A Incoming Inspection Report Document Sample for Components provides a detailed template for recording the quality and condition of received parts. It includes key information such as part specifications, inspection results, and any detected defects to ensure compliance with standards. This document helps streamline quality control processes and supports efficient supplier evaluation.

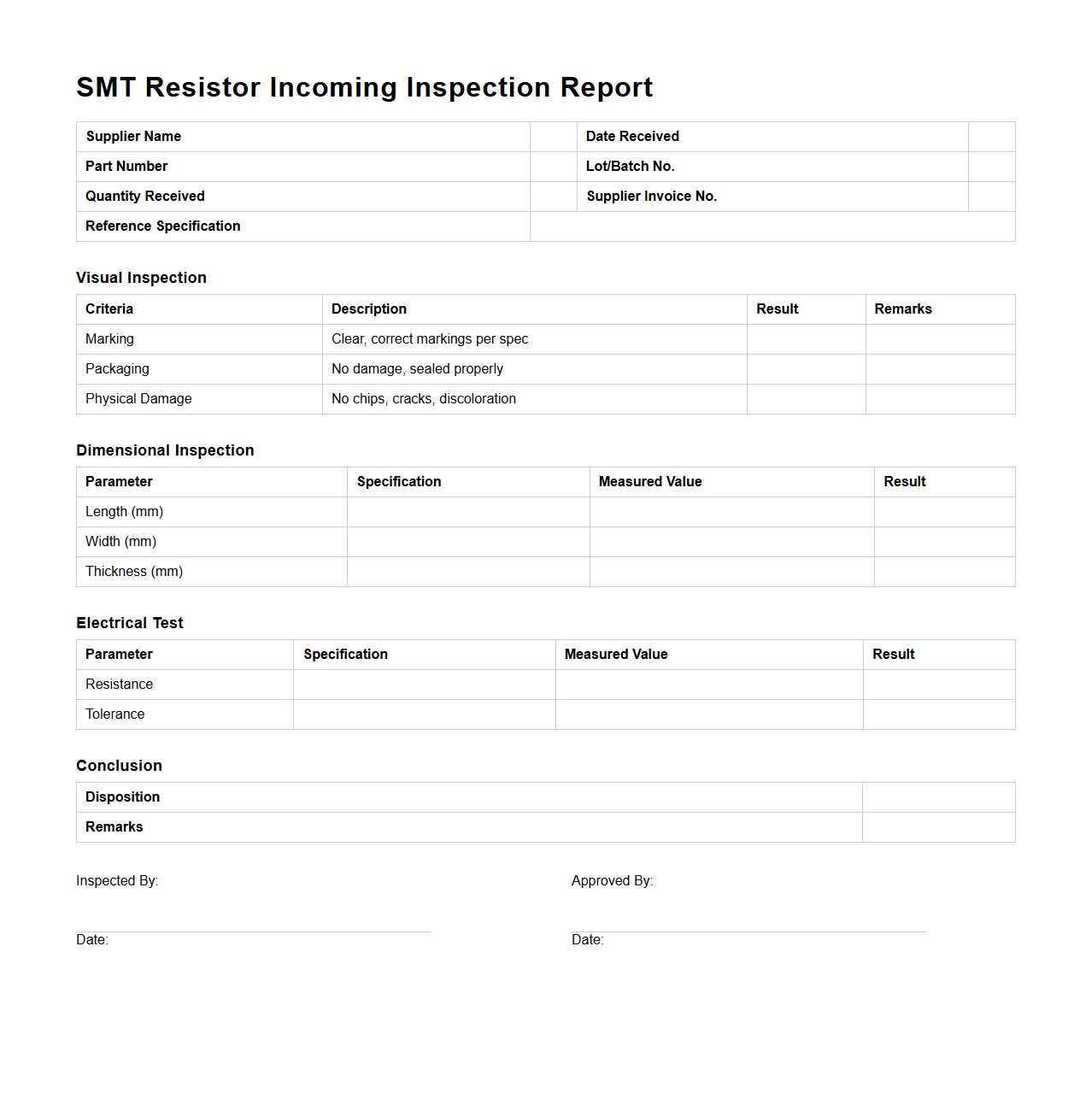

SMT Resistor Incoming Inspection Report Sample

The

SMT Resistor Incoming Inspection Report Sample document records the quality and specifications of surface-mount technology (SMT) resistors upon receipt from suppliers. It details parameters such as resistance value, tolerance, packaging condition, and quantity verification to ensure compliance with industry standards. This report serves as a critical tool for quality control teams to identify defects early and maintain component reliability in electronics manufacturing.

