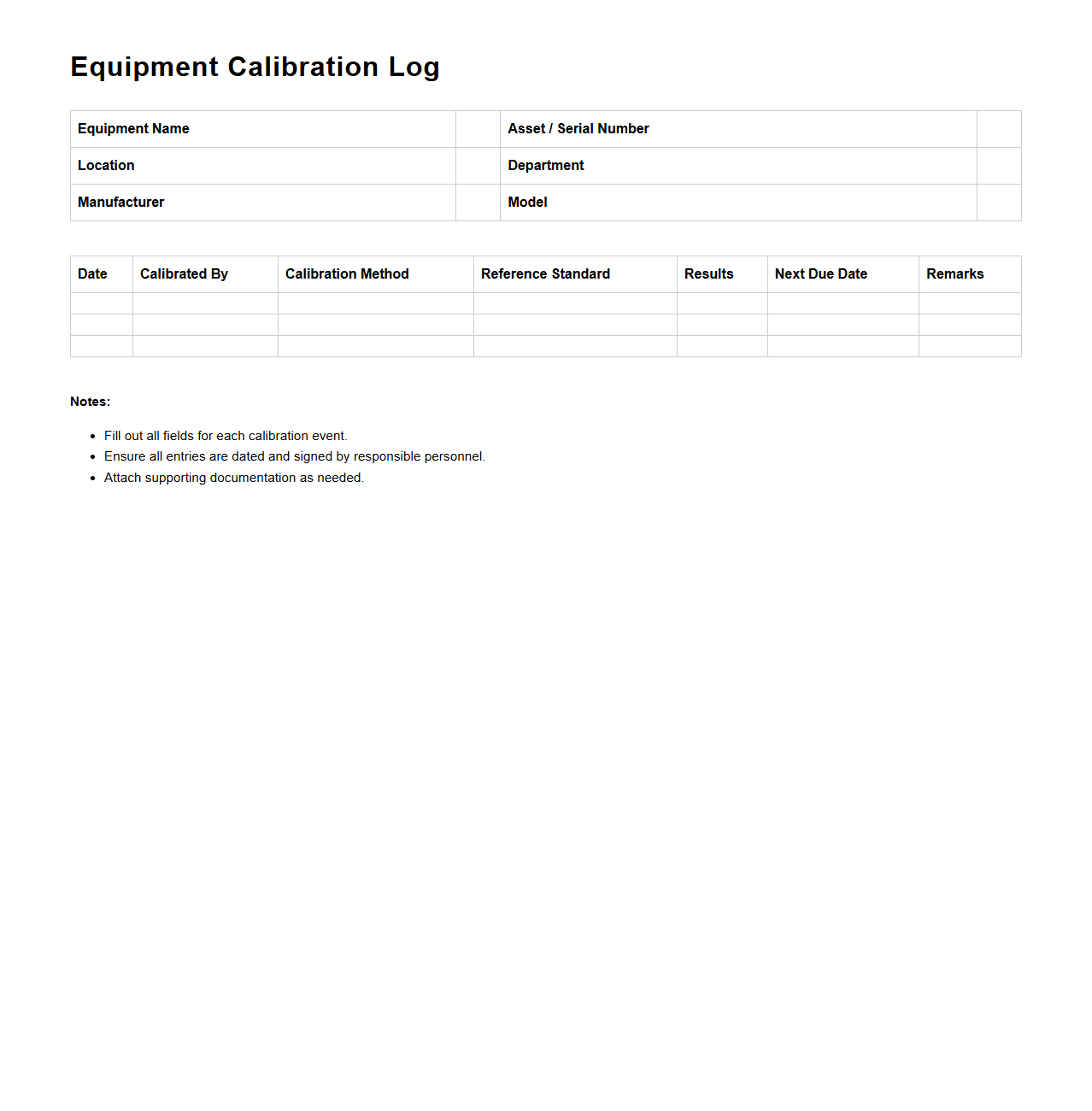

Equipment Calibration Log Template for Manufacturing

An

Equipment Calibration Log Template for manufacturing is a structured document used to systematically record calibration activities of manufacturing machinery and tools, ensuring accuracy and compliance with industry standards. It tracks essential details such as equipment ID, calibration date, technician's name, calibration results, and next scheduled calibration, which helps maintain operational efficiency and product quality. This template supports regulatory audits and continuous improvement by providing a clear historical record of equipment performance and maintenance.

