A Product Traceability Document Sample for Food Manufacturing provides a detailed record of the entire production process, from raw material sourcing to final product distribution. This document ensures compliance with food safety regulations by enabling quick identification and tracking of ingredients and batches. It is essential for maintaining quality control, managing recalls, and enhancing transparency within the food supply chain.

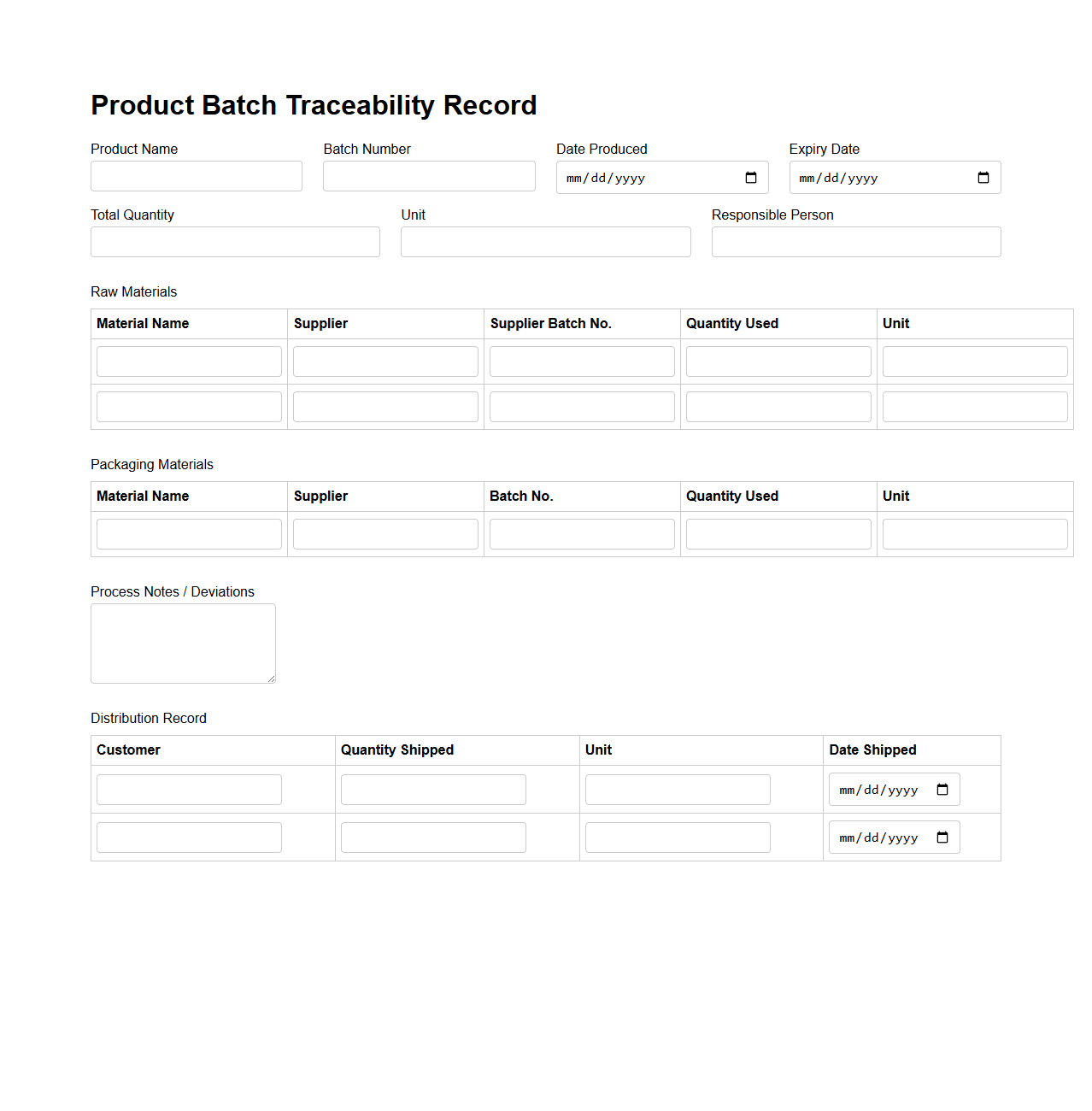

Product Batch Traceability Record for Food Manufacturing

The

Product Batch Traceability Record for food manufacturing is a detailed document that tracks the entire lifecycle of a specific batch of food products, from raw material sourcing to final distribution. It includes critical data such as ingredient origins, processing steps, quality control measures, and packaging information to ensure compliance with food safety regulations. This record enables quick identification and resolution of issues related to contamination, recalls, or quality deviations, enhancing transparency and consumer safety.

