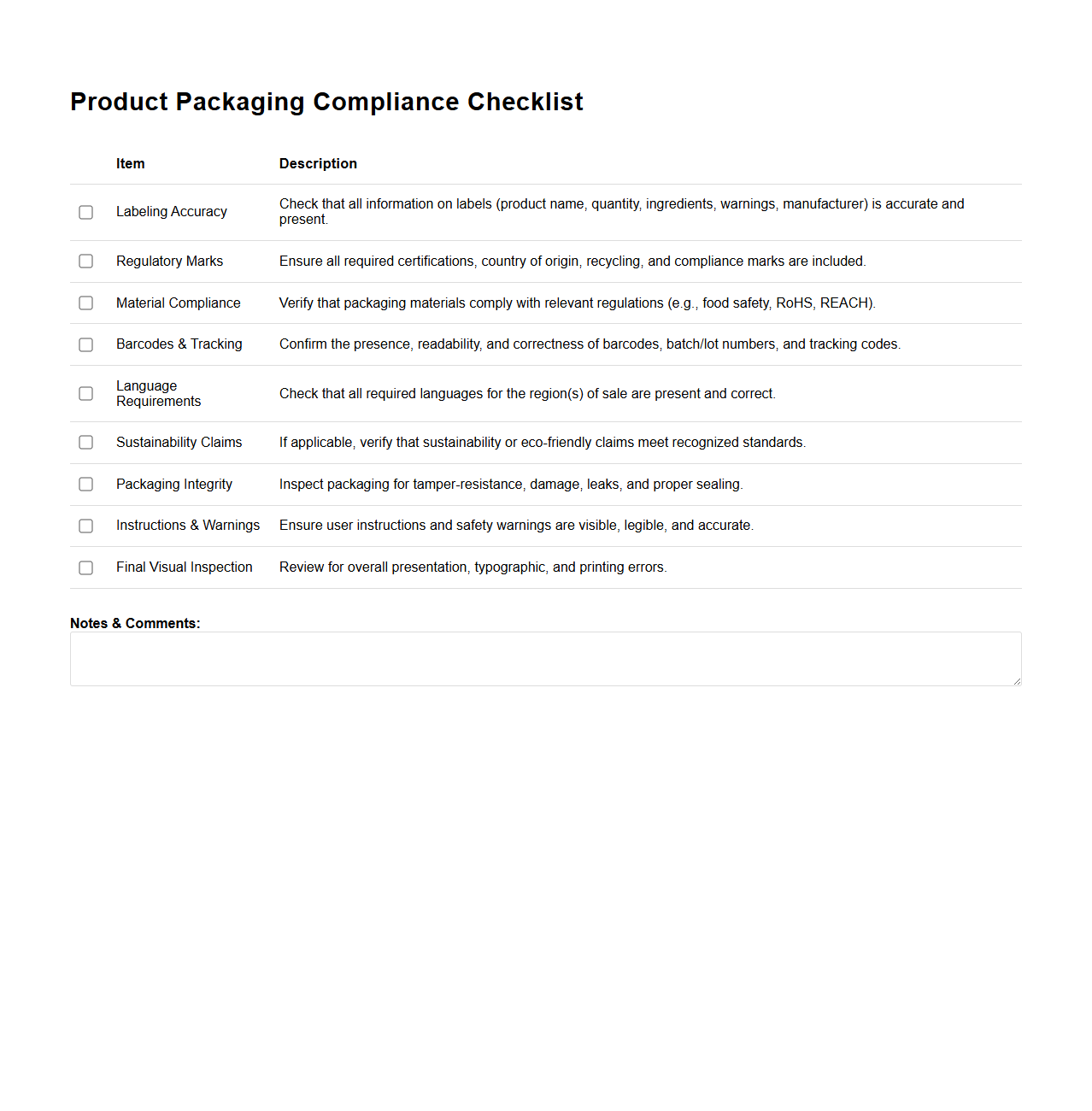

Product Packaging Compliance Checklist for Final Goods

The

Product Packaging Compliance Checklist for Final Goods document ensures that all packaging materials and labels meet regulatory standards, environmental guidelines, and company policies before shipment. This checklist verifies critical elements such as packaging durability, correct labeling, safety warnings, and sustainability compliance to avoid legal risks and consumer dissatisfaction. Using this document streamlines quality control processes and helps maintain brand integrity across global markets.

