A Quality Control Document Sample for Manufacturing outlines the procedures and standards used to ensure product consistency and compliance with industry regulations. It typically includes inspection criteria, testing methods, and corrective actions to maintain high-quality production. This document serves as a crucial reference for manufacturing teams to monitor processes and address defects efficiently.

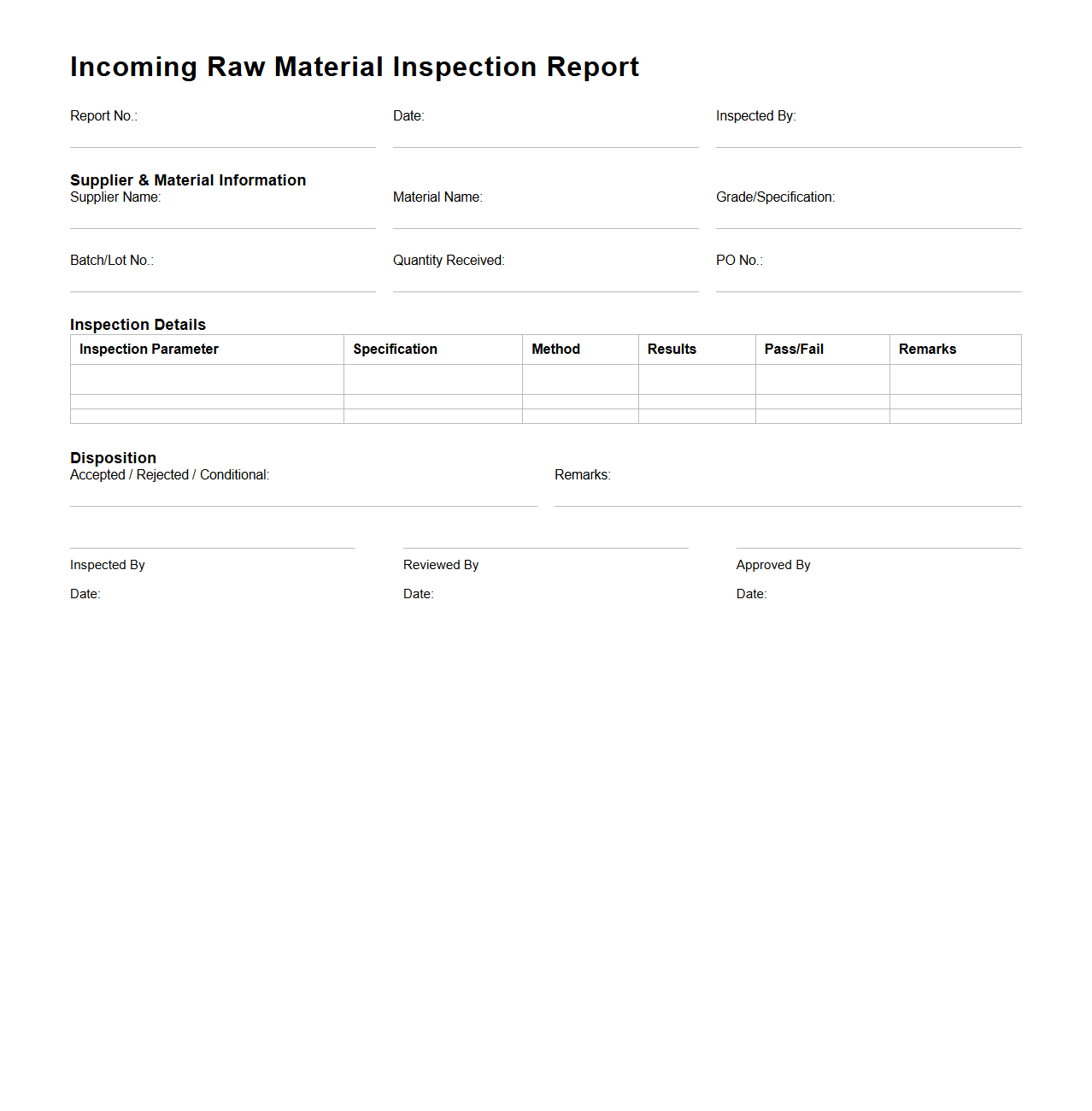

Incoming Raw Material Inspection Report Template

The

Incoming Raw Material Inspection Report Template document is a standardized form used to record and evaluate the quality and specifications of raw materials received from suppliers. It ensures that materials meet predetermined standards by documenting inspection criteria, test results, and acceptance status to prevent defects in the production process. This template is essential for maintaining consistent quality control and compliance with industry regulations.

