A Root Cause Analysis Document Sample for Process Failures provides a structured approach to identify the underlying reasons behind process disruptions. It typically includes sections for problem identification, root cause investigation, corrective actions, and preventive measures to ensure continuous improvement. This sample helps organizations systematically address failures and enhance operational efficiency.

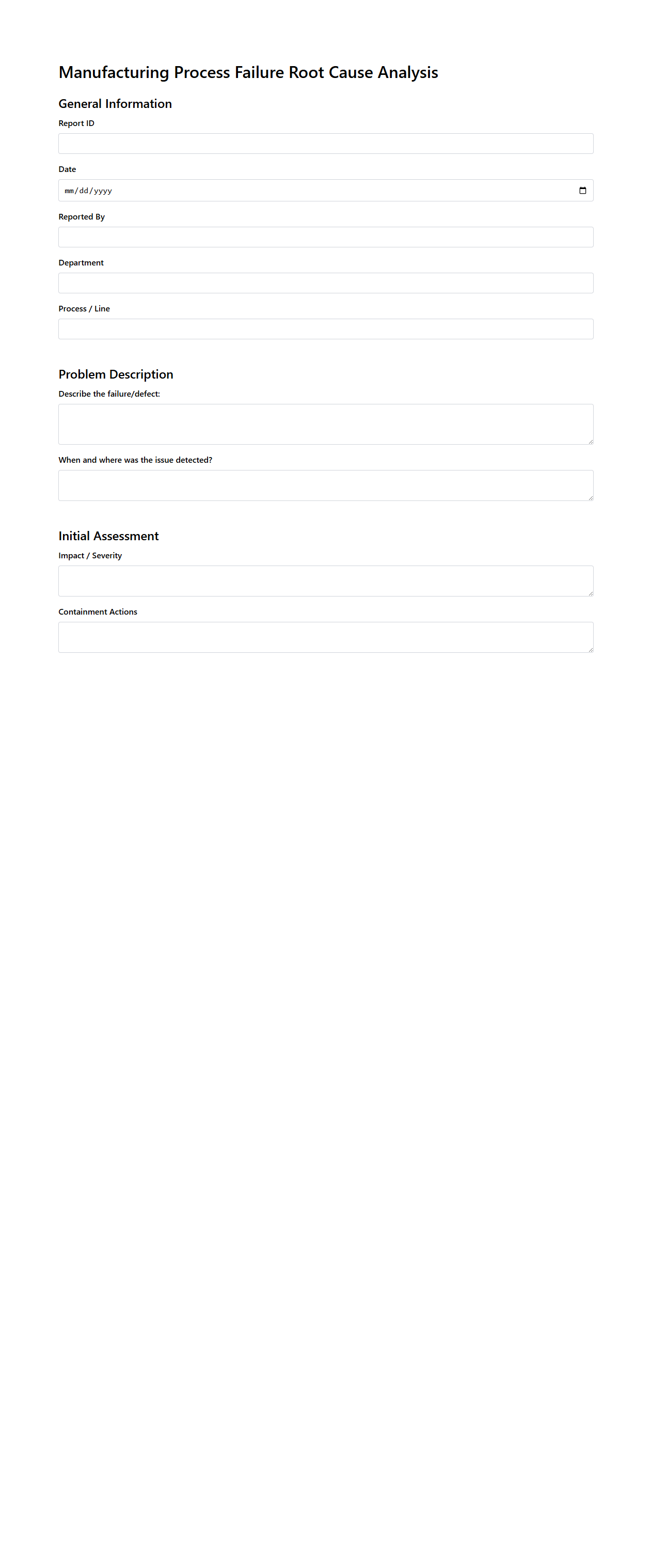

Manufacturing Process Failure Root Cause Analysis Template

The

Manufacturing Process Failure Root Cause Analysis Template document is a structured tool designed to systematically identify and analyze the underlying causes of failures in manufacturing processes. It guides quality and production teams through a step-by-step investigation, helping pinpoint issues related to equipment, materials, methods, or human factors. Using this template improves problem-solving efficiency and supports continuous process improvement efforts.