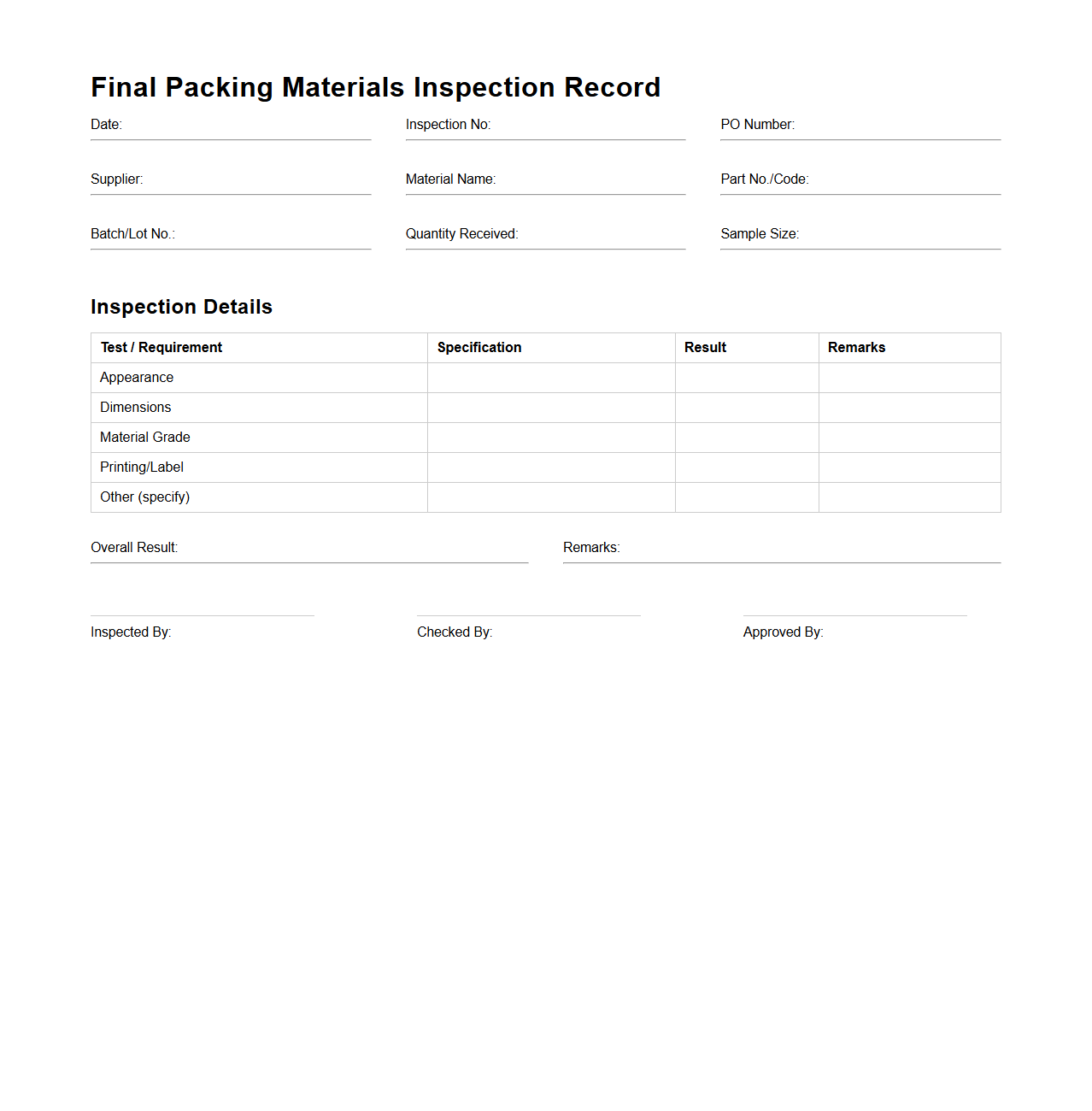

Final Packing Materials Inspection Record Sample

The

Final Packing Materials Inspection Record Sample document serves as a comprehensive checklist used to verify the quality and compliance of packing materials before shipment. It includes detailed criteria such as material type, durability, dimensions, and sealing integrity to ensure packaging meets industry standards and customer specifications. This record is essential for maintaining consistent product protection and minimizing damage during transportation.