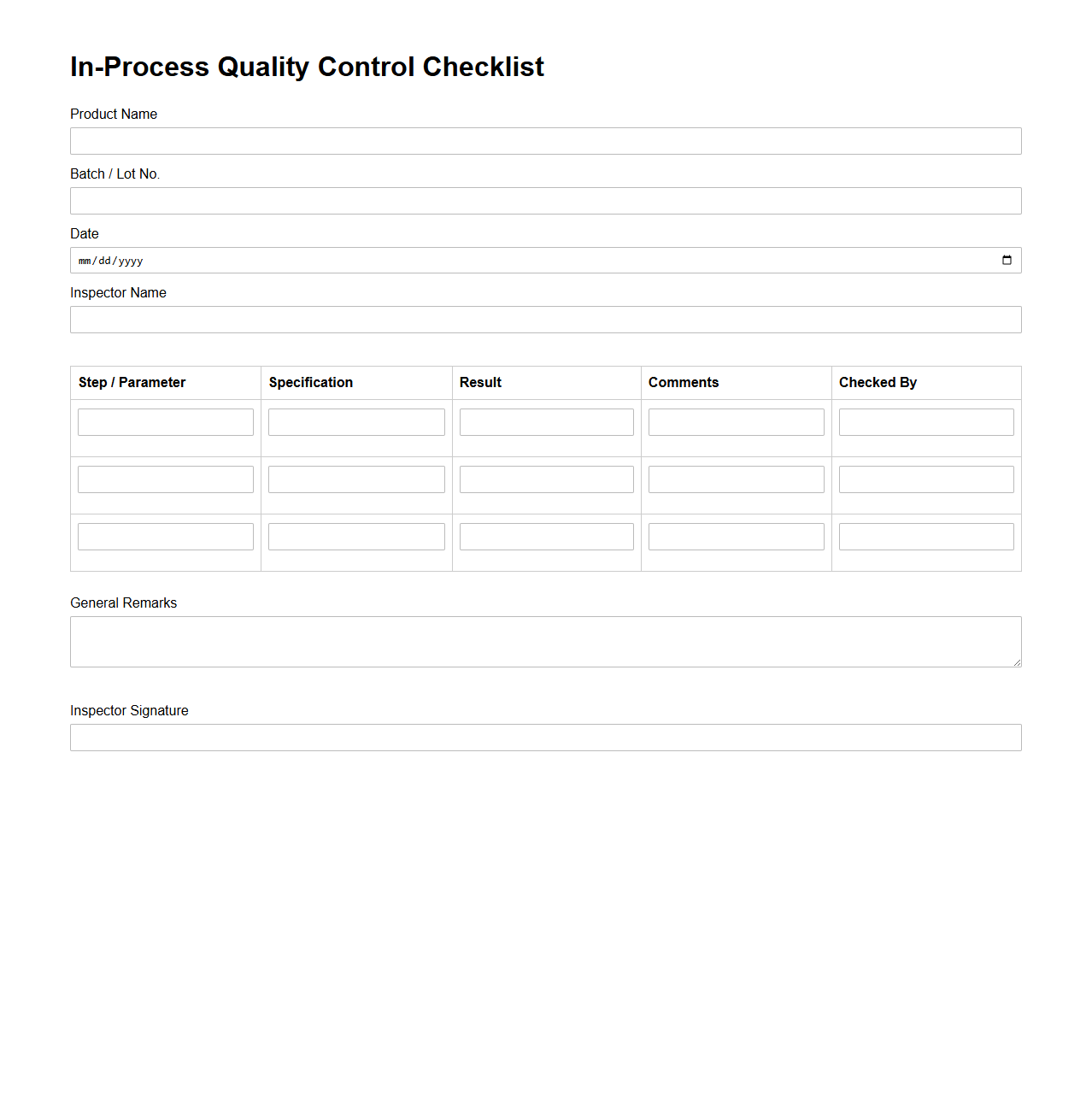

In-Process Quality Control Checklist

An

In-Process Quality Control Checklist document is a structured tool used during manufacturing or production to monitor and verify compliance with quality standards at various stages. It ensures that specific parameters such as dimensions, materials, and operational processes meet predefined criteria, reducing defects and enhancing product consistency. This checklist helps maintain process control, facilitates timely corrective actions, and supports regulatory compliance by documenting inspection results systematically.

Finished Goods Quality Assurance Form

The

Finished Goods Quality Assurance Form document serves as a critical record in manufacturing and production, verifying that final products meet specific quality standards before shipment or distribution. It typically includes detailed inspection criteria, test results, and compliance checks to ensure consistency, safety, and customer satisfaction. This document helps prevent defective goods from reaching the market, supporting regulatory adherence and continuous improvement efforts.

