The Raw Material Inspection Document Sample for Manufacturing serves as a critical tool to verify the quality and specifications of incoming materials before production begins. It ensures that raw materials meet industry standards and company requirements, minimizing defects and production delays. Proper documentation supports traceability and compliance with quality control protocols in manufacturing processes.

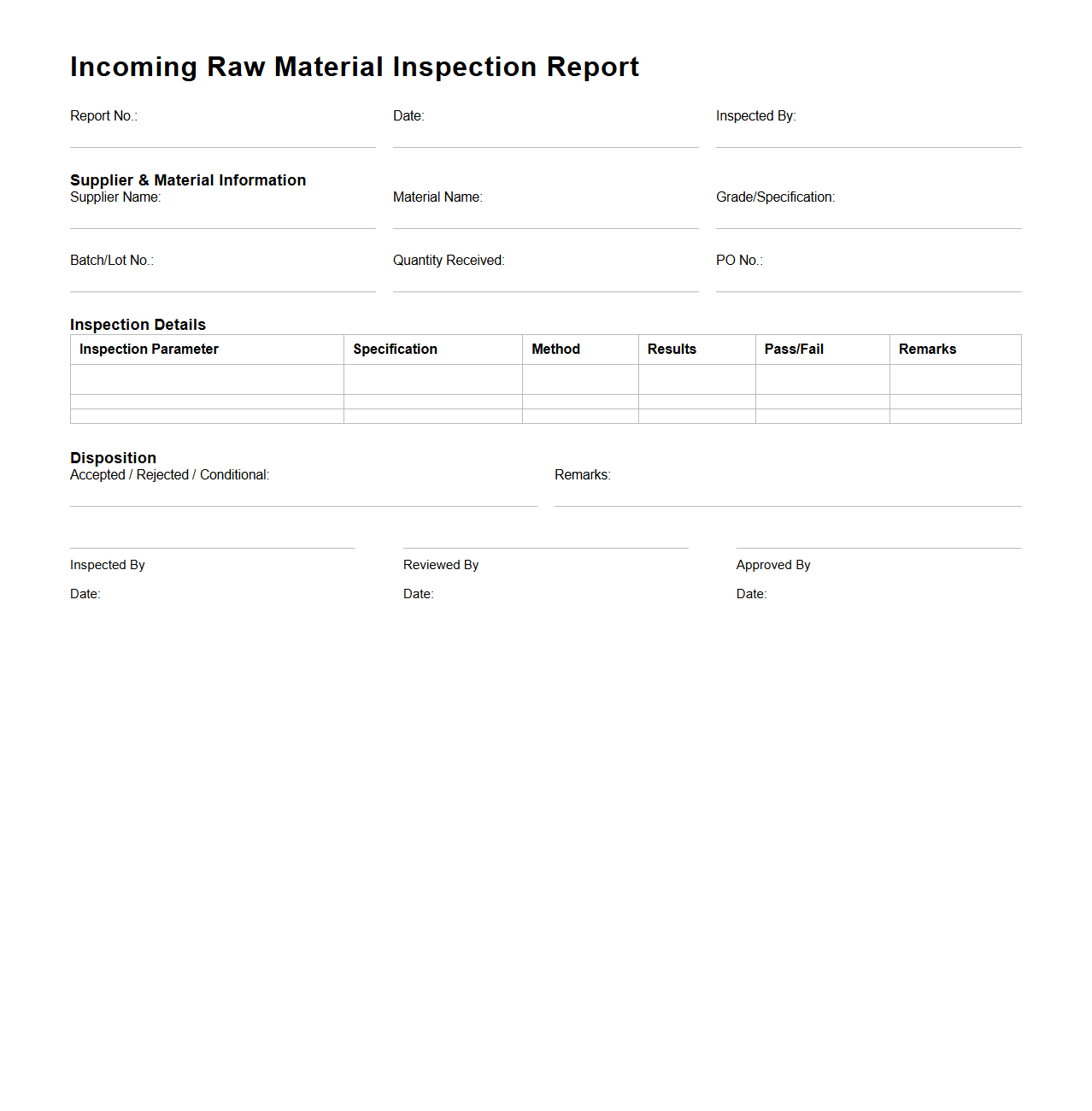

Incoming Raw Material Inspection Report Template

The

Incoming Raw Material Inspection Report Template is a standardized document used to record and evaluate the quality and compliance of raw materials received from suppliers. It ensures that all incoming materials meet specified industry standards and company requirements before entering the production process. This template typically includes fields for material identification, supplier information, inspection criteria, test results, and approval status, facilitating consistent quality control and traceability.