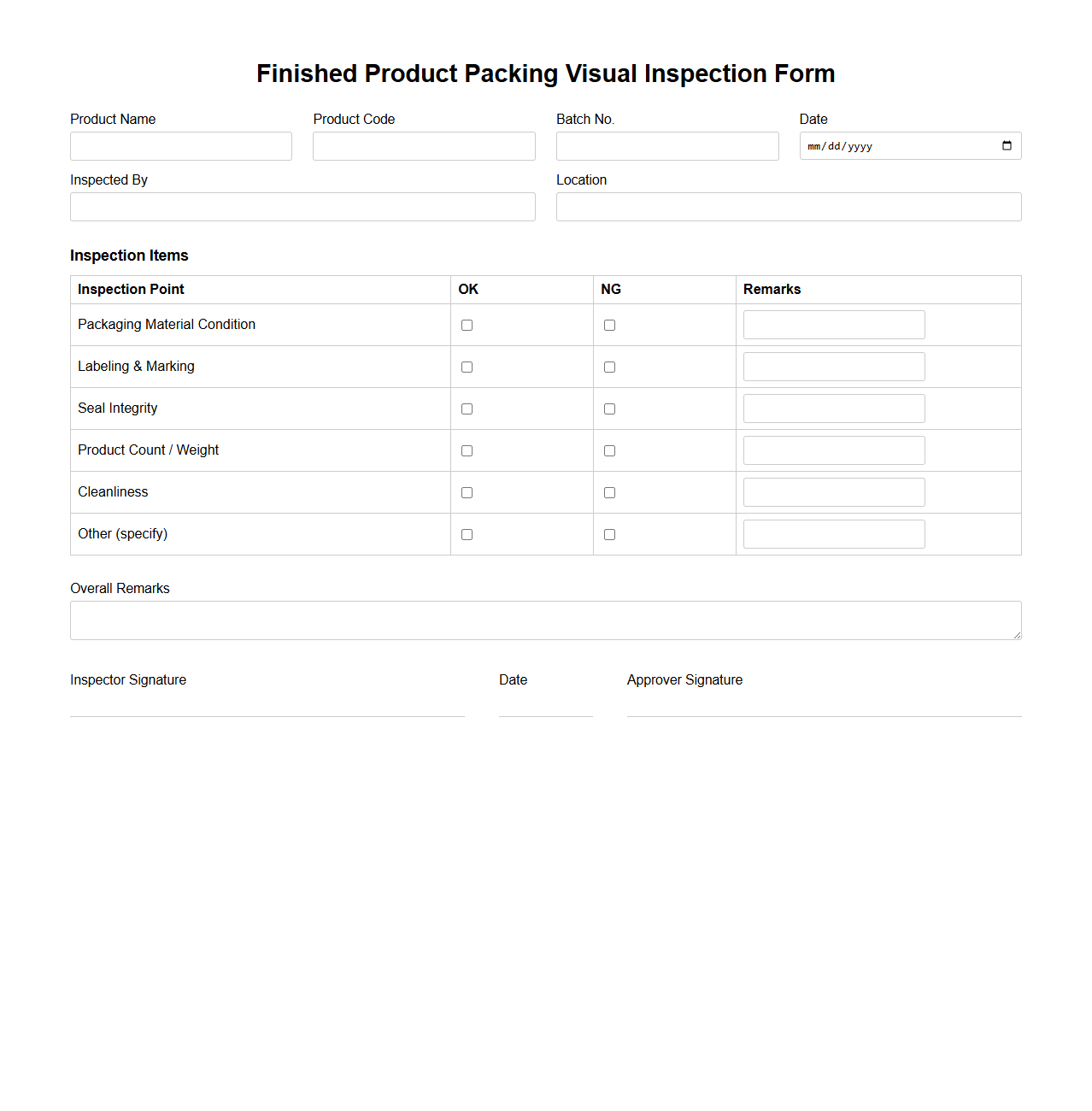

Finished Product Packing Visual Inspection Form

The

Finished Product Packing Visual Inspection Form document is used to systematically assess the packaging quality of finalized products, ensuring they meet established standards and specifications. It records detailed observations related to packaging integrity, labeling accuracy, and conformity to safety guidelines, helping to prevent defective or non-compliant items from reaching customers. This form is integral in maintaining quality control and supporting traceability in production workflows.