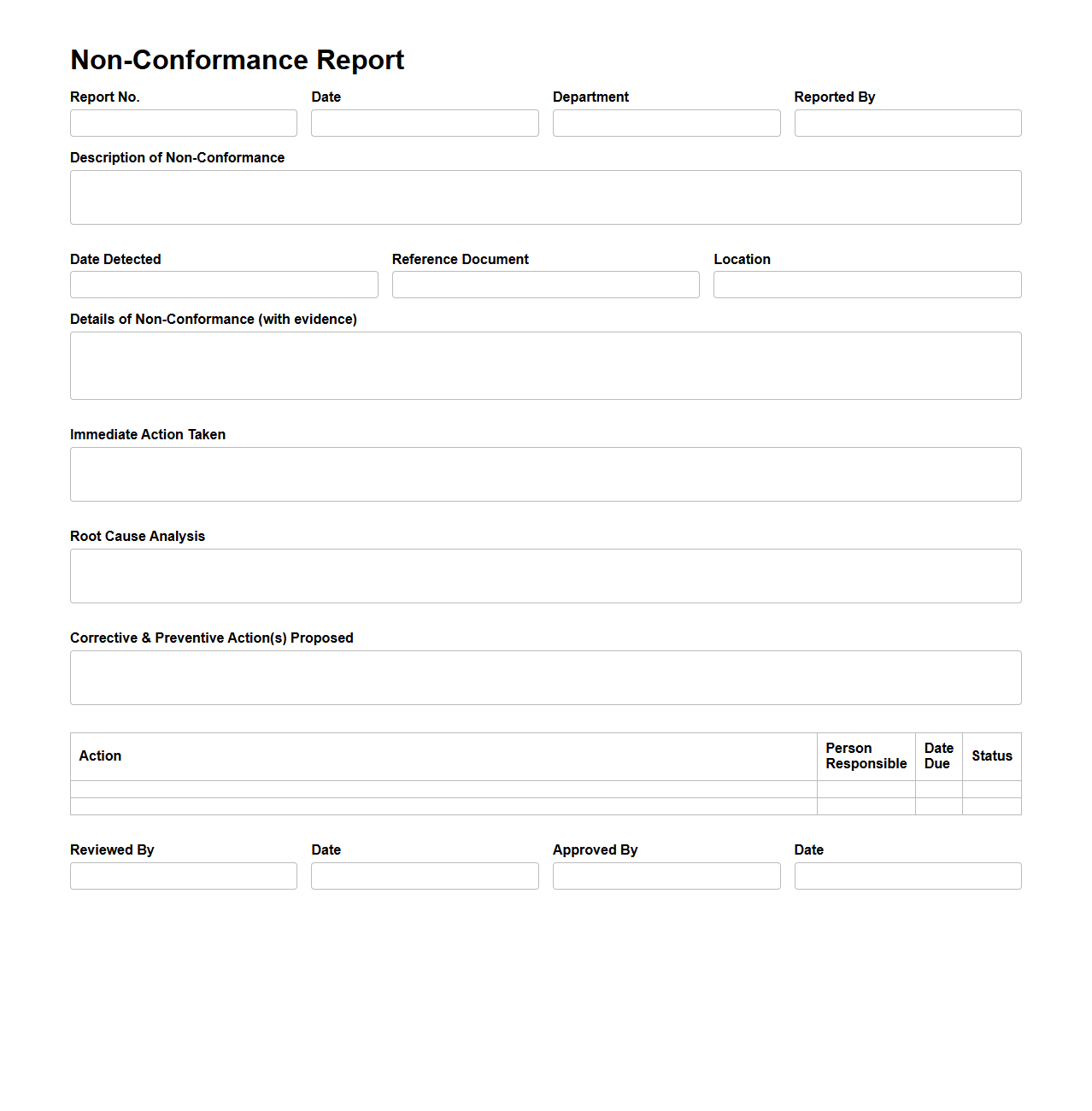

Non-Conformance Report Sample

A

Non-Conformance Report Sample document is a standardized template used to identify, document, and address deviations from specified requirements or standards in quality management processes. It facilitates clear communication of non-conformances, detailing the nature of the issue, its impact, root cause analysis, and corrective actions to prevent recurrence. This document is essential in industries such as manufacturing, construction, and quality assurance to maintain compliance and continuous improvement.

Corrective and Preventive Action (CAPA) Form

A

Corrective and Preventive Action (CAPA) Form document is a structured tool used to identify, record, and address non-conformities or quality issues within processes or products. It facilitates the documentation of root cause analysis, corrective measures taken to resolve existing problems, and preventive steps to mitigate future risks. This form is essential for maintaining compliance with industry standards such as ISO 9001 and ensuring continuous improvement in quality management systems.