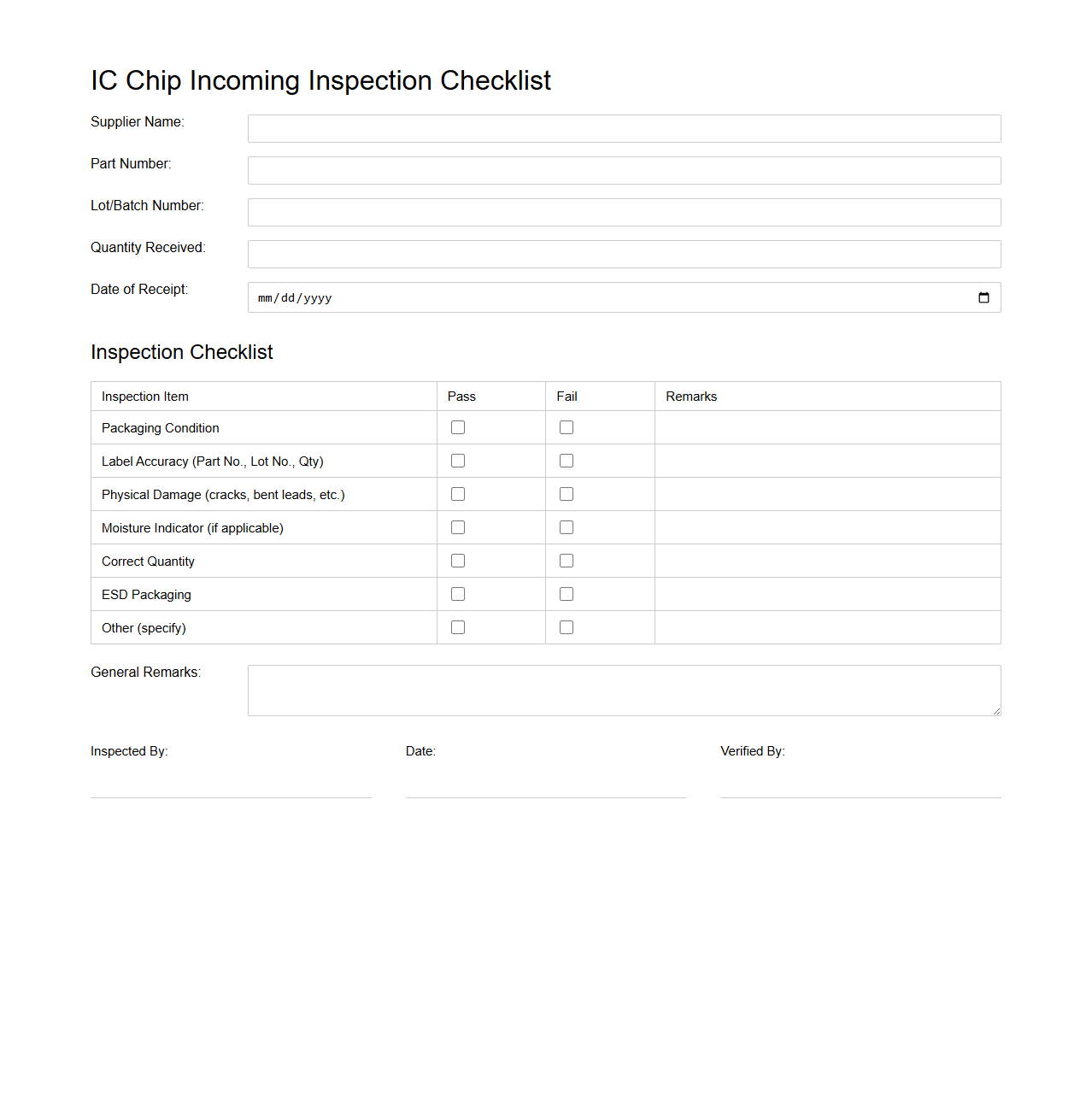

IC Chip Incoming Inspection Checklist Example

The

IC Chip Incoming Inspection Checklist Example document is a crucial tool used by quality assurance teams to verify the condition and specifications of integrated circuit chips upon receipt. It details specific inspection criteria such as package integrity, pin alignment, labeling accuracy, and compliance with supplier documentation to ensure chips meet industry standards. This checklist helps prevent defective components from entering the production line, thereby reducing manufacturing risks and enhancing overall product reliability.