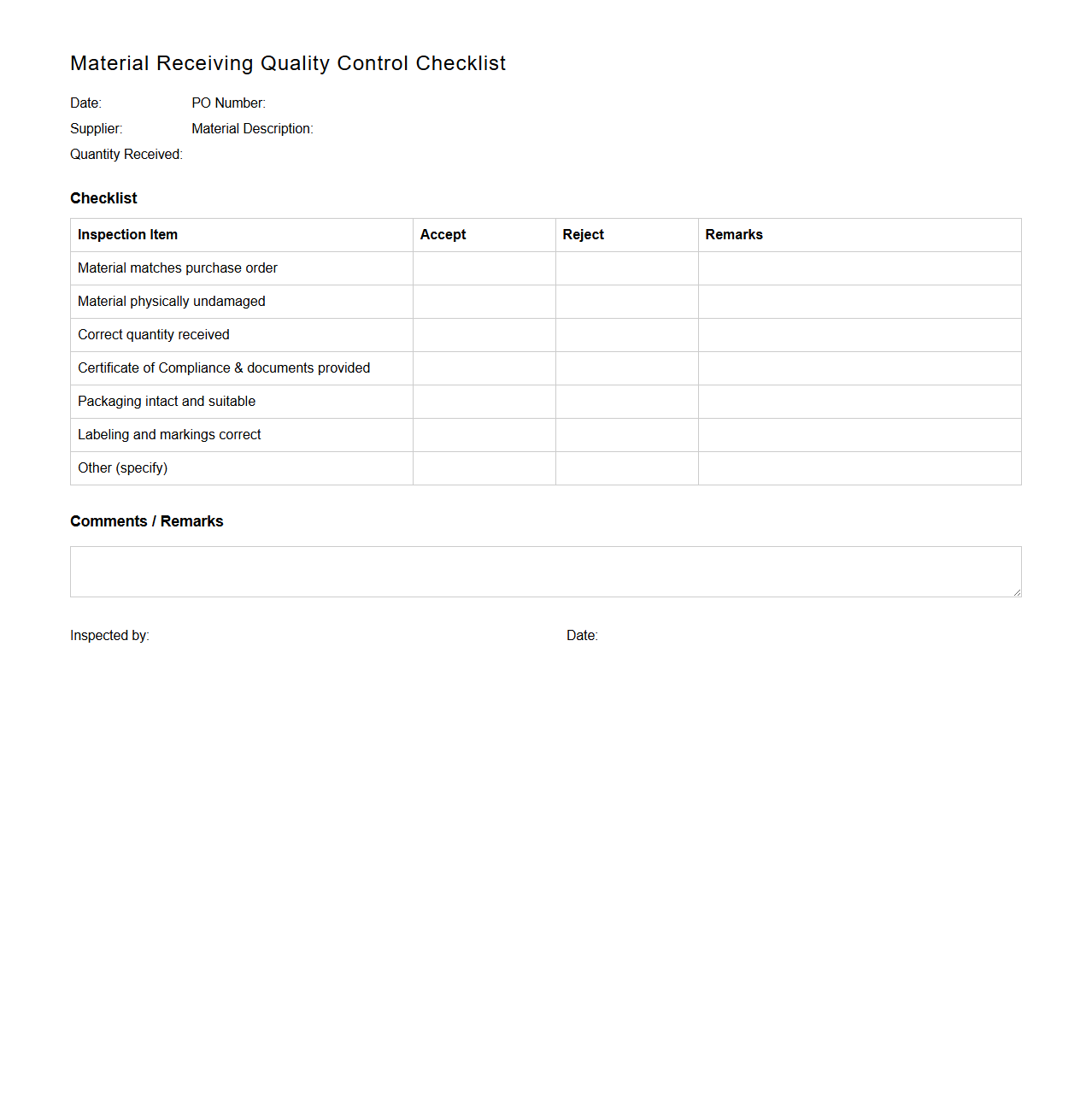

Material Receiving Quality Control Checklist Example

A

Material Receiving Quality Control Checklist Example document is a standardized tool used to verify the quality and specifications of materials upon delivery. It outlines specific criteria such as material type, quantity, condition, and compliance with purchase orders to ensure accuracy and prevent defects. This checklist enhances accountability and streamlines the inspection process in procurement and quality assurance departments.

