The Operator Training Record Document Sample for Manufacturing serves as a vital tool to track employee skills and training progress efficiently. It ensures compliance with industry standards by documenting completed courses, hands-on experience, and certification dates. This structured record enhances workforce competency and supports continuous improvement within manufacturing operations.

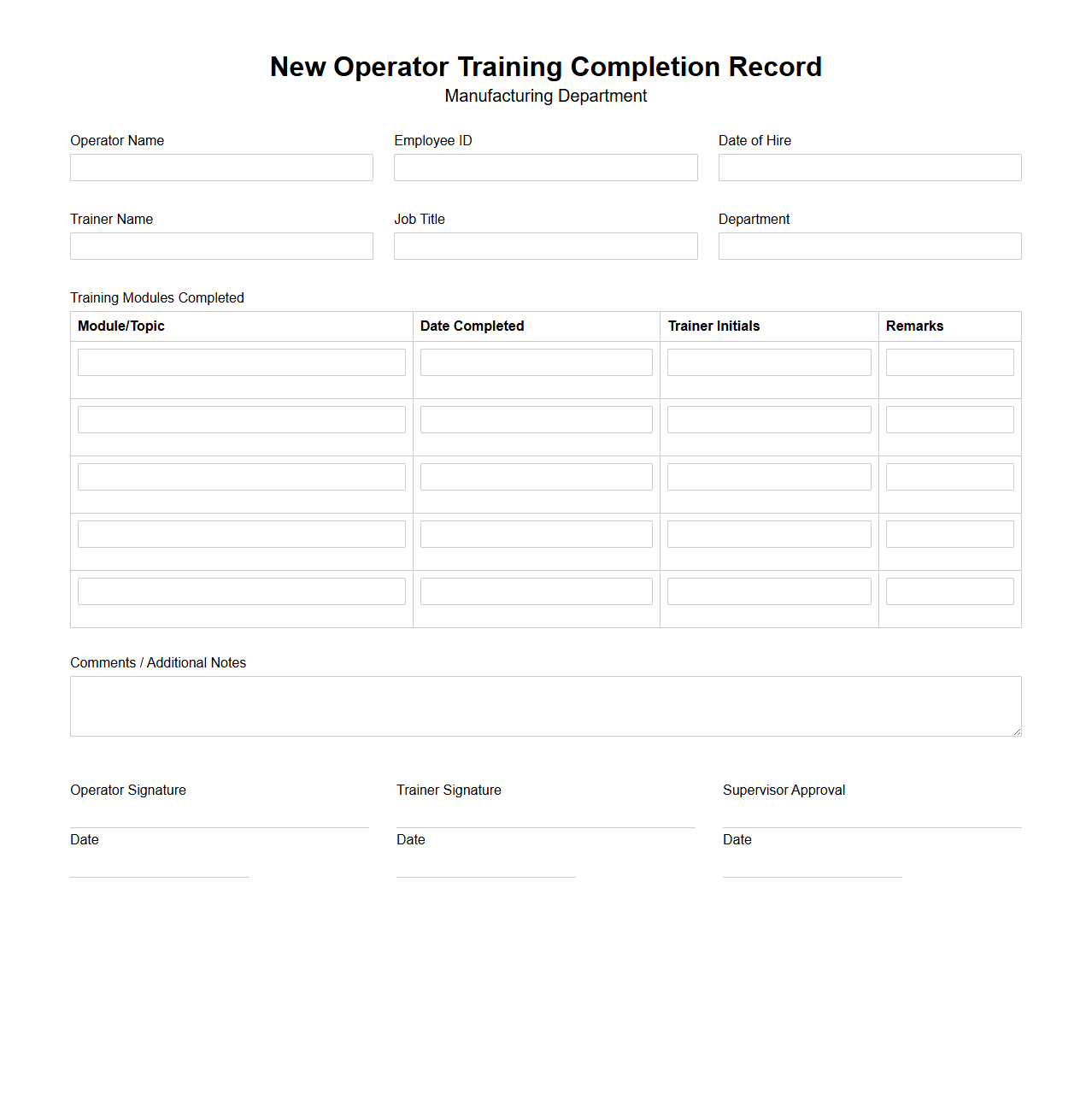

New Operator Training Completion Record for Manufacturing

The

New Operator Training Completion Record for manufacturing documents the successful completion of essential training modules by new employees, ensuring they meet safety, operational, and quality standards. This record serves as verified proof that operators have acquired the necessary skills and knowledge to perform their tasks effectively within the manufacturing environment. Maintaining this document helps companies comply with regulatory requirements and supports continuous workforce development and operational efficiency.

