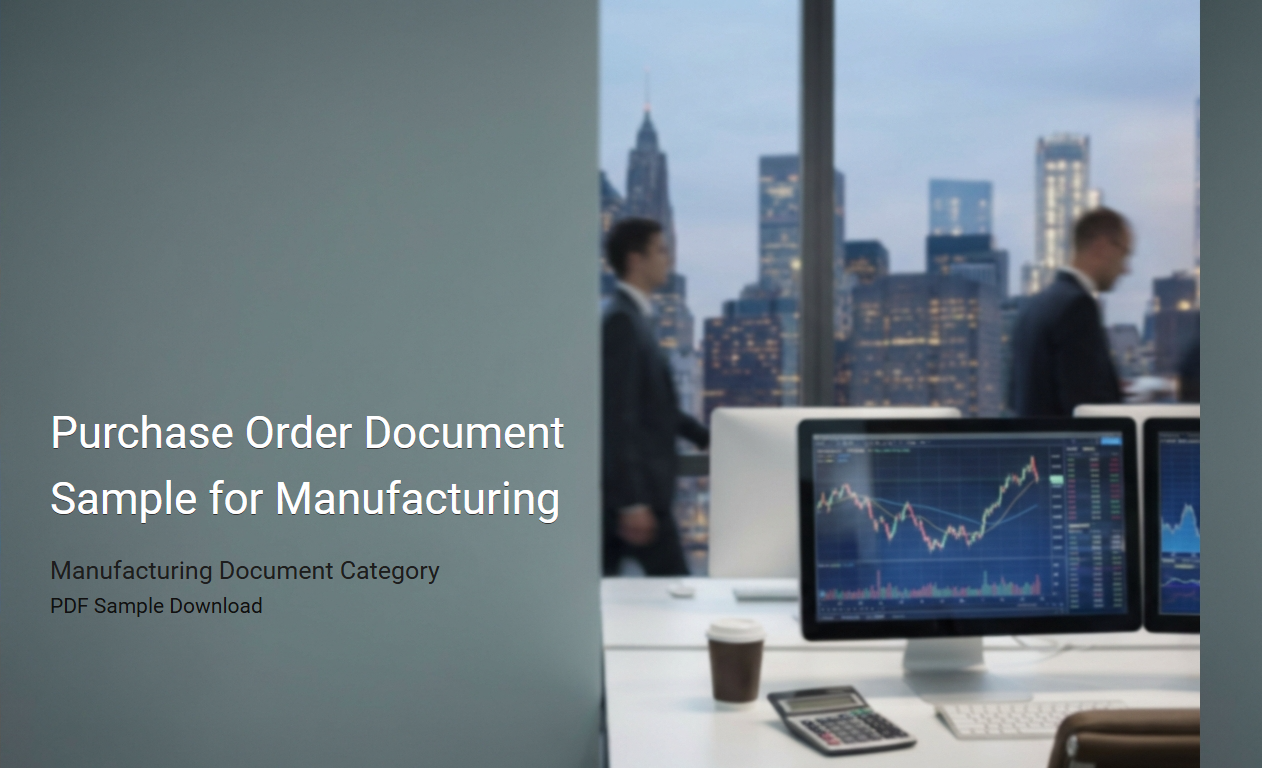

Standard Purchase Order Template for Manufacturing

A

Standard Purchase Order Template for Manufacturing is a structured document used to formally request goods or materials from suppliers, specifying quantities, specifications, and delivery schedules essential for production. It ensures accuracy and consistency in procurement processes, streamlining communication between manufacturers and vendors. This template typically includes fields for item descriptions, pricing, purchase terms, and approval signatures to maintain clear and traceable transactions.

