A Inventory Control Document Sample for Warehouse Management provides a structured template to efficiently track stock levels, monitor item movement, and manage storage locations. This document ensures accuracy in inventory records, reduces discrepancies, and facilitates timely restocking. By implementing such a sample, warehouses can streamline operations and improve overall inventory accuracy.

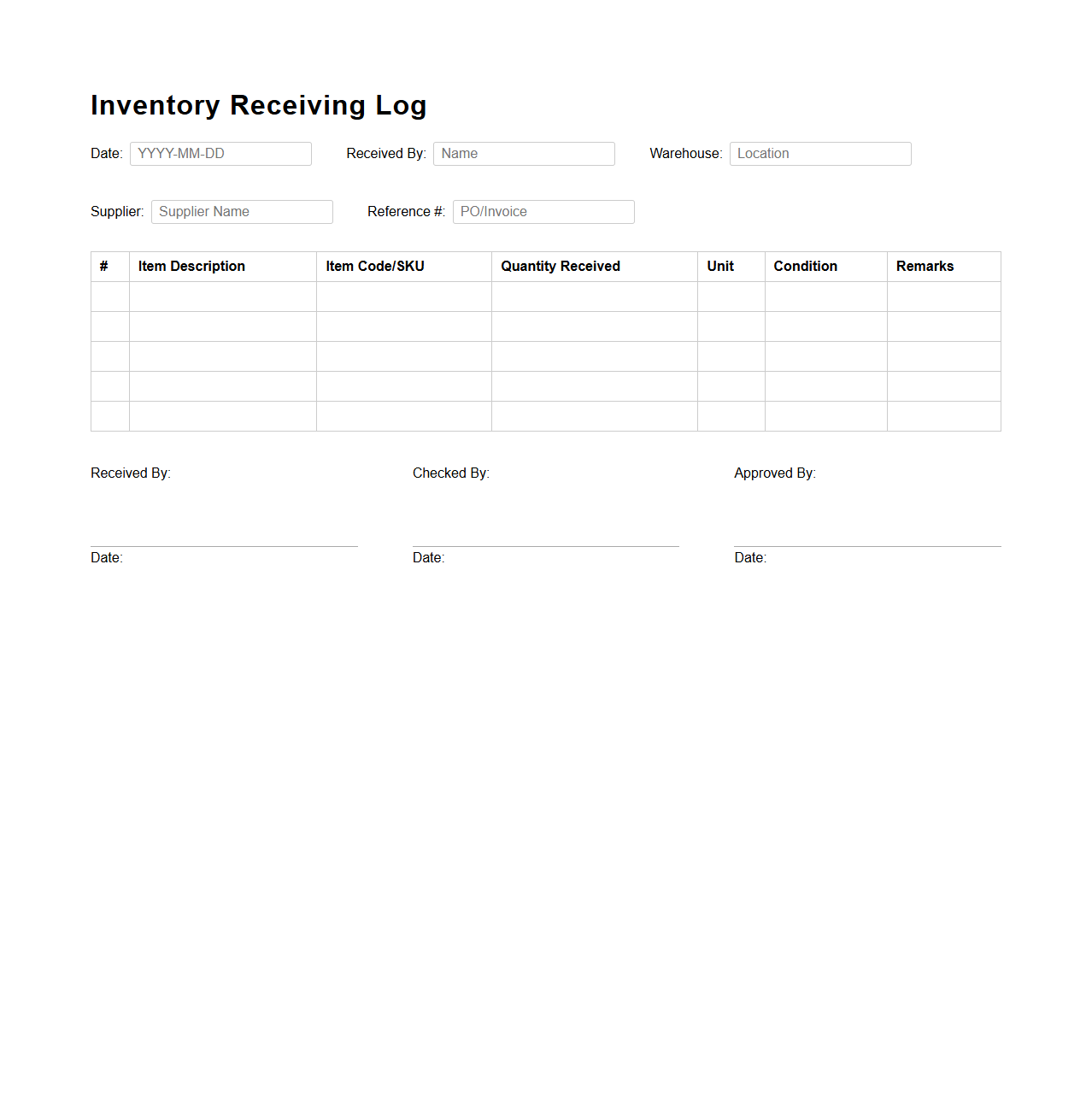

Inventory Receiving Log Template for Warehouse

An

Inventory Receiving Log Template for a warehouse document is a structured form used to accurately record details of incoming shipments, including item descriptions, quantities, dates, and supplier information. This template ensures efficient tracking of received goods, minimizes discrepancies, and facilitates inventory management by providing a clear, organized record for warehouse staff. Proper use of the template helps maintain stock accuracy and supports timely reconciliation with purchase orders and inventory systems.