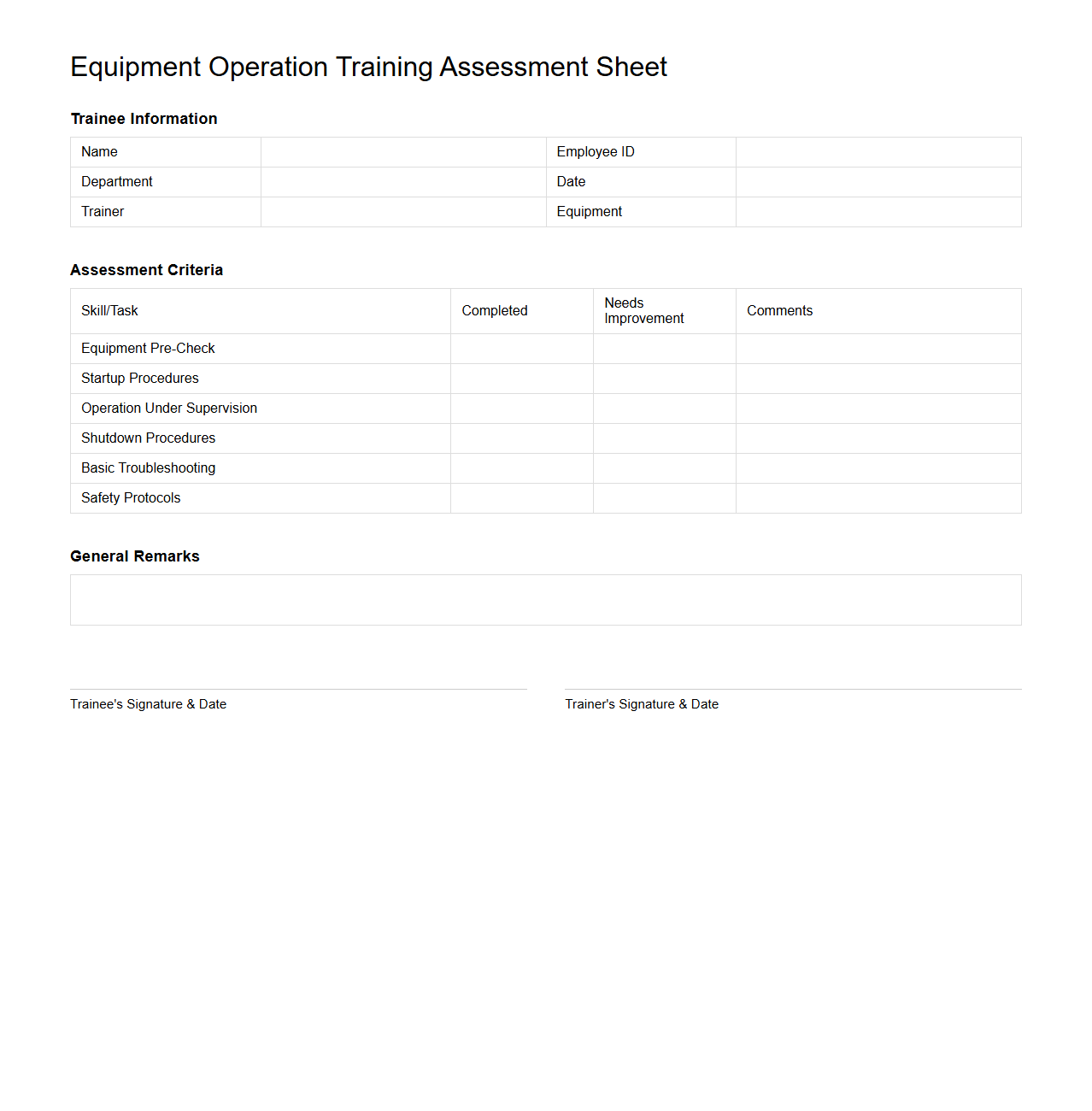

Equipment Operation Training Assessment Sheet

The

Equipment Operation Training Assessment Sheet document serves as a structured tool to evaluate an individual's competency in operating specific machinery or equipment. It records detailed performance metrics, safety adherence, and skill proficiency to ensure operators meet industry standards. This assessment sheet facilitates targeted training improvements and compliance with workplace safety regulations.

