A Equipment Maintenance Document Sample for Manufacturing provides a structured template to record routine inspections, repairs, and servicing of machinery. This ensures consistent tracking of equipment performance and helps prevent unexpected downtime in manufacturing processes. Proper documentation supports compliance with safety regulations and maximizes operational efficiency.

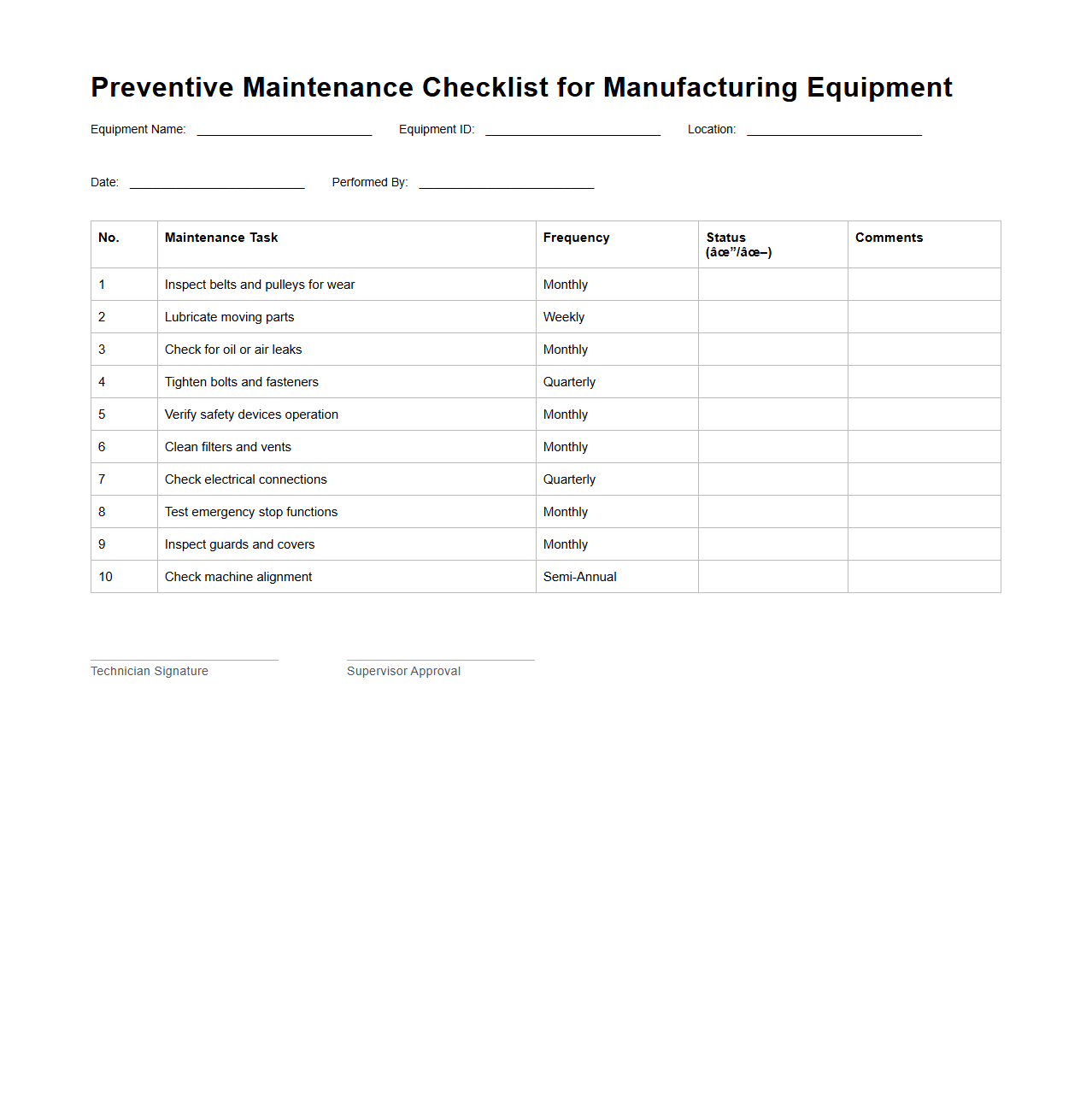

Preventive Maintenance Checklist for Manufacturing Equipment

A

Preventive Maintenance Checklist for Manufacturing Equipment document is a detailed guide used to systematically inspect, clean, and service machinery to prevent unexpected breakdowns and ensure optimal performance. It typically includes scheduled tasks such as lubrication, parts replacement, calibration, and safety checks tailored to specific equipment types. Utilizing this checklist helps manufacturers reduce downtime, extend the lifespan of machines, and maintain consistent production quality.