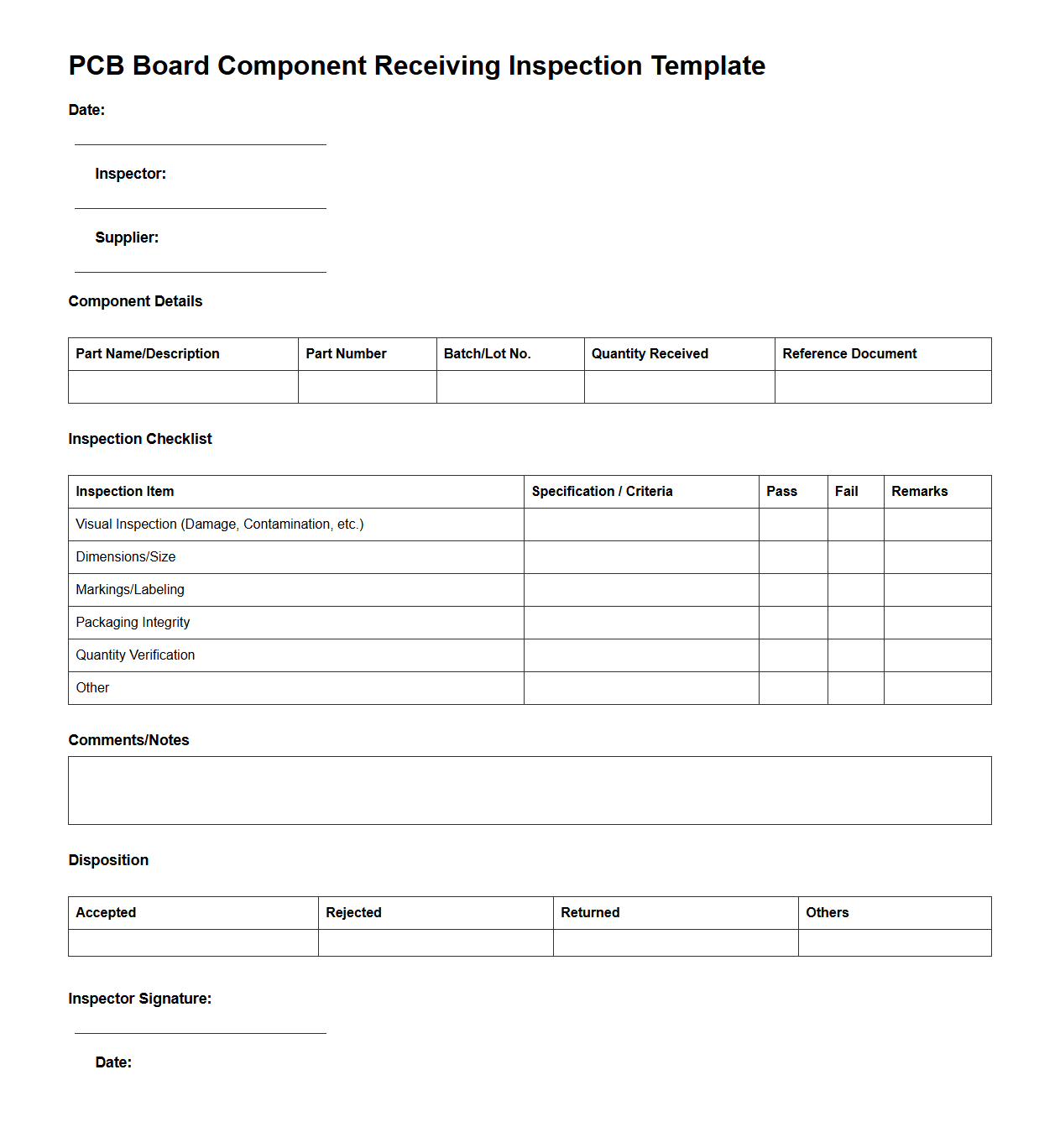

PCB Board Component Receiving Inspection Template

The

PCB Board Component Receiving Inspection Template document is used to systematically verify the quality and accuracy of electronic components received for printed circuit board assembly. It includes specific criteria such as component specifications, visual defects, part numbers, and quantity checks to ensure compliance with procurement requirements. This template helps prevent defective or incorrect parts from entering the production line, thus improving manufacturing reliability and product quality.