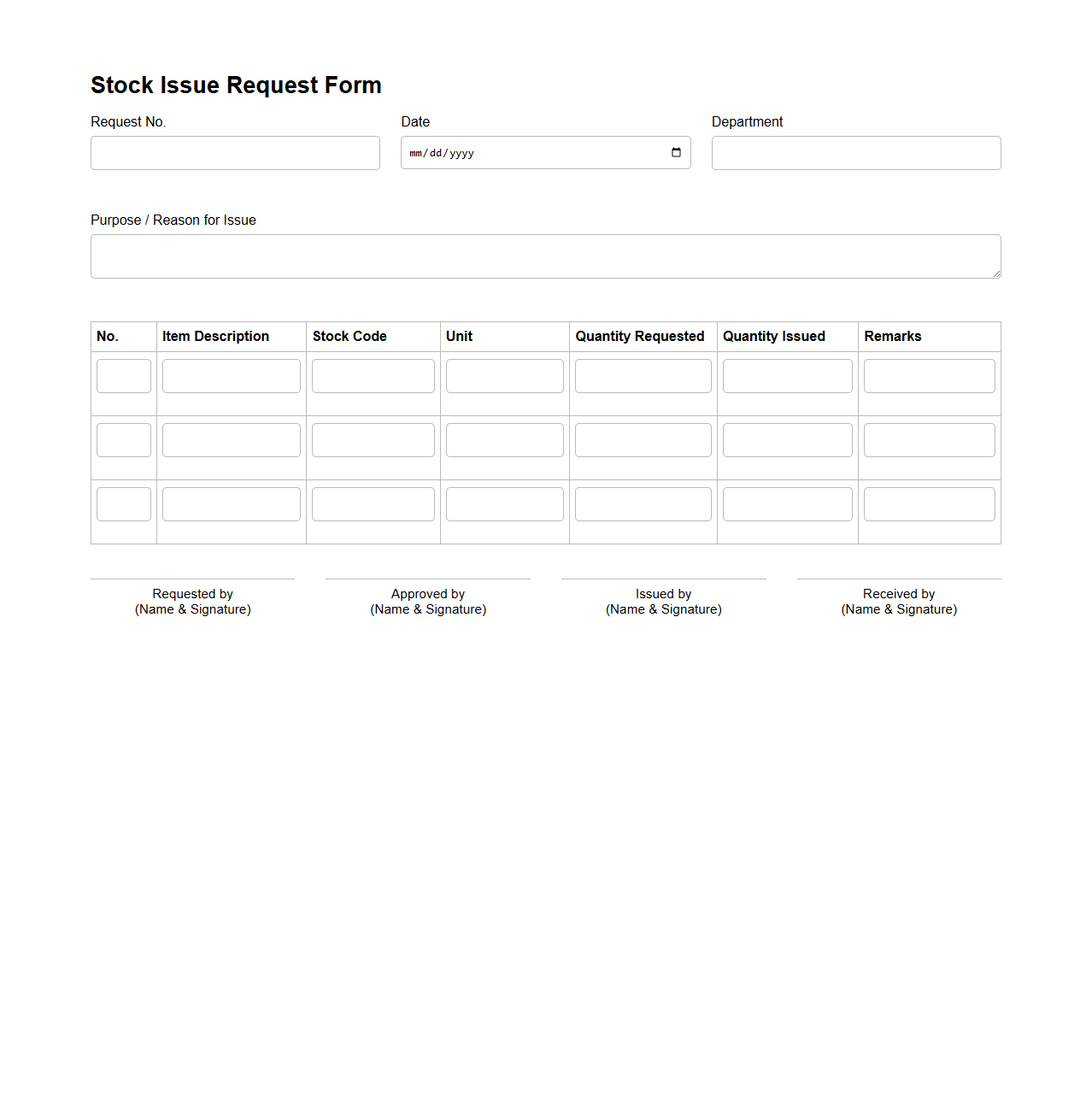

Stock Issue Request Form for Inventory Control

A

Stock Issue Request Form is a critical document used in inventory control to authorize and track the release of stock items from the warehouse to various departments or project sites. It captures essential details such as item descriptions, quantities requested, approval signatures, and dates to ensure accountability and accurate record-keeping. This form helps maintain inventory accuracy, prevent stock discrepancies, and streamline stock management processes.