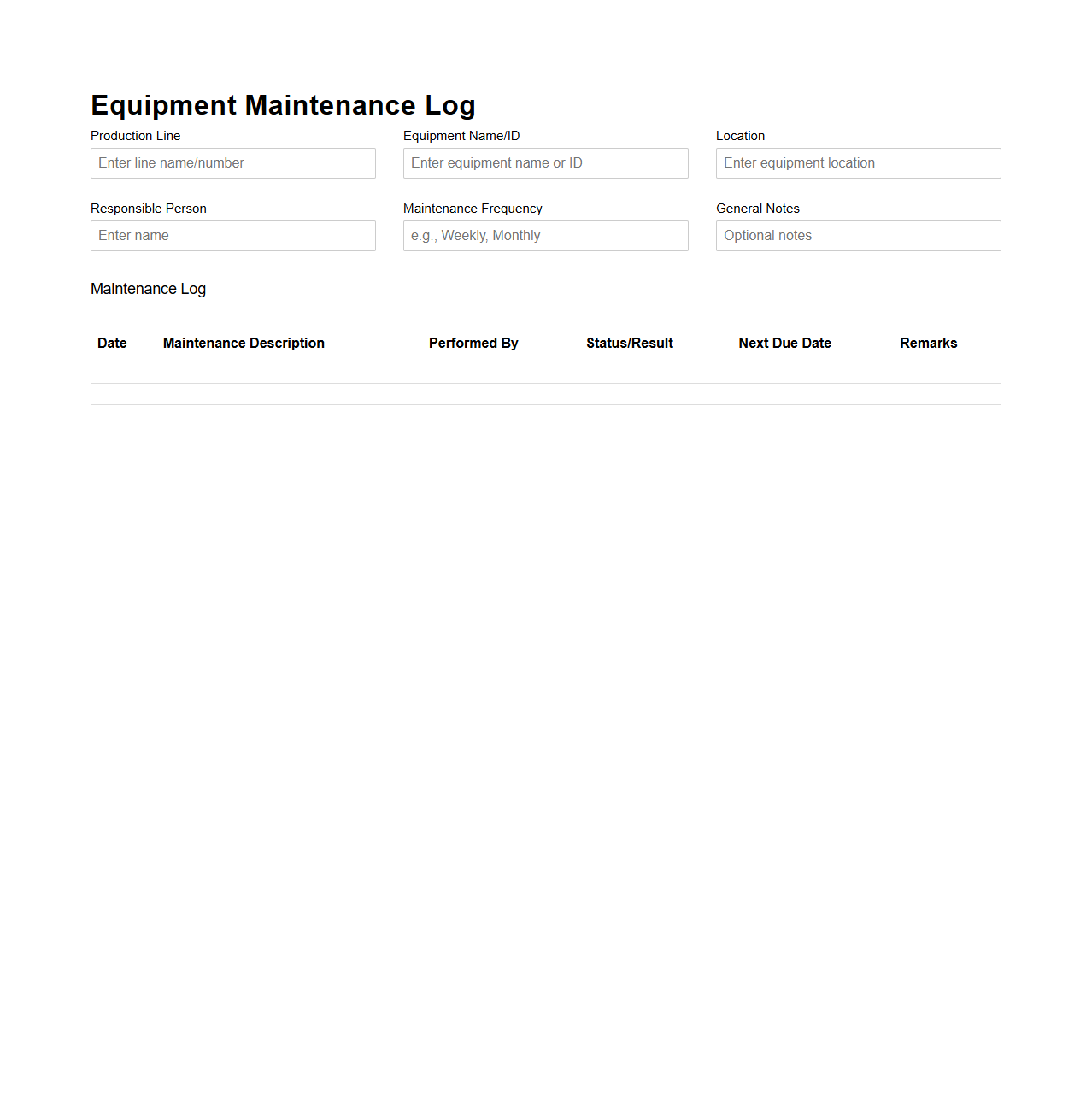

Equipment Maintenance Log Template for Production Lines

An

Equipment Maintenance Log Template for Production Lines is a structured document designed to track and record the maintenance activities performed on machinery within a manufacturing environment. It ensures systematic documentation of service dates, types of maintenance, technician details, and equipment status to enhance operational efficiency and minimize downtime. Using this template helps production managers monitor preventive maintenance schedules, identify recurring issues, and extend the lifespan of critical production equipment.

