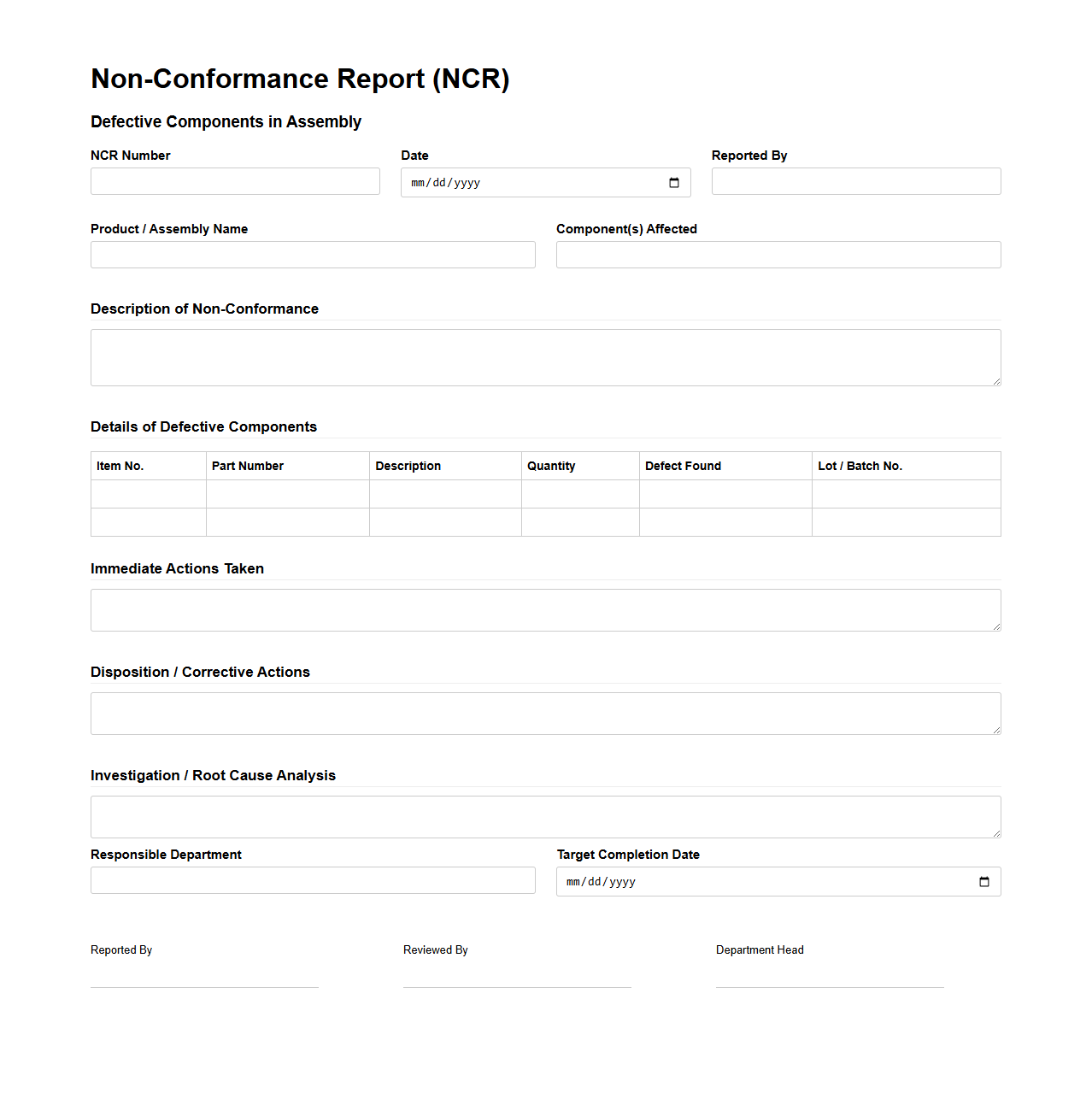

Non-Conformance Report for Defective Components in Assembly

A

Non-Conformance Report (NCR) for Defective Components in Assembly document identifies and records instances where parts or components fail to meet specified requirements during the assembly process. It details the nature of the defect, root cause analysis, and corrective actions to prevent recurrence, ensuring quality control and compliance with industry standards. This document is critical for maintaining production integrity and facilitating continuous improvement in manufacturing operations.