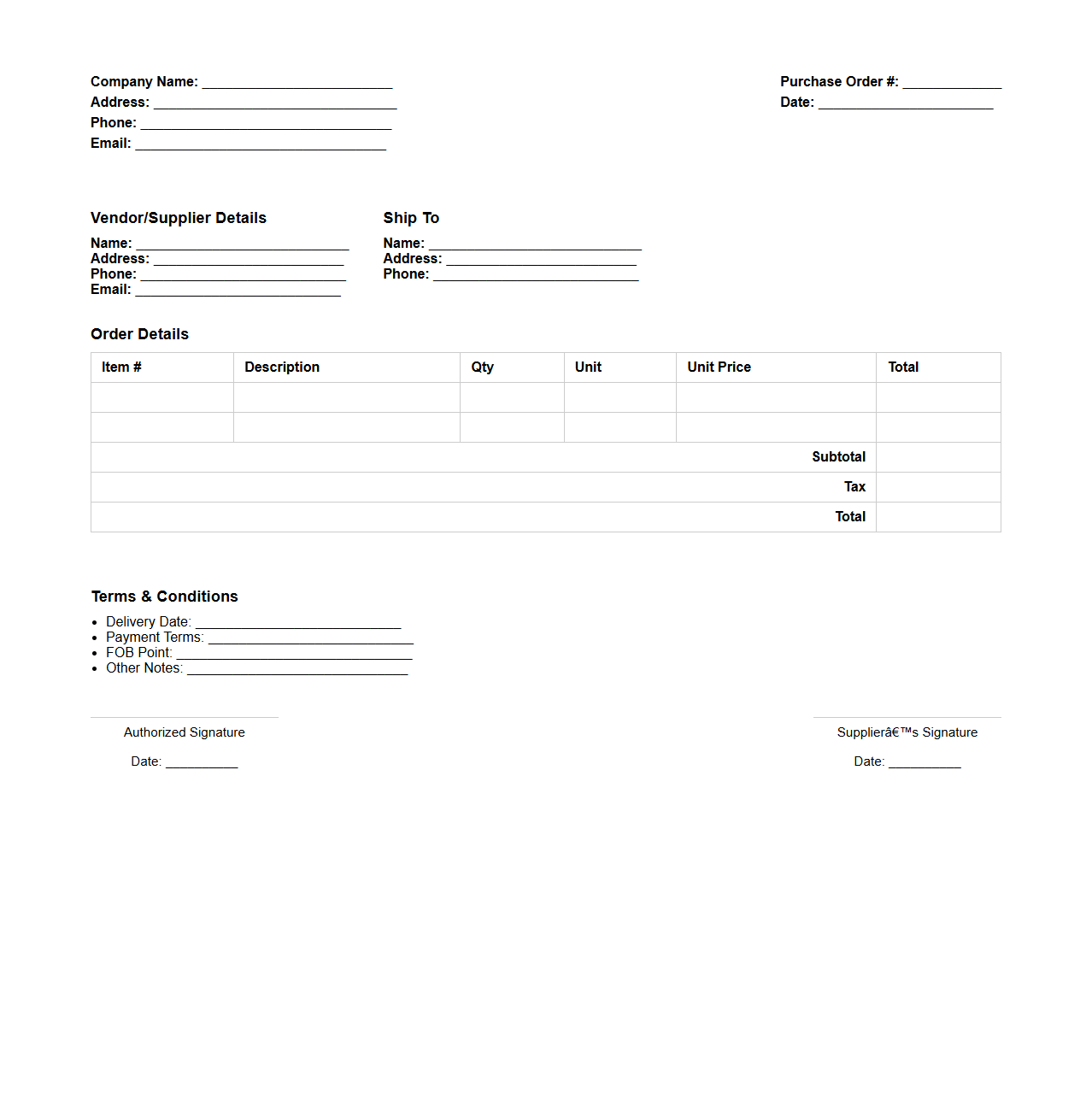

Blanket Purchase Order Example for Manufacturing

A

Blanket Purchase Order (BPO) for manufacturing is a long-term purchasing agreement between a buyer and supplier that outlines the terms, pricing, and quantities for recurring orders of raw materials or components. This document streamlines procurement by reducing administrative work and ensuring consistent supply without repeated approvals. Manufacturing companies use BPOs to improve inventory management, reduce lead times, and maintain production continuity.

