The Batch Production Yield Document Sample for Manufacturing provides a detailed template to record the efficiency and output quality of a production batch. This document helps manufacturers track product quantities, defect rates, and overall yield metrics to optimize processes. Using this sample ensures consistent documentation and facilitates quality control in manufacturing operations.

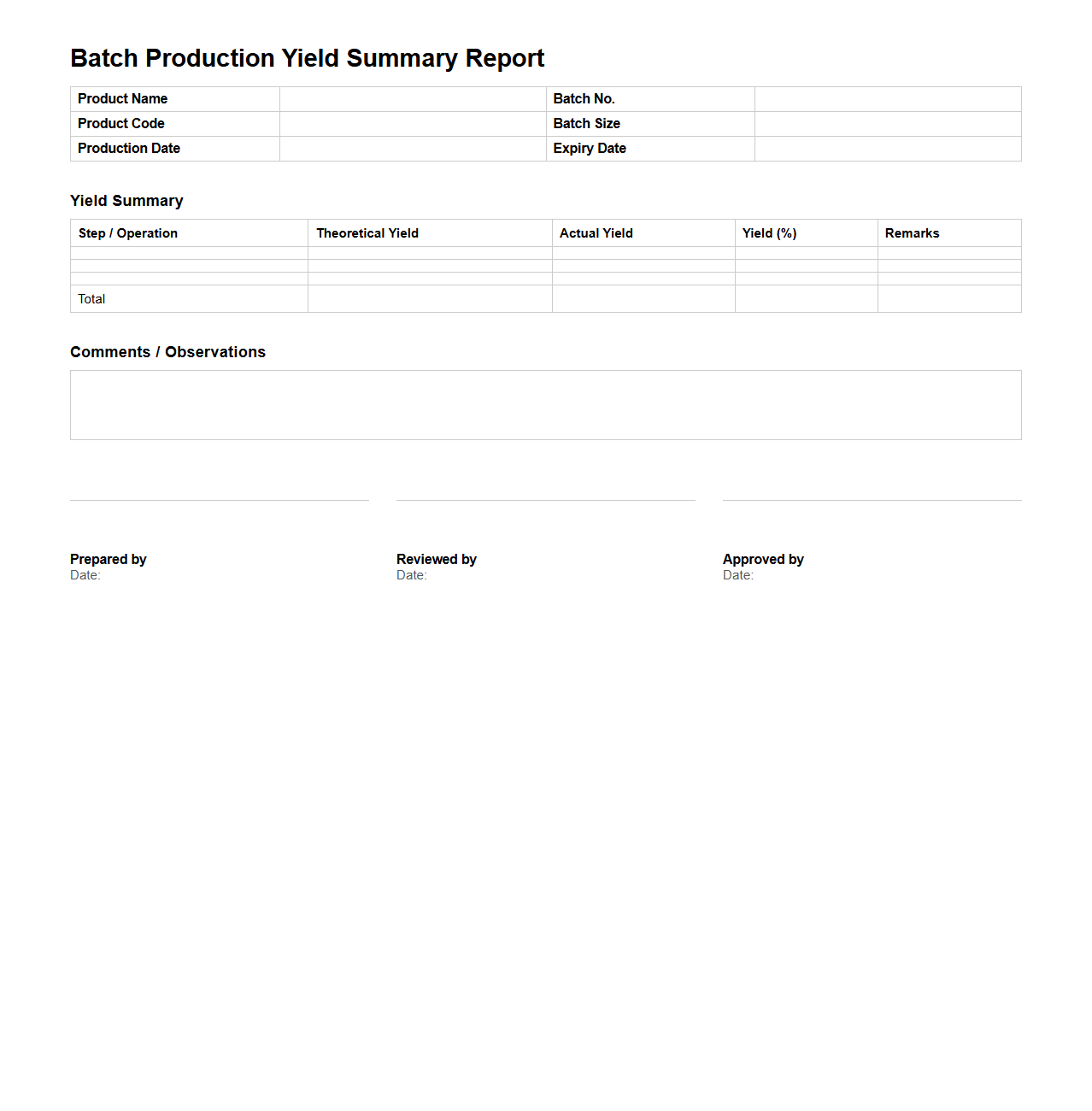

Batch Production Yield Summary Report Template

The

Batch Production Yield Summary Report Template document is designed to systematically capture and analyze the yield data of manufacturing batches, providing critical insights into production efficiency and quality control. It typically tracks key metrics such as input quantities, output quantities, defect rates, and yield percentages, enabling manufacturers to identify trends and areas for improvement. This template supports data-driven decision-making by organizing production results in a clear, concise format that enhances operational performance and reduces waste.

Batch Manufacturing Yield Tracking Sheet

The

Batch Manufacturing Yield Tracking Sheet is a critical document used in production environments to monitor and record the efficiency and output quality of manufacturing batches. It tracks key metrics such as input quantities, output quantities, defects, and yield percentages to identify production performance and areas for improvement. This sheet supports data-driven decision-making by providing clear visibility into batch yields and helping optimize manufacturing processes.