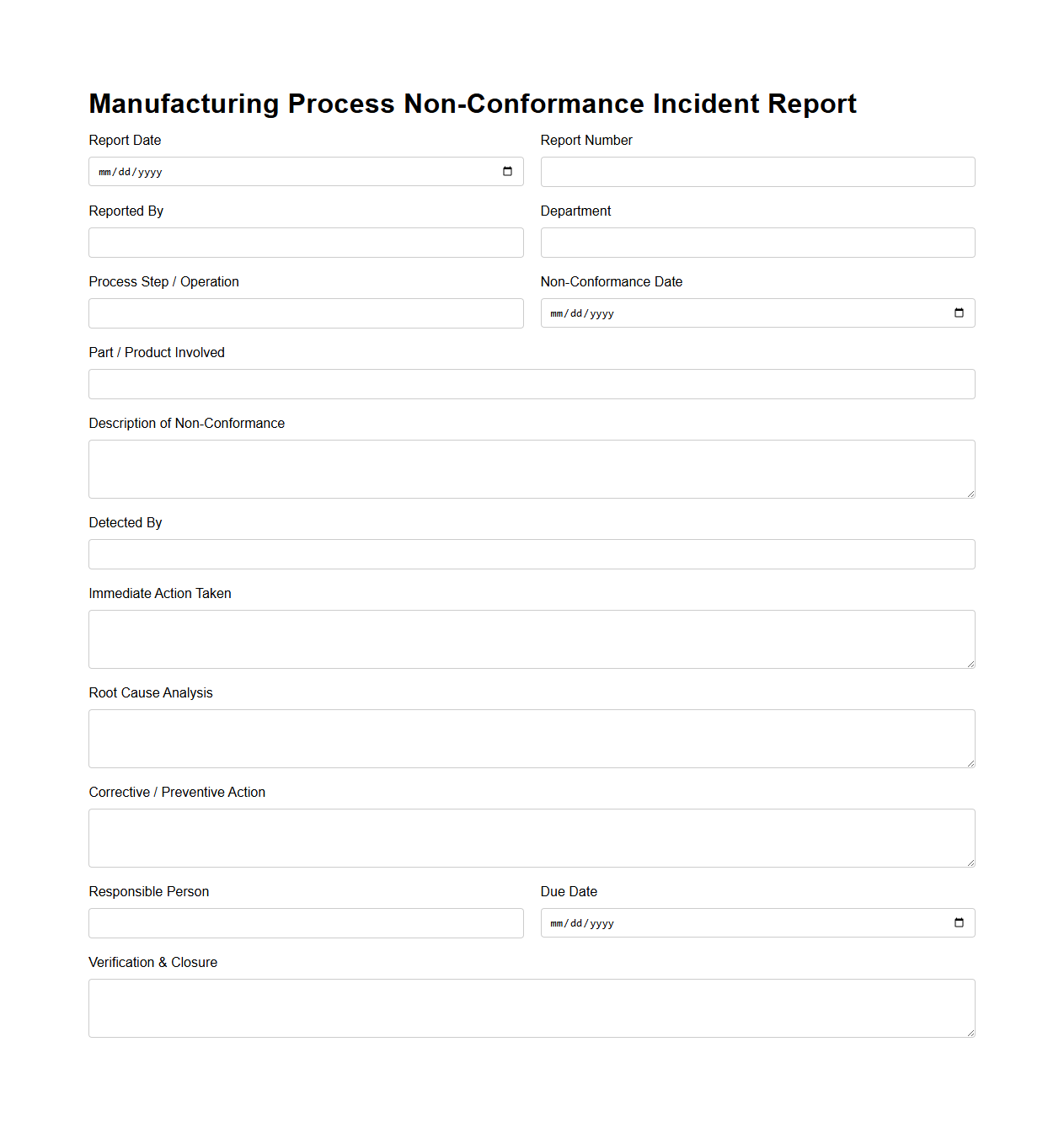

Manufacturing Process Non-Conformance Incident Report

The

Manufacturing Process Non-Conformance Incident Report document details deviations from established manufacturing standards, capturing specific instances where processes fail to meet quality or regulatory requirements. It records critical information such as the nature of the non-conformance, affected materials or components, root cause analysis, and corrective actions to prevent recurrence. This report serves as a key tool for quality control teams to maintain compliance, improve operational efficiency, and reduce production defects.