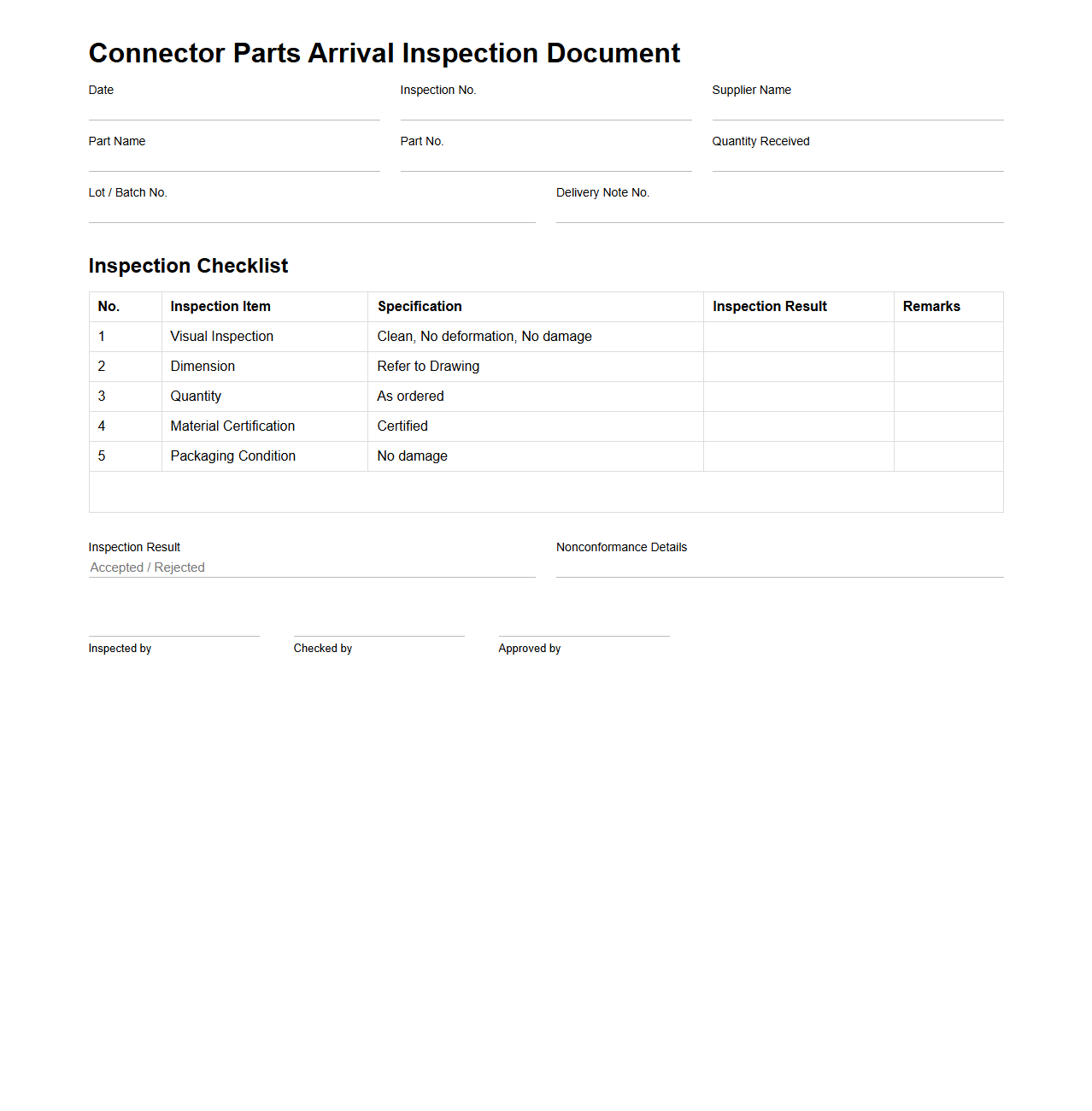

Connector Parts Arrival Inspection Document

The

Connector Parts Arrival Inspection Document serves as a critical record verifying the quality and conformity of connector parts upon delivery. It details inspection criteria such as dimensional accuracy, material specification, and functional testing results to ensure components meet industry standards. This document helps prevent defective parts from entering production, maintaining reliability and efficiency in manufacturing processes.