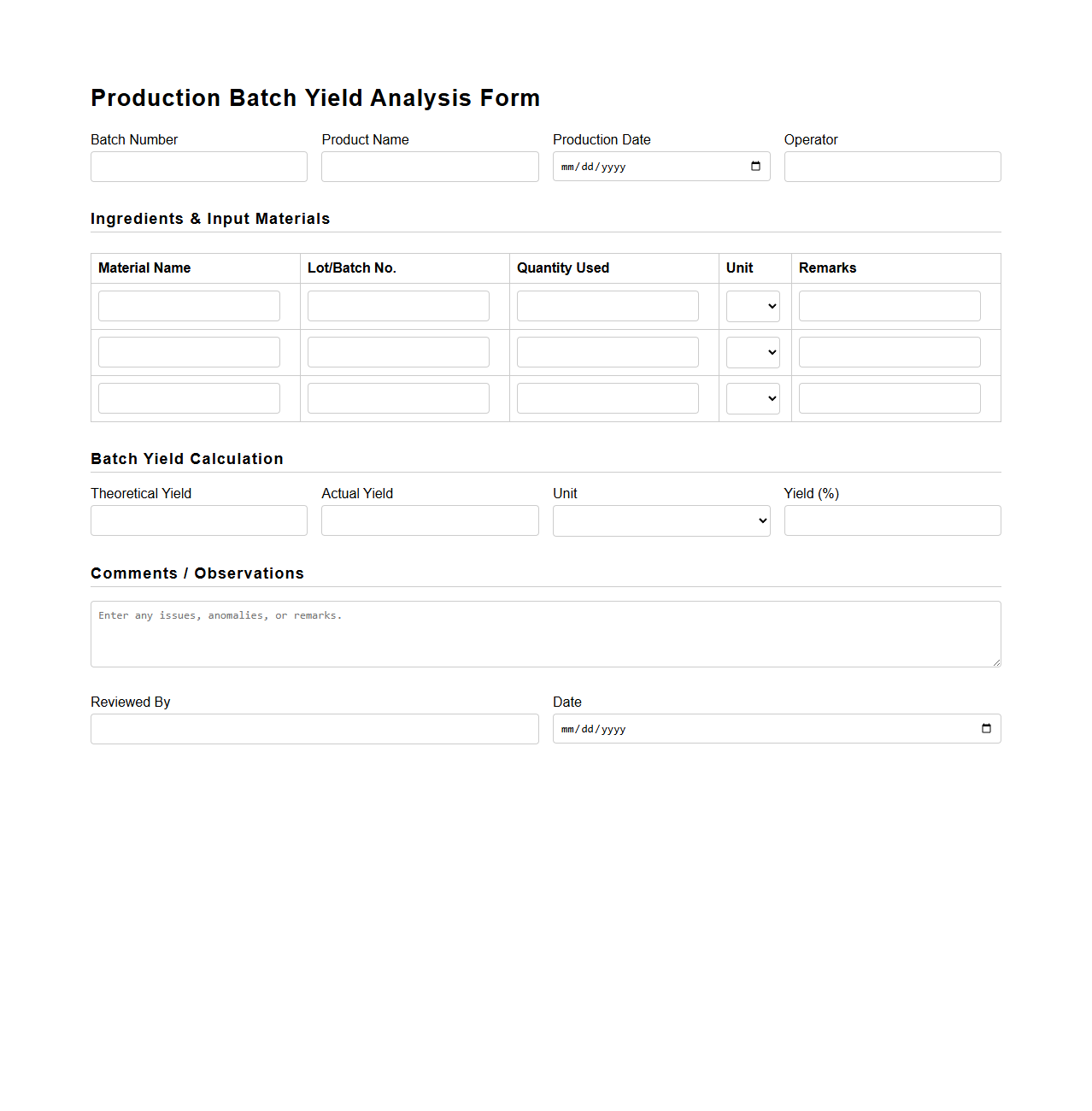

Production Batch Yield Analysis Form

The

Production Batch Yield Analysis Form is a crucial document used to evaluate the efficiency and output quality of a manufacturing batch. It captures key data such as total units produced, defective units, and yield percentage to identify production performance and areas for improvement. This form supports quality control by facilitating detailed analysis of batch yields, enabling manufacturers to optimize processes and reduce waste.

