A Cleaning Log Document Sample for Manufacturing serves as a crucial record to track and verify cleaning activities within production areas. It helps ensure compliance with hygiene standards, maintain product quality, and prevent contamination risks. This document typically includes details such as cleaning date, personnel involved, cleaning materials used, and inspection results.

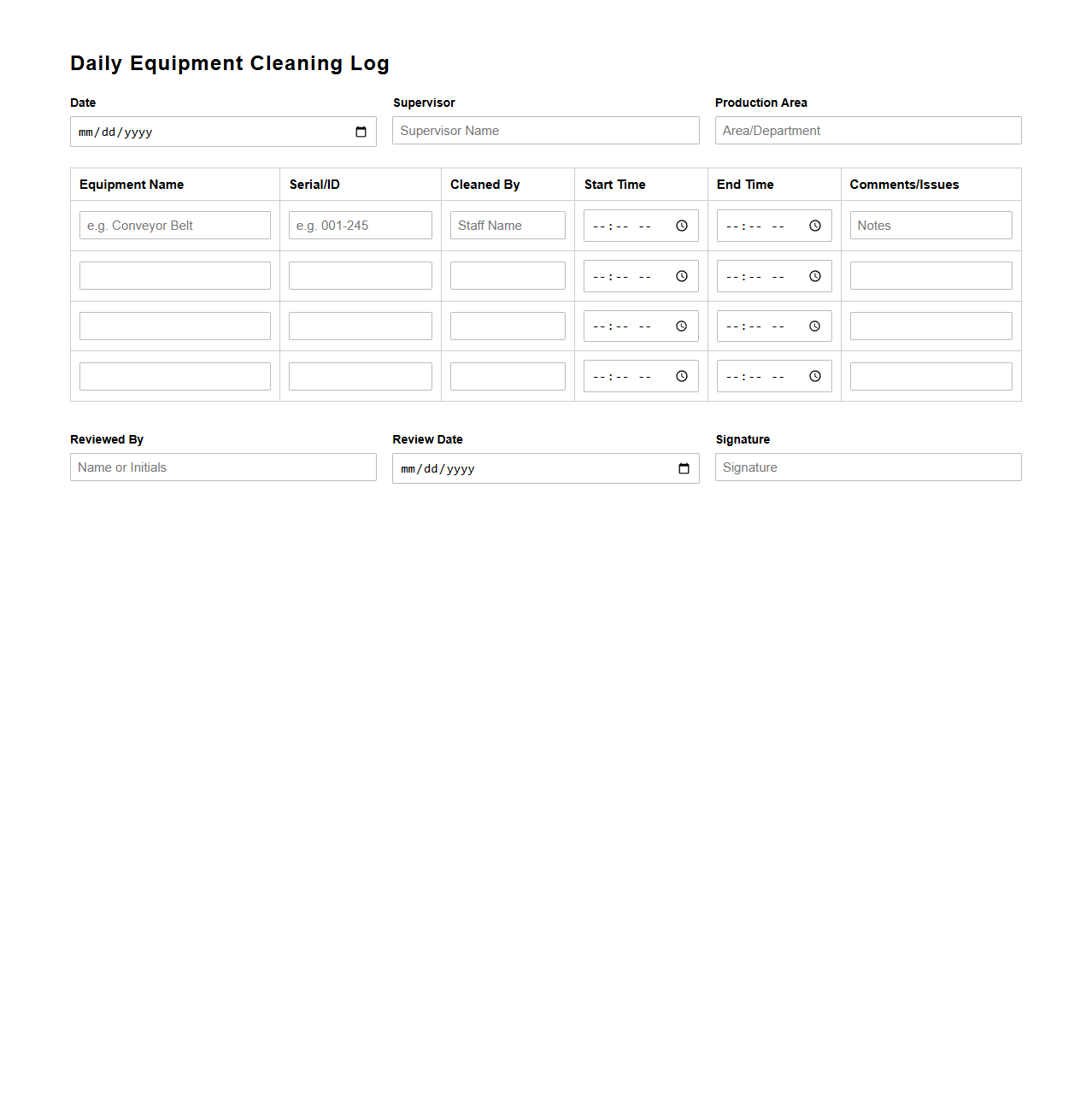

Daily Equipment Cleaning Log for Manufacturing

The

Daily Equipment Cleaning Log for manufacturing is a critical document used to record the cleaning activities of machinery and equipment on a daily basis. It ensures compliance with hygiene and safety standards, helps track maintenance schedules, and supports quality control processes by preventing contamination and operational failures. This log typically includes details such as the date, time, personnel involved, cleaning procedures performed, and verification signatures.