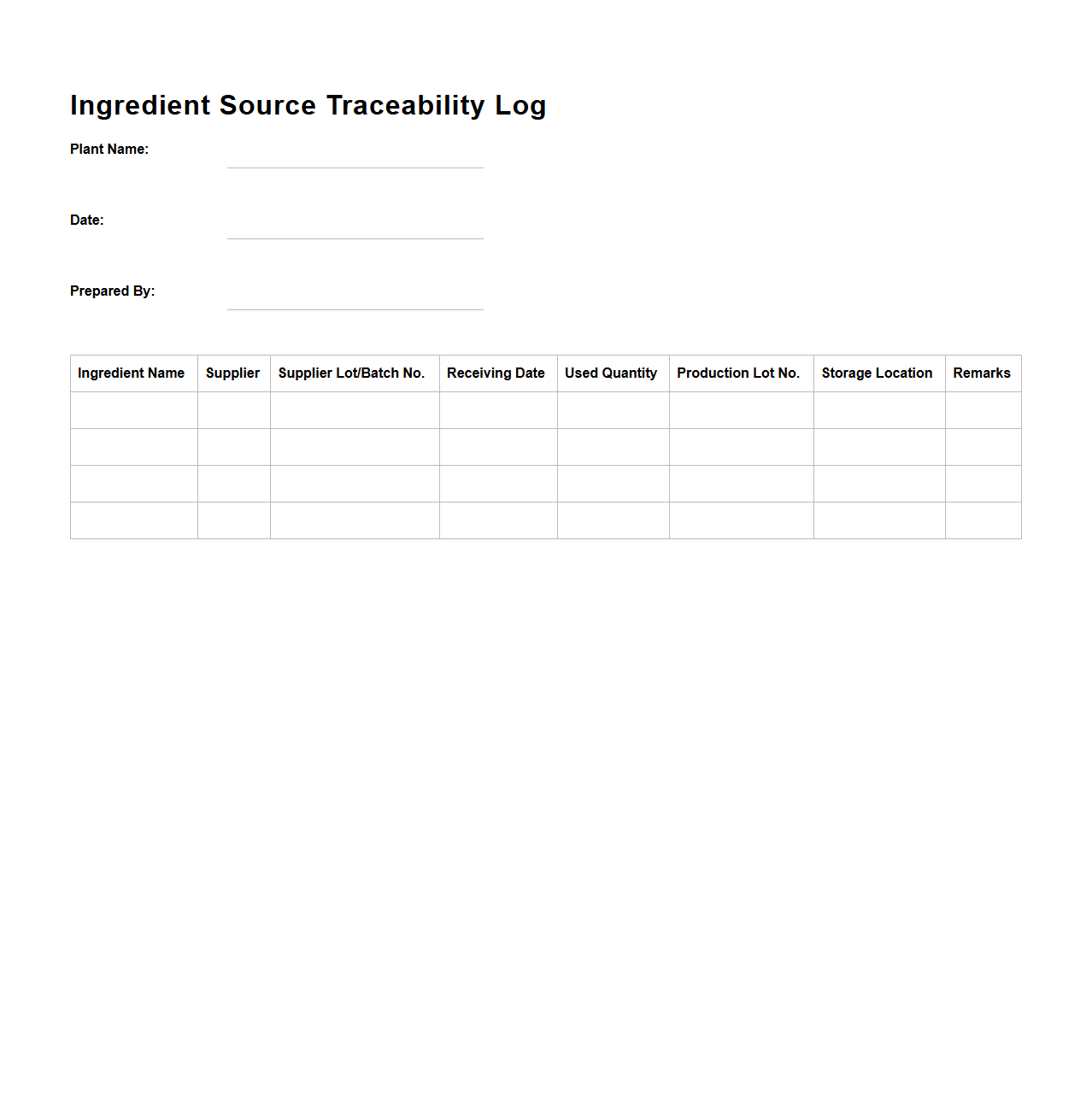

Ingredient Source Traceability Log for Food Plants

The

Ingredient Source Traceability Log for food plants is a critical document that tracks the origin of raw materials used in production, ensuring safety and compliance with industry standards. This log records detailed information such as supplier details, batch numbers, delivery dates, and verification statuses to facilitate quick identification during recalls or quality audits. Maintaining accurate traceability supports transparency, enhances food safety protocols, and mitigates risks from contamination or fraud.