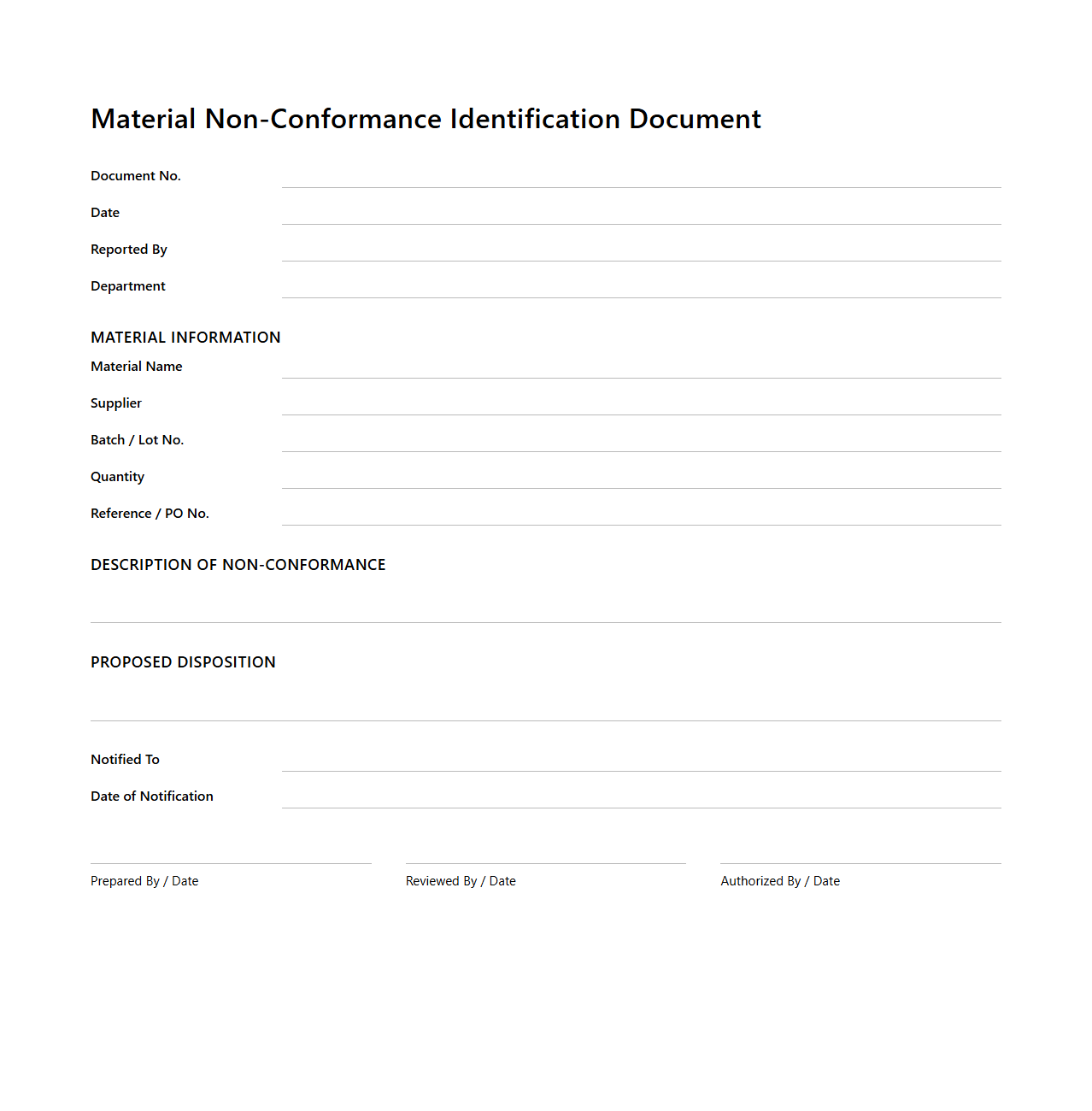

Material Non-Conformance Identification Document

A

Material Non-Conformance Identification Document is a formal record used to report and track deviations from specified material standards or requirements in manufacturing and quality control processes. It details the nature of the non-conformance, including descriptions, affected materials, causes, and corrective actions to ensure compliance with industry standards. This document plays a critical role in maintaining product quality, regulatory adherence, and continuous improvement within supply chain management.