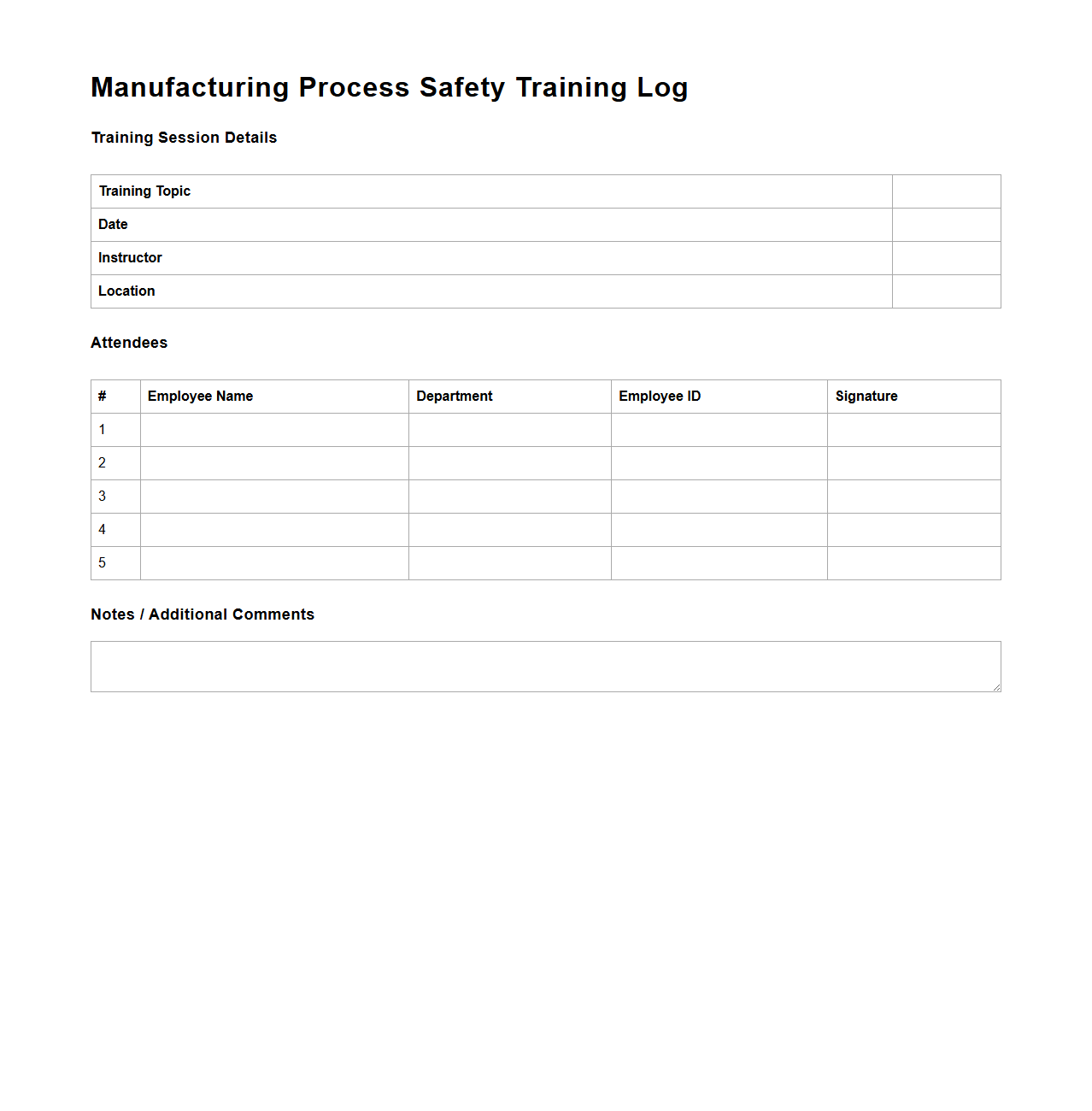

Manufacturing Process Safety Training Log

A

Manufacturing Process Safety Training Log document records all safety training sessions completed by employees involved in manufacturing processes, ensuring compliance with industry regulations. It includes dates, training topics, participant names, and instructor details to track skill development and hazard awareness. Maintaining this log helps organizations minimize workplace accidents and supports audits by demonstrating a commitment to safety protocols.