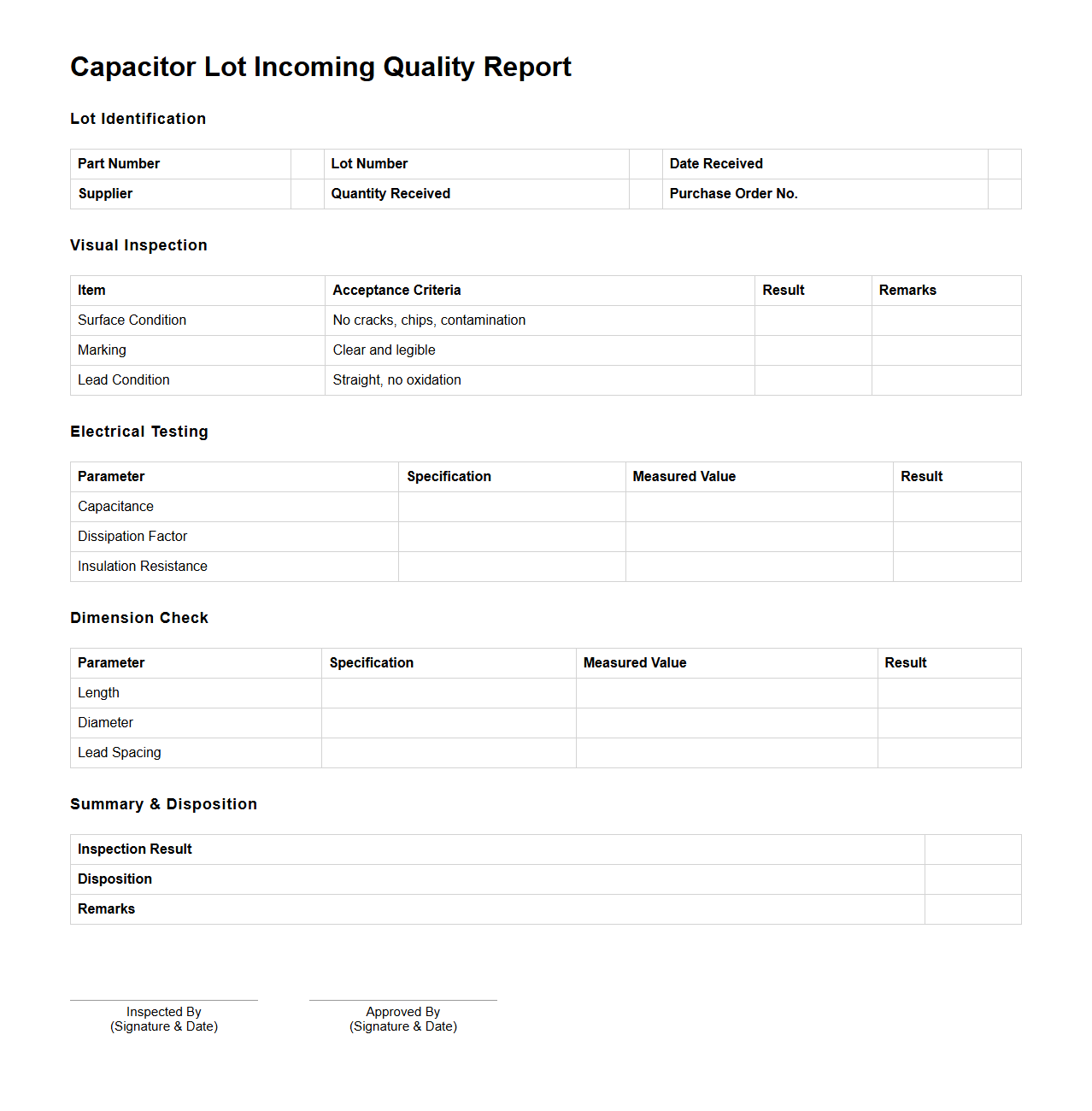

Capacitor Lot Incoming Quality Report Sample

The

Capacitor Lot Incoming Quality Report sample document serves as a detailed record used to evaluate the quality and specifications of capacitor batches received from suppliers. It includes key data points such as capacitance values, tolerance levels, voltage ratings, and physical condition checks to ensure compliance with industry standards before use in production. This report is essential for identifying any defects or deviations early, minimizing risks and maintaining product reliability.

Transistor First Article Inspection Form

The

Transistor First Article Inspection Form is a critical quality assurance document used to verify the specifications and performance of a transistor before mass production. It ensures that parameters such as electrical characteristics, physical dimensions, and material composition meet the design requirements established by industry standards or customer specifications. This form helps manufacturers detect defects early, reduce production errors, and maintain consistent quality control throughout the manufacturing process.