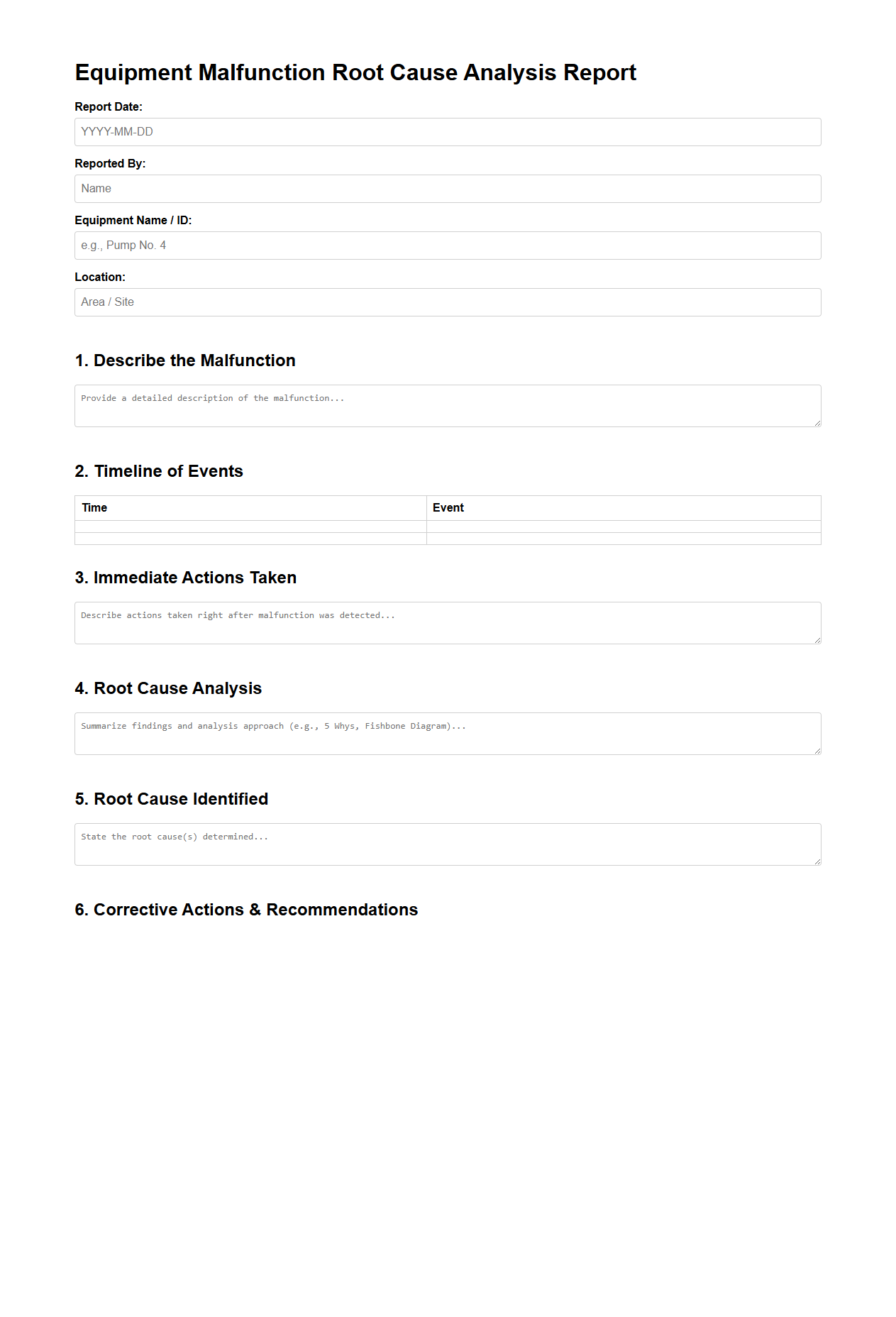

Equipment Malfunction Root Cause Analysis Report

An

Equipment Malfunction Root Cause Analysis Report document systematically identifies the underlying causes of equipment failure to prevent recurrence. It includes detailed data on failure symptoms, inspection results, and recommended corrective actions based on engineering principles and operational history. This report supports maintenance teams in enhancing equipment reliability and minimizing downtime through targeted interventions.