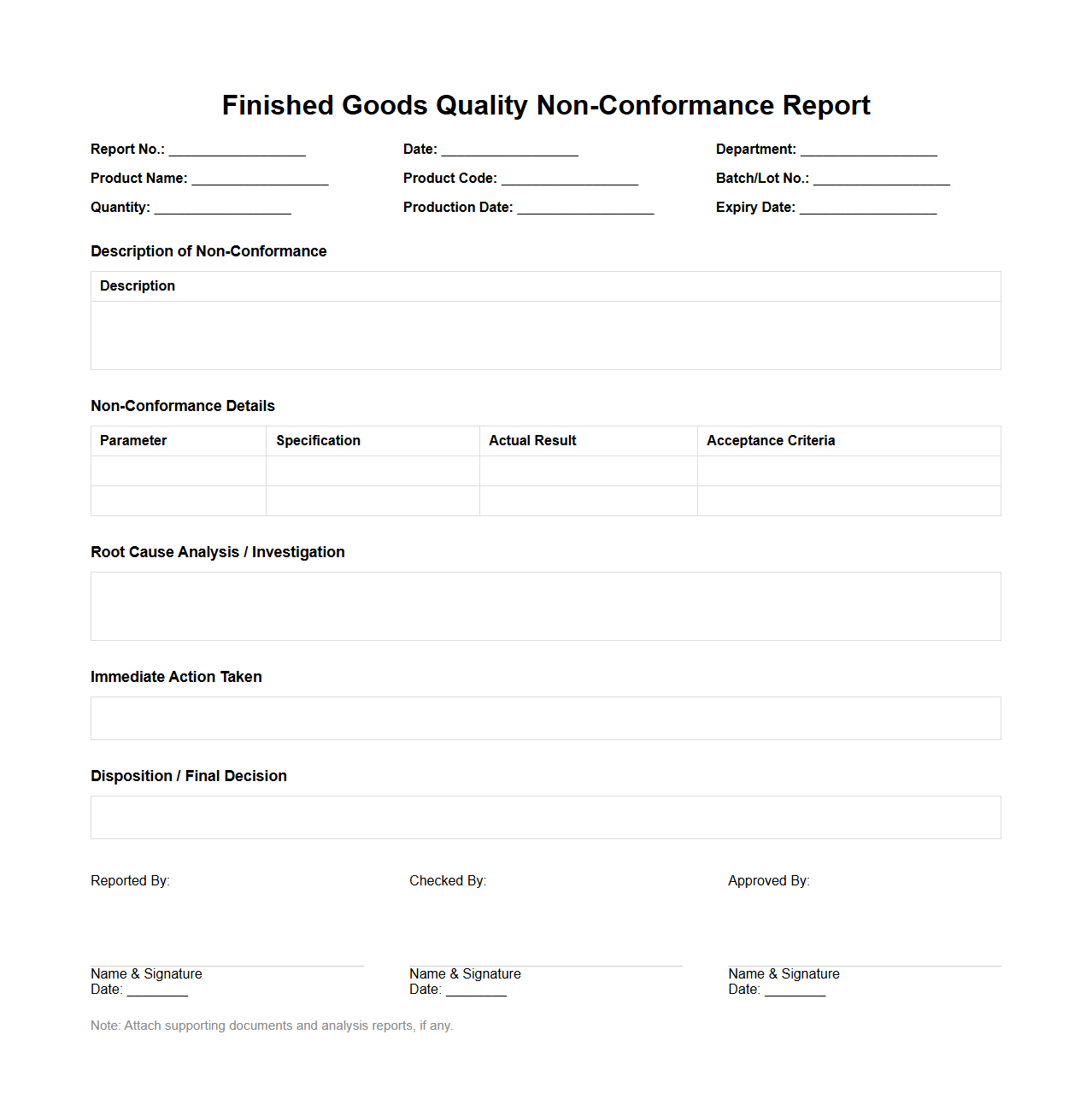

Finished Goods Quality Non-Conformance Report Sample

A

Finished Goods Quality Non-Conformance Report Sample document is used to identify, document, and analyze defects or deviations found in finished products that do not meet specified quality standards. It serves as a crucial tool for quality control teams to track non-conformances, determine root causes, and implement corrective actions to prevent recurrence. This report typically includes details such as product identification, nature of the non-conformance, inspection results, and recommended remedies.