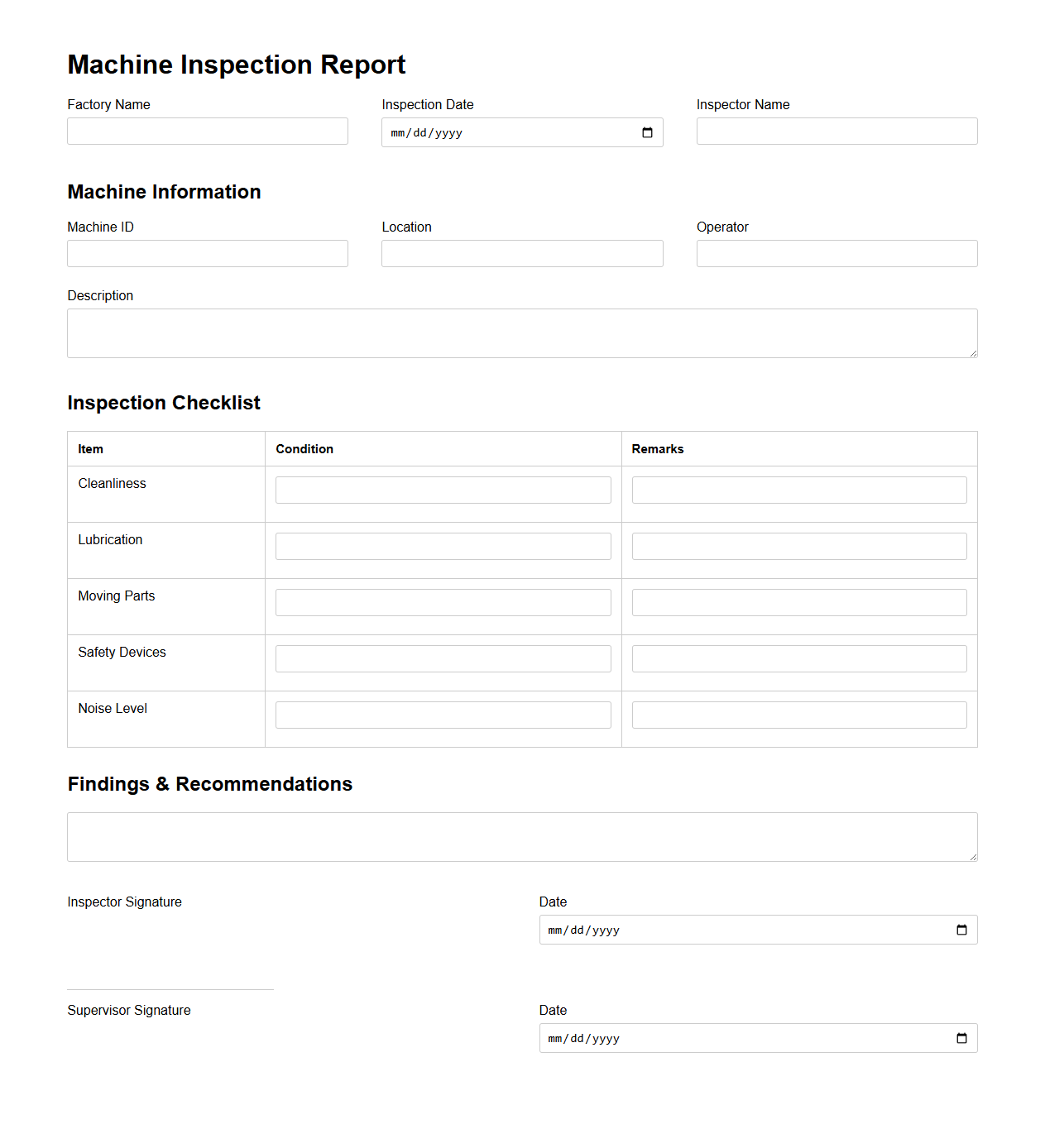

Machine Inspection Report for Factory Operations

A

Machine Inspection Report for factory operations is a detailed document that records the condition, performance, and maintenance status of machinery used in production processes. It includes data on operational efficiency, wear and tear, and any detected faults to ensure equipment reliability and prevent unexpected downtimes. This report is essential for scheduling preventive maintenance and supporting compliance with safety standards in industrial environments.

Scheduled Maintenance Tracking Sheet for Plant Machinery

A

Scheduled Maintenance Tracking Sheet for Plant Machinery is a crucial document used to monitor and record routine maintenance activities, ensuring machinery operates efficiently and downtime is minimized. It details maintenance schedules, task descriptions, responsible personnel, and completion dates to facilitate accurate tracking and compliance with operational standards. This sheet supports preventive maintenance strategies by providing clear insights into equipment health and maintenance history.