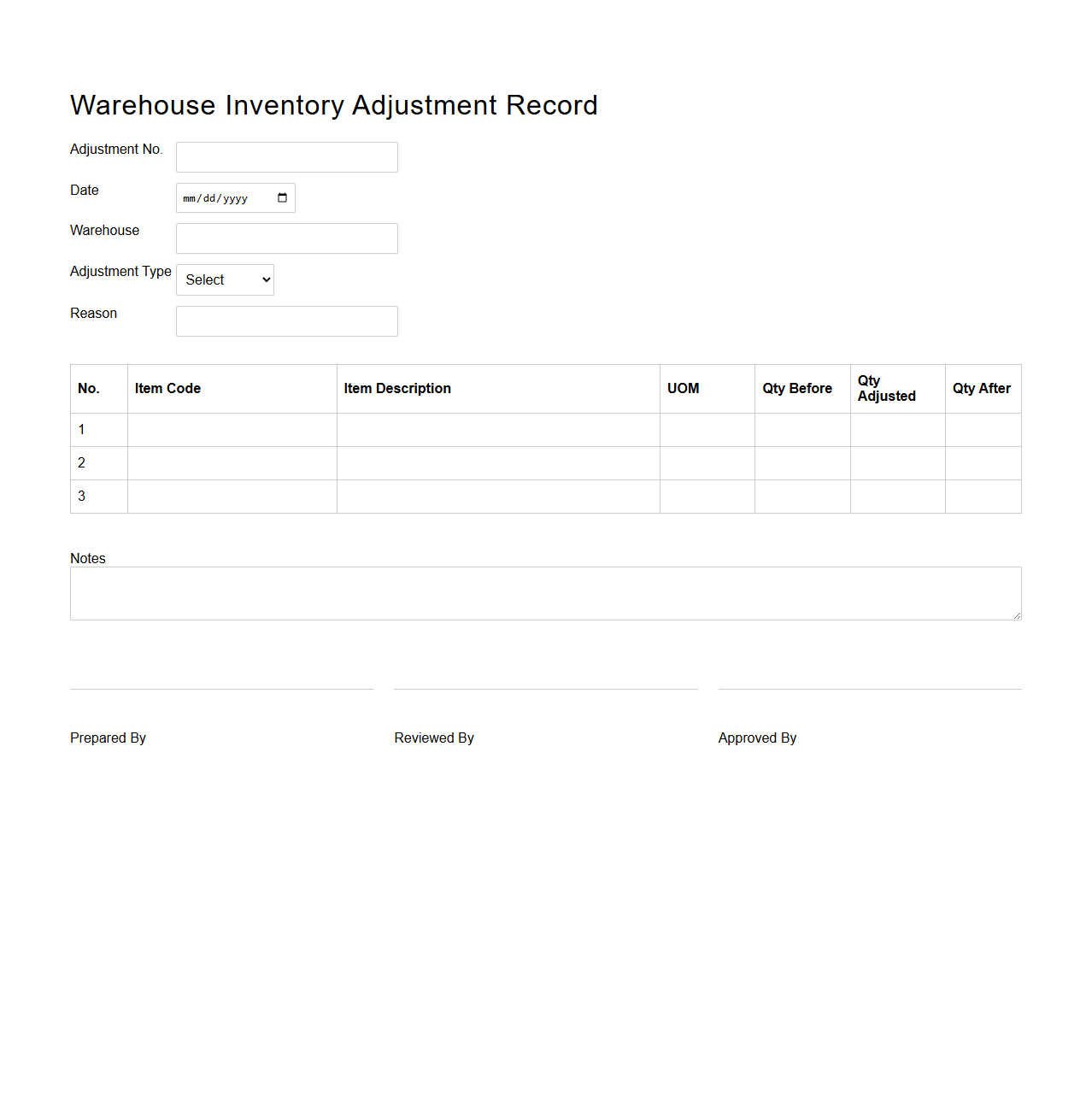

Warehouse Inventory Adjustment Record Sample

A

Warehouse Inventory Adjustment Record Sample document serves as a detailed log that tracks changes in inventory levels within a warehouse. It records discrepancies between recorded stock and actual quantities, including reasons for increases or decreases, such as damage, theft, or miscounts. This ensures accurate inventory management, supports audit compliance, and enhances operational efficiency.