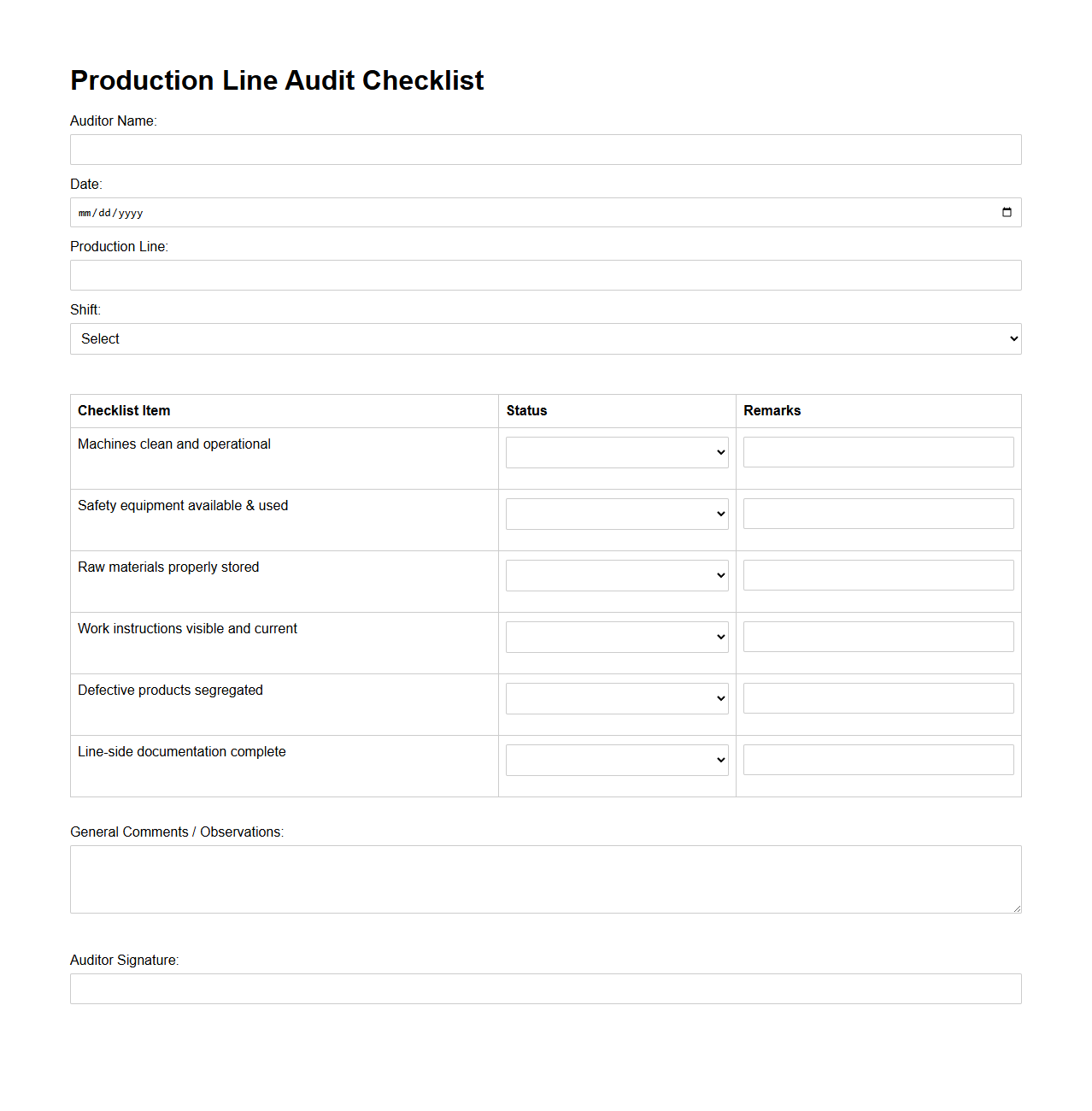

Production Line Audit Checklist

A

Production Line Audit Checklist document is a detailed tool used to systematically assess the efficiency, safety, and quality standards of a manufacturing production line. It includes specific criteria such as equipment condition, workflow processes, employee compliance, and product quality checkpoints to ensure operational consistency and regulatory adherence. Regular use of this checklist helps identify potential issues early, optimize productivity, and maintain high-quality output throughout the production cycle.