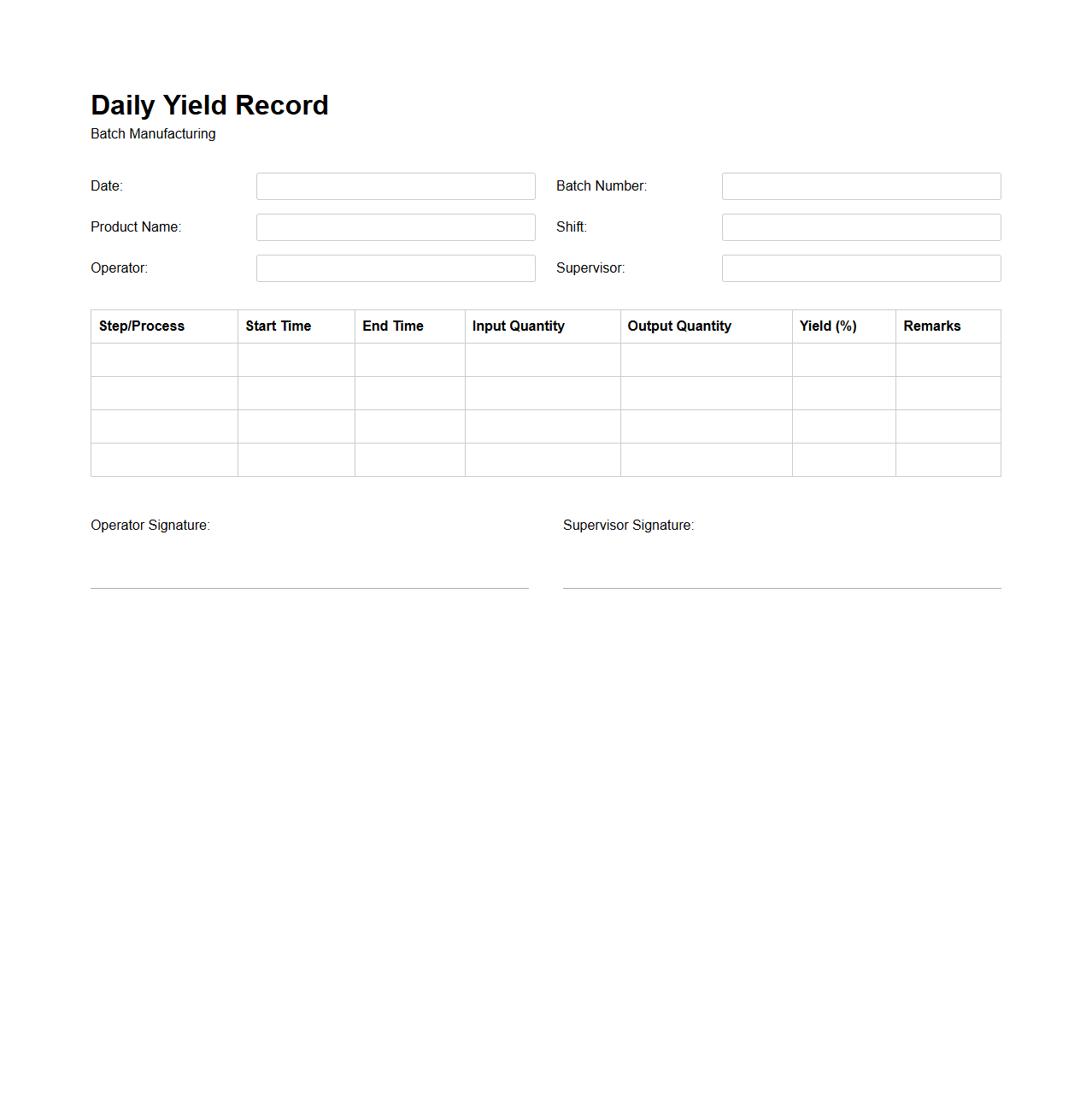

Daily Yield Record for Batch Manufacturing

The

Daily Yield Record for Batch Manufacturing document tracks the quantity of products produced and the yield efficiency for each batch on a daily basis. It captures key data such as input materials, output quantities, and any deviations or losses during production, ensuring accurate monitoring of manufacturing performance. This record is essential for quality control, regulatory compliance, and optimizing production processes within batch manufacturing operations.