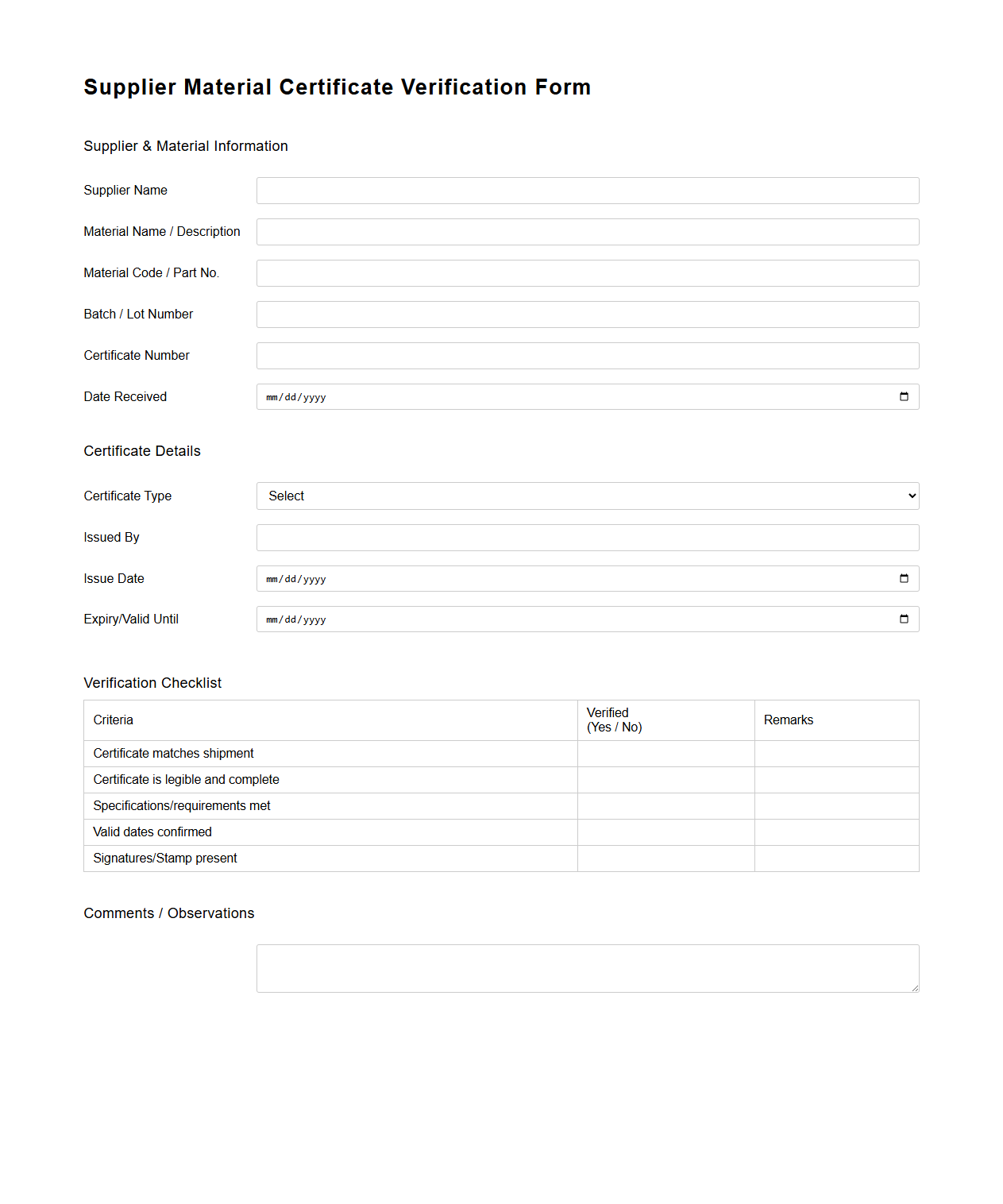

Supplier Material Certificate Verification Form

The

Supplier Material Certificate Verification Form is a document used to confirm the authenticity and compliance of materials supplied by vendors. It verifies that all materials meet specified quality standards, certifications, and regulatory requirements before acceptance. This form plays a crucial role in ensuring traceability, quality assurance, and adherence to procurement policies in manufacturing and construction industries.