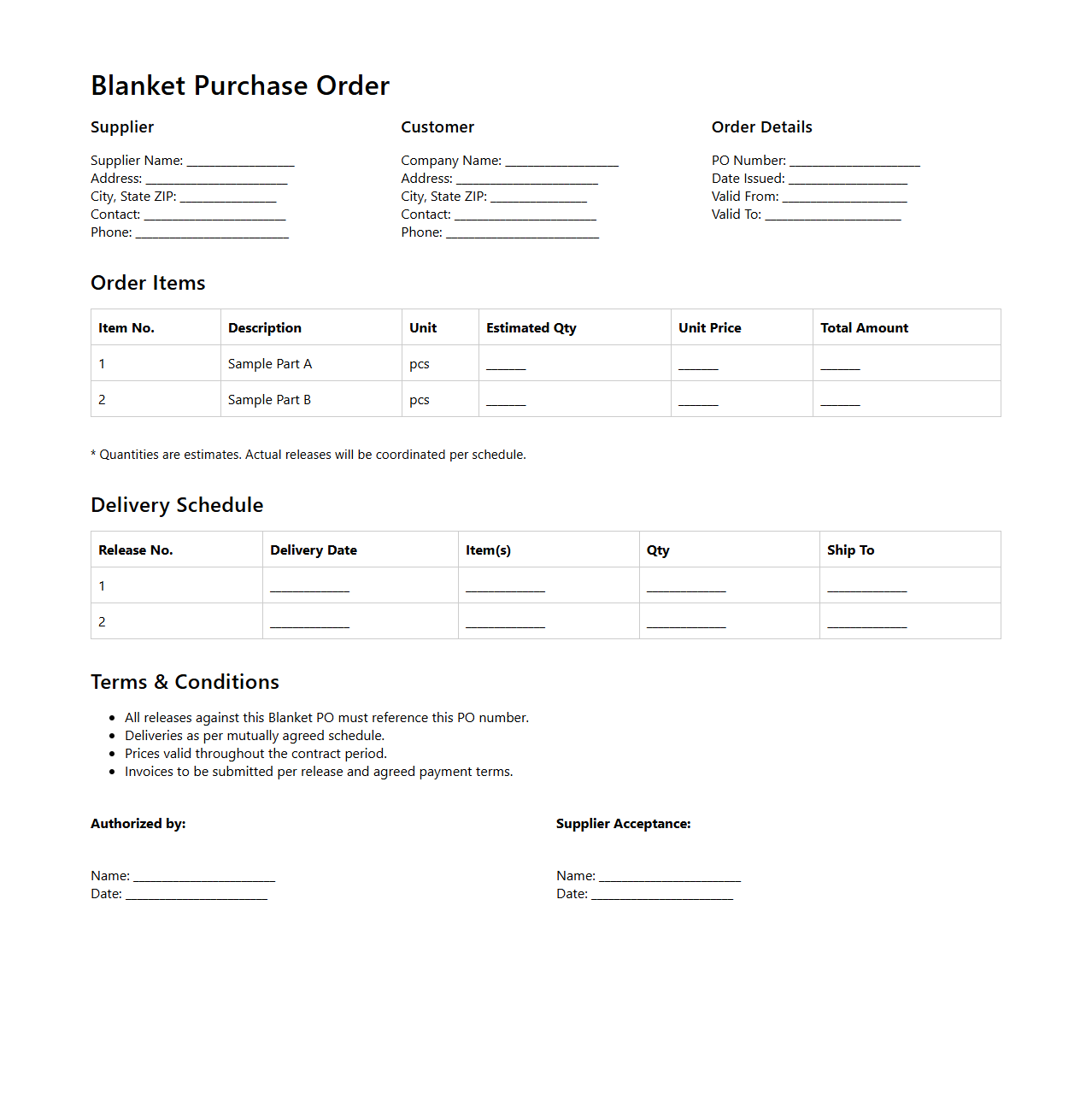

Manufacturing Component Purchase Order Format

A

Manufacturing Component Purchase Order Format document specifies the detailed requirements and terms for procuring individual parts or components essential to the production process. It includes critical information such as item descriptions, quantities, unit prices, delivery schedules, and supplier details to ensure accurate order fulfillment. This format streamlines procurement operations, reduces errors, and facilitates clear communication between manufacturers and suppliers.

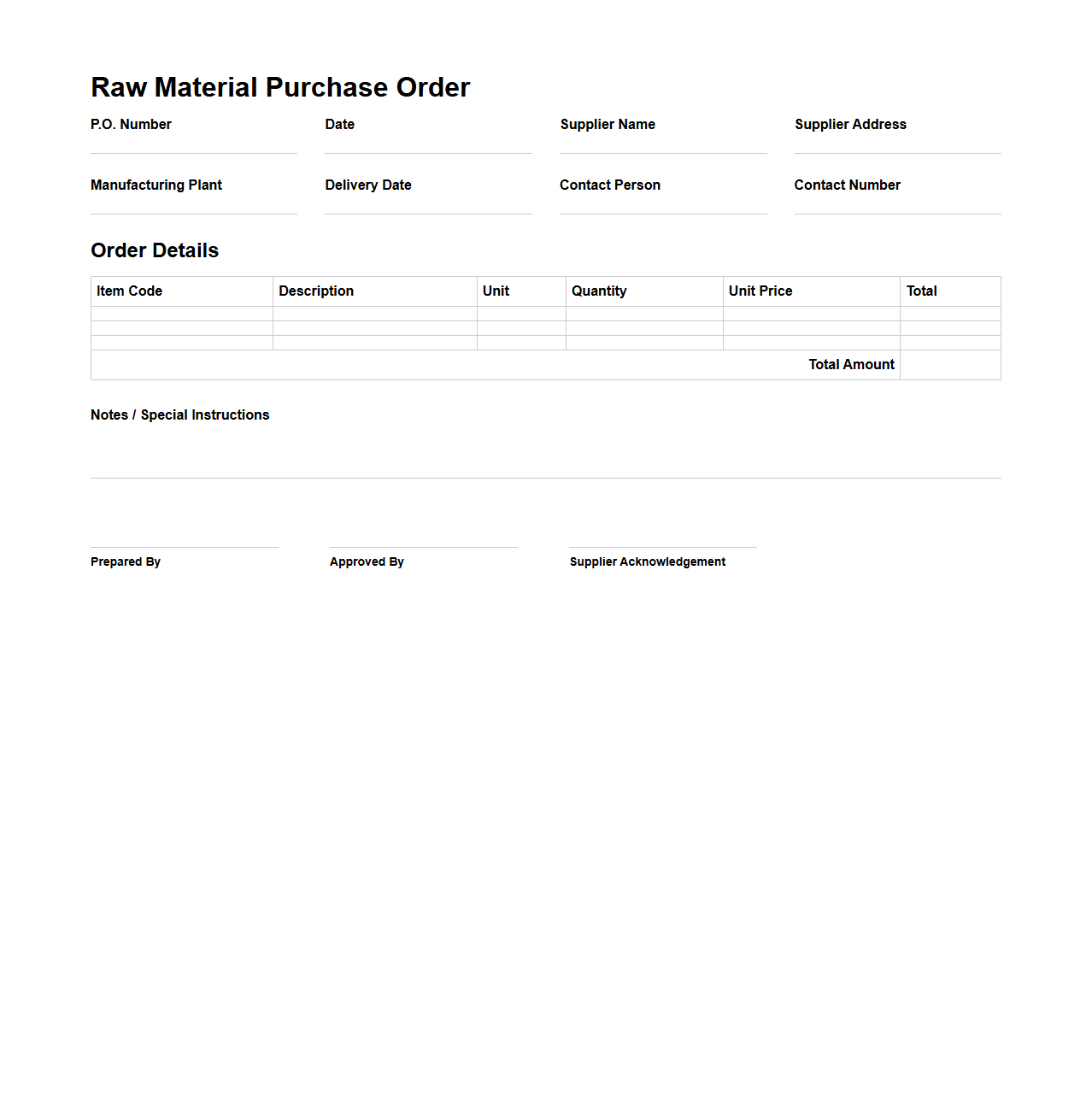

Raw Material Purchase Order Document for Manufacturing

A

Raw Material Purchase Order Document in manufacturing serves as an official contract between the manufacturer and supplier, detailing the types, quantities, and agreed prices of raw materials required for production. This document ensures accurate tracking of inventory needs, streamlines procurement processes, and reduces delays by specifying delivery timelines and quality standards. It plays a critical role in maintaining supply chain efficiency and supporting cost management within the manufacturing workflow.