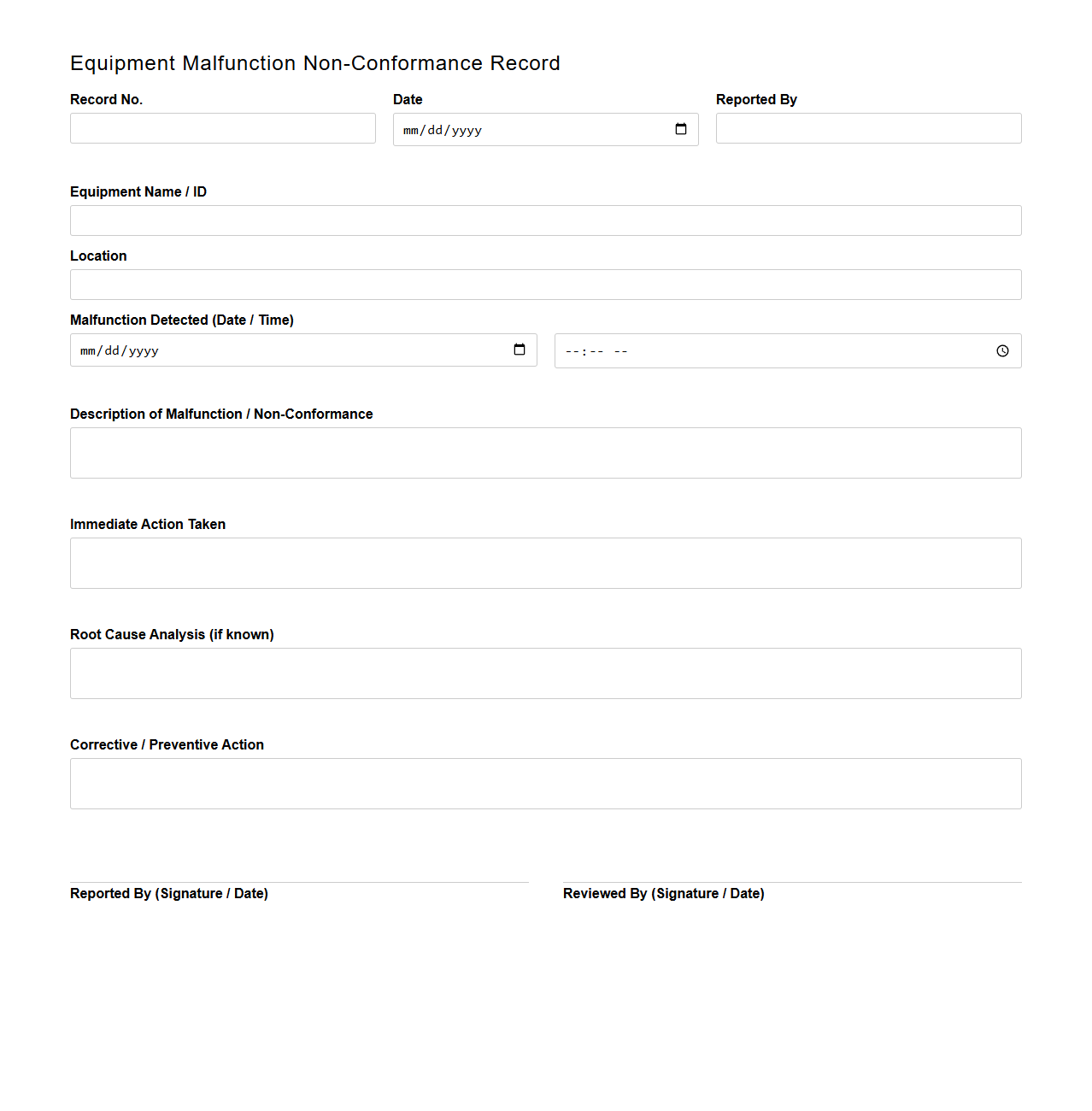

Equipment Malfunction Non-Conformance Record

An

Equipment Malfunction Non-Conformance Record document is a critical tool used to systematically identify and document instances where equipment fails to operate within specified parameters. This record helps track the nature, cause, and impact of malfunctions, enabling timely corrective actions and continuous improvement in maintenance processes. Maintaining accurate non-conformance records supports compliance with industry standards and enhances overall operational reliability.