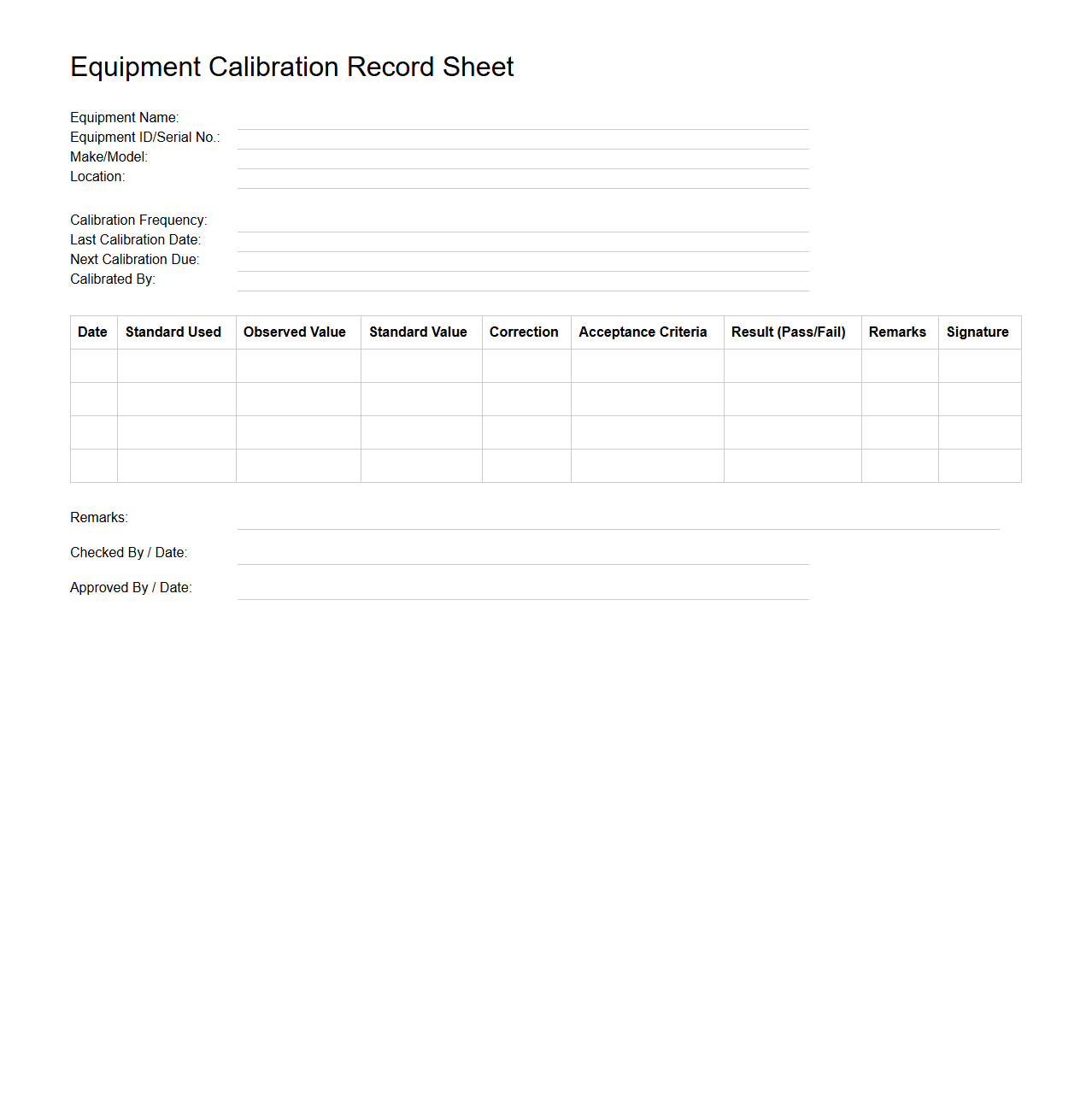

Equipment Calibration Record Sheet

An

Equipment Calibration Record Sheet is a detailed document used to track the calibration history and status of measurement instruments and equipment. It ensures accuracy by recording calibration dates, results, technician details, and any adjustments made. Maintaining this record is essential for quality control, compliance with industry standards, and preventing measurement errors in manufacturing or laboratory processes.