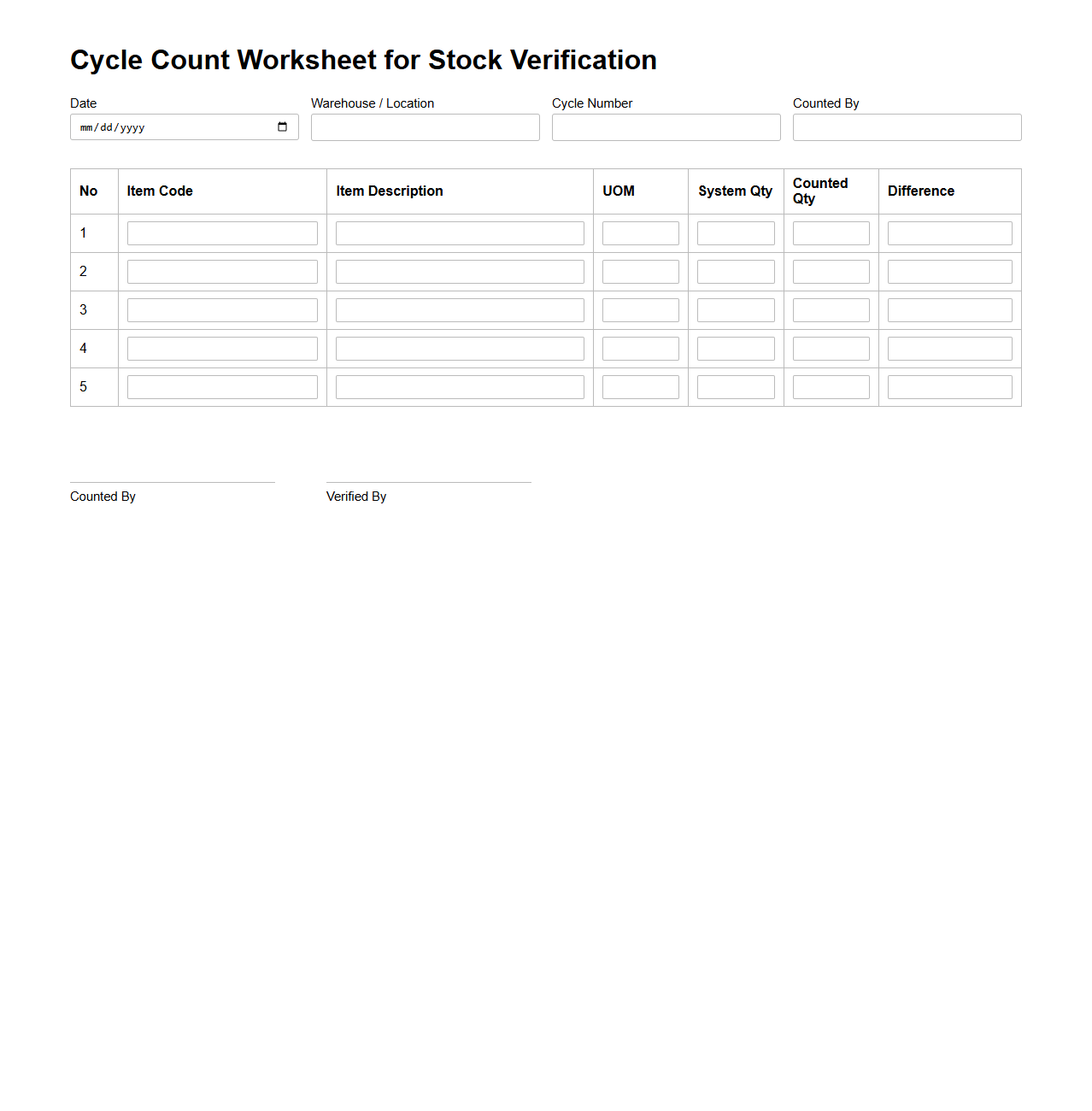

Cycle Count Worksheet for Stock Verification

A

Cycle Count Worksheet for stock verification is a document used to systematically record and verify inventory quantities on a regular basis, ensuring accuracy between physical stock and recorded data. This worksheet helps identify discrepancies, track variances, and maintain optimal stock levels without the need for a full physical inventory count. The process improves inventory management efficiency and reduces errors related to stock misplacement or data entry.