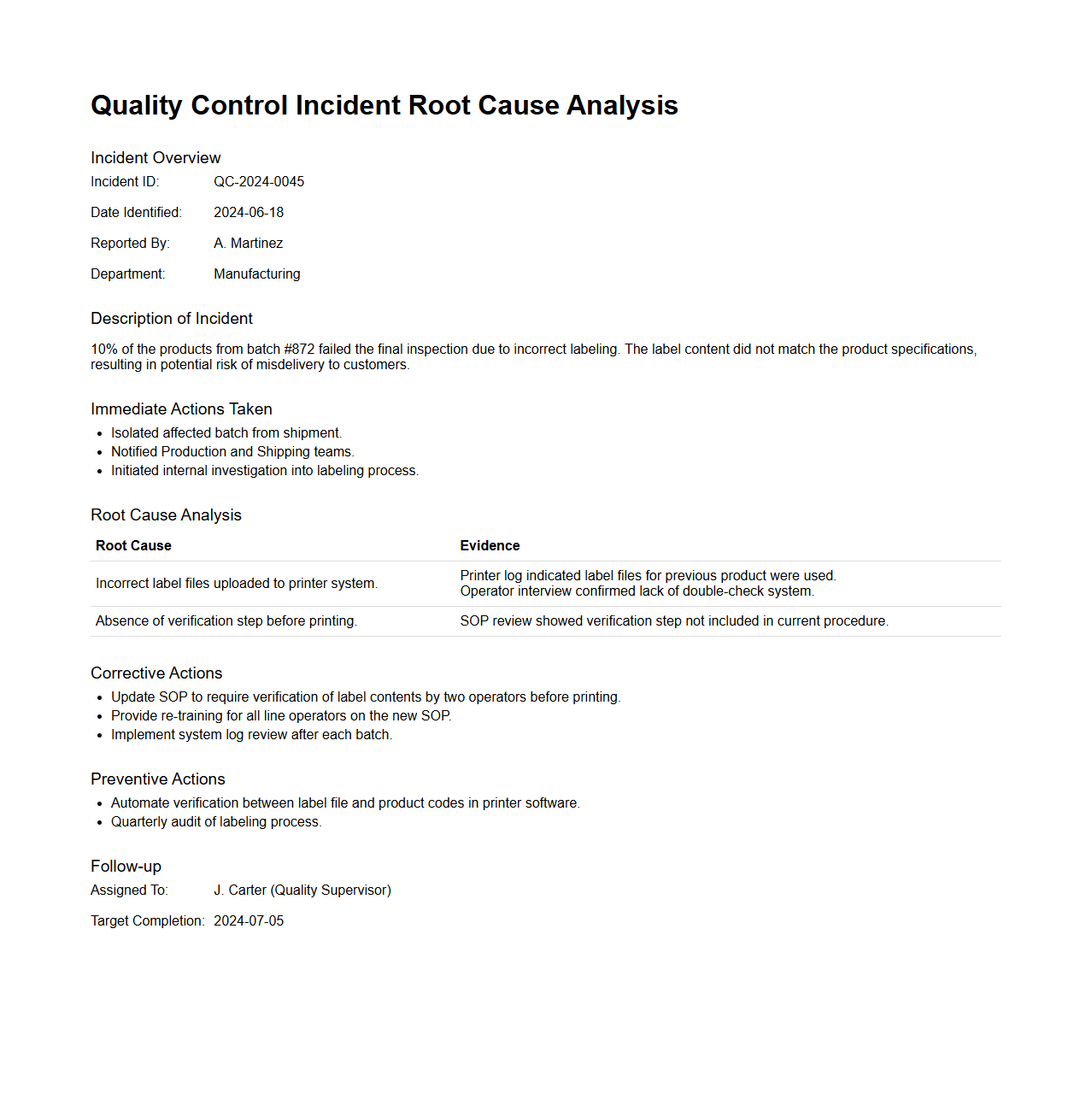

Quality Control Incident Root Cause Analysis Example

A

Quality Control Incident Root Cause Analysis Example document provides a detailed examination of a specific quality control failure to identify underlying causes and prevent recurrence. It includes a systematic approach involving data collection, process mapping, and the use of analytical tools like fishbone diagrams or the 5 Whys technique. This document is essential for improving product quality, ensuring compliance with standards, and enhancing overall operational efficiency.

Supply Chain Disruption Root Cause Analysis Form

A

Supply Chain Disruption Root Cause Analysis Form document is a structured tool used to identify and analyze the underlying causes of interruptions in the supply chain process. It facilitates systematic investigation by capturing data on the disruption event, contributing factors, and potential areas for improvement. This form supports organizations in implementing corrective actions to enhance supply chain resilience and minimize future risks.