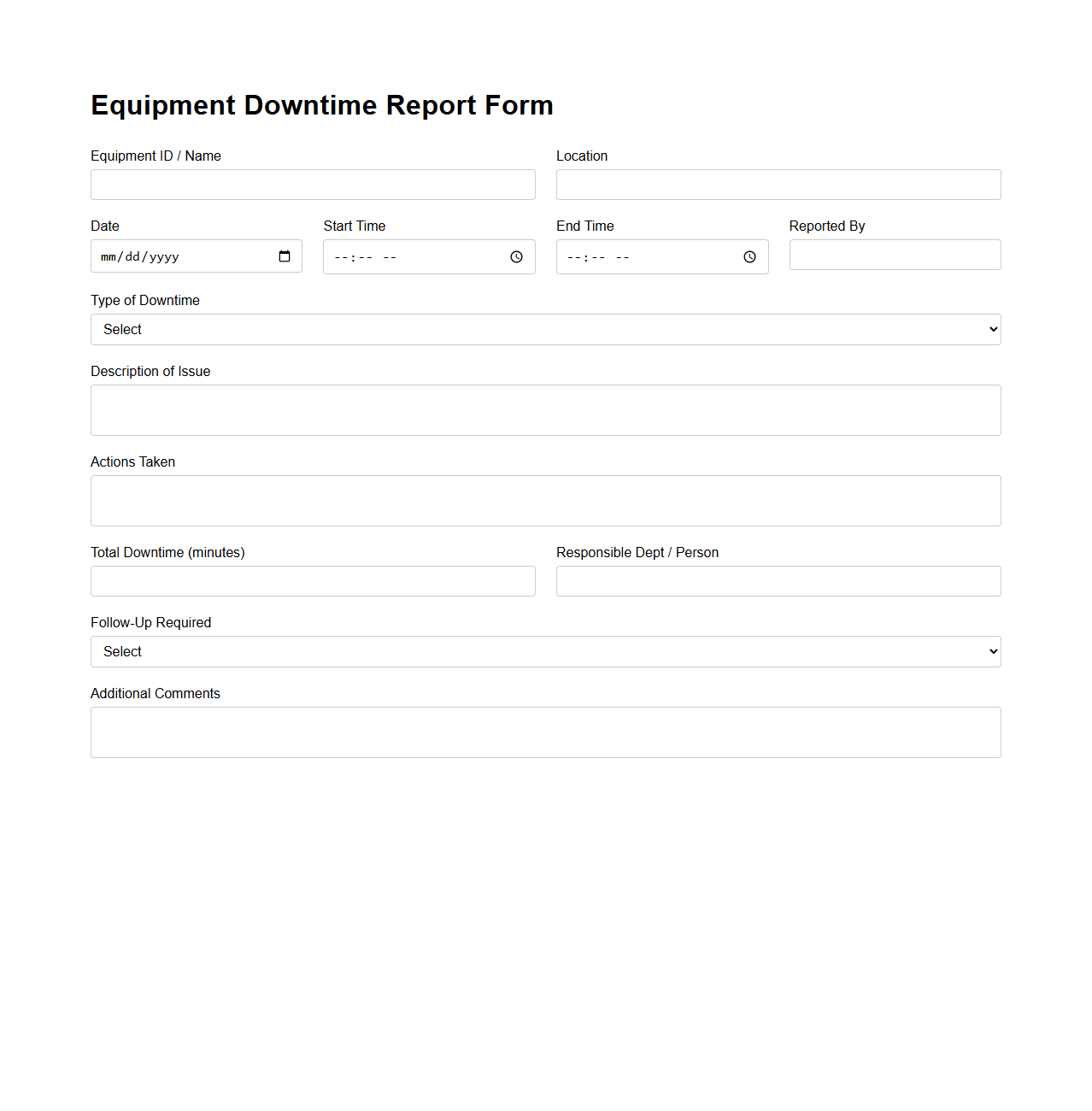

Equipment Downtime Report Form for Manufacturing Facilities

The

Equipment Downtime Report Form for manufacturing facilities is a critical document used to systematically record instances when machinery or equipment is not operational. It captures essential data such as the downtime duration, cause of failure, and the impact on production schedules, enabling effective analysis and resolution. This report supports maintenance teams in identifying recurring issues and optimizing equipment reliability to minimize production losses.