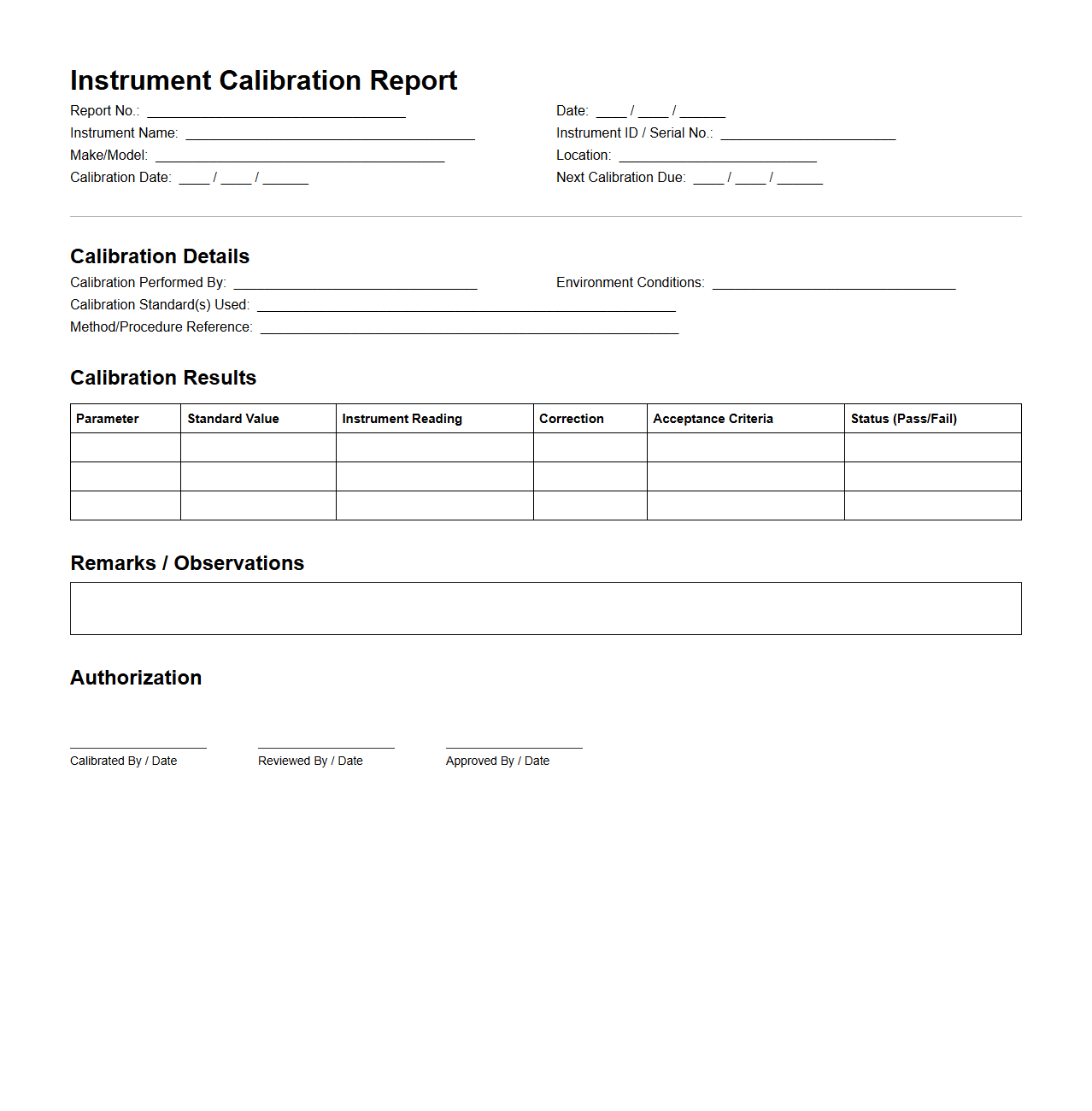

Instrument Calibration Report Format for Quality Assurance

An

Instrument Calibration Report Format for Quality Assurance documents the detailed process and results of calibrating measurement instruments, ensuring accuracy and compliance with industry standards. This format includes sections for instrument identification, calibration procedure, measurement data, deviation analysis, and certification by authorized personnel. Proper use of this report format supports consistent quality control, traceability, and regulatory adherence in manufacturing and laboratory environments.