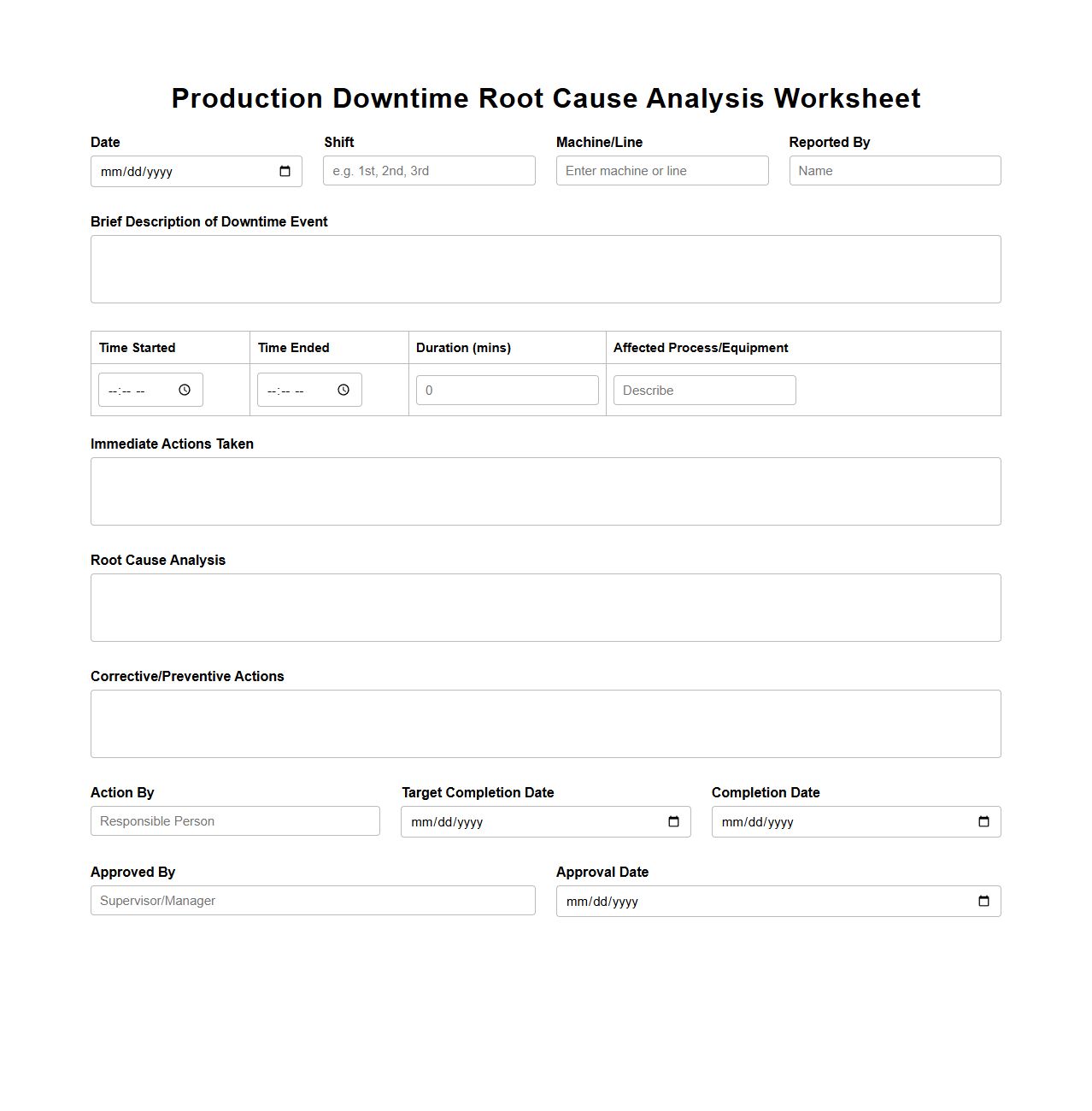

Production Downtime Root Cause Analysis Worksheet

The

Production Downtime Root Cause Analysis Worksheet document is a structured tool designed to identify and analyze the underlying causes of production interruptions. It helps manufacturing teams systematically record downtime events, categorize issues, and pinpoint specific faults such as equipment failures, process inefficiencies, or operator errors. This worksheet supports continuous improvement efforts by providing clear data for corrective actions that reduce future downtime and enhance overall operational efficiency.