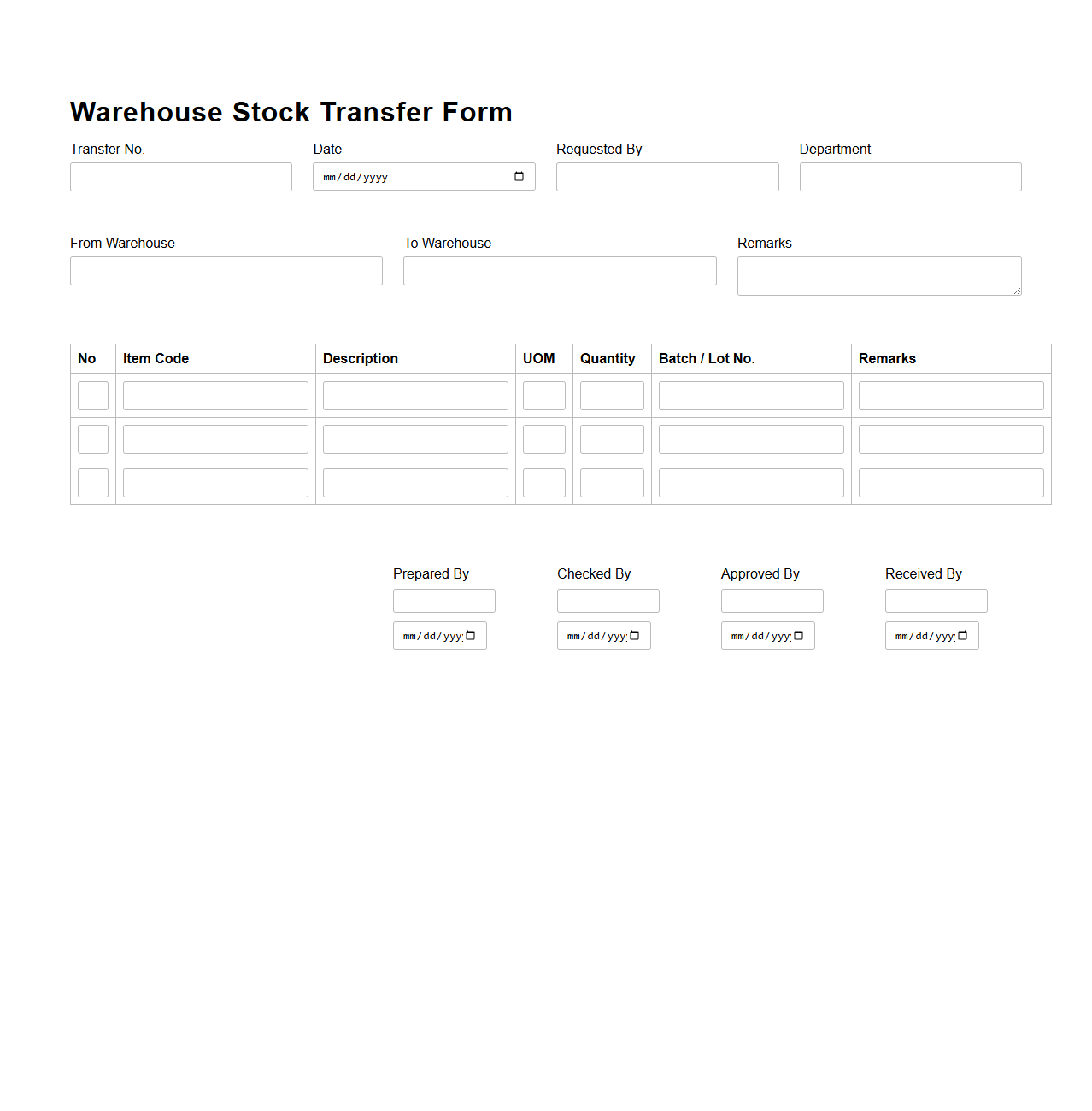

Warehouse Stock Transfer Form Example

A

Warehouse Stock Transfer Form Example document is a standardized template used to record the movement of inventory between different warehouse locations within a company. This form captures essential details such as item description, quantity, source and destination warehouses, and transfer date to ensure accurate tracking and inventory management. Utilizing this document helps maintain inventory accuracy, reduce discrepancies, and support efficient supply chain operations.

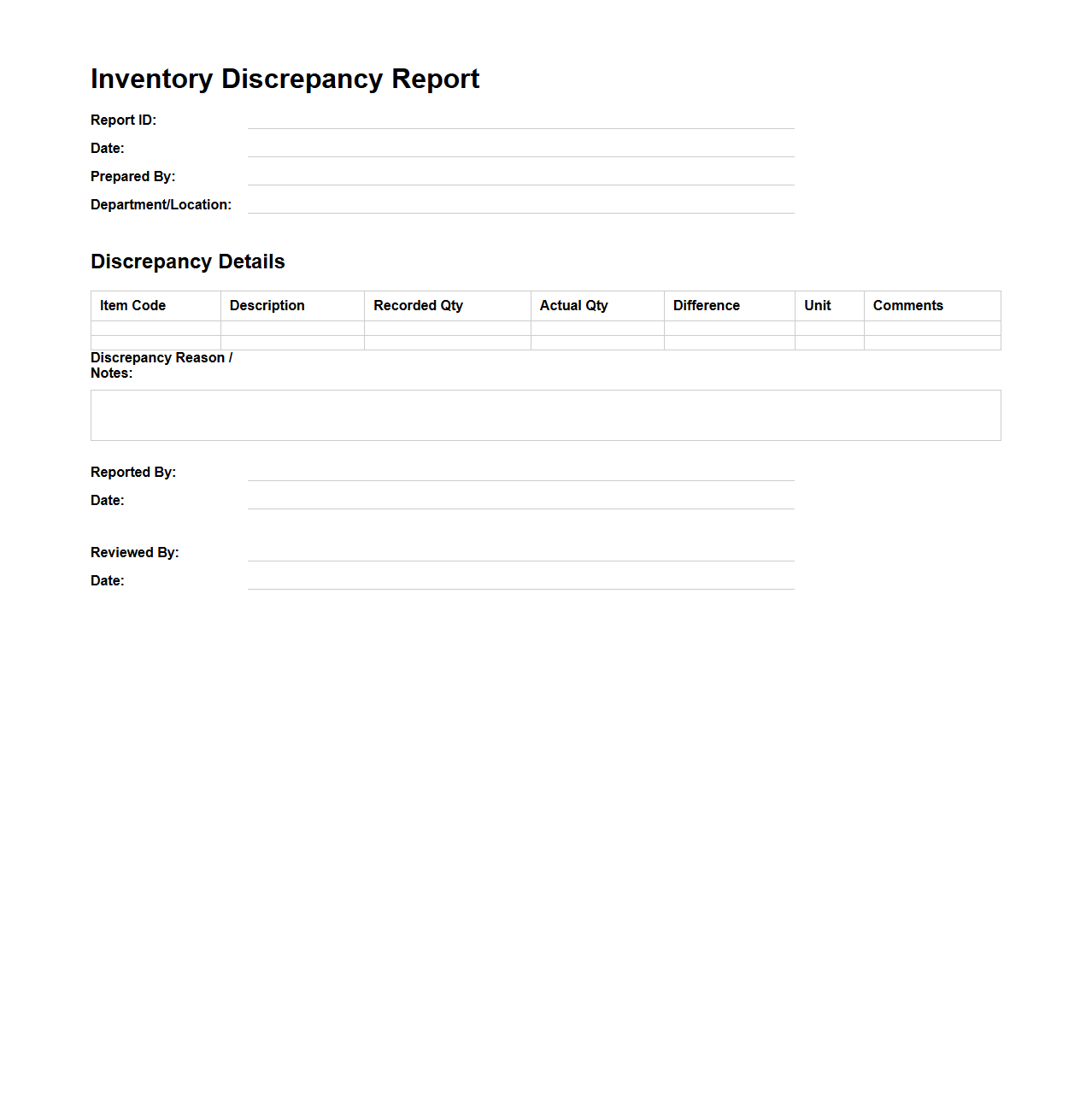

Inventory Discrepancy Report Template

An

Inventory Discrepancy Report Template document is used to systematically record and analyze differences between recorded inventory levels and physical stock counts. It helps businesses identify errors, theft, or mismanagement by documenting variances, item details, quantities, and responsible personnel. This template streamlines the reconciliation process and supports accurate inventory control and auditing.