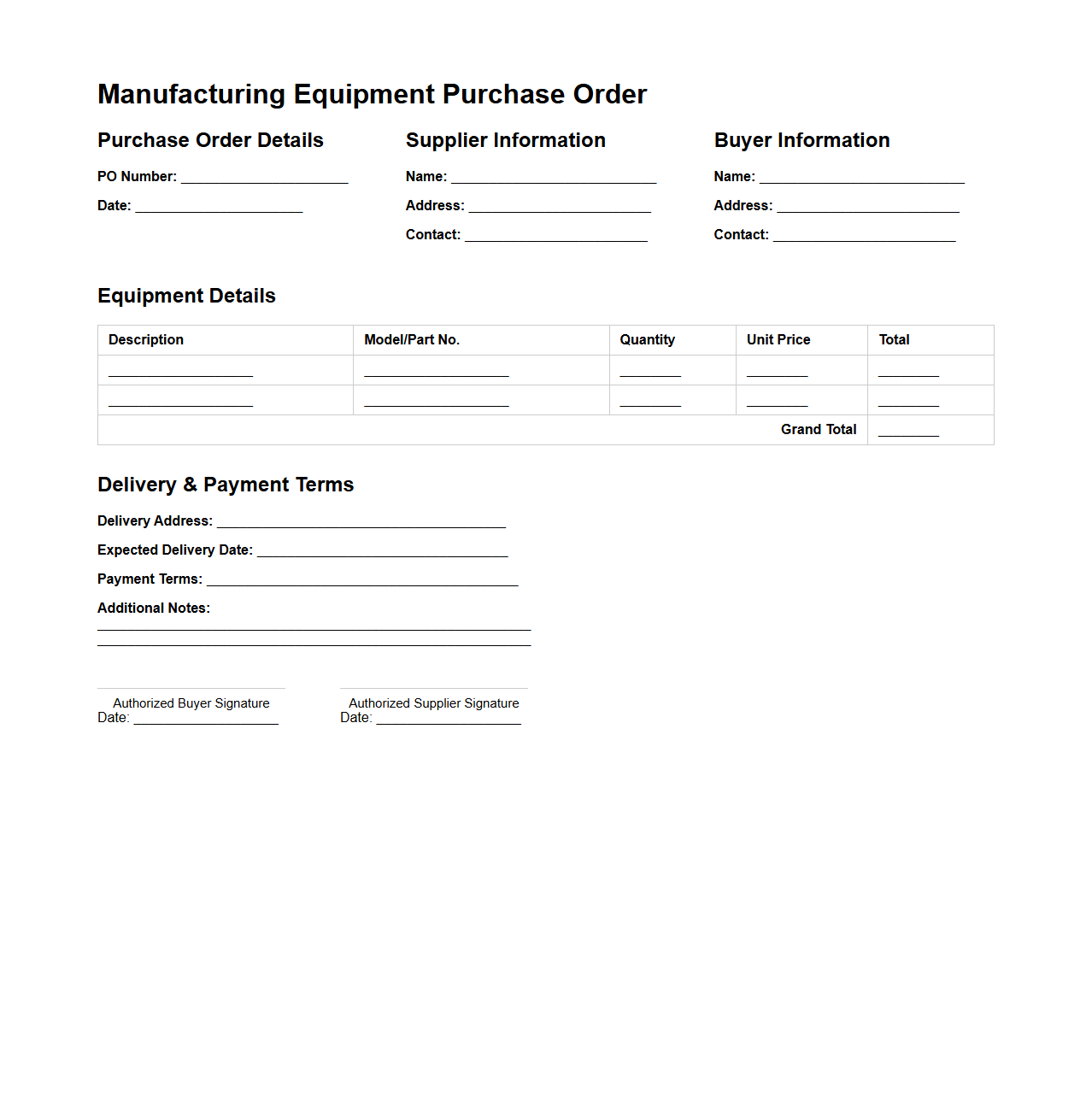

Manufacturing Equipment Purchase Order Sample

A

Manufacturing Equipment Purchase Order Sample document serves as a formal template used by companies to specify the details of equipment procurement, including item descriptions, quantities, prices, and delivery terms. This sample ensures clear communication between the buyer and supplier, helping to prevent misunderstandings and streamline the procurement process. Utilizing a standardized purchase order sample improves accuracy in order fulfillment and supports efficient financial tracking within manufacturing operations.