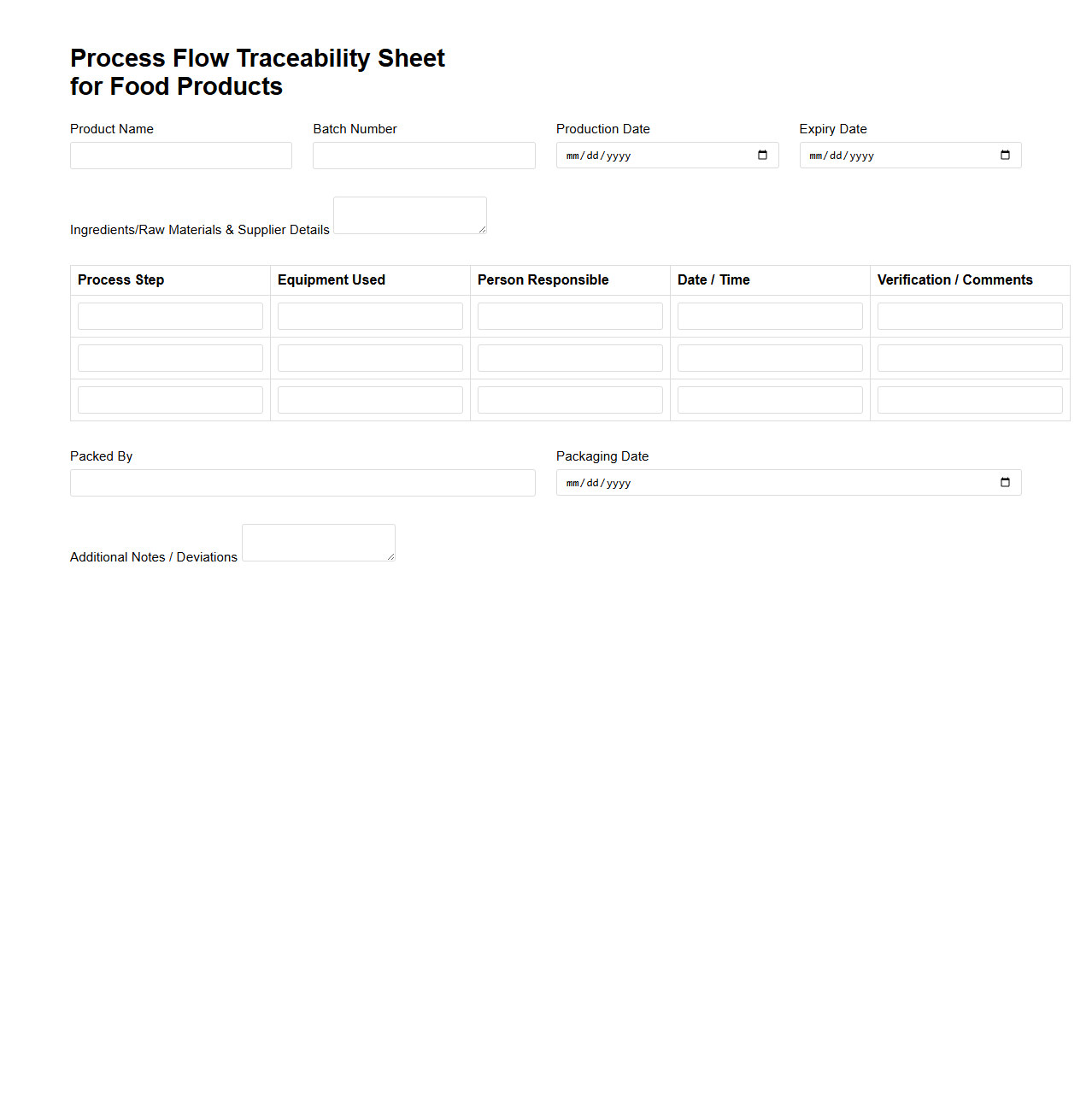

Process Flow Traceability Sheet for Food Products

A

Process Flow Traceability Sheet for food products is a documented tool used to track and record each step of the production process, ensuring transparency and accountability from raw material sourcing to finished goods. This sheet enables precise identification of product batches, facilitates quick response to quality issues, and supports compliance with food safety regulations such as HACCP and FSMA. By maintaining detailed traceability, companies improve food safety management, recall efficiency, and customer trust.