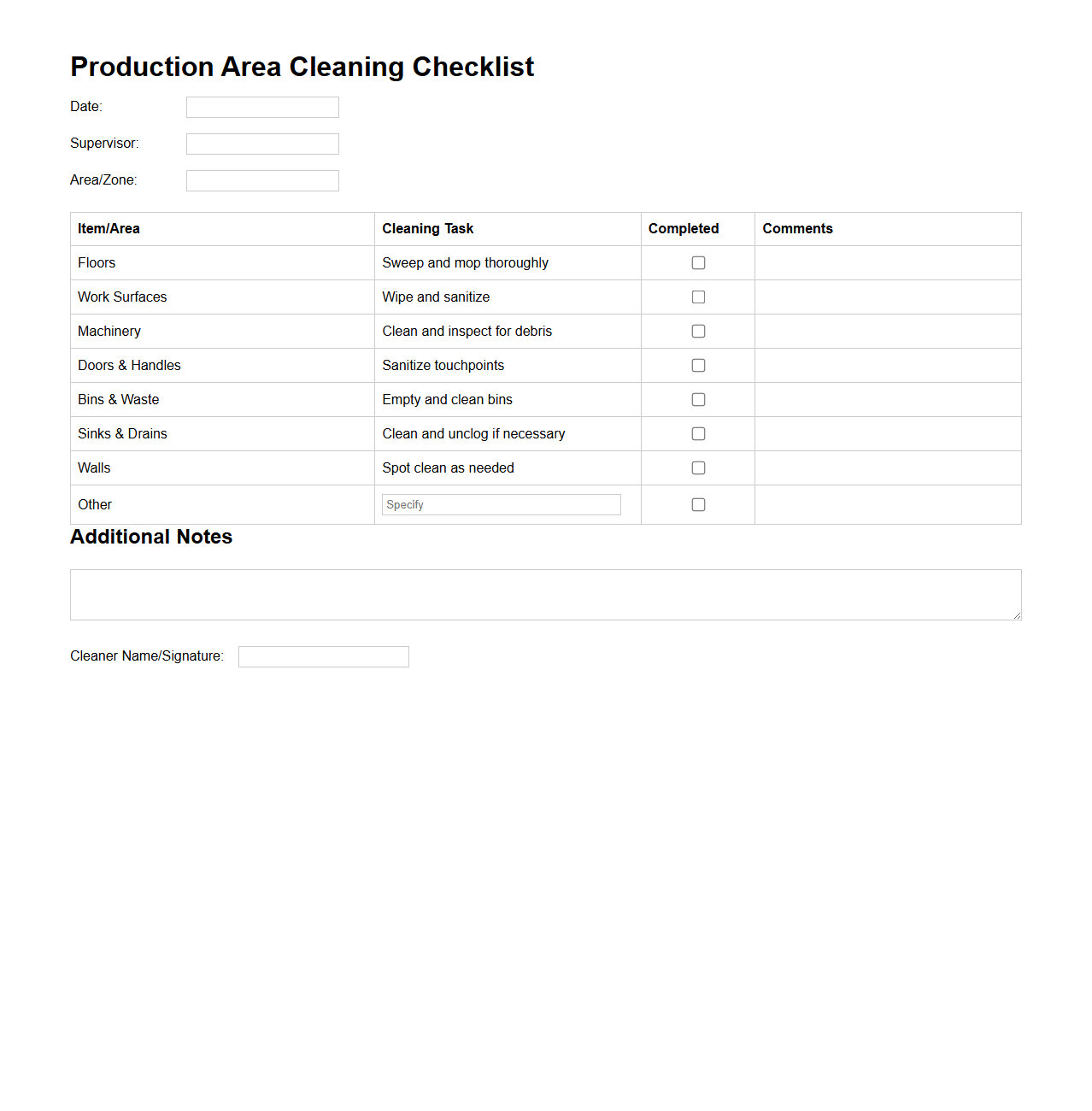

Production Area Cleaning Checklist Template

A

Production Area Cleaning Checklist Template document is a structured tool designed to ensure comprehensive and consistent sanitation of manufacturing or production spaces. It outlines specific cleaning tasks, frequencies, responsible personnel, and inspection criteria to maintain hygiene standards and prevent contamination risks. This checklist enhances operational efficiency by providing a clear framework for routine cleaning activities and regulatory compliance.