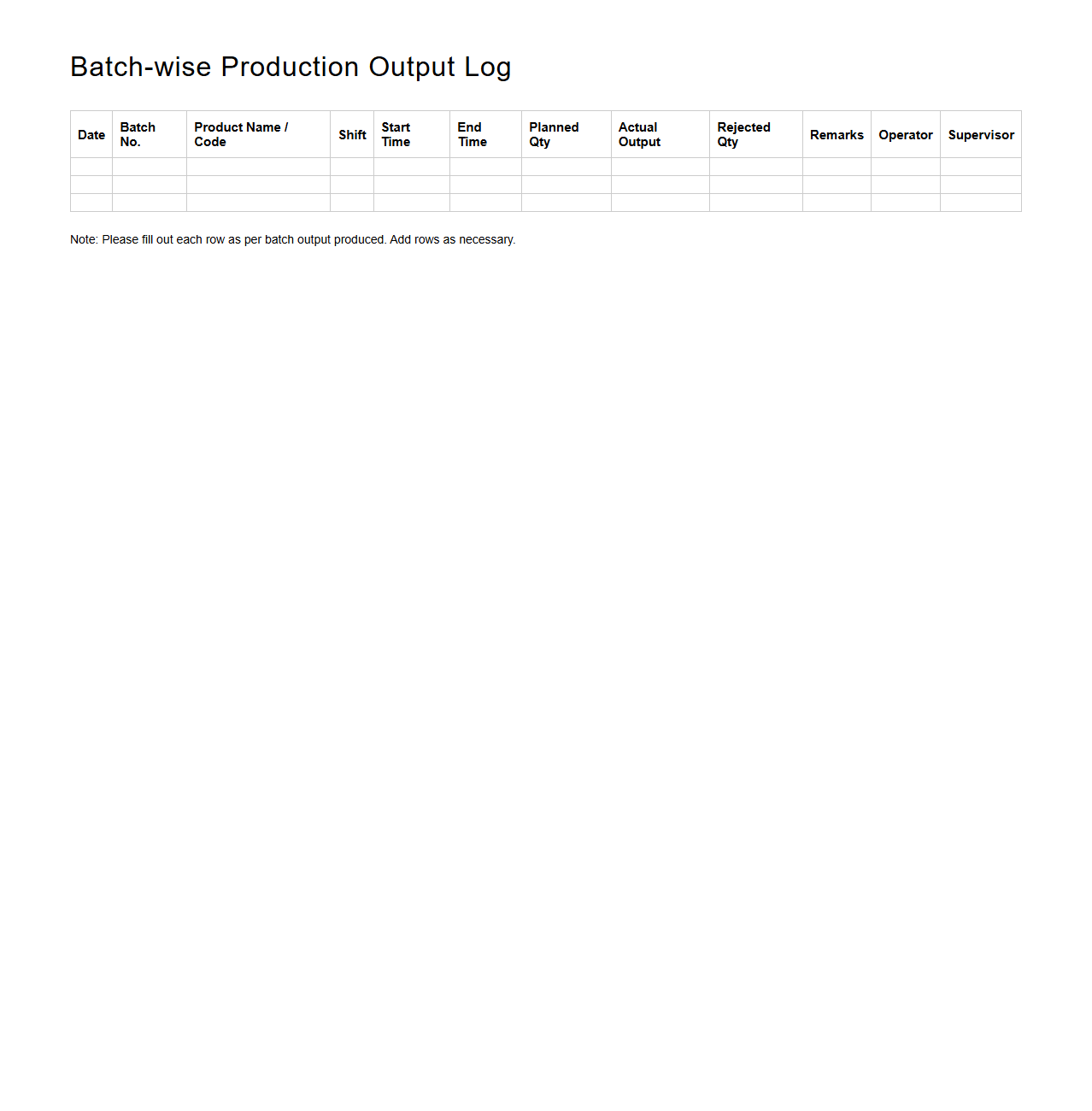

Batch-wise Production Output Log

The

Batch-wise Production Output Log document records detailed information about the quantity and quality of products produced during specific manufacturing batches. It tracks parameters such as production time, batch numbers, machine settings, and operator details to ensure traceability and accountability. This log is essential for monitoring production efficiency, identifying defects, and maintaining compliance with industry standards.