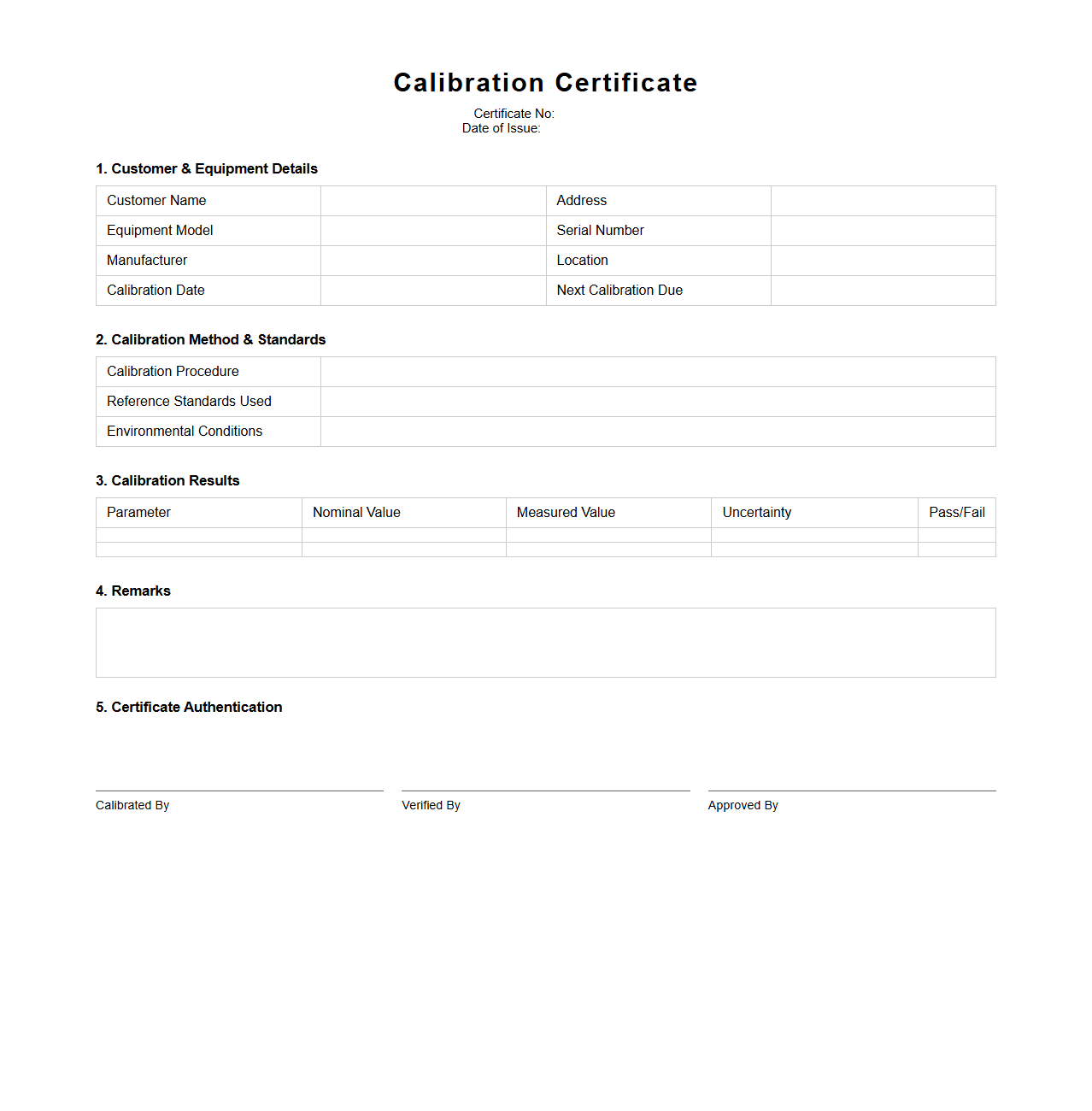

Calibration Certificate Template for Production Machinery

A

Calibration Certificate Template for Production Machinery document is a standardized form used to record the calibration results of industrial machines, ensuring accuracy and compliance with quality standards. It includes essential data such as machine identification, calibration date, measured values, acceptable tolerance limits, and the technician's signature. This template streamlines the documentation process, facilitates traceability, and supports maintenance schedules for optimal machinery performance.