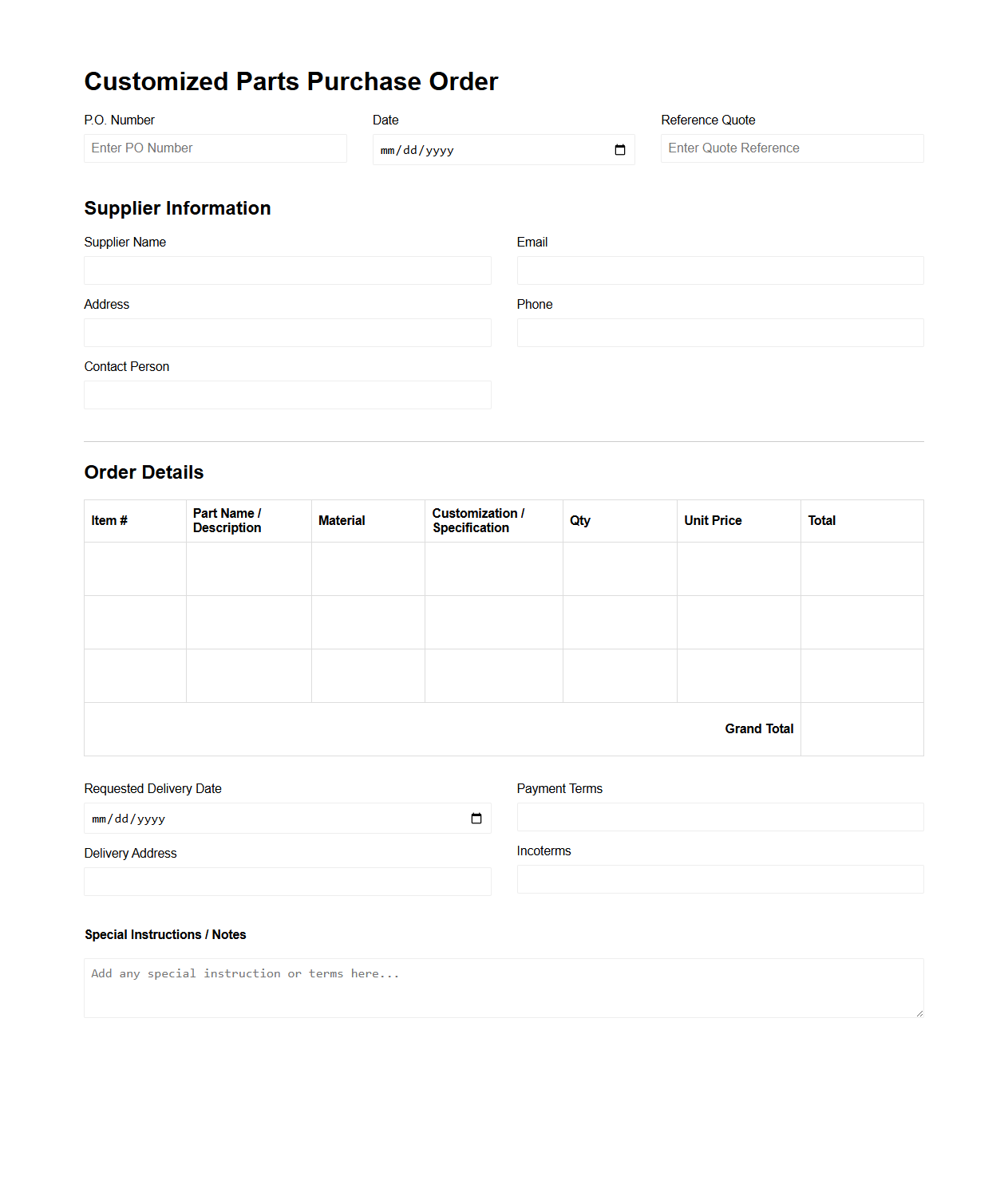

Customized Parts Purchase Order Template for Manufacturing

A

Customized Parts Purchase Order Template for manufacturing is a specialized document designed to streamline the procurement process by clearly specifying detailed part requirements, quantities, and delivery schedules tailored to the unique needs of a manufacturing project. This template ensures accuracy in communication between manufacturers and suppliers, reducing errors and delays by including precise technical specifications, pricing, and terms of purchase. Utilizing a customized template enhances operational efficiency, supports inventory management, and improves vendor relationships through consistent and clear order documentation.