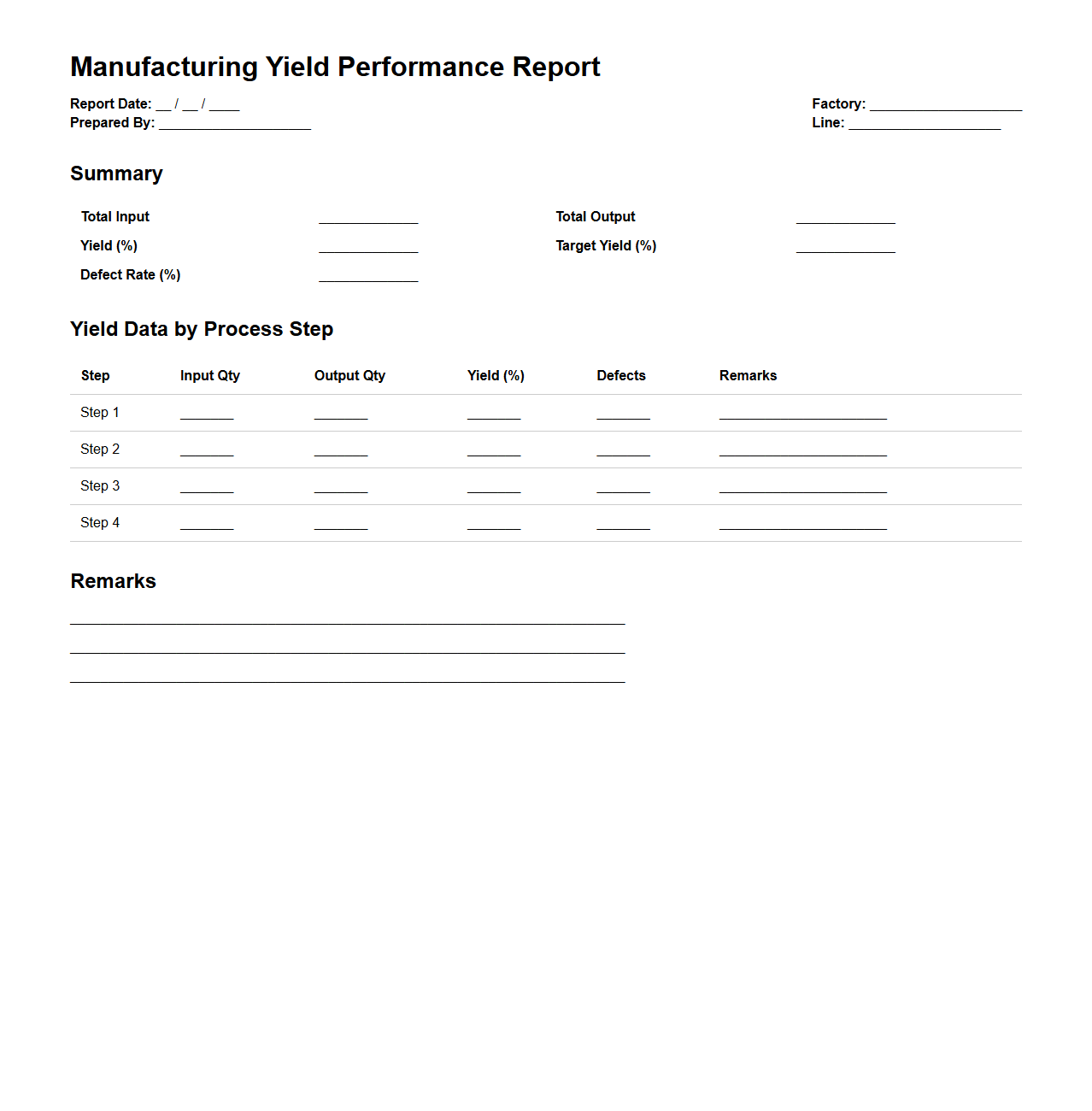

Manufacturing Yield Performance Report

The

Manufacturing Yield Performance Report is a critical document that tracks and analyzes the efficiency of production processes by measuring the ratio of good units produced to the total units started. It highlights key metrics such as defect rates, process variations, and equipment performance to identify areas for improvement in manufacturing operations. This report supports decision-making by providing actionable insights to optimize yield, reduce waste, and enhance overall production quality.