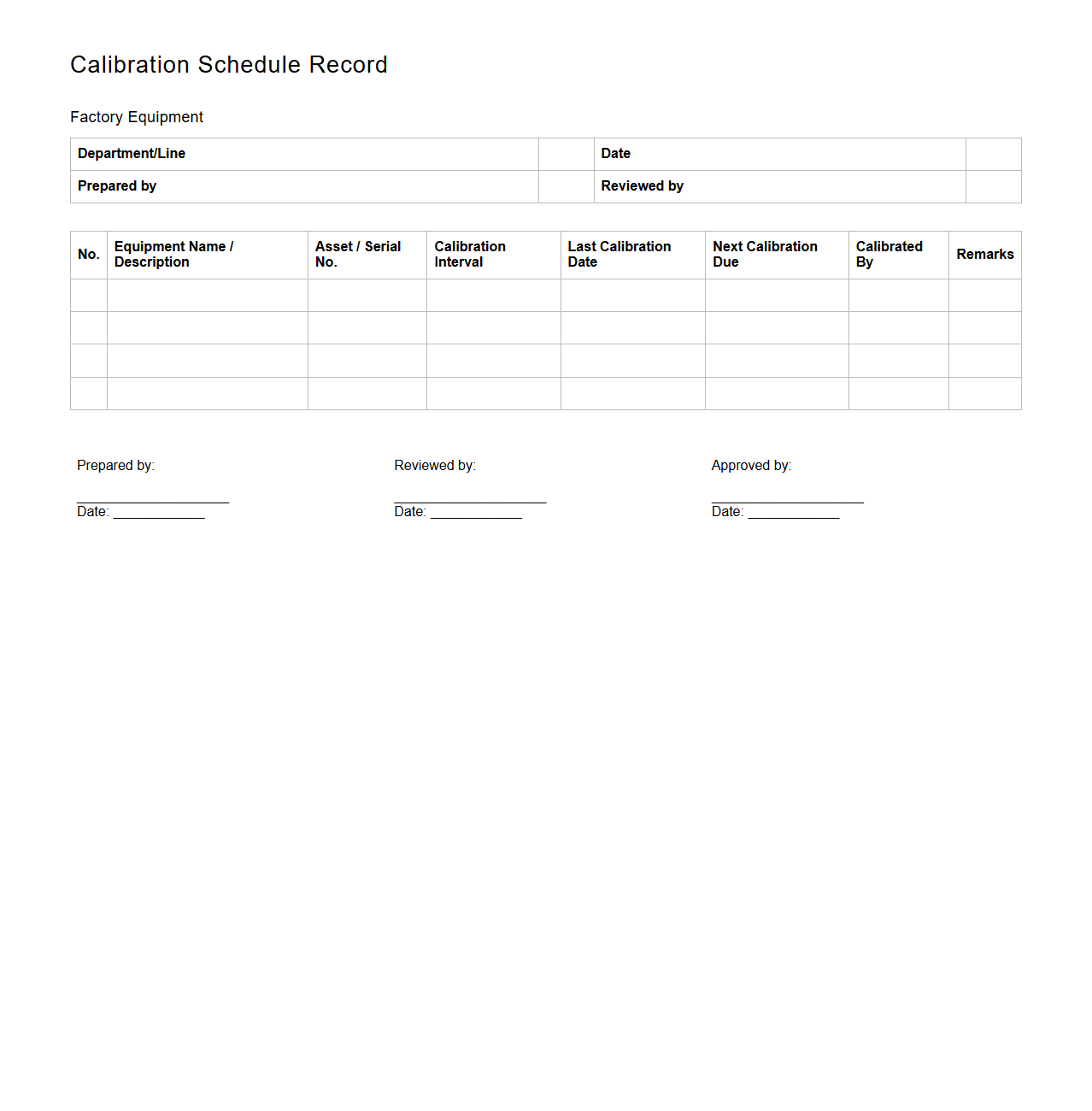

Calibration Schedule Record for Factory Equipment

A

Calibration Schedule Record for factory equipment is a documented plan that outlines the timing and details for regular calibration of machinery to ensure accurate and reliable performance. This record includes specific dates, equipment identifiers, calibration procedures, and responsible personnel, helping maintain compliance with industry standards and quality control requirements. Proper calibration scheduling prevents equipment malfunctions and supports operational efficiency in manufacturing processes.