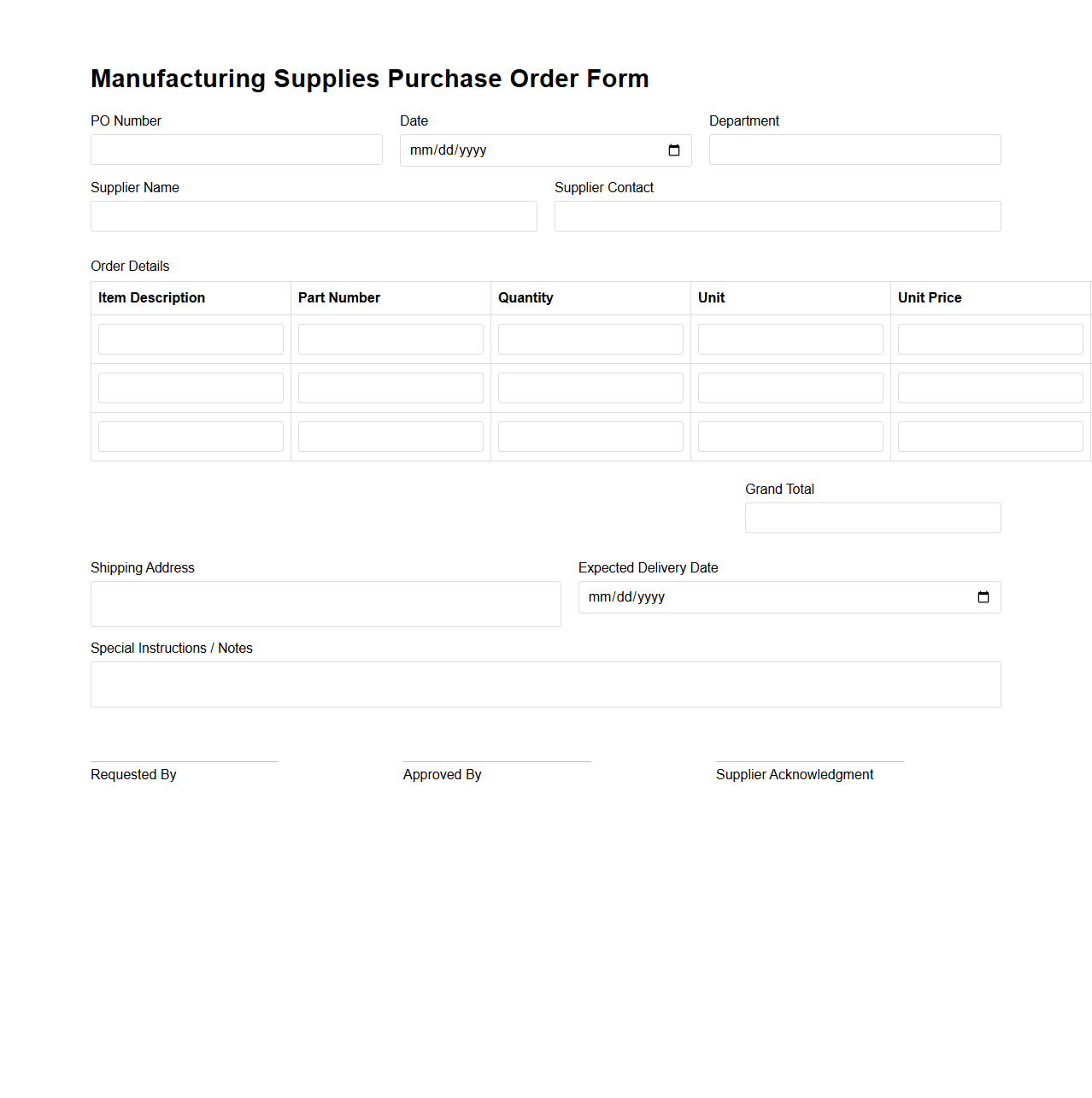

Manufacturing Supplies Purchase Order Form

The

Manufacturing Supplies Purchase Order Form is a critical document used to request and authorize the purchase of raw materials and components essential for production processes. It details quantities, specifications, supplier information, and agreed prices, ensuring accurate inventory management and cost control. This form streamlines procurement, enhances communication between manufacturing and purchasing departments, and helps maintain efficient supply chain operations.