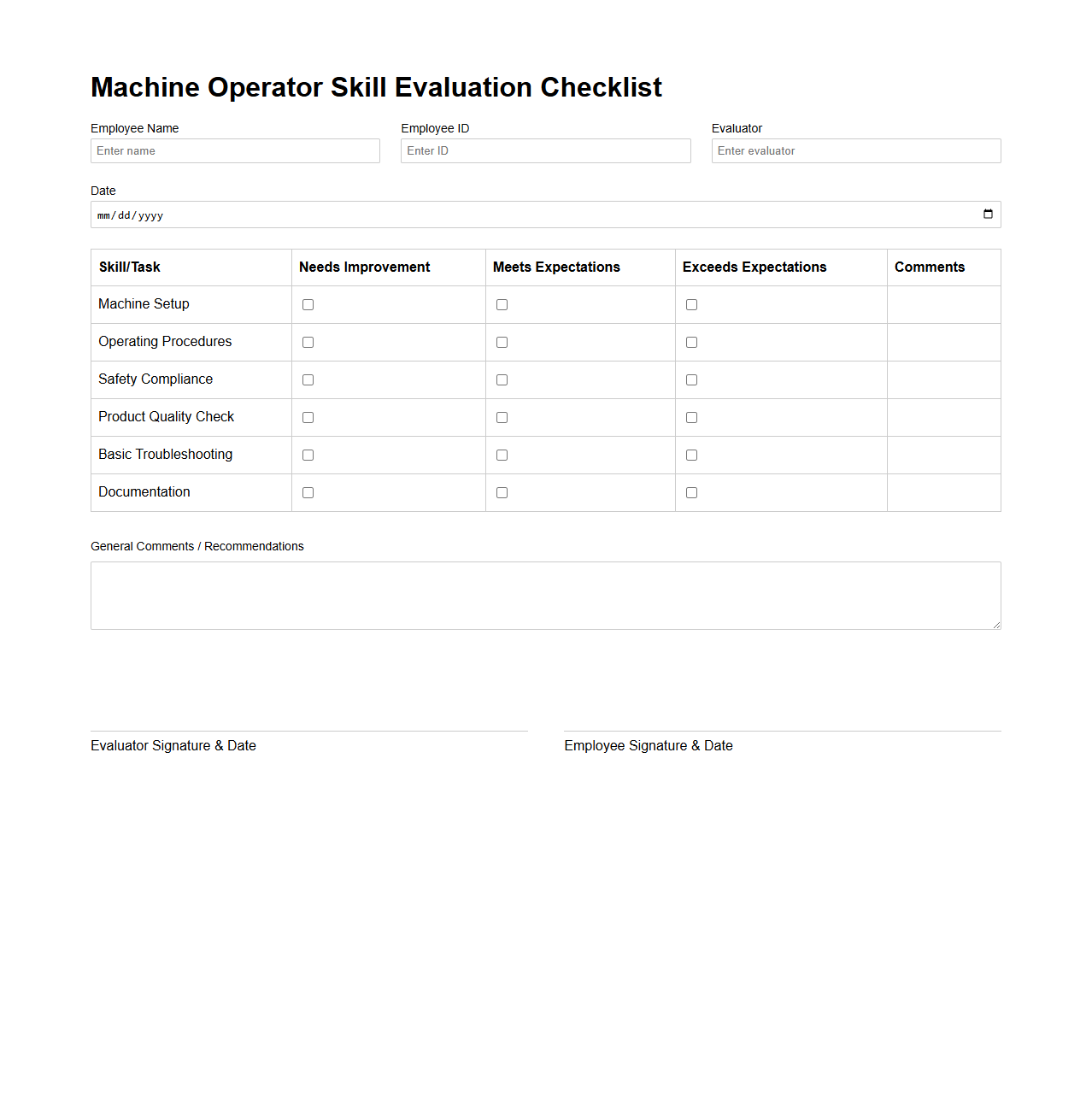

Machine Operator Skill Evaluation Checklist

A

Machine Operator Skill Evaluation Checklist document systematically assesses an operator's proficiency in handling, maintaining, and troubleshooting machinery, ensuring compliance with safety and operational standards. The checklist typically includes criteria such as equipment knowledge, operational techniques, safety practices, and problem-solving abilities. This tool helps identify skill gaps, guide training programs, and enhance overall machine efficiency and workplace safety.

Production Line Standard Operating Procedure Training Form

The

Production Line Standard Operating Procedure Training Form document ensures consistent training and adherence to established manufacturing processes by detailing step-by-step instructions and performance criteria. It serves as a formal record verifying that employees have reviewed and understood the specific operational standards required on the production line. This document enhances quality control, reduces errors, and supports compliance with industry regulations.