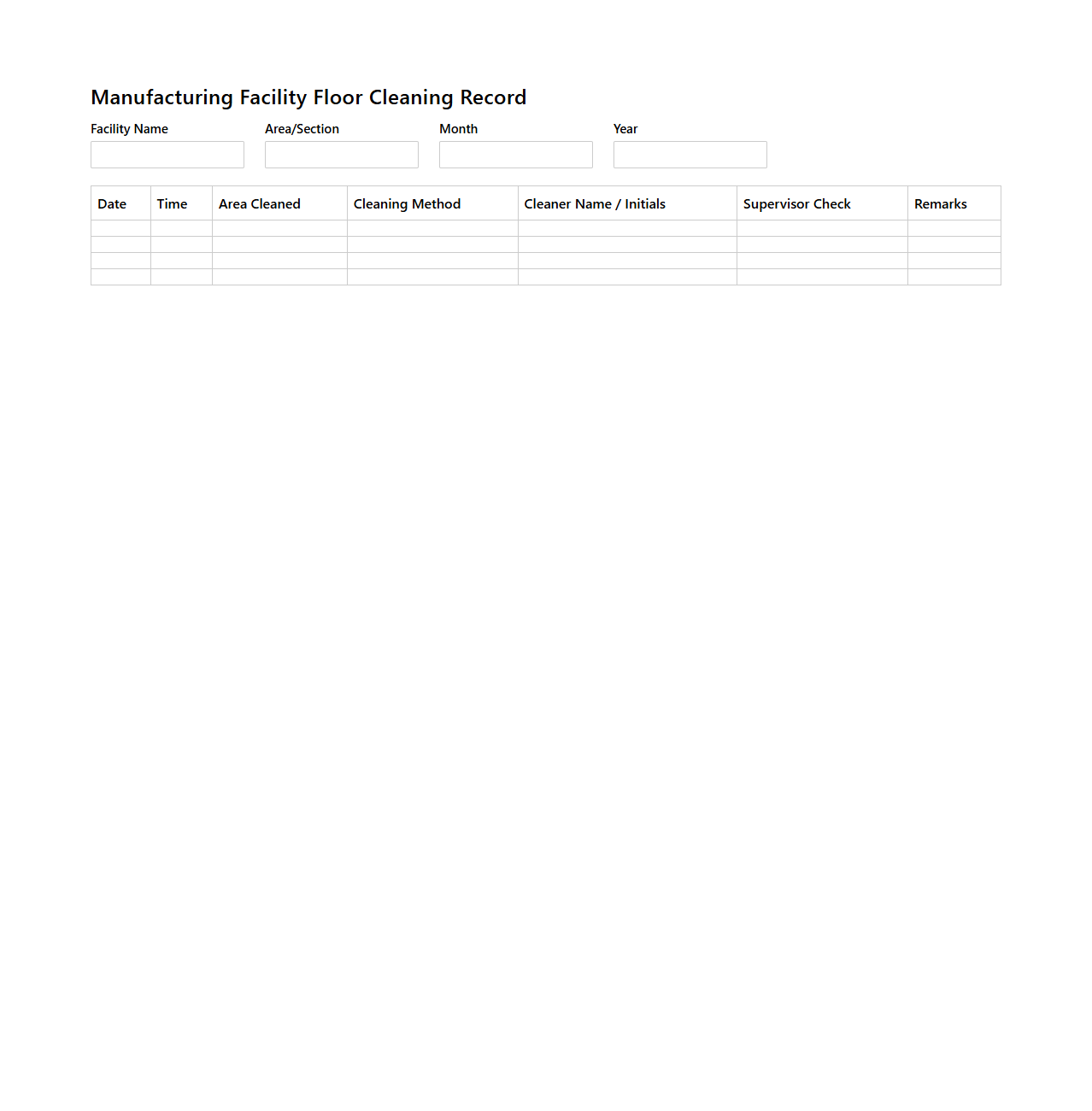

Manufacturing Facility Floor Cleaning Record

A

Manufacturing Facility Floor Cleaning Record document is a detailed log that tracks cleaning activities within production areas to ensure hygiene and safety standards are consistently met. It includes information such as cleaning schedules, responsible personnel, cleaning agents used, and inspection results to maintain compliance with regulatory requirements. This record supports quality control by preventing contamination and maintaining a clean manufacturing environment.

Machine Sanitization Tracking Sheet

A

Machine Sanitization Tracking Sheet document is a vital tool used to record and monitor the cleaning and sanitization schedules of machinery in industrial, manufacturing, or food processing environments. This document ensures compliance with hygiene standards by tracking the date, time, personnel involved, and specific cleaning procedures performed on each machine. Maintaining accurate records on this sheet helps prevent contamination risks, supports regulatory audits, and promotes operational safety and efficiency.