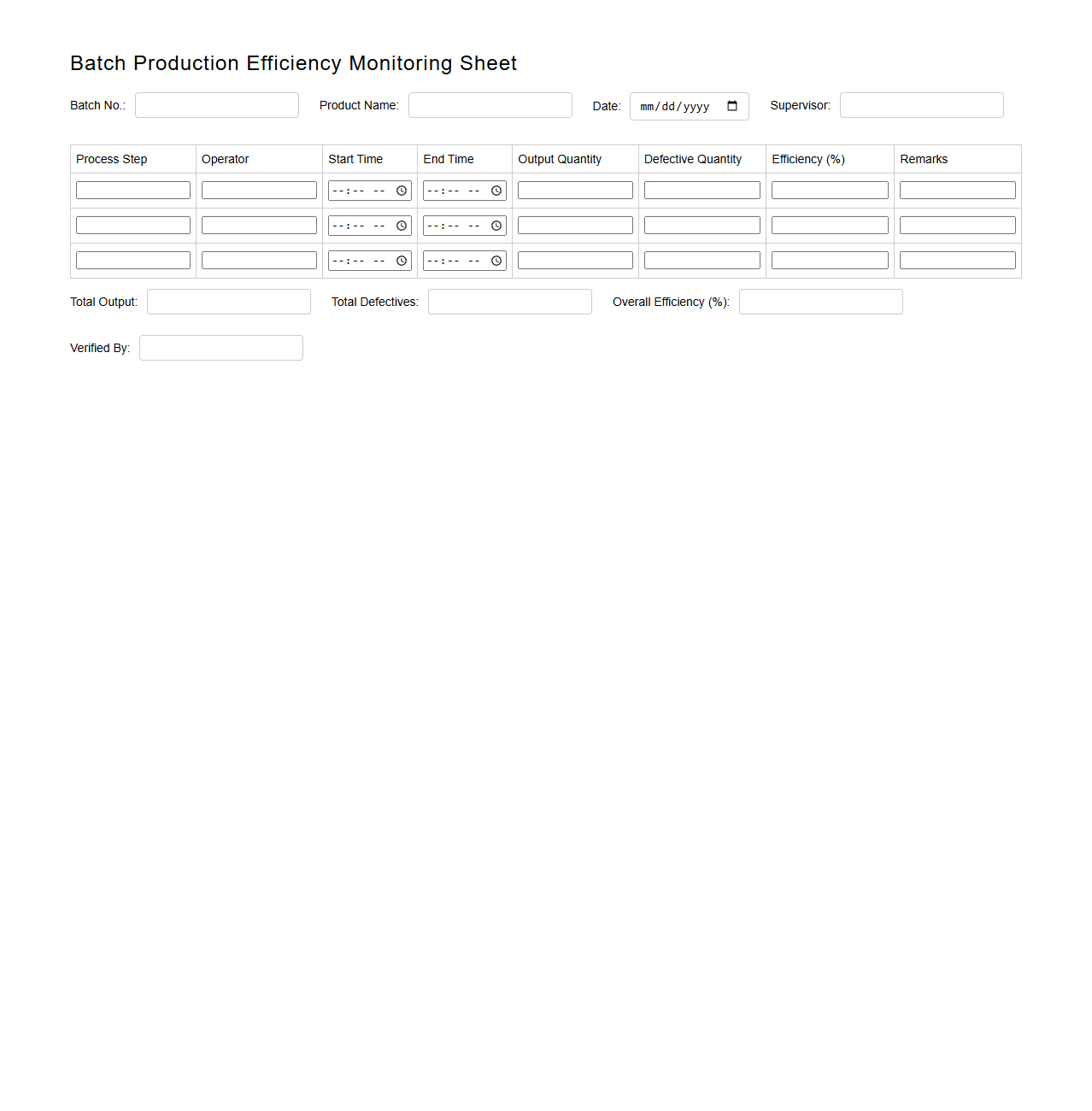

Batch Production Efficiency Monitoring Sheet

The

Batch Production Efficiency Monitoring Sheet is a crucial document used to track and analyze the efficiency of production batches in manufacturing processes. It records essential data such as production time, output quantity, downtime, and resource utilization, enabling managers to identify bottlenecks and optimize workflow. Consistent use of this sheet enhances productivity by providing actionable insights into operational performance and process improvements.

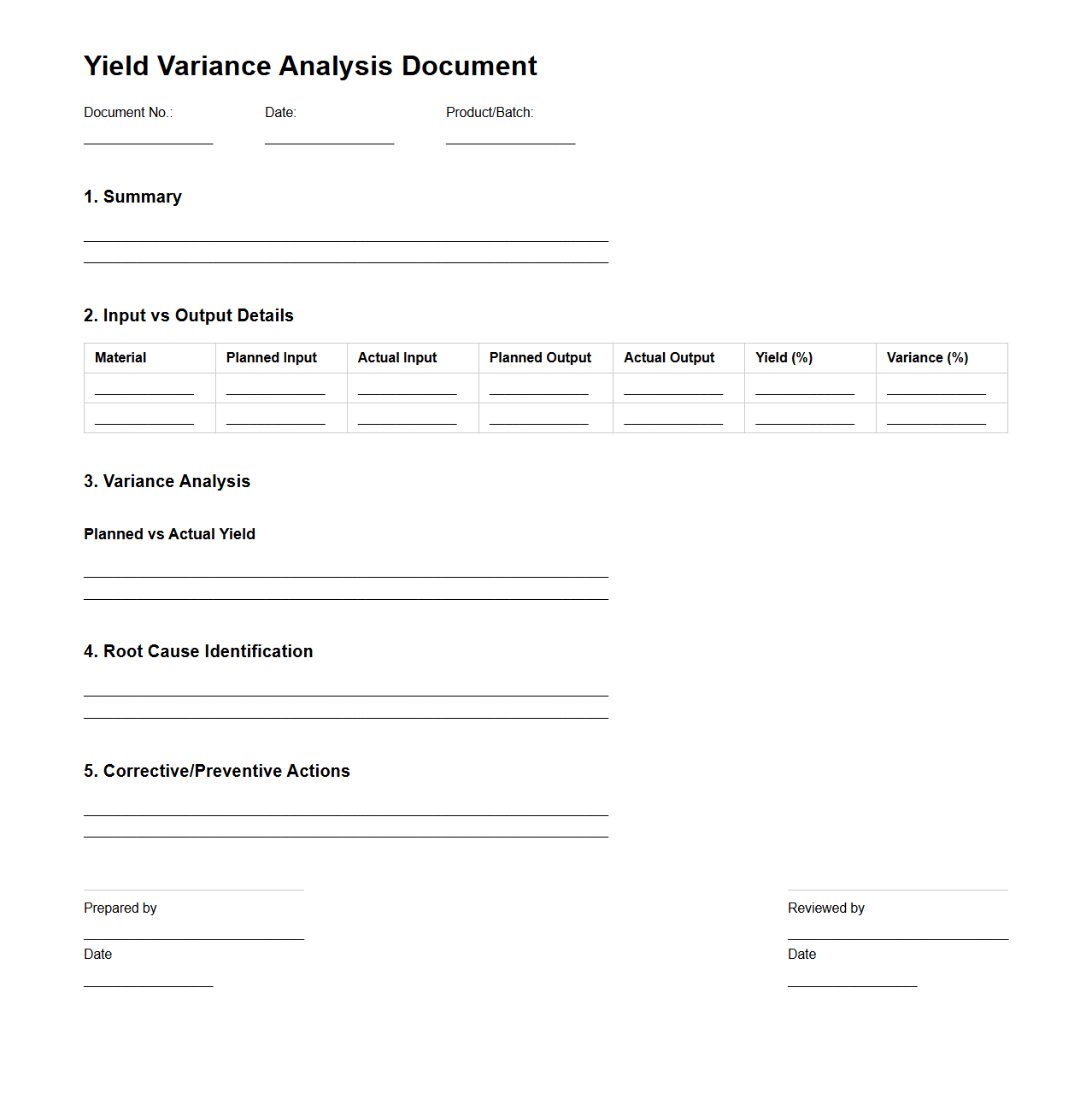

Yield Variance Analysis Document

Yield Variance Analysis Document is a critical financial tool that measures the difference between the expected output and the actual output in production processes. This document helps identify inefficiencies by quantifying the variance in

yield performance, enabling businesses to optimize resource utilization and improve cost management. It serves as a basis for strategic decision-making by highlighting areas where production processes deviate from planned targets.