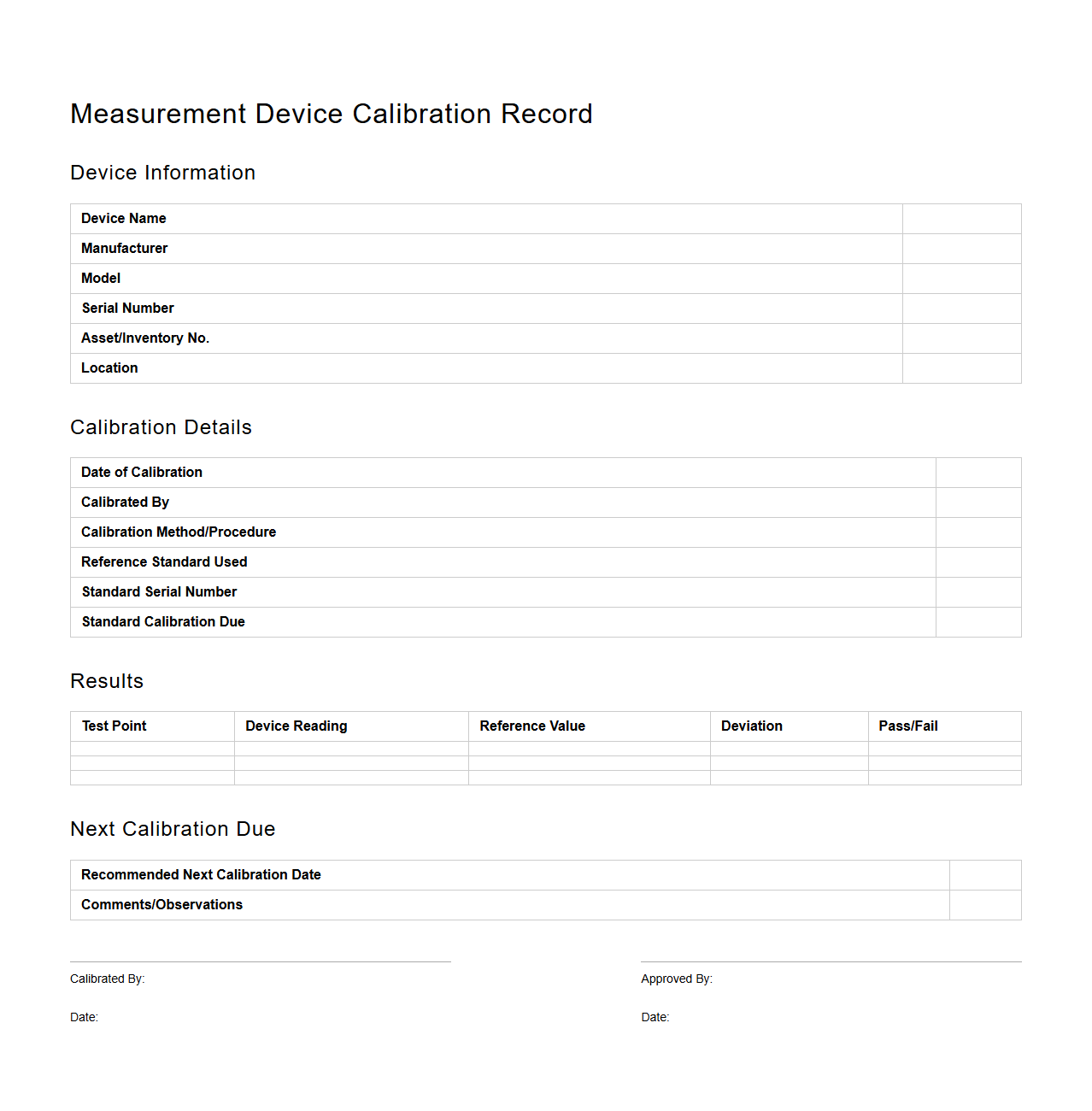

Measurement Device Calibration Documentation for ISO Compliance

Measurement Device Calibration Documentation for ISO Compliance is a critical record that verifies the accuracy and reliability of measuring instruments used in quality management systems. This document ensures all calibration processes align with ISO standards, maintaining traceability to national or international measurement standards. Maintaining

calibration documentation supports regulatory audits, minimizes measurement errors, and guarantees consistent product quality.