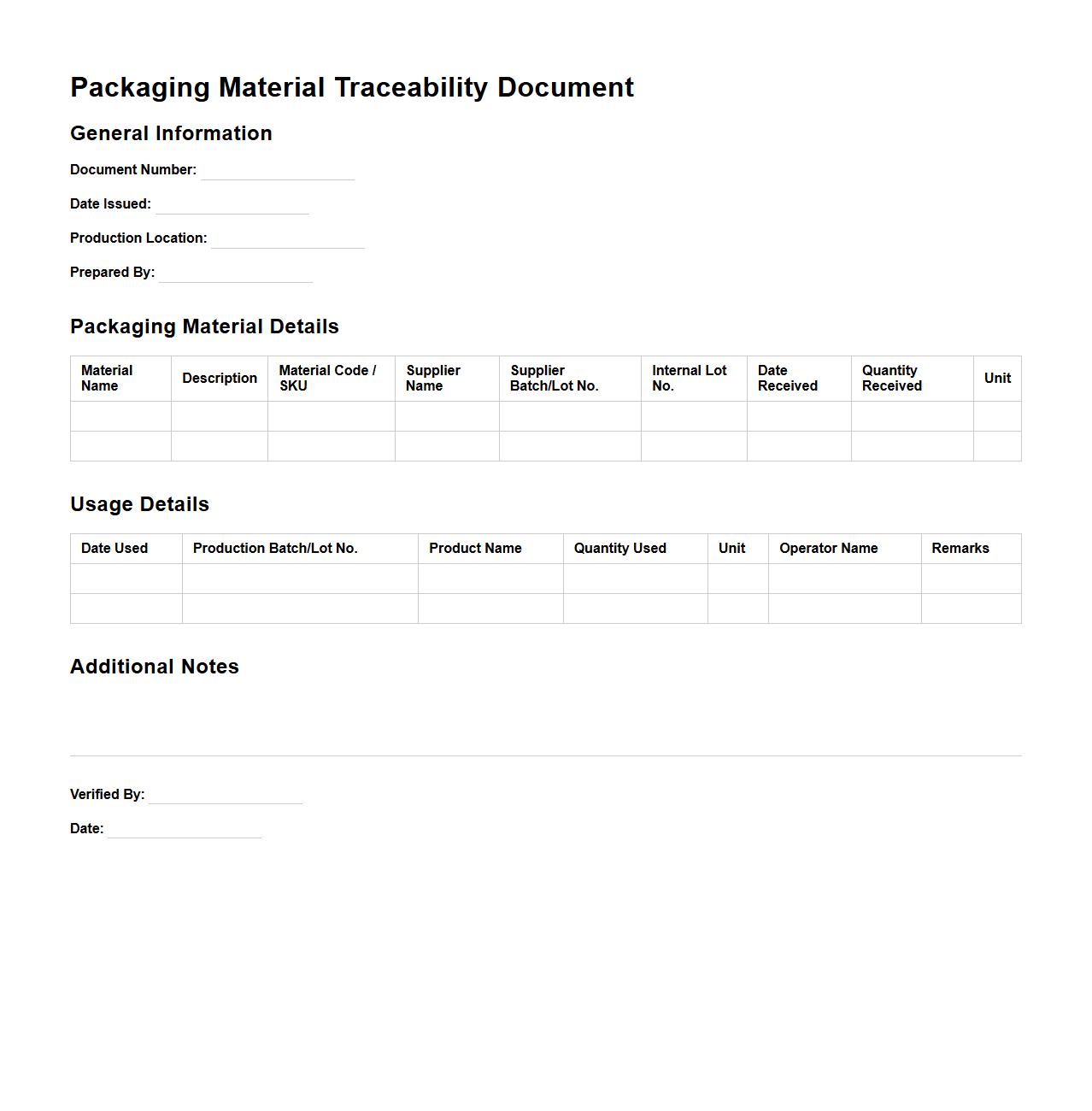

Packaging Material Traceability Document for Food Production

A

Packaging Material Traceability Document for food production records the detailed history and origin of all materials used in packaging, ensuring compliance with safety and quality standards. It tracks batch numbers, supplier information, and production dates to enable swift identification of sources during audits or product recalls. This document supports food safety management systems by maintaining transparency and accountability throughout the packaging supply chain.