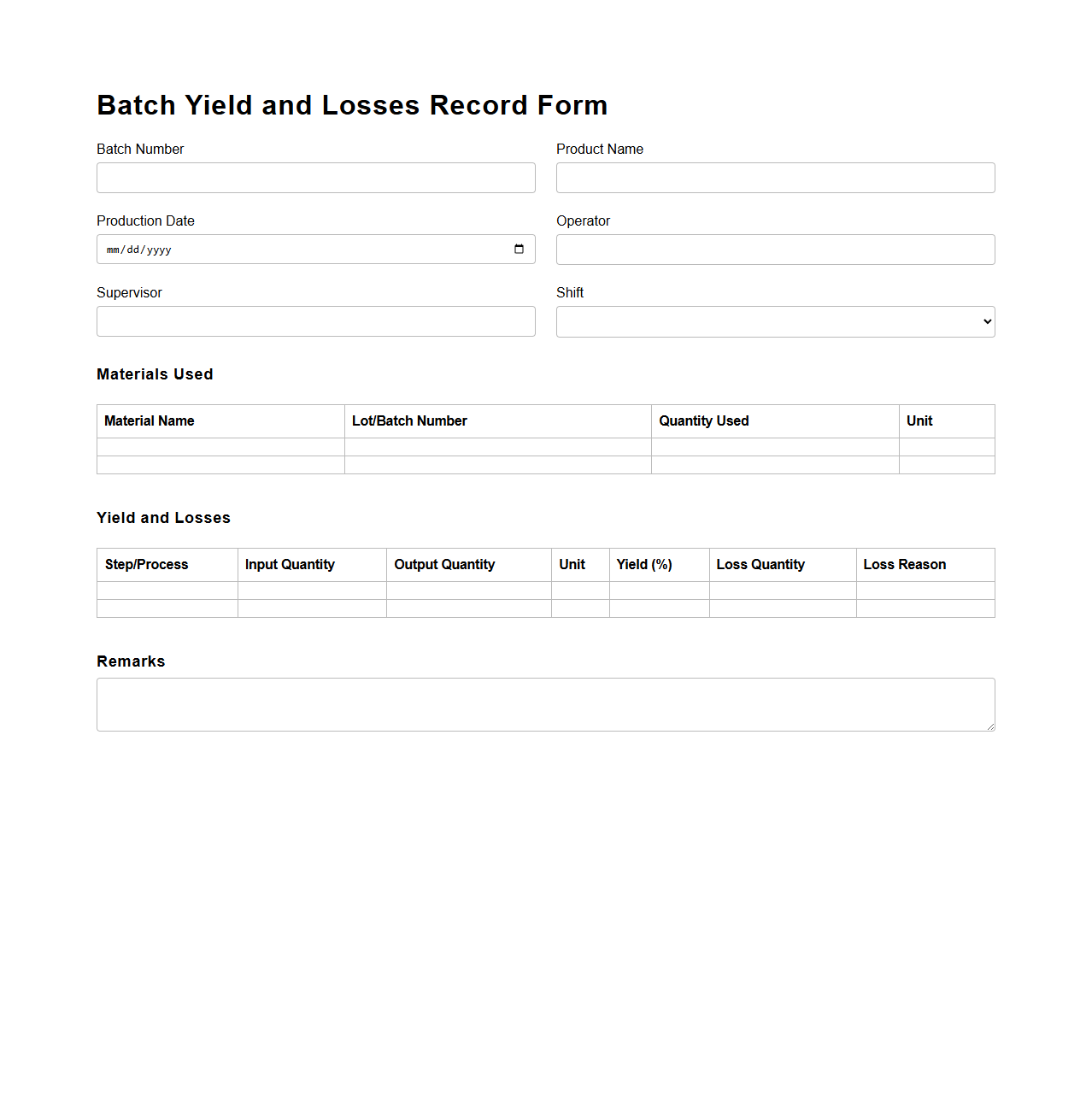

Batch Yield and Losses Record Form

The

Batch Yield and Losses Record Form is a crucial document used in manufacturing and production processes to track the quantity of output generated from a specific batch and record any associated losses. It provides detailed information on the yield percentage, material consumption, and any discrepancies that occur during production, facilitating accurate monitoring and control of process efficiency. This form aids in identifying inconsistencies, optimizing resource usage, and ensuring compliance with quality standards.