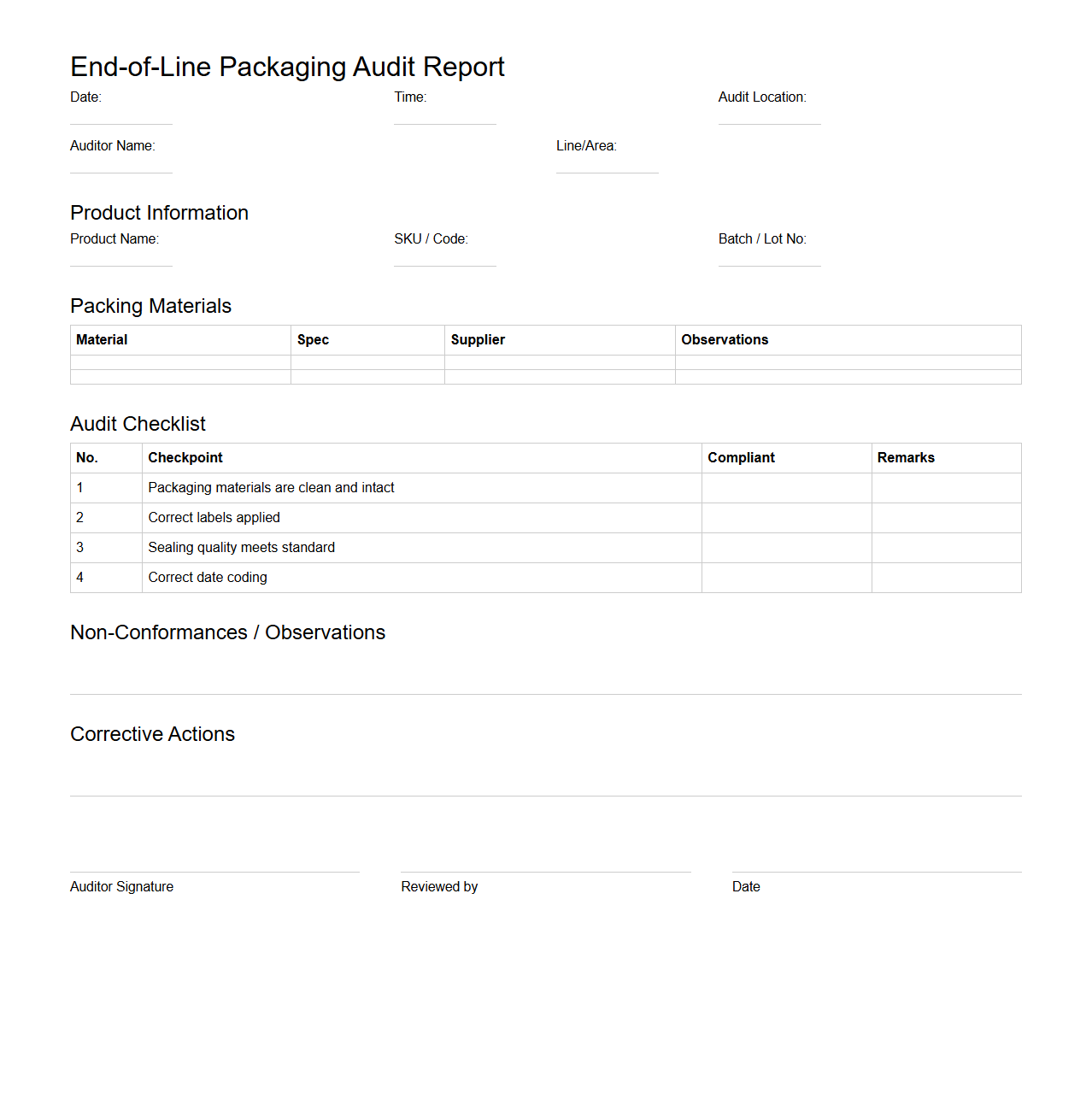

End-of-Line Packaging Audit Report Layout

The

End-of-Line Packaging Audit Report Layout document serves as a structured template for recording and evaluating packaging quality at the final stage of production. It includes sections for specifying packaging defects, compliance with standards, and corrective actions required, ensuring consistent documentation and traceability. This report layout helps streamline quality control processes and facilitates communication between production and quality assurance teams.