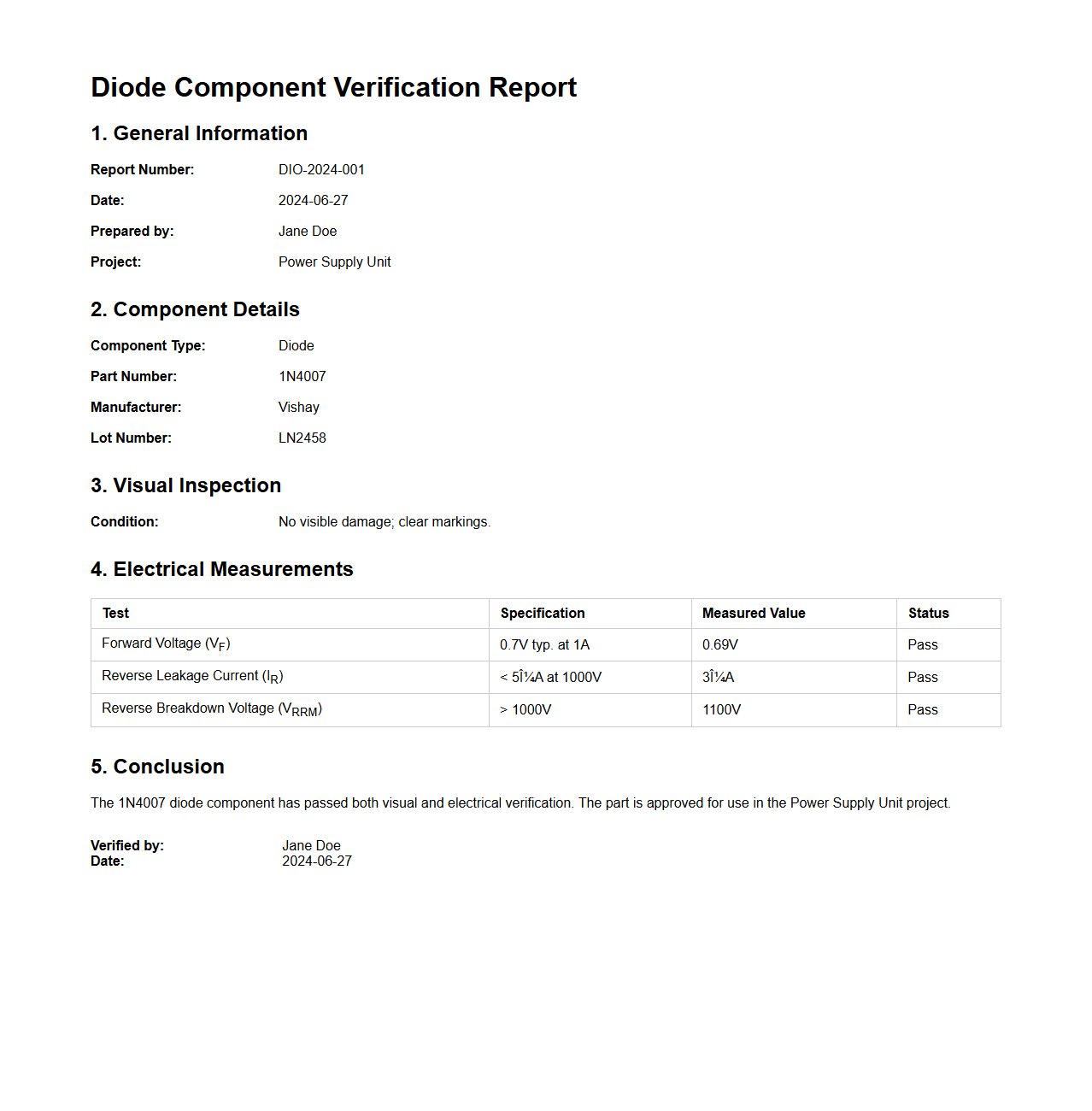

Diode Component Verification Report Example

The

Diode Component Verification Report Example document provides a comprehensive analysis of a diode's electrical and physical characteristics to ensure it meets specified standards and performance criteria. It includes test results such as forward voltage, leakage current, and reverse recovery time, alongside visual inspections and compliance assessments. This report is essential for quality assurance in semiconductor manufacturing and product development.

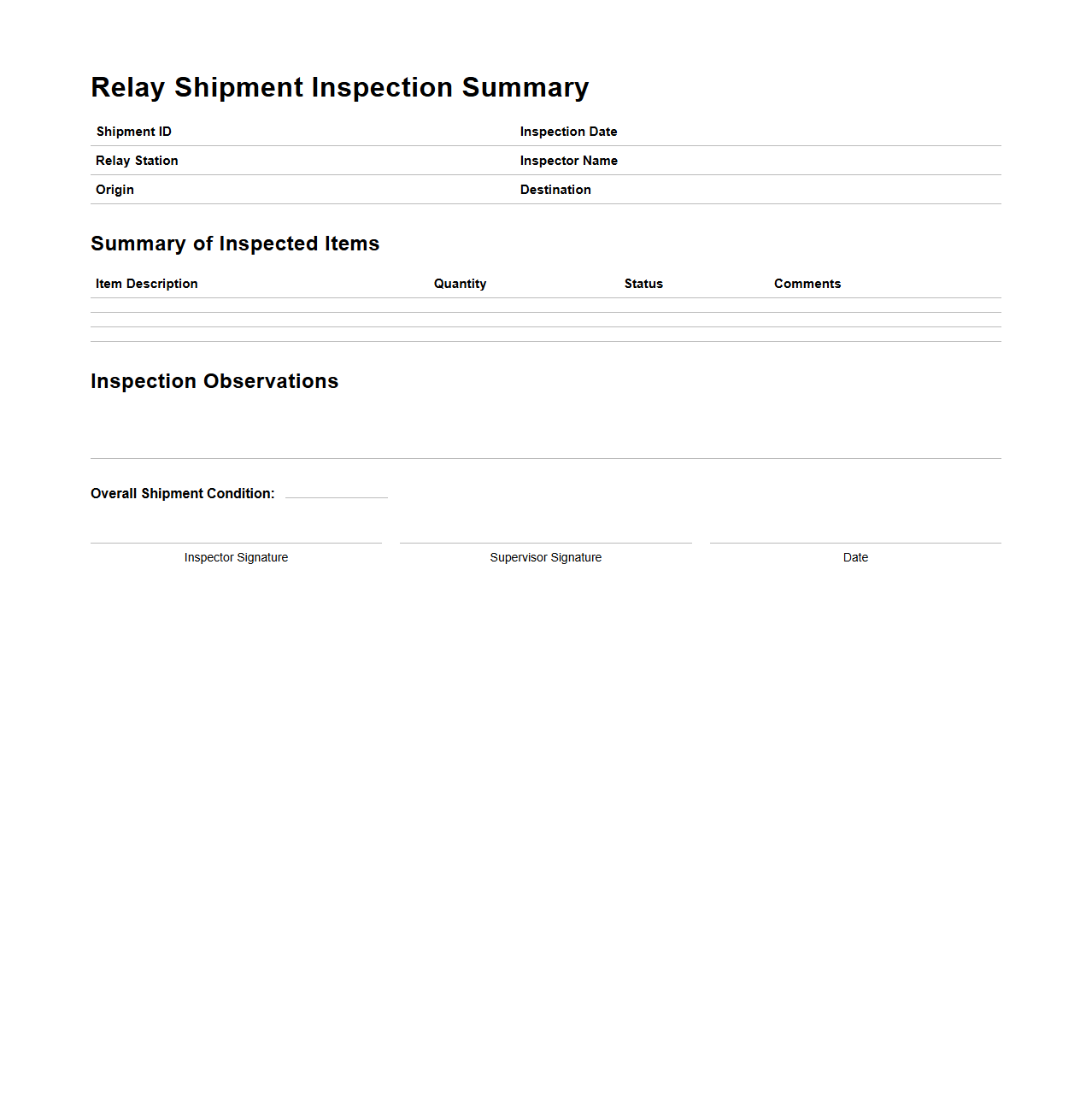

Relay Shipment Inspection Summary Template

The

Relay Shipment Inspection Summary Template document serves as a structured format to record and evaluate the inspection results of shipments during transit. It consolidates key information such as shipment ID, inspection date, item conditions, discrepancies found, and compliance status, enabling efficient tracking and quality assurance. This template supports logistics teams in maintaining transparency, accountability, and timely resolution of shipment issues.