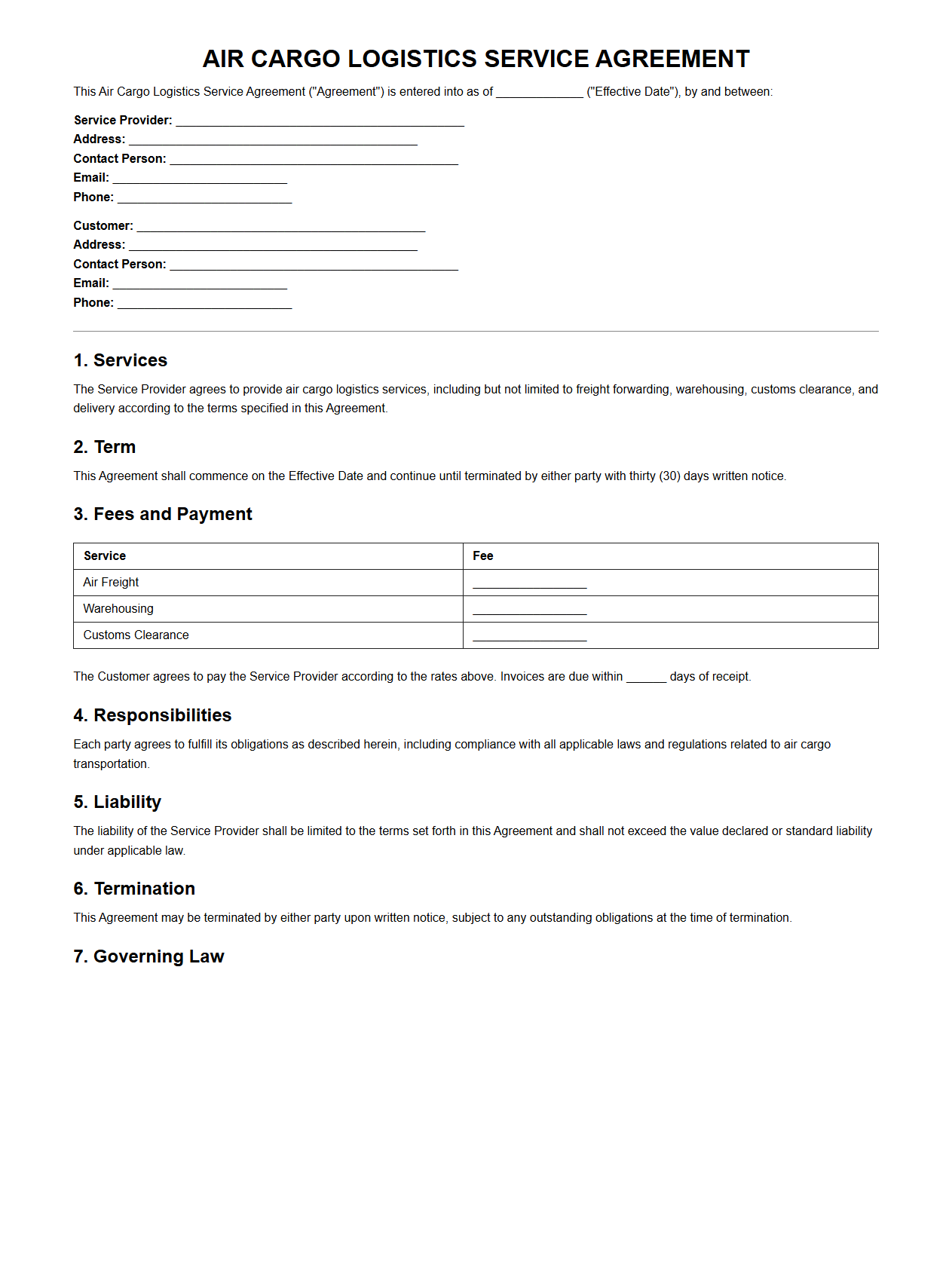

Annual Operator Refresher Training Record

The

Annual Operator Refresher Training Record document serves as a vital tool for tracking employee participation in required safety and operational training sessions conducted yearly. It ensures compliance with industry standards and regulatory requirements by documenting the completion dates, training topics, and assessment results of each operator. Maintaining accurate records helps organizations enhance workplace safety, improve operational efficiency, and reduce liability risks.