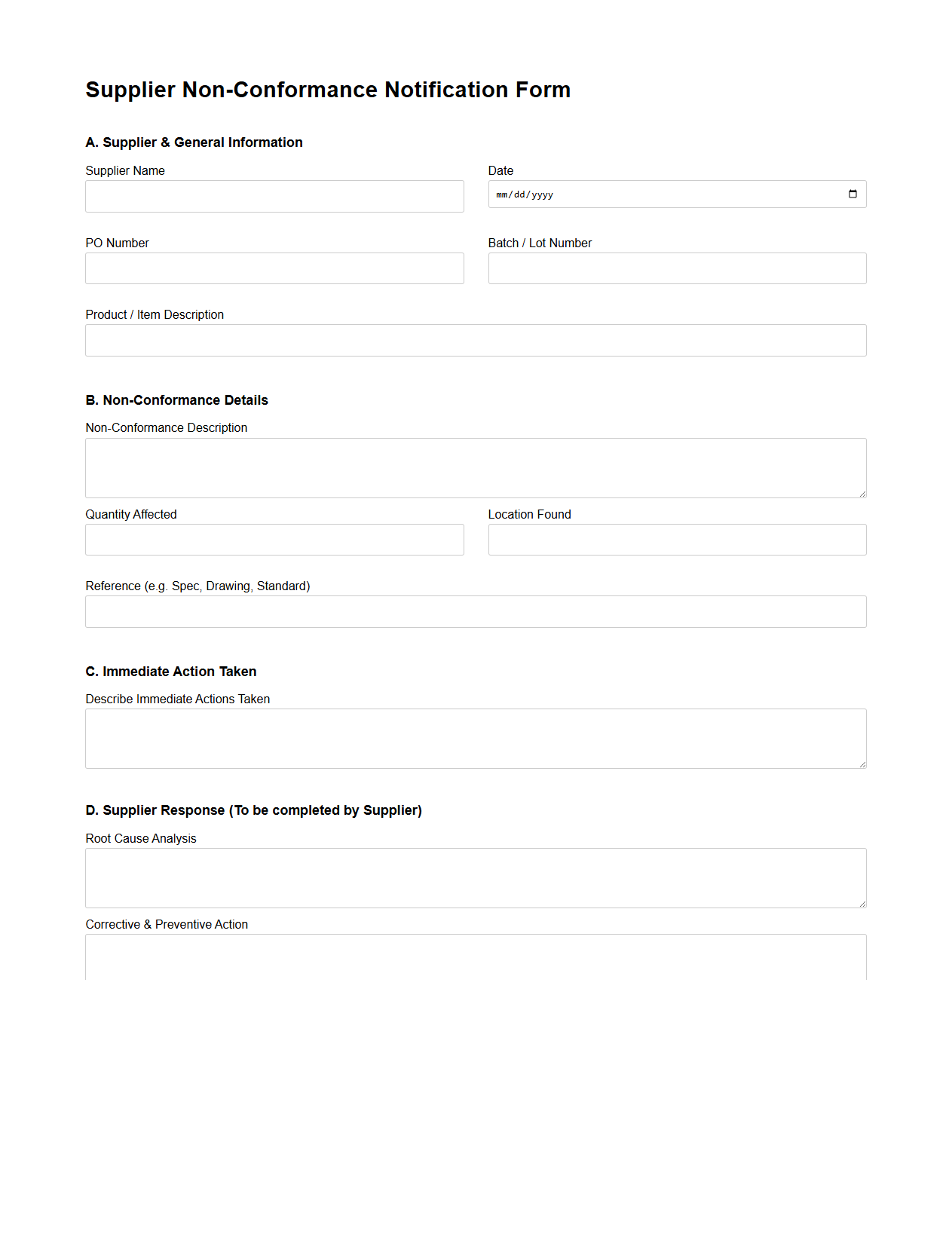

Supplier Non-Conformance Notification Form

The

Supplier Non-Conformance Notification Form is a critical document used to formally report and track instances where supplied materials or services do not meet specified quality standards or contract requirements. This form facilitates clear communication between the purchaser and supplier, detailing the nature of the non-conformance, its impact, and the corrective actions required. Proper documentation through this form helps ensure accountability, traceability, and continuous improvement in the supply chain.

Production Line Non-Conformance Tracking Sheet

The

Production Line Non-Conformance Tracking Sheet document is a tool used to systematically record and monitor defects or deviations in manufacturing processes. It captures critical data such as the nature of the non-conformance, production stage, root cause analysis, and corrective actions taken, enabling effective quality control and continuous improvement. This document ensures traceability and accountability, reducing production errors and enhancing product reliability.