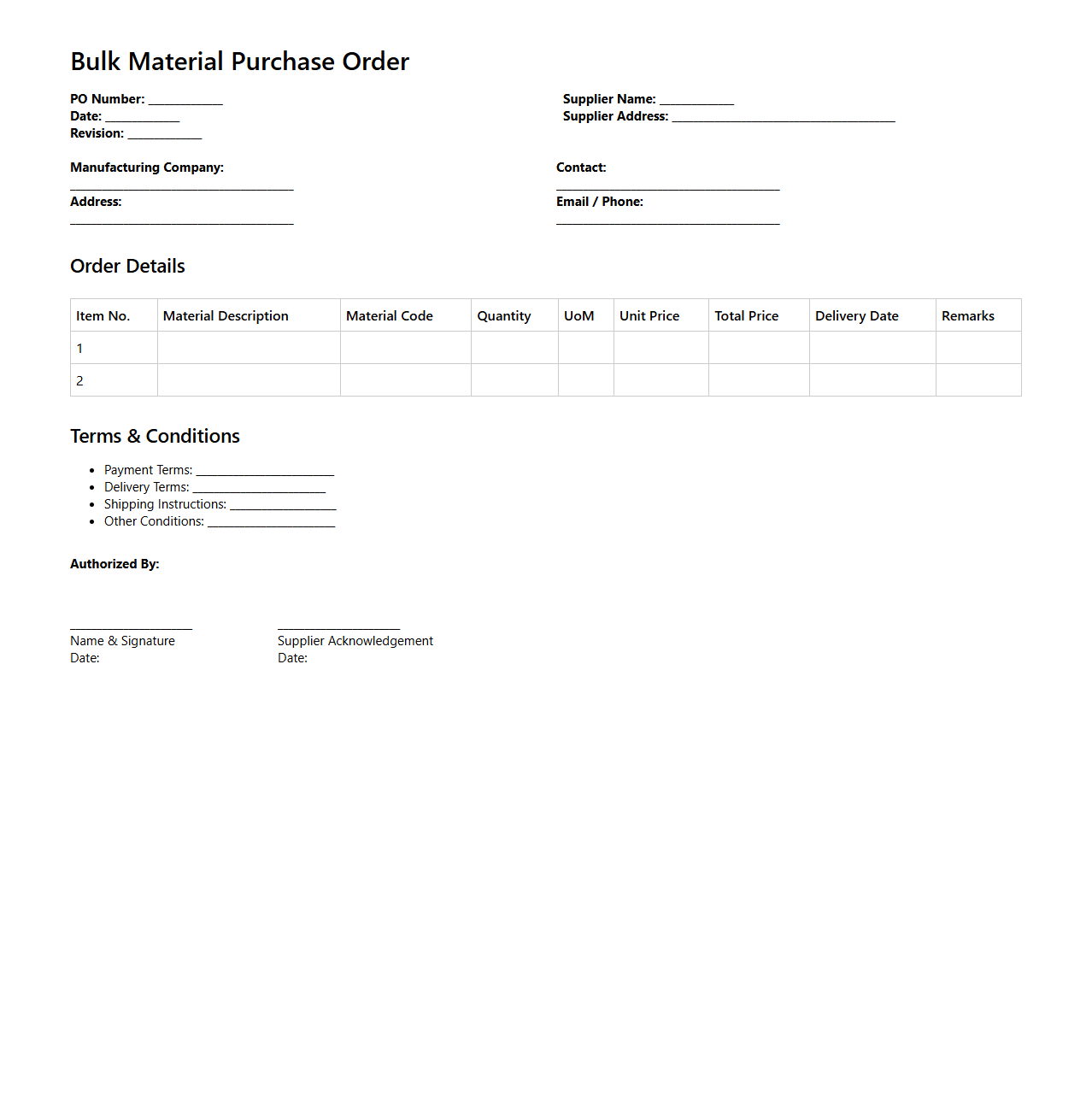

Bulk Material Purchase Order Document for Manufacturing

The

Bulk Material Purchase Order Document in manufacturing serves as a formal agreement specifying the quantity, quality, and delivery schedule of raw materials required for production. It ensures accurate procurement, cost control, and supplier accountability by detailing specifications, pricing, and terms. This document is essential for maintaining uninterrupted manufacturing workflows and inventory management.

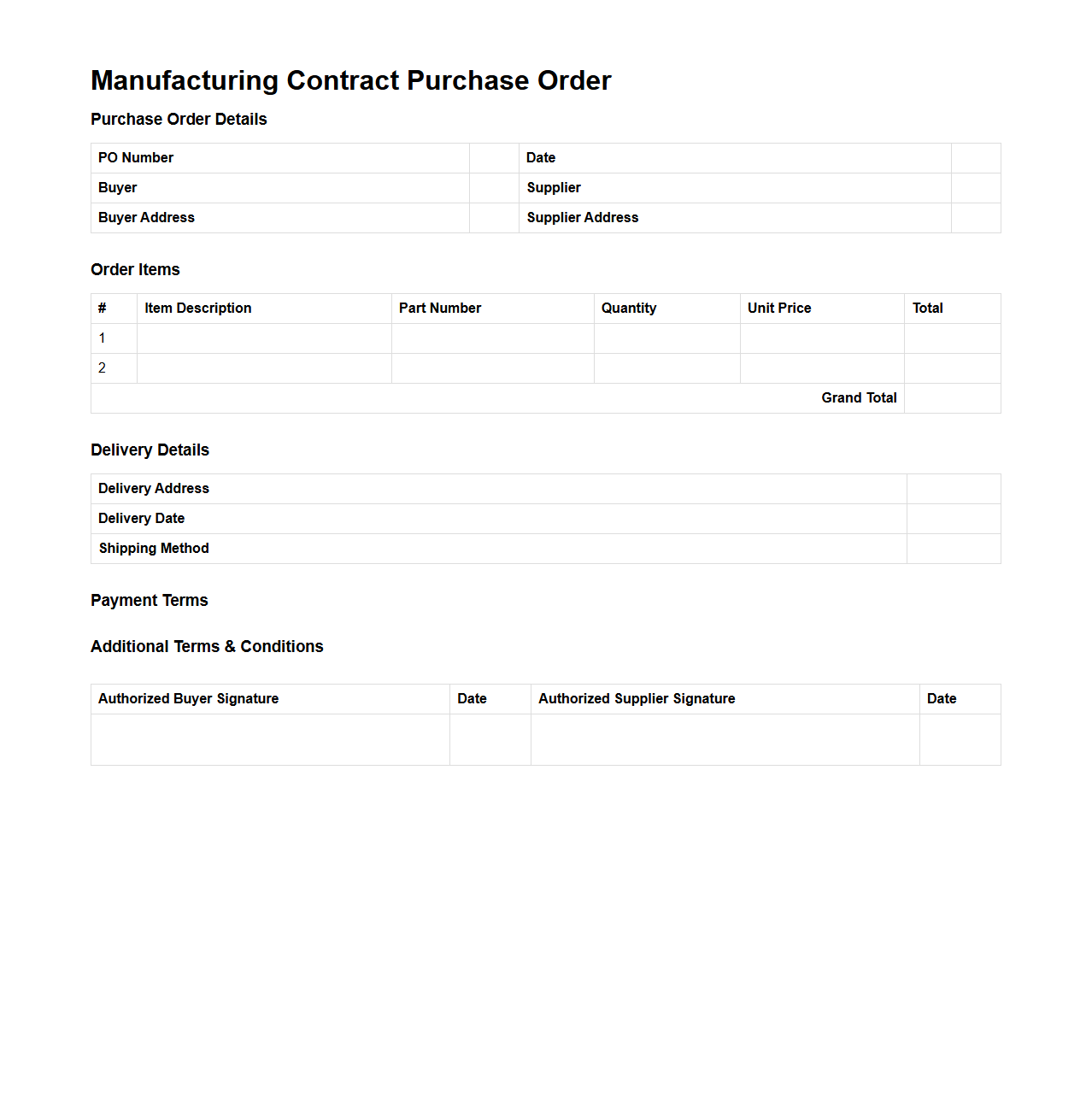

Manufacturing Contract Purchase Order Example

A

Manufacturing Contract Purchase Order Example document serves as a formal agreement between a buyer and a manufacturer, specifying detailed terms such as product specifications, quantities, pricing, delivery schedules, and payment conditions. This document ensures clarity and legal protection for both parties by outlining responsibilities, quality standards, and compliance requirements. It is essential for streamlining production processes and minimizing risks associated with manufacturing transactions.