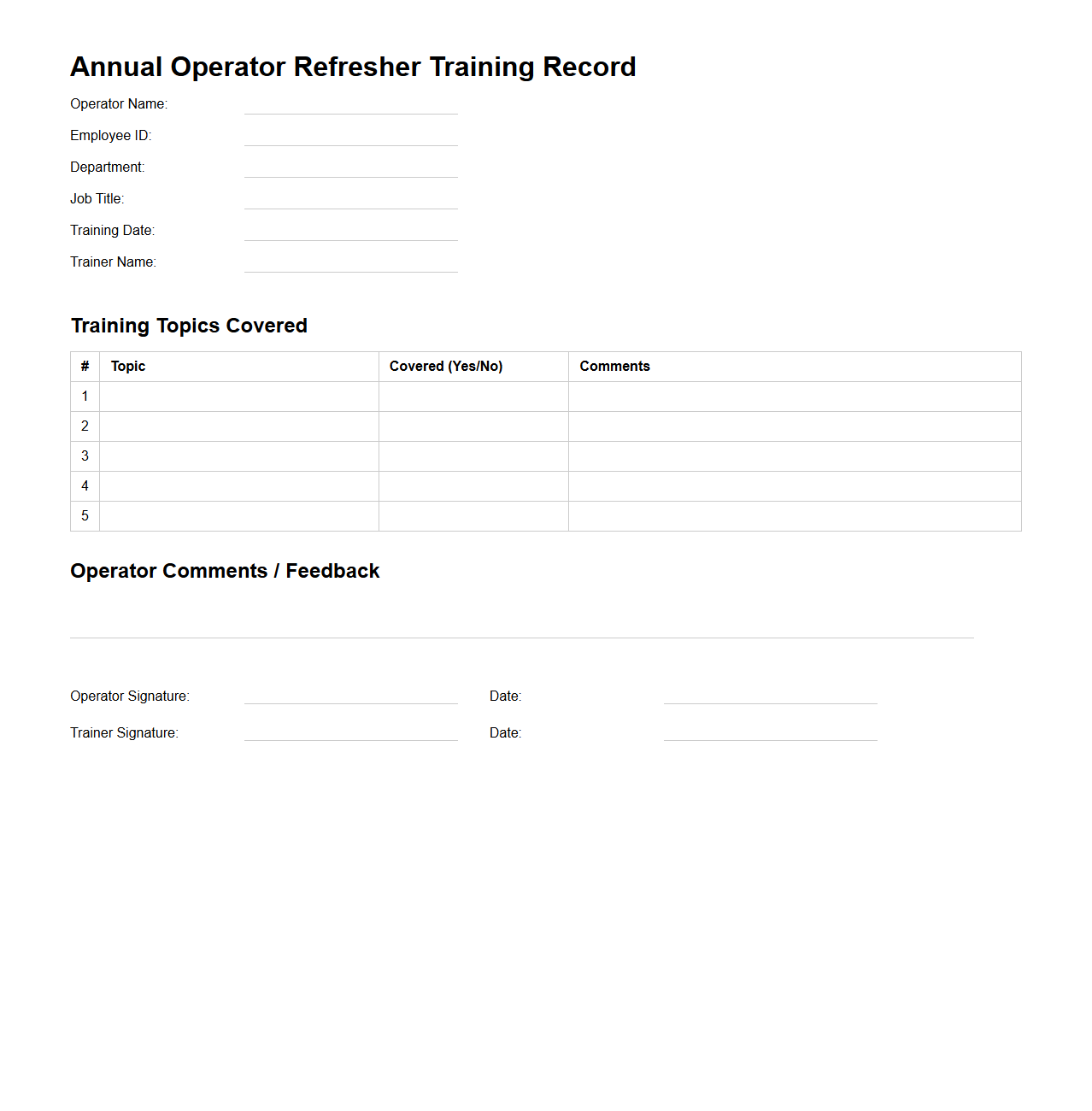

GMP Compliance Training Attendance Sheet

The

GMP Compliance Training Attendance Sheet document serves as an essential record ensuring that all personnel participating in Good Manufacturing Practice (GMP) training sessions are accurately tracked. This sheet typically includes details such as attendee names, signatures, training dates, and the specific topics covered, enabling companies to demonstrate adherence to regulatory requirements. Maintaining this documentation supports quality assurance processes and helps organizations meet regulatory audits and compliance standards in pharmaceutical and manufacturing industries.

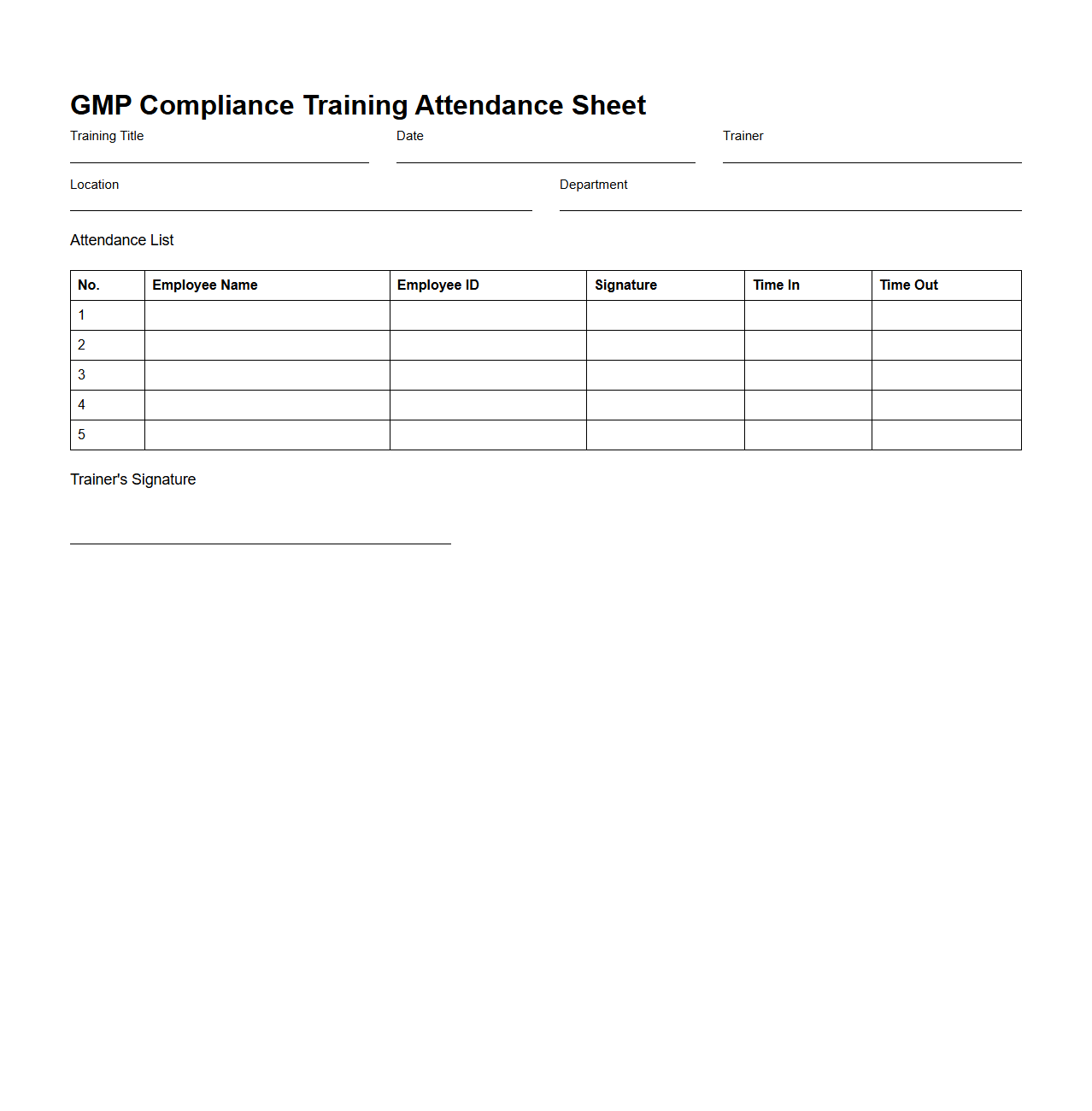

Forklift Operation Certification Record for Plant Operators

The

Forklift Operation Certification Record for Plant Operators is an essential document that verifies an operator's training and competency in safely handling forklift machinery within industrial settings. It details certification dates, types of forklifts operated, and compliance with safety standards to ensure workplace safety and regulatory adherence. Maintaining this record helps plants monitor operator qualifications and reduce the risk of accidents caused by untrained personnel.