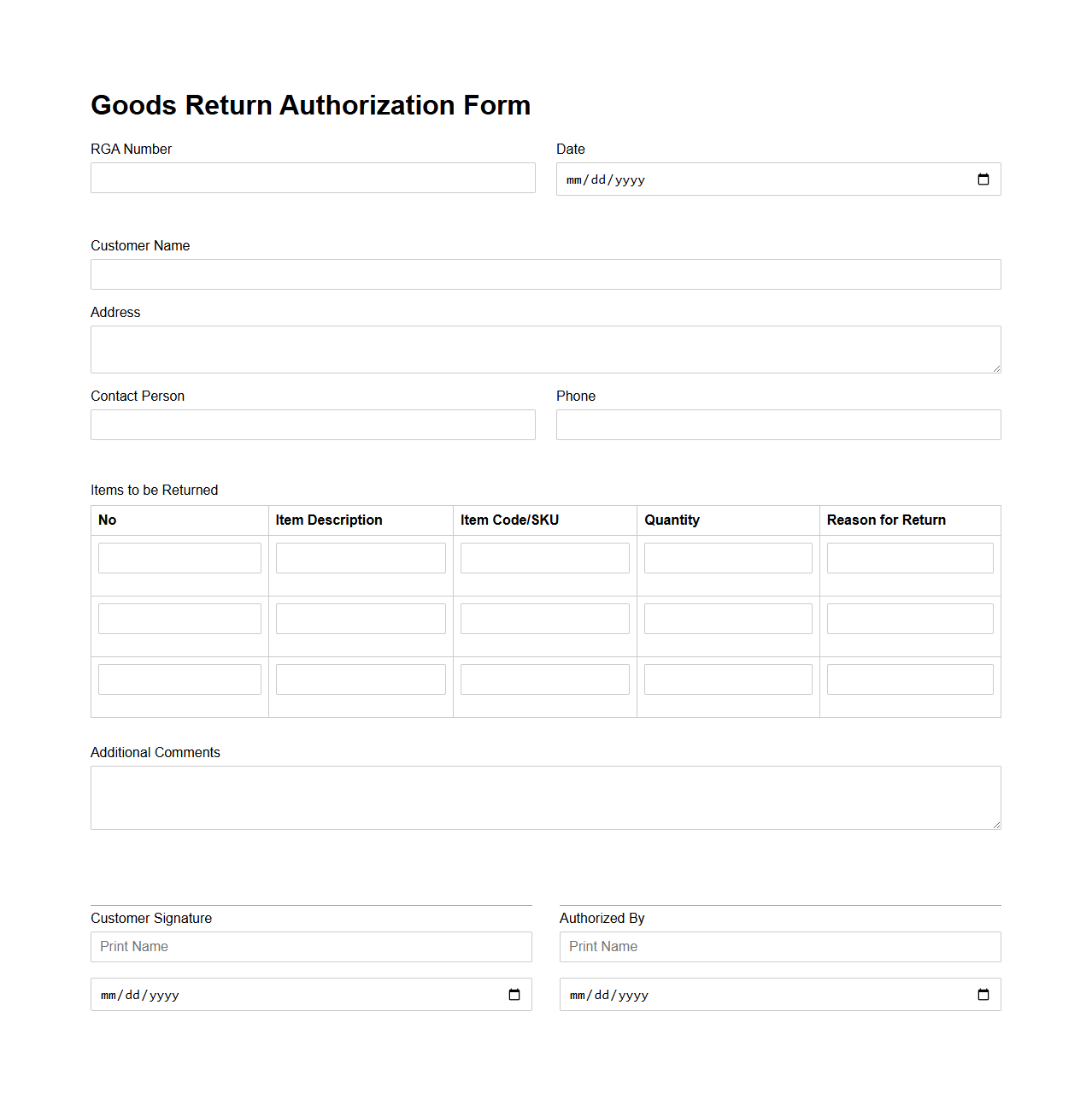

Goods Return Authorization Form Sample

A

Goods Return Authorization Form Sample document is a standardized template used by businesses to streamline the process of returning products. It includes essential details such as product information, reason for return, and authorization approval, ensuring clear communication between the customer and the company. This form helps manage inventory accurately and facilitates efficient processing of refunds or exchanges.