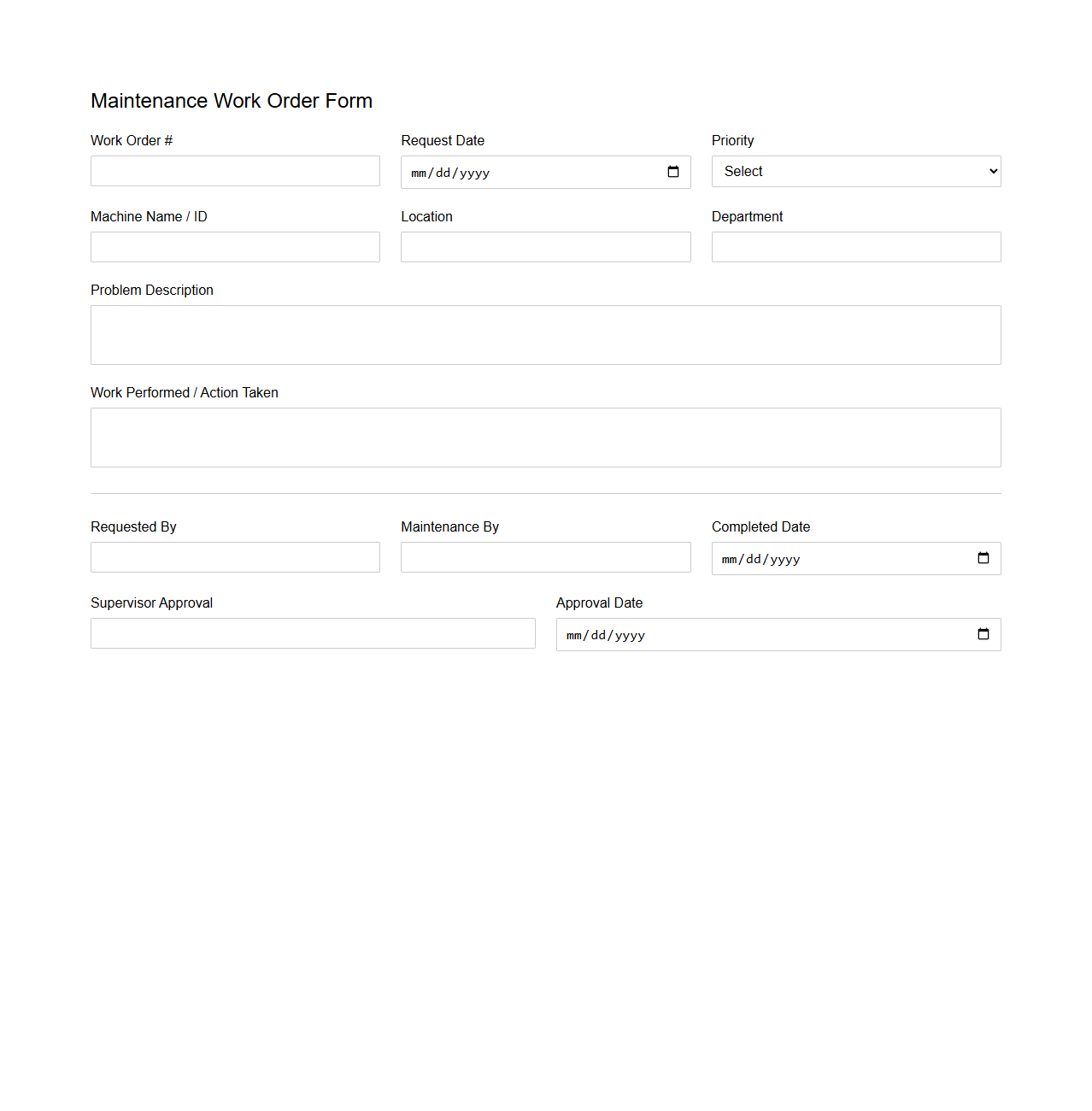

Maintenance Work Order Form for Industrial Machines

A

Maintenance Work Order Form for industrial machines is a detailed document used to request, track, and record maintenance activities on machinery within a facility. It includes essential information such as machine identification, type of maintenance required, description of the issue, assigned technicians, and timelines for completion. This form ensures systematic management of repairs and preventive maintenance, minimizing downtime and enhancing equipment reliability.