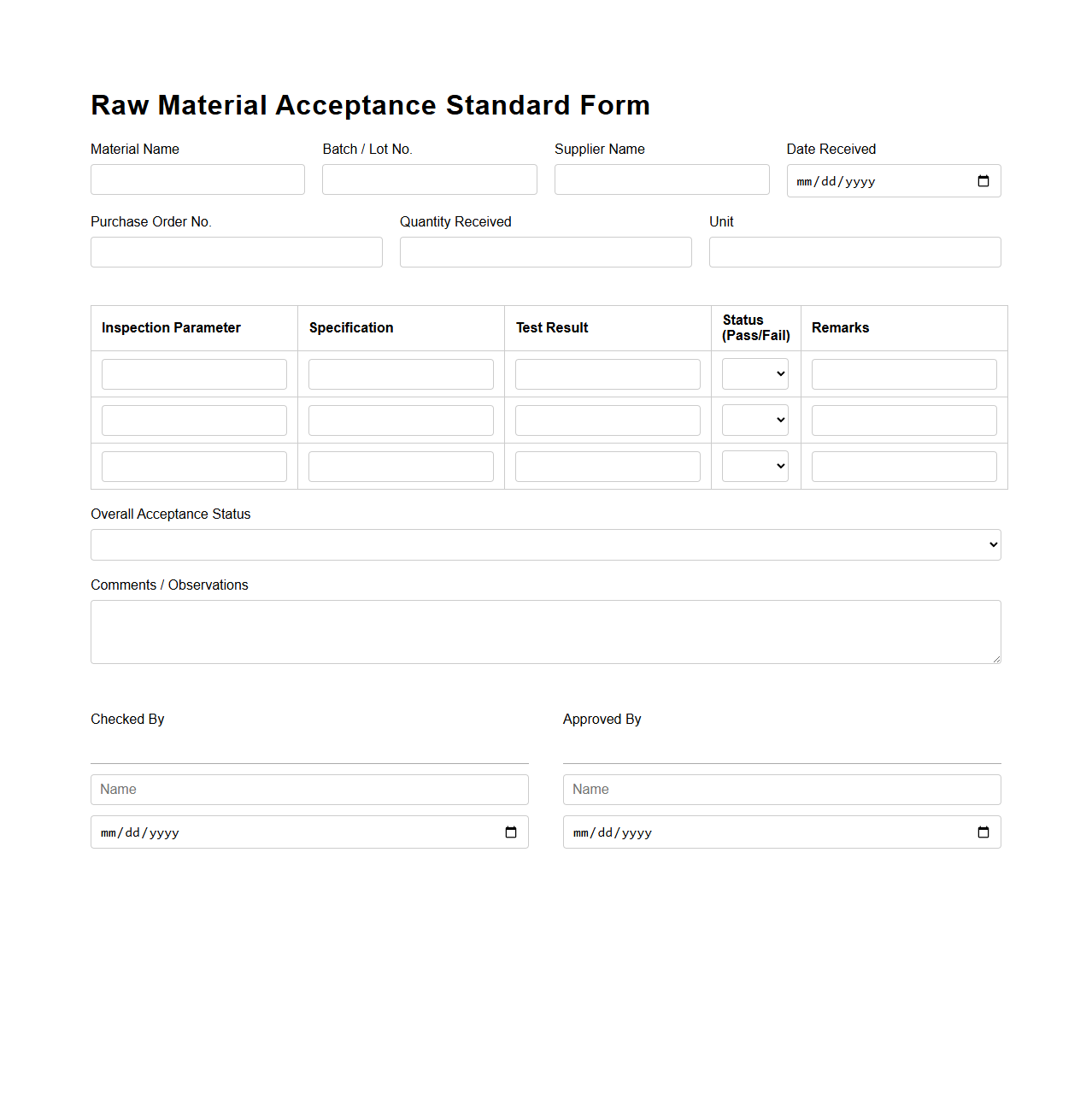

Raw Material Acceptance Standard Form

The

Raw Material Acceptance Standard Form document serves as a critical tool for quality control in manufacturing, ensuring that all incoming raw materials meet predetermined specifications and standards. It details the criteria for material acceptance, including physical properties, chemical composition, and safety requirements, facilitating consistent quality assessments. This form helps prevent the use of substandard materials, reducing production risks and maintaining product integrity throughout the supply chain.