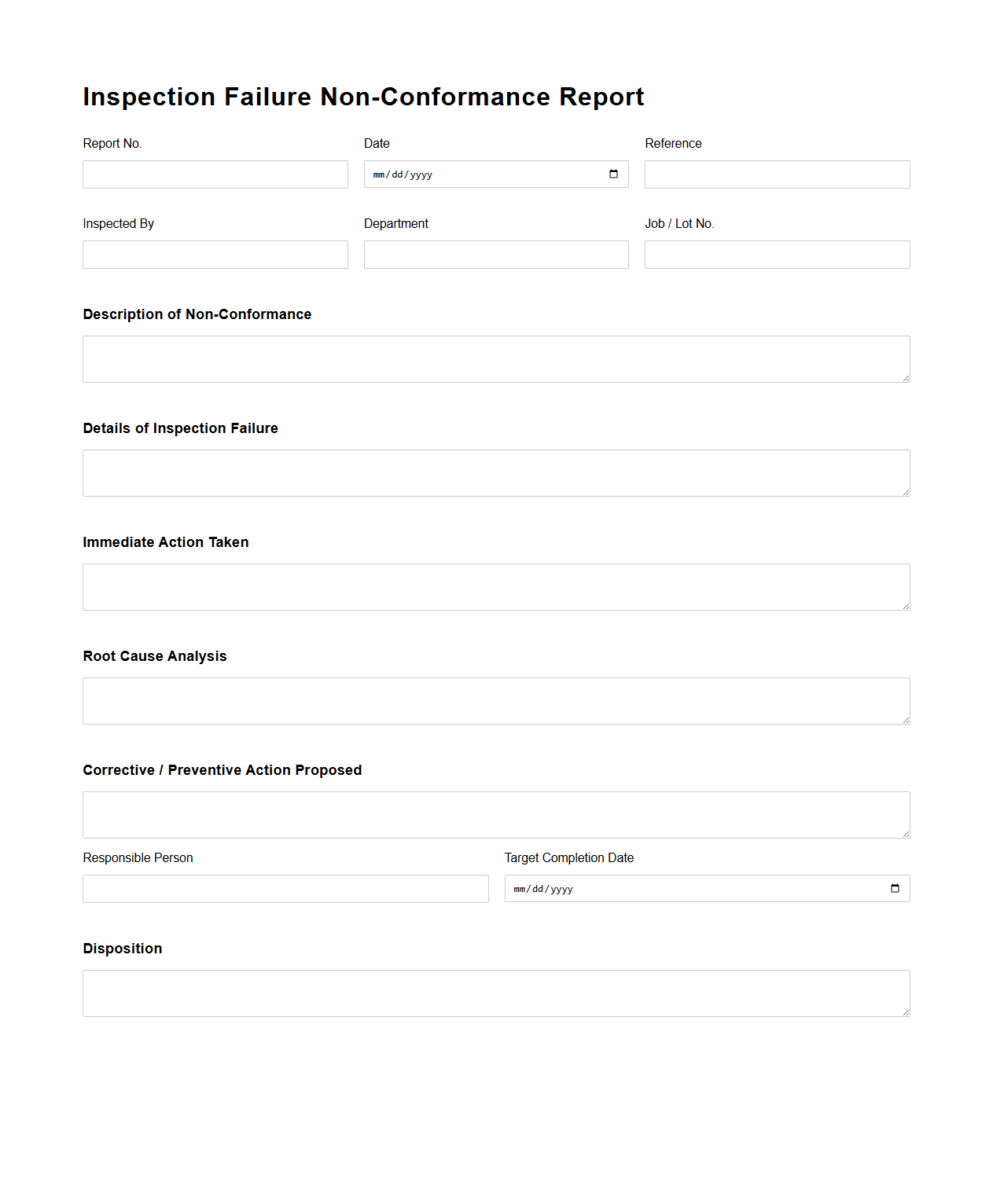

Inspection Failure Non-Conformance Report Template

An

Inspection Failure Non-Conformance Report Template document is a standardized form used to document and track deviations from specified inspection criteria during quality control processes. It details the nature of the failure, provides evidence such as photographs or measurements, and records corrective actions to prevent recurrence. This template ensures consistent reporting, facilitates root cause analysis, and supports compliance with industry quality standards.