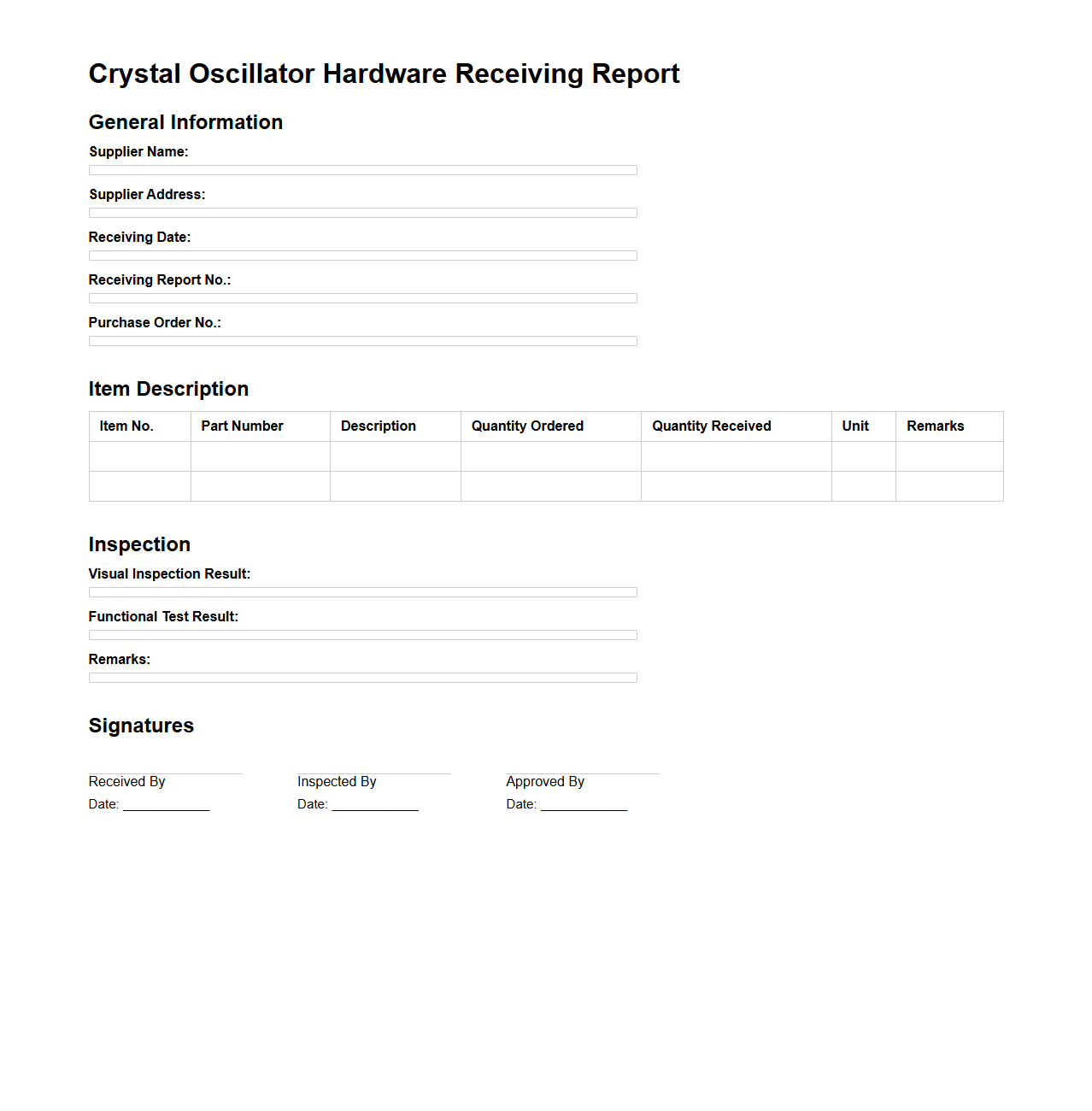

Crystal Oscillator Hardware Receiving Report

The

Crystal Oscillator Hardware Receiving Report document serves as a formal record verifying the receipt and condition of crystal oscillator components during hardware procurement. It details specifications such as frequency stability, load capacitance, and physical integrity to ensure compliance with technical requirements. This report is critical for quality control and traceability in electronic manufacturing processes.