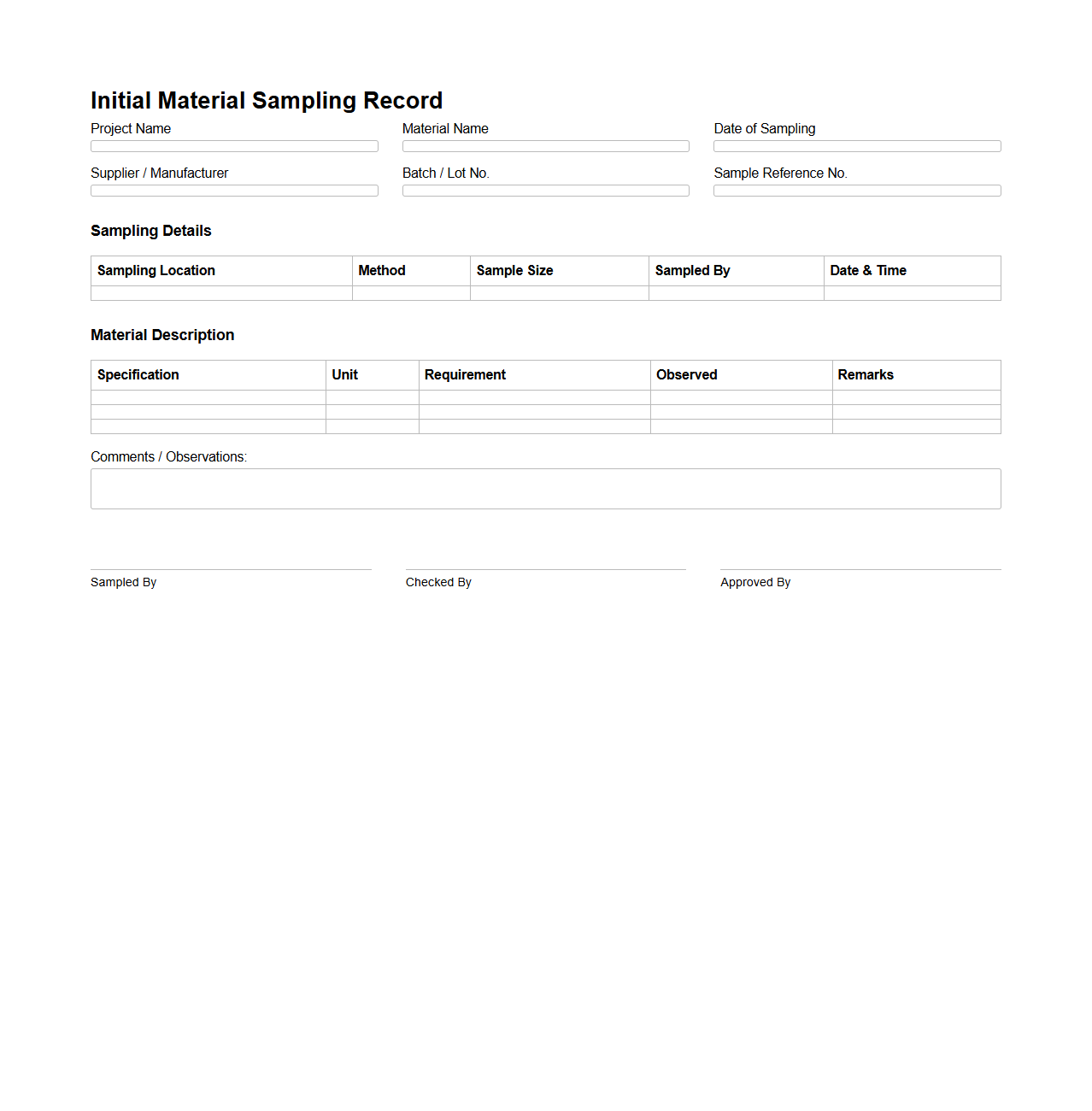

Initial Material Sampling Record Sample

The

Initial Material Sampling Record Sample document serves as a detailed log that captures the first set of material samples collected for quality control and testing purposes. It includes critical data such as sample identification, collection date, source, and specific characteristics, ensuring traceability and compliance with industry standards. This document is essential for validating material quality before production processes begin, reducing the risk of defects and ensuring consistency in manufacturing.

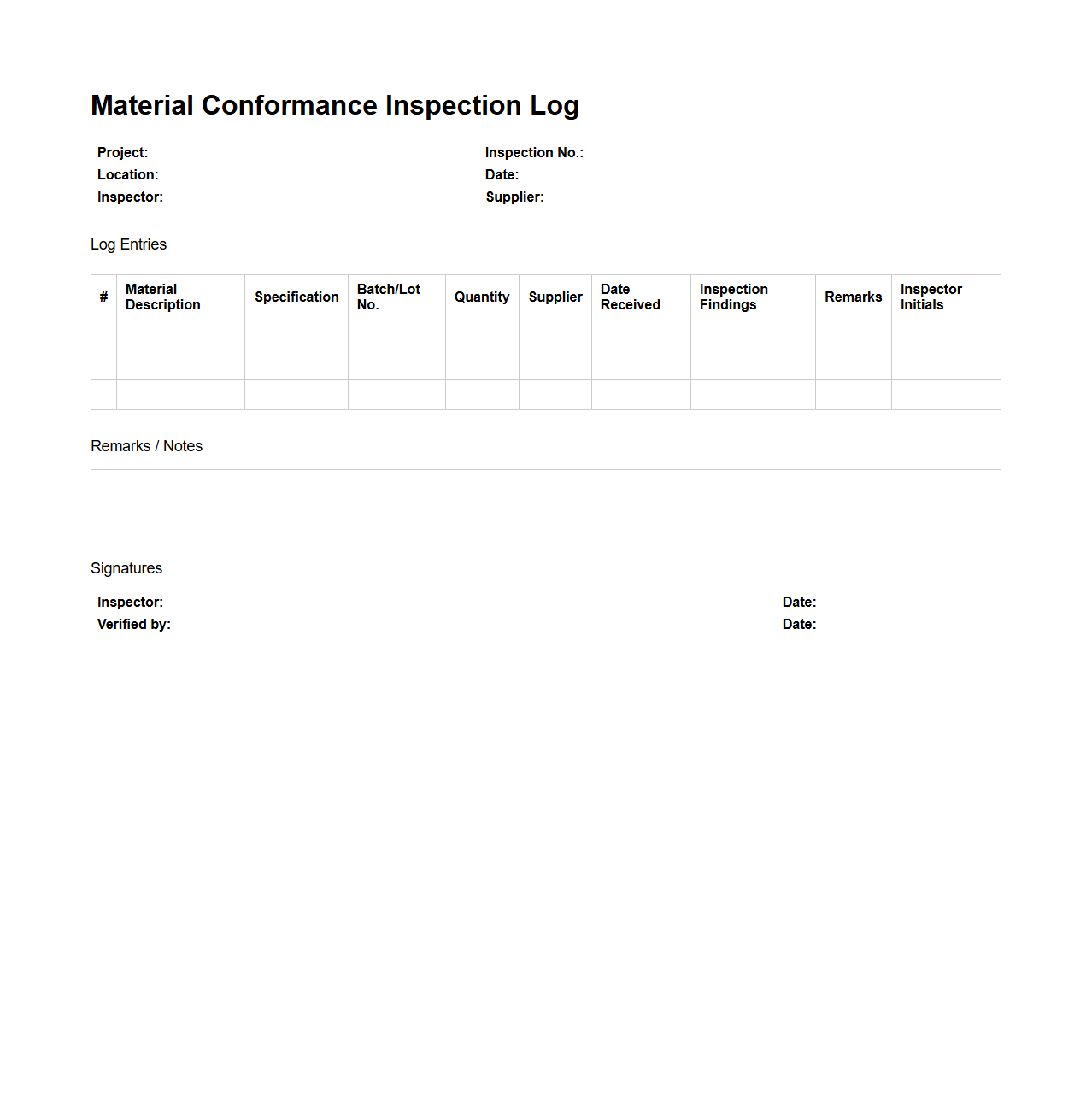

Material Conformance Inspection Log Format

The

Material Conformance Inspection Log Format document serves as a standardized record for verifying that materials meet specified quality standards and project requirements. It systematically captures inspection results, material certifications, and compliance statuses to ensure traceability and accountability throughout the supply chain. This format aids quality assurance teams in maintaining consistent material quality and regulatory adherence during production and construction phases.