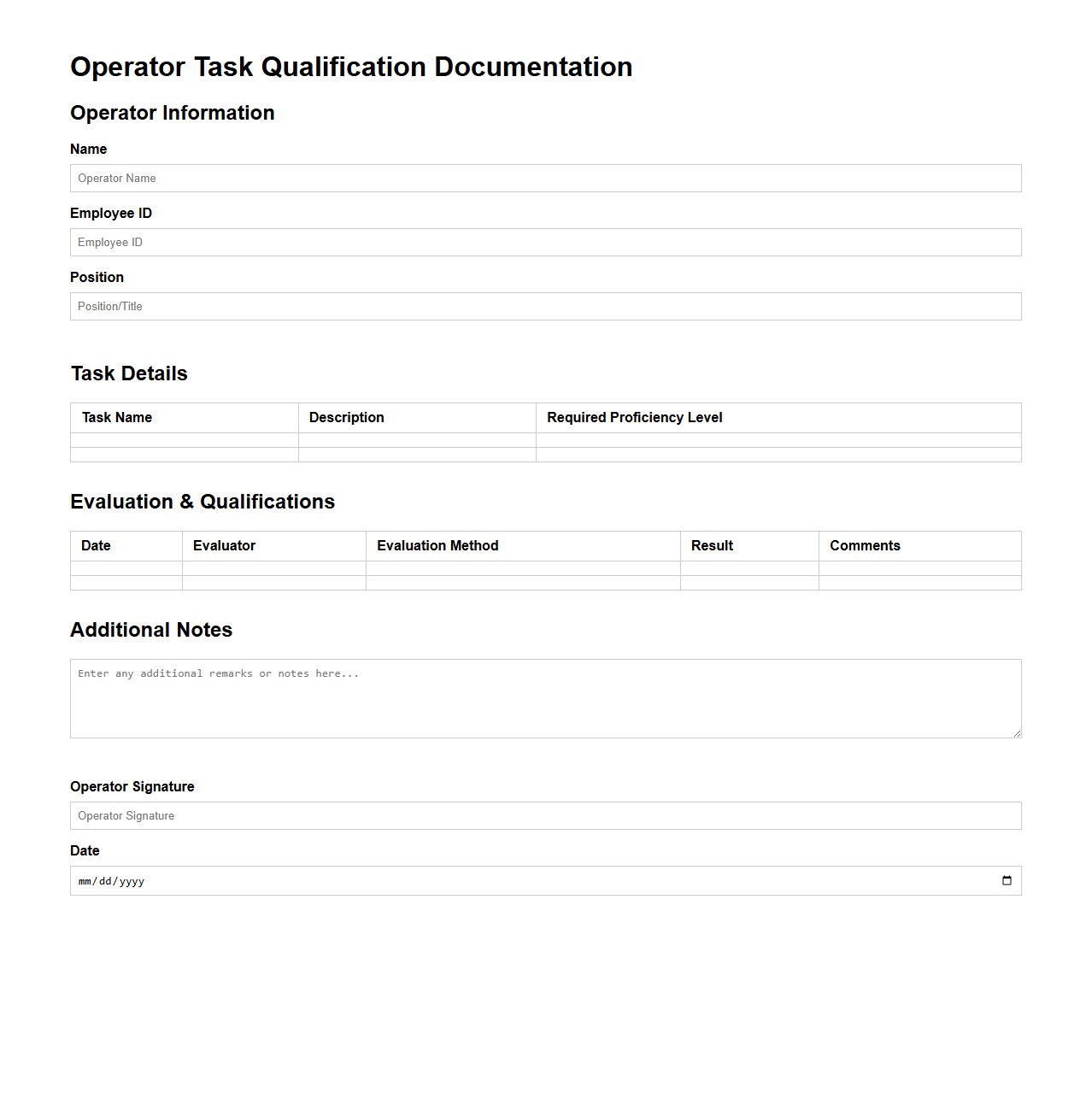

Operator Task Qualification Documentation

Operator Task Qualification Documentation is a critical record that verifies an operator's competence in performing specific tasks within industrial or technical environments. This document outlines the requirements, training, and assessment criteria necessary to ensure operators meet safety, quality, and operational standards. Maintaining accurate

Operator Task Qualification Documentation supports regulatory compliance and enhances workforce reliability.