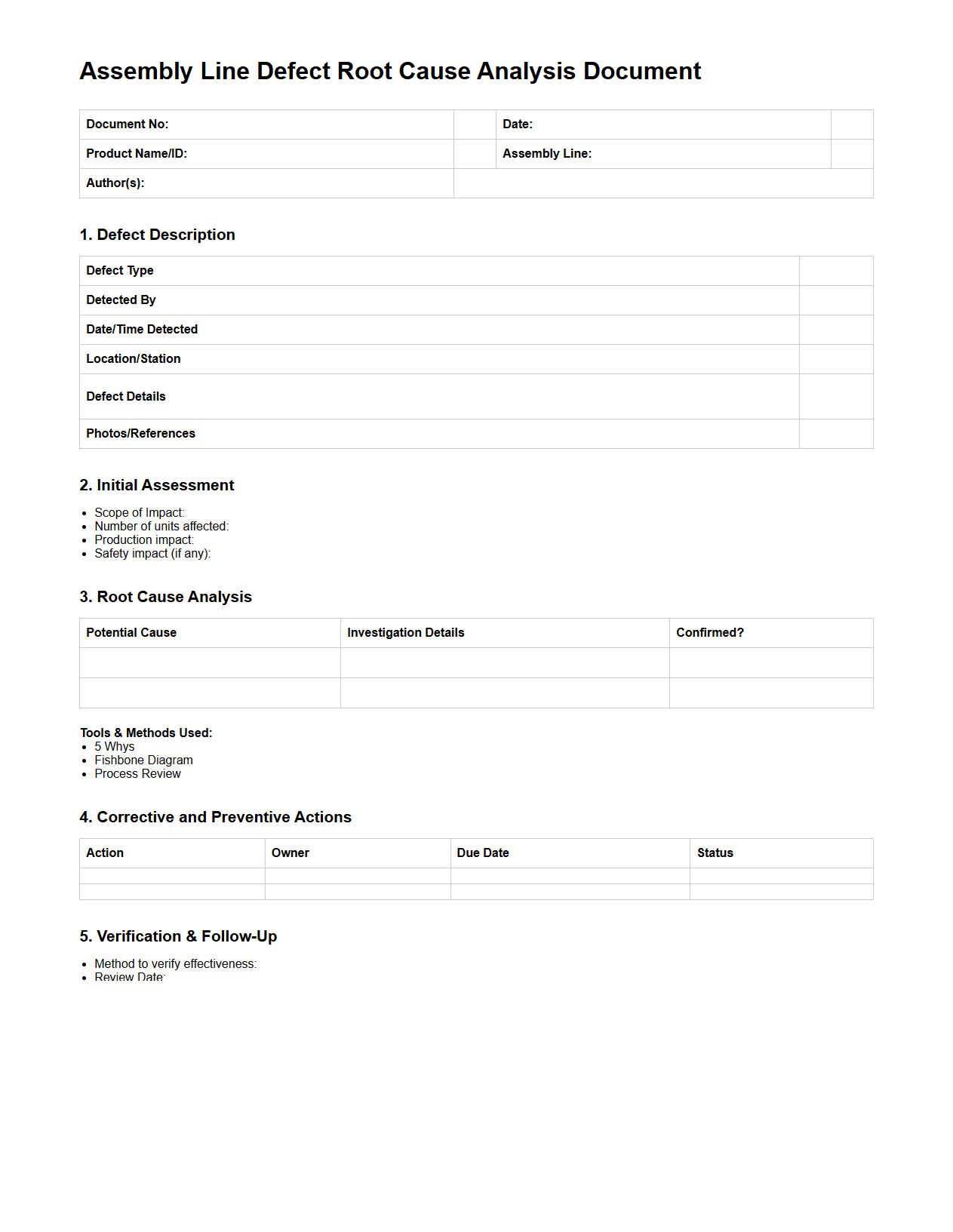

Assembly Line Defect Root Cause Analysis Document

The

Assembly Line Defect Root Cause Analysis Document is a detailed report that identifies and investigates the underlying causes of defects occurring during the manufacturing process. It systematically records defect types, potential sources, and contributing factors to facilitate targeted corrective actions and continuous improvement. This document is essential for quality control teams aiming to reduce production errors and enhance product reliability.