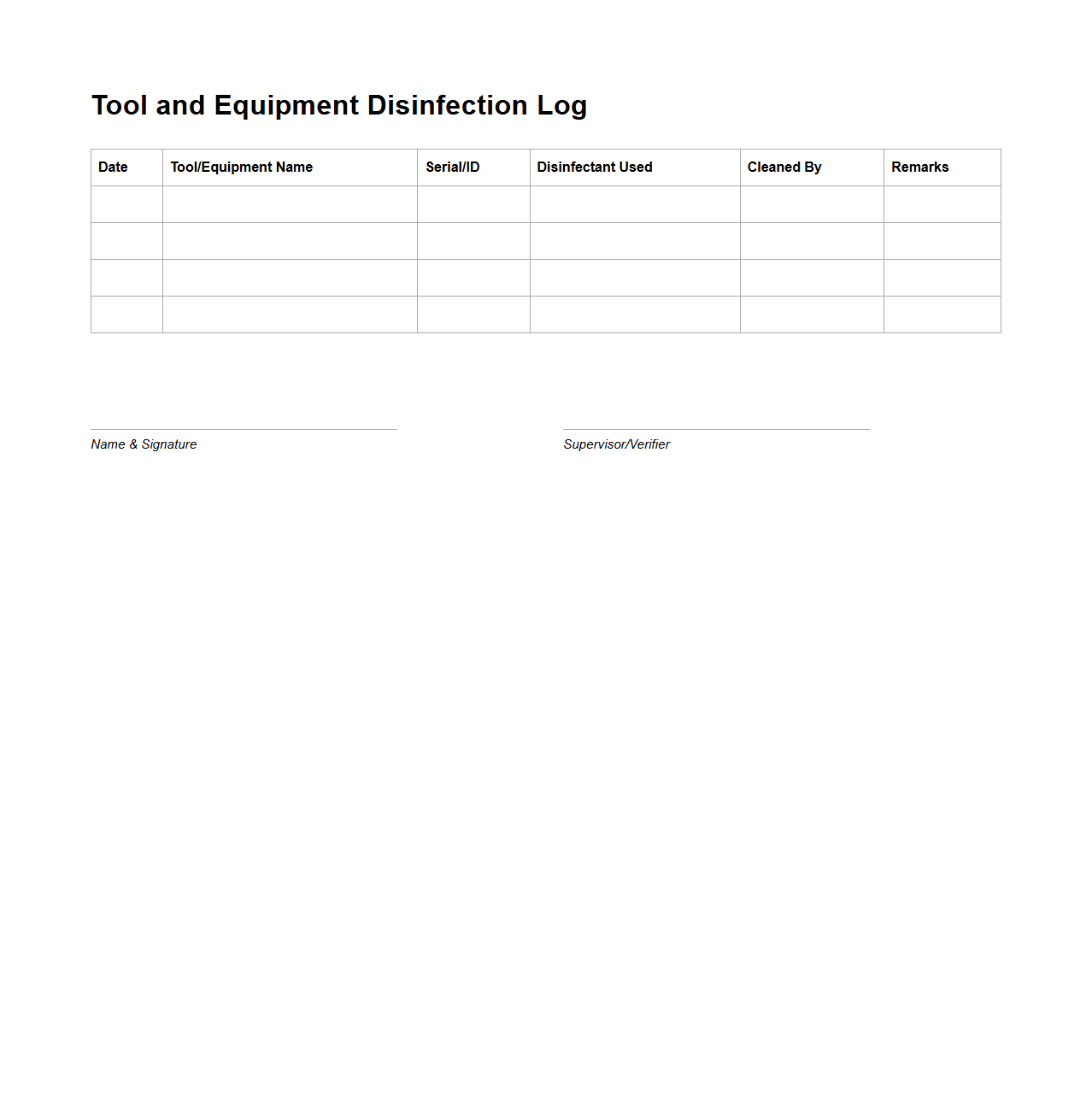

Tool and Equipment Disinfection Log

A

Tool and Equipment Disinfection Log document is a systematic record used to track the cleaning and sanitization of tools and equipment in various settings such as healthcare, manufacturing, and food production. It ensures compliance with hygiene standards by documenting the date, time, method of disinfection, and personnel responsible. This log helps prevent contamination, maintain safety protocols, and supports auditing processes for quality control.