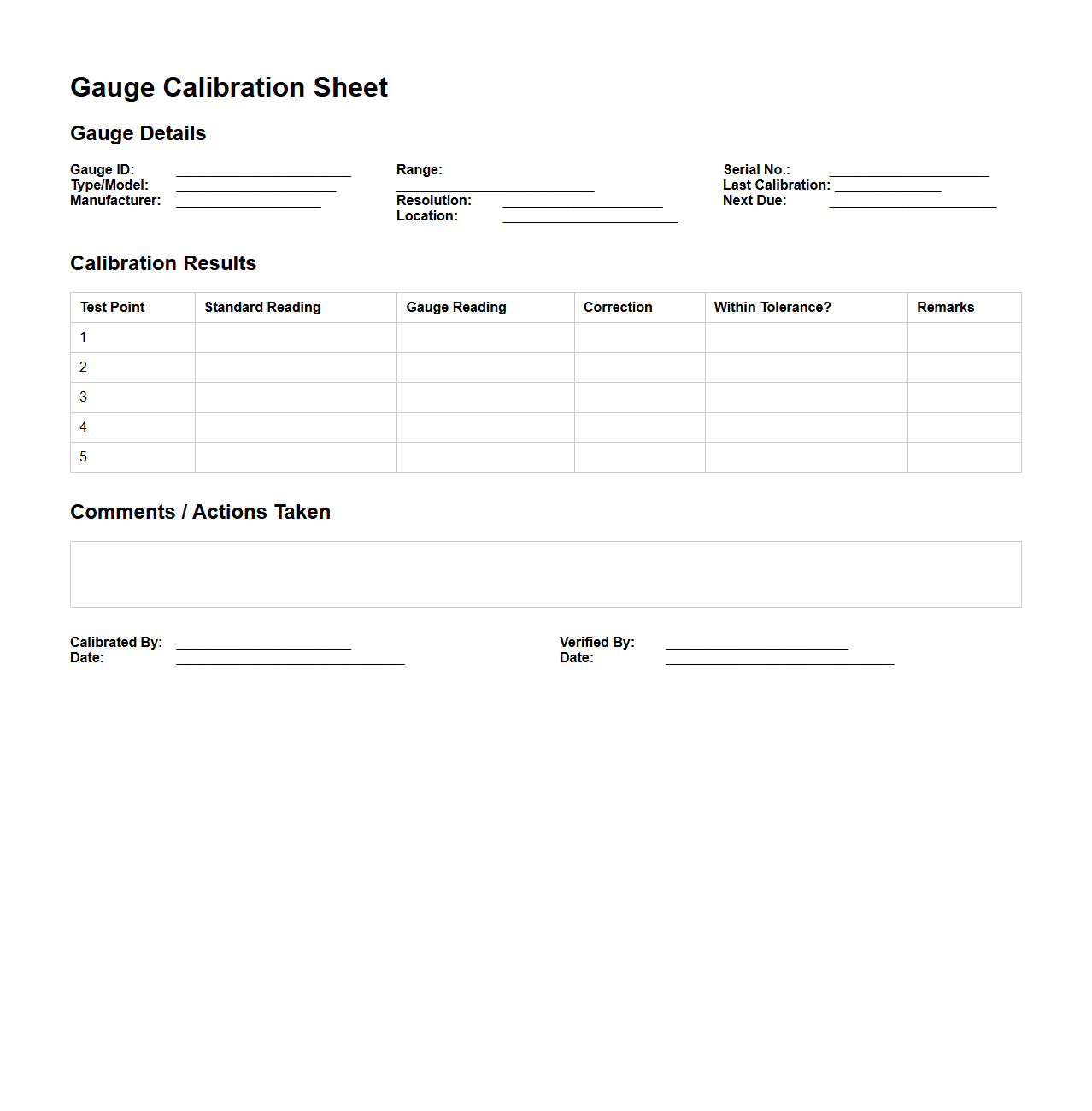

Gauge Calibration Sheet Example for Industrial Applications

A Gauge Calibration Sheet Example for Industrial Applications document serves as a detailed record used to verify the accuracy and precision of measurement instruments in manufacturing environments. It includes critical data such as identification numbers, calibration dates, measurement standards, and tolerance limits to ensure compliance with industry quality control standards. Maintaining an accurate

gauge calibration sheet is essential for minimizing measurement errors and ensuring product consistency in industrial processes.

Calibration Verification Record for Process Instruments

The

Calibration Verification Record for Process Instruments document serves as a formal record that ensures all process instruments are inspected and verified for accuracy against established standards. It includes detailed information such as instrument identification, calibration date, technician credentials, and measurement results to maintain traceability and compliance. This document is essential for quality control, regulatory audits, and maintaining the reliability of process instrumentation in industrial environments.

Temperature Sensor Calibration Record Form

The

Temperature Sensor Calibration Record Form documents the precise calibration data of temperature sensors, ensuring their accuracy and reliability in measurements. It includes details such as sensor identification, calibration date, reference standards used, and recorded measurement deviations. This form is essential for maintaining quality control and compliance with industry calibration standards.