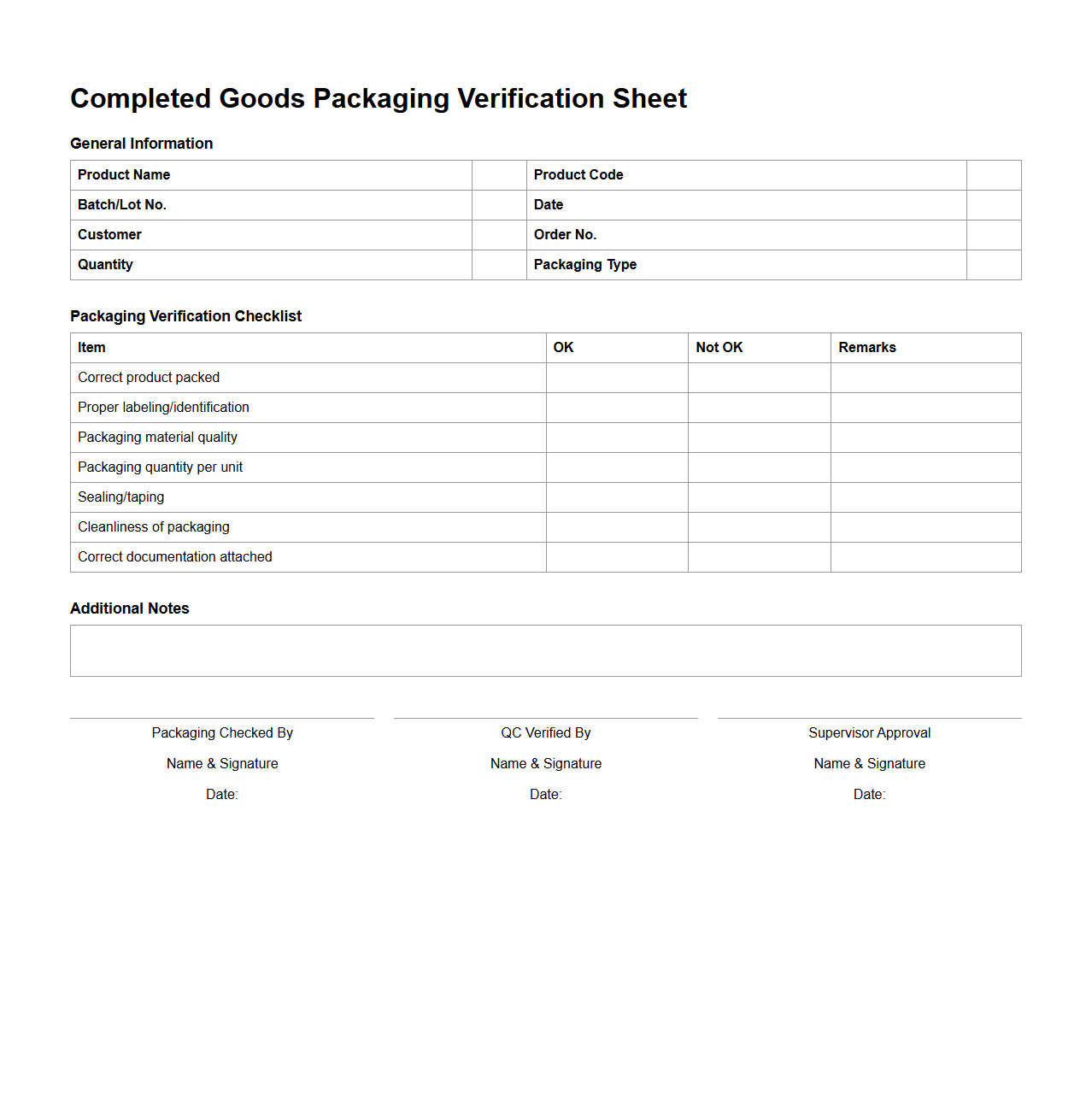

Completed Goods Packaging Verification Sheet

The

Completed Goods Packaging Verification Sheet is a quality control document used to ensure that finished products are packaged according to specified standards before shipment. It details the inspection criteria, including packaging integrity, labeling accuracy, and compliance with regulatory requirements. This sheet serves as a critical verification step to prevent errors, reduce returns, and maintain customer satisfaction.

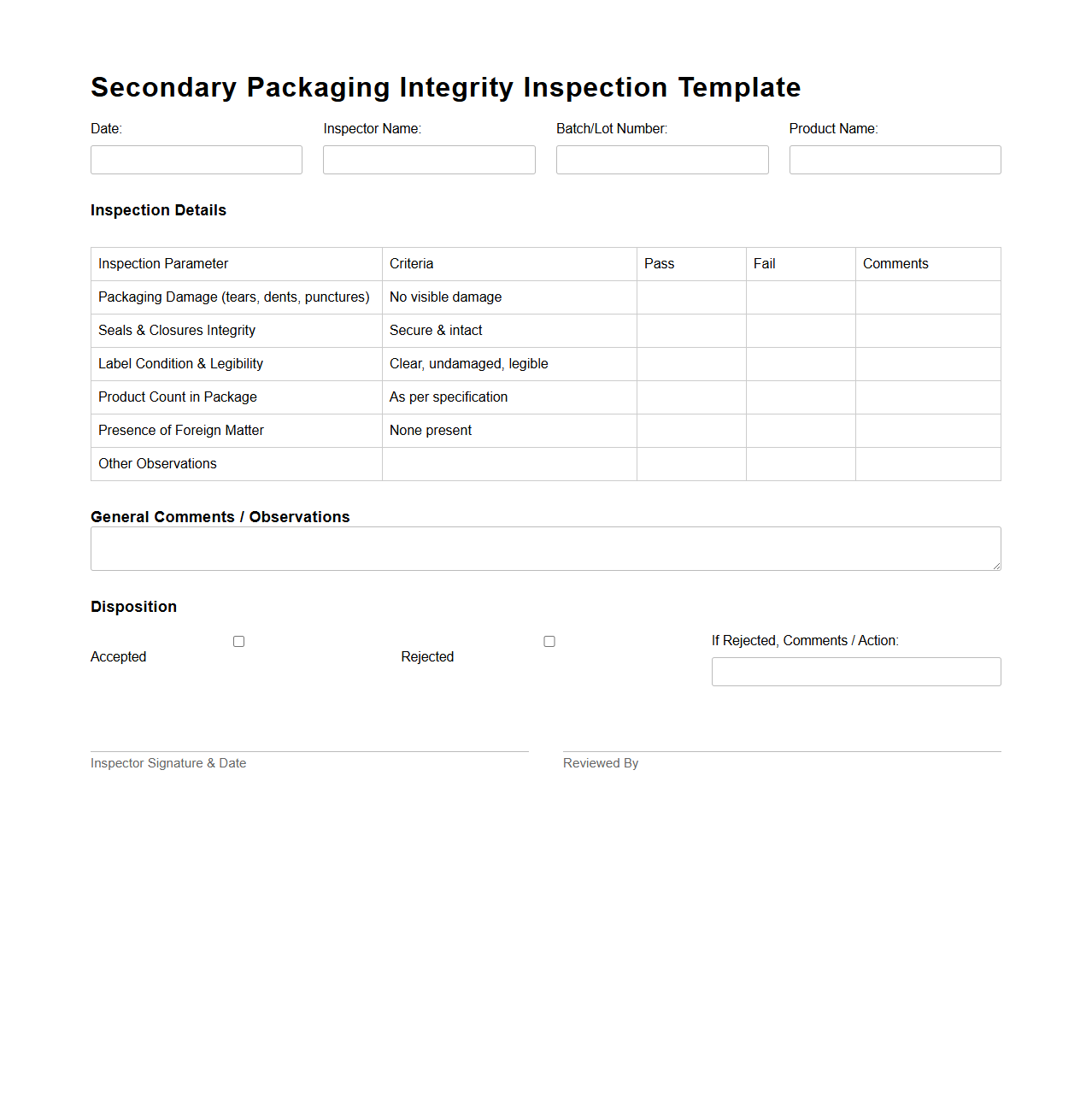

Secondary Packaging Integrity Inspection Template

The

Secondary Packaging Integrity Inspection Template document serves as a standardized tool to assess the quality and durability of secondary packaging materials used in product distribution. It outlines specific criteria for evaluating packaging strength, seal integrity, and protection against environmental factors to ensure products remain intact during transit. This template helps maintain compliance with industry standards and minimizes risks of damage, contamination, or product recalls.