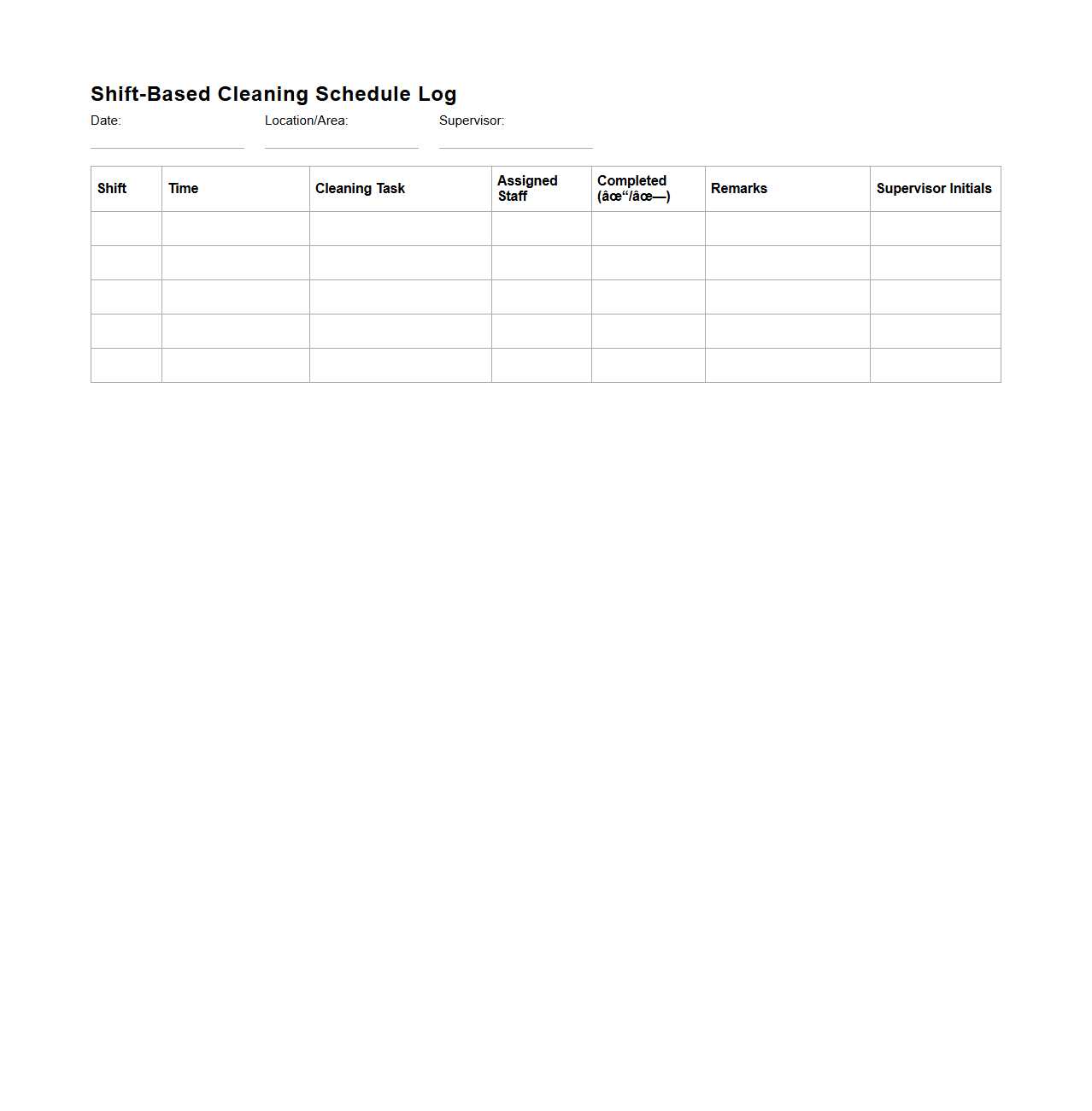

Shift-Based Cleaning Schedule Log

A

Shift-Based Cleaning Schedule Log document is a detailed record used to track cleaning tasks completed during specific work shifts in various settings such as offices, hospitals, and manufacturing facilities. It ensures accountability by documenting the time, cleaning activities performed, and personnel responsible, helping maintain hygiene standards and operational efficiency. This log supports regulatory compliance and can be used for auditing and optimizing cleaning processes.