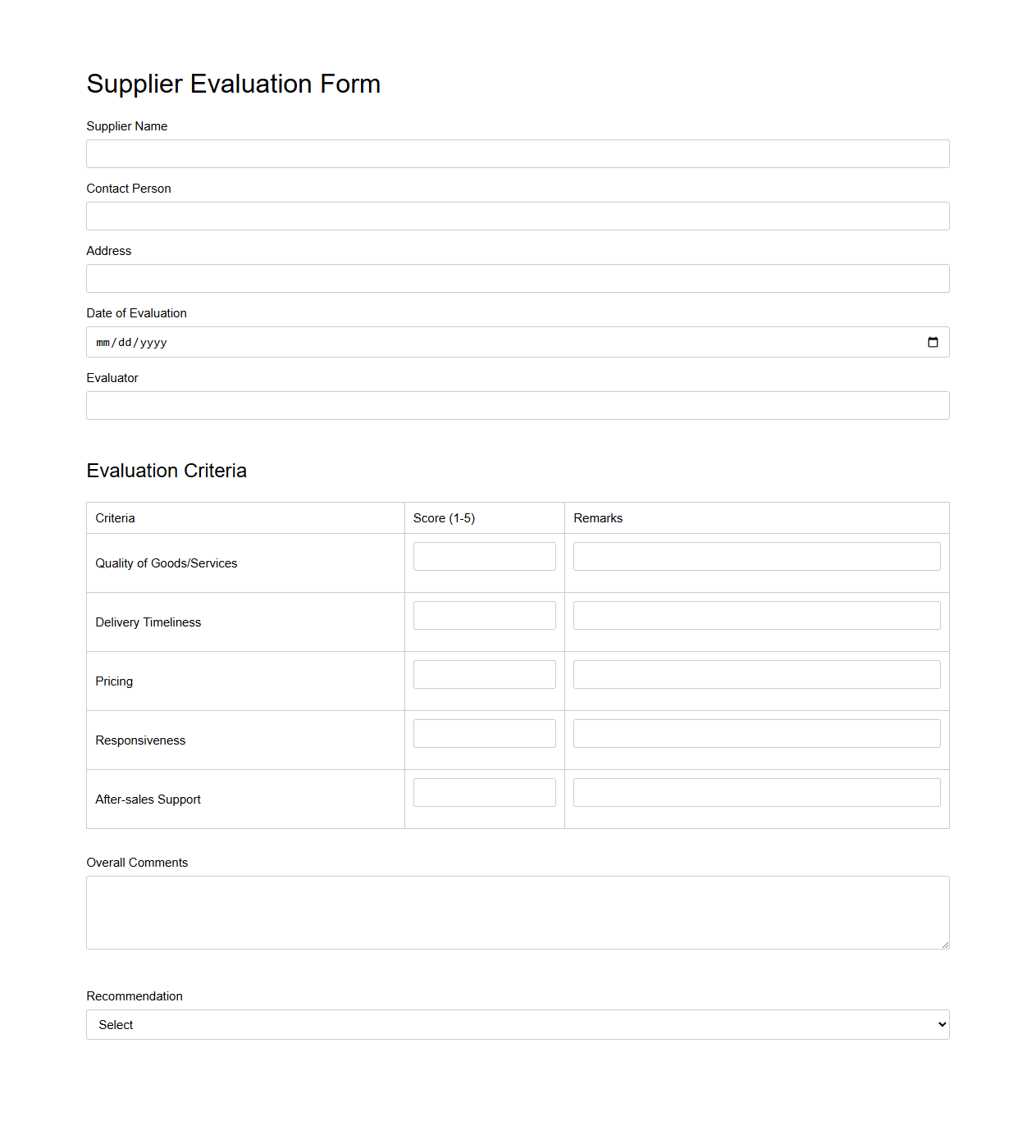

Supplier Evaluation Form

A

Supplier Evaluation Form document is a systematic tool used by businesses to assess and rate the performance of their suppliers based on criteria such as quality, delivery time, cost, and compliance. It helps organizations measure supplier reliability and identify areas for improvement to ensure the procurement of high-quality goods and services. This form plays a crucial role in maintaining strong supplier relationships and optimizing supply chain efficiency.

Defect Tracking Log Example

A

Defect Tracking Log Example document is a structured tool used to record, monitor, and manage software defects throughout the development lifecycle. It typically includes fields such as defect ID, description, severity, status, assigned personnel, and resolution details, enabling effective communication and prioritization. By maintaining this log, teams can systematically track defect progress and ensure timely resolution, improving overall software quality.