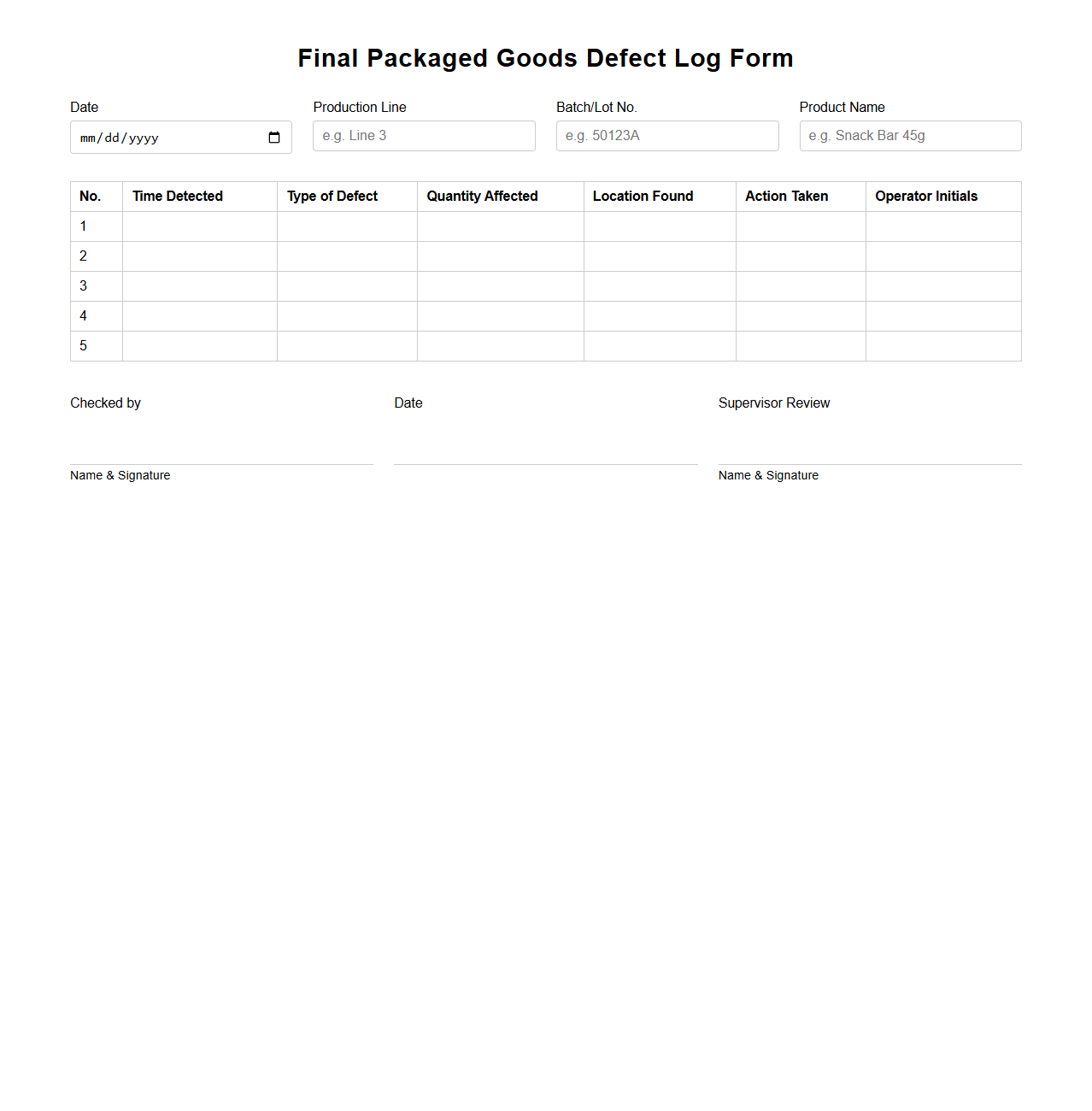

Final Packaged Goods Defect Log Form

The

Final Packaged Goods Defect Log Form document serves as a comprehensive record for tracking and documenting defects identified in finished packaged products. It enables quality control teams to systematically capture defect types, quantities, and root causes, facilitating efficient analysis and corrective actions. Maintaining this form ensures compliance with industry standards and supports continuous improvement in product quality and customer satisfaction.