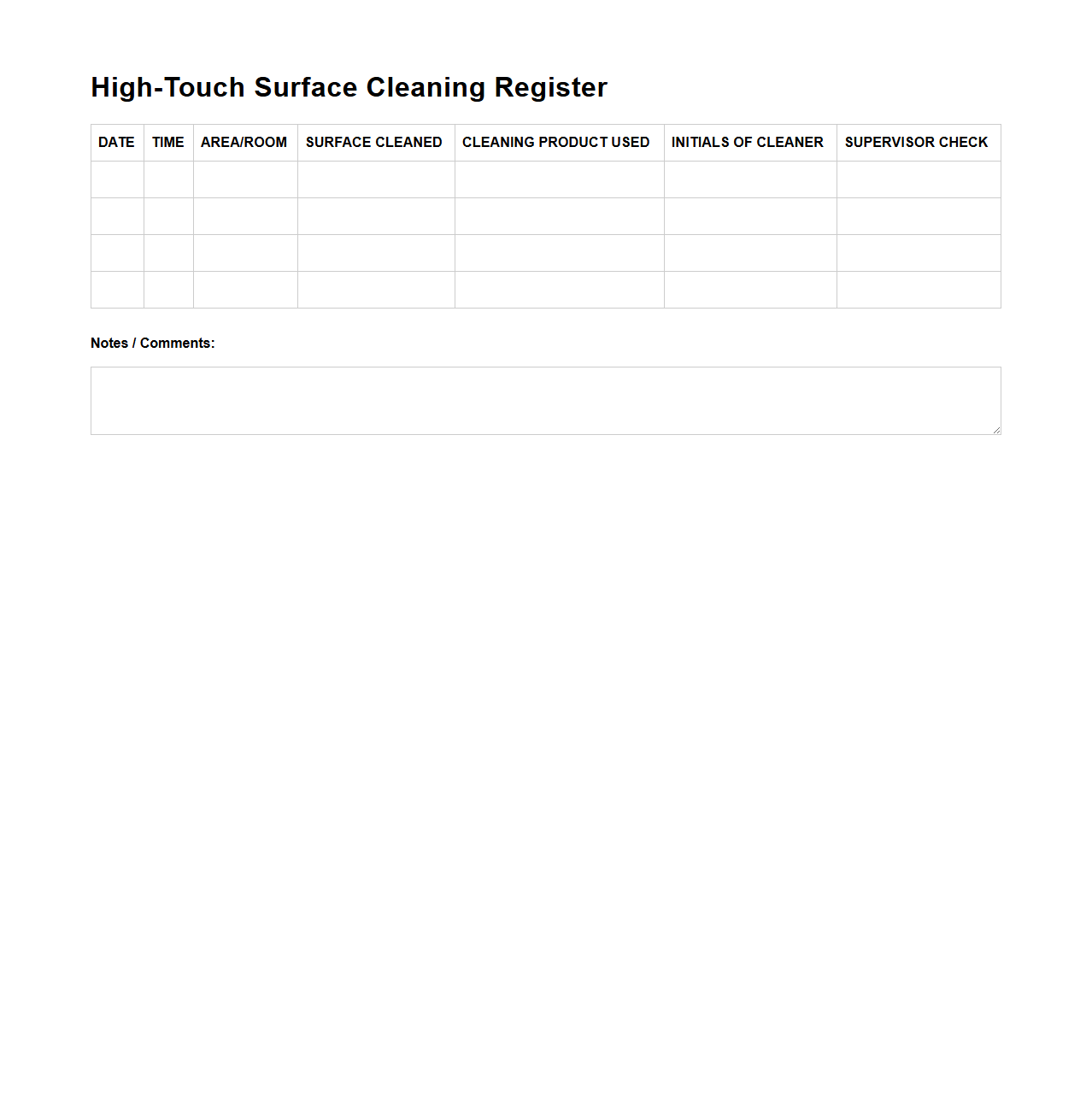

High-Touch Surface Cleaning Register

The

High-Touch Surface Cleaning Register document is a detailed log used to track the cleaning and disinfection of frequently touched surfaces in environments such as hospitals, offices, and public spaces. It ensures accountability by recording the date, time, cleaning agent used, and the personnel responsible for each cleaning task. This register helps maintain hygiene standards, reduce the risk of cross-contamination, and supports compliance with health and safety regulations.

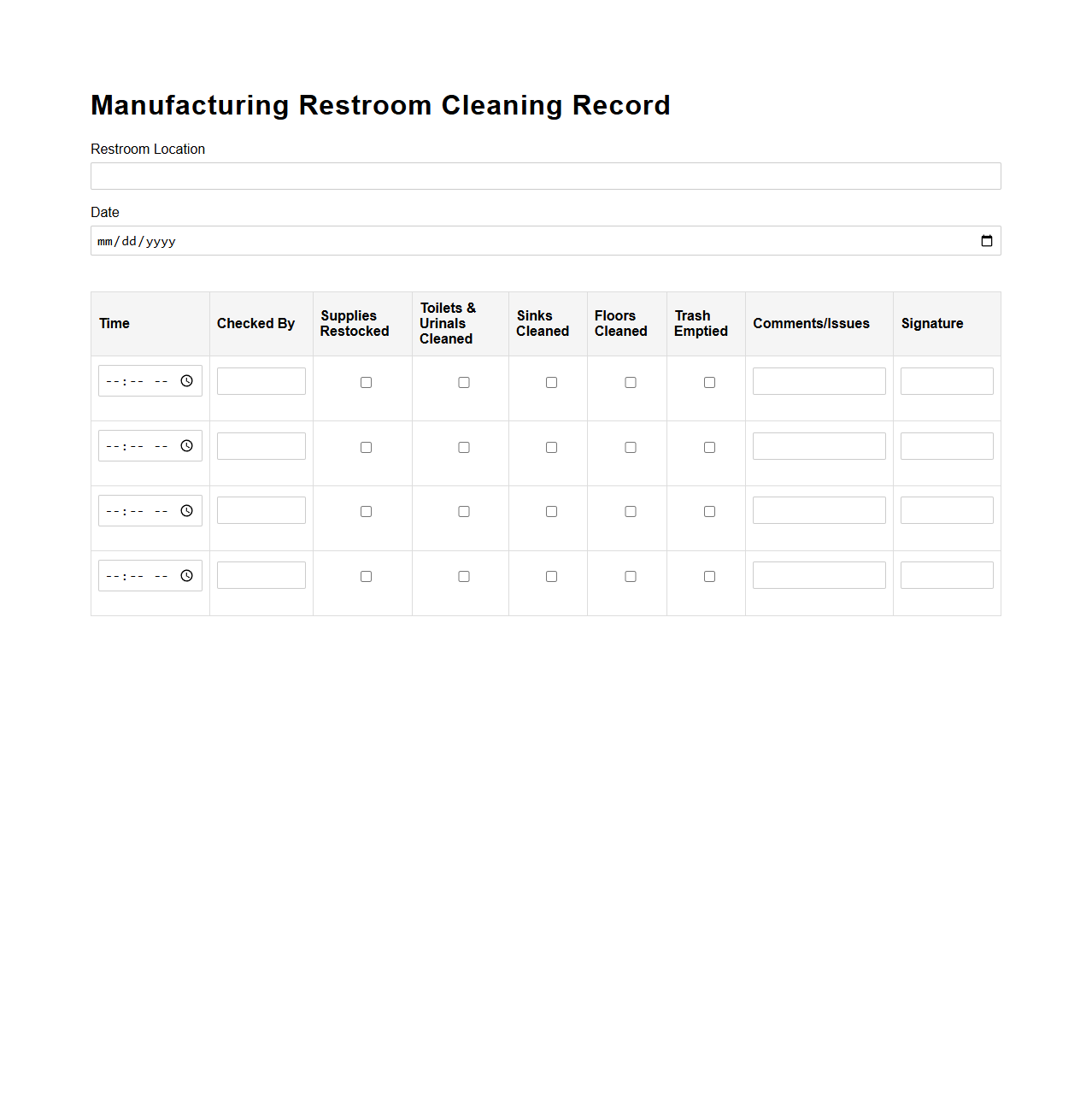

Manufacturing Restroom Cleaning Record

A

Manufacturing Restroom Cleaning Record document is a detailed log used to track the cleaning schedule, tasks performed, and responsible personnel for restrooms within a manufacturing facility. It ensures compliance with hygiene standards and regulatory requirements by documenting the frequency and quality of cleaning activities. This record supports quality control and workplace safety by maintaining a sanitized environment critical for manufacturing operations.