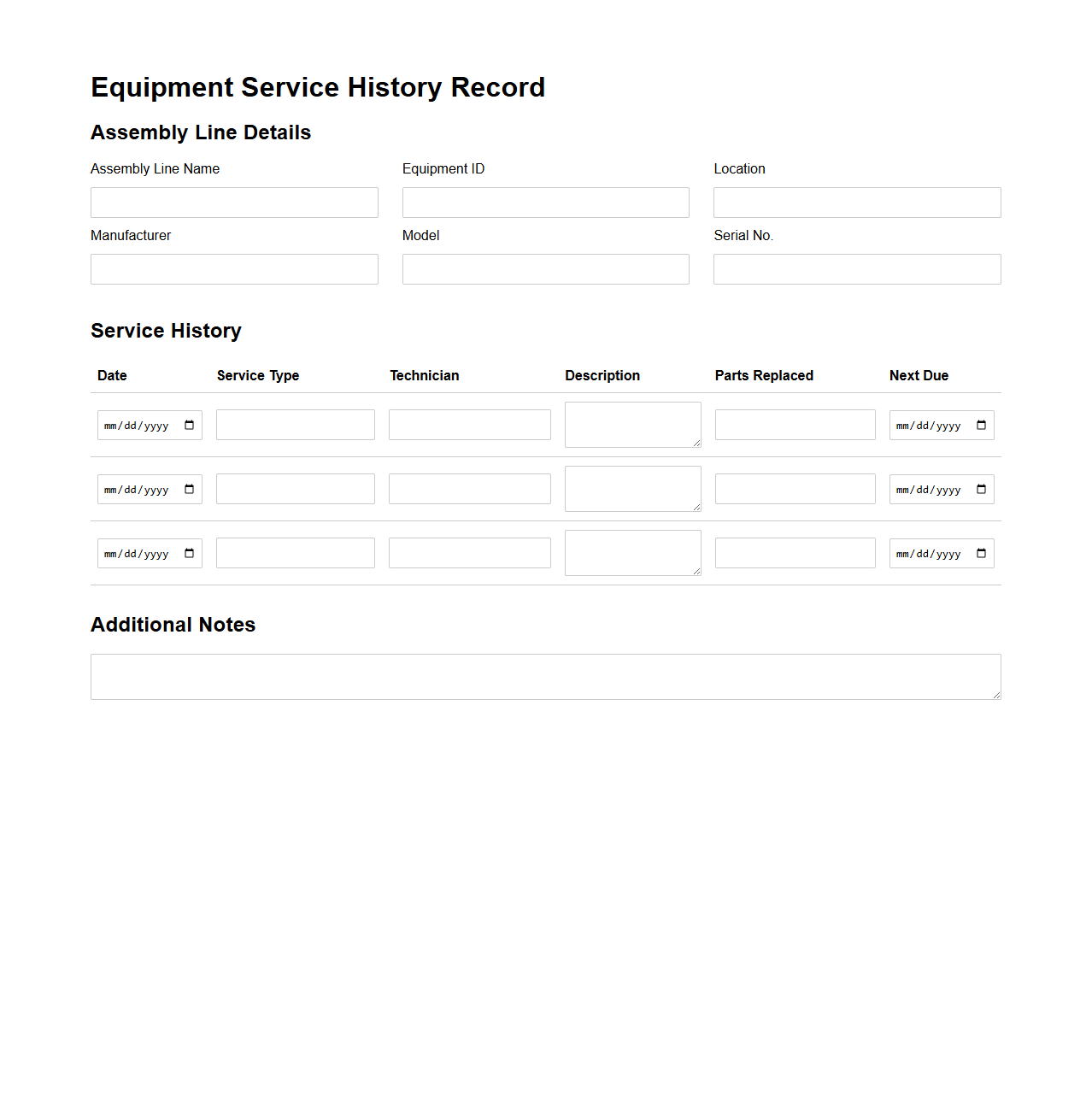

Equipment Service History Record for Assembly Lines

The

Equipment Service History Record for Assembly Lines document systematically logs all maintenance, repairs, and inspections performed on machinery to ensure optimal performance and minimize downtime. It provides a detailed timeline of service activities, helping technicians identify recurring issues and plan preventive maintenance effectively. This record is crucial for maintaining equipment reliability, compliance with safety standards, and extending the lifespan of assembly line machinery.

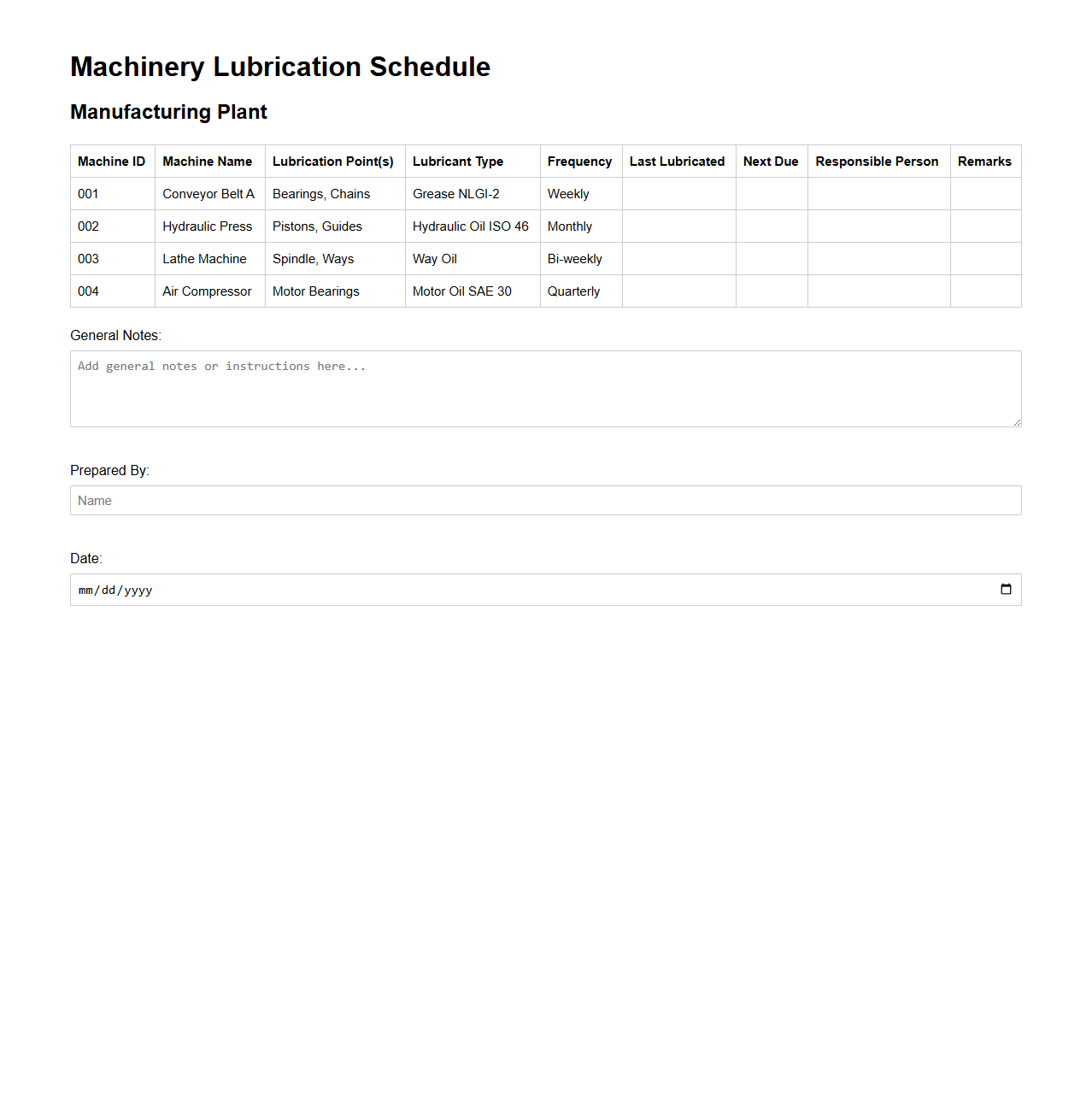

Machinery Lubrication Schedule for Manufacturing Plants

A

Machinery Lubrication Schedule for manufacturing plants is a detailed document that outlines the specific lubrication requirements, intervals, and types of lubricants for various machines and equipment to ensure optimal performance and longevity. It includes critical data such as machine operating conditions, lubrication points, and maintenance frequencies to prevent wear, reduce downtime, and increase efficiency. Proper adherence to this schedule helps in minimizing equipment failures and extends the lifecycle of manufacturing assets.