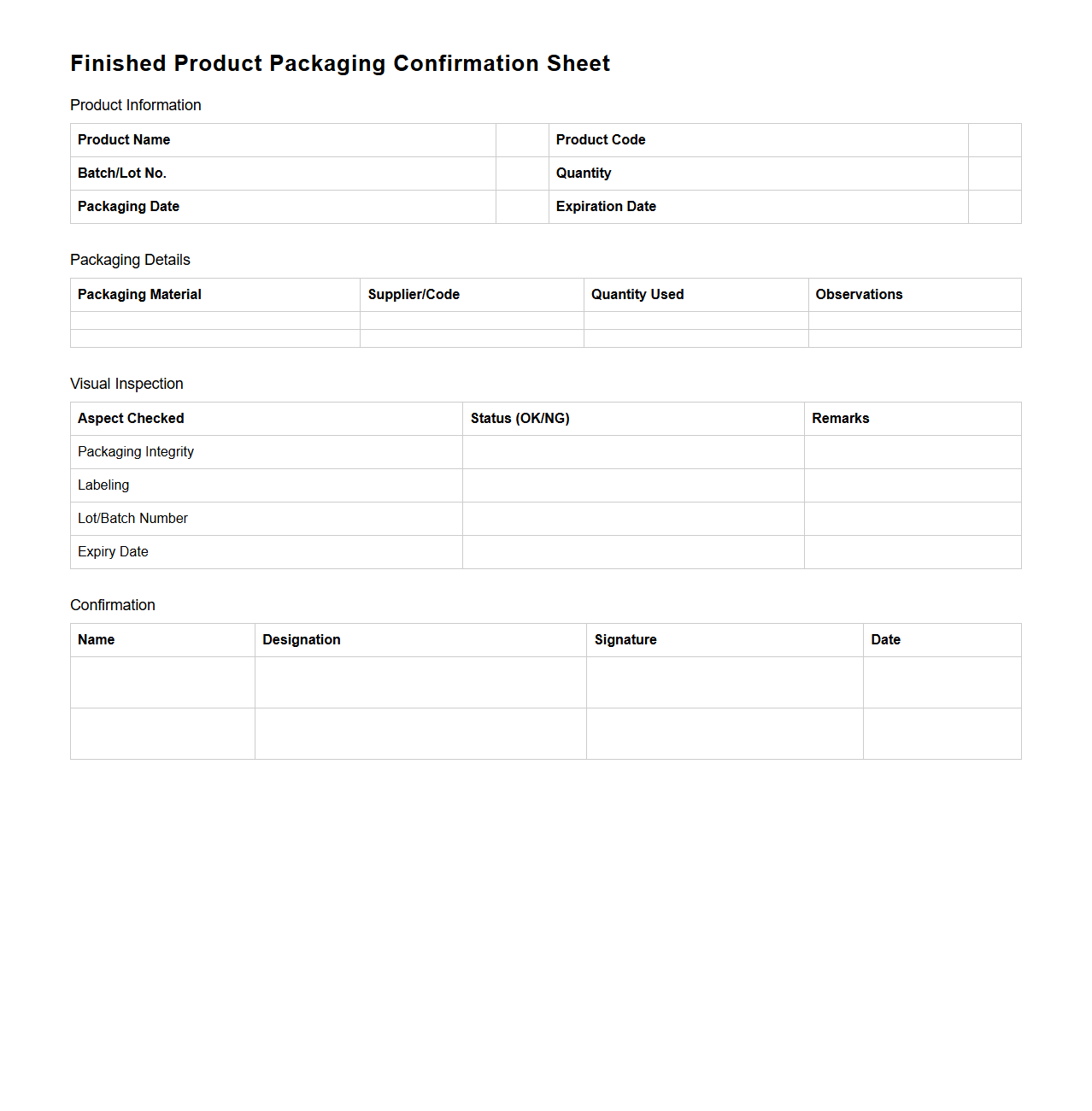

Finished Product Packaging Confirmation Sheet

The

Finished Product Packaging Confirmation Sheet is a critical document used in manufacturing and logistics to verify that packaging meets predefined quality and specification standards before shipment. It details product information, packaging materials, dimensions, and quantity, ensuring compliance with client requirements and regulatory guidelines. This sheet serves as a formal confirmation for quality control teams and stakeholders, minimizing packaging errors and supporting traceability throughout the supply chain.