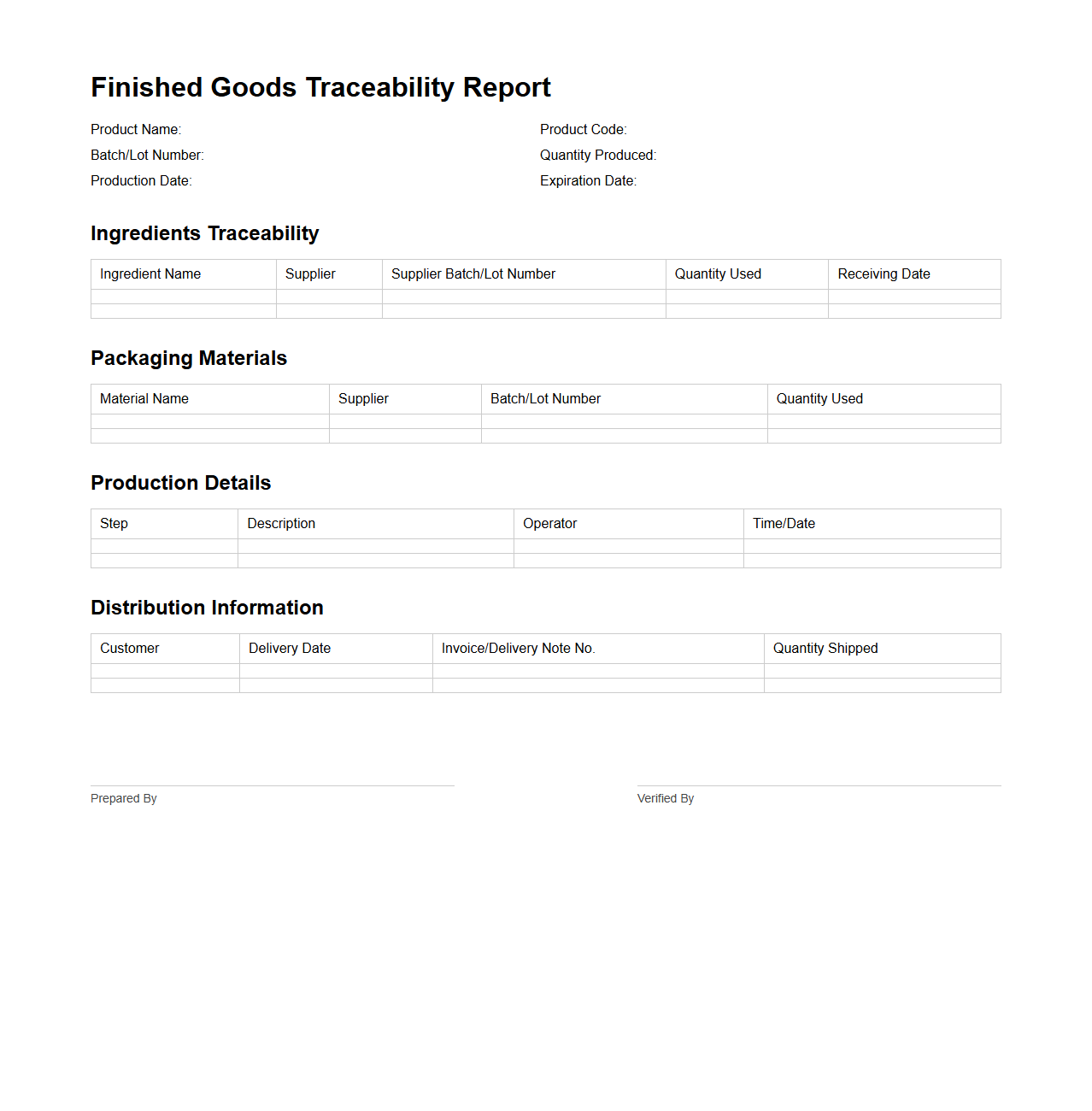

Finished Goods Traceability Report for Food Manufacturing

The

Finished Goods Traceability Report in food manufacturing is a detailed document that tracks the movement and history of finished products from production to distribution. It includes essential data such as batch numbers, production dates, ingredient sources, and shipping details to ensure compliance with food safety regulations. This report is critical for identifying and isolating affected products during recalls, minimizing risk to consumers and protecting brand integrity.

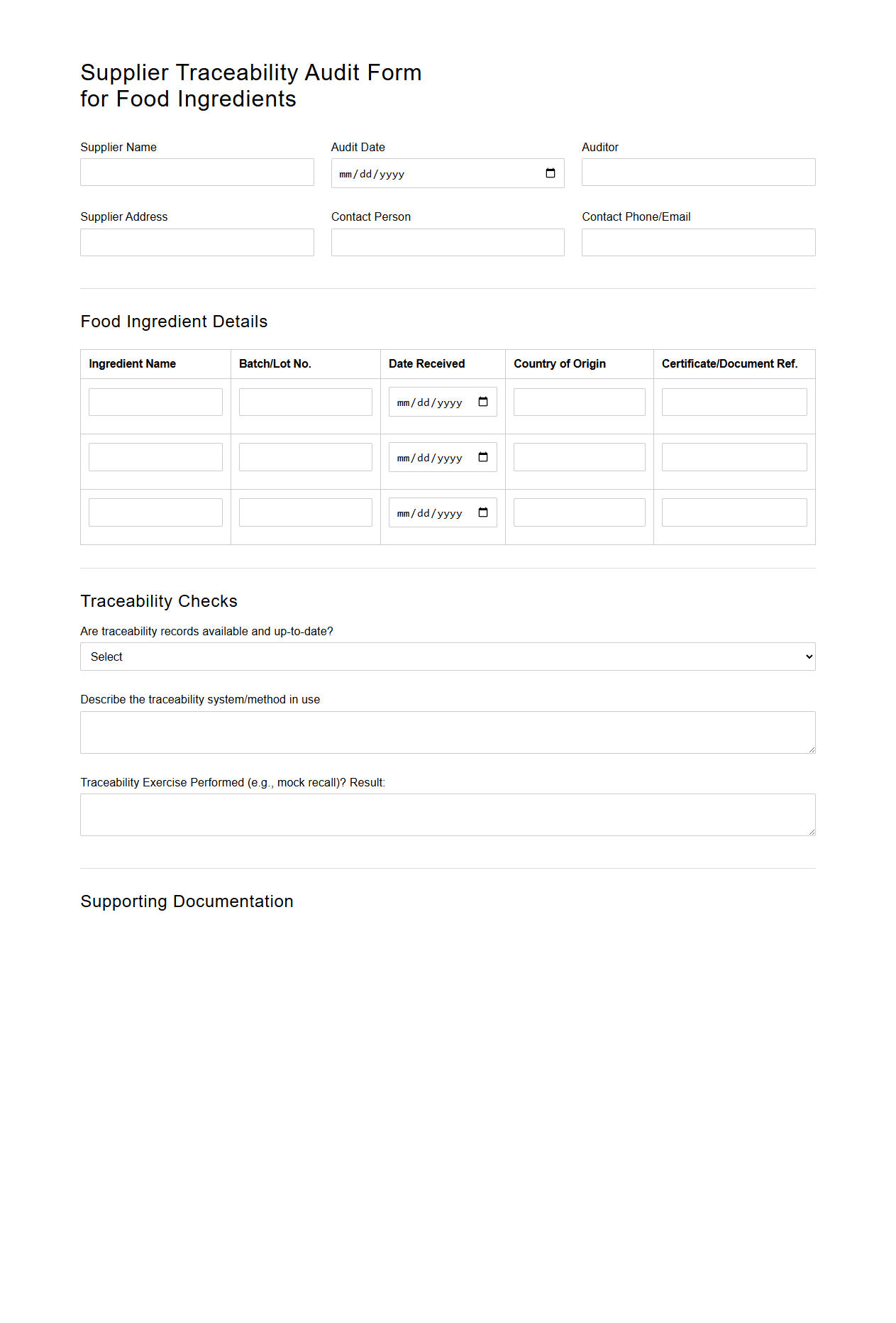

Supplier Traceability Audit Form for Food Ingredients

A

Supplier Traceability Audit Form for Food Ingredients is a critical document used to verify and track the origin, handling, and distribution of food ingredient supplies. It ensures compliance with food safety standards by documenting supplier information, batch numbers, and traceability processes. This form supports risk management and regulatory requirements by enabling quick identification and resolution of potential contamination or quality issues.