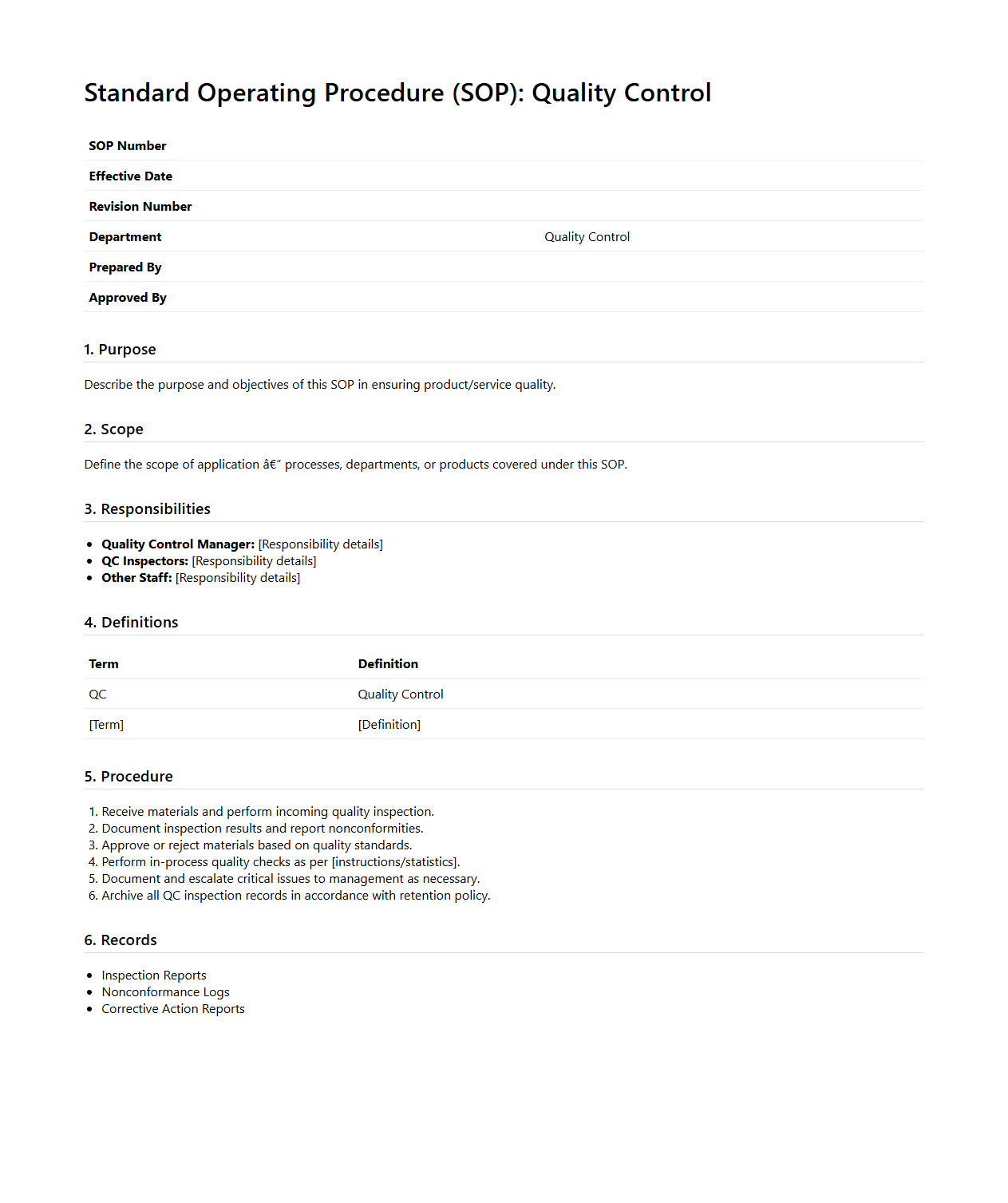

Standard Operating Procedure (SOP) Template for Quality Control

A

Standard Operating Procedure (SOP) Template for Quality Control document provides a structured framework for consistency and accuracy in quality assurance processes. It outlines step-by-step instructions, including inspection criteria, testing methods, and documentation standards, to ensure products meet regulatory and company quality requirements. Using this template helps streamline quality control workflows, minimize errors, and maintain compliance with industry standards such as ISO 9001.

Key Criteria for Determining Product Conformity

The document emphasizes the importance of adherence to specified product dimensions, materials, and performance standards as primary criteria for product conformity. It mandates that products must meet all outlined specifications to ensure quality and safety. Additionally, the criteria include visual inspections, functional tests, and compliance with regulatory requirements.

Standardized Testing Methods for Manufacturing Validation

The quality control document specifies the use of internationally recognized testing methods such as ISO 9001 and ASTM standards to validate manufacturing processes. It outlines procedures for performance testing, durability assessments, and safety evaluations. These methods help ensure consistent product quality and regulatory compliance.

Definition of Acceptable Tolerances and Defect Limits

The document clearly defines acceptable tolerances by providing precise numerical ranges for dimensions and performance variables. Defect limits are categorized by severity, with allowable thresholds established for minor, major, and critical defects. These standards aim to minimize product failures while maintaining efficient production.

Procedures for Documenting and Addressing Non-Conformities

Non-conformities found during inspections are required to be documented systematically using standardized forms and logs. The document describes a corrective action process that includes root cause analysis, immediate containment, and preventive measures. It also mandates follow-up inspections to verify the effectiveness of corrective actions.

Roles Responsible for Each Step in Quality Control Process

The document assigns specific responsibilities to roles such as Quality Inspectors, Process Engineers, and Quality Managers to ensure accountability. Quality Inspectors conduct initial product assessments, while Process Engineers oversee testing methods and procedural compliance. Quality Managers have oversight over the entire quality control process and authorization of final product release.

More Manufacturing Templates