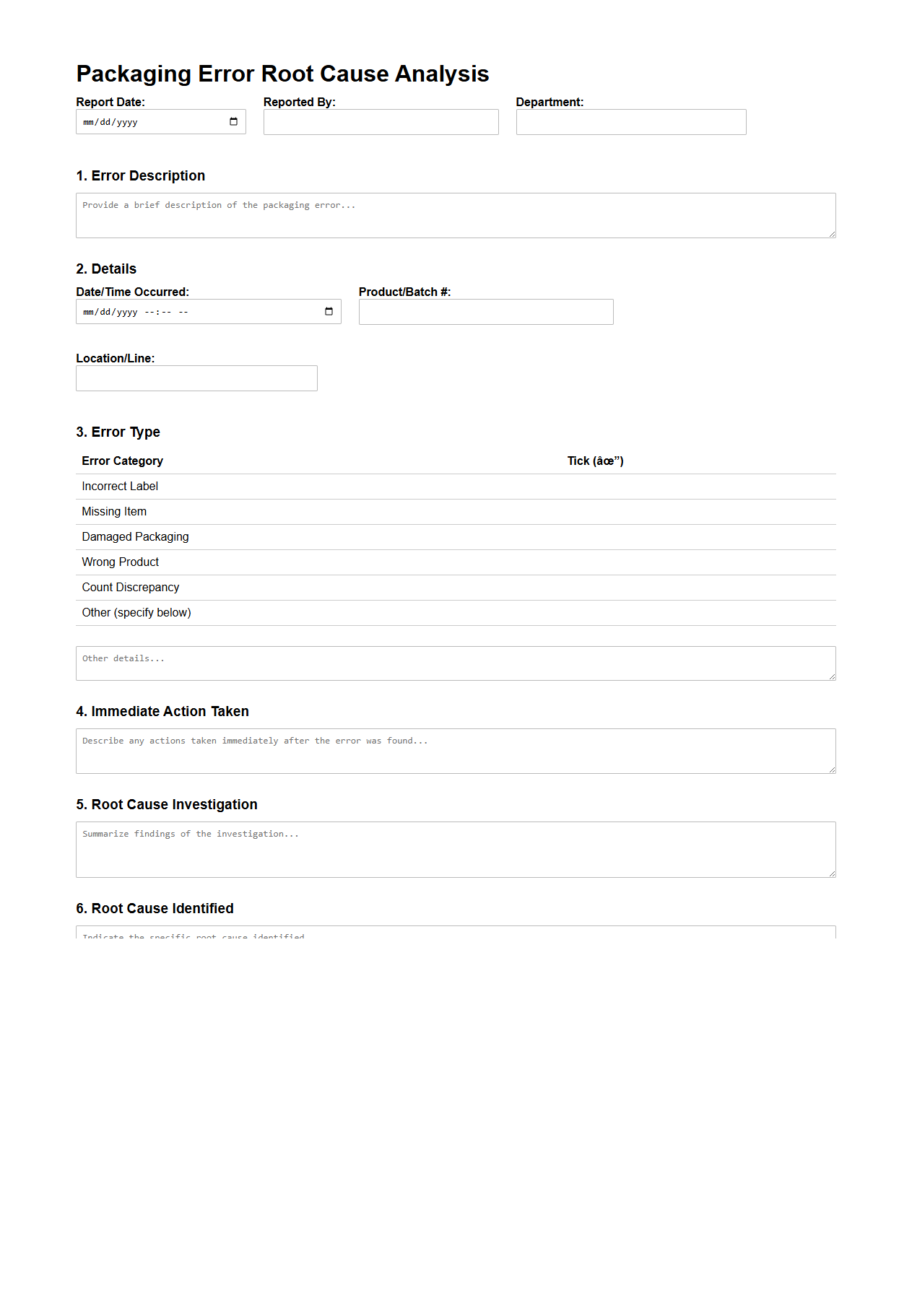

Packaging Error Root Cause Analysis Sample

A

Packaging Error Root Cause Analysis Sample document systematically identifies the underlying causes of packaging defects to prevent recurrence and improve quality control. It includes detailed steps such as problem description, data collection, analysis techniques like fishbone diagrams or 5 Whys, and corrective action plans. Using this sample, organizations can streamline troubleshooting processes and enhance packaging reliability in manufacturing or distribution environments.

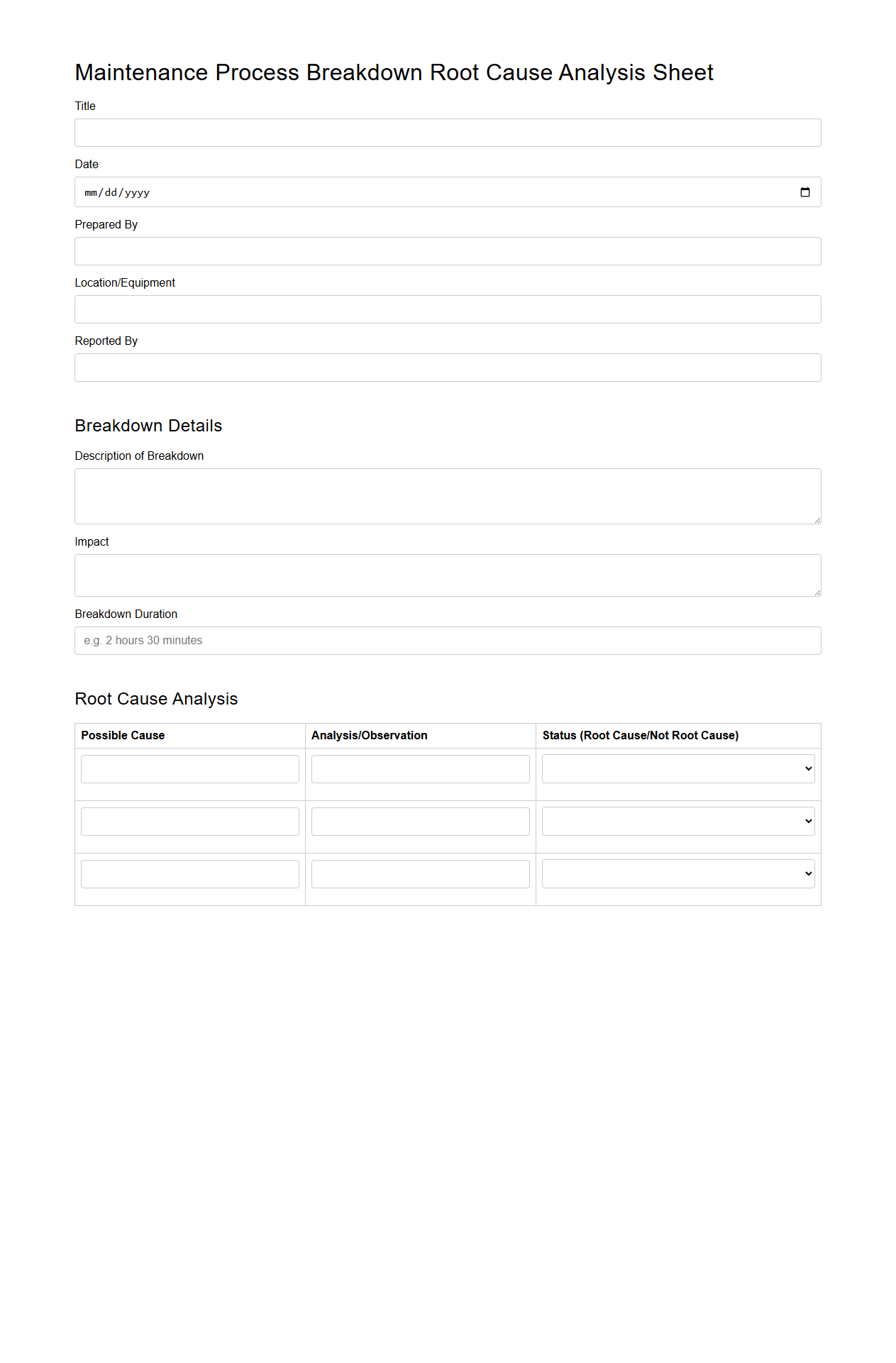

Maintenance Process Breakdown Root Cause Analysis Sheet

The

Maintenance Process Breakdown Root Cause Analysis Sheet document is a structured tool used to identify and analyze the underlying causes of equipment failures or process breakdowns. It systematically records data such as failure symptoms, contributing factors, and corrective actions to prevent recurrence. This document supports continuous improvement by enabling maintenance teams to pinpoint precise root causes and improve operational reliability.