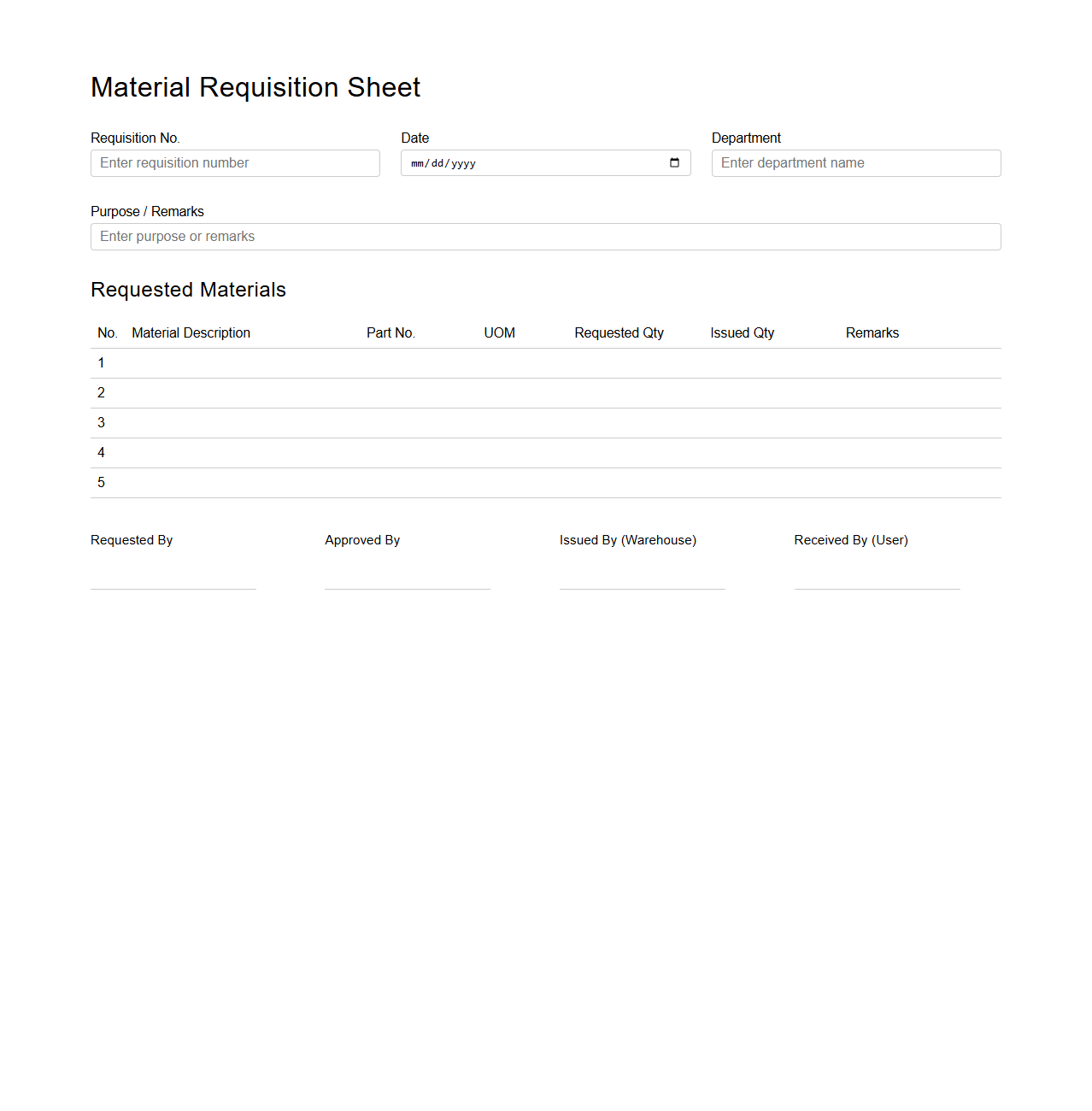

Material Requisition Sheet for Warehouse Management

A

Material Requisition Sheet is a crucial document in warehouse management that facilitates the formal request of materials or inventory from the storage area for production or operational use. It details the specific quantities, descriptions, and codes of materials needed, ensuring accurate tracking and accountability throughout the supply chain process. This document helps streamline inventory control, reduce errors, and maintain optimal stock levels for efficient warehouse operations.

Damaged Goods Report for Inventory Tracking

The

Damaged Goods Report for Inventory Tracking is a crucial document used to record items that have been identified as defective, broken, or unsellable within a warehouse or retail environment. This report helps businesses maintain accurate inventory counts by accounting for losses due to damage, enabling better stock management and financial reconciliation. It typically includes details such as item descriptions, quantities damaged, reasons for damage, and the date of discovery to support effective decision-making and process improvements.