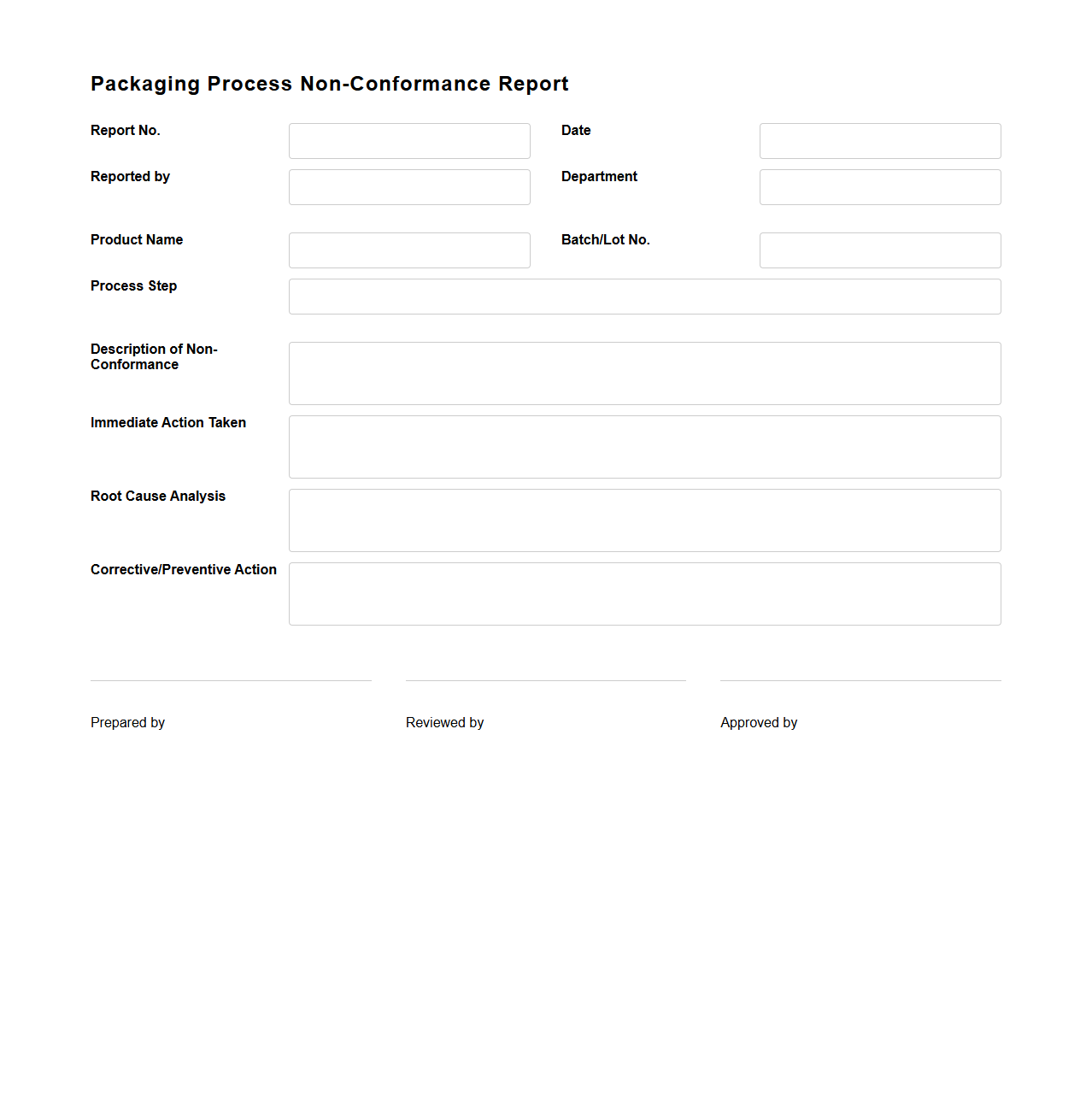

Packaging Process Non-Conformance Report

A

Packaging Process Non-Conformance Report document identifies and records deviations from specified packaging standards during production. It details the nature of the non-conformance, root causes, and corrective actions to prevent recurrence, ensuring quality control and regulatory compliance. This document is critical for maintaining consistent packaging integrity and minimizing product defects.

Internal Audit Non-Conformance Document for Manufacturing

An

Internal Audit Non-Conformance Document for manufacturing is a formal record identifying deviations from established quality standards, processes, or regulatory requirements during internal audits. It details specific non-conformities found in production, equipment, or procedural controls, enabling corrective and preventive actions to improve operational efficiency. This document is critical for maintaining compliance, reducing risks, and supporting continuous improvement within manufacturing quality management systems.

Types of Non-Conformances Identified and Documented

The report categorizes non-conformances into product defects, process deviations, and documentation errors. Each type is clearly identified to ensure proper corrective measures. Thorough documentation facilitates tracking and resolution of issues.

Specific Product or Process Affected According to the NCR Sample

The NCR sample highlights a defective widget assembly as the primary affected product. It also specifies a manufacturing process step where the deviation occurred. Detailed identification aids in targeted investigation.

Proposed or Implemented Corrective Actions in the Document

The document outlines corrective actions such as retraining personnel, process adjustments, and enhanced inspections. These measures are intended to prevent recurrence of the non-conformance. Implementation timelines are also specified for accountability.

Responsibility for Reviewing and Closing the Non-Conformance Report

The Quality Assurance Manager is responsible for reviewing and approving the closure of the NCR. They ensure all corrective actions are completed satisfactorily. Final sign-off confirms resolution and report closure.

Measuring and Documenting Effectiveness of Corrective Actions in the NCR Sample

Effectiveness is measured through follow-up audits, product testing, and process monitoring. The NCR sample includes records of these evaluations to demonstrate improvements. Documentation confirms the permanent resolution of the issue.