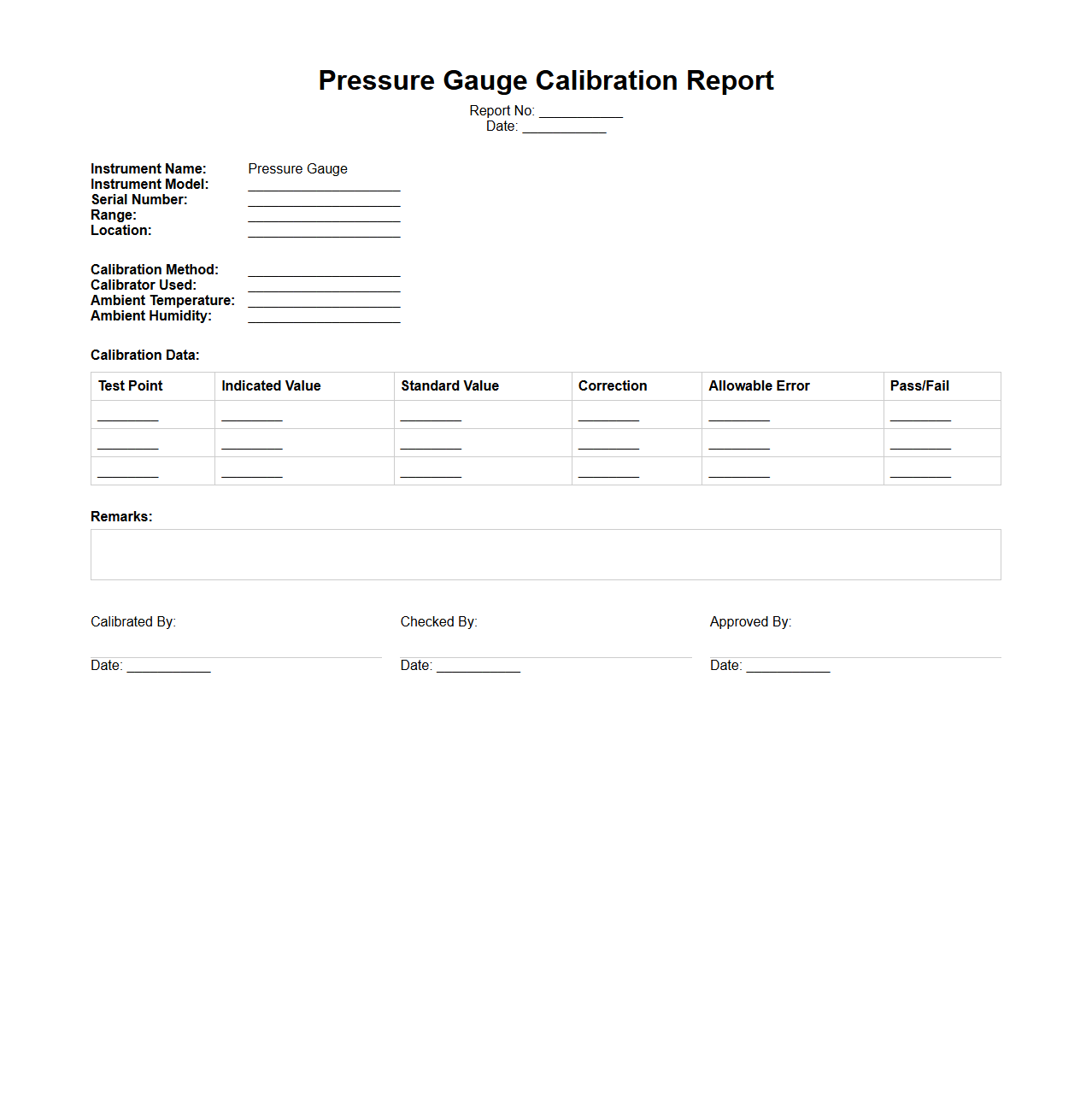

Pressure Gauge Calibration Report Example

A

Pressure Gauge Calibration Report Example document provides a detailed record of the calibration process for pressure gauges, including measured values, reference standards, environmental conditions, and results. This report ensures the accuracy and reliability of the pressure measurement instruments by comparing readings against certified standards. It serves as essential documentation for quality control, compliance with industry regulations, and maintenance of measurement traceability.