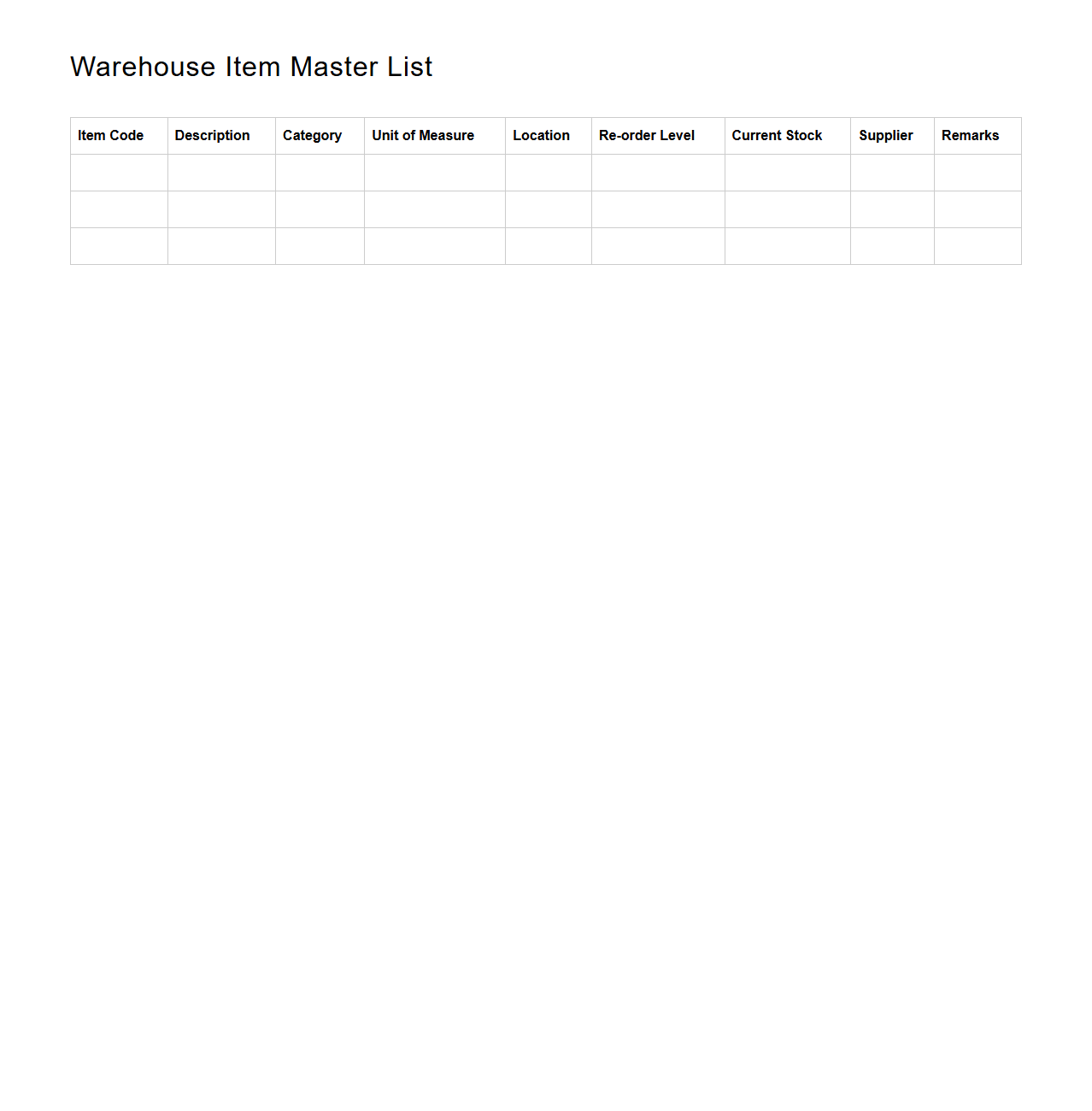

Warehouse Item Master List Format

The

Warehouse Item Master List Format document is a structured template used to catalog and manage inventory items within a warehouse efficiently. It includes detailed fields such as item codes, descriptions, quantities, storage locations, and supplier information to ensure accurate tracking and retrieval. Maintaining this format helps streamline inventory control, minimize errors, and optimize warehouse operations.

Key Information in Inventory Control Document

An Inventory Control Document must include accurate item descriptions, unique identification numbers, and quantities. It should also list locations within the warehouse to enable efficient stock retrieval. Tracking batch numbers and expiry dates is critical for managing perishable inventory effectively.

Tracking Item Movement and Stock Levels

The document records all incoming and outgoing stock through detailed transaction logs. It updates stock levels in real-time, reflecting any adjustments due to transfers or damages. Barcode or RFID scanning data is commonly integrated to automate and streamline item movement tracking.

Methods to Identify Inventory Discrepancies

Regular stock counts and cycle counts are documented to verify physical inventory against records. Discrepancies are flagged using variance reports highlighting differences in quantity or condition. Root cause analysis is often conducted to resolve issues such as theft, misplacement, or data entry errors.

Ensuring Compliance with Audit and Reporting Standards

The document adheres to strict audit trails by maintaining chronological transaction histories for transparency. It complies with regulatory guidelines by enforcing standardized reporting formats and data accuracy checks. Periodic reviews and audits ensure ongoing adherence to warehouse management policies.

User Roles Authorized for Inventory Document Management

Warehouse managers and inventory controllers are primarily authorized to create and modify the document. Supervisors and quality assurance personnel typically have approval rights to validate changes before implementation. Access controls and role-based permissions safeguard the document's integrity and prevent unauthorized edits.

More Manufacturing Templates