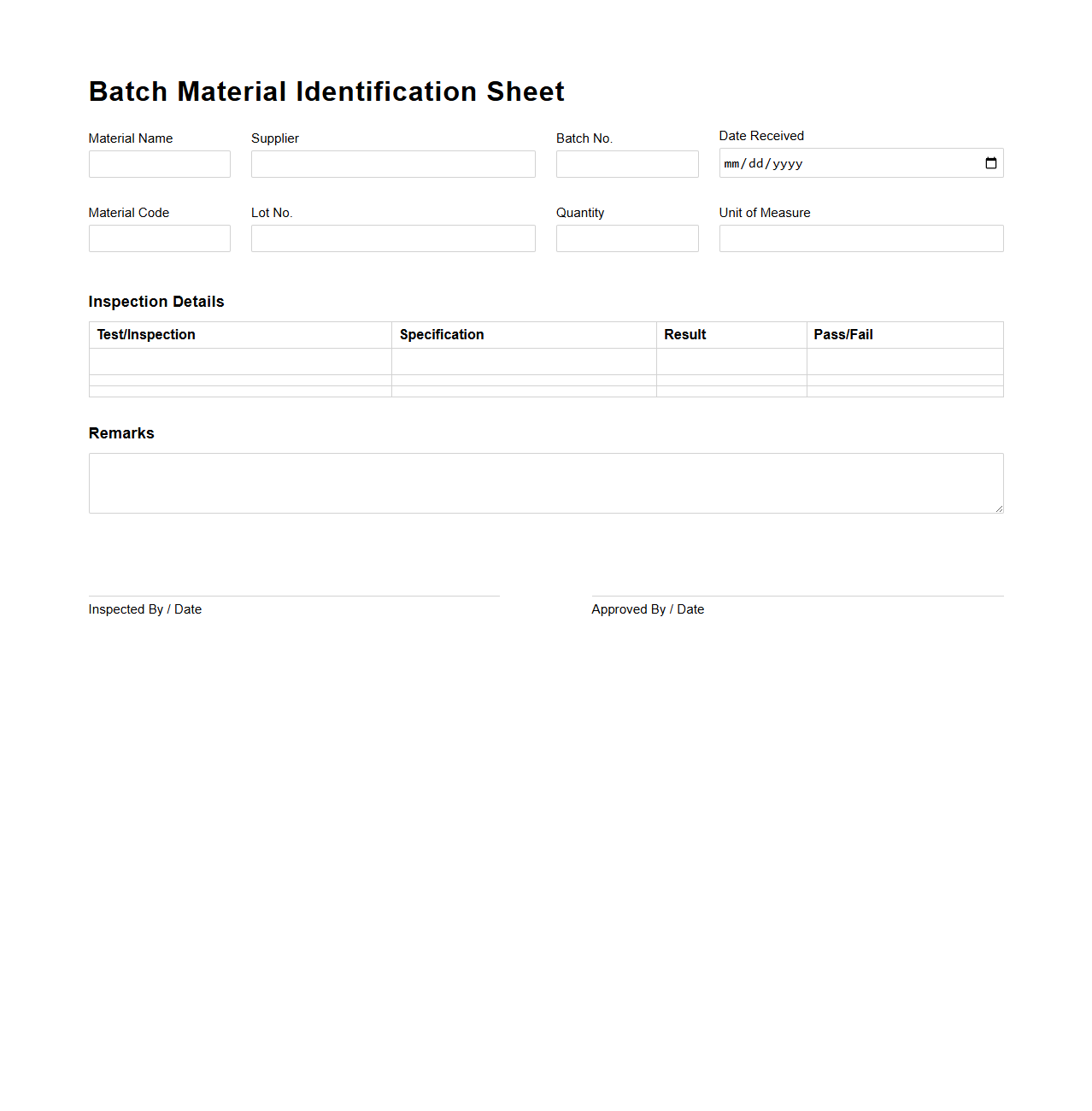

Batch Material Identification Sheet

The

Batch Material Identification Sheet is a critical document used in manufacturing and quality control to track and verify materials used in a specific production batch. It contains detailed information such as material specifications, batch numbers, supplier details, and inspection results to ensure traceability and compliance with industry standards. This document helps reduce errors, maintain quality consistency, and supports effective inventory management throughout the production process.