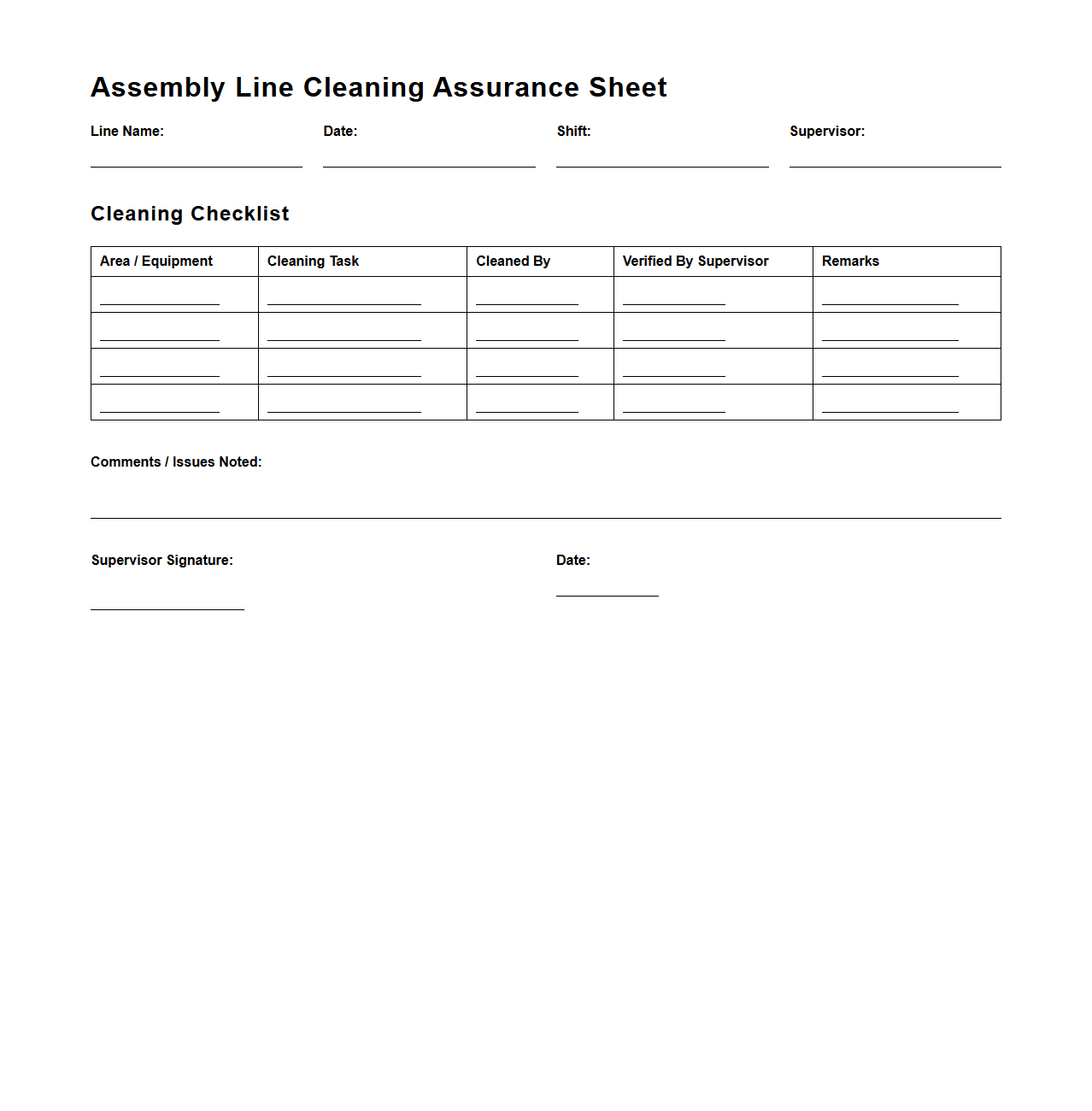

Assembly Line Cleaning Assurance Sheet

The

Assembly Line Cleaning Assurance Sheet is a critical document used in manufacturing environments to verify and record the cleanliness of assembly lines before production begins. It ensures that all equipment and surfaces meet predefined hygiene standards, reducing contamination risks and maintaining product quality. This sheet typically includes checklists, cleaning procedures, responsible personnel, and timestamps to provide a clear audit trail for quality control compliance.