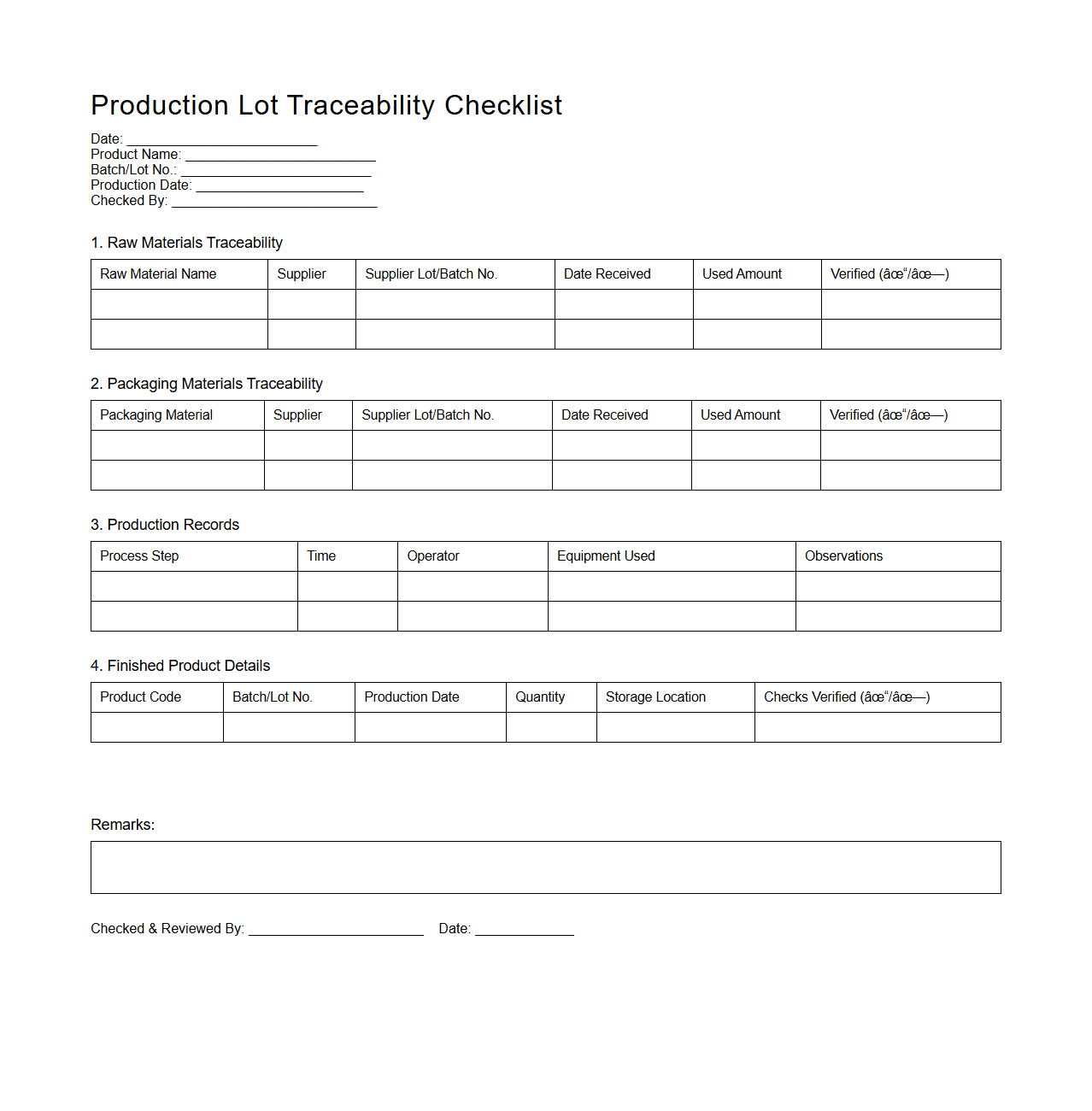

Production Lot Traceability Checklist for Food Factories

The

Production Lot Traceability Checklist for food factories is a critical document ensuring complete tracking of raw materials and finished products throughout the manufacturing process. It systematically verifies key factors such as batch numbers, production dates, supplier information, and storage conditions to maintain compliance with food safety standards. This checklist supports effective recall management and enhances transparency in food production operations.

Distribution Traceability Tracking Form for Food Industry

The

Distribution Traceability Tracking Form for the food industry is a critical document designed to record and monitor the movement of food products through the supply chain, from production to final delivery. This form captures detailed information such as batch numbers, shipment dates, and recipient details, enabling quick identification and response during recalls or safety incidents. Effective use of this form ensures regulatory compliance and enhances food safety by maintaining transparency and accountability throughout distribution.