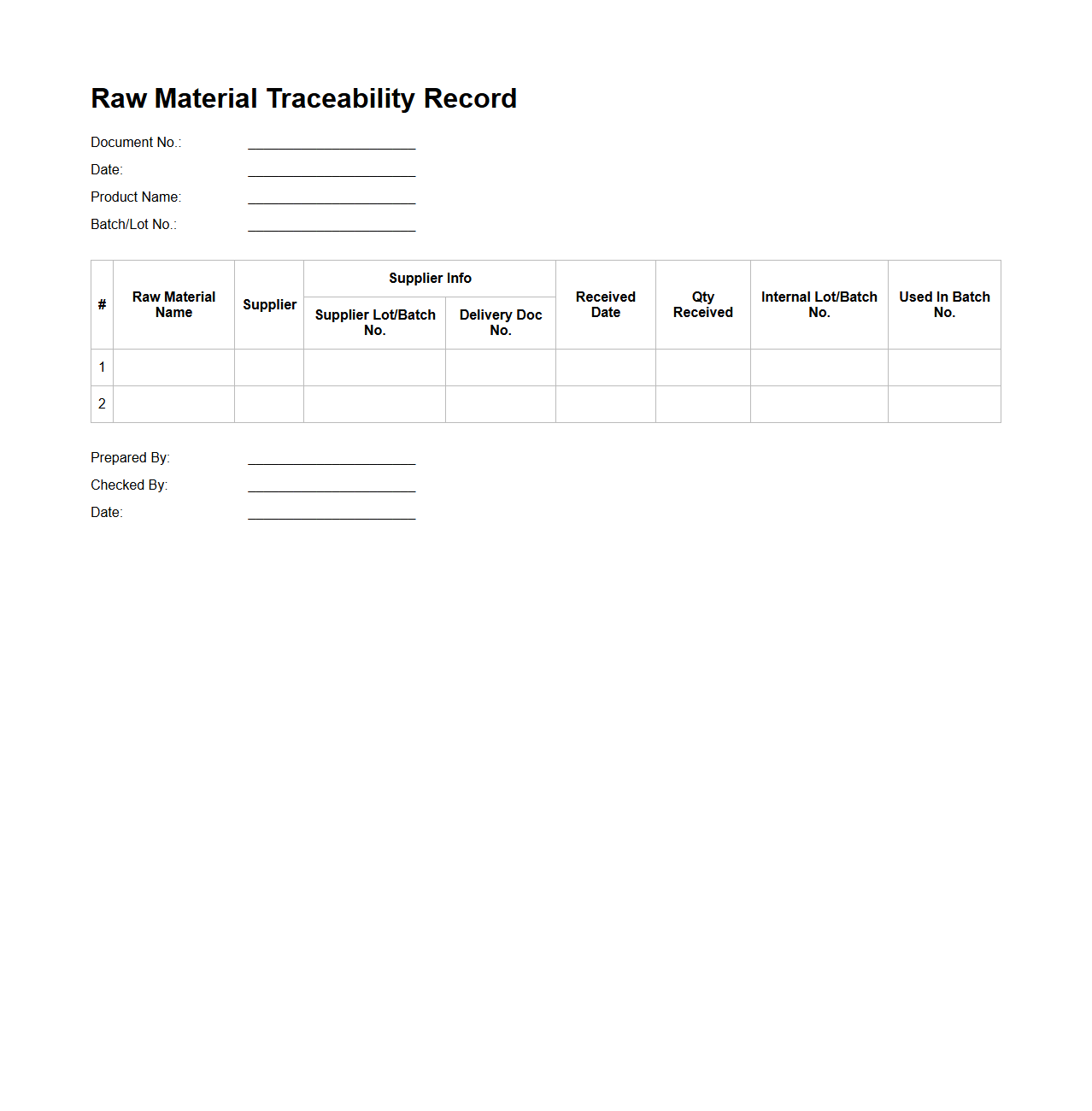

Raw Material Traceability Record Example

A

Raw Material Traceability Record Example document serves as a crucial tool for tracking the origin, batch number, supplier details, and movement history of raw materials used in manufacturing processes. This record ensures compliance with industry standards and regulatory requirements by providing transparent documentation for quality control and recall management. It helps businesses maintain product integrity by linking finished goods back to their raw material sources for effective traceability.