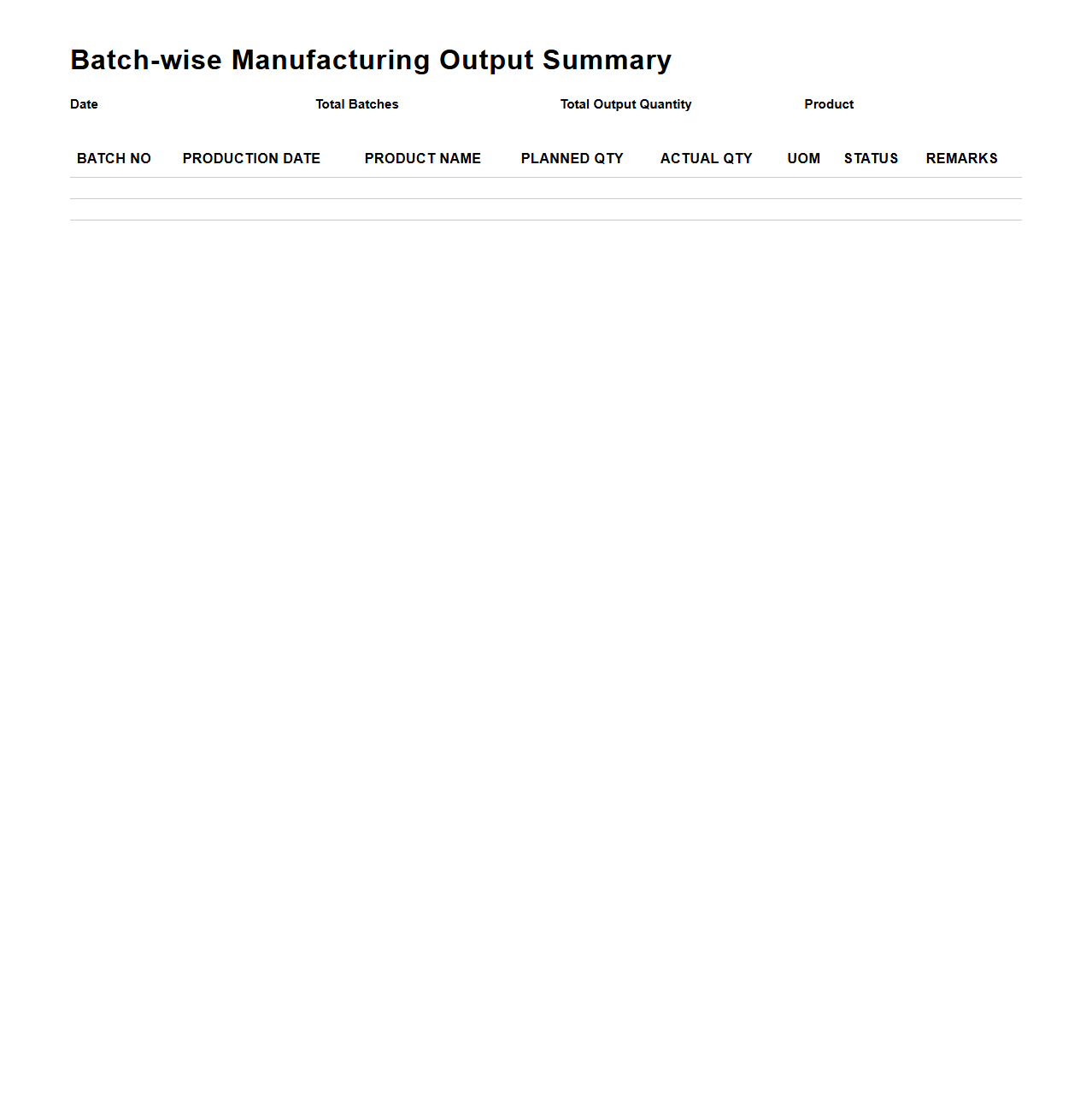

Batch-wise Manufacturing Output Summary

The

Batch-wise Manufacturing Output Summary document provides a detailed record of production metrics for each batch processed within a manufacturing cycle. It includes data such as batch identification, quantity produced, quality control results, and timestamps, ensuring traceability and accountability. This summary enables efficient monitoring of production efficiency, batch consistency, and helps in identifying deviations for continuous improvement.

What key data fields must be included in a Batch Production Yield Document?

A Batch Production Yield Document must include critical data fields such as batch number, production date, and product name. It should also have fields for input quantities of raw materials and output quantities of finished product. These fields ensure accurate tracking and assessment of production efficiency.

How does the document define and calculate actual versus expected yield?

The document defines actual yield as the real output obtained from the batch production process. Expected yield is the forecasted quantity based on standard formulations or historical data. The yield calculation is typically performed by dividing actual yield by expected yield and multiplying by 100 to express it as a percentage.

What information is required to trace raw material usage in the batch?

Raw material tracing requires detailed information such as lot or batch numbers, quantities used, and supplier details. The Batch Production Yield Document must record these data to maintain full traceability and regulatory compliance. This ensures any issues in raw materials can be swiftly identified and addressed.

How are deviations or discrepancies in yield documented and explained?

All deviations or discrepancies in yield must be documented with a clear description and analysis of potential causes. The document should include an investigation report and any corrective actions taken. This process is vital for quality control and continuous improvement in production operations.

Which approval signatures or authorizations are necessary for document finalization?

The document must include signatures from key personnel such as the production supervisor, quality control manager, and sometimes regulatory compliance officers. These approval signatures confirm the validity and accuracy of the reported data. Final sign-off ensures accountability and formal acceptance of batch yield results.

More Manufacturing Templates