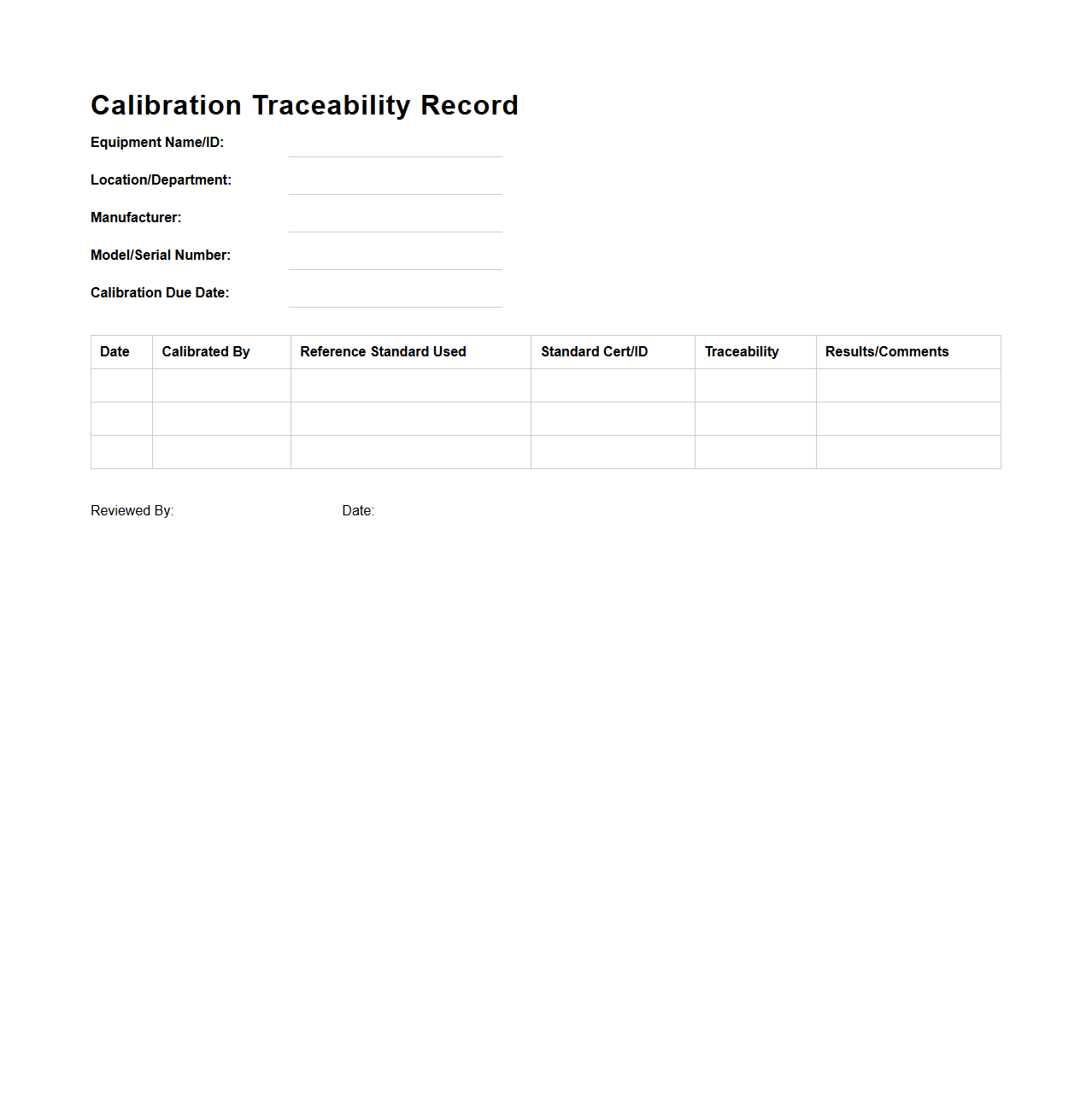

Calibration Traceability Record for Manufacturing Operations

A

Calibration Traceability Record for Manufacturing Operations document ensures that all measurement instruments used in production are calibrated against recognized standards, maintaining accuracy and consistency across processes. It provides a comprehensive history of calibration activities, including dates, results, and responsible personnel, supporting quality control and compliance with industry regulations. This document is critical for verifying that equipment performance meets specified tolerances, reducing defects and enhancing product reliability.

What is the primary purpose of a Calibration Record Document in manufacturing processes?

The primary purpose of a Calibration Record Document is to provide a detailed log of the calibration status of measurement instruments used in manufacturing. It ensures that equipment maintains accuracy and reliability over time. This document helps maintain quality control and compliance with industry standards.

Which key parameters must be recorded on a Calibration Record Document for compliance?

A Calibration Record Document must include key parameters such as the instrument's identification number, the date of calibration, and the results of the calibration tests. It should also document the environmental conditions during calibration and the technician's name who performed the calibration. Recording these details ensures transparency and adherence to regulatory requirements.

How does the Calibration Record Document ensure traceability of measurement equipment?

The Calibration Record Document ensures traceability by providing a clear historical record linking each measuring instrument to its calibration data. This allows manufacturers to follow the calibration chain back to national or international standards. Traceability guarantees that measurements are consistent and verifiable across all production stages.

Who is typically authorized to complete and verify entries on a Calibration Record Document?

Entries on a Calibration Record Document are typically completed and verified by qualified calibration technicians or metrologists. Supervisors or quality control personnel may conduct reviews to ensure accuracy and completeness. This authorization process maintains the document's integrity and compliance with audit requirements.

What actions are required if a device fails calibration as documented in the Calibration Record?

If a device fails calibration, immediate steps must be taken to remove it from service to prevent inaccurate measurements. The device should be repaired or recalibrated before being returned to use. Additionally, any affected manufacturing processes must be reviewed for potential impact due to the faulty measurements.