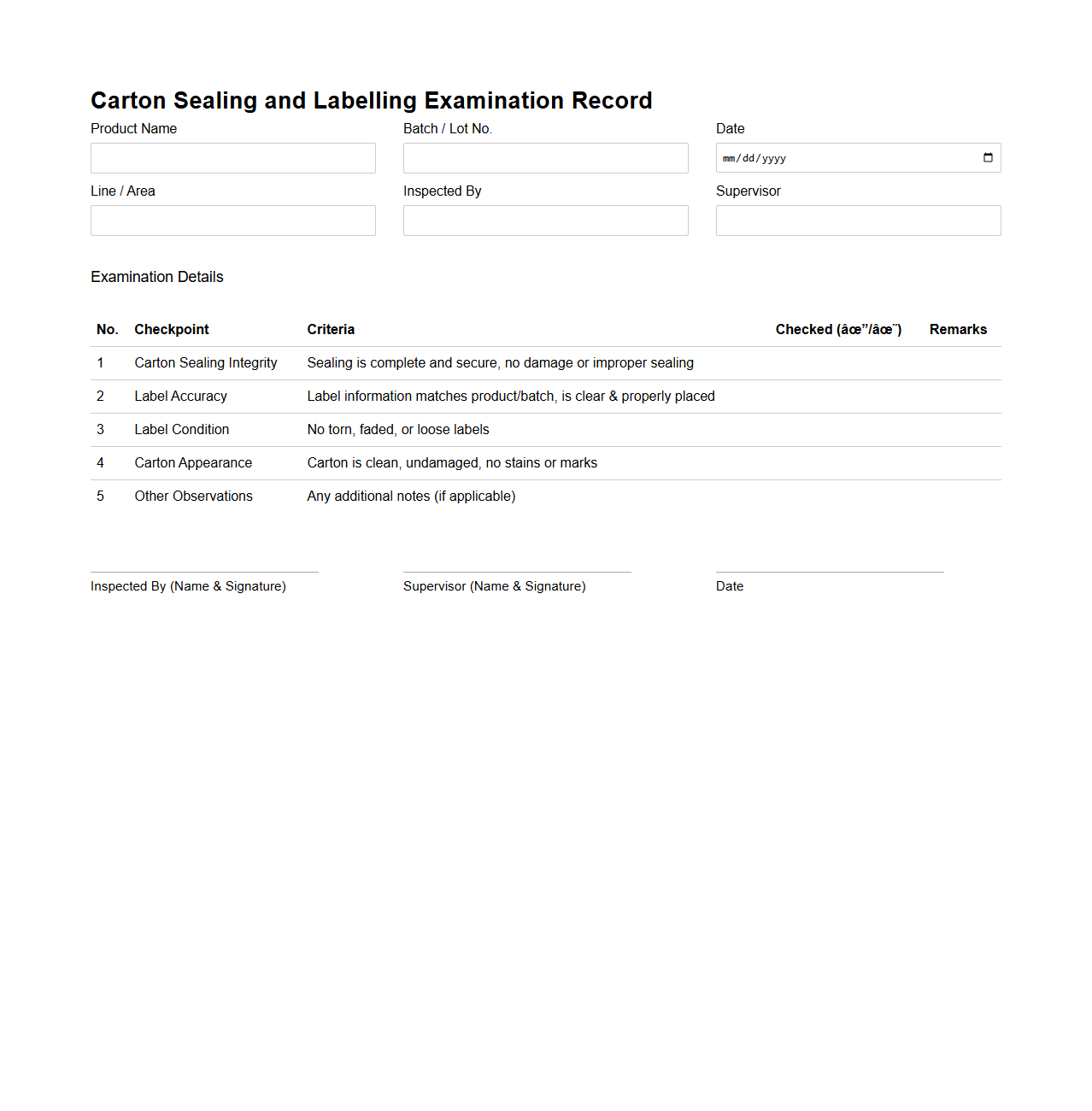

Carton Sealing and Labelling Examination Record

The

Carton Sealing and Labelling Examination Record document is a critical quality control tool used to verify the integrity and accuracy of packaging in the supply chain. It ensures each carton is properly sealed to prevent damage or tampering during transit and that labels accurately reflect product information, batch numbers, and shipping details. This record helps maintain compliance with industry standards and facilitates traceability throughout the logistics process.

Mandatory Components in Packaging Inspection Document for Finished Goods

The packaging inspection document must include key components such as product identification, inspection criteria, and detailed observations. It also requires clear documentation of packaging materials and methods used to ensure consistency. This document is crucial for maintaining quality control across finished goods.

Definition of Acceptance or Rejection Criteria for Packaging Quality

The document defines acceptance criteria based on pre-established quality standards, such as material integrity, labeling accuracy, and package sealing quality. Rejection criteria emphasize defects like tears, leaks, or incorrect labeling. These criteria ensure uniformity in packaging quality for shipment and customer satisfaction.

Specific Checkpoints or Inspection Stages Outlined

The inspection document outlines stages including initial material verification, in-process packaging checks, and final finished goods inspection. Each checkpoint focuses on aspects like packaging durability, compliance with specifications, and proper sealing. This comprehensive approach ensures consistent quality throughout the packaging process.

Documentation and Photographic Evidence Required

Photographic evidence must capture key packaging attributes such as labeling, seals, and batch numbers for visual verification. Additionally, detailed documentation of inspection results and any deviations is mandatory. This procedure guarantees reliable record keeping and supports quality assurance investigations.

Ensuring Traceability and Accountability of Inspectors and Batch Numbers

The document mandates recording the inspector's name or ID, date of inspection, and specific batch numbers on each report. This traceability facilitates accountability and easy follow-up in case of discrepancies. Proper traceability is vital for managing product recalls and maintaining customer trust.

More Manufacturing Templates