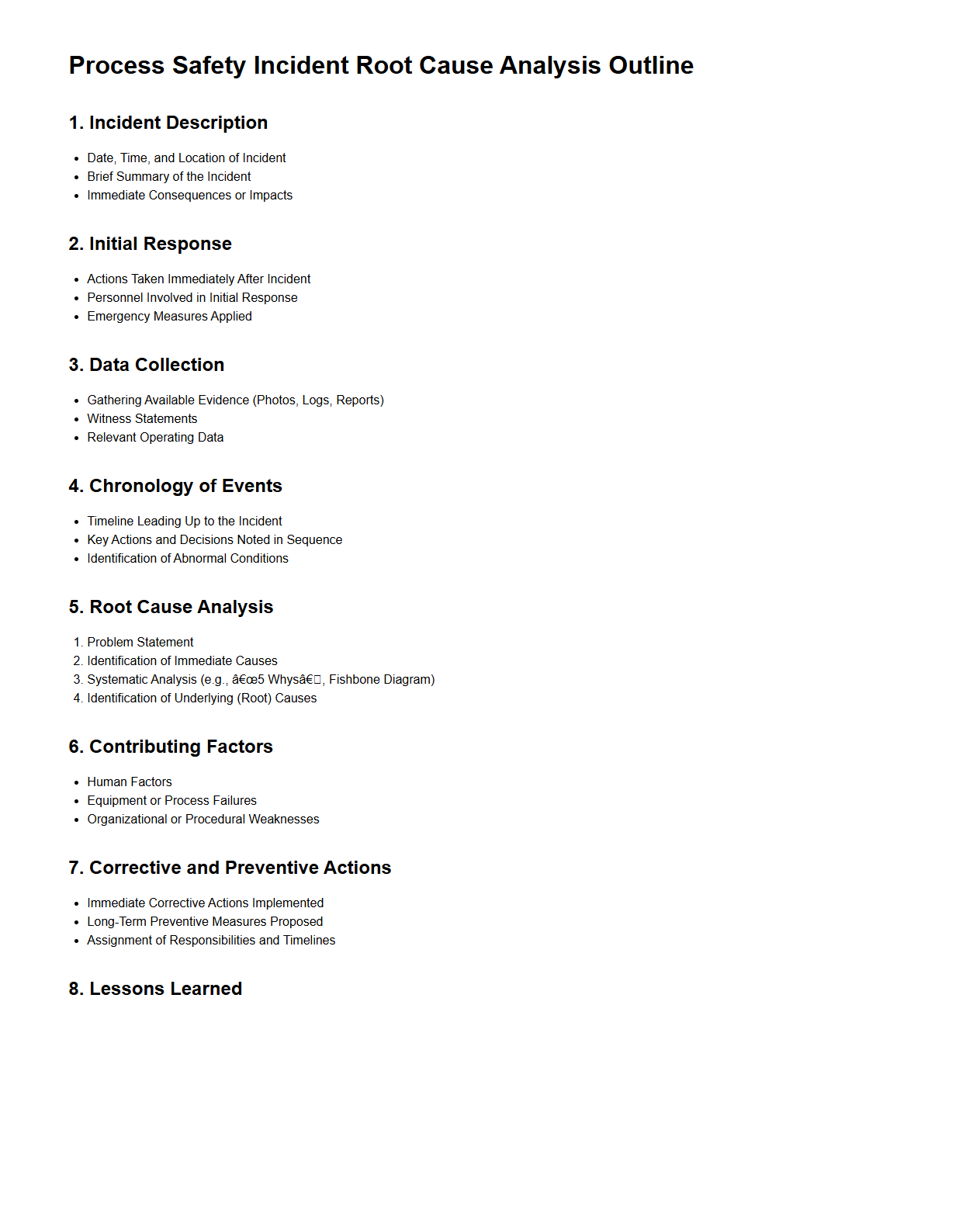

Process Safety Incident Root Cause Analysis Outline

A

Process Safety Incident Root Cause Analysis Outline document provides a structured framework to identify the fundamental reasons behind safety incidents in industrial processes. It systematically guides investigators through data collection, incident chronology, and causal factor identification to prevent recurrence. This document is essential for enhancing workplace safety, regulatory compliance, and continuous improvement in process safety management systems.