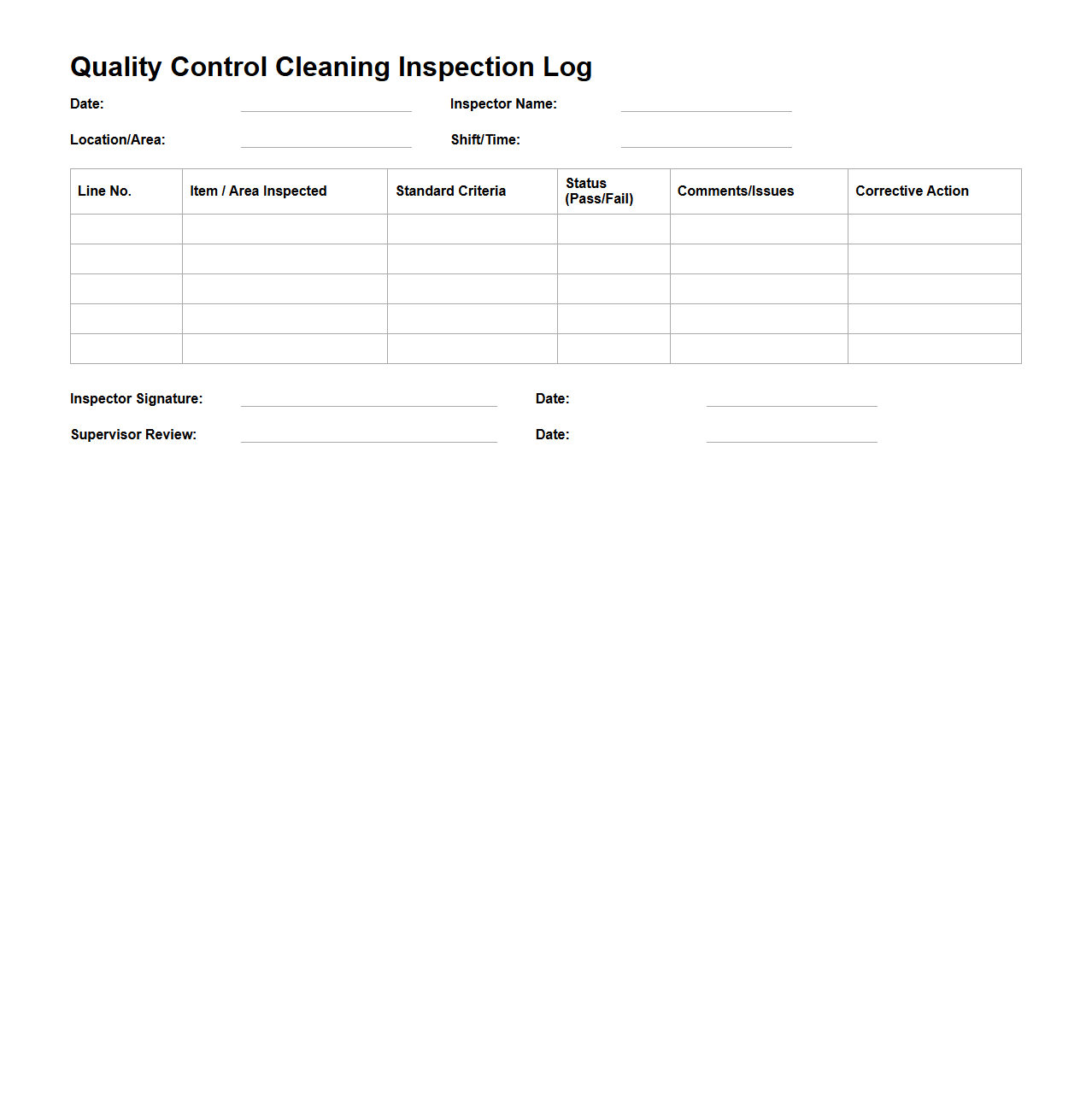

Quality Control Cleaning Inspection Log

A

Quality Control Cleaning Inspection Log document systematically records the results of cleaning inspections to ensure compliance with established hygiene and cleanliness standards. It serves as a critical tool for tracking cleaning activities, identifying potential issues, and maintaining accountability in environments such as manufacturing plants, healthcare facilities, and food processing units. This log supports regulatory compliance and continuous quality improvement by providing verifiable evidence of cleaning performance.

What critical information must be recorded in a manufacturing cleaning log document?

The cleaning log document must record detailed information about the cleaning process, including date and time of cleaning activity. It should also capture the type of cleaning materials used and the methods applied to ensure thorough sanitation. Additionally, recording any deviations or issues encountered during cleaning is essential for quality control and traceability.

Which cleaning frequency and schedule details are typically documented?

Cleaning logs typically include the frequency of cleaning activities, such as daily, weekly, or after specific production runs. The schedule detailing exact times or production stages when cleaning is required must be recorded to maintain consistency. This documentation helps prevent contamination and ensures that cleaning aligns with production demands.

How is personnel accountability established within the cleaning log?

Personnel accountability is ensured by requiring signatures or initials of the individuals performing the cleaning in the cleaning log. The log should also document the time of cleaning and supervisor verification to maintain oversight. This process guarantees that authorized and trained staff handle cleaning processes, enhancing responsibility and compliance.

What specific equipment or areas are identified for cleaning in the sample document?

The cleaning log specifically lists equipment and areas critical to manufacturing, such as mixing machines, conveyor belts, and storage tanks. It also identifies sanitation zones like production floors, walls, and drains to ensure comprehensive coverage. This focused identification helps target cleaning efforts where contamination risk is highest.

How does the document ensure compliance with manufacturing regulatory standards?

The cleaning log incorporates regulatory compliance by adhering to standards set by organizations such as FDA and GMP. It includes detailed records that can be audited to verify cleaning practices meet legal and safety requirements. Proper documentation helps prevent product contamination and supports quality assurance in manufacturing operations.

More Manufacturing Templates