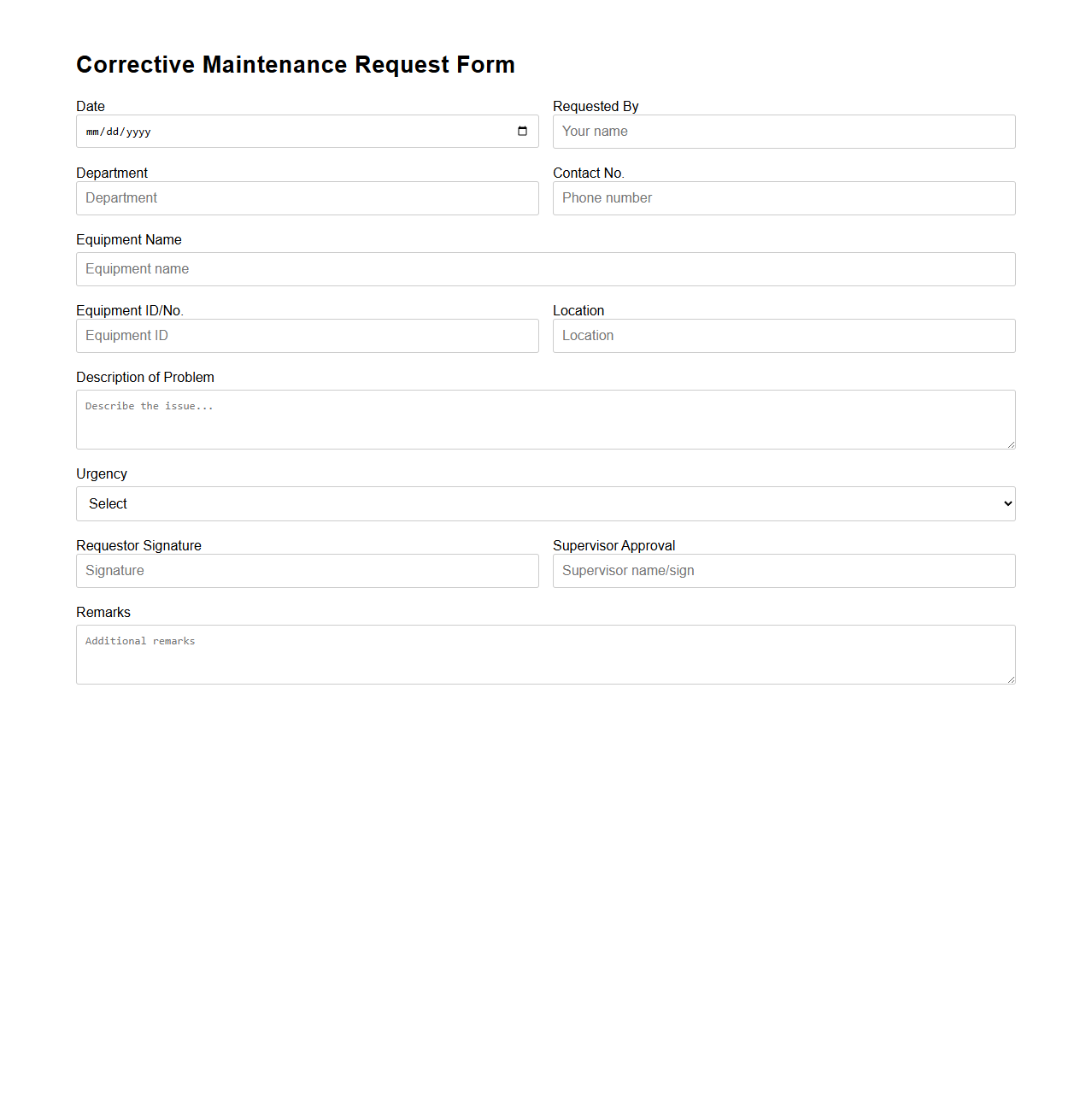

Corrective Maintenance Request Form for Factory Equipment

A

Corrective Maintenance Request Form for factory equipment is a standardized document used to report and initiate repairs for machinery malfunctions or breakdowns. It captures essential details such as equipment identification, issue description, urgency level, and requester information to ensure timely and accurate maintenance response. This form helps streamline communication between operators and maintenance teams, minimizing downtime and optimizing factory operations.