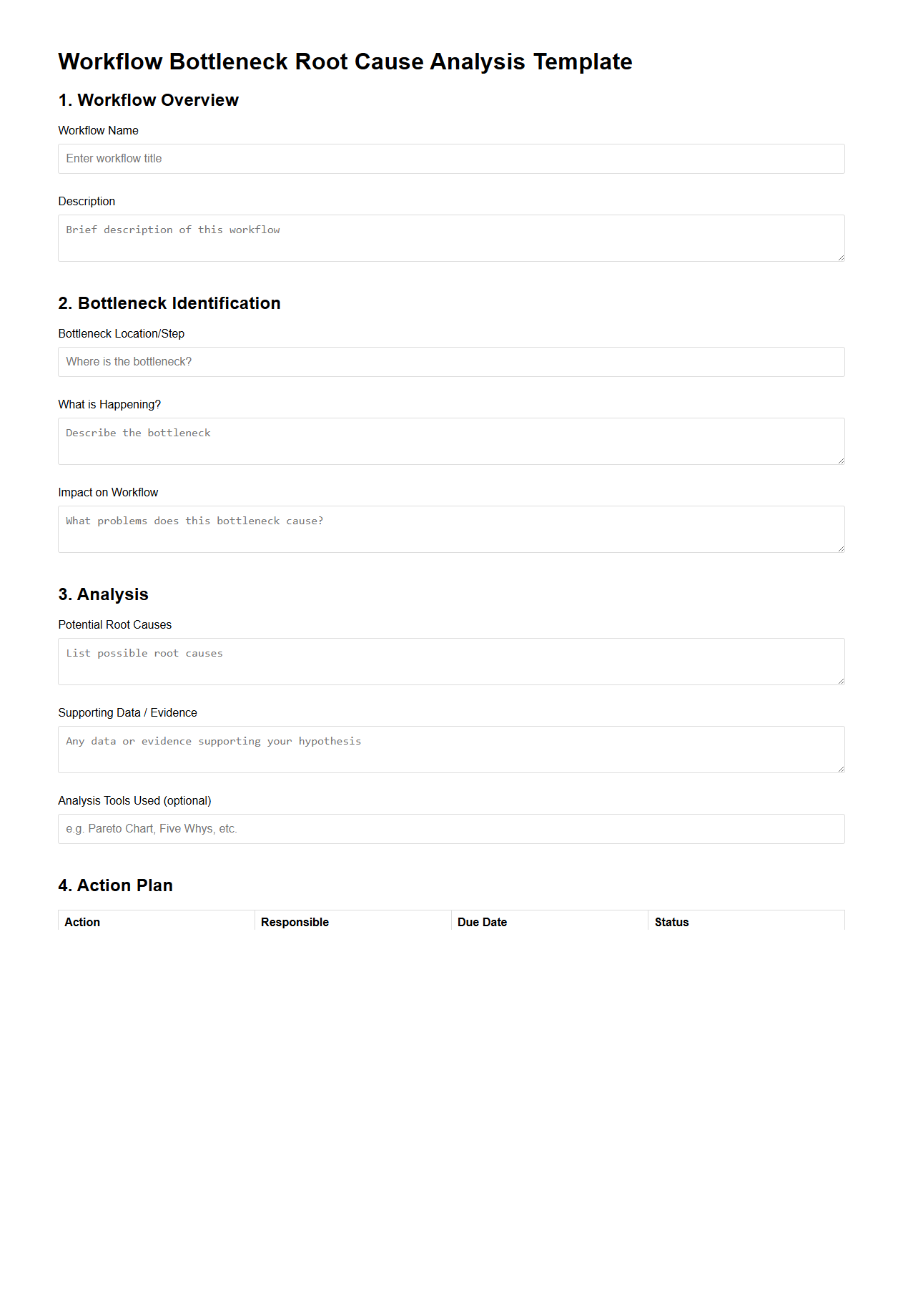

Workflow Bottleneck Root Cause Analysis Template

The

Workflow Bottleneck Root Cause Analysis Template document is a structured tool designed to identify and analyze the primary causes of delays or inefficiencies within a business process. It facilitates systematic examination of workflow steps to pinpoint specific issues that hinder productivity, enabling targeted improvements. Utilizing this template helps organizations optimize operations and enhance overall process efficiency.

What specific problem or process failure is the Root Cause Analysis document addressing?

The Root Cause Analysis (RCA) document addresses a significant process failure that has led to operational inefficiencies and quality defects. This failure impacts overall productivity and customer satisfaction. The document aims to pinpoint the exact moment and cause of the disruption within the process flow.

Which data sources and evidence are used to support the investigation in the document?

The investigation relies on data sources such as process logs, quality inspection reports, and employee interviews. Statistical analysis and historical incident records are also reviewed to provide comprehensive evidence. These data points help build a factual basis for identifying underlying issues.

What are the identified root causes contributing to the process failure in the document?

The document identifies multiple root causes, including equipment malfunction, inadequate training, and communication breakdowns. These factors collectively contributed to the deviation from standard operating procedures. Addressing these root causes is crucial to restoring smooth process performance.

What corrective actions or solutions are proposed within the document to prevent recurrence?

The proposed corrective actions include equipment maintenance schedules, enhanced employee training programs, and improved communication protocols. Additionally, process audits are recommended to ensure adherence to standards. These solutions aim to mitigate risks and prevent future failures.

How does the document measure and verify the effectiveness of implemented corrective actions?

The effectiveness of corrective actions is measured through performance metrics, regular audits, and feedback loops. Key indicators such as defect rates and process cycle time are monitored to assess improvement. Ongoing verification ensures continuous process optimization and sustainability.

More Manufacturing Templates