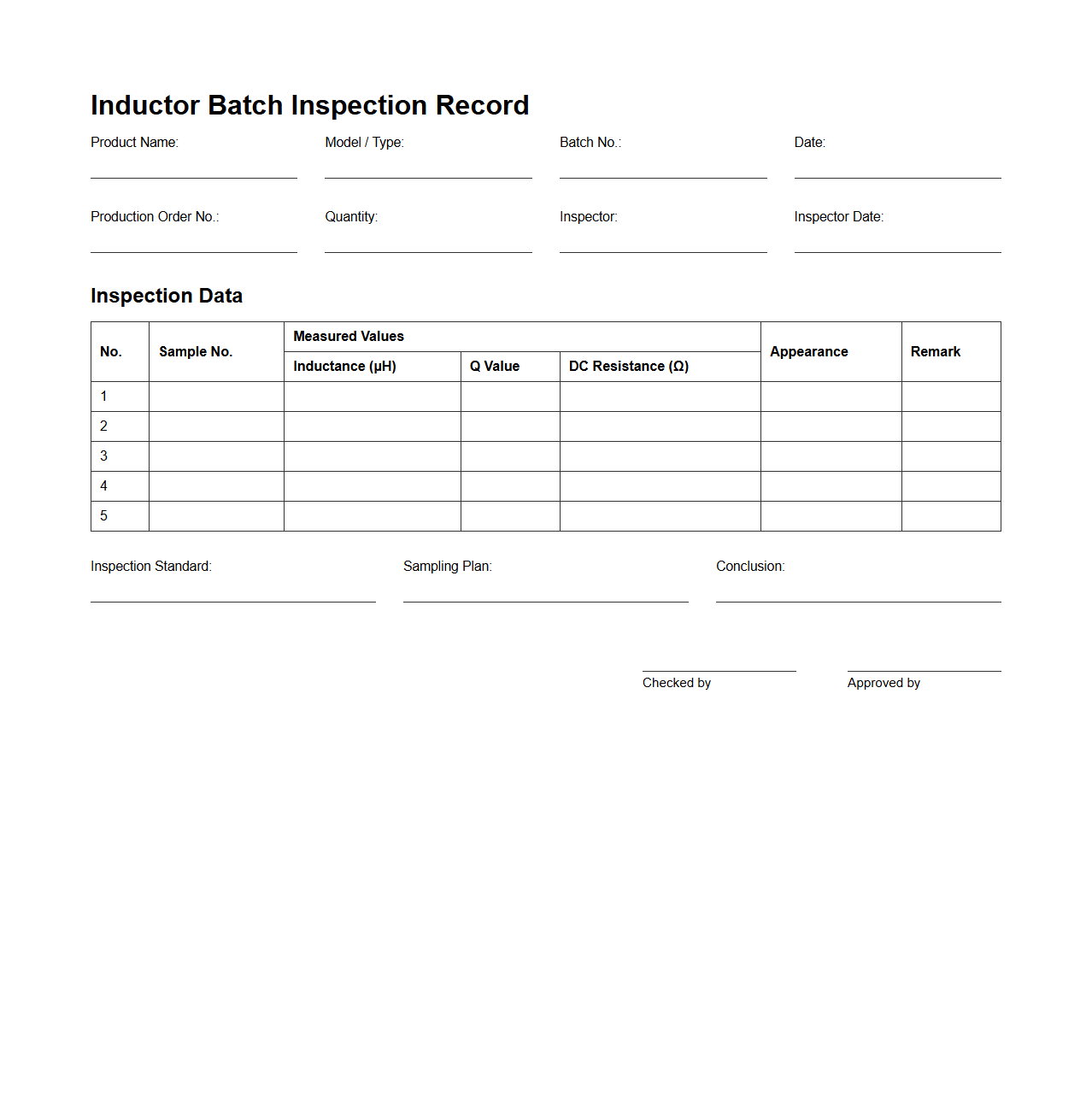

Inductor Batch Inspection Record Sample

An

Inductor Batch Inspection Record Sample document serves as a detailed template used in quality control to systematically record inspection results of inductors during manufacturing. It includes critical parameters such as inductance values, tolerance levels, visual defects, and batch identification numbers to ensure compliance with industry standards. This document aids in traceability and quality assurance by providing a comprehensive overview of each batch's inspection data.

What key information must be recorded in the Incoming Inspection Report for each component received?

The Incoming Inspection Report must capture essential details such as component identification, quantity received, and condition upon arrival. Recording the supplier information and unique serial or batch numbers is crucial for traceability. Additionally, the date of inspection and name of the inspector should be documented to maintain accountability.

Which acceptance criteria should be referenced when evaluating component quality during inspection?

Component quality evaluation should reference the specified standards and purchase order requirements that define acceptable parameters. These acceptance criteria include dimensional tolerances, material specifications, and performance tests outlined by engineering or quality documentation. Inspectors must ensure all criteria are met to confirm compliance before approving components.

How does the document specify procedures for handling nonconforming components?

The document mandates immediate isolation and labeling of nonconforming components to prevent unintended use. It also requires notification to the quality department and initiation of a disposition process such as rework, return to supplier, or scrap. Proper documentation of actions taken ensures traceability and effectiveness of corrective measures.

What documentation or evidence is required to verify supplier compliance in the report?

The report must include certificates of conformity, test results, and inspection records validating supplier compliance with contract specifications. Additional evidence such as calibration certificates for measuring instruments used during inspection reinforces reliability. Documentation supporting supplier audits or corrective actions further strengthens the verification process.

Which traceability features are included to link inspected components to their corresponding purchase orders?

Traceability is maintained via recording the purchase order number, batch or lot numbers, and component serial numbers on the inspection report. This information links the physical components directly to procurement records for accountability. Detailed traceability ensures accurate tracking throughout the supply chain and supports corrective action if necessary.

More Manufacturing Templates