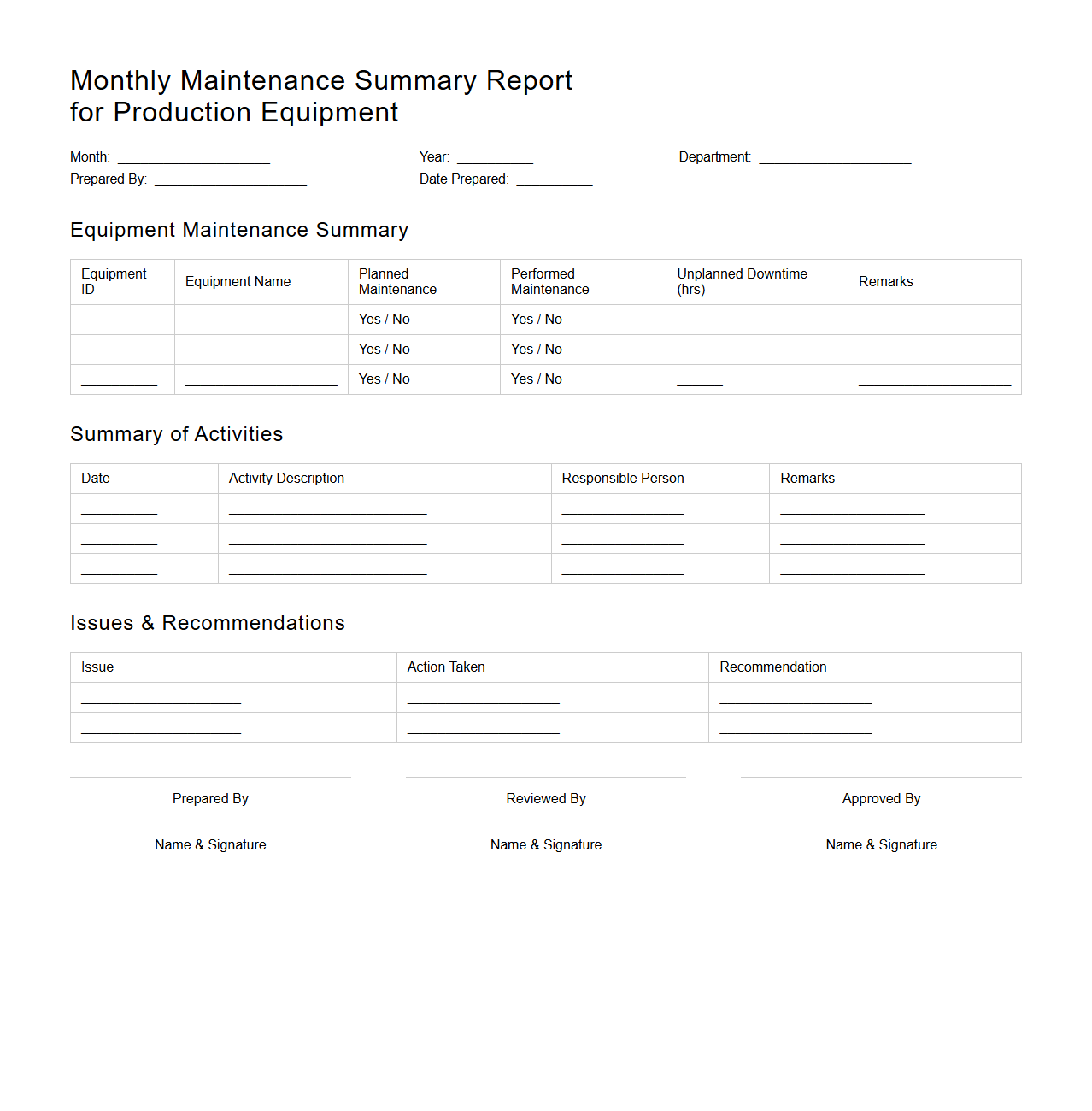

Monthly Maintenance Summary Report for Production Equipment

The

Monthly Maintenance Summary Report for Production Equipment document consolidates detailed records of maintenance activities, including inspections, repairs, and preventive measures performed over the month. It tracks equipment downtime, maintenance costs, and identifies recurring issues to optimize operational efficiency. This report serves as a critical tool for evaluating equipment reliability and planning future maintenance strategies.

Key Sections in Standard Equipment Maintenance Document

A standard equipment maintenance document should include sections such as equipment identification, maintenance schedules, and detailed task instructions. It must also have sections for maintenance records and safety guidelines to ensure comprehensive coverage. These components ensure clarity and consistency in maintaining manufacturing equipment.

Specifying Procedures for Preventive and Corrective Maintenance

The document clearly differentiates between preventive maintenance routines and corrective actions for unexpected issues. Preventive procedures include scheduled inspections and servicing, while corrective procedures outline steps for troubleshooting and repairs. This dual approach helps extend equipment life and minimize downtime.

Methods for Tracking Maintenance History and Equipment Performance

Tracking methods include detailed logs, electronic maintenance management systems, and performance metrics analysis. The document emphasizes the use of maintenance history records to monitor equipment reliability and identify recurring issues. Such tracking enhances decision-making for future maintenance planning.

Roles and Responsibilities for Maintenance Personnel

The document clearly defines roles, assigning specific responsibilities for technicians, supervisors, and engineers. It ensures accountability by outlining who performs, approves, and reviews maintenance tasks. This clarity improves coordination and effectiveness within the maintenance team.

Safety and Compliance Protocols in Maintenance Document

Safety protocols include lockout/tagout procedures, hazard identification, and use of personal protective equipment (PPE). The document also aligns maintenance activities with industry regulatory compliance standards to prevent accidents. Emphasizing safety ensures both personnel protection and legal adherence.

More Manufacturing Templates