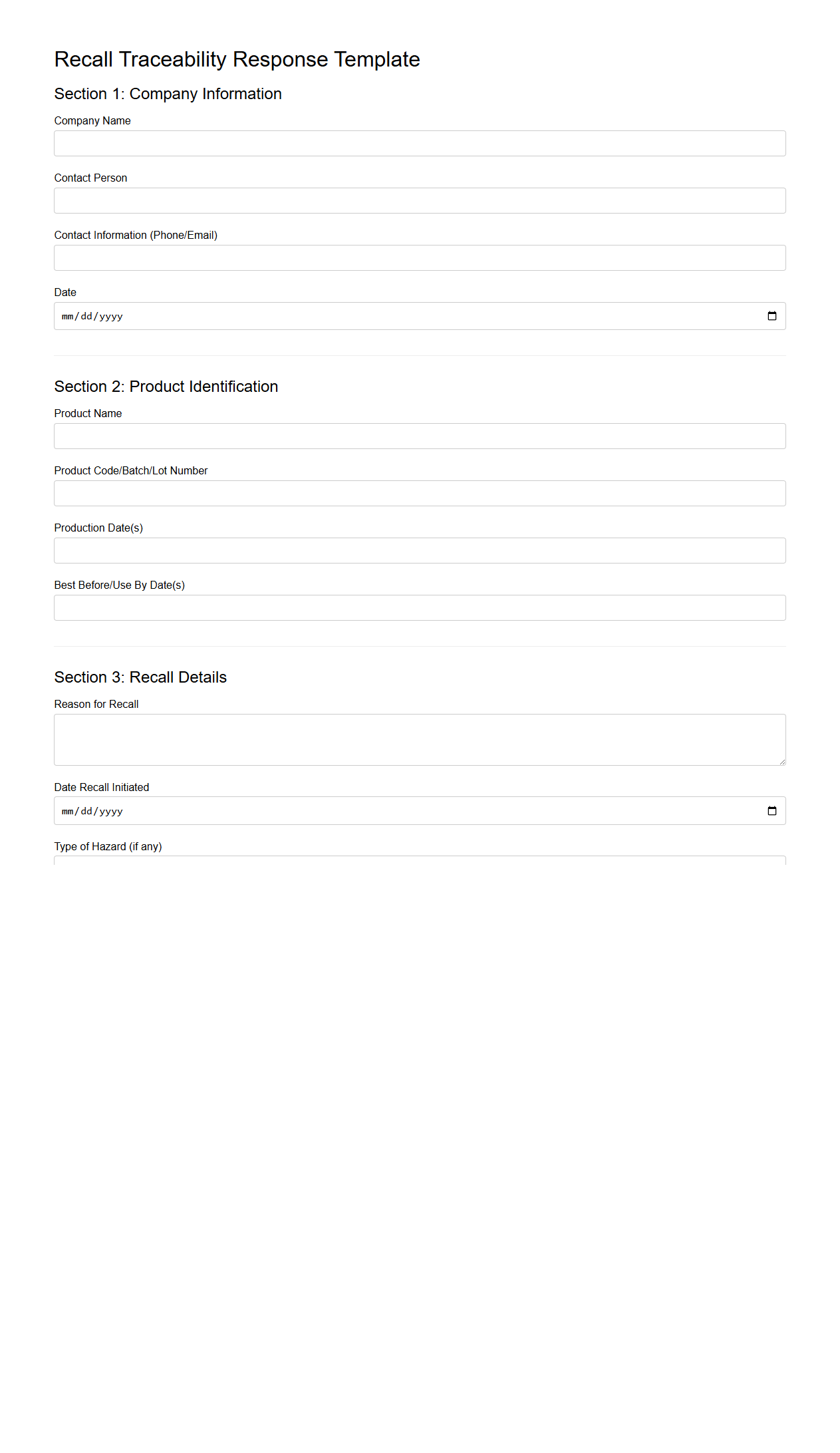

Recall Traceability Response Template for Food Manufacturers

The

Recall Traceability Response Template for food manufacturers is a standardized document designed to streamline and document the process of identifying, tracing, and responding to product recalls efficiently. It helps manufacturers systematically record critical data such as batch numbers, distribution channels, and corrective actions taken to ensure regulatory compliance and protect consumer safety. This template supports faster decision-making and communication during recall events, minimizing risks and potential damages.