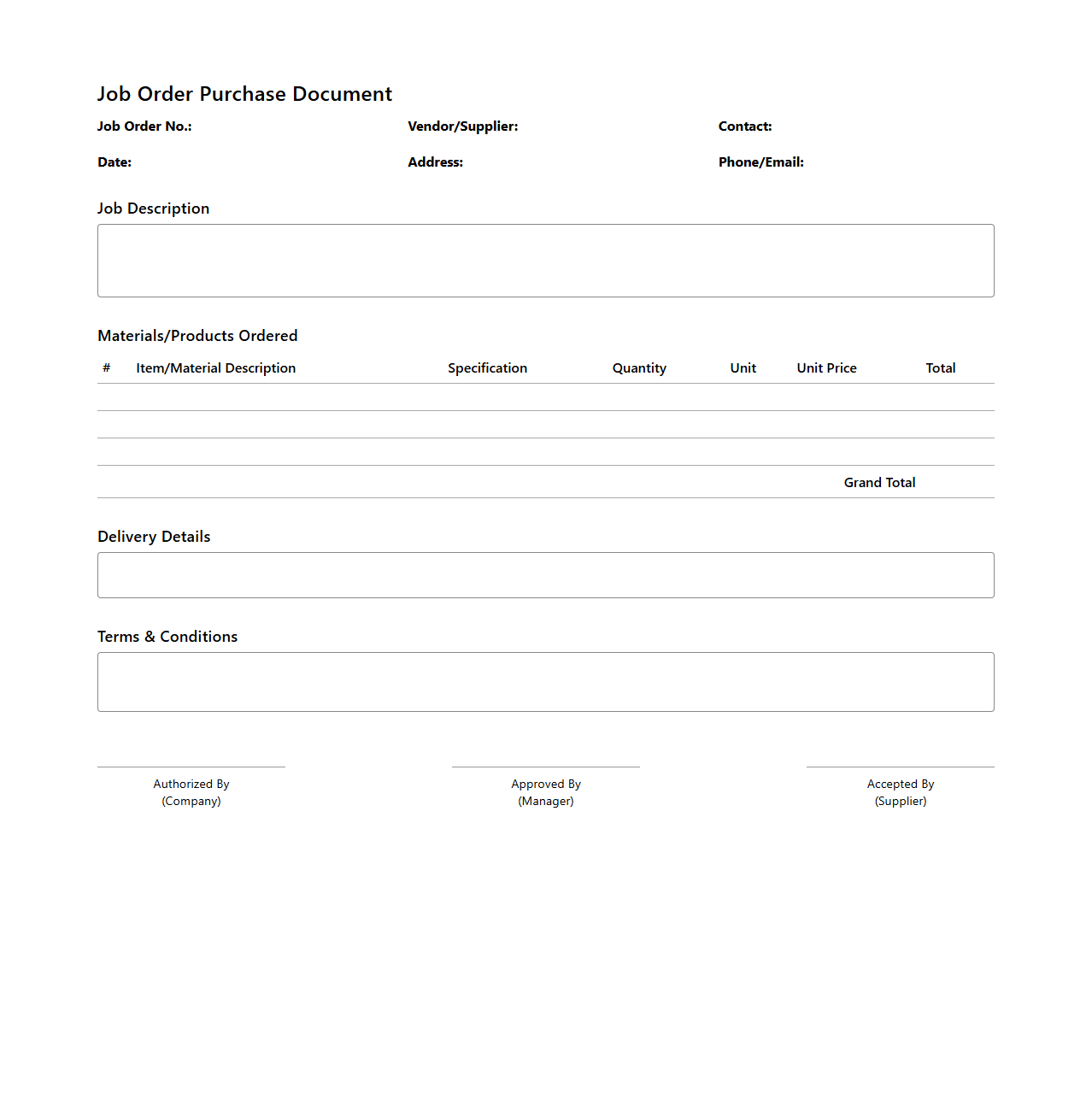

Job Order Purchase Document for Manufacturing

A

Job Order Purchase Document in manufacturing is a formal record used to authorize and track the procurement of materials and services specific to a particular job or production order. It ensures accurate allocation of costs and resources by linking purchase requests directly to a job order number, facilitating efficient inventory management and cost control. This document helps streamline communication between purchasing and production departments, enhancing overall operational efficiency.

Essential Supplier and Buyer Information in a Manufacturing Purchase Order

A manufacturing purchase order must include the full legal names and contact details of both the supplier and the buyer. This ensures clear identification and facilitates communication between parties. Additionally, billing and shipping addresses are critical to avoid delivery errors.

Mandatory Order Details for Product Quantities, Descriptions, and Part Numbers

The purchase order should clearly specify the exact quantities of products required to prevent misunderstandings. Detailed product descriptions help ensure the correct items are supplied. Importantly, part numbers provide a unique identifier that aligns with inventory and manufacturing systems.

Defining Delivery Timelines and Shipping Instructions in the Purchase Order

The document must state the expected delivery dates to coordinate manufacturing schedules. Shipping instructions clarify the preferred method of transport and packaging requirements. These details help ensure timely and compliant receipt of goods.

Payment Terms and Conditions in a Manufacturing Purchase Order

The purchase order clearly outlines payment methods such as wire transfer or credit terms to avoid disputes. It also defines the payment schedule, including any advance or milestone payments. Conditions for penalties, discounts, or late payments are essential for financial clarity.

Approval Signatures and Authorization Processes in the Purchase Order Document

Authorization is evidenced by signatures from designated representatives to validate the agreement. The document often includes sections for multiple approvals depending on order value. This process ensures accountability and legal enforceability for both parties.