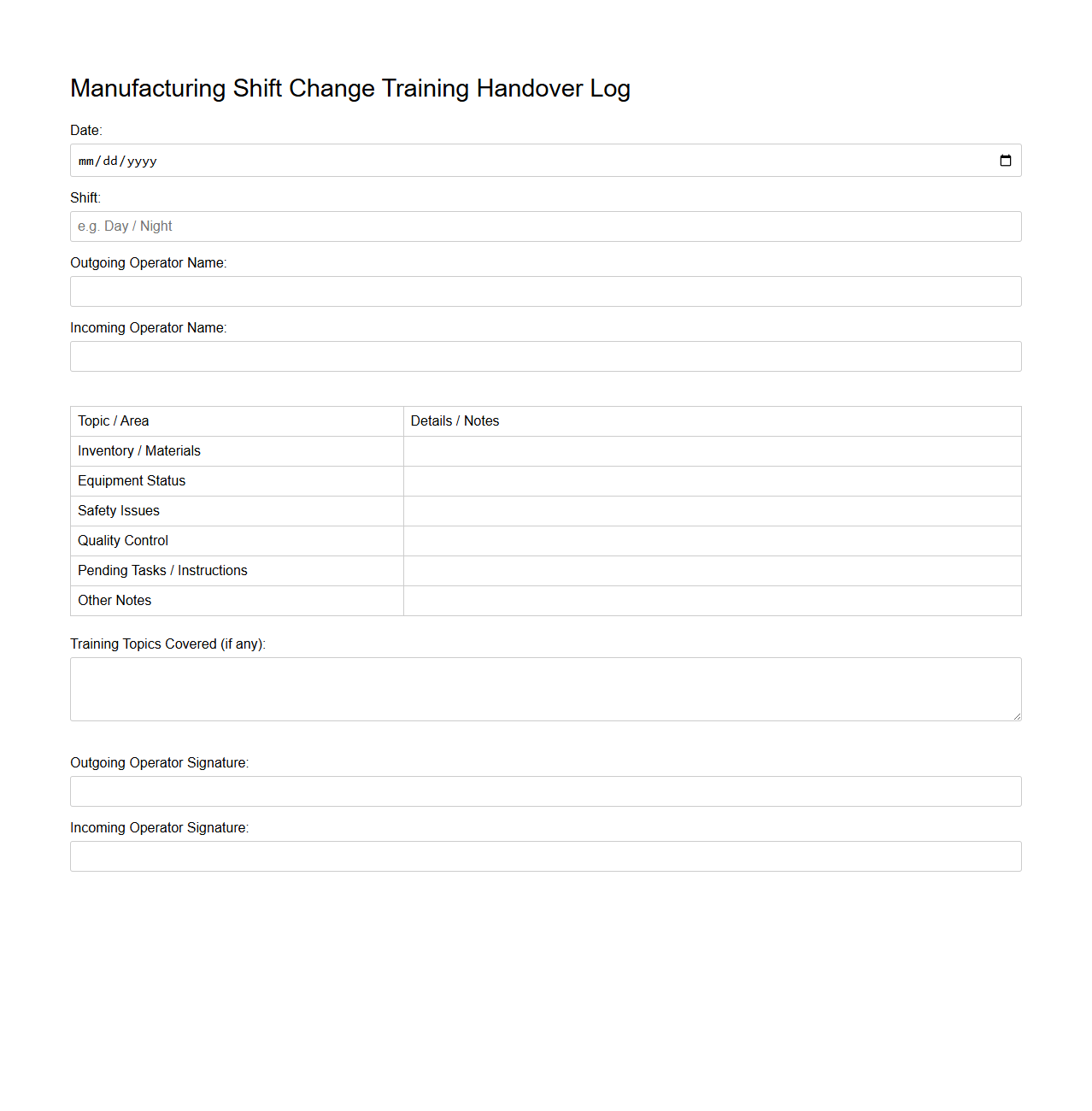

Manufacturing Shift Change Training Handover Log

The

Manufacturing Shift Change Training Handover Log document is a critical tool used to ensure seamless communication between outgoing and incoming shifts in a manufacturing environment. It records essential information such as ongoing tasks, equipment status, safety concerns, and training updates, helping to minimize errors and maintain operational continuity. This log supports workforce training by documenting knowledge transfer and shift-specific instructions, promoting productivity and safety compliance.

What specific skills or processes are validated in the Operator Training Record Document for manufacturing staff?

The Operator Training Record Document validates critical manufacturing skills such as equipment operation, safety procedures, and quality control techniques. It ensures staff are proficient in both standard operating procedures and specialized equipment handling. This validation process confirms that operators have received comprehensive instructions applicable to their roles.

How does the document ensure traceability of operator competency and training dates?

The document includes detailed entries of training dates and competency assessments, creating an auditable trail for each operator. Each training event is logged with specifics about the course content and the operator's performance. This traceability supports compliance audits and continuous workforce development.

Which regulatory or quality standards does the Operator Training Record Document reference or adhere to?

The document aligns with key regulatory standards such as ISO 9001, GMP (Good Manufacturing Practices), and OSHA requirements. It incorporates industry best practices to maintain compliance and ensure product quality. Adherence to these standards is critical for operational consistency and regulatory approval.

What criteria determine successful completion or re-training requirements within the record?

Successful completion criteria are based on demonstrated proficiency and passing formal competency evaluations listed in the record. Re-training is triggered by performance gaps, procedural updates, or scheduled periodic refreshers. This systematic approach maintains high operator skill levels and minimizes operational risks.

How is supervisor or trainer authorization documented and verified on the Operator Training Record?

Supervisor or trainer authorization is documented through signatures and dates recorded in the document, confirming validation of the operator's competency. This verification step ensures accountability and authenticity of the training process. Electronic or handwritten approvals serve as official records for internal and external audits.

More Manufacturing Templates