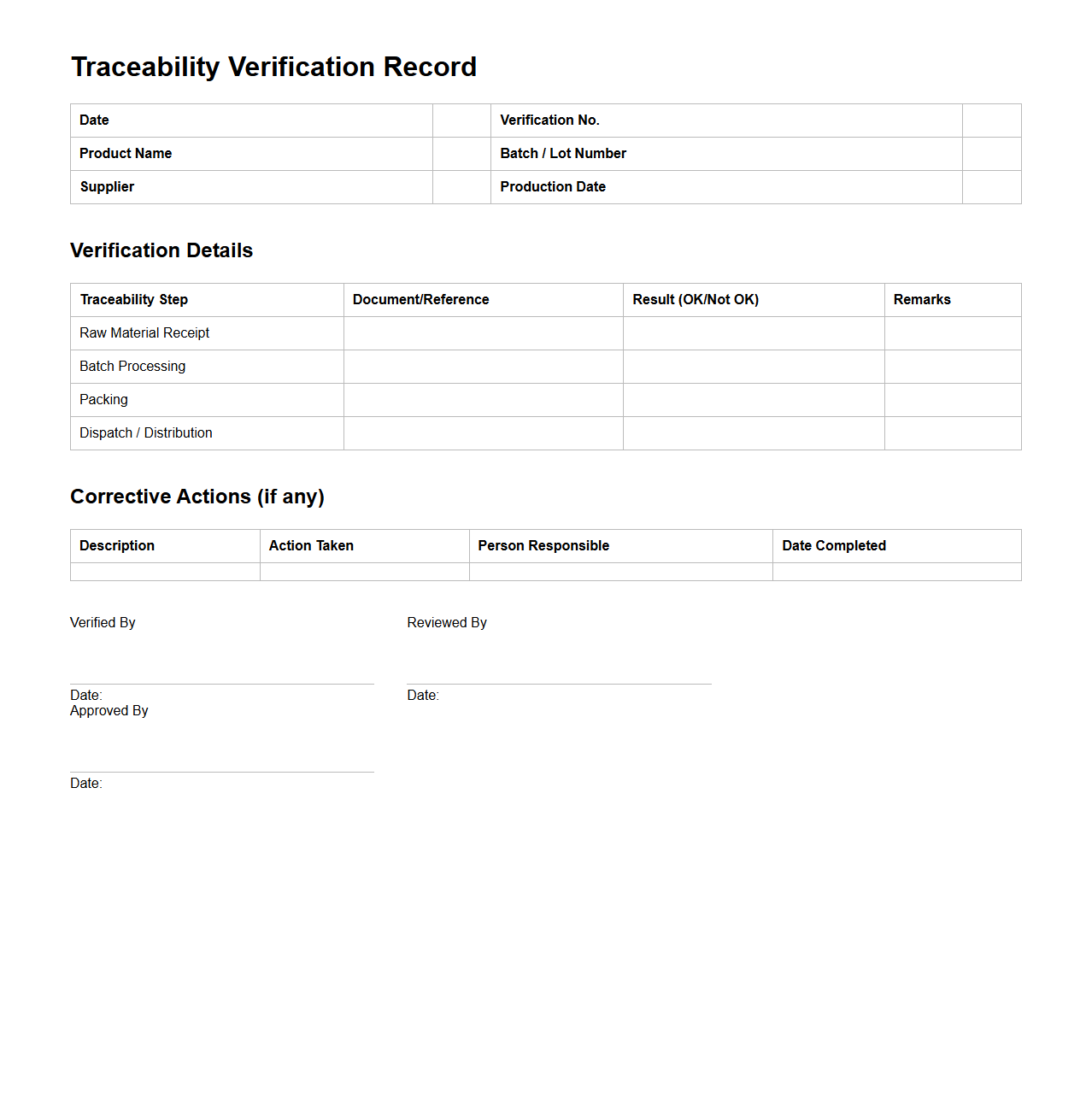

Traceability Verification Record for Food Quality Systems

A

Traceability Verification Record for Food Quality Systems document ensures accurate tracking of food products throughout the supply chain, from raw materials to finished goods. It verifies that all steps in production, processing, and distribution are documented and compliant with safety standards to manage recalls and prevent contamination effectively. This record supports regulatory compliance and enhances transparency by maintaining a detailed history of product movement and handling.

What critical data fields are typically included in a Product Traceability Document for food manufacturing?

A Product Traceability Document usually includes essential data fields such as batch or lot numbers, production dates, and expiration dates to ensure precise tracking. It also records the source of raw materials, including supplier details and material specifications, crucial for quality control. Additionally, storage conditions and transportation records may be included to maintain product integrity throughout the supply chain.

How does the document record the movement of raw materials through each stage of production?

The document systematically logs the movement of raw materials by recording timestamps and location details at every production stage. Each entry tracks processing steps, equipment used, and personnel involved, providing a clear production timeline. This comprehensive log ensures transparency and accountability during the transformation from raw materials to finished goods.

What identification methods (e.g., batch numbers, barcodes) are documented for product traceability?

Identification methods such as unique batch numbers, barcodes, and RFID tags are prominently documented to facilitate rapid traceability. These identifiers enable efficient scanning and tracking of products throughout manufacturing and distribution. They play a pivotal role in minimizing errors and expediting information retrieval during quality checks or recalls.

How does the document link finished products to their originating suppliers or farms?

The document establishes clear connections between finished products and their originating suppliers or farms through detailed supplier records and corresponding batch numbers. This linking enables swift verification of raw material sources, enhancing food safety and quality assurance. Maintaining this linkage is vital for transparency and regulatory compliance in the supply chain.

What procedures are outlined in the document for handling and documenting product recalls or tracebacks?

The traceability document outlines strict procedures for product recalls, including immediate identification of affected batches and affected distribution points. It details steps for isolation, notification of relevant stakeholders, and documentation of corrective actions taken. These protocols ensure swift response to safety issues, minimizing risks to consumers and protecting brand reputation.

More Manufacturing Templates