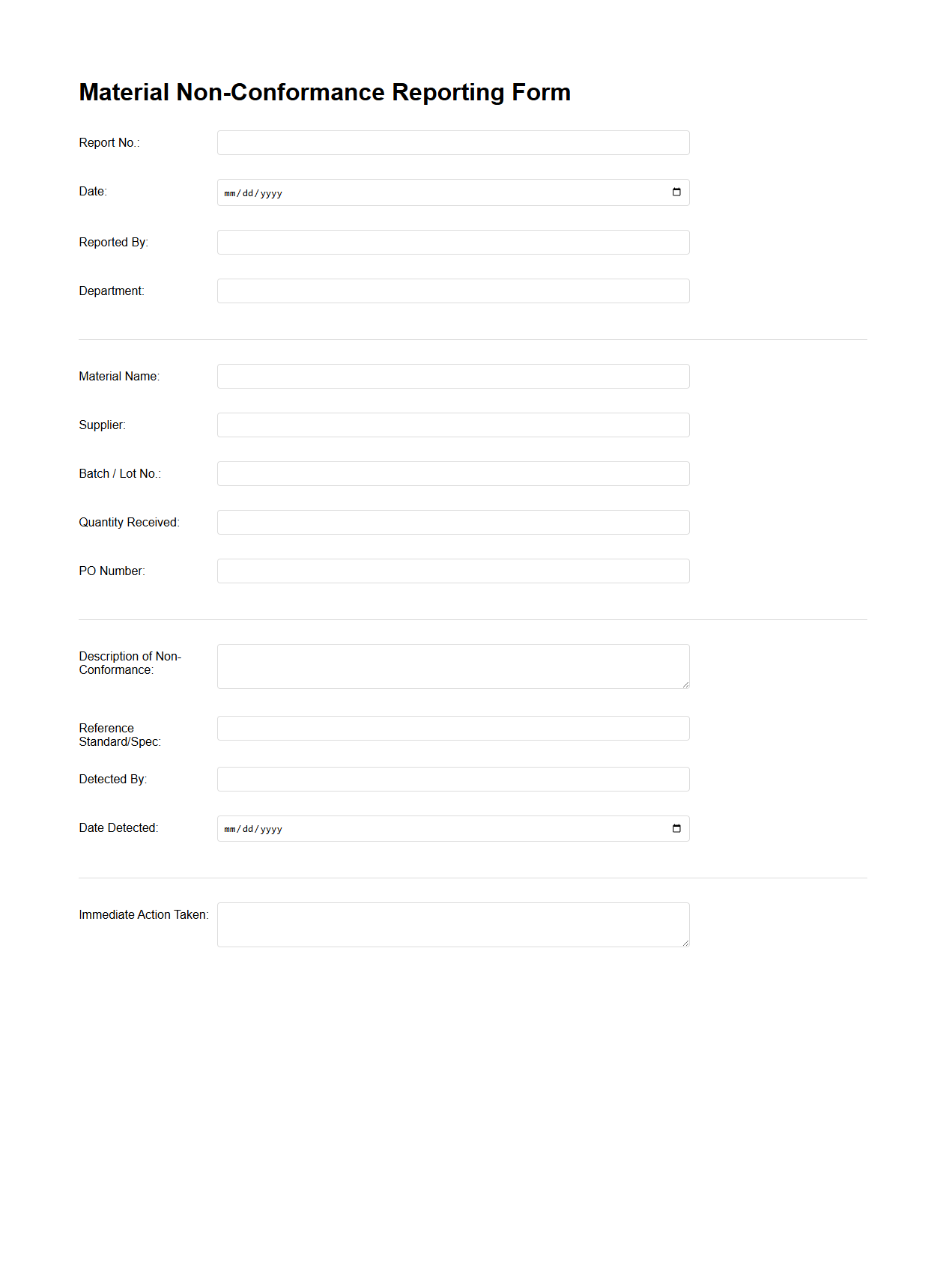

Material Non-Conformance Reporting Form

A

Material Non-Conformance Reporting Form is a critical document used to identify, document, and track materials that fail to meet specified quality standards or requirements in manufacturing and construction processes. It captures detailed information about the non-conformance, including description, location, cause, and corrective actions, ensuring traceability and accountability. This form is essential for maintaining quality control, preventing defects, and facilitating continuous improvement in production workflows.

Material Inspection Summary Sheet

A

Material Inspection Summary Sheet is a document used to record and consolidate the results of material inspections for quality control purposes. It details information such as material specifications, batch numbers, inspection criteria, findings, and approval status. This sheet ensures traceability and compliance with industry standards throughout the manufacturing or construction process.

What critical parameters are verified during the raw material inspection process as per the document sample?

The document sample specifies verification of material composition, physical properties, and dimensions as critical parameters. It also includes checks for contamination and compliance with specified standards. These parameters ensure the raw materials meet the necessary quality requirements before production.

How does the document sample ensure traceability of inspected raw materials?

Traceability is ensured by assigning unique identification codes to each inspected batch. The document mandates recording inspection dates, inspector details, and material source information. This systematic approach allows tracking of raw materials throughout the supply chain.

What acceptance criteria are defined in the document for raw material quality?

The acceptance criteria include specific thresholds for chemical purity, dimensional tolerances, and absence of defects. The document outlines allowable variance ranges to clearly distinguish acceptable from non-conforming materials. Compliance with these criteria guarantees consistency in raw material quality.

Which documentation and certification are required to accompany raw materials according to the sample?

The sample specifies that raw materials must be accompanied by material safety data sheets (MSDS), certificates of analysis (COA), and compliance certificates. These documents validate the origin and quality standards of the materials. Proper documentation supports regulatory adherence and quality assurance.

How are non-conforming raw materials documented and handled in the sample inspection document?

Non-conforming materials are documented using non-conformance reports (NCRs) detailing the nature of defects. The document outlines procedures for segregation, notification of relevant personnel, and disposition decisions such as rework, return, or disposal. This process minimizes risk and maintains the integrity of